steering DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 909 of 1285

(25) Turn the key to OFF and remove the scan tool

from the vehicle.

(26) Test the operation of the horn, wipers and any

other functions that are steering column operated. If

applicable, reset the radio and the clock.

(27) If the steering column is a tilt column, verify

the tilt mechanism operates properly.

(28) Road test the vehicle to ensure proper opera-

tion of the steering system and the speed control sys-

tem.

STEERING COLUMN LOWER COUPLING

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section and in STEERING

GEAR.

REMOVAL

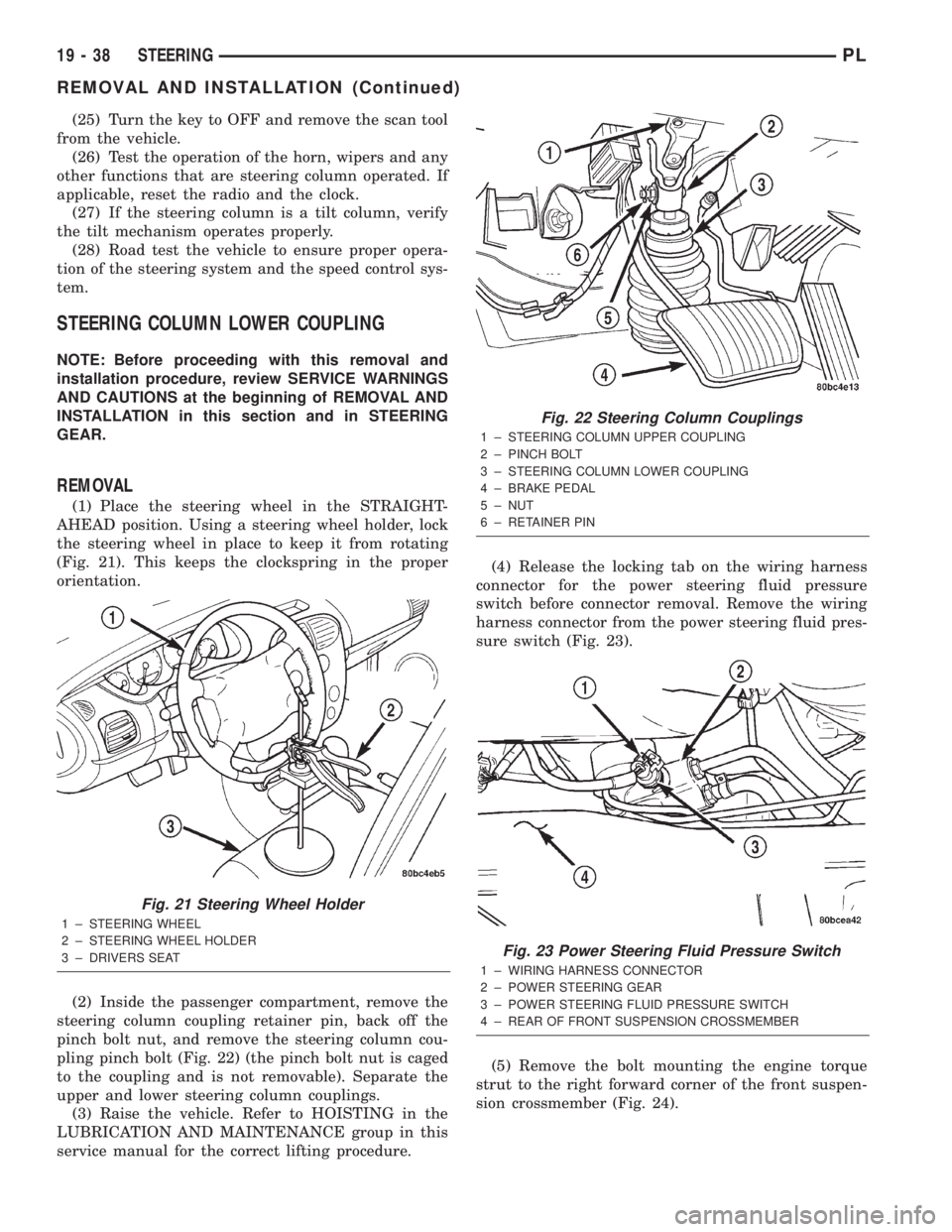

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 21). This keeps the clockspring in the proper

orientation.

