wheel bolts DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 32 of 1285

(4) Lower the vehicle.

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

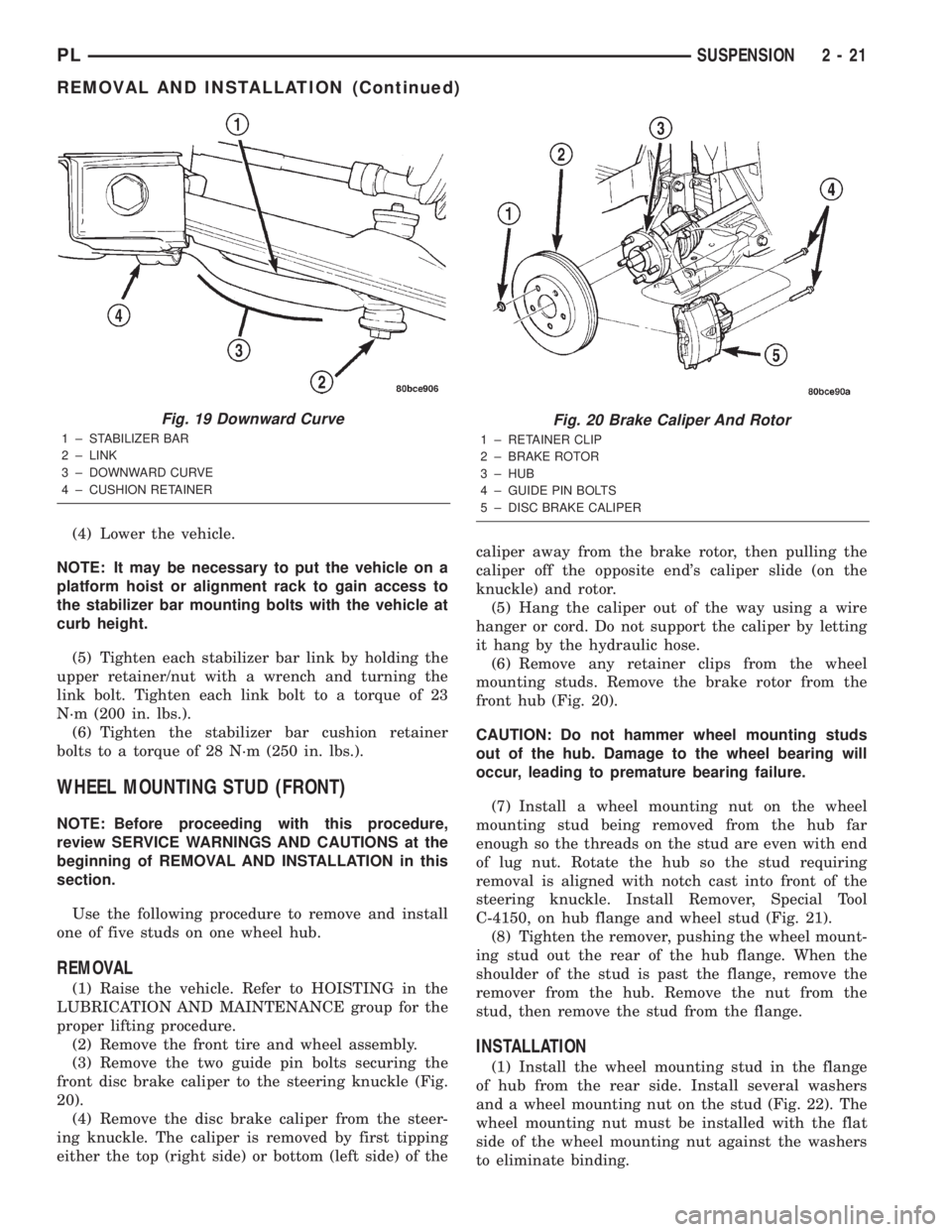

(5) Tighten each stabilizer bar link by holding the

upper retainer/nut with a wrench and turning the

link bolt. Tighten each link bolt to a torque of 23

N´m (200 in. lbs.).

(6) Tighten the stabilizer bar cushion retainer

bolts to a torque of 28 N´m (250 in. lbs.).

WHEEL MOUNTING STUD (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

Use the following procedure to remove and install

one of five studs on one wheel hub.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the front tire and wheel assembly.

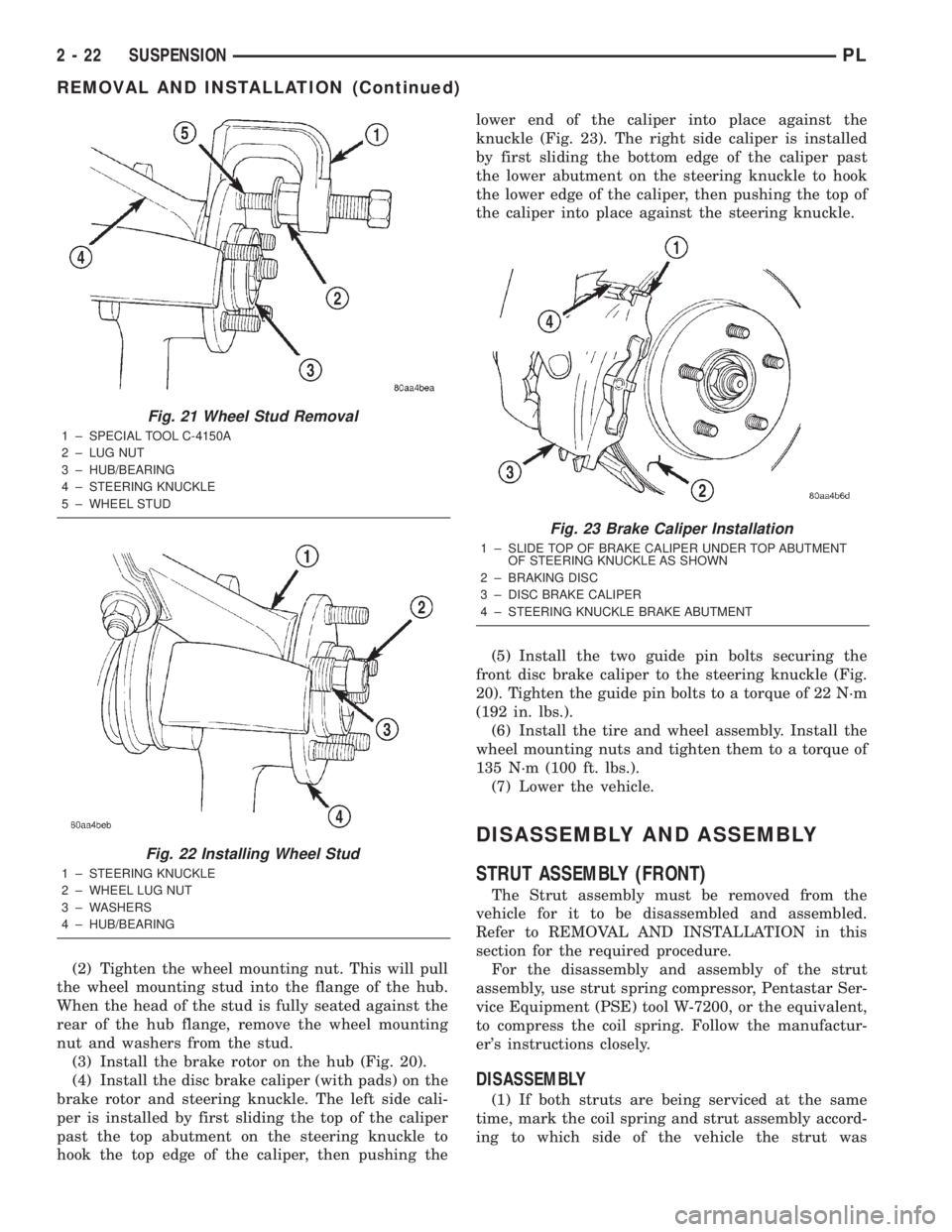

(3) Remove the two guide pin bolts securing the

front disc brake caliper to the steering knuckle (Fig.

