battery DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 109 of 1285

(4) Fill the reservoir with fresh clean DOT 3 brake

fluid. Refer to BRAKE FLUID LEVEL CHECKING

in the SERVICE PROCEDURES section in this sec-

tion of this service manual group.

BRAKE FLUID LEVEL SWITCH

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).

(2) Push together the retaining tabs holding the

brake fluid level switch in place in the brake fluid

reservoir (Fig. 46).

(3) Pull the brake fluid level switch out the other

side of the reservoir.

INSTALLATION

(1) Align the brake fluid level switch with its

mounting hole on the left side of the master cylinder

brake fluid reservoir. Push the switch into the fluid

reservoir until the switch retaining tabs are

expanded on the other side of the reservoir, locking it

in place (Fig. 46).

(2) Connect the brake fluid level switch wiring

connector (Fig. 44).

POWER BRAKE BOOSTER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Disconnect negative (ground) cable from the

battery and isolate the cable.

(2) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(3) Remove the one nut and one bolt securing the

air cleaner box in place, then disconnect the wiring

harness connector at the air inlet sensor.

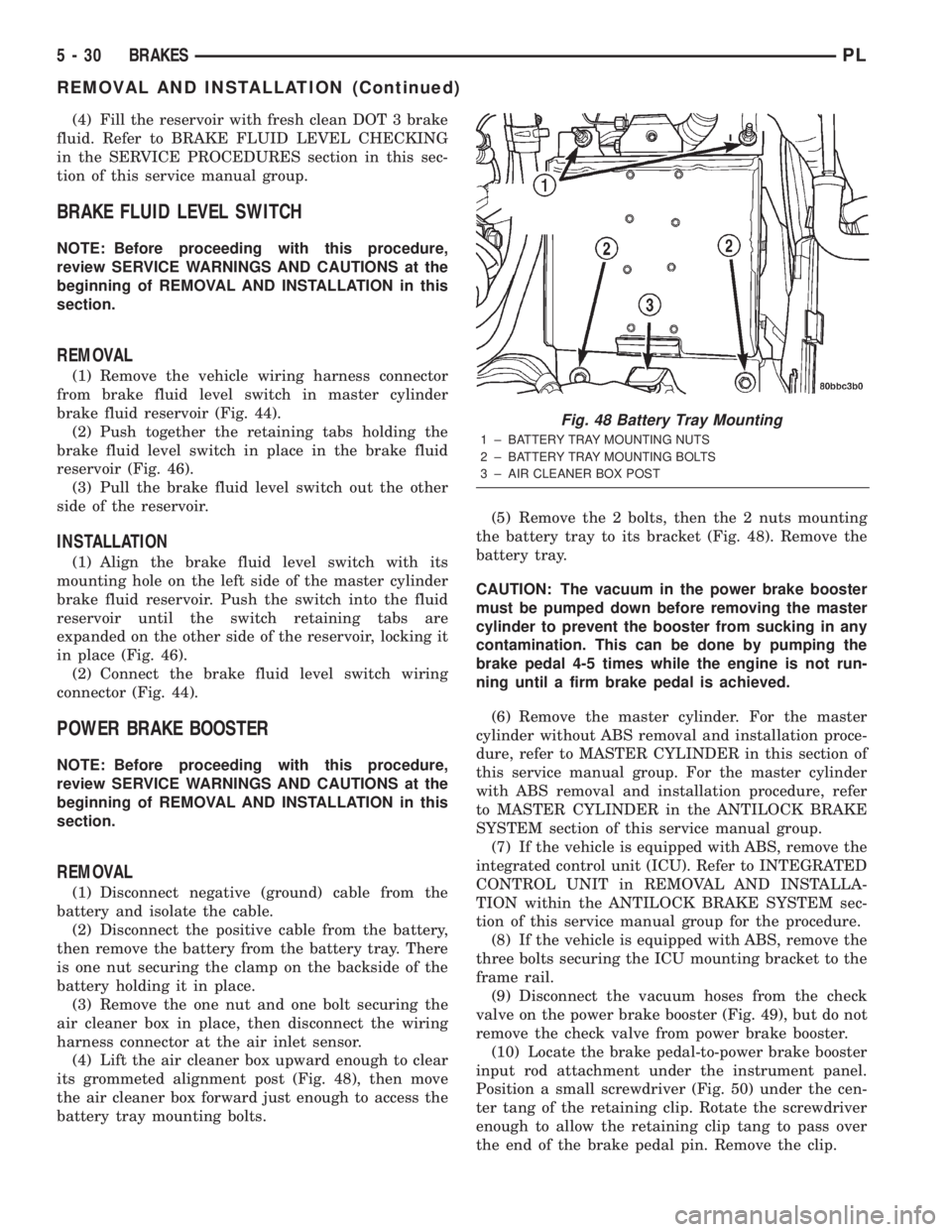

(4) Lift the air cleaner box upward enough to clear

its grommeted alignment post (Fig. 48), then move

the air cleaner box forward just enough to access the

battery tray mounting bolts.(5) Remove the 2 bolts, then the 2 nuts mounting

the battery tray to its bracket (Fig. 48). Remove the

battery tray.

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal 4-5 times while the engine is not run-

ning until a firm brake pedal is achieved.

(6) Remove the master cylinder. For the master

cylinder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(7) If the vehicle is equipped with ABS, remove the

integrated control unit (ICU). Refer to INTEGRATED

CONTROL UNIT in REMOVAL AND INSTALLA-

TION within the ANTILOCK BRAKE SYSTEM sec-

tion of this service manual group for the procedure.

(8) If the vehicle is equipped with ABS, remove the

three bolts securing the ICU mounting bracket to the

frame rail.

(9) Disconnect the vacuum hoses from the check

valve on the power brake booster (Fig. 49), but do not

remove the check valve from power brake booster.

(10) Locate the brake pedal-to-power brake booster

input rod attachment under the instrument panel.

Position a small screwdriver (Fig. 50) under the cen-

ter tang of the retaining clip. Rotate the screwdriver

enough to allow the retaining clip tang to pass over

the end of the brake pedal pin. Remove the clip.

Fig. 48 Battery Tray Mounting

1 ± BATTERY TRAY MOUNTING NUTS

2 ± BATTERY TRAY MOUNTING BOLTS

3 ± AIR CLEANER BOX POST

5 - 30 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 111 of 1285

CAUTION: Use only a new brake booster input rod-

to-brake pedal retaining clip to ensure proper

retainment.

(4) Connect the power brake booster input rod-to-

brake pedal pin. Install a new retaining clip. Do not

use the old clip.

(5) Connect all previously removed vacuum hoses

to the vacuum check valve (Fig. 49).

(6) If the vehicle is equipped with ABS, install the

ICU mounting bracket on the frame rail using its

three bolts. Tighten the nuts to a torque of 23 N´m

(200 in. lbs.).

