wheel bolts DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 53 of 1285

²Place the link center sleeve and bushings

between the eye in the end of the stabilizer bar and

the link mounting bracket on the strut.

²Start the stabilizer bar link bolt with bushing

from the top, down through the stabilizer bar, inner

link bushings and sleeve, and strut link mounting

bracket.

²Install a lower bushing, then the nut. Do not

tighten the nut at this time.

(8) If the vehicle is equipped with the antilock

brake system (ABS), install the screw securing the

ABS wheel speed sensor bracket to the rear of the

strut assembly (Fig. 6). Tighten the mounting screw

to a torque of 13 N´m (120 in. lbs.).

(9) If the vehicle is equipped with rear drum

brakes, install the screw securing the brake hose

bracket to the rear of the strut assembly (Fig. 5).

Tighten the screw to a torque of 31 N´m (275 in. lbs.).

(10) Install the tire and wheel assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Repeat the tightening sequence, this time, to

full specified torque of 135 N´m (100 ft. lbs.).

(11) Lower the vehicle to ground level.

(12) Tighten the stabilizer bar link nut to a torque

of 23 N´m (200 in. lbs.).

(13) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

KNUCKLE (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear wheel and tire assembly from

the vehicle.

(3) If the vehicle is equipped with rear drum

brakes, remove the screw securing the brake hose

bracket to the rear of the strut assembly (Fig. 5).

(4) If the vehicle is equipped with the antilock

brake system (ABS), remove the screw securing the

ABS wheel speed sensor bracket to the rear of the

strut assembly (Fig. 6).

(5) If the vehicle is equipped with rear drum

brakes, remove any retainer clips from the wheel

mounting studs, then pull the brake drum off the

hub and bearing.

(6) If the vehicle is equipped with rear disc brakes

(Fig. 7), perform the following:²Remove the two guide pin bolts securing the

front disc brake caliper to the steering knuckle.

²Remove the disc brake caliper from the knuckle

and brake rotor.

²Hang the caliper out of the way using a wire

hanger or cord. Do not support the caliper by letting

it hang by the hydraulic hose.

²Remove any retainer clips from the wheel

mounting studs, then pull the brake rotor off the hub

and bearing.

(7) Remove the dust cap from the hub and bearing

assembly (Fig. 7).

(8) Remove the retaining nut, then the hub and

bearing from the knuckle's spindle (Fig. 7).

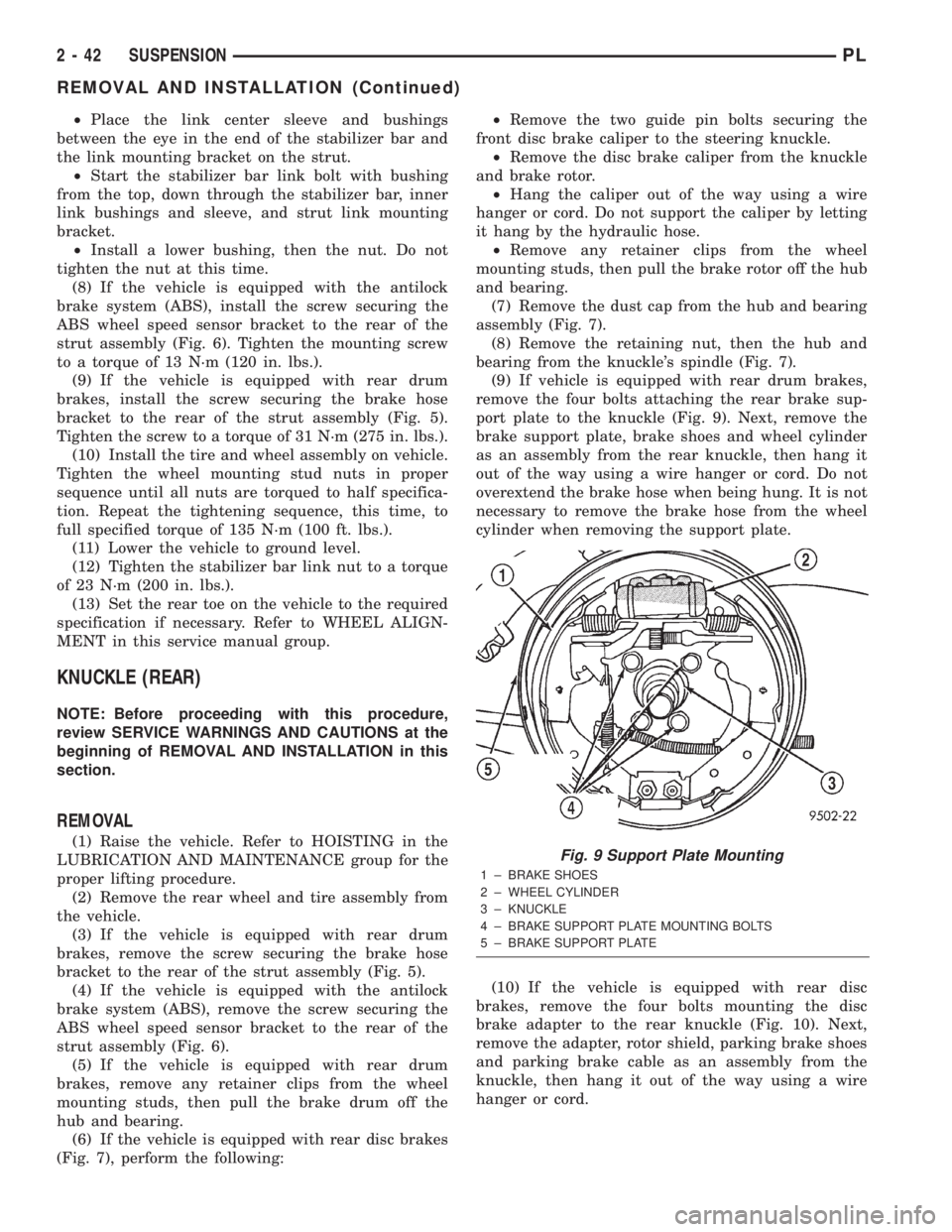

(9) If vehicle is equipped with rear drum brakes,

remove the four bolts attaching the rear brake sup-

port plate to the knuckle (Fig. 9). Next, remove the

brake support plate, brake shoes and wheel cylinder

as an assembly from the rear knuckle, then hang it

out of the way using a wire hanger or cord. Do not

overextend the brake hose when being hung. It is not

necessary to remove the brake hose from the wheel

cylinder when removing the support plate.

(10) If the vehicle is equipped with rear disc

brakes, remove the four bolts mounting the disc

brake adapter to the rear knuckle (Fig. 10). Next,

remove the adapter, rotor shield, parking brake shoes

and parking brake cable as an assembly from the

knuckle, then hang it out of the way using a wire

hanger or cord.Fig. 9 Support Plate Mounting

1 ± BRAKE SHOES

2 ± WHEEL CYLINDER

3 ± KNUCKLE

4 ± BRAKE SUPPORT PLATE MOUNTING BOLTS

5 ± BRAKE SUPPORT PLATE

2 - 42 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 55 of 1285

the front side. Install the nut, but do not completely

tighten it at this time. The nut will need to be tight-

ened when the vehicle is at curb height.

(4) Install the rear bayonet bushing on the tension

strut. Be sure the stepped area of the bushing is

squarely seated into the hole in the knuckle.

(5) Install the rear tension strut retainer, then the

nut. To completely install the nut, place a wrench on

the flat formed into the tension strut and tighten the

nut (Fig. 12). Tighten the nut to a torque of 95 N´m

(70 ft. lbs.).

(6) If vehicle is equipped with rear drum brakes,

install the brake support plate on the knuckle and

attach it using it's four mounting bolts (Fig. 9).

Tighten the mounting bolts to a torque of 75 N´m (55

ft. lbs.).