20).

(4) Remove the disc brake caliper from the steer-

ing knuckle. The caliper is removed by first tipping

either the top (right side) or bottom (left side) of thecaliper away from the brake rotor, then pulling the

caliper off the opposite end's caliper slide (on the

knuckle) and rotor.

(5) Hang the caliper out of the way using a wire

hanger or cord. Do not support the caliper by letting

it hang by the hydraulic hose.

(6) Remove any retainer clips from the wheel

mounting studs. Remove the brake rotor from the

front hub (Fig. 20).

CAUTION: Do not hammer wheel mounting studs

out of the hub. Damage to the wheel bearing will

occur, leading to premature bearing failure.

(7) Install a wheel mounting nut on the wheel

mounting stud being removed from the hub far

enough so the threads on the stud are even with end

of lug nut. Rotate the hub so the stud requiring

removal is aligned with notch cast into front of the

steering knuckle. Install Remover, Special Tool

C-4150, on hub flange and wheel stud (Fig. 21).

(8) Tighten the remover, pushing the wheel mount-

ing stud out the rear of the hub flange. When the

shoulder of the stud is past the flange, remove the

remover from the hub. Remove the nut from the

stud, then remove the stud from the flange.

INSTALLATION

(1) Install the wheel mounting stud in the flange

of hub from the rear side. Install several washers

and a wheel mounting nut on the stud (Fig. 22). The

wheel mounting nut must be installed with the flat

side of the wheel mounting nut against the washers

to eliminate binding.

Fig. 19 Downward Curve

1 ± STABILIZER BAR

2 ± LINK

3 ± DOWNWARD CURVE

4 ± CUSHION RETAINER

Fig. 20 Brake Caliper And Rotor

1 ± RETAINER CLIP

2 ± BRAKE ROTOR

3 ± HUB

4 ± GUIDE PIN BOLTS

5 ± DISC BRAKE CALIPER

PLSUSPENSION 2 - 21

REMOVAL AND INSTALLATION (Continued)

Page 33 of 1285

(2) Tighten the wheel mounting nut. This will pull

the wheel mounting stud into the flange of the hub.

When the head of the stud is fully seated against the

rear of the hub flange, remove the wheel mounting

nut and washers from the stud.

(3) Install the brake rotor on the hub (Fig. 20).

(4) Install the disc brake caliper (with pads) on the

brake rotor and steering knuckle. The left side cali-

per is installed by first sliding the top of the caliper

past the top abutment on the steering knuckle to

hook the top edge of the caliper, then pushing thelower end of the caliper into place against the

knuckle (Fig. 23). The right side caliper is installed

by first sliding the bottom edge of the caliper past

the lower abutment on the steering knuckle to hook

the lower edge of the caliper, then pushing the top of

the caliper into place against the steering knuckle.

(5) Install the two guide pin bolts securing the

front disc brake caliper to the steering knuckle (Fig.

20). Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(6) Install the tire and wheel assembly. Install the

wheel mounting nuts and tighten them to a torque of

135 N´m (100 ft. lbs.).

(7) Lower the vehicle.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (FRONT)

The Strut assembly must be removed from the

vehicle for it to be disassembled and assembled.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

For the disassembly and assembly of the strut

assembly, use strut spring compressor, Pentastar Ser-

vice Equipment (PSE) tool W-7200, or the equivalent,

to compress the coil spring. Follow the manufactur-

er's instructions closely.