(7) If the vehicle is equipped with ABS, reinstall

the ICU. Refer to INTEGRATED CONTROL UNIT in

REMOVAL AND INSTALLATION within the

ANTILOCK BRAKE SYSTEM section of this service

manual group for the procedure.

(8) Install the master cylinder. For the master cyl-

inder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(9) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 48). Tighten the two

bolts and nuts to a torque of 34 N´m (25 ft. lbs.).

(10) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 48).

(11) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(12) Install the battery and clamp it in place.

(13) Connect the positive, then the negative

(ground) cable on the battery.

(14) Adjust the stop lamp switch as necessary.

Refer to STOP LAMP SWITCH in the ADJUST-

MENTS section of this group.

(15) Bleed the base brake system.

(16) Road test the vehicle to ensure proper opera-

tion of the brakes.

PROPORTIONING VALVE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

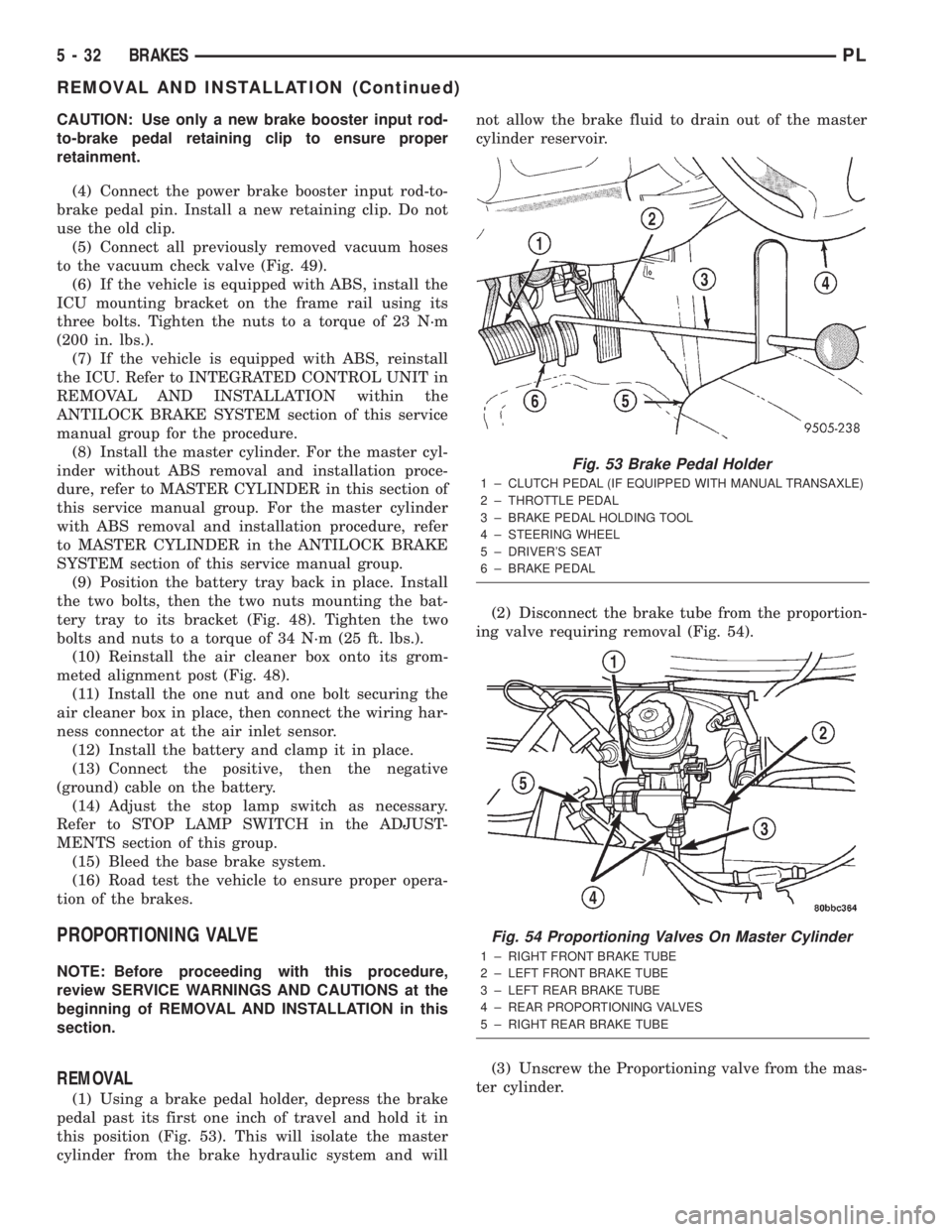

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 53). This will isolate the master

cylinder from the brake hydraulic system and willnot allow the brake fluid to drain out of the master

cylinder reservoir.

(2) Disconnect the brake tube from the proportion-

ing valve requiring removal (Fig. 54).

(3) Unscrew the Proportioning valve from the mas-

ter cylinder.

Fig. 53 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 54 Proportioning Valves On Master Cylinder

1 ± RIGHT FRONT BRAKE TUBE

2 ± LEFT FRONT BRAKE TUBE

3 ± LEFT REAR BRAKE TUBE

4 ± REAR PROPORTIONING VALVES

5 ± RIGHT REAR BRAKE TUBE

5 - 32 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 147 of 1285

CONTROLLER ANTILOCK BRAKE INPUTS

²wheel speed sensors (four)

²stop lamp switch

²ignition switch

²system relay voltage

²ground

²traction control lamp

²diagnostic communication (PCI)

CONTROLLER ANTILOCK BRAKE OUTPUTS

²amber ABS warning lamp actuation (through

MIC)

²red BRAKE warning lamp actuation (through

MIC)

²traction control lamp actuation (through MIC)

²diagnostic communication. (PCI)

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 2). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet solenoid valves. The inlet valves are spring-

loaded in the open position and the outlet valves are

spring-loaded in the closed position during normal

braking. The fluid is allowed to flow from the master

cylinder to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

There are four other valves in the HCU. These four

remaining valves are used for traction control. Two

traction control (TC) valves, mounted in the HCU

valve block, are normally in the open position and

close only when the traction control is applied. There

are also two shuttle valves which control pressure

return to the master cylinder under ABS and traction

control conditions.

These TC valves are used to isolate the rear (non-

driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is beingapplied so the rear wheels do not drag. For more

information on the TC and shuttle valves, see TRAC-

TION CONTROL SYSTEM in this section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU: one

for the primary hydraulic circuit, and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 3 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

There are two noise dampening chambers in the

HCU on this vehicle equipped with traction control.

PUMP/MOTOR

There are two pump assemblies in the HCU: one

for the primary hydraulic circuit, and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor (Fig. 2). This DC-type motor

is integral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, these pistons

are used to purge fluid from the accumulators back

into the master cylinder circuits. When the antilock

stop is complete, the pump/motor drains the accumu-

lators.

