drain bolt DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(33) Remove the upper engine torque strut.

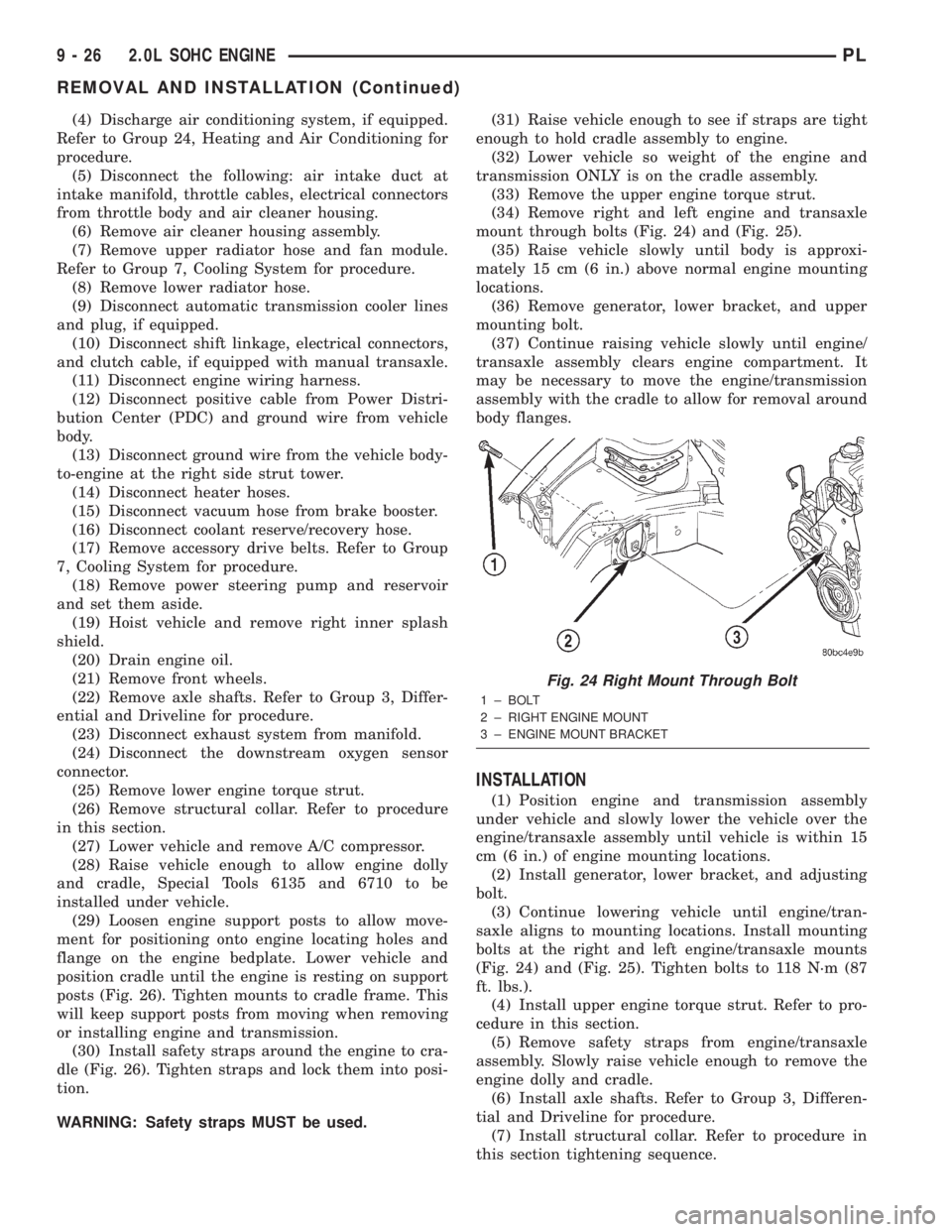

(34) Remove right and left engine and transaxle

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 760 of 1285

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Disconnect negative battery cable.

(3) Remove power steering/air conditioning drive

belt. Refer to Group 7, Cooling System Accessory

Drive for procedure.

(4) Raise vehicle.

(5) Drain cooling system. Refer to Group 7, Cooling

System.

(6) Remove exhaust pipe from manifold.

(7) Remove right front wheel.

(8) Remove right side splash shield.

(9) Remove generator belt. Refer to Group 7, Cool-

ing System Accessory Drive Belts for procedure.

(10) Remove crankshaft damper. Refer to proce-

dure in this section.

(11) Remove lower torque strut.

(12) Lower vehicle and remove upper torque strut.

(13) Remove ground strap and power steering hose

support clip from engine mount bracket.

(14) Remove power steering pump assembly and

set aside.

(15) Support engine from beneath with a suitable

jack.

(16) Remove right side engine mount to bracket

through bolt.

(17) Remove the lower engine mount bracket bolt.

Raise engine slightly and remove the upper engine

mount bracket bolts.(18) Remove engine mount bracket. This procedure

may require additional raising/lowering of engine

until bracket will clear engine components.

(19) Remove front timing belt cover.

(20) Rotate engine until timing marks are aligned.

(21) Remove timing belt and tensioner. Refer to

procedures in this section.

(22) Remove camshaft sprocket. Refer to proce-

dures in this section.

(23) Remove rear timing belt cover.

(24) Disconnect fuel line at fuel rail.

(25) Remove coolant recovery container.

(26) Remove ground wire to cylinder head.

(27) Remove upper radiator hose.

(28) Remove intake manifold. Refer to procedure

in this section.

(29) Disconnect ignition coil electrical connector.

Remove coil pack and spark plug cables from engine.

(30) Remove Crankcase Closed Ventilation (CCV)

hose from cylinder head cover.

(31) Disconnect cam sensor and coolant tempera-

ture electrical connectors.

(32) Remove heater tube to cylinder head attach-

ing fasteners.

(33) Remove heater hose from thermostat housing

connector.

(34) Remove cylinder head cover.

(35) Remove cylinder head bolts.

(36) Remove cylinder head and gasket (Fig. 55).