DISASSEMBLY

(1) If both struts are being serviced at the same

time, mark the coil spring and strut assembly accord-

ing to which side of the vehicle the strut was

Fig. 21 Wheel Stud Removal

1 ± SPECIAL TOOL C-4150A

2 ± LUG NUT

3 ± HUB/BEARING

4 ± STEERING KNUCKLE

5 ± WHEEL STUD

Fig. 22 Installing Wheel Stud

1 ± STEERING KNUCKLE

2 ± WHEEL LUG NUT

3 ± WASHERS

4 ± HUB/BEARING

Fig. 23 Brake Caliper Installation

1 ± SLIDE TOP OF BRAKE CALIPER UNDER TOP ABUTMENT

OF STEERING KNUCKLE AS SHOWN

2 ± BRAKING DISC

3 ± DISC BRAKE CALIPER

4 ± STEERING KNUCKLE BRAKE ABUTMENT

2 - 22 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 37 of 1285

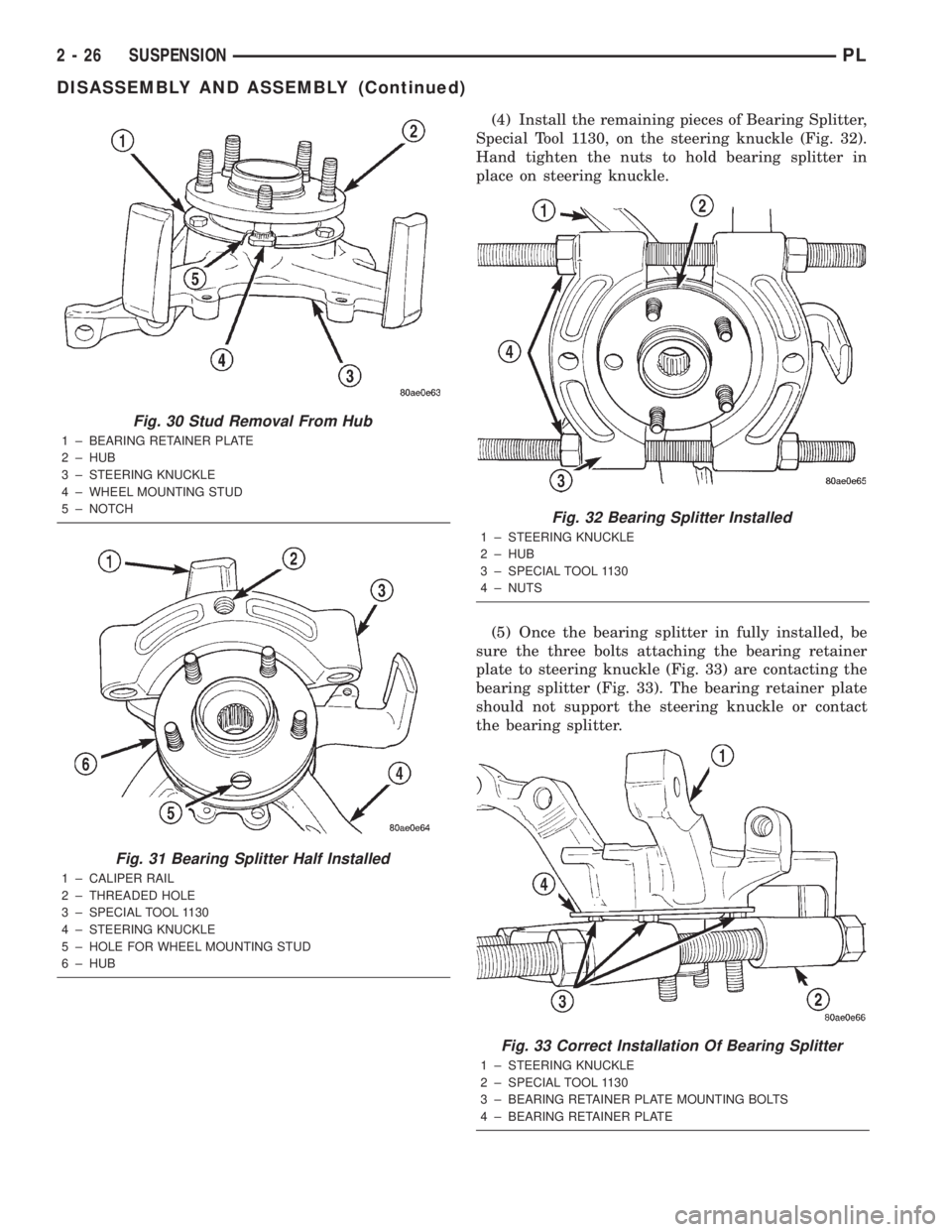

(4) Install the remaining pieces of Bearing Splitter,

Special Tool 1130, on the steering knuckle (Fig. 32).

Hand tighten the nuts to hold bearing splitter in

place on steering knuckle.

(5) Once the bearing splitter in fully installed, be

sure the three bolts attaching the bearing retainer

plate to steering knuckle (Fig. 33) are contacting the

bearing splitter (Fig. 33). The bearing retainer plate

should not support the steering knuckle or contact

the bearing splitter.

Fig. 30 Stud Removal From Hub

1 ± BEARING RETAINER PLATE

2 ± HUB

3 ± STEERING KNUCKLE

4 ± WHEEL MOUNTING STUD

5 ± NOTCH

Fig. 31 Bearing Splitter Half Installed

1 ± CALIPER RAIL

2 ± THREADED HOLE

3 ± SPECIAL TOOL 1130

4 ± STEERING KNUCKLE

5 ± HOLE FOR WHEEL MOUNTING STUD

6 ± HUB

Fig. 32 Bearing Splitter Installed

1 ± STEERING KNUCKLE

2 ± HUB

3 ± SPECIAL TOOL 1130

4 ± NUTS

Fig. 33 Correct Installation Of Bearing Splitter

1 ± STEERING KNUCKLE

2 ± SPECIAL TOOL 1130

3 ± BEARING RETAINER PLATE MOUNTING BOLTS

4 ± BEARING RETAINER PLATE

2 - 26 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 38 of 1285

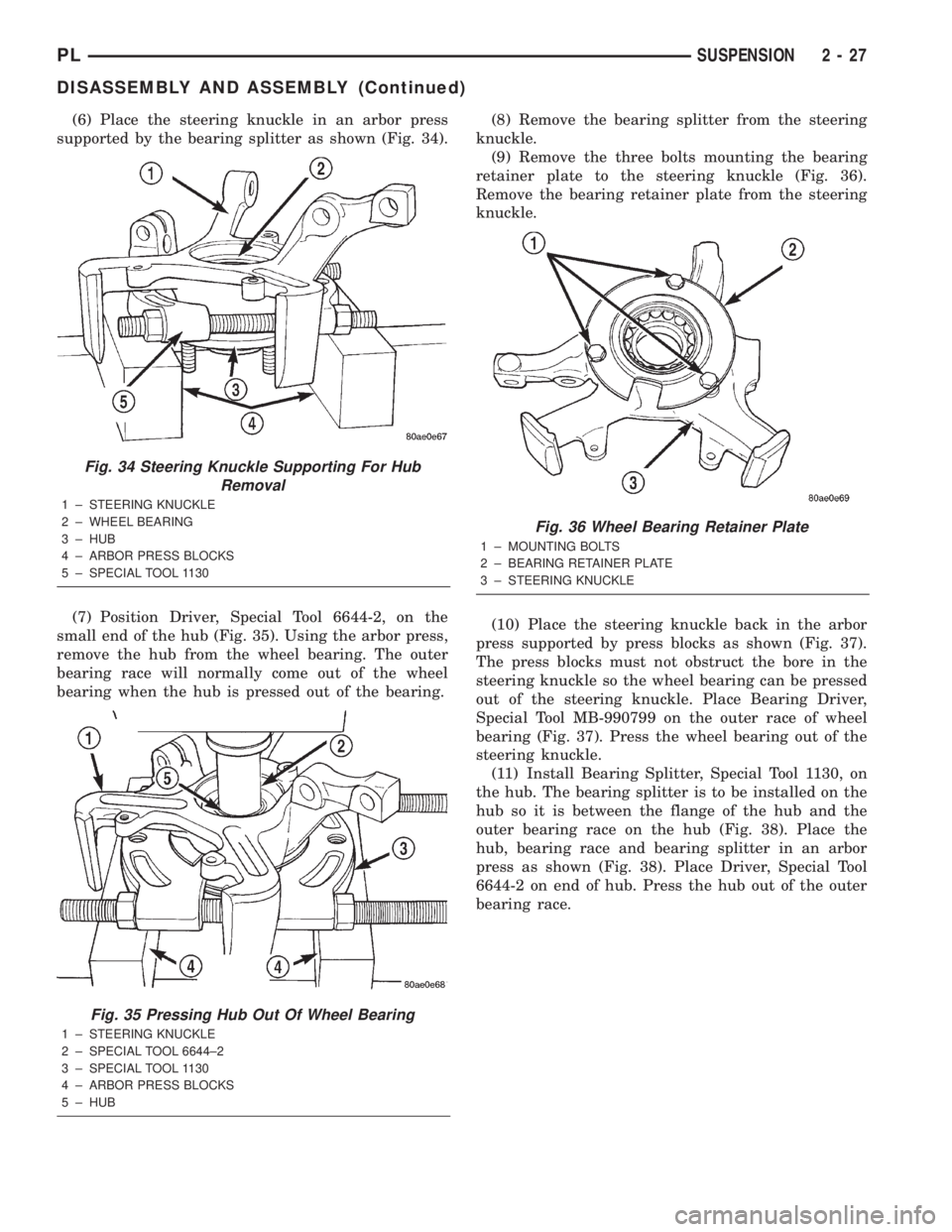

(6) Place the steering knuckle in an arbor press

supported by the bearing splitter as shown (Fig. 34).

(7) Position Driver, Special Tool 6644-2, on the

small end of the hub (Fig. 35). Using the arbor press,

remove the hub from the wheel bearing. The outer

bearing race will normally come out of the wheel

bearing when the hub is pressed out of the bearing.(8) Remove the bearing splitter from the steering

knuckle.

(9) Remove the three bolts mounting the bearing

retainer plate to the steering knuckle (Fig. 36).

Remove the bearing retainer plate from the steering

knuckle.