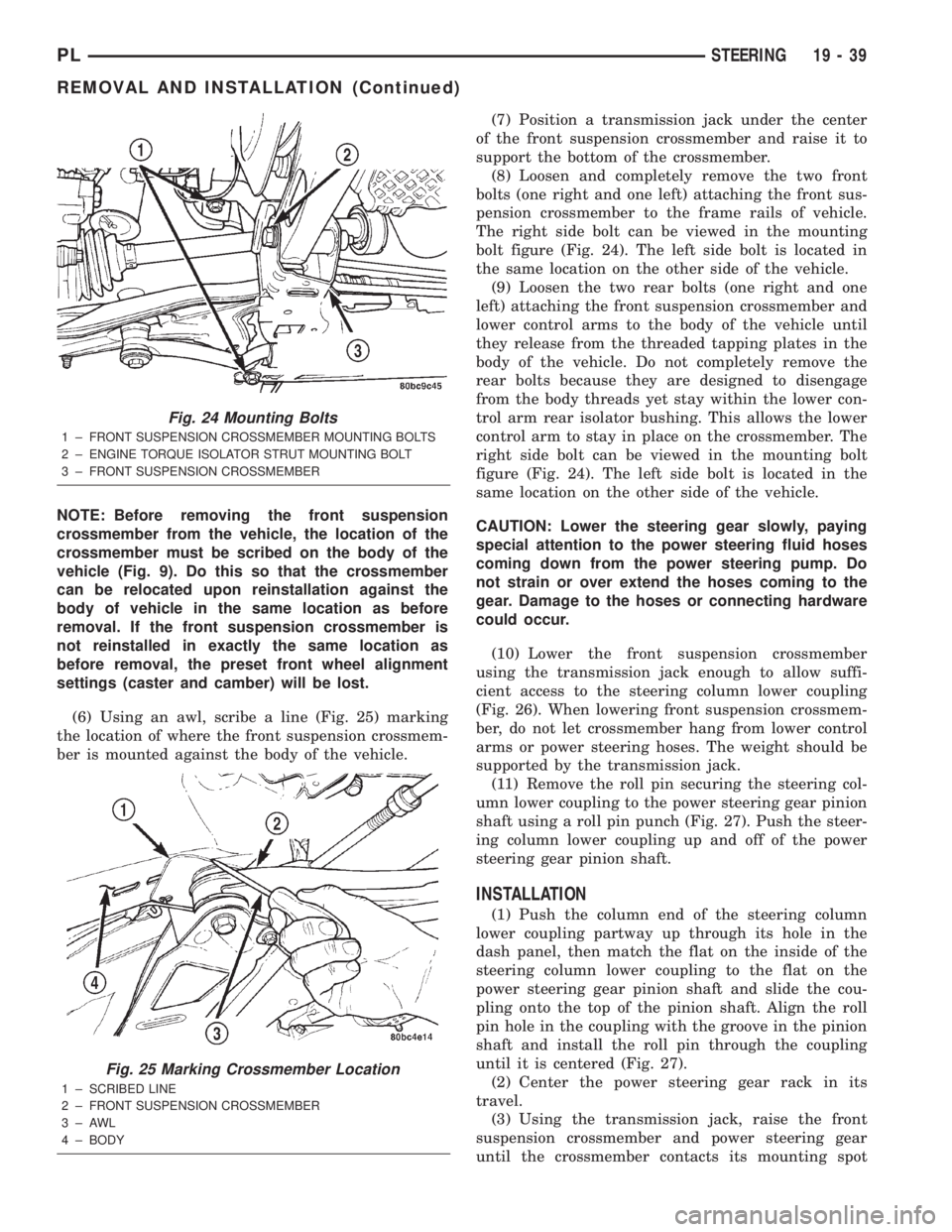

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 22) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

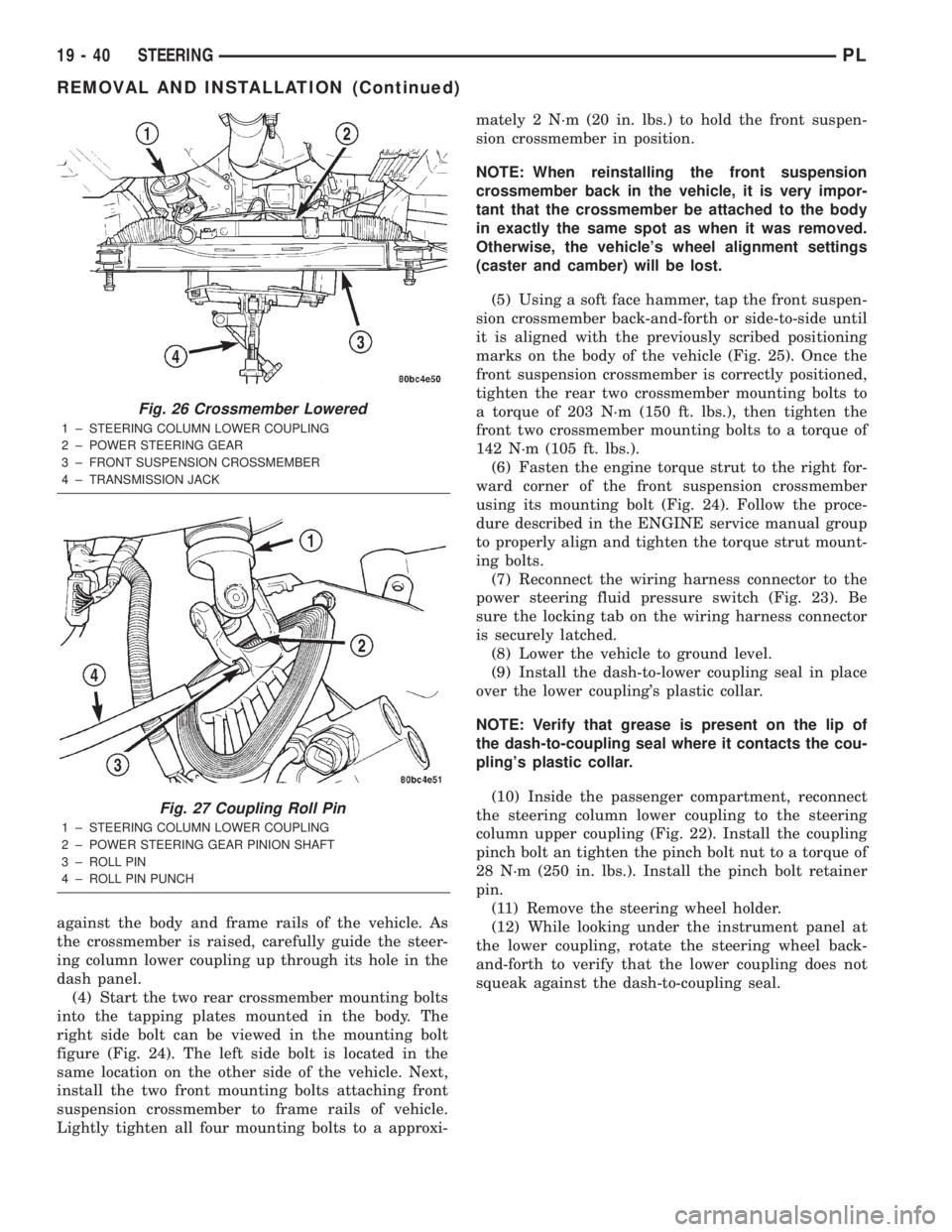

service manual for the correct lifting procedure.(4) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 23).