PL2.0L SOHC ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 770 of 1285

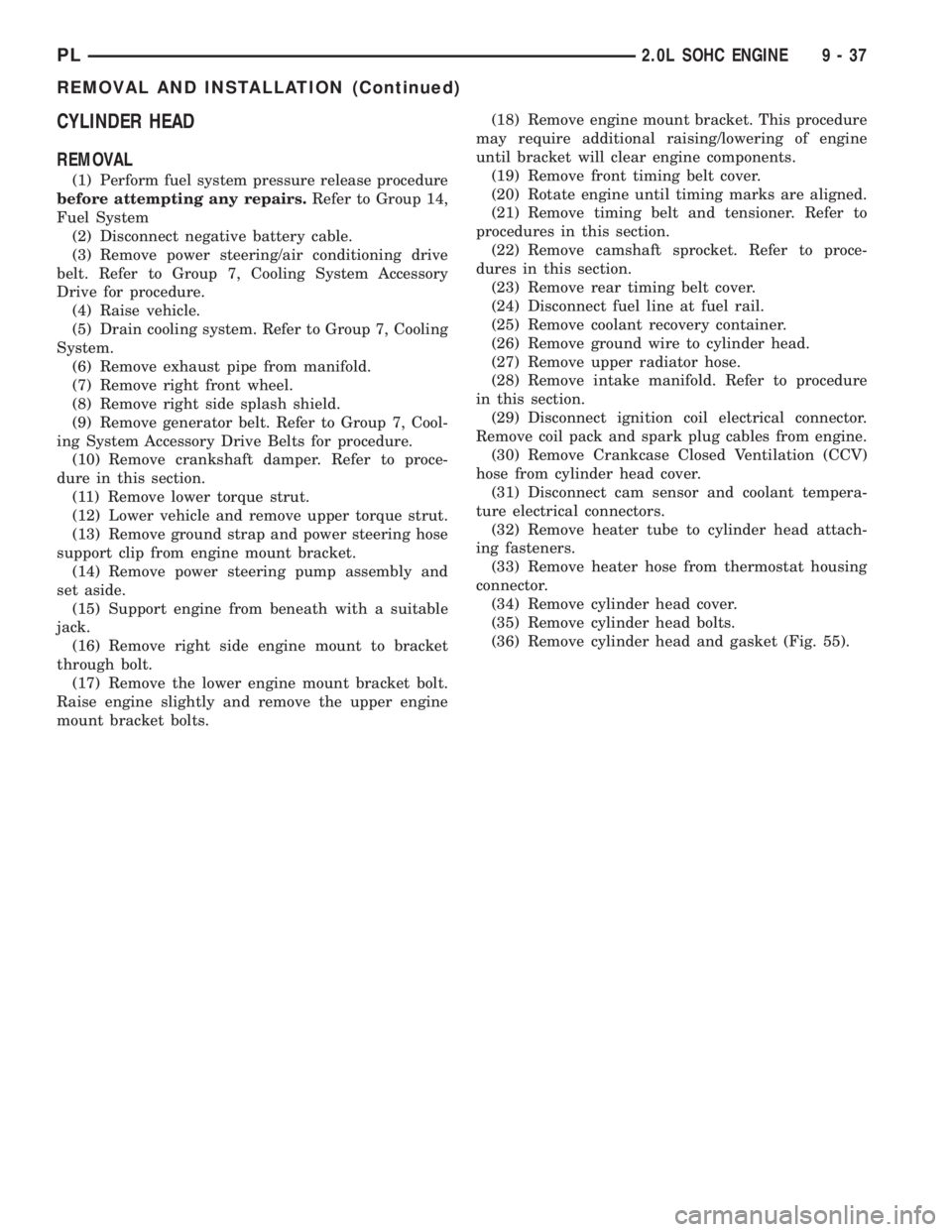

(5) Remove camshaft seal by carefully using a suit-

able pry tool. Be careful not to nick or damage thecamshaft seal surface or cylinder head seal retaining

bore.

CAUTION: Do not nick shaft seal surface or seal

bore.

(6) Shaft seal lip surface must be free of varnish,

dirt or nicks. Polish with 400 grit paper, if necessary.

INSTALLATION

(1) Install camshaft seal flush with cylinder head

using Special Tool MD998306 (Fig. 80).

(2) Install rear timing belt cover.

(3) Install camshaft sprocket retaining bolt. Hold

camshaft sprocket with Special Tools C-4687 and

modified C-4687-1 (Fig. 79) and tighten bolt to 115

N´m (85 ft. lbs.).

(4) Install timing belt tensioner, timing belt, front

cover, and crankshaft damper. Refer to procedures in

this section.

OIL PAN

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Drain engine oil and remove oil filter.

(4) Remove oil filter adaptor from engine block

(Fig. 81).

(5) Remove structural collar. Refer to procedure in

this section.

(6) Remove lateral bending brace attaching bolts

(Fig. 82).

(7) Remove lateral bending brace (Fig. 82).

(8) Remove transaxle dust cover (Fig. 82).

(9) Remove oil pan bolts.

(10) Remove oil pan.

INSTALLATION

(1) Clean oil pan and all sealing surfaces.

Fig. 78 Timing Belt Tensioner AssemblyÐRemoval/

Installation

1 ± TIMING BELT TENSIONER ASSEMBLY

2 ± TENSIONER ASSEMBLY ATTACHING BOLTS

Fig. 79 Modification to Special Tool

1 ± GRIND LOCATION

2 ± 12.7 MM (1/2 IN.)

3 ± 50.8 MM (2 IN.)

Fig. 80 Camshaft Oil SealÐInstallation

1 ± SPECIAL TOOL MD 998306

PL2.0L SOHC ENGINE 9 - 47

REMOVAL AND INSTALLATION (Continued)

Page 778 of 1285

(17) Install rear timing belt cover and camshaft

sprocket.

(18) Install crankshaft sprocket, timing belt ten-

sioner, timing belt, and cover.

(19) Install front engine mount bracket.

(20) Remove engine from repair stand and position

on Special Tools 6135 and 6710 Engine Dolly and

Cradle. Install safety straps around the engine to

cradle and tighten and lock them into position.

(21) Install crankshaft rear oil seal. Refer to proce-

dure in this section.

(22) Install drive plate/flywheel. Apply Mopart

Lock & Seal Adhesive to bolt threads and tighten to

95 N´m (70 ft. lbs.).

(23) Install transaxle to engine.

(24) Install structural collar. Refer to procedure in

this section.