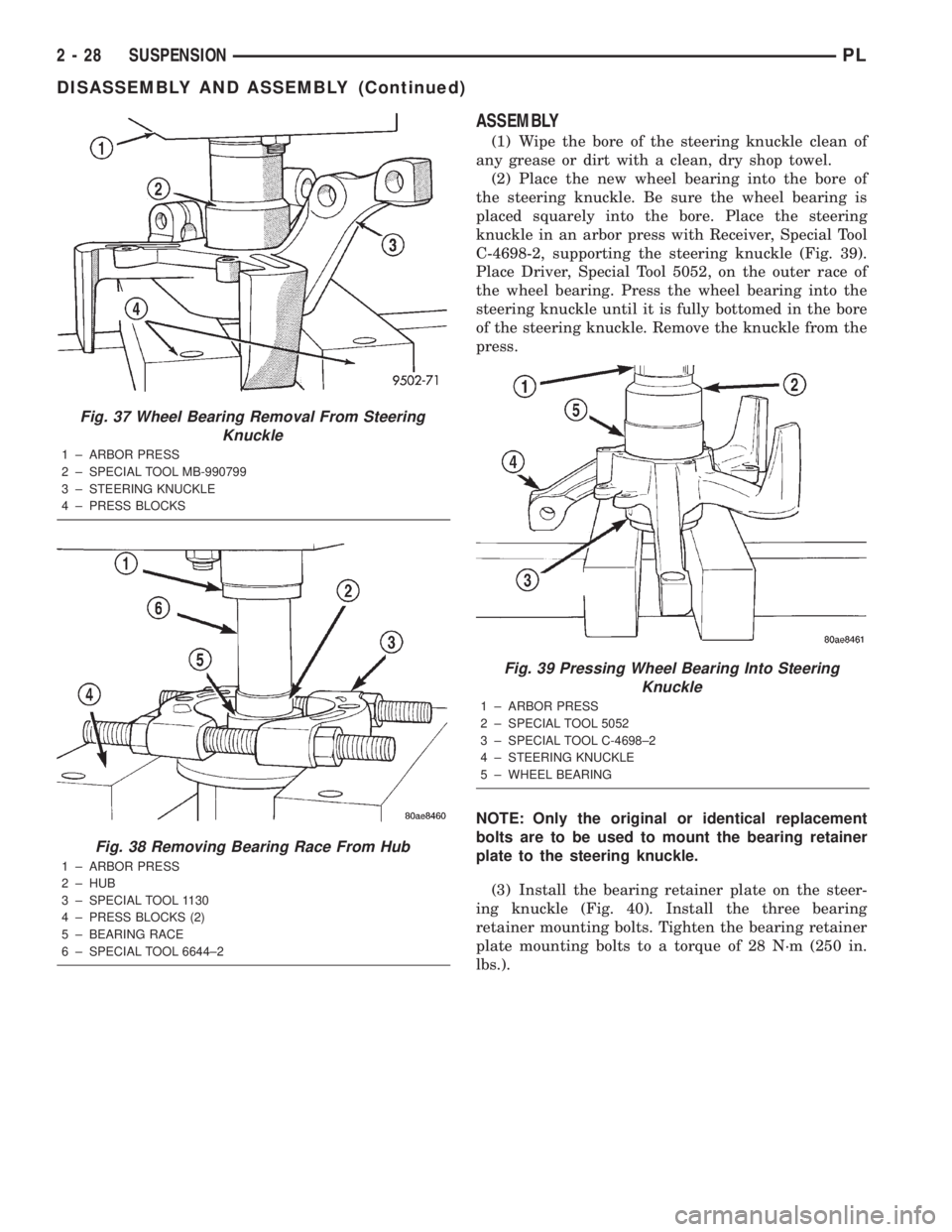

(10) Place the steering knuckle back in the arbor

press supported by press blocks as shown (Fig. 37).

The press blocks must not obstruct the bore in the

steering knuckle so the wheel bearing can be pressed

out of the steering knuckle. Place Bearing Driver,

Special Tool MB-990799 on the outer race of wheel

bearing (Fig. 37). Press the wheel bearing out of the

steering knuckle.

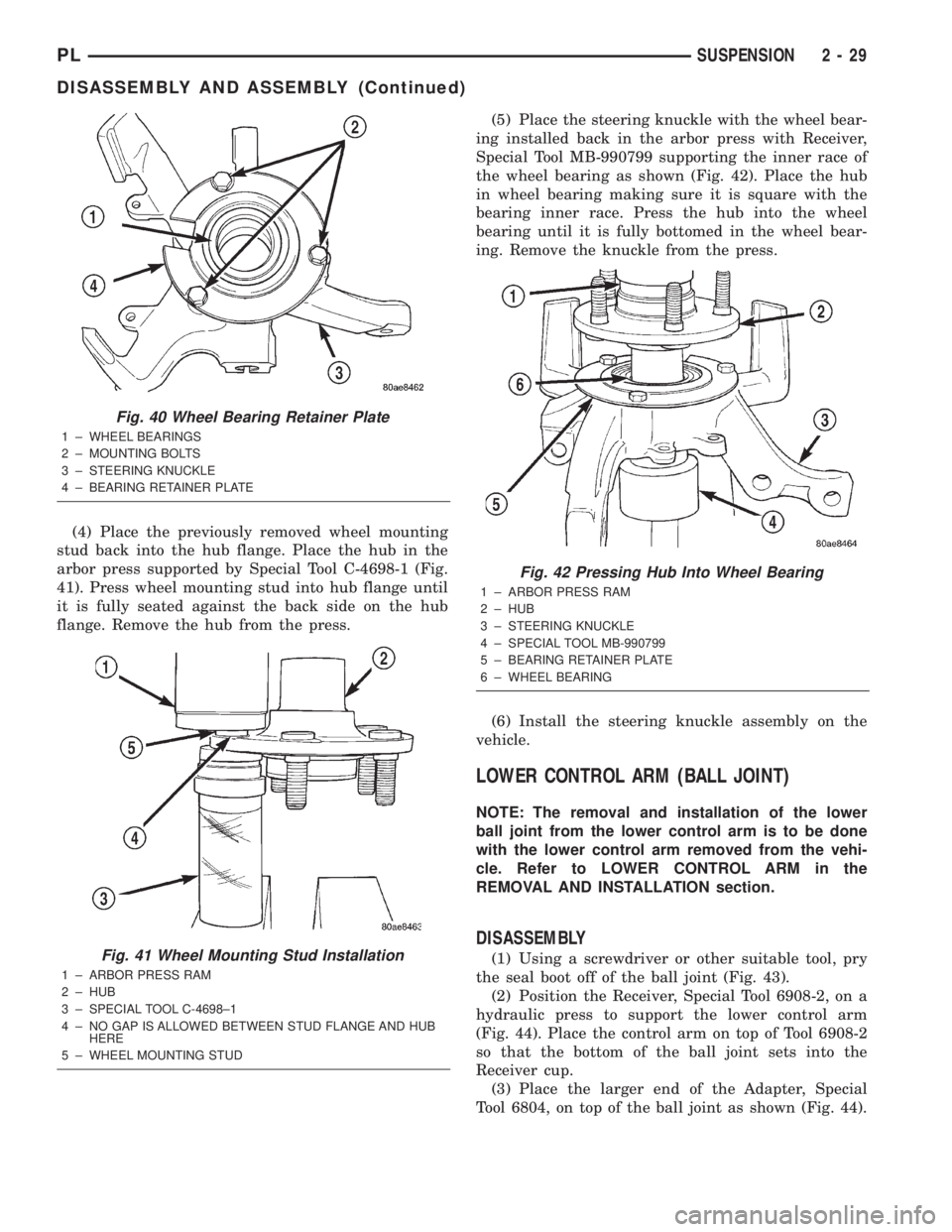

(11) Install Bearing Splitter, Special Tool 1130, on

the hub. The bearing splitter is to be installed on the

hub so it is between the flange of the hub and the

outer bearing race on the hub (Fig. 38). Place the

hub, bearing race and bearing splitter in an arbor

press as shown (Fig. 38). Place Driver, Special Tool

6644-2 on end of hub. Press the hub out of the outer

bearing race.