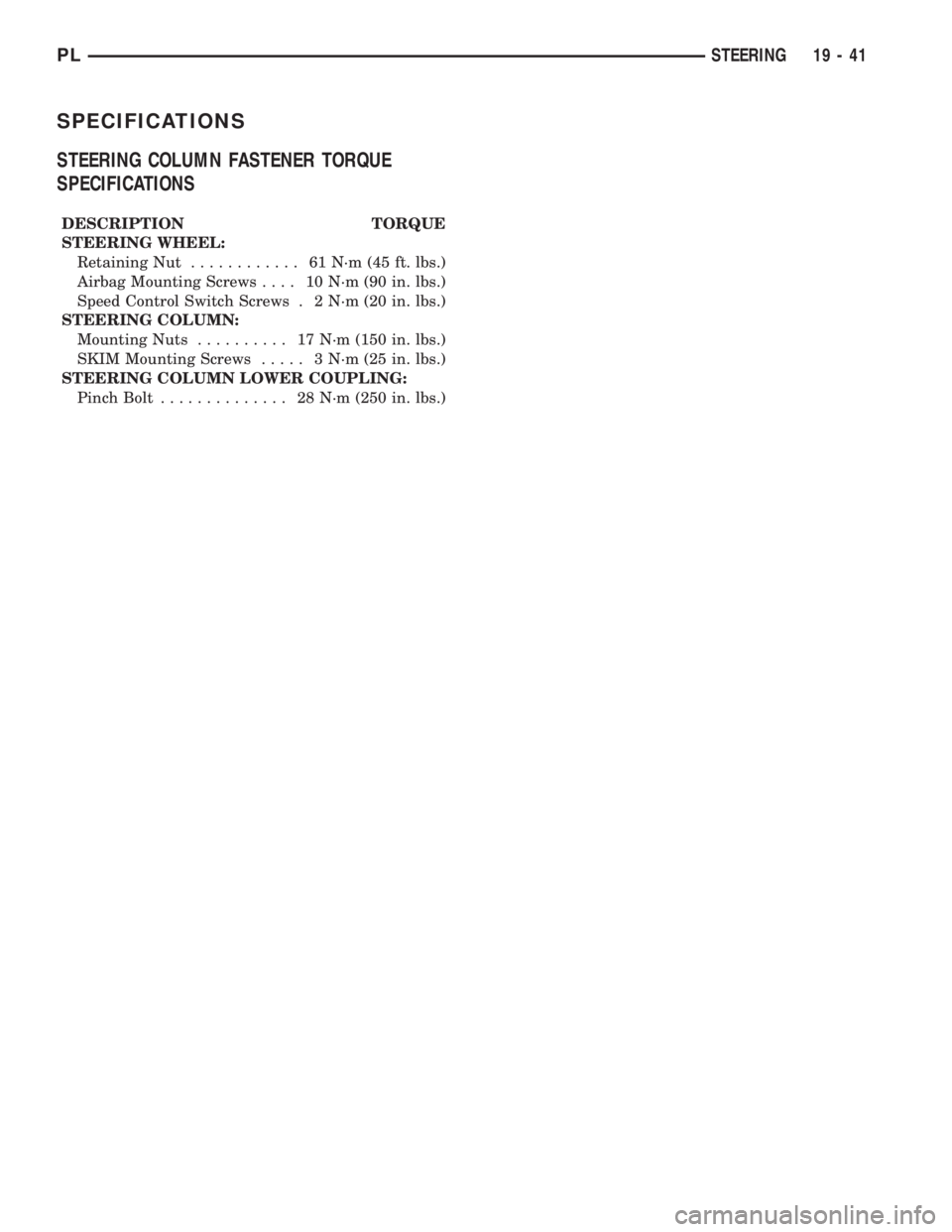

(5) Remove the bolt mounting the engine torque

strut to the right forward corner of the front suspen-

sion crossmember (Fig. 24).

Fig. 21 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 22 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 23 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 910 of 1285

NOTE: Before removing the front suspension

crossmember from the vehicle, the location of the

crossmember must be scribed on the body of the

vehicle (Fig. 9). Do this so that the crossmember

can be relocated upon reinstallation against the

body of vehicle in the same location as before

removal. If the front suspension crossmember is

not reinstalled in exactly the same location as

before removal, the preset front wheel alignment

settings (caster and camber) will be lost.

(6) Using an awl, scribe a line (Fig. 25) marking

the location of where the front suspension crossmem-

ber is mounted against the body of the vehicle.(7) Position a transmission jack under the center

of the front suspension crossmember and raise it to

support the bottom of the crossmember.

(8) Loosen and completely remove the two front

bolts (one right and one left) attaching the front sus-

pension crossmember to the frame rails of vehicle.

The right side bolt can be viewed in the mounting

bolt figure (Fig. 24). The left side bolt is located in

the same location on the other side of the vehicle.

(9) Loosen the two rear bolts (one right and one

left) attaching the front suspension crossmember and

lower control arms to the body of the vehicle until

they release from the threaded tapping plates in the

body of the vehicle. Do not completely remove the

rear bolts because they are designed to disengage

from the body threads yet stay within the lower con-

trol arm rear isolator bushing. This allows the lower

control arm to stay in place on the crossmember. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle.

CAUTION: Lower the steering gear slowly, paying

special attention to the power steering fluid hoses

coming down from the power steering pump. Do

not strain or over extend the hoses coming to the

gear. Damage to the hoses or connecting hardware

could occur.

(10) Lower the front suspension crossmember

using the transmission jack enough to allow suffi-

cient access to the steering column lower coupling

(Fig. 26). When lowering front suspension crossmem-

ber, do not let crossmember hang from lower control

arms or power steering hoses. The weight should be

supported by the transmission jack.

(11) Remove the roll pin securing the steering col-

umn lower coupling to the power steering gear pinion

shaft using a roll pin punch (Fig. 27). Push the steer-

ing column lower coupling up and off of the power

steering gear pinion shaft.

INSTALLATION

(1) Push the column end of the steering column

lower coupling partway up through its hole in the

dash panel, then match the flat on the inside of the

steering column lower coupling to the flat on the

power steering gear pinion shaft and slide the cou-

pling onto the top of the pinion shaft. Align the roll

pin hole in the coupling with the groove in the pinion

shaft and install the roll pin through the coupling

until it is centered (Fig. 27).

(2) Center the power steering gear rack in its

travel.

(3) Using the transmission jack, raise the front

suspension crossmember and power steering gear

until the crossmember contacts its mounting spot

Fig. 24 Mounting Bolts

1 ± FRONT SUSPENSION CROSSMEMBER MOUNTING BOLTS

2 ± ENGINE TORQUE ISOLATOR STRUT MOUNTING BOLT

3 ± FRONT SUSPENSION CROSSMEMBER

Fig. 25 Marking Crossmember Location

1 ± SCRIBED LINE

2 ± FRONT SUSPENSION CROSSMEMBER

3±AWL

4 ± BODY

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)

Page 911 of 1285

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(4) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(5) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 25). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(6) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 24). Follow the proce-

dure described in the ENGINE service manual group

to properly align and tighten the torque strut mount-

ing bolts.

(7) Reconnect the wiring harness connector to the

power steering fluid pressure switch (Fig. 23). Be

sure the locking tab on the wiring harness connector

is securely latched.

(8) Lower the vehicle to ground level.

(9) Install the dash-to-lower coupling seal in place

over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(10) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 22). Install the coupling

pinch bolt an tighten the pinch bolt nut to a torque of

28 N´m (250 in. lbs.). Install the pinch bolt retainer

pin.

(11) Remove the steering wheel holder.