(7) If the vehicle is equipped with rear disc brakes,

install the disc brake adapter on the knuckle and

attach it using it's four mounting bolts (Fig. 10).

Tighten the mounting bolts to a torque of 75 N´m (55

ft. lbs.).

(8) Install the hub and bearing on the knuckle's

spindle, then install a new retaining nut (Fig. 7). Do

not reuse the original nut. Tighten the nut to a

torque of 217 N´m (160 ft. lbs.).

(9) Install the dust cap on the end of the hub and

bearing (Fig. 7).

(10) If the vehicle is equipped with rear disc

brakes (Fig. 7), install the brake rotor and disc brake

caliper on the knuckle. Install the two guide pin bolts

securing the front disc brake caliper to the steering

knuckle. Tighten the guide pin bolts to a torque of 22

N´m (192 in. lbs.).

(11) If the vehicle is equipped with rear drum

brakes, install the screw securing the brake hose

bracket to the rear of the strut assembly (Fig. 5).

Tighten the screw to a torque of 31 N´m (275 in. lbs.).

(12) If the vehicle is equipped with the antilock

brake system (ABS), install the screw securing the

ABS wheel speed sensor bracket to the rear of the

strut assembly (Fig. 6). Tighten the mounting screw

to a torque of 13 N´m (120 in. lbs.).

(13) Install the tire and wheel assembly. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification. Repeat the

tightening sequence, this time, to full specified

torque of 135 N´m (100 ft. lbs.).

(14) Lower the vehicle to ground level.

(15) Tighten the lateral arm-to-knuckle mounting

bolt nut to a torque of 95 N´m (70 ft. lbs.).

(16) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.HUB AND BEARING (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear wheel and tire assembly from

the vehicle.

(3) If the vehicle is equipped with rear drum

brakes, remove any retainer clips from the wheel

mounting studs, then pull the brake drum off the

hub and bearing.

(4) If the vehicle is equipped with rear disc brakes

(Fig. 7), perform the following:

²Remove the two guide pin bolts securing the

front disc brake caliper to the steering knuckle.

²Remove the disc brake caliper from the knuckle

and brake rotor.

²Hang the caliper out of the way using a wire

hanger or cord. Do not support the caliper by letting

it hang by the hydraulic hose.

²Remove any retainer clips from the wheel

mounting studs, then pull the brake rotor off the hub

and bearing.

(5) Remove the dust cap from the hub and bearing

assembly (Fig. 7).

(6) Remove the retaining nut, then the hub and

bearing from the knuckle's spindle (Fig. 7).

INSTALLATION

(1) Install the hub and bearing on the knuckle's

spindle, then install a new retaining nut (Fig. 7). Do

not reuse the original nut. Tighten the nut to a

torque of 217 N´m (160 ft. lbs.).

(2) Install the dust cap on the end of the hub and

bearing (Fig. 7).

(3) If the vehicle is equipped with rear disc brakes

(Fig. 7), install the brake rotor and disc brake caliper

on the knuckle. Install the two guide pin bolts secur-

ing the front disc brake caliper to the steering

knuckle. Tighten the guide pin bolts to a torque of 22

N´m (192 in. lbs.).

(4) Install the tire and wheel assembly. Tighten

the wheel mounting nuts in proper sequence until all

nuts are torqued to half specification. Repeat the

tightening sequence, this time, to full specified

torque of 135 N´m (100 ft. lbs.).

(5) Lower the vehicle to ground level.

2 - 44 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 57 of 1285

(10) With suspension at curb height, tighten the

lateral arm mounting bolt nut at the crossmember to

88 N´m (65 ft. lbs.).

(11) Set the rear toe on the vehicle to the required

specification as necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

TENSION STRUT

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear wheel and tire assembly from

the vehicle.

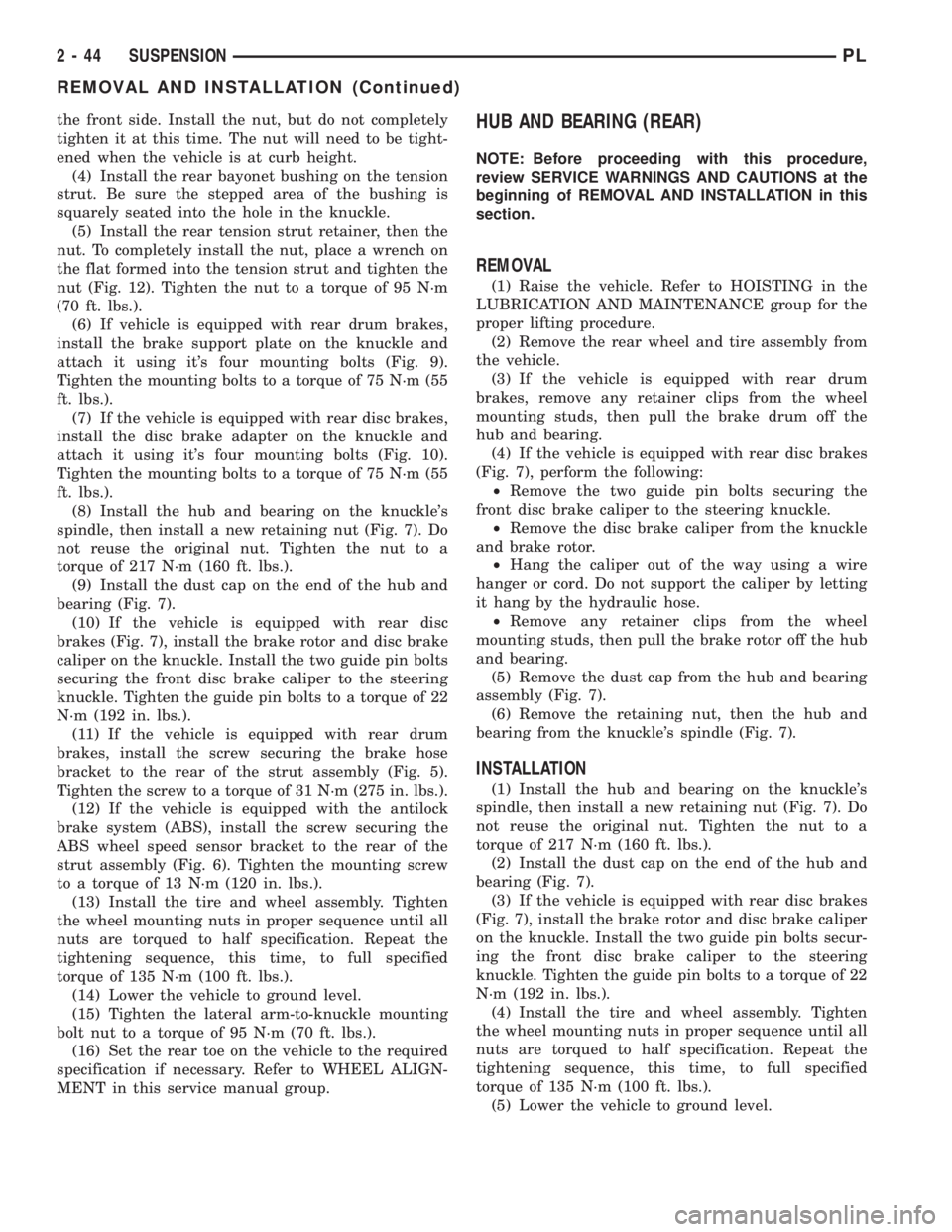

(3) Disconnect the tension strut from the knuckle.

To do this, first hold the tension strut from turning

by using a wrench on the flat on the tension strut

and then remove the nut from the rear of the tension

strut (Fig. 14). Next, remove the tension strut

retainer, then the rear tension strut bayonet bushing

from the tension strut.