Fig. 34 Steering Knuckle Supporting For Hub

Removal

1 ± STEERING KNUCKLE

2 ± WHEEL BEARING

3 ± HUB

4 ± ARBOR PRESS BLOCKS

5 ± SPECIAL TOOL 1130

Fig. 35 Pressing Hub Out Of Wheel Bearing

1 ± STEERING KNUCKLE

2 ± SPECIAL TOOL 6644±2

3 ± SPECIAL TOOL 1130

4 ± ARBOR PRESS BLOCKS

5 ± HUB

Fig. 36 Wheel Bearing Retainer Plate

1 ± MOUNTING BOLTS

2 ± BEARING RETAINER PLATE

3 ± STEERING KNUCKLE

PLSUSPENSION 2 - 27

DISASSEMBLY AND ASSEMBLY (Continued)

Page 39 of 1285

ASSEMBLY

(1) Wipe the bore of the steering knuckle clean of

any grease or dirt with a clean, dry shop towel.

(2) Place the new wheel bearing into the bore of

the steering knuckle. Be sure the wheel bearing is

placed squarely into the bore. Place the steering

knuckle in an arbor press with Receiver, Special Tool

C-4698-2, supporting the steering knuckle (Fig. 39).

Place Driver, Special Tool 5052, on the outer race of

the wheel bearing. Press the wheel bearing into the

steering knuckle until it is fully bottomed in the bore

of the steering knuckle. Remove the knuckle from the

press.

NOTE: Only the original or identical replacement

bolts are to be used to mount the bearing retainer

plate to the steering knuckle.

(3) Install the bearing retainer plate on the steer-

ing knuckle (Fig. 40). Install the three bearing

retainer mounting bolts. Tighten the bearing retainer

plate mounting bolts to a torque of 28 N´m (250 in.

lbs.).

Fig. 37 Wheel Bearing Removal From Steering

Knuckle

1 ± ARBOR PRESS

2 ± SPECIAL TOOL MB-990799

3 ± STEERING KNUCKLE

4 ± PRESS BLOCKS

Fig. 38 Removing Bearing Race From Hub

1 ± ARBOR PRESS

2 ± HUB

3 ± SPECIAL TOOL 1130

4 ± PRESS BLOCKS (2)

5 ± BEARING RACE

6 ± SPECIAL TOOL 6644±2

Fig. 39 Pressing Wheel Bearing Into Steering

Knuckle

1 ± ARBOR PRESS

2 ± SPECIAL TOOL 5052

3 ± SPECIAL TOOL C-4698±2

4 ± STEERING KNUCKLE

5 ± WHEEL BEARING

2 - 28 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 40 of 1285

(4) Place the previously removed wheel mounting

stud back into the hub flange. Place the hub in the

arbor press supported by Special Tool C-4698-1 (Fig.

41). Press wheel mounting stud into hub flange until

it is fully seated against the back side on the hub

flange. Remove the hub from the press.(5) Place the steering knuckle with the wheel bear-

ing installed back in the arbor press with Receiver,

Special Tool MB-990799 supporting the inner race of

the wheel bearing as shown (Fig. 42). Place the hub

in wheel bearing making sure it is square with the

bearing inner race. Press the hub into the wheel

bearing until it is fully bottomed in the wheel bear-

ing. Remove the knuckle from the press.

(6) Install the steering knuckle assembly on the

vehicle.

LOWER CONTROL ARM (BALL JOINT)

NOTE: The removal and installation of the lower

ball joint from the lower control arm is to be done

with the lower control arm removed from the vehi-

cle. Refer to LOWER CONTROL ARM in the

REMOVAL AND INSTALLATION section.

DISASSEMBLY

(1) Using a screwdriver or other suitable tool, pry

the seal boot off of the ball joint (Fig. 43).

(2) Position the Receiver, Special Tool 6908-2, on a

hydraulic press to support the lower control arm

(Fig. 44). Place the control arm on top of Tool 6908-2

so that the bottom of the ball joint sets into the

Receiver cup.

(3) Place the larger end of the Adapter, Special

Tool 6804, on top of the ball joint as shown (Fig. 44).

Fig. 40 Wheel Bearing Retainer Plate

1 ± WHEEL BEARINGS

2 ± MOUNTING BOLTS

3 ± STEERING KNUCKLE

4 ± BEARING RETAINER PLATE

Fig. 41 Wheel Mounting Stud Installation

1 ± ARBOR PRESS RAM

2 ± HUB

3 ± SPECIAL TOOL C-4698±1

4 ± NO GAP IS ALLOWED BETWEEN STUD FLANGE AND HUB

HERE

5 ± WHEEL MOUNTING STUD

Fig. 42 Pressing Hub Into Wheel Bearing

1 ± ARBOR PRESS RAM

2 ± HUB

3 ± STEERING KNUCKLE

4 ± SPECIAL TOOL MB-990799

5 ± BEARING RETAINER PLATE

6 ± WHEEL BEARING

PLSUSPENSION 2 - 29

DISASSEMBLY AND ASSEMBLY (Continued)