(12) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

Fig. 26 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

Fig. 27 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 912 of 1285

SPECIFICATIONS

STEERING COLUMN FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STEERING WHEEL:

Retaining Nut............ 61N´m(45ft.lbs.)

Airbag Mounting Screws.... 10N´m(90in.lbs.)

Speed Control Switch Screws . 2 N´m (20 in. lbs.)

STEERING COLUMN:

Mounting Nuts.......... 17N´m(150 in. lbs.)

SKIM Mounting Screws..... 3N´m(25in.lbs.)

STEERING COLUMN LOWER COUPLING:

Pinch Bolt.............. 28N´m(250 in. lbs.)

PLSTEERING 19 - 41

Page 970 of 1285

The kickdown valve makes possible a forced down-

shift from third to second, second to first, or third to

first (depending on vehicle speed). This can be done

by depressing the accelerator pedal past the detent

feel near wide open throttle.

The shuttle valve has two separate functions and

performs each independently of the other. The first is

providing fast release of the kickdown band, and

smooth front clutch engagement when a lift-foot

upshift from second to third is made. The second

function is to regulate the application of the kick-

down servo and band when making third±to±second

kickdown.

The bypass valve provides for smooth application

of the kickdown band on 1-2 upshifts.

The torque converter clutch solenoid allows for the

electronic control of the torque converter clutch. It

also disengages the torque converter at closed throt-

tle. This is done during engine warm-up and part-

throttle acceleration.

The switch valve directs oil to apply the torque

converter clutch in one position. The switch valve

releases the torque converter clutch in the other posi-

tion.

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR

The front and rear clutch pistons, and both servo

pistons, are moved hydraulically to engage the

clutches and apply the bands. The pistons are

released by spring tension when hydraulic pressure

is released. On the 2-3 upshift, the kickdown servo

piston is released by spring tension and hydraulic

pressure.

The accumulator controls the hydraulic pressure

on the apply±side of the kickdown servo during the

1-2 upshift; thereby cushioning the kickdown band

application at any throttle position.

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

The Brake Transmission Shifter/Ignition Interlock

(BTSI) is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The system locks the shifter into the PARK

position. The interlock system is engaged whenever

the ignition switch is in the LOCK or ACCESSORY

position. An additional electrically activated feature

will prevent shifting out of the PARK position unless

the brake pedal is depressed at least one-half inch. A

magnetic holding device integral to the interlock

cable is energized when the ignition is in the RUN

position. When the key is in the RUN position and

the brake pedal is depressed, the shifter is unlocked

and will move into any position. The interlock systemalso prevents the ignition switch from being turned

to the LOCK or ACCESSORY position, unless the

shifter is in the gated PARK position.

The following chart describes the normal operation

of the Brake Transmission Shift Interlock (BTSI) sys-

tem. If the ªexpected responseº differs from the vehi-

cle's response, then system repair and/or adjustment

is necessary.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by alever typegear-

shift incorporated within the console. The control has

six selector lever positions: P (Park), R (Reverse), N

(Neutral), and D (Drive), 2 (Second), and 1 (First).

The parking lock is applied by moving the selector

lever past a gate to the (P) position.Do not apply

the parking lock until the vehicle has stopped;

otherwise, a severe banging noise will occur.

COOLER BYPASS VALVE

Some 31TH transaxles are equipped with a cooler

bypass valve (Fig. 2). The valve is designed to bypass

the transaxle oil cooler circuit in cold weather condi-

tions, or when circuit restriction exceeds 25±30 p.s.i.

The valve consists of an integrated check ball and

spring, and a return tube to carry bypassed oil back

to the pump. The bypass valve is mounted to the

valve body transfer plate and is sealed with a rubber

o-ring seal (Fig. 3).

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

PLTRANSAXLE 21 - 57

DESCRIPTION AND OPERATION (Continued)