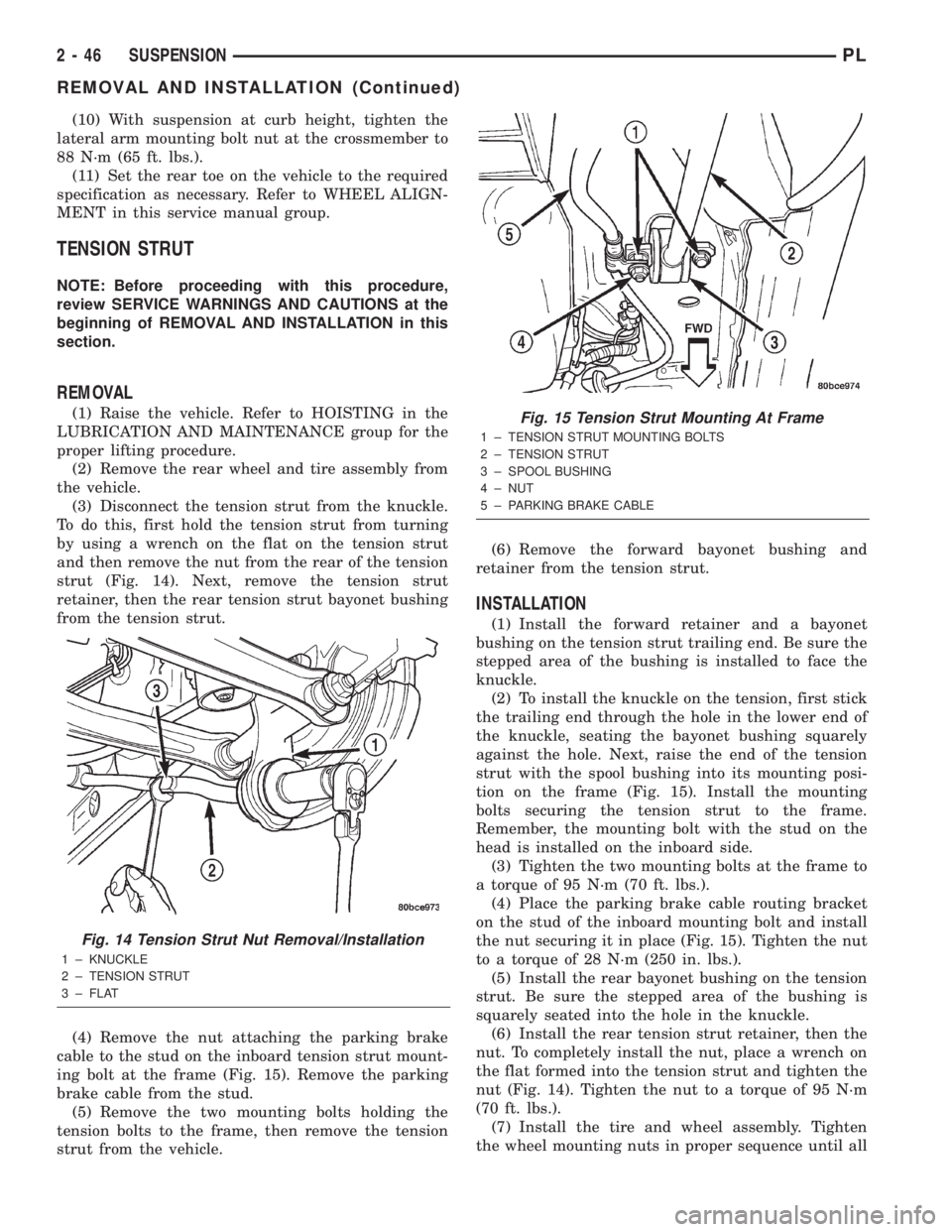

(4) Remove the nut attaching the parking brake

cable to the stud on the inboard tension strut mount-

ing bolt at the frame (Fig. 15). Remove the parking

brake cable from the stud.

(5) Remove the two mounting bolts holding the

tension bolts to the frame, then remove the tension

strut from the vehicle.(6) Remove the forward bayonet bushing and

retainer from the tension strut.

INSTALLATION

(1) Install the forward retainer and a bayonet

bushing on the tension strut trailing end. Be sure the

stepped area of the bushing is installed to face the

knuckle.

(2) To install the knuckle on the tension, first stick

the trailing end through the hole in the lower end of

the knuckle, seating the bayonet bushing squarely

against the hole. Next, raise the end of the tension

strut with the spool bushing into its mounting posi-

tion on the frame (Fig. 15). Install the mounting

bolts securing the tension strut to the frame.

Remember, the mounting bolt with the stud on the

head is installed on the inboard side.

(3) Tighten the two mounting bolts at the frame to

a torque of 95 N´m (70 ft. lbs.).

(4) Place the parking brake cable routing bracket

on the stud of the inboard mounting bolt and install

the nut securing it in place (Fig. 15). Tighten the nut

to a torque of 28 N´m (250 in. lbs.).

(5) Install the rear bayonet bushing on the tension

strut. Be sure the stepped area of the bushing is

squarely seated into the hole in the knuckle.

(6) Install the rear tension strut retainer, then the

nut. To completely install the nut, place a wrench on

the flat formed into the tension strut and tighten the

nut (Fig. 14). Tighten the nut to a torque of 95 N´m

(70 ft. lbs.).

(7) Install the tire and wheel assembly. Tighten

the wheel mounting nuts in proper sequence until all

Fig. 14 Tension Strut Nut Removal/Installation

1 ± KNUCKLE

2 ± TENSION STRUT

3 ± FLAT

Fig. 15 Tension Strut Mounting At Frame

1 ± TENSION STRUT MOUNTING BOLTS

2 ± TENSION STRUT

3 ± SPOOL BUSHING

4 ± NUT

5 ± PARKING BRAKE CABLE

2 - 46 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 58 of 1285

nuts are torqued to half specification. Repeat the

tightening sequence, this time, to full specified

torque of 135 N´m (100 ft. lbs.).

(8) Lower the vehicle to ground level.

(9) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

STABILIZER BAR (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove both rear wheel and tire assemblies

from the vehicle.