Page 44 of 1285

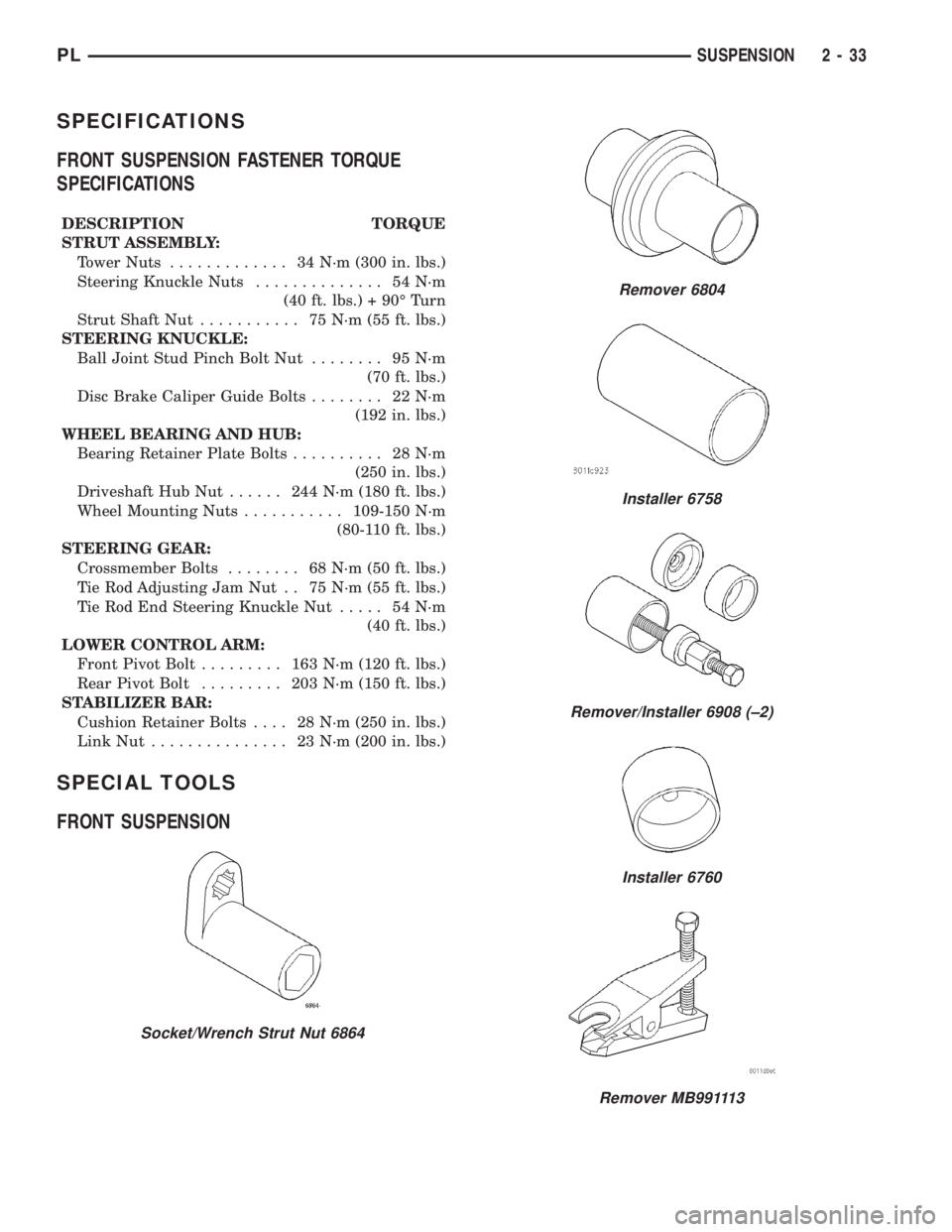

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STRUT ASSEMBLY:

Tower Nuts............. 34N´m(300 in. lbs.)

Steering Knuckle Nuts.............. 54N´m

(40 ft. lbs.) + 90É Turn

Strut Shaft Nut........... 75N´m(55ft.lbs.)

STEERING KNUCKLE:

Ball Joint Stud Pinch Bolt Nut........ 95N´m

(70 ft. lbs.)

Disc Brake Caliper Guide Bolts........ 22N´m

(192 in. lbs.)

WHEEL BEARING AND HUB:

Bearing Retainer Plate Bolts.......... 28N´m

(250 in. lbs.)

Driveshaft Hub Nut...... 244N´m(180 ft. lbs.)

Wheel Mounting Nuts...........109-150 N´m

(80-110 ft. lbs.)

STEERING GEAR:

Crossmember Bolts........ 68N´m(50ft.lbs.)

Tie Rod Adjusting Jam Nut . . 75 N´m (55 ft. lbs.)

Tie Rod End Steering Knuckle Nut..... 54N´m

(40 ft. lbs.)

LOWER CONTROL ARM:

Front Pivot Bolt......... 163N´m(120 ft. lbs.)

Rear Pivot Bolt......... 203N´m(150 ft. lbs.)

STABILIZER BAR:

Cushion Retainer Bolts.... 28N´m(250 in. lbs.)

Link Nut............... 23N´m(200 in. lbs.)

SPECIAL TOOLS

FRONT SUSPENSION

Socket/Wrench Strut Nut 6864

Remover 6804

Installer 6758

Remover/Installer 6908 (±2)

Installer 6760

Remover MB991113

PLSUSPENSION 2 - 33

Page 48 of 1285

For more information on the description and oper-

ation of an individual component, refer to the appli-

cable component heading in this section.

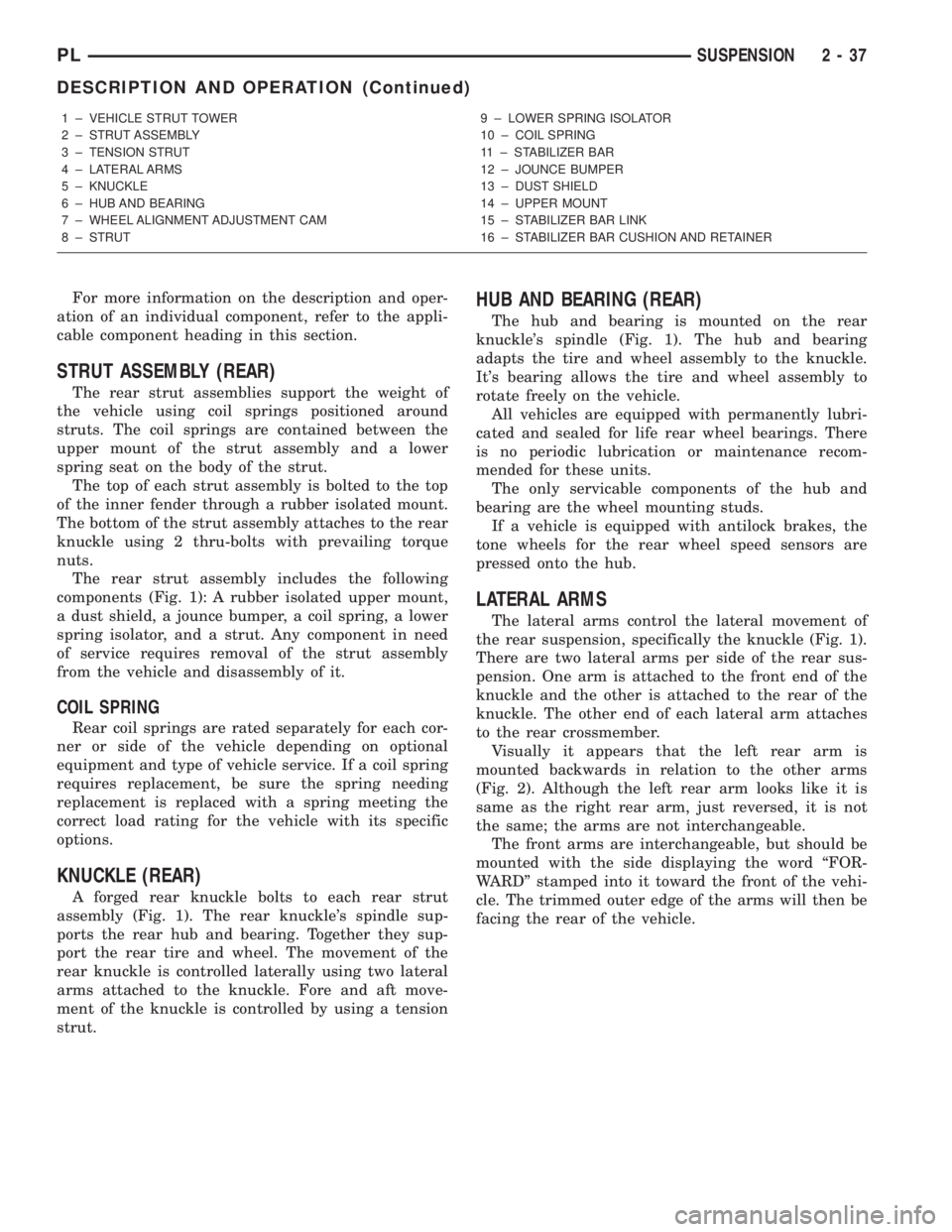

STRUT ASSEMBLY (REAR)

The rear strut assemblies support the weight of

the vehicle using coil springs positioned around

struts. The coil springs are contained between the

upper mount of the strut assembly and a lower

spring seat on the body of the strut.

The top of each strut assembly is bolted to the top

of the inner fender through a rubber isolated mount.

The bottom of the strut assembly attaches to the rear

knuckle using 2 thru-bolts with prevailing torque

nuts.

The rear strut assembly includes the following

components (Fig. 1): A rubber isolated upper mount,

a dust shield, a jounce bumper, a coil spring, a lower

spring isolator, and a strut. Any component in need

of service requires removal of the strut assembly

from the vehicle and disassembly of it.