Page 993 of 1285

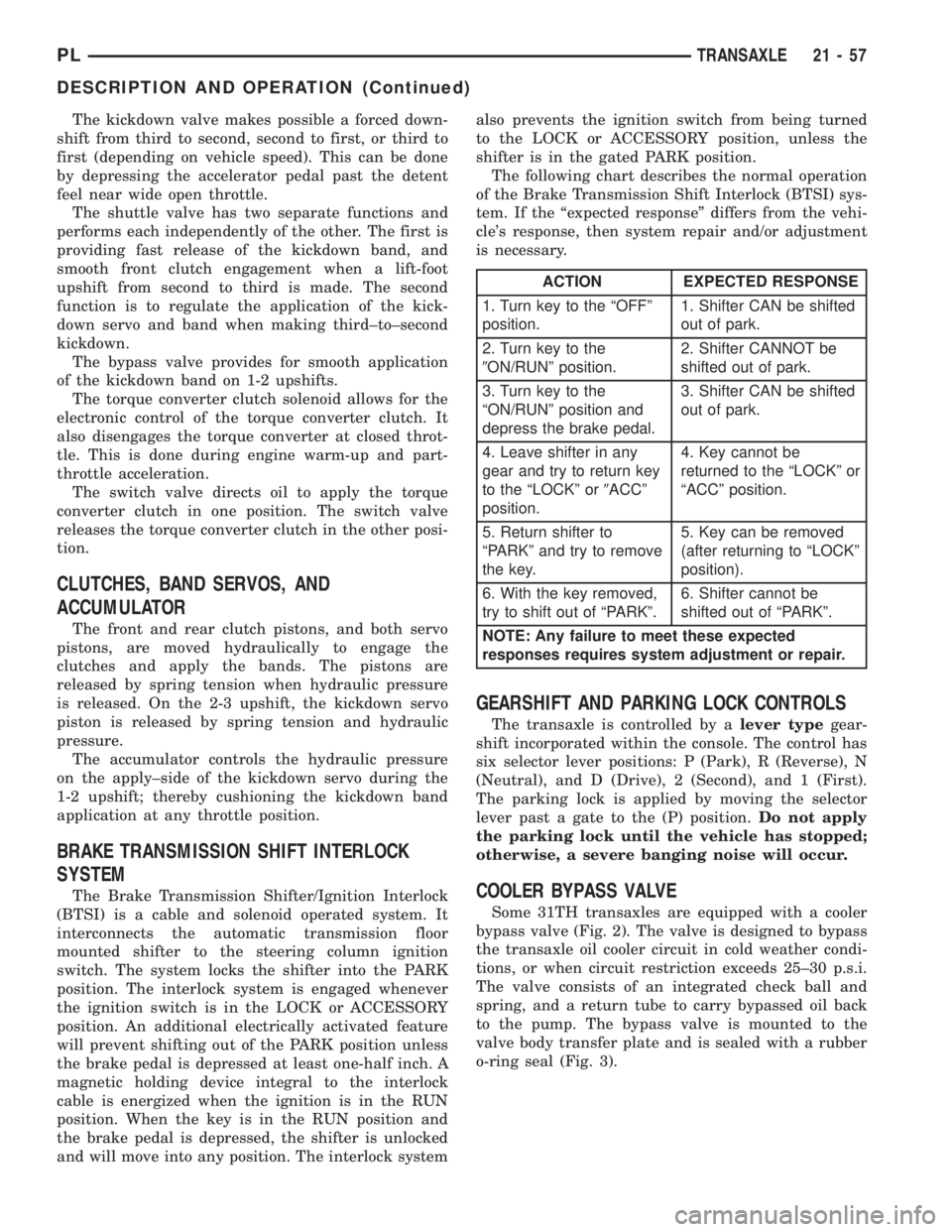

(4) Remove shifter bezel (Fig. 31).

(5) Disconnect the shifter/ignition interlock cable

from the shifter lever and bracket as shown in (Fig.

32). Remove the cable core end from the plastic cam

of the shifter mechanism and release cable from

shifter bracket

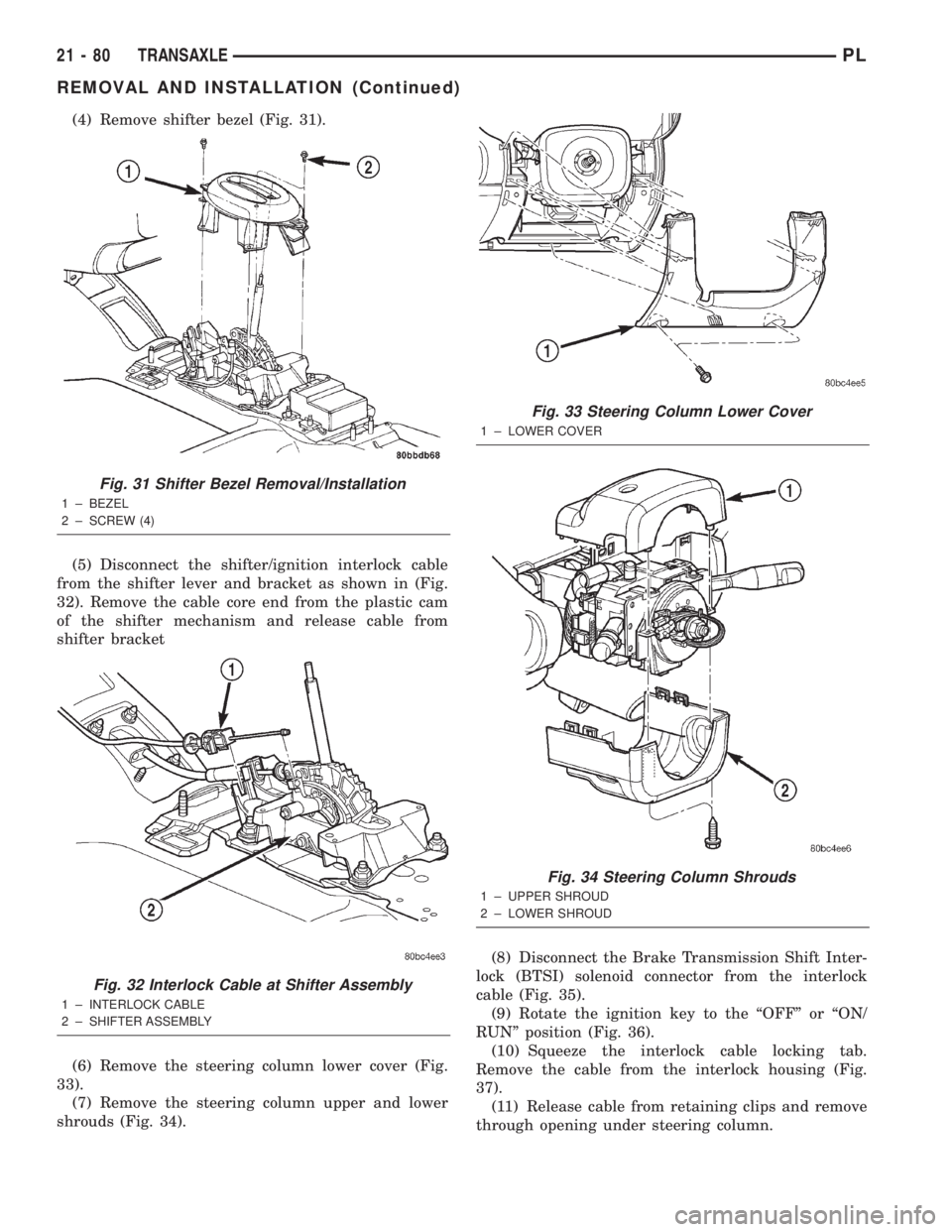

(6) Remove the steering column lower cover (Fig.

33).