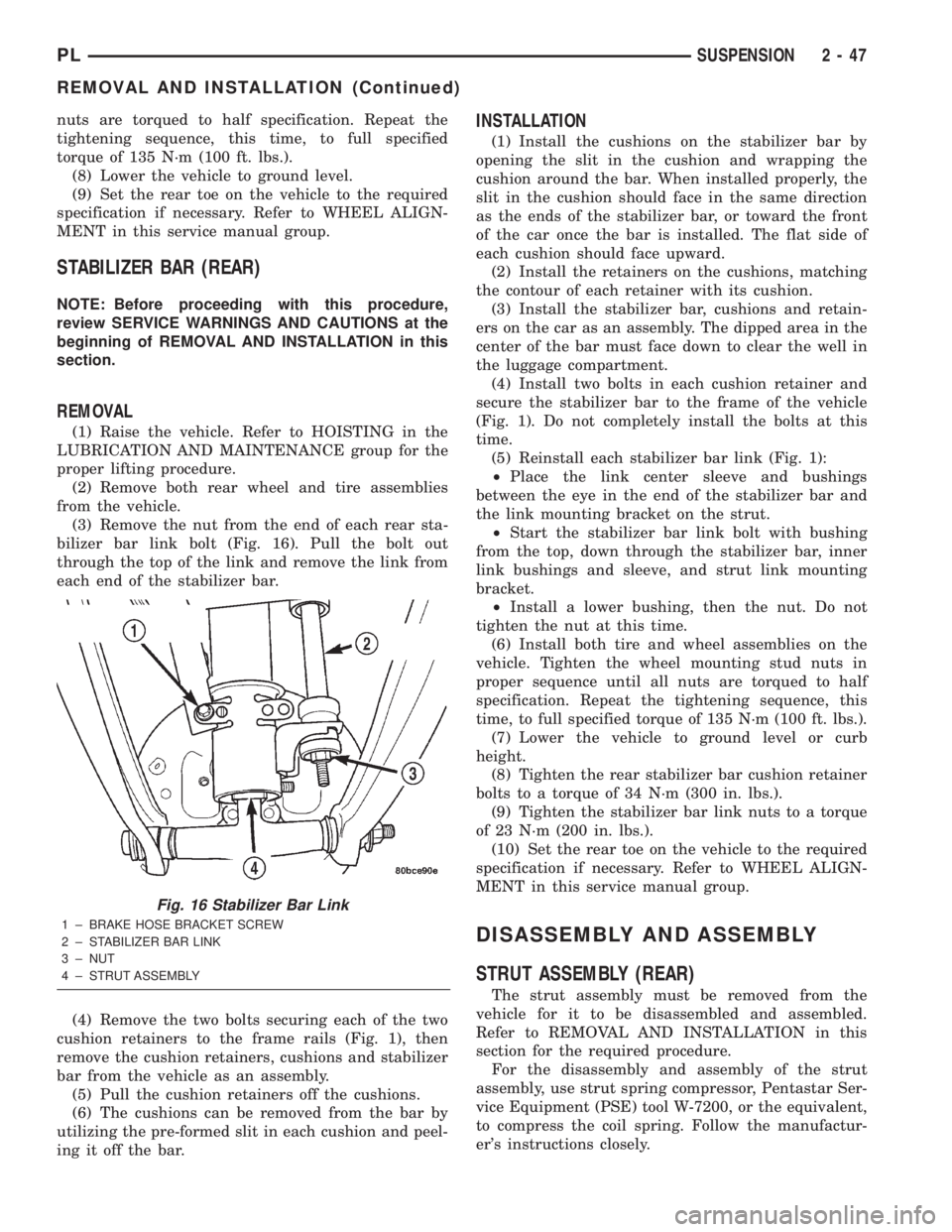

(3) Remove the nut from the end of each rear sta-

bilizer bar link bolt (Fig. 16). Pull the bolt out

through the top of the link and remove the link from

each end of the stabilizer bar.

(4) Remove the two bolts securing each of the two

cushion retainers to the frame rails (Fig. 1), then

remove the cushion retainers, cushions and stabilizer

bar from the vehicle as an assembly.

(5) Pull the cushion retainers off the cushions.

(6) The cushions can be removed from the bar by

utilizing the pre-formed slit in each cushion and peel-

ing it off the bar.

INSTALLATION

(1) Install the cushions on the stabilizer bar by

opening the slit in the cushion and wrapping the

cushion around the bar. When installed properly, the

slit in the cushion should face in the same direction

as the ends of the stabilizer bar, or toward the front

of the car once the bar is installed. The flat side of

each cushion should face upward.

(2) Install the retainers on the cushions, matching

the contour of each retainer with its cushion.

(3) Install the stabilizer bar, cushions and retain-

ers on the car as an assembly. The dipped area in the

center of the bar must face down to clear the well in

the luggage compartment.

(4) Install two bolts in each cushion retainer and

secure the stabilizer bar to the frame of the vehicle

(Fig. 1). Do not completely install the bolts at this

time.

(5) Reinstall each stabilizer bar link (Fig. 1):

²Place the link center sleeve and bushings

between the eye in the end of the stabilizer bar and

the link mounting bracket on the strut.

²Start the stabilizer bar link bolt with bushing

from the top, down through the stabilizer bar, inner

link bushings and sleeve, and strut link mounting

bracket.

²Install a lower bushing, then the nut. Do not

tighten the nut at this time.

(6) Install both tire and wheel assemblies on the

vehicle. Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Repeat the tightening sequence, this

time, to full specified torque of 135 N´m (100 ft. lbs.).

(7) Lower the vehicle to ground level or curb

height.

(8) Tighten the rear stabilizer bar cushion retainer

bolts to a torque of 34 N´m (300 in. lbs.).

(9) Tighten the stabilizer bar link nuts to a torque

of 23 N´m (200 in. lbs.).

(10) Set the rear toe on the vehicle to the required

specification if necessary. Refer to WHEEL ALIGN-

MENT in this service manual group.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (REAR)

The strut assembly must be removed from the

vehicle for it to be disassembled and assembled.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

For the disassembly and assembly of the strut

assembly, use strut spring compressor, Pentastar Ser-

vice Equipment (PSE) tool W-7200, or the equivalent,

to compress the coil spring. Follow the manufactur-

er's instructions closely.

Fig. 16 Stabilizer Bar Link

1 ± BRAKE HOSE BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

PLSUSPENSION 2 - 47

REMOVAL AND INSTALLATION (Continued)

Page 61 of 1285

hex on the end of the strut shaft. While holding the

strut shaft from turning, tighten the strut shaft

retaining nut to a torque of 75 N´m (55 ft. lbs.).

(10) Slowly release the tension from the coil spring

by backing off the compressor drive completely. As

the tension is relieved, make sure the upper mount's

seat aligns properly with the coil spring.

(11) Verify the arrow on the upper mount is point-

ing in the same direction as the strut clevis bracket

as mentioned in step 9.

(12) Remove the clamp from the lower end of the

coil spring and strut. Push back the spring compres-

sor upper and lower hooks, then remove the strut

assembly from the spring compressor.

(13) Install the strut assembly on the vehicle.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

STRUT ASSEMBLY:

Tower Attaching Nuts..... 34N´m(300 in. lbs.)

Knuckle Attaching Bolts.... 88N´m(65ft.lbs.)

Strut Assembly Shaft Nut . . . 75 N´m (55 ft. lbs.)

Brake Hose Bracket Mounting Bolt..... 31N´m

(275 in. lbs.)

KNUCKLE:

Brake Support Plate Mounting Bolts.... 75N´m

(55 ft. lbs.)

Disc Brake Adapter Mounting Bolts.... 75N´m

(55 ft. lbs.)

HUB AND BEARING:

To Knuckle Retaining Nut........... 217N´m

(160 ft. lbs.)

Wheel Mounting Nuts...........109-150 N´m

(80-110 ft. lbs.)

LATERAL ARM:

Nut At Crossmember....... 88N´m(65ft.lbs.)

Nut At Knuckle........... 95N´m(70ft.lbs.)

TENSION STRUT:

Rear Nut................ 95N´m(70ft.lbs.)

Frame Rail Bolts.......... 95N´m(70ft.lbs.)

Parking Brake Cable Nut . . 28 N´m (250 in. lbs.)

STABILIZER BAR:

Cushion Retainer Bolts.... 34N´m(300 in. lbs.)

Link Bolt Nut........... 23N´m(200 in. lbs.)