(25) Install engine assembly. Refer to procedure in

this section.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

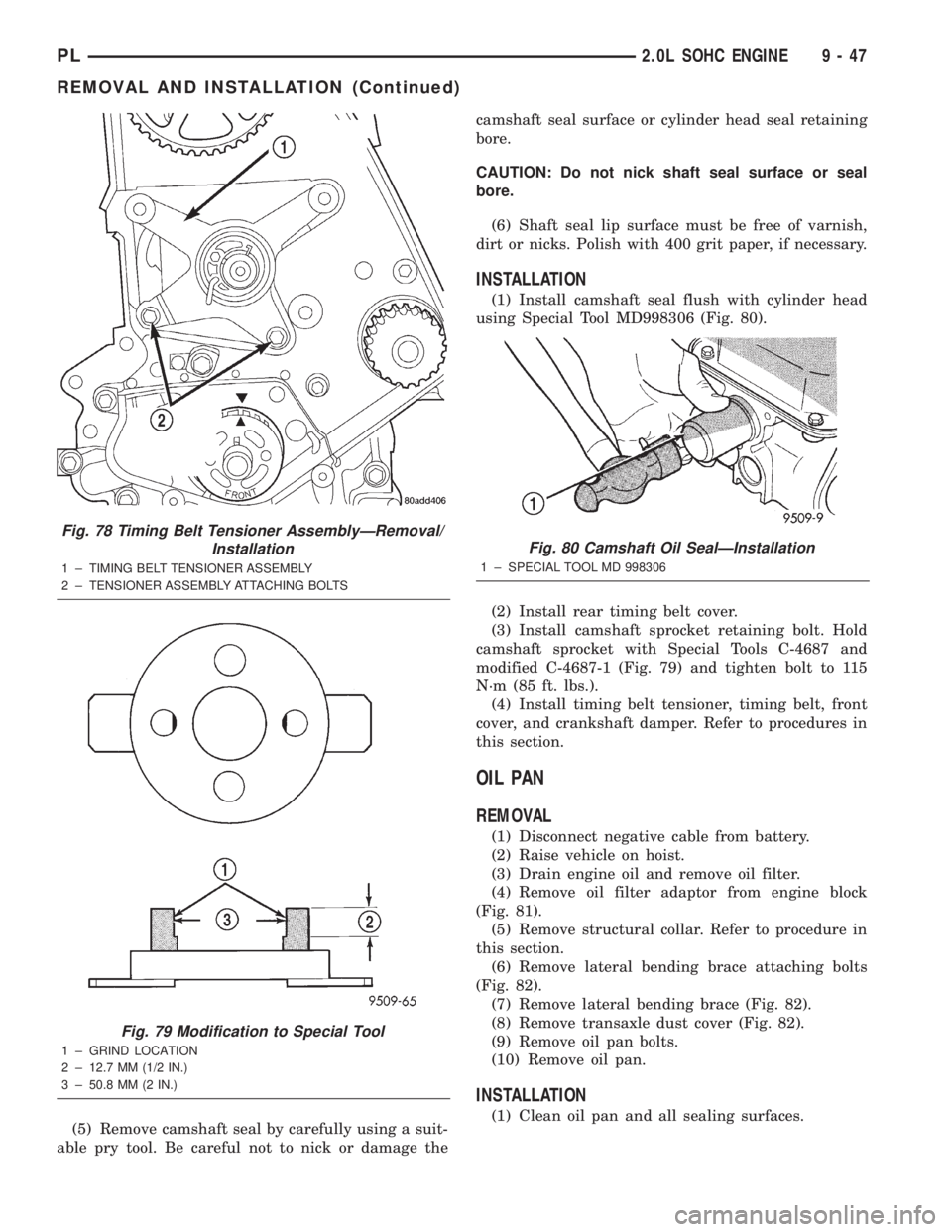

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 101).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 102),

avoid deforming the filter. Use an appropriate oil fil-

ter removing tool. Position filter wrench strap close

the seam at the base of the filter. The oil filter seam

that joins the can to the base, is reinforced by the

base plate.

(1) Turn filter counterclockwise to remove.

(2) Clean and check the filter mounting surface.

The surface must be smooth, flat and free of debris

or old pieces of rubber.

(3) To install, lubricate new filter gasket. Screw fil-

ter on until gasket contacts base. Tighten to 21 N´m

(15 ft. lbs.).