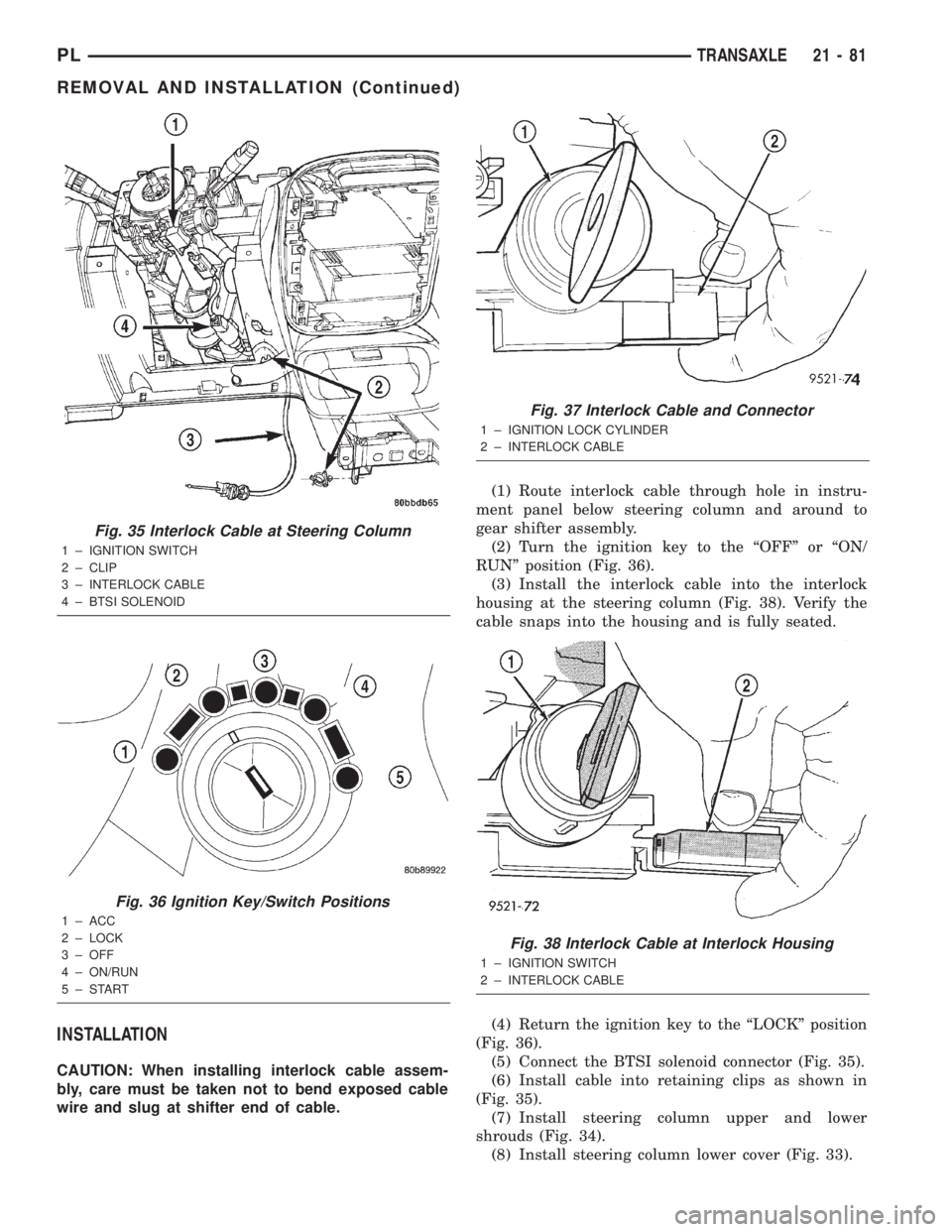

(7) Remove the steering column upper and lower

shrouds (Fig. 34).(8) Disconnect the Brake Transmission Shift Inter-

lock (BTSI) solenoid connector from the interlock

cable (Fig. 35).

(9) Rotate the ignition key to the ªOFFº or ªON/

RUNº position (Fig. 36).

(10) Squeeze the interlock cable locking tab.

Remove the cable from the interlock housing (Fig.

37).

(11) Release cable from retaining clips and remove

through opening under steering column.

Fig. 31 Shifter Bezel Removal/Installation

1 ± BEZEL

2 ± SCREW (4)

Fig. 32 Interlock Cable at Shifter Assembly

1 ± INTERLOCK CABLE

2 ± SHIFTER ASSEMBLY

Fig. 33 Steering Column Lower Cover

1 ± LOWER COVER

Fig. 34 Steering Column Shrouds

1 ± UPPER SHROUD

2 ± LOWER SHROUD

21 - 80 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 994 of 1285

INSTALLATION

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.(1) Route interlock cable through hole in instru-

ment panel below steering column and around to

gear shifter assembly.

(2) Turn the ignition key to the ªOFFº or ªON/

RUNº position (Fig. 36).

(3) Install the interlock cable into the interlock

housing at the steering column (Fig. 38). Verify the

cable snaps into the housing and is fully seated.

(4) Return the ignition key to the ªLOCKº position

(Fig. 36).

(5) Connect the BTSI solenoid connector (Fig. 35).

(6) Install cable into retaining clips as shown in

(Fig. 35).

(7) Install steering column upper and lower

shrouds (Fig. 34).

(8) Install steering column lower cover (Fig. 33).