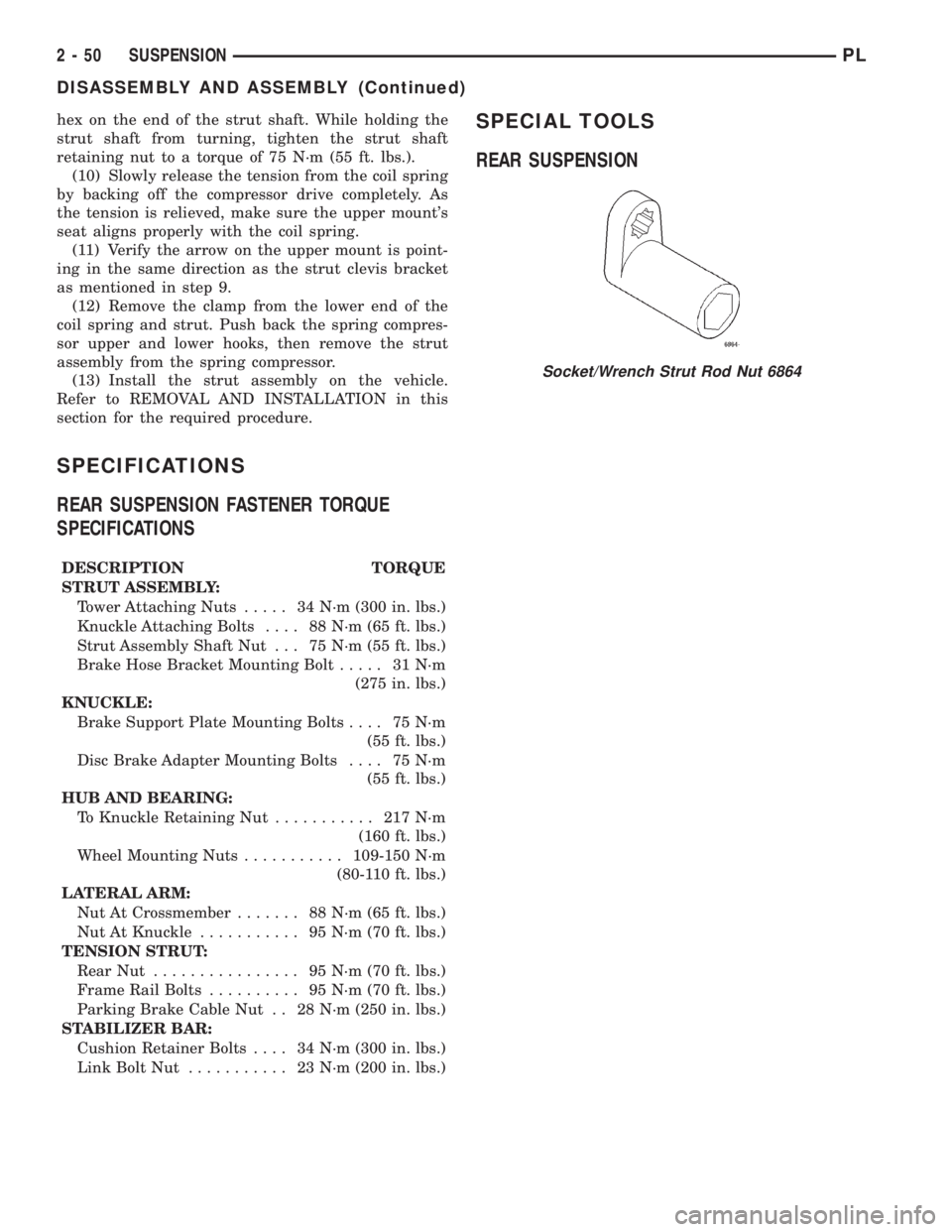

SPECIAL TOOLS

REAR SUSPENSION

Socket/Wrench Strut Rod Nut 6864

2 - 50 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 83 of 1285

Proportioning valves balance front to rear braking

by controlling the brake fluid hydraulic pressure to

the rear brakes. Under light pedal application, the

proportioning valve allows normal fluid flow to the

rear brakes. Under higher pedal effort, the valve

reduces fluid pressure to the rear brakes.

The non-antilock master cylinder is a four-outlet

design with two screw-in proportioning valves

attached directly to the master cylinder housing (Fig.

3). One proportioning valve controls each rear brake.

BRAKE TUBES AND HOSES

The purpose of the brake tubes and flex hoses is to

transfer the pressurized brake fluid developed by the

master cylinder to the brakes at each wheel of the

vehicle. The flex hoses connect the chassis brake

tubes, which are mounted to the vehicle's underbody,

to the brake at each wheel, allowing for movement of

the vehicle's suspension. The brake tubes are steel

with a corrosion-resistant nylon coating applied to

the external surfaces. The flex hoses are made of

reinforced rubber.

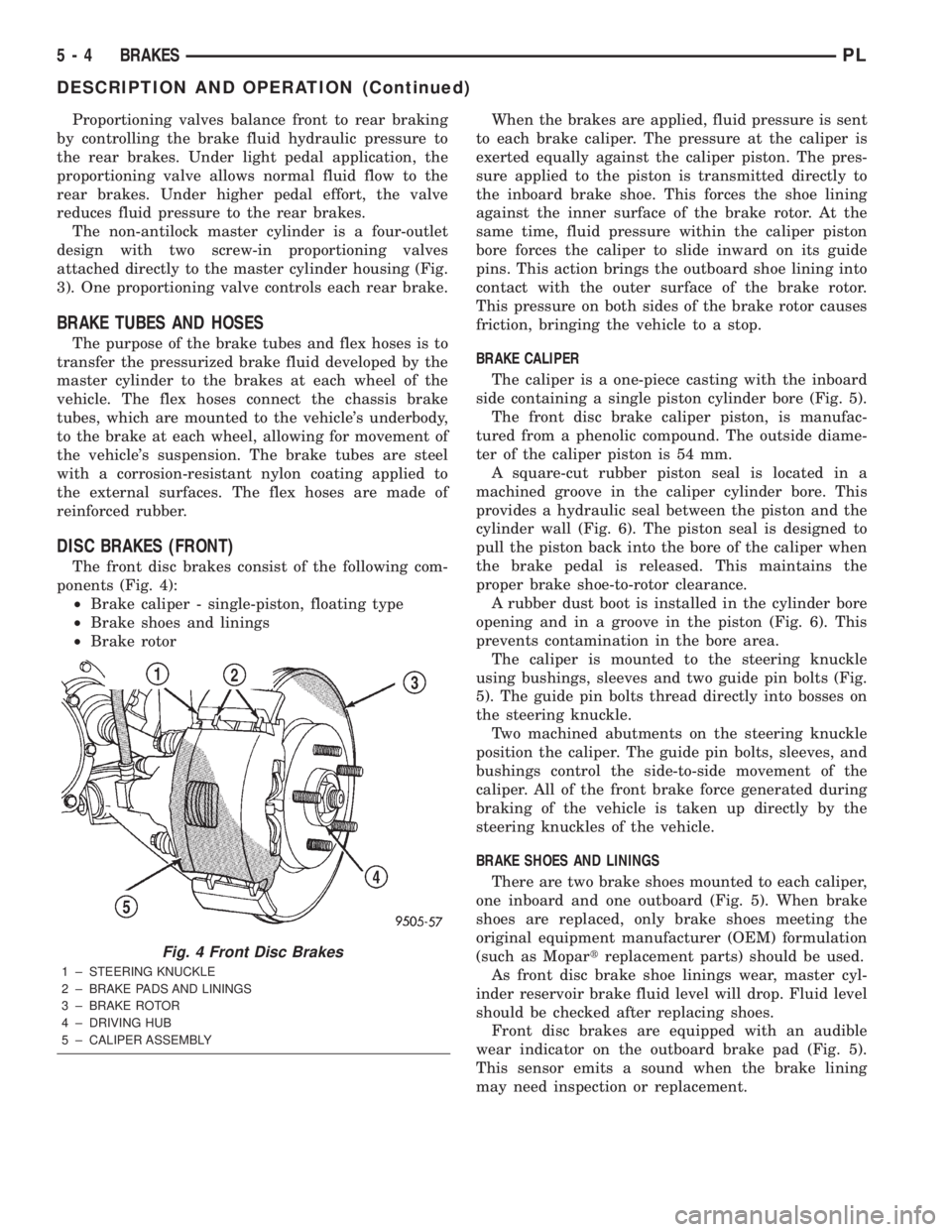

DISC BRAKES (FRONT)

The front disc brakes consist of the following com-

ponents (Fig. 4):

²Brake caliper - single-piston, floating type

²Brake shoes and linings

²Brake rotorWhen the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

BRAKE CALIPER

The caliper is a one-piece casting with the inboard

side containing a single piston cylinder bore (Fig. 5).

The front disc brake caliper piston, is manufac-

tured from a phenolic compound. The outside diame-

ter of the caliper piston is 54 mm.