The pump motor is also used to build pressure

when the system goes into traction control mode. For

more information, refer to TRACTION CONTROL

SYSTEM in this section.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

ABS FUSES

The ABS fuse and the ABS pump/motor fuse are

located in the power distribution center (PDC). Refer

to the sticker on the inside of the PDC cover for the

location of these fuses. The PDC is located on the

driver's side of the engine compartment between the

back of the battery and the brake master cylinder.

The CAB fuse can be found in the fuse junction

block under the instrument panel.

5 - 68 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 153 of 1285

DIAGNOSIS AND TESTING

SERVICE WARNINGS AND CAUTIONS

The ABS uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.

CAUTION: In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so for a diagnostic proce-

dure.

CAUTION: These circuits should only be tested

using a high impedance multi-meter or the DRB

scan tool as described in this section. Power

should never be removed or applied to any control

module with the ignition in the ON position. Before

removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF

position.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of after-market electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, etc.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

ABS GENERAL DIAGNOSTICS INFORMATION

This section contains information necessary to

diagnose the antilock brake system. Specifically, this

section should be used to help diagnose conditions

which result in any of the following:

(1) amber ABS warning lamp turned on.

(2) brakes lock-up on hard application.

Diagnosis of base brake conditions that are obvi-

ously mechanical in nature should be directed to

BASE BRAKE SYSTEM at the beginning of this

group.

Many ABS conditions judged to be a problem by

the driver may be normal operating conditions. See

ABS OPERATION in the DESCRIPTION AND

OPERATION section of this group to become famil-

iarized with the normal characteristics of this

antilock brake system.

ABS WIRING DIAGRAM INFORMATION

During the diagnosis and testing of the antilock

brake system it may become necessary to reference

the wiring diagrams covering the antilock brake sys-

tem and its components. For wiring diagrams refer to

GROUP 8W of this service manual. It will provide

you with the wiring diagrams and the circuit descrip-

tion and operation information covering the antilock

brake system.

ABS VEHICLE TEST DRIVE

Most ABS complaints will require a test drive to

properly duplicate and diagnose the condition.

WARNING: CONDITIONS THAT RESULT IN TURN-

ING ON THE RED BRAKE WARNING LAMP MAY

INDICATE REDUCED BRAKING ABILITY.

Before test driving a brake complaint vehicle, note

whether the red BRAKE warning lamp, amber ABS

warning lamp, or both are turned on. If it is the red

BRAKE warning lamp, there is a brake hydraulic

problem that must be corrected before driving the

vehicle. Refer to the BASE BRAKE SYSTEM for

diagnosis of the red BRAKE warning lamp. If the red

brake warning lamp is illuminated, there is also a

possibility that there is an ABS problem and the

amber ABS warning lamp is not able to illuminate,

so the MIC turns on the red Brake warning lamp by

default.

If the amber ABS warning lamp is on, test drive

the vehicle as described below. While the amber ABS

warning lamp is on, the ABS is not functional. The

ability to stop the car using the base brake system

should not be affected.

If a functional problem of the ABS is determined

while test driving the vehicle, refer to the Chassis

Diagnostic Procedures manual.

(1) Turn the key to the OFF position and then

back to the ON position. Note whether the amber

ABS warning lamp continues to stay on. If it does,

refer to the diagnostic manual.

(2) If the amber ABS warning lamp goes out, shift

into gear and drive the car to a speed of 20 kph (12

mph) to complete the ABS start-up and drive-off

cycles (see ABS ELECTRONIC DIAGNOSIS). If at

this time the amber ABS warning lamp comes on,

refer to the diagnostic manual.

(3) If the amber ABS warning lamp remains out,

drive the vehicle a short distance. Accelerate the

vehicle to a speed of at least 40 mph. Bring the vehi-

cle to a complete stop, braking hard enough to cause

the ABS to cycle. Again accelerate the vehicle past 25

mph. Refer to the diagnostic manual for further test-

ing of the antilock brake system.

5 - 74 BRAKESPL

Page 154 of 1285

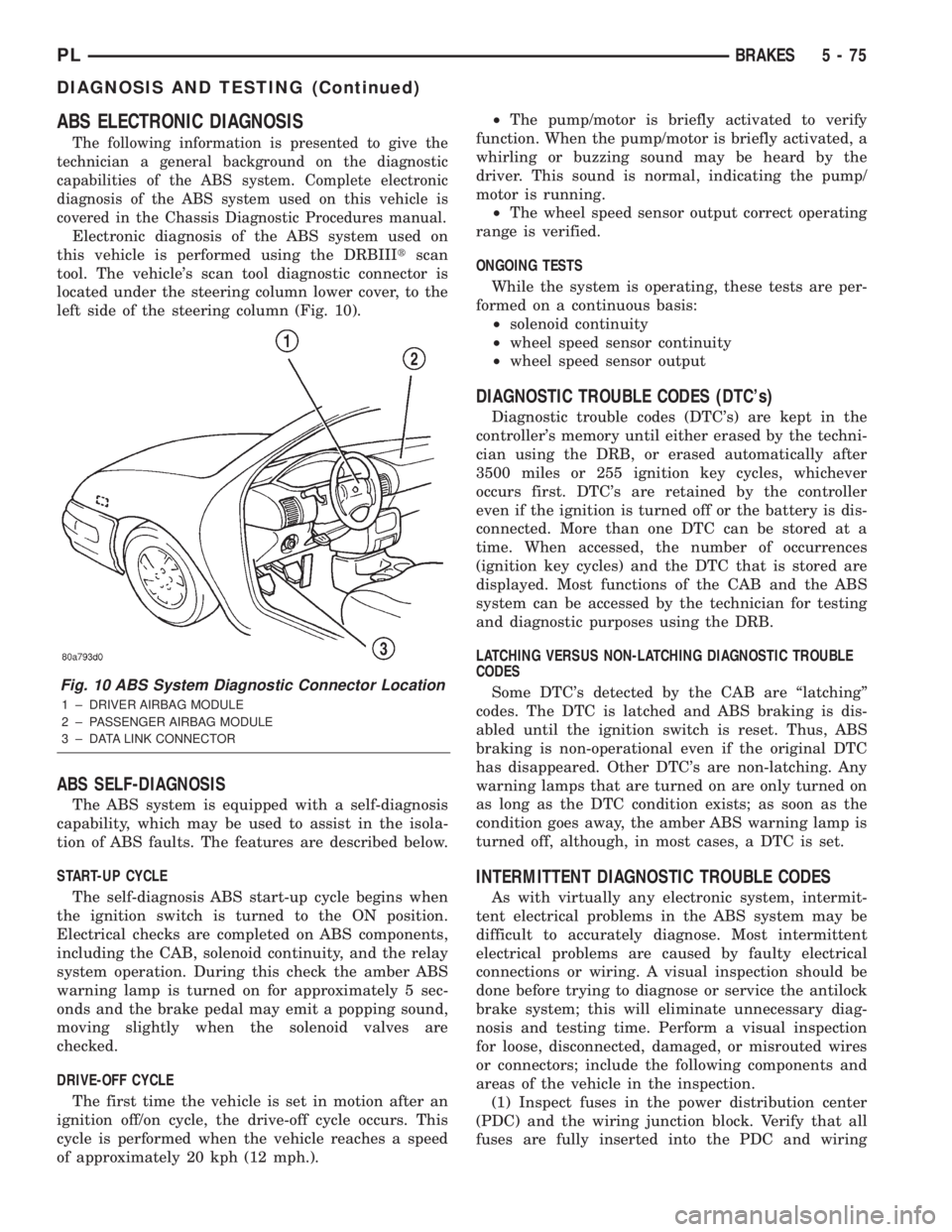

ABS ELECTRONIC DIAGNOSIS

The following information is presented to give the

technician a general background on the diagnostic

capabilities of the ABS system. Complete electronic

diagnosis of the ABS system used on this vehicle is

covered in the Chassis Diagnostic Procedures manual.