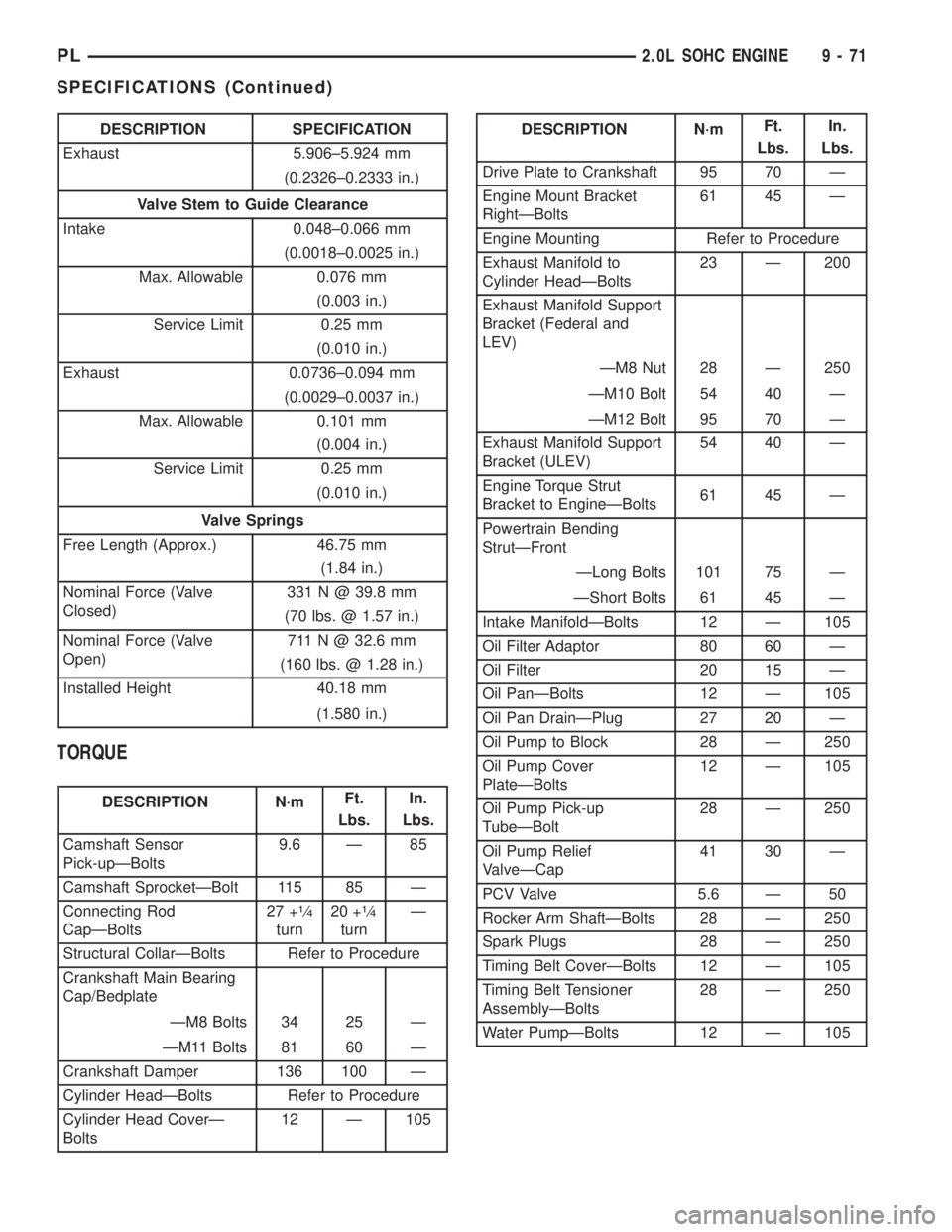

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(3) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(4) Remove oil pan. Refer to procedure in this sec-

tion.

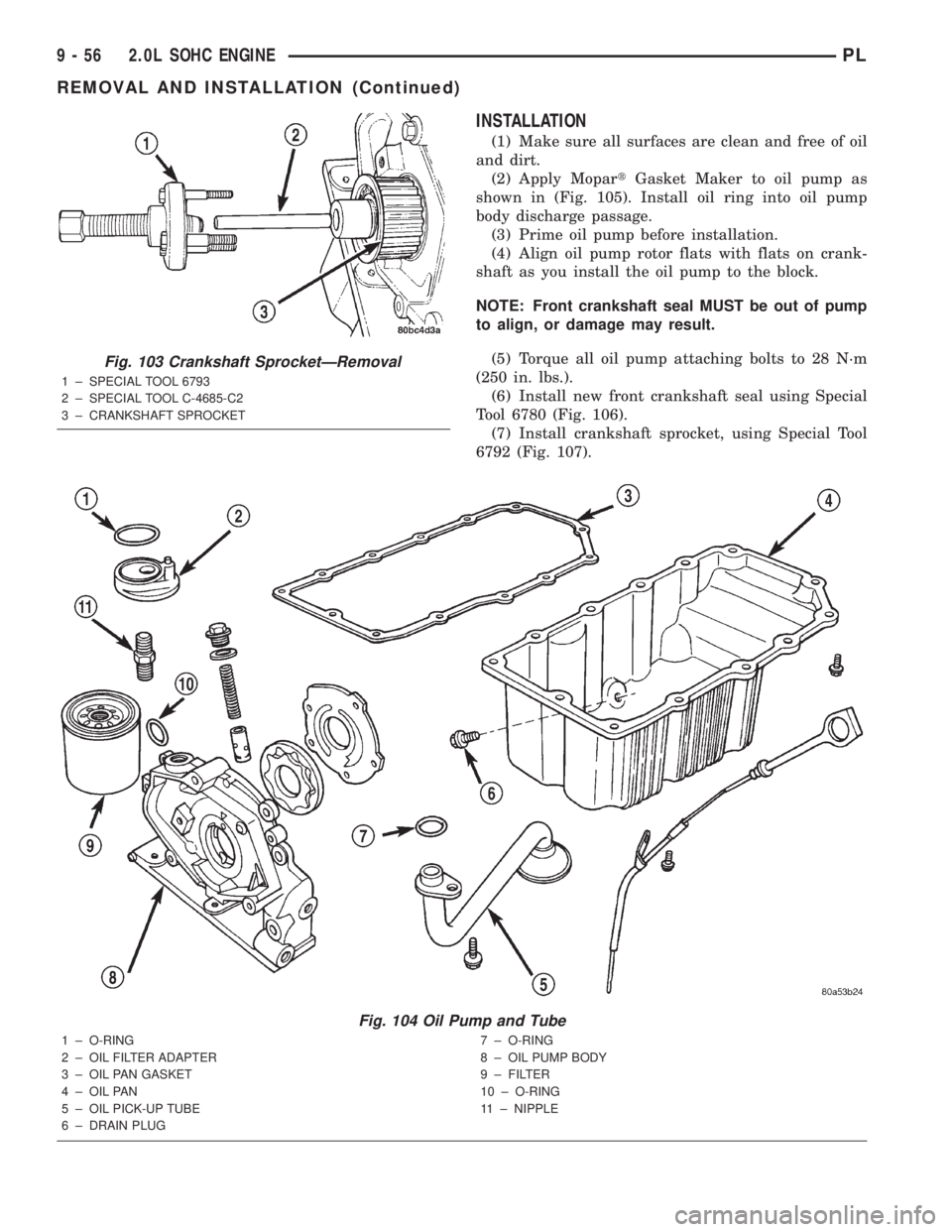

(5) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 103).

(6) Remove oil pick-up tube.

(7) Remove oil pump (Fig. 104) and front crank-

shaft seal.

Fig. 101 Engine Oil Filter Adapter to Engine Block

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 102 Engine Oil Filter

1 ± OIL FILTER

2 ± DRAIN PLUG

PL2.0L SOHC ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 779 of 1285

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 105). Install oil ring into oil pump

body discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.).

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 106).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 107).

Fig. 104 Oil Pump and Tube

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

Fig. 103 Crankshaft SprocketÐRemoval

1 ± SPECIAL TOOL 6793

2 ± SPECIAL TOOL C-4685-C2

3 ± CRANKSHAFT SPROCKET

9 - 56 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 794 of 1285

DESCRIPTION SPECIFICATION

Exhaust 5.906±5.924 mm

(0.2326±0.2333 in.)