A square-cut rubber piston seal is located in a

machined groove in the caliper cylinder bore. This

provides a hydraulic seal between the piston and the

cylinder wall (Fig. 6). The piston seal is designed to

pull the piston back into the bore of the caliper when

the brake pedal is released. This maintains the

proper brake shoe-to-rotor clearance.

A rubber dust boot is installed in the cylinder bore

opening and in a groove in the piston (Fig. 6). This

prevents contamination in the bore area.

The caliper is mounted to the steering knuckle

using bushings, sleeves and two guide pin bolts (Fig.

5). The guide pin bolts thread directly into bosses on

the steering knuckle.

Two machined abutments on the steering knuckle

position the caliper. The guide pin bolts, sleeves, and

bushings control the side-to-side movement of the

caliper. All of the front brake force generated during

braking of the vehicle is taken up directly by the

steering knuckles of the vehicle.

BRAKE SHOES AND LININGS

There are two brake shoes mounted to each caliper,

one inboard and one outboard (Fig. 5). When brake

shoes are replaced, only brake shoes meeting the

original equipment manufacturer (OEM) formulation

(such as Mopartreplacement parts) should be used.

As front disc brake shoe linings wear, master cyl-

inder reservoir brake fluid level will drop. Fluid level

should be checked after replacing shoes.

Front disc brakes are equipped with an audible

wear indicator on the outboard brake pad (Fig. 5).

This sensor emits a sound when the brake lining

may need inspection or replacement.

Fig. 4 Front Disc Brakes

1 ± STEERING KNUCKLE

2 ± BRAKE PADS AND LININGS

3 ± BRAKE ROTOR

4 ± DRIVING HUB

5 ± CALIPER ASSEMBLY

5 - 4 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 85 of 1285

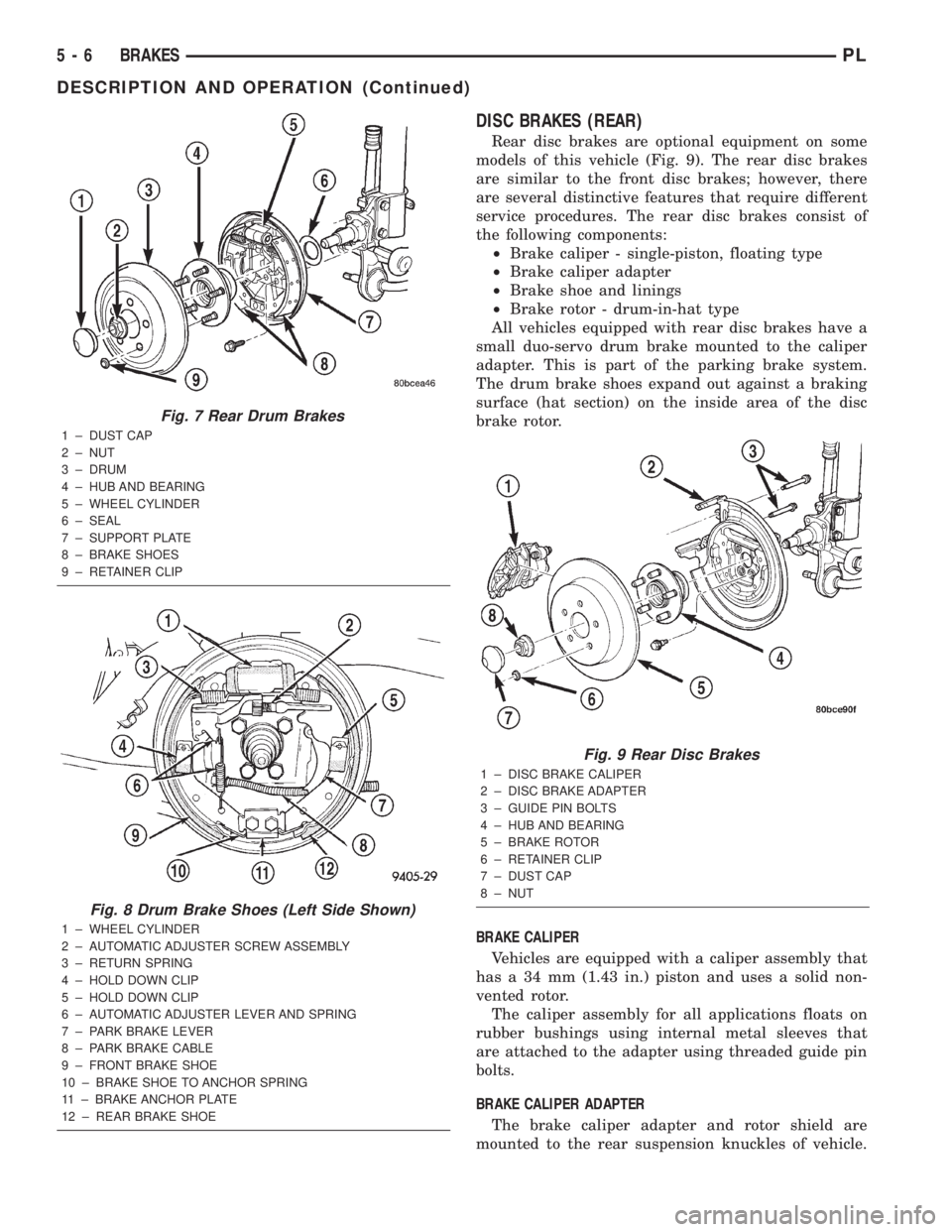

DISC BRAKES (REAR)

Rear disc brakes are optional equipment on some

models of this vehicle (Fig. 9). The rear disc brakes

are similar to the front disc brakes; however, there

are several distinctive features that require different

service procedures. The rear disc brakes consist of

the following components:

²Brake caliper - single-piston, floating type

²Brake caliper adapter

²Brake shoe and linings

²Brake rotor - drum-in-hat type

All vehicles equipped with rear disc brakes have a

small duo-servo drum brake mounted to the caliper

adapter. This is part of the parking brake system.

The drum brake shoes expand out against a braking

surface (hat section) on the inside area of the disc

brake rotor.

BRAKE CALIPER

Vehicles are equipped with a caliper assembly that

has a 34 mm (1.43 in.) piston and uses a solid non-

vented rotor.

The caliper assembly for all applications floats on

rubber bushings using internal metal sleeves that

are attached to the adapter using threaded guide pin

bolts.

BRAKE CALIPER ADAPTER

The brake caliper adapter and rotor shield are

mounted to the rear suspension knuckles of vehicle.

Fig. 7 Rear Drum Brakes

1 ± DUST CAP

2 ± NUT

3 ± DRUM

4 ± HUB AND BEARING

5 ± WHEEL CYLINDER

6 ± SEAL

7 ± SUPPORT PLATE

8 ± BRAKE SHOES

9 ± RETAINER CLIP

Fig. 8 Drum Brake Shoes (Left Side Shown)