Fig. 35 Interlock Cable at Steering Column

1 ± IGNITION SWITCH

2 ± CLIP

3 ± INTERLOCK CABLE

4 ± BTSI SOLENOID

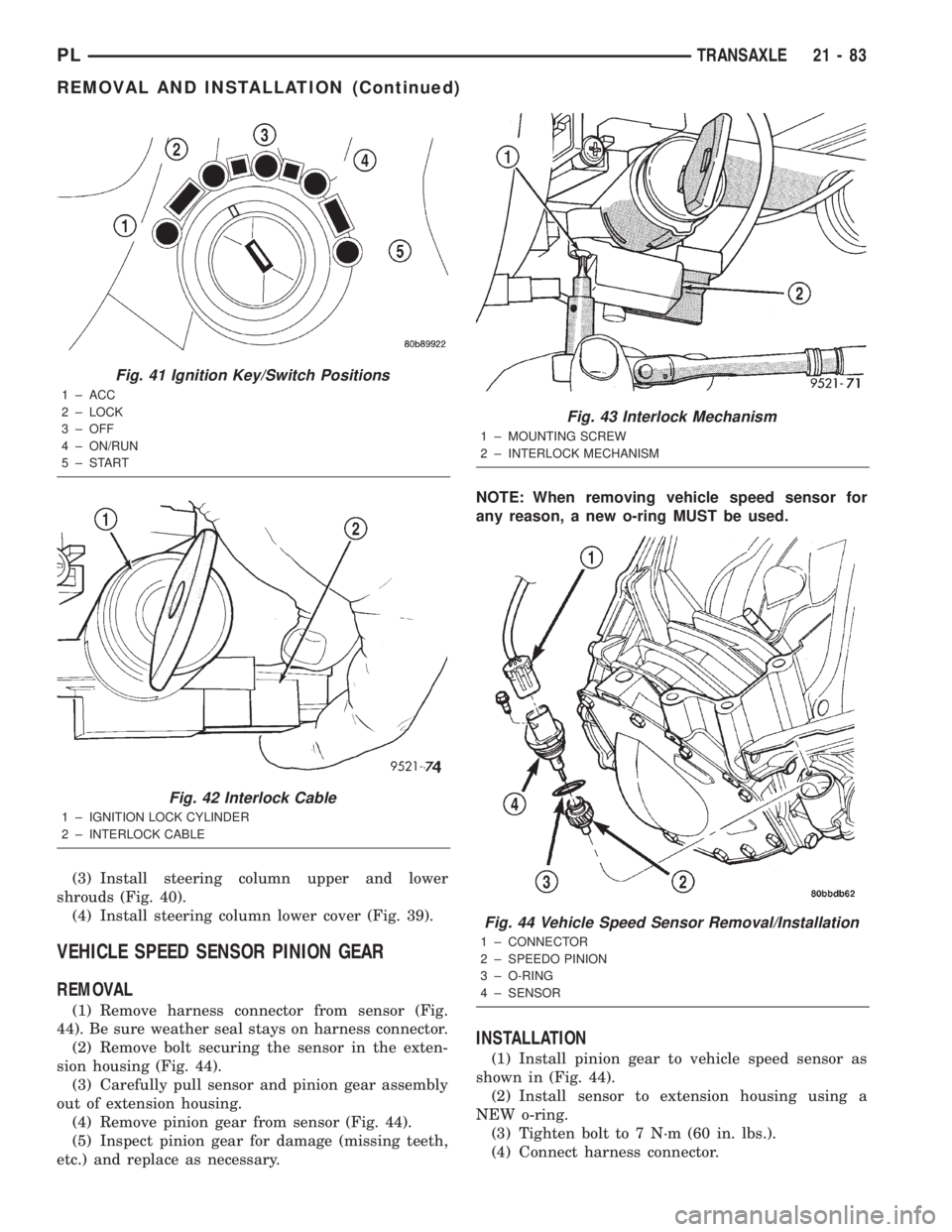

Fig. 36 Ignition Key/Switch Positions

1 ± ACC

2 ± LOCK

3 ± OFF

4 ± ON/RUN

5±START

Fig. 37 Interlock Cable and Connector

1 ± IGNITION LOCK CYLINDER

2 ± INTERLOCK CABLE

Fig. 38 Interlock Cable at Interlock Housing

1 ± IGNITION SWITCH

2 ± INTERLOCK CABLE

PLTRANSAXLE 21 - 81

REMOVAL AND INSTALLATION (Continued)

Page 995 of 1285

(9) Verify that shifter is in gated ªPARKº.

(10) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism as shown in (Fig. 32).

(11)Adjust interlock cable/system as follows:

If interlock cable is being replaced, it will come with

an adjustment pin. Remove the pin from the cable

and allow the cable to ªself-adjustº. Lock cable

adjustment by pressing down on the adjuster lock

until bottomed at the cable housing. If interlock cable

is being re-used, no pin will be provided. Pry up on

cable adjuster lock to release and allow cable to ªself-

adjustº. Lock cable adjustment by pressing down on

the adjuster lock until bottomed at the cable housing.

(12)Connect battery negative cable and ver-

ify interlock system operation as follows:

(13) Install shifter bezel (Fig. 31).

(14) Install center console assembly (Fig. 30).

(15) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 29).

INTERLOCK MECHANISM

REMOVAL

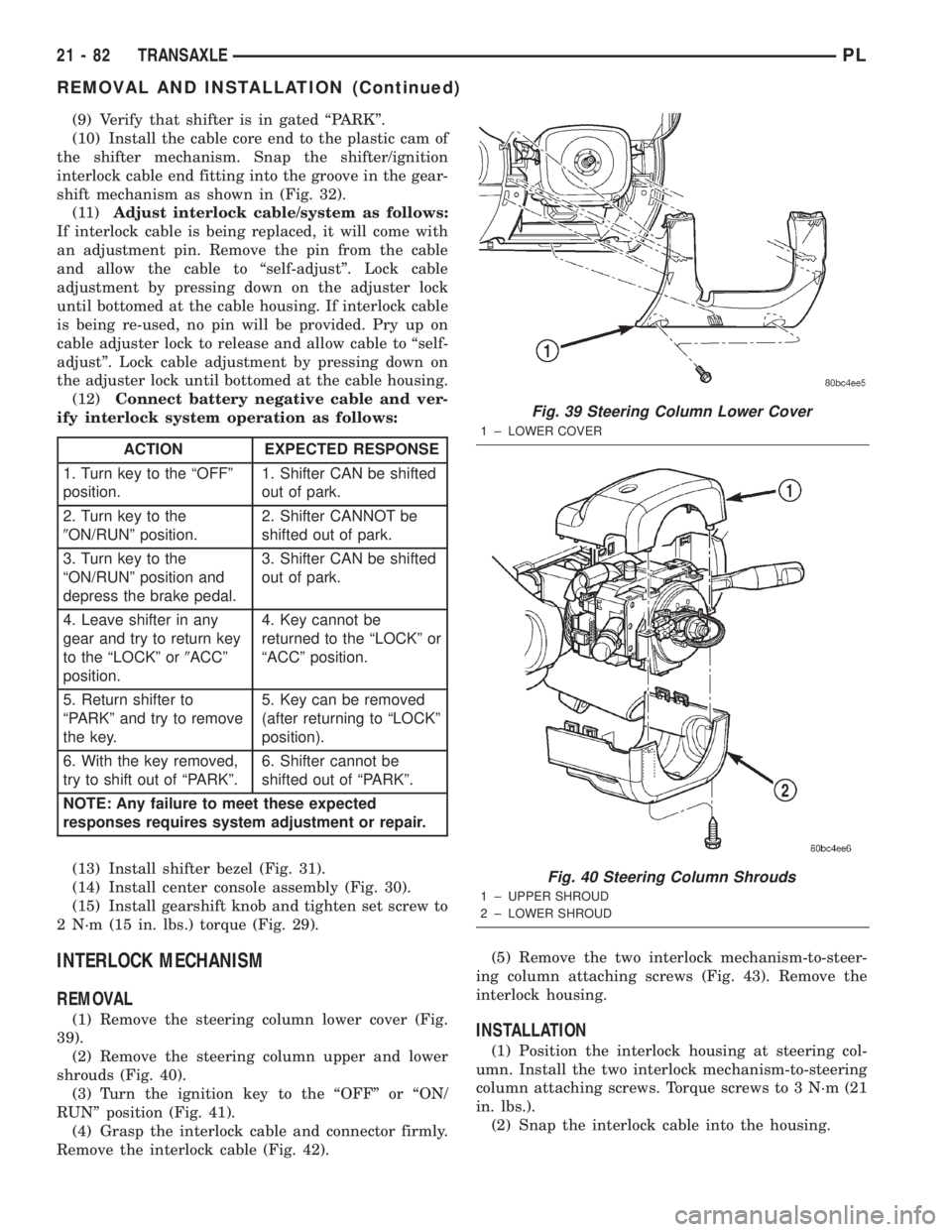

(1) Remove the steering column lower cover (Fig.

39).

(2) Remove the steering column upper and lower

shrouds (Fig. 40).