Electronic diagnosis of the ABS system used on

this vehicle is performed using the DRBIIItscan

tool. The vehicle's scan tool diagnostic connector is

located under the steering column lower cover, to the

left side of the steering column (Fig. 10).

ABS SELF-DIAGNOSIS

The ABS system is equipped with a self-diagnosis

capability, which may be used to assist in the isola-

tion of ABS faults. The features are described below.

START-UP CYCLE

The self-diagnosis ABS start-up cycle begins when

the ignition switch is turned to the ON position.

Electrical checks are completed on ABS components,

including the CAB, solenoid continuity, and the relay

system operation. During this check the amber ABS

warning lamp is turned on for approximately 5 sec-

onds and the brake pedal may emit a popping sound,

moving slightly when the solenoid valves are

checked.

DRIVE-OFF CYCLE

The first time the vehicle is set in motion after an

ignition off/on cycle, the drive-off cycle occurs. This

cycle is performed when the vehicle reaches a speed

of approximately 20 kph (12 mph.).²The pump/motor is briefly activated to verify

function. When the pump/motor is briefly activated, a

whirling or buzzing sound may be heard by the

driver. This sound is normal, indicating the pump/

motor is running.

²The wheel speed sensor output correct operating

range is verified.

ONGOING TESTS

While the system is operating, these tests are per-

formed on a continuous basis:

²solenoid continuity

²wheel speed sensor continuity

²wheel speed sensor output

DIAGNOSTIC TROUBLE CODES (DTC's)

Diagnostic trouble codes (DTC's) are kept in the

controller's memory until either erased by the techni-

cian using the DRB, or erased automatically after

3500 miles or 255 ignition key cycles, whichever

occurs first. DTC's are retained by the controller

even if the ignition is turned off or the battery is dis-

connected. More than one DTC can be stored at a

time. When accessed, the number of occurrences

(ignition key cycles) and the DTC that is stored are

displayed. Most functions of the CAB and the ABS

system can be accessed by the technician for testing

and diagnostic purposes using the DRB.

LATCHING VERSUS NON-LATCHING DIAGNOSTIC TROUBLE

CODES

Some DTC's detected by the CAB are ªlatchingº

codes. The DTC is latched and ABS braking is dis-

abled until the ignition switch is reset. Thus, ABS

braking is non-operational even if the original DTC

has disappeared. Other DTC's are non-latching. Any

warning lamps that are turned on are only turned on

as long as the DTC condition exists; as soon as the

condition goes away, the amber ABS warning lamp is

turned off, although, in most cases, a DTC is set.

INTERMITTENT DIAGNOSTIC TROUBLE CODES

As with virtually any electronic system, intermit-

tent electrical problems in the ABS system may be

difficult to accurately diagnose. Most intermittent

electrical problems are caused by faulty electrical

connections or wiring. A visual inspection should be

done before trying to diagnose or service the antilock

brake system; this will eliminate unnecessary diag-

nosis and testing time. Perform a visual inspection

for loose, disconnected, damaged, or misrouted wires

or connectors; include the following components and

areas of the vehicle in the inspection.

(1) Inspect fuses in the power distribution center

(PDC) and the wiring junction block. Verify that all

fuses are fully inserted into the PDC and wiring

Fig. 10 ABS System Diagnostic Connector Location

1 ± DRIVER AIRBAG MODULE

2 ± PASSENGER AIRBAG MODULE

3 ± DATA LINK CONNECTOR

PLBRAKES 5 - 75

DIAGNOSIS AND TESTING (Continued)

Page 155 of 1285

junction block. A label on the underside of the PDC

cover identifies the locations of the ABS fuses.

(2) Inspect the 25-way electrical connector at the

CAB for damaged, spread, or backed-out wiring ter-

minals. Verify that the 25-way connector is fully

inserted in the socket of the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Look for poor mating of connector halves or ter-

minals not fully seated in the connector body.

(5)

Check for improperly formed or damaged termi-

nals. All connector terminals in a suspect circuit should

be carefully reformed to increase contact tension.

(6) Look for poor terminal-to-wire connections.

This requires removing the terminal from the connec-

tor body to inspect it.

(7) Verify pin presence in the connector assembly

(8) Check for proper ground connections. Check all

ground connections for signs of corrosion, loose fas-

teners, or other potential defects. Refer to the wiring

diagrams for ground locations.

(9) Look for problems with the main power sources

of the vehicle. Inspect the battery, generator, ignition

circuits and other related relays and fuses.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record any trouble codes.

Most failures of the ABS disable the ABS function

for the entire ignition cycle even if the fault clears

before key-off. There are some failure conditions,

however, that allow ABS operation to resume during

the ignition cycle in which the trouble occurred even

if the trouble conditions are no longer present.

The following trouble conditions may result in

intermittent illumination of the amber ABS warning

lamp.

²Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.

²High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

Additional possible causes that may result in the

illumination of the amber ABS warning lamp are as

follows:

²Any condition that interrupts electrical current

to the CAB may cause the amber ABS warning lamp

to turn on intermittently.

²If PCI communication between the body control-

ler and the CAB is interrupted, the body controller

can turn on the amber ABS warning lamp.

TONE WHEEL

Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes:

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. Refer to the

DIFFERENTIAL AND DRIVELINE group in this

service manual for removal and installation.

If a rear tone wheel is found to need replacement,

the rear hub and bearing must be replaced. No

attempt should be made to replace just the tone

wheel. Refer to the SUSPENSION group in this ser-

vice manual for removal and installation.

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

Refer to SPECIFICATIONS in this section of the ser-

vice manual for the minimum and maximum wheel

speed sensor to tone wheel clearance.

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout. If tone

wheel runout is excessive, determine if it is caused

by a defect in the driveshaft assembly or hub and

bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft or rear hub and bearing is necessary.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swelling indicates the

presence of petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If the fluid sep-

arates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If the brake fluid is contaminated, drain and thor-

oughly flush the brake system. Replace all the rubber

parts or components containing rubber coming into

contact with the brake fluid including: the master

cylinder; proportioning valves; caliper seals; wheel

cylinder seals; ABS hydraulic control unit; and all

hydraulic fluid hoses.