COIL SPRING

Rear coil springs are rated separately for each cor-

ner or side of the vehicle depending on optional

equipment and type of vehicle service. If a coil spring

requires replacement, be sure the spring needing

replacement is replaced with a spring meeting the

correct load rating for the vehicle with its specific

options.

KNUCKLE (REAR)

A forged rear knuckle bolts to each rear strut

assembly (Fig. 1). The rear knuckle's spindle sup-

ports the rear hub and bearing. Together they sup-

port the rear tire and wheel. The movement of the

rear knuckle is controlled laterally using two lateral

arms attached to the knuckle. Fore and aft move-

ment of the knuckle is controlled by using a tension

strut.

HUB AND BEARING (REAR)

The hub and bearing is mounted on the rear

knuckle's spindle (Fig. 1). The hub and bearing

adapts the tire and wheel assembly to the knuckle.

It's bearing allows the tire and wheel assembly to

rotate freely on the vehicle.

All vehicles are equipped with permanently lubri-

cated and sealed for life rear wheel bearings. There

is no periodic lubrication or maintenance recom-

mended for these units.

The only servicable components of the hub and

bearing are the wheel mounting studs.

If a vehicle is equipped with antilock brakes, the

tone wheels for the rear wheel speed sensors are

pressed onto the hub.

LATERAL ARMS

The lateral arms control the lateral movement of

the rear suspension, specifically the knuckle (Fig. 1).

There are two lateral arms per side of the rear sus-

pension. One arm is attached to the front end of the

knuckle and the other is attached to the rear of the

knuckle. The other end of each lateral arm attaches

to the rear crossmember.

Visually it appears that the left rear arm is

mounted backwards in relation to the other arms

(Fig. 2). Although the left rear arm looks like it is

same as the right rear arm, just reversed, it is not

the same; the arms are not interchangeable.

The front arms are interchangeable, but should be

mounted with the side displaying the word ªFOR-

WARDº stamped into it toward the front of the vehi-

cle. The trimmed outer edge of the arms will then be

facing the rear of the vehicle.

1 ± VEHICLE STRUT TOWER

2 ± STRUT ASSEMBLY

3 ± TENSION STRUT

4 ± LATERAL ARMS

5 ± KNUCKLE

6 ± HUB AND BEARING

7 ± WHEEL ALIGNMENT ADJUSTMENT CAM

8 ± STRUT9 ± LOWER SPRING ISOLATOR

10 ± COIL SPRING

11 ± STABILIZER BAR

12 ± JOUNCE BUMPER

13 ± DUST SHIELD

14 ± UPPER MOUNT

15 ± STABILIZER BAR LINK

16 ± STABILIZER BAR CUSHION AND RETAINER

PLSUSPENSION 2 - 37

DESCRIPTION AND OPERATION (Continued)

Page 49 of 1285

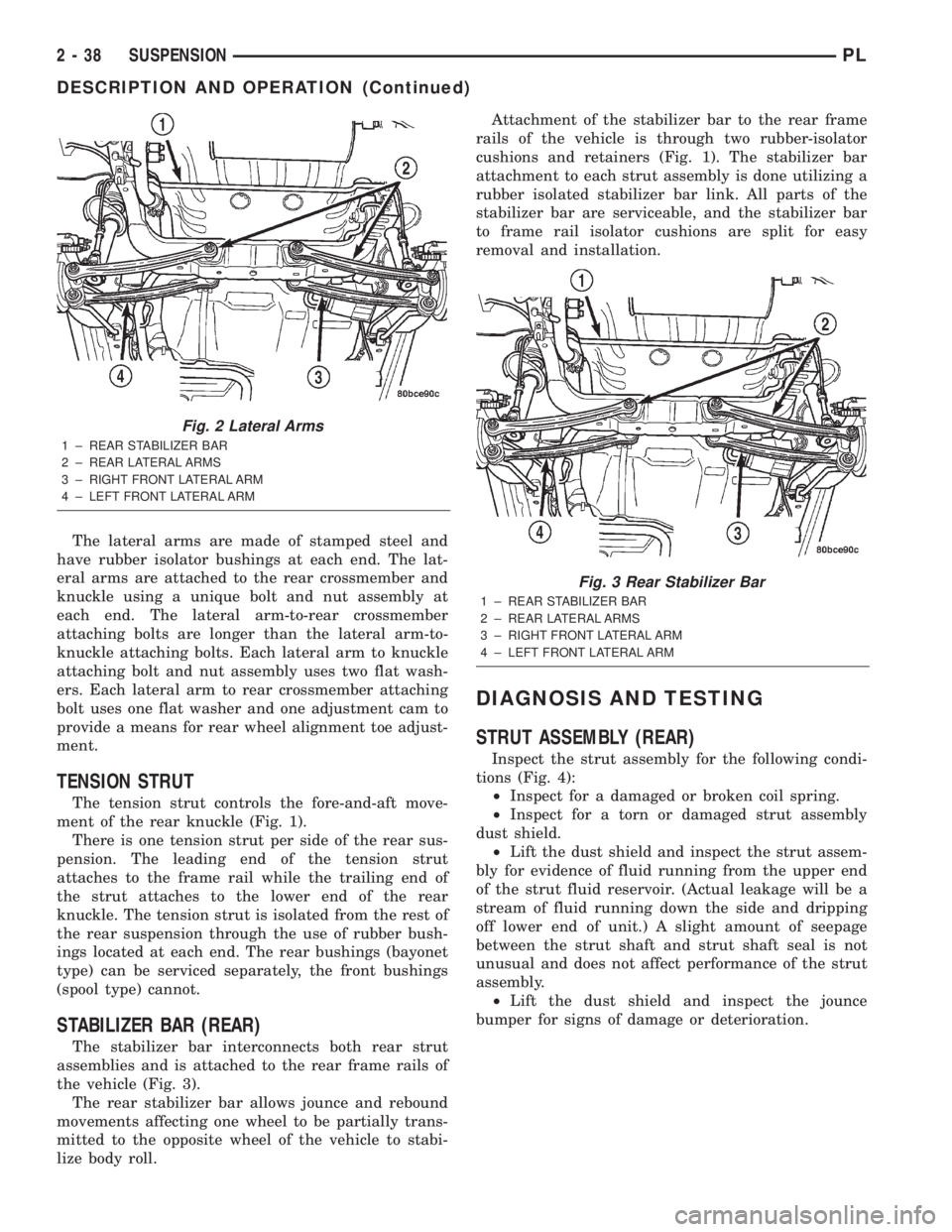

The lateral arms are made of stamped steel and

have rubber isolator bushings at each end. The lat-

eral arms are attached to the rear crossmember and

knuckle using a unique bolt and nut assembly at

each end. The lateral arm-to-rear crossmember

attaching bolts are longer than the lateral arm-to-

knuckle attaching bolts. Each lateral arm to knuckle

attaching bolt and nut assembly uses two flat wash-

ers. Each lateral arm to rear crossmember attaching

bolt uses one flat washer and one adjustment cam to

provide a means for rear wheel alignment toe adjust-

ment.

TENSION STRUT

The tension strut controls the fore-and-aft move-

ment of the rear knuckle (Fig. 1).

There is one tension strut per side of the rear sus-

pension. The leading end of the tension strut

attaches to the frame rail while the trailing end of

the strut attaches to the lower end of the rear

knuckle. The tension strut is isolated from the rest of

the rear suspension through the use of rubber bush-

ings located at each end. The rear bushings (bayonet

type) can be serviced separately, the front bushings

(spool type) cannot.