Valve Stem to Guide Clearance

Intake 0.048±0.066 mm

(0.0018±0.0025 in.)

Max. Allowable 0.076 mm

(0.003 in.)

Service Limit 0.25 mm

(0.010 in.)

Exhaust 0.0736±0.094 mm

(0.0029±0.0037 in.)

Max. Allowable 0.101 mm

(0.004 in.)

Service Limit 0.25 mm

(0.010 in.)

Valve Springs

Free Length (Approx.) 46.75 mm

(1.84 in.)

Nominal Force (Valve

Closed)331 N @ 39.8 mm

(70 lbs. @ 1.57 in.)

Nominal Force (Valve

Open)711 N @ 32.6 mm

(160 lbs. @ 1.28 in.)

Installed Height 40.18 mm

(1.580 in.)

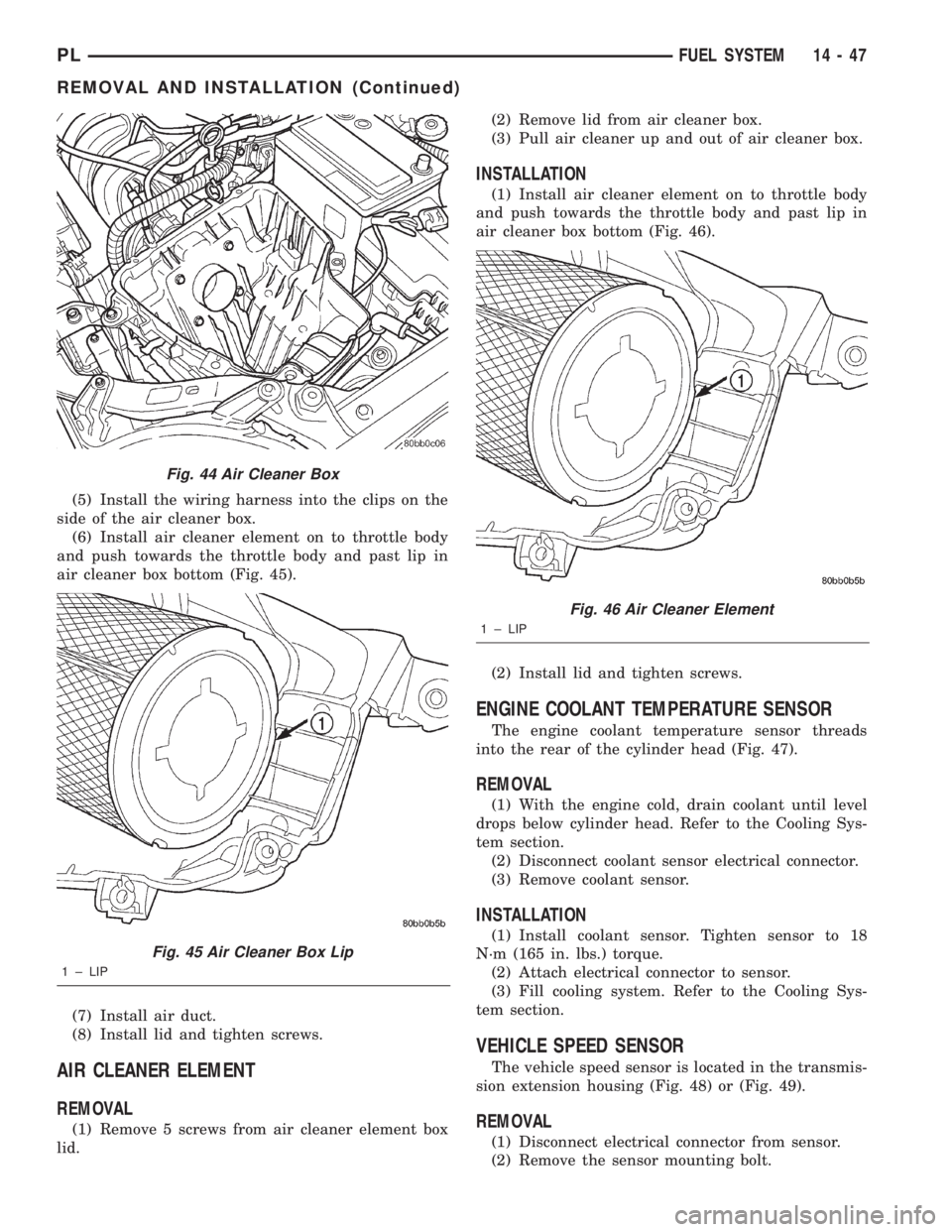

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Camshaft Sensor

Pick-upÐBolts9.6 Ð 85

Camshaft SprocketÐBolt 115 85 Ð

Connecting Rod

CapÐBolts27 +

1¤4

turn20 +

1¤4

turnÐ

Structural CollarÐBolts Refer to Procedure

Crankshaft Main Bearing

Cap/Bedplate

ÐM8 Bolts 34 25 Ð

ÐM11 Bolts 81 60 Ð

Crankshaft Damper 136 100 Ð

Cylinder HeadÐBolts Refer to Procedure

Cylinder Head CoverÐ

Bolts12 Ð 105

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Drive Plate to Crankshaft 95 70 Ð

Engine Mount Bracket

RightÐBolts61 45 Ð

Engine Mounting Refer to Procedure

Exhaust Manifold to

Cylinder HeadÐBolts23 Ð 200

Exhaust Manifold Support

Bracket (Federal and

LEV)

ÐM8 Nut 28 Ð 250

ÐM10 Bolt 54 40 Ð

ÐM12 Bolt 95 70 Ð

Exhaust Manifold Support

Bracket (ULEV)54 40 Ð

Engine Torque Strut

Bracket to EngineÐBolts61 45 Ð

Powertrain Bending

StrutÐFront

ÐLong Bolts 101 75 Ð

ÐShort Bolts 61 45 Ð

Intake ManifoldÐBolts 12 Ð 105

Oil Filter Adaptor 80 60 Ð

Oil Filter 20 15 Ð

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pump to Block 28 Ð 250

Oil Pump Cover

PlateÐBolts12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 Ð 250

Oil Pump Relief

ValveÐCap41 30 Ð

PCV Valve 5.6 Ð 50

Rocker Arm ShaftÐBolts 28 Ð 250

Spark Plugs 28 Ð 250

Timing Belt CoverÐBolts 12 Ð 105

Timing Belt Tensioner

AssemblyÐBolts28 Ð 250

Water PumpÐBolts 12 Ð 105

PL2.0L SOHC ENGINE 9 - 71

SPECIFICATIONS (Continued)

Page 868 of 1285

(5) Install the wiring harness into the clips on the

side of the air cleaner box.