5 - 76 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 157 of 1285

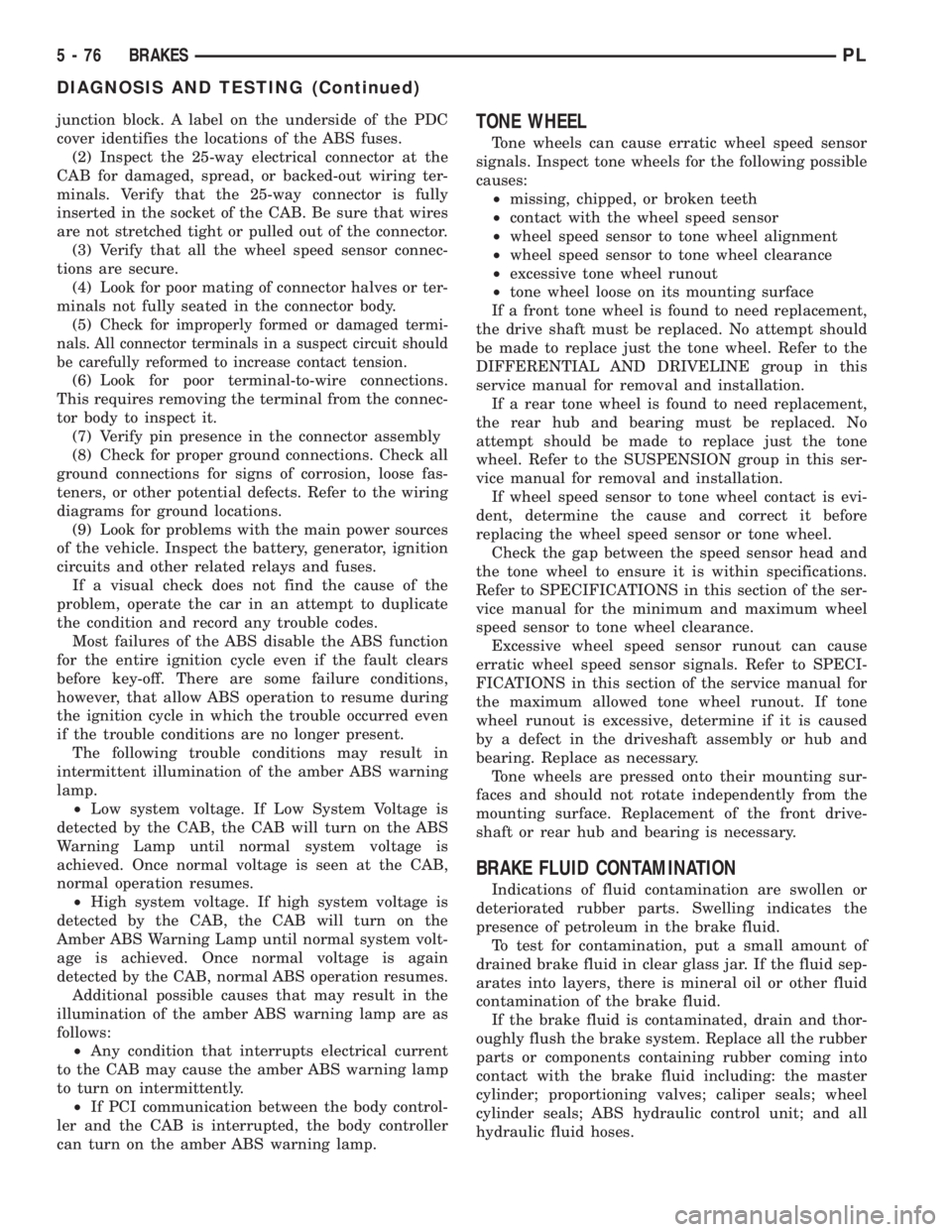

NOTE: It is not necessary to bleed the entire

hydraulic system after replacing just the master cyl-

inder unless the brake system has been open to air

for an excessive amount of time or air is present in

the lines. Only the master cylinder must be bled

and filled.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

Review this entire section prior to performing any

mechanical work on a vehicle equipped with ABS.

This section contains information on precautions per-

taining to potential component damage, vehicle dam-

age and personal injury which could result when

servicing an ABS equipped vehicle.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-

ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash off with water immediately.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.

CAUTION: If welding work is to be performed on

the vehicle, using an electric arc welder, the CAB

connector should be disconnected during the weld-

ing operation.

CAUTION: The CAB 25-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

Many components of the ABS System are not ser-

viceable and must be replaced as an assembly. Do not

disassemble any component which is not designed to

be serviced.