(3) Turn the ignition key to the ªOFFº or ªON/

RUNº position (Fig. 41).

(4) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 42).(5) Remove the two interlock mechanism-to-steer-

ing column attaching screws (Fig. 43). Remove the

interlock housing.INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism-to-steering

column attaching screws. Torque screws to 3 N´m (21

in. lbs.).

(2) Snap the interlock cable into the housing.

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

Fig. 39 Steering Column Lower Cover

1 ± LOWER COVER

Fig. 40 Steering Column Shrouds

1 ± UPPER SHROUD

2 ± LOWER SHROUD

21 - 82 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 996 of 1285

(3) Install steering column upper and lower

shrouds (Fig. 40).

(4) Install steering column lower cover (Fig. 39).

VEHICLE SPEED SENSOR PINION GEAR

REMOVAL

(1) Remove harness connector from sensor (Fig.

44). Be sure weather seal stays on harness connector.

(2) Remove bolt securing the sensor in the exten-

sion housing (Fig. 44).

(3) Carefully pull sensor and pinion gear assembly

out of extension housing.

(4) Remove pinion gear from sensor (Fig. 44).

(5) Inspect pinion gear for damage (missing teeth,

etc.) and replace as necessary.NOTE: When removing vehicle speed sensor for

any reason, a new o-ring MUST be used.

INSTALLATION

(1) Install pinion gear to vehicle speed sensor as

shown in (Fig. 44).

(2) Install sensor to extension housing using a

NEW o-ring.

(3) Tighten bolt to 7 N´m (60 in. lbs.).

(4) Connect harness connector.

Fig. 41 Ignition Key/Switch Positions

1 ± ACC

2 ± LOCK

3 ± OFF

4 ± ON/RUN

5±START

Fig. 42 Interlock Cable

1 ± IGNITION LOCK CYLINDER

2 ± INTERLOCK CABLE

Fig. 43 Interlock Mechanism

1 ± MOUNTING SCREW

2 ± INTERLOCK MECHANISM

Fig. 44 Vehicle Speed Sensor Removal/Installation

1 ± CONNECTOR

2 ± SPEEDO PINION

3 ± O-RING

4 ± SENSOR

PLTRANSAXLE 21 - 83

REMOVAL AND INSTALLATION (Continued)

Page 1072 of 1285

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

SPARE TIRE±TEMPORARY

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M. P. H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capabilityIt is recommend that tires equivalent to the origi-

nal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

DIAGNOSIS AND TESTING

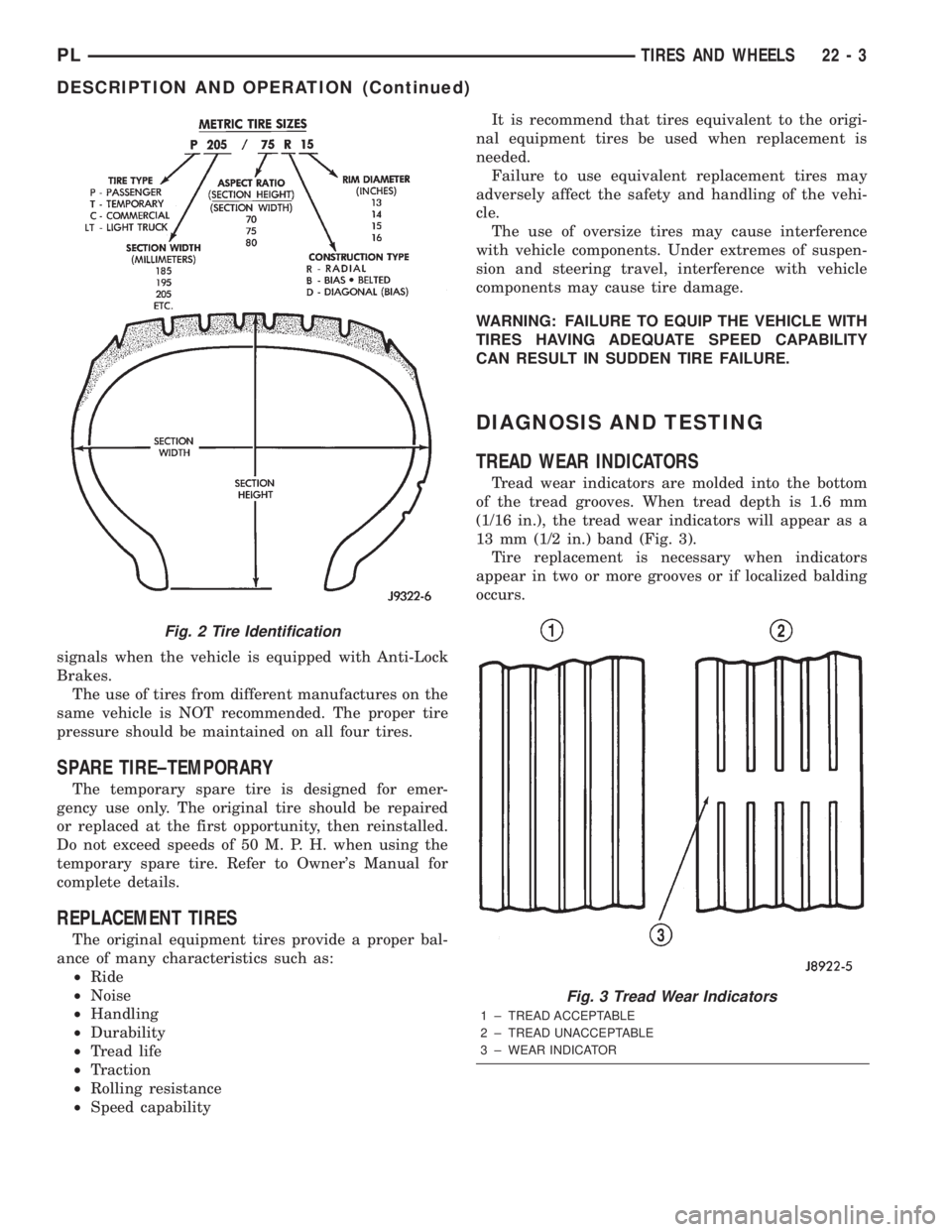

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 3).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

Fig. 2 Tire Identification

Fig. 3 Tread Wear Indicators

1 ± TREAD ACCEPTABLE

2 ± TREAD UNACCEPTABLE

3 ± WEAR INDICATOR

PLTIRES AND WHEELS 22 - 3

DESCRIPTION AND OPERATION (Continued)