(6) Install air cleaner element on to throttle body

and push towards the throttle body and past lip in

air cleaner box bottom (Fig. 45).

(7) Install air duct.

(8) Install lid and tighten screws.

AIR CLEANER ELEMENT

REMOVAL

(1) Remove 5 screws from air cleaner element box

lid.(2) Remove lid from air cleaner box.

(3) Pull air cleaner up and out of air cleaner box.

INSTALLATION

(1) Install air cleaner element on to throttle body

and push towards the throttle body and past lip in

air cleaner box bottom (Fig. 46).

(2) Install lid and tighten screws.

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor threads

into the rear of the cylinder head (Fig. 47).

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to the Cooling Sys-

tem section.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 18

N´m (165 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to the Cooling Sys-

tem section.

VEHICLE SPEED SENSOR

The vehicle speed sensor is located in the transmis-

sion extension housing (Fig. 48) or (Fig. 49).

REMOVAL

(1) Disconnect electrical connector from sensor.

(2) Remove the sensor mounting bolt.

Fig. 44 Air Cleaner Box

Fig. 45 Air Cleaner Box Lip

1 ± LIP

Fig. 46 Air Cleaner Element

1 ± LIP

PLFUEL SYSTEM 14 - 47

REMOVAL AND INSTALLATION (Continued)

Page 928 of 1285

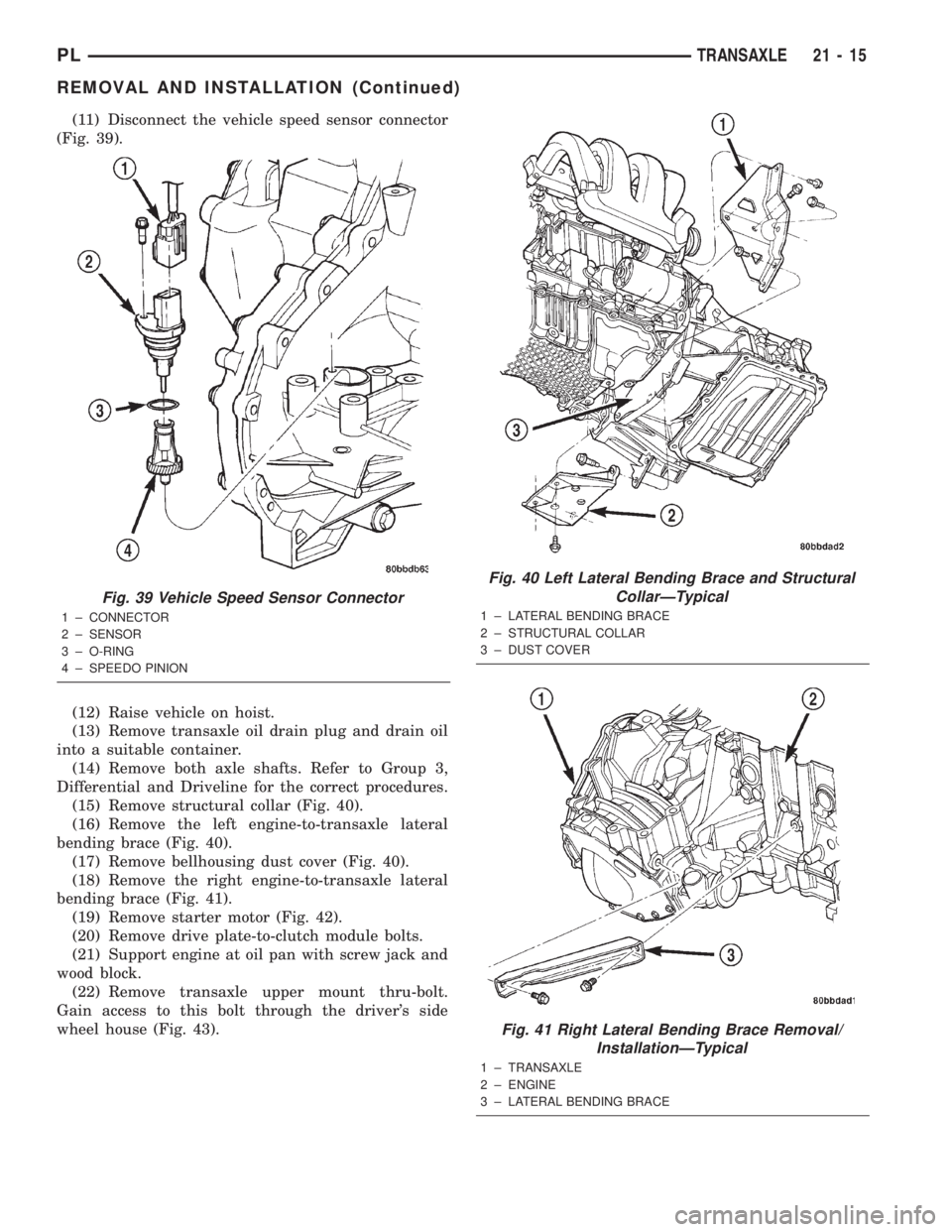

(11) Disconnect the vehicle speed sensor connector

(Fig. 39).

(12) Raise vehicle on hoist.

(13) Remove transaxle oil drain plug and drain oil

into a suitable container.

(14) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.

(15) Remove structural collar (Fig. 40).

(16) Remove the left engine-to-transaxle lateral

bending brace (Fig. 40).

(17) Remove bellhousing dust cover (Fig. 40).

(18) Remove the right engine-to-transaxle lateral

bending brace (Fig. 41).

(19) Remove starter motor (Fig. 42).

(20) Remove drive plate-to-clutch module bolts.

(21) Support engine at oil pan with screw jack and

wood block.

(22) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 43).