MASTER CYLINDER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

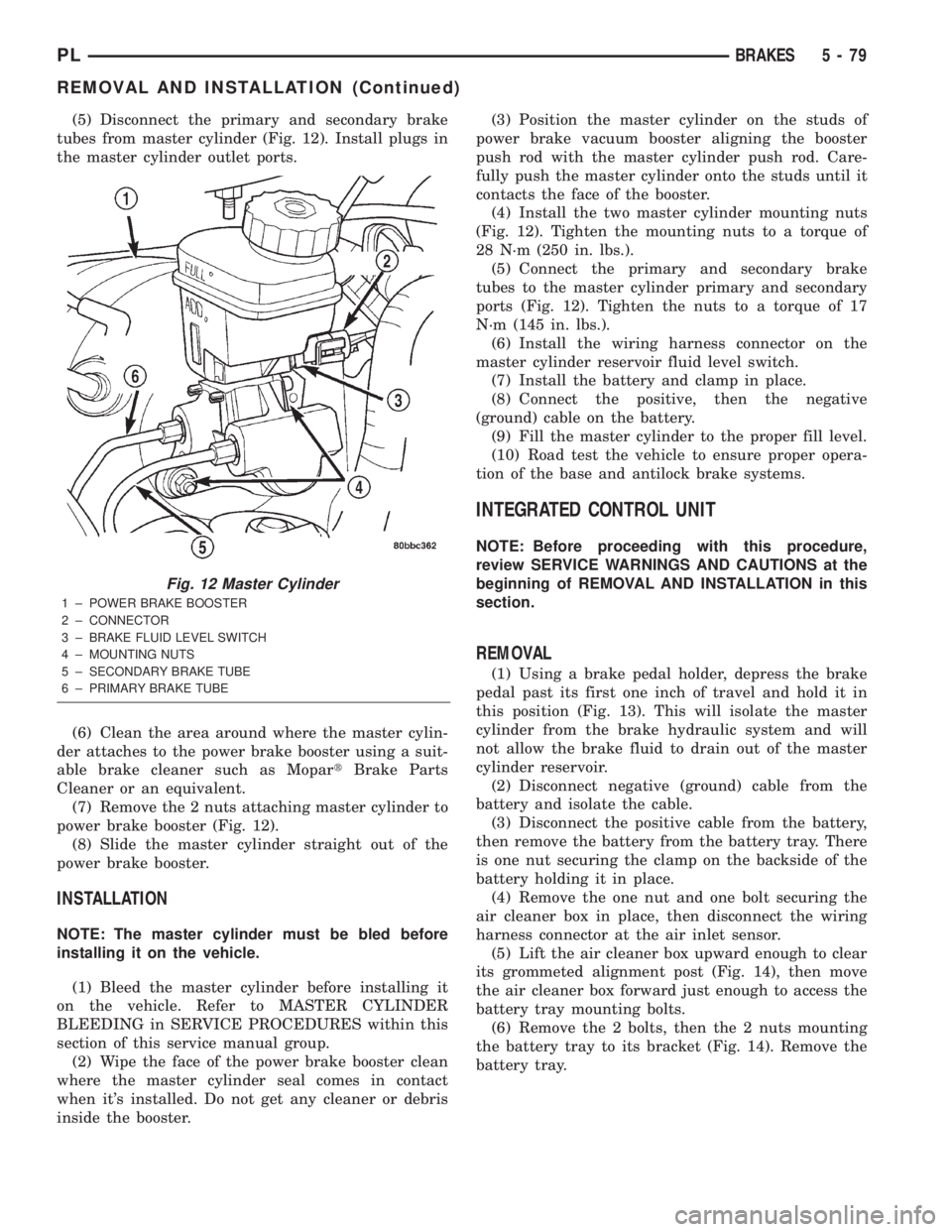

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal while the engine is not running until a

firm brake pedal is achieved.

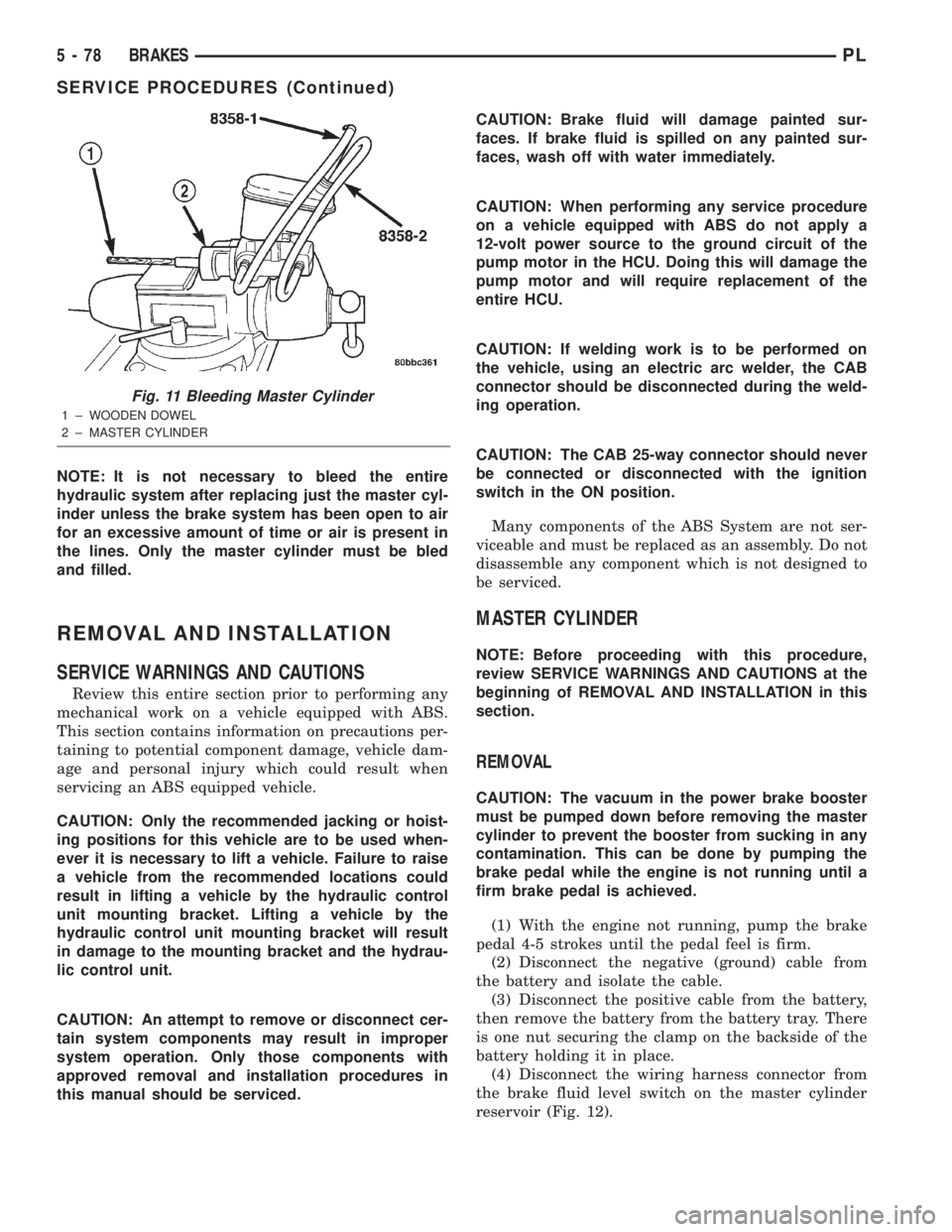

(1) With the engine not running, pump the brake

pedal 4-5 strokes until the pedal feel is firm.

(2) Disconnect the negative (ground) cable from

the battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(4) Disconnect the wiring harness connector from

the brake fluid level switch on the master cylinder

reservoir (Fig. 12).

Fig. 11 Bleeding Master Cylinder

1 ± WOODEN DOWEL

2 ± MASTER CYLINDER

5 - 78 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 158 of 1285

(5) Disconnect the primary and secondary brake

tubes from master cylinder (Fig. 12). Install plugs in

the master cylinder outlet ports.

(6) Clean the area around where the master cylin-

der attaches to the power brake booster using a suit-

able brake cleaner such as MopartBrake Parts

Cleaner or an equivalent.

(7) Remove the 2 nuts attaching master cylinder to

power brake booster (Fig. 12).

(8) Slide the master cylinder straight out of the

power brake booster.

INSTALLATION

NOTE: The master cylinder must be bled before

installing it on the vehicle.

(1) Bleed the master cylinder before installing it

on the vehicle. Refer to MASTER CYLINDER

BLEEDING in SERVICE PROCEDURES within this

section of this service manual group.

(2) Wipe the face of the power brake booster clean

where the master cylinder seal comes in contact

when it's installed. Do not get any cleaner or debris

inside the booster.(3) Position the master cylinder on the studs of

power brake vacuum booster aligning the booster

push rod with the master cylinder push rod. Care-

fully push the master cylinder onto the studs until it

contacts the face of the booster.