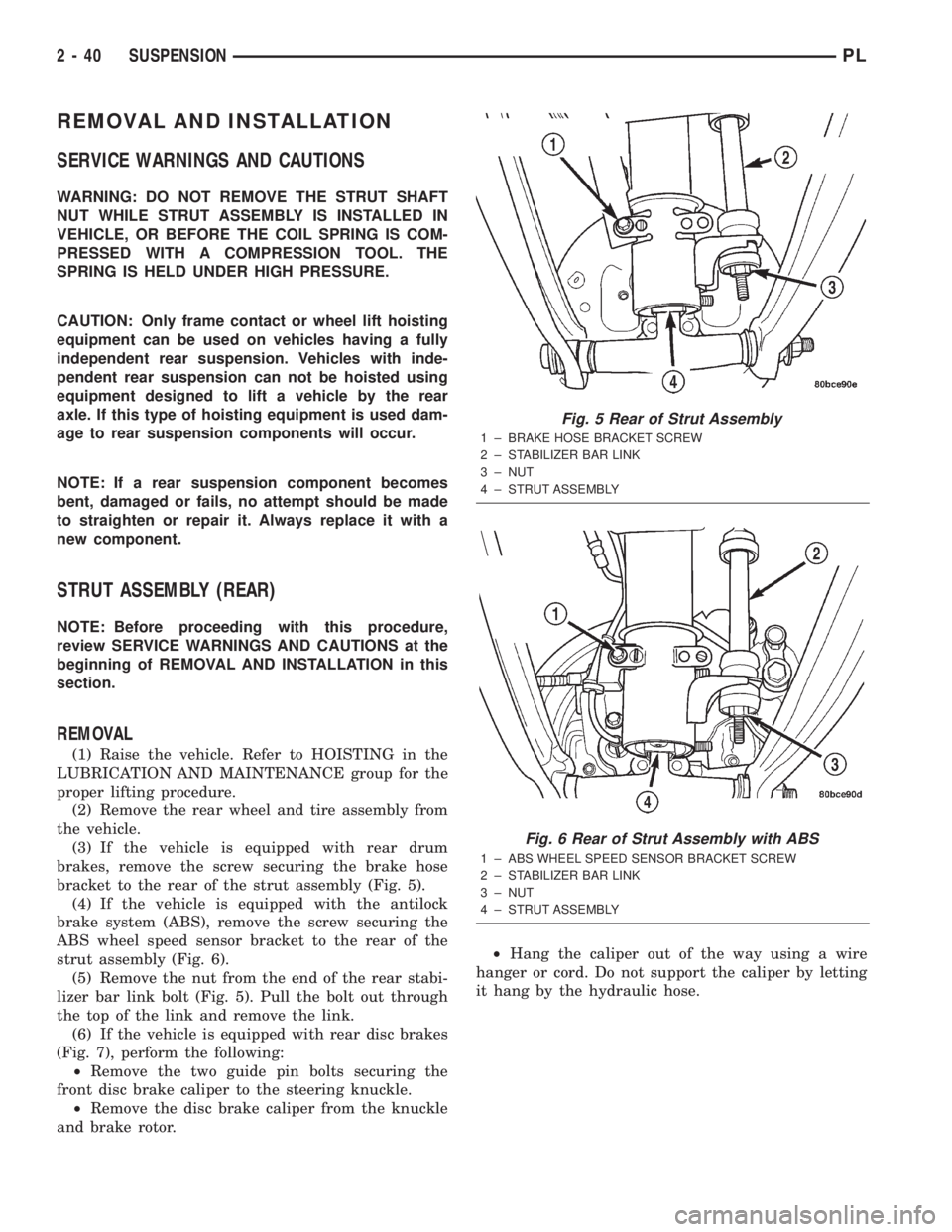

STABILIZER BAR (REAR)

The stabilizer bar interconnects both rear strut

assemblies and is attached to the rear frame rails of

the vehicle (Fig. 3).

The rear stabilizer bar allows jounce and rebound

movements affecting one wheel to be partially trans-

mitted to the opposite wheel of the vehicle to stabi-

lize body roll.Attachment of the stabilizer bar to the rear frame

rails of the vehicle is through two rubber-isolator

cushions and retainers (Fig. 1). The stabilizer bar

attachment to each strut assembly is done utilizing a

rubber isolated stabilizer bar link. All parts of the

stabilizer bar are serviceable, and the stabilizer bar

to frame rail isolator cushions are split for easy

removal and installation.

DIAGNOSIS AND TESTING

STRUT ASSEMBLY (REAR)

Inspect the strut assembly for the following condi-

tions (Fig. 4):

²Inspect for a damaged or broken coil spring.

²Inspect for a torn or damaged strut assembly

dust shield.

²Lift the dust shield and inspect the strut assem-

bly for evidence of fluid running from the upper end

of the strut fluid reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit.) A slight amount of seepage

between the strut shaft and strut shaft seal is not

unusual and does not affect performance of the strut

assembly.

²Lift the dust shield and inspect the jounce

bumper for signs of damage or deterioration.

Fig. 2 Lateral Arms

1 ± REAR STABILIZER BAR

2 ± REAR LATERAL ARMS

3 ± RIGHT FRONT LATERAL ARM

4 ± LEFT FRONT LATERAL ARM

Fig. 3 Rear Stabilizer Bar

1 ± REAR STABILIZER BAR

2 ± REAR LATERAL ARMS

3 ± RIGHT FRONT LATERAL ARM

4 ± LEFT FRONT LATERAL ARM

2 - 38 SUSPENSIONPL

DESCRIPTION AND OPERATION (Continued)

Page 51 of 1285

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT WHILE STRUT ASSEMBLY IS INSTALLED IN

VEHICLE, OR BEFORE THE COIL SPRING IS COM-

PRESSED WITH A COMPRESSION TOOL. THE

SPRING IS HELD UNDER HIGH PRESSURE.

CAUTION: Only frame contact or wheel lift hoisting

equipment can be used on vehicles having a fully

independent rear suspension. Vehicles with inde-

pendent rear suspension can not be hoisted using

equipment designed to lift a vehicle by the rear

axle. If this type of hoisting equipment is used dam-

age to rear suspension components will occur.

NOTE: If a rear suspension component becomes

bent, damaged or fails, no attempt should be made

to straighten or repair it. Always replace it with a

new component.

STRUT ASSEMBLY (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear wheel and tire assembly from

the vehicle.

(3) If the vehicle is equipped with rear drum

brakes, remove the screw securing the brake hose

bracket to the rear of the strut assembly (Fig. 5).

(4) If the vehicle is equipped with the antilock

brake system (ABS), remove the screw securing the

ABS wheel speed sensor bracket to the rear of the

strut assembly (Fig. 6).

(5) Remove the nut from the end of the rear stabi-

lizer bar link bolt (Fig. 5). Pull the bolt out through

the top of the link and remove the link.

(6) If the vehicle is equipped with rear disc brakes

(Fig. 7), perform the following:

²Remove the two guide pin bolts securing the

front disc brake caliper to the steering knuckle.

²Remove the disc brake caliper from the knuckle

and brake rotor.²Hang the caliper out of the way using a wire

hanger or cord. Do not support the caliper by letting

it hang by the hydraulic hose.

Fig. 5 Rear of Strut Assembly

1 ± BRAKE HOSE BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

Fig. 6 Rear of Strut Assembly with ABS

1 ± ABS WHEEL SPEED SENSOR BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

2 - 40 SUSPENSIONPL