Fig. 39 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

Fig. 40 Left Lateral Bending Brace and Structural

CollarÐTypical

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 41 Right Lateral Bending Brace Removal/

InstallationÐTypical

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

PLTRANSAXLE 21 - 15

REMOVAL AND INSTALLATION (Continued)

Page 964 of 1285

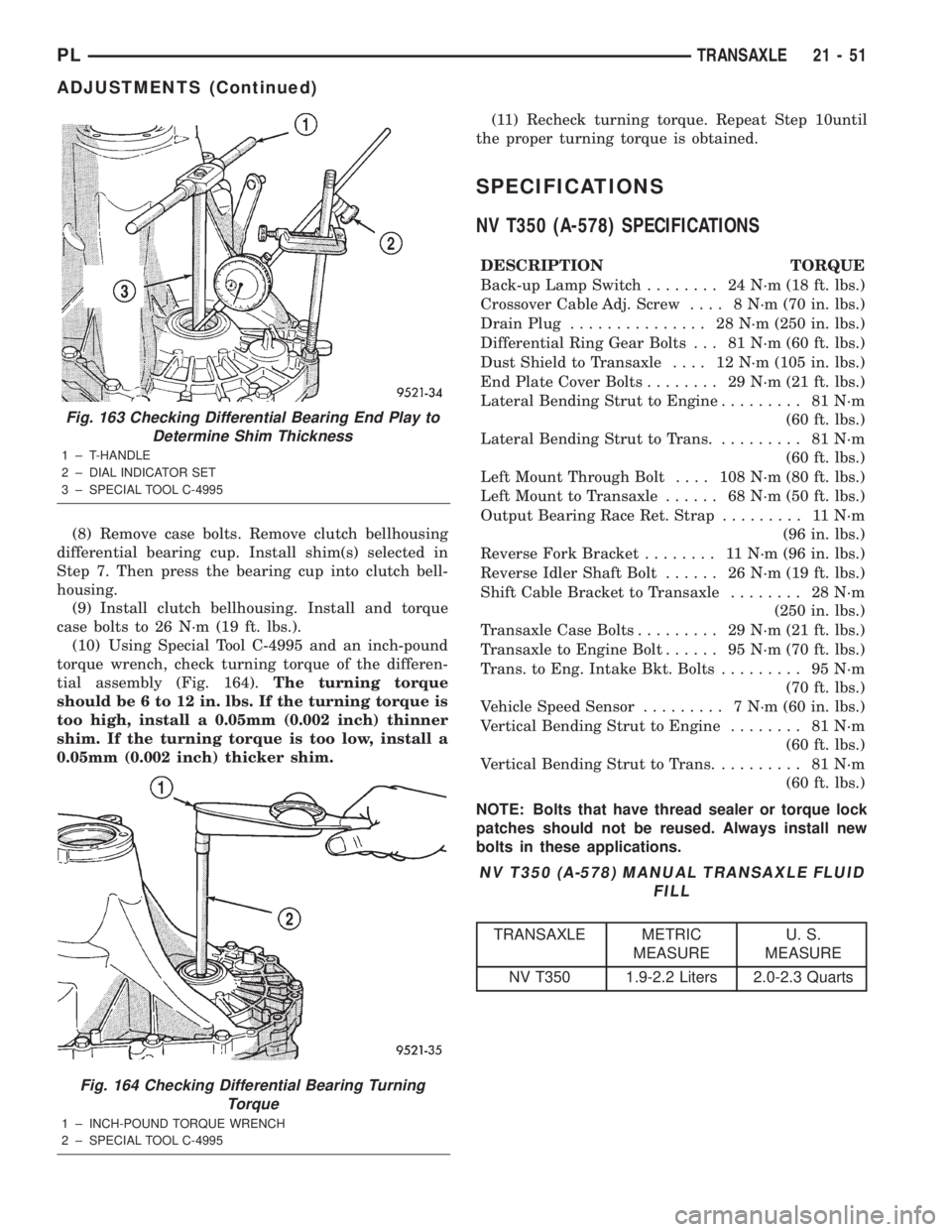

(8) Remove case bolts. Remove clutch bellhousing

differential bearing cup. Install shim(s) selected in

Step 7. Then press the bearing cup into clutch bell-

housing.

(9) Install clutch bellhousing. Install and torque

case bolts to 26 N´m (19 ft. lbs.).