(4) Install the two master cylinder mounting nuts

(Fig. 12). Tighten the mounting nuts to a torque of

28 N´m (250 in. lbs.).

(5) Connect the primary and secondary brake

tubes to the master cylinder primary and secondary

ports (Fig. 12). Tighten the nuts to a torque of 17

N´m (145 in. lbs.).

(6) Install the wiring harness connector on the

master cylinder reservoir fluid level switch.

(7) Install the battery and clamp in place.

(8) Connect the positive, then the negative

(ground) cable on the battery.

(9) Fill the master cylinder to the proper fill level.

(10) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

INTEGRATED CONTROL UNIT

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

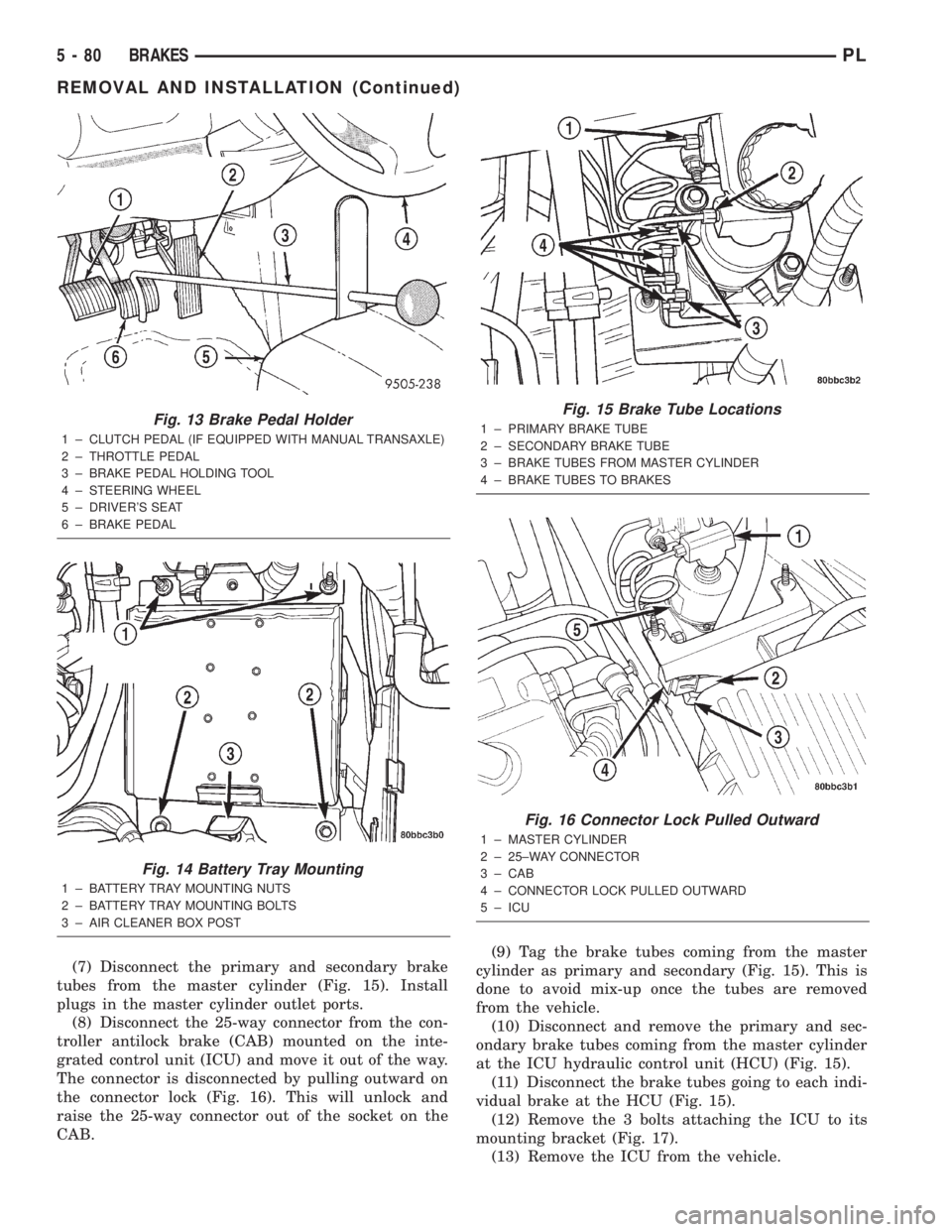

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 13). This will isolate the master

cylinder from the brake hydraulic system and will

not allow the brake fluid to drain out of the master

cylinder reservoir.

(2) Disconnect negative (ground) cable from the

battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(4) Remove the one nut and one bolt securing the

air cleaner box in place, then disconnect the wiring

harness connector at the air inlet sensor.