1 ± WHEEL CYLINDER

2 ± AUTOMATIC ADJUSTER SCREW ASSEMBLY

3 ± RETURN SPRING

4 ± HOLD DOWN CLIP

5 ± HOLD DOWN CLIP

6 ± AUTOMATIC ADJUSTER LEVER AND SPRING

7 ± PARK BRAKE LEVER

8 ± PARK BRAKE CABLE

9 ± FRONT BRAKE SHOE

10 ± BRAKE SHOE TO ANCHOR SPRING

11 ± BRAKE ANCHOR PLATE

12 ± REAR BRAKE SHOE

Fig. 9 Rear Disc Brakes

1 ± DISC BRAKE CALIPER

2 ± DISC BRAKE ADAPTER

3 ± GUIDE PIN BOLTS

4 ± HUB AND BEARING

5 ± BRAKE ROTOR

6 ± RETAINER CLIP

7 ± DUST CAP

8 ± NUT

5 - 6 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 88 of 1285

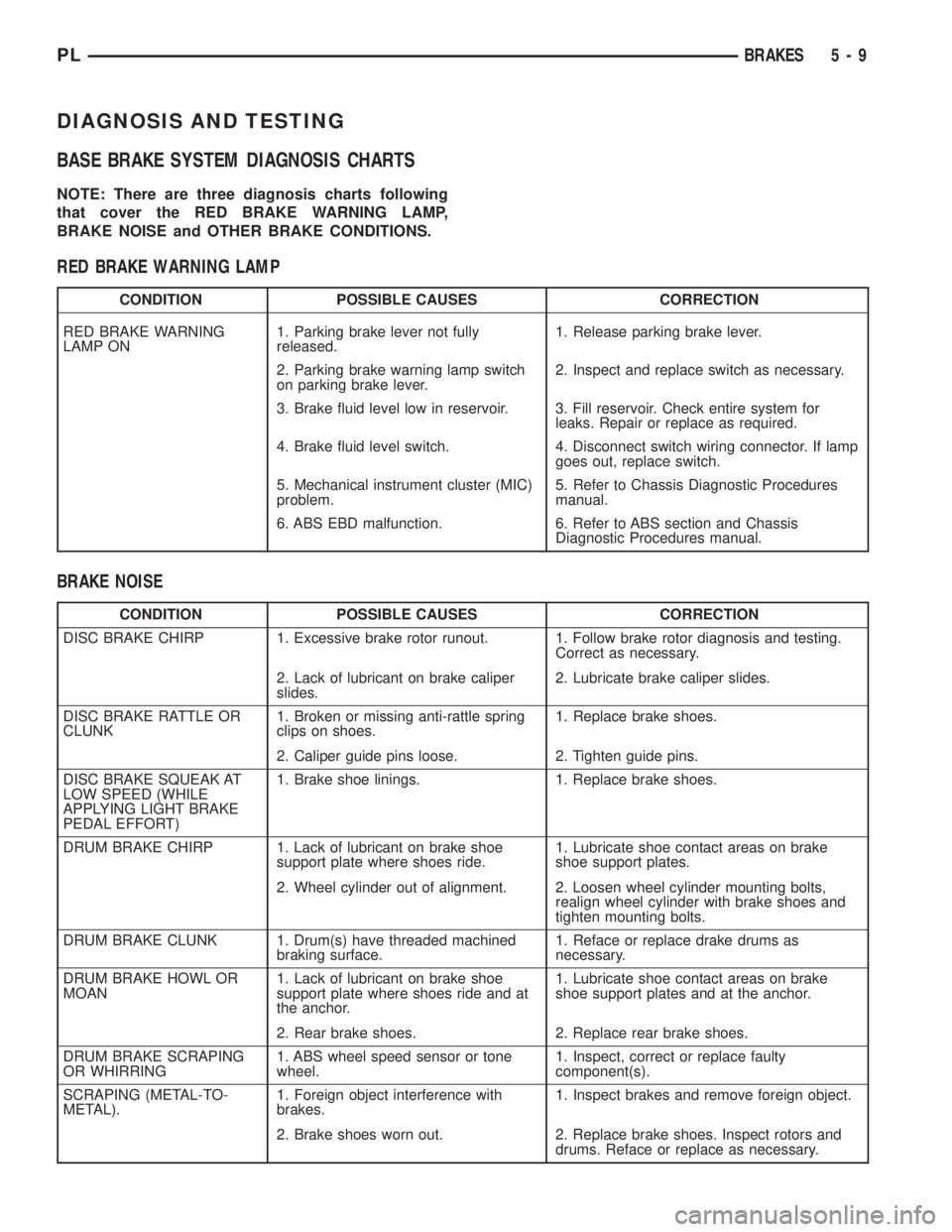

DIAGNOSIS AND TESTING

BASE BRAKE SYSTEM DIAGNOSIS CHARTS

NOTE: There are three diagnosis charts following

that cover the RED BRAKE WARNING LAMP,

BRAKE NOISE and OTHER BRAKE CONDITIONS.

RED BRAKE WARNING LAMP

CONDITION POSSIBLE CAUSES CORRECTION

RED BRAKE WARNING

LAMP ON1. Parking brake lever not fully

released.1. Release parking brake lever.

2. Parking brake warning lamp switch

on parking brake lever.2. Inspect and replace switch as necessary.

3. Brake fluid level low in reservoir. 3. Fill reservoir. Check entire system for

leaks. Repair or replace as required.

4. Brake fluid level switch. 4. Disconnect switch wiring connector. If lamp

goes out, replace switch.

5. Mechanical instrument cluster (MIC)

problem.5. Refer to Chassis Diagnostic Procedures

manual.

6. ABS EBD malfunction. 6. Refer to ABS section and Chassis

Diagnostic Procedures manual.

BRAKE NOISE

CONDITION POSSIBLE CAUSES CORRECTION

DISC BRAKE CHIRP 1. Excessive brake rotor runout. 1. Follow brake rotor diagnosis and testing.

Correct as necessary.

2. Lack of lubricant on brake caliper

slides.2. Lubricate brake caliper slides.

DISC BRAKE RATTLE OR

CLUNK1. Broken or missing anti-rattle spring

clips on shoes.1. Replace brake shoes.

2. Caliper guide pins loose. 2. Tighten guide pins.

DISC BRAKE SQUEAK AT

LOW SPEED (WHILE

APPLYING LIGHT BRAKE

PEDAL EFFORT)1. Brake shoe linings. 1. Replace brake shoes.

DRUM BRAKE CHIRP 1. Lack of lubricant on brake shoe

support plate where shoes ride.1. Lubricate shoe contact areas on brake

shoe support plates.

2. Wheel cylinder out of alignment. 2. Loosen wheel cylinder mounting bolts,

realign wheel cylinder with brake shoes and

tighten mounting bolts.

DRUM BRAKE CLUNK 1. Drum(s) have threaded machined

braking surface.1. Reface or replace drake drums as

necessary.

DRUM BRAKE HOWL OR

MOAN1. Lack of lubricant on brake shoe

support plate where shoes ride and at

the anchor.1. Lubricate shoe contact areas on brake

shoe support plates and at the anchor.

2. Rear brake shoes. 2. Replace rear brake shoes.

DRUM BRAKE SCRAPING

OR WHIRRING1. ABS wheel speed sensor or tone

wheel.1. Inspect, correct or replace faulty

component(s).

SCRAPING (METAL-TO-

METAL).1. Foreign object interference with

brakes.1. Inspect brakes and remove foreign object.

2. Brake shoes worn out. 2. Replace brake shoes. Inspect rotors and

drums. Reface or replace as necessary.

PLBRAKES 5 - 9

Page 111 of 1285

CAUTION: Use only a new brake booster input rod-

to-brake pedal retaining clip to ensure proper

retainment.

(4) Connect the power brake booster input rod-to-

brake pedal pin. Install a new retaining clip. Do not

use the old clip.

(5) Connect all previously removed vacuum hoses

to the vacuum check valve (Fig. 49).

(6) If the vehicle is equipped with ABS, install the

ICU mounting bracket on the frame rail using its

three bolts. Tighten the nuts to a torque of 23 N´m

(200 in. lbs.).

(7) If the vehicle is equipped with ABS, reinstall

the ICU. Refer to INTEGRATED CONTROL UNIT in

REMOVAL AND INSTALLATION within the

ANTILOCK BRAKE SYSTEM section of this service

manual group for the procedure.

(8) Install the master cylinder. For the master cyl-

inder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(9) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 48). Tighten the two

bolts and nuts to a torque of 34 N´m (25 ft. lbs.).

(10) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 48).

(11) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(12) Install the battery and clamp it in place.

(13) Connect the positive, then the negative

(ground) cable on the battery.

(14) Adjust the stop lamp switch as necessary.

Refer to STOP LAMP SWITCH in the ADJUST-

MENTS section of this group.

(15) Bleed the base brake system.

(16) Road test the vehicle to ensure proper opera-

tion of the brakes.

PROPORTIONING VALVE

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

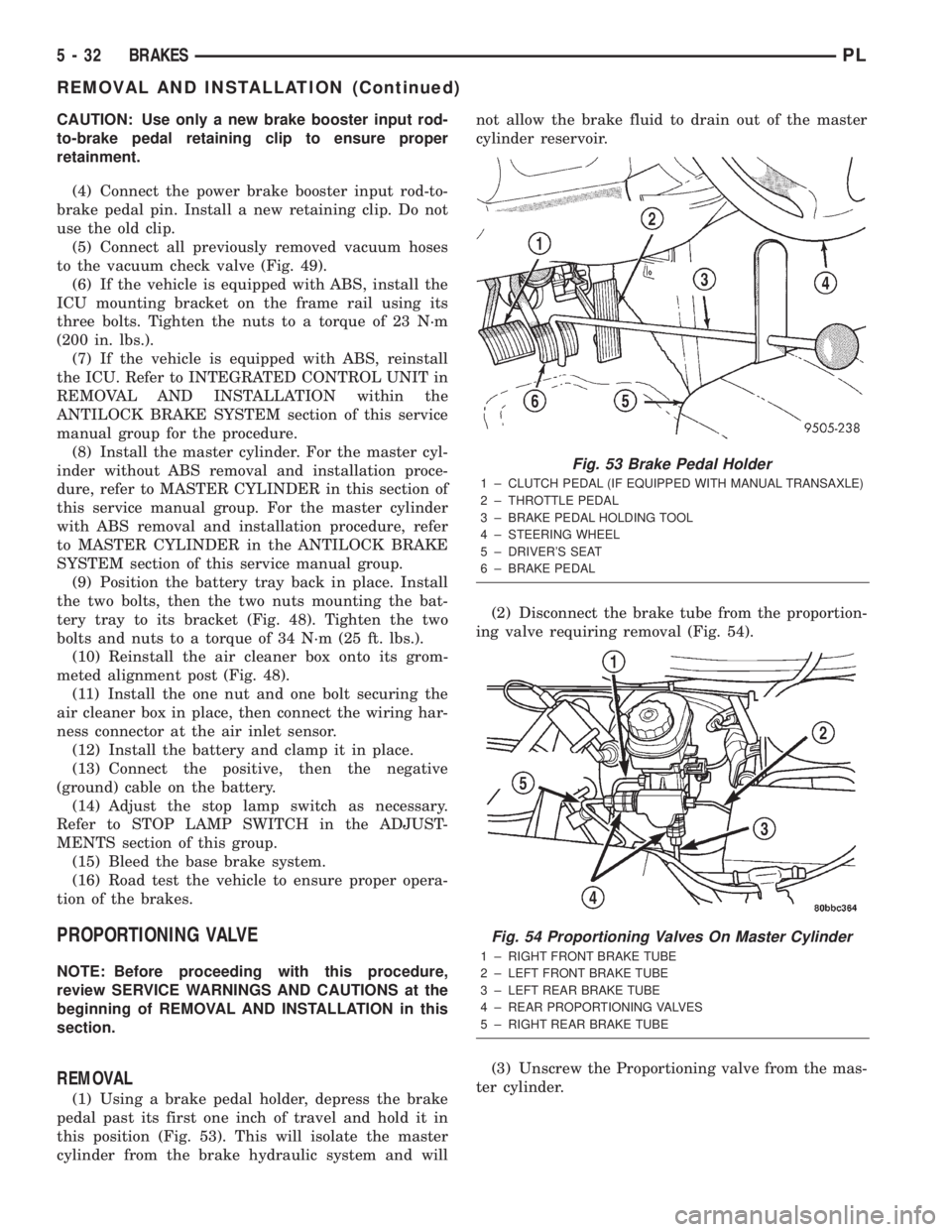

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 53). This will isolate the master

cylinder from the brake hydraulic system and willnot allow the brake fluid to drain out of the master

cylinder reservoir.

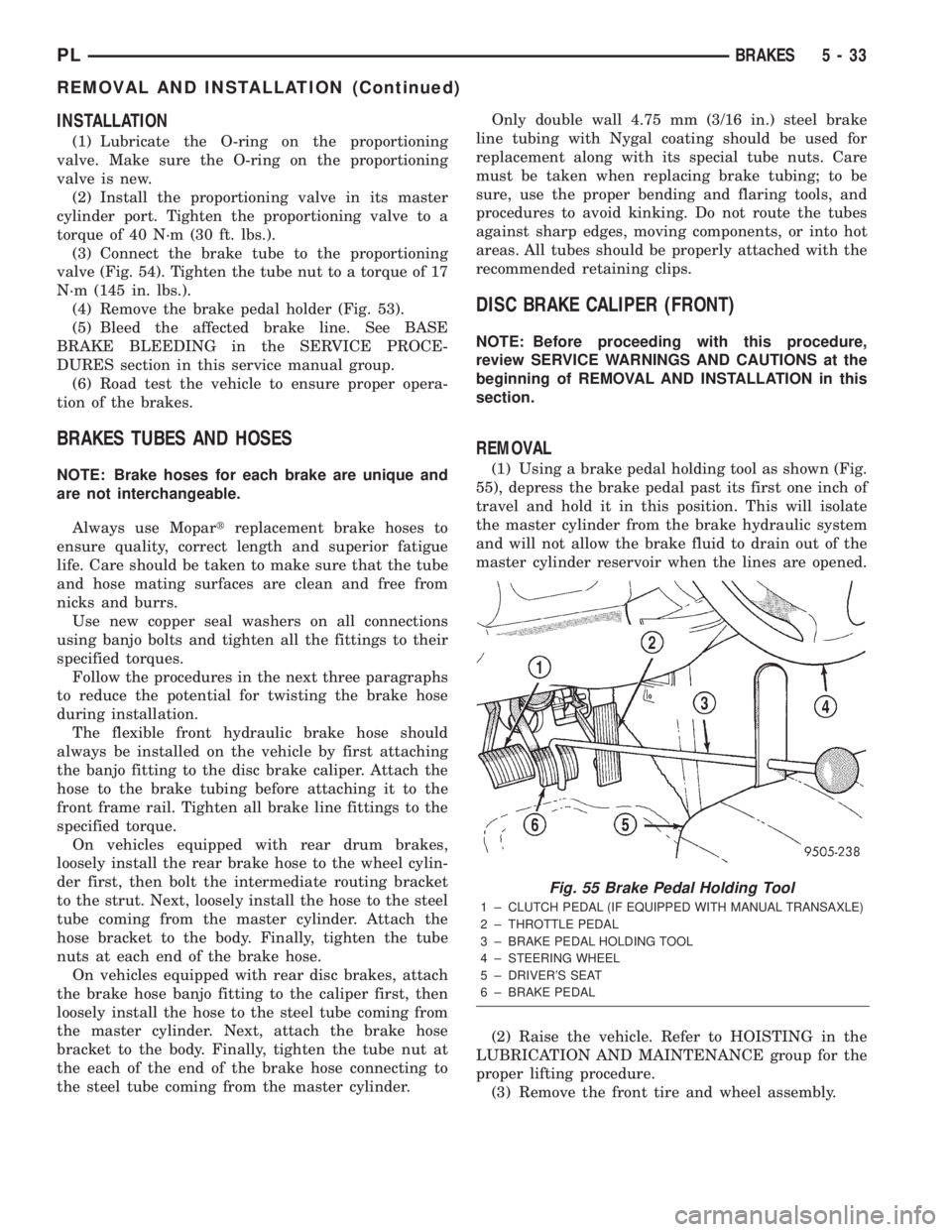

(2) Disconnect the brake