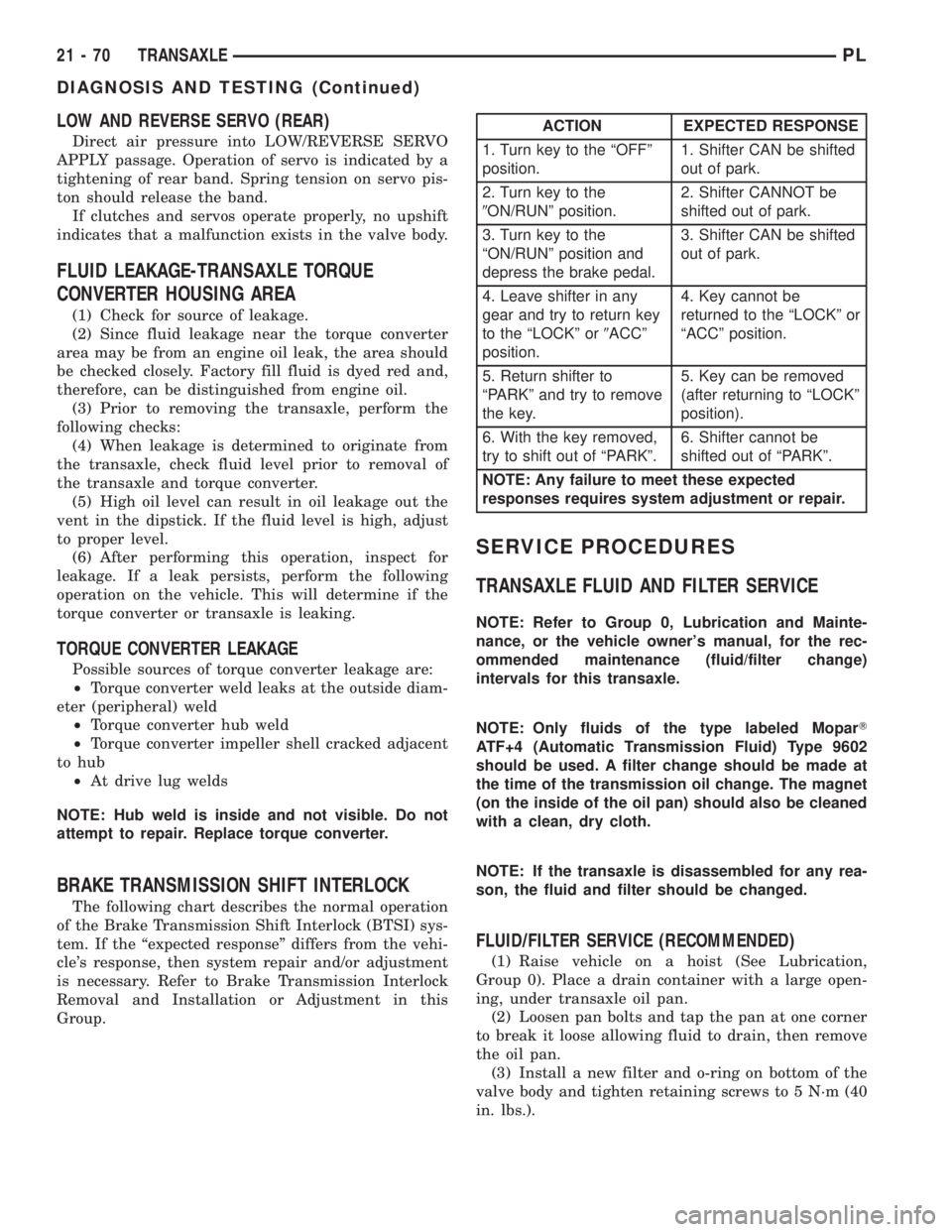

(10) Using Special Tool C-4995 and an inch-pound

torque wrench, check turning torque of the differen-

tial assembly (Fig. 164).The turning torque

should be 6 to 12 in. lbs. If the turning torque is

too high, install a 0.05mm (0.002 inch) thinner

shim. If the turning torque is too low, install a

0.05mm (0.002 inch) thicker shim.(11) Recheck turning torque. Repeat Step 10until

the proper turning torque is obtained.

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS

DESCRIPTION TORQUE

Back-up Lamp Switch........ 24N´m(18ft.lbs.)

Crossover Cable Adj. Screw.... 8N´m(70in.lbs.)

Drain Plug............... 28N´m(250 in. lbs.)

Differential Ring Gear Bolts . . . 81 N´m (60 ft. lbs.)

Dust Shield to Transaxle.... 12N´m(105 in. lbs.)

End Plate Cover Bolts........ 29N´m(21ft.lbs.)

Lateral Bending Strut to Engine......... 81N´m

(60 ft. lbs.)

Lateral Bending Strut to Trans.......... 81N´m

(60 ft. lbs.)

Left Mount Through Bolt.... 108N´m(80ft.lbs.)

Left Mount to Transaxle...... 68N´m(50ft.lbs.)

Output Bearing Race Ret. Strap......... 11N´m

(96 in. lbs.)

Reverse Fork Bracket........ 11N´m(96in.lbs.)

Reverse Idler Shaft Bolt...... 26N´m(19ft.lbs.)

Shift Cable Bracket to Transaxle........ 28N´m

(250 in. lbs.)

Transaxle Case Bolts......... 29N´m(21ft.lbs.)

Transaxle to Engine Bolt...... 95N´m(70ft.lbs.)

Trans. to Eng. Intake Bkt. Bolts......... 95N´m

(70 ft. lbs.)

Vehicle Speed Sensor......... 7N´m(60in.lbs.)

Vertical Bending Strut to Engine........ 81N´m

(60 ft. lbs.)

Vertical Bending Strut to Trans.......... 81N´m

(60 ft. lbs.)

NOTE: Bolts that have thread sealer or torque lock

patches should not be reused. Always install new

bolts in these applications.

Fig. 163 Checking Differential Bearing End Play to

Determine Shim Thickness

1 ± T-HANDLE

2 ± DIAL INDICATOR SET

3 ± SPECIAL TOOL C-4995

Fig. 164 Checking Differential Bearing Turning

Torque

1 ± INCH-POUND TORQUE WRENCH

2 ± SPECIAL TOOL C-4995

NV T350 (A-578) MANUAL TRANSAXLE FLUID

FILL

TRANSAXLE METRIC

MEASUREU. S.

MEASURE

NV T350 1.9-2.2 Liters 2.0-2.3 Quarts

PLTRANSAXLE 21 - 51

ADJUSTMENTS (Continued)

Page 983 of 1285

LOW AND REVERSE SERVO (REAR)

Direct air pressure into LOW/REVERSE SERVO

APPLY passage. Operation of servo is indicated by a

tightening of rear band. Spring tension on servo pis-

ton should release the band.

If clutches and servos operate properly, no upshift

indicates that a malfunction exists in the valve body.

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA

(1) Check for source of leakage.

(2) Since fluid leakage near the torque converter

area may be from an engine oil leak, the area should

be checked closely. Factory fill fluid is dyed red and,

therefore, can be distinguished from engine oil.

(3) Prior to removing the transaxle, perform the

following checks:

(4) When leakage is determined to originate from

the transaxle, check fluid level prior to removal of

the transaxle and torque converter.

(5) High oil level can result in oil leakage out the

vent in the dipstick. If the fluid level is high, adjust

to proper level.

(6) After performing this operation, inspect for

leakage. If a leak persists, perform the following

operation on the vehicle. This will determine if the

torque converter or transaxle is leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside diam-

eter (peripheral) weld

²Torque converter hub weld

²Torque converter impeller shell cracked adjacent

to hub

²At drive lug welds

NOTE: Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

BRAKE TRANSMISSION SHIFT INTERLOCK

The following chart describes the normal operation

of the Brake Transmission Shift Interlock (BTSI) sys-

tem. If the ªexpected responseº differs from the vehi-

cle's response, then system repair and/or adjustment

is necessary. Refer to Brake Transmission Interlock

Removal and Installation or Adjustment in this

Group.

SERVICE PROCEDURES

TRANSAXLE FLUID AND FILTER SERVICE

NOTE: Refer to Group 0, Lubrication and Mainte-

nance, or the vehicle owner's manual, for the rec-

ommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparT

ATF+4 (Automatic Transmission Fluid) Type 9602

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist (See Lubrication,

Group 0). Place a drain container with a large open-

ing, under transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Install a new filter and o-ring on bottom of the

valve body and tighten retaining screws to 5 N´m (40

in. lbs.).

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

21 - 70 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)