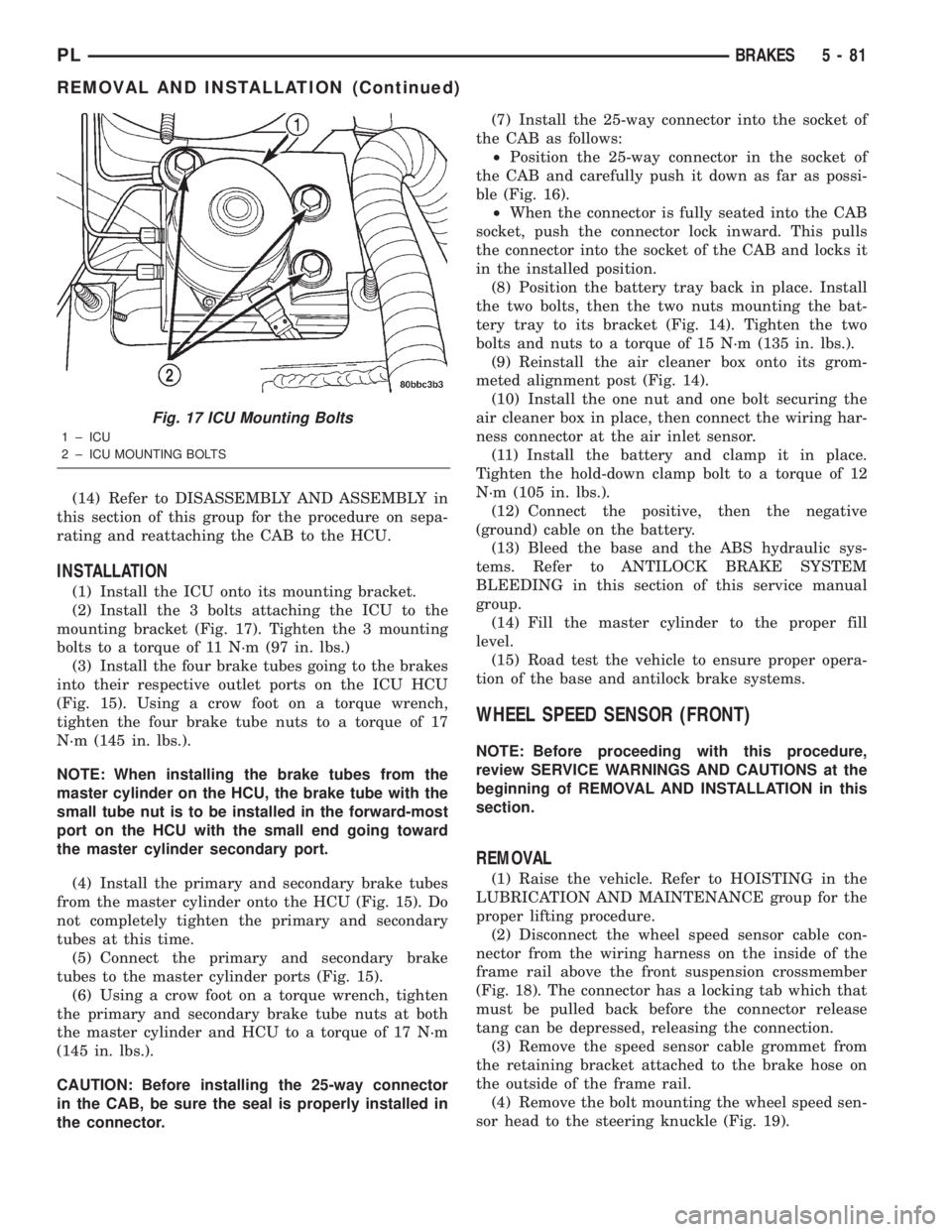

(5) Lift the air cleaner box upward enough to clear

its grommeted alignment post (Fig. 14), then move

the air cleaner box forward just enough to access the

battery tray mounting bolts.

(6) Remove the 2 bolts, then the 2 nuts mounting

the battery tray to its bracket (Fig. 14). Remove the

battery tray.

Fig. 12 Master Cylinder

1 ± POWER BRAKE BOOSTER

2 ± CONNECTOR

3 ± BRAKE FLUID LEVEL SWITCH

4 ± MOUNTING NUTS

5 ± SECONDARY BRAKE TUBE

6 ± PRIMARY BRAKE TUBE

PLBRAKES 5 - 79

REMOVAL AND INSTALLATION (Continued)

Page 159 of 1285

(7) Disconnect the primary and secondary brake

tubes from the master cylinder (Fig. 15). Install

plugs in the master cylinder outlet ports.

(8) Disconnect the 25-way connector from the con-

troller antilock brake (CAB) mounted on the inte-

grated control unit (ICU) and move it out of the way.

The connector is disconnected by pulling outward on

the connector lock (Fig. 16). This will unlock and

raise the 25-way connector out of the socket on the

CAB.(9) Tag the brake tubes coming from the master

cylinder as primary and secondary (Fig. 15). This is

done to avoid mix-up once the tubes are removed

from the vehicle.

(10) Disconnect and remove the primary and sec-

ondary brake tubes coming from the master cylinder

at the ICU hydraulic control unit (HCU) (Fig. 15).

(11) Disconnect the brake tubes going to each indi-

vidual brake at the HCU (Fig. 15).

(12) Remove the 3 bolts attaching the ICU to its

mounting bracket (Fig. 17).

(13) Remove the ICU from the vehicle.

Fig. 13 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 14 Battery Tray Mounting

1 ± BATTERY TRAY MOUNTING NUTS

2 ± BATTERY TRAY MOUNTING BOLTS

3 ± AIR CLEANER BOX POST

Fig. 15 Brake Tube Locations

1 ± PRIMARY BRAKE TUBE

2 ± SECONDARY BRAKE TUBE

3 ± BRAKE TUBES FROM MASTER CYLINDER

4 ± BRAKE TUBES TO BRAKES

Fig. 16 Connector Lock Pulled Outward

1 ± MASTER CYLINDER

2 ± 25±WAY CONNECTOR

3 ± CAB

4 ± CONNECTOR LOCK PULLED OUTWARD

5 ± ICU

5 - 80 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 160 of 1285

(14) Refer to DISASSEMBLY AND ASSEMBLY in

this section of this group for the procedure on sepa-

rating and reattaching the CAB to the HCU.

INSTALLATION

(1) Install the ICU onto its mounting bracket.

(2) Install the 3 bolts attaching the ICU to the

mounting bracket (Fig. 17). Tighten the 3 mounting

bolts to a torque of 11 N´m (97 in. lbs.)

(3) Install the four brake tubes going to the brakes

into their respective outlet ports on the ICU HCU

(Fig. 15). Using a crow foot on a torque wrench,

tighten the four brake tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: When installing the brake tubes from the

master cylinder on the HCU, the brake tube with the

small tube nut is to be installed in the forward-most

port on the HCU with the small end going toward

the master cylinder secondary port.

(4) Install the primary and secondary brake tubes

from the master cylinder onto the HCU (Fig. 15). Do

not completely tighten the primary and secondary

tubes at this time.

(5) Connect the primary and secondary brake

tubes to the master cylinder ports (Fig. 15).

(6) Using a crow foot on a torque wrench, tighten

the primary and secondary brake tube nuts at both

the master cylinder and HCU to a torque of 17 N´m

(145 in. lbs.).

CAUTION: Before installing the 25-way connector

in the CAB, be sure the seal is properly installed in

the connector.(7) Install the 25-way connector into the socket of

the CAB as follows:

²Position the 25-way connector in the socket of

the CAB and carefully push it down as far as possi-

ble (Fig. 16).

²When the connector is fully seated into the CAB

socket, push the connector lock inward. This pulls

the connector into the socket of the CAB and locks it

in the installed position.

(8) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 14). Tighten the two

bolts and nuts to a torque of 15 N´m (135 in. lbs.).

(9) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 14).

(10) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(11) Install the battery and clamp it in place.

Tighten the hold-down clamp bolt to a torque of 12

N´m (105 in. lbs.).

(12) Connect the positive, then the negative

(ground) cable on the battery.

(13) Bleed the base and the ABS hydraulic sys-

tems. Refer to ANTILOCK BRAKE SYSTEM

BLEEDING in this section of this service manual

group.

(14) Fill the master cylinder to the proper fill

level.

(15) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

WHEEL SPEED SENSOR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Disconnect the wheel speed sensor cable con-

nector from the wiring harness on the inside of the

frame rail above the front suspension crossmember

(Fig. 18). The connector has a locking tab which that

must be pulled back before the connector release

tang can be depressed, releasing the connection.

(3) Remove the speed sensor cable grommet from

the retaining bracket attached to the brake hose on

the outside of the frame rail.

(4) Remove the bolt mounting the wheel speed sen-

sor head to the steering knuckle (Fig. 19).

Fig. 17 ICU Mounting Bolts

1 ± ICU

2 ± ICU MOUNTING BOLTS

PLBRAKES 5 - 81

REMOVAL AND INSTALLATION (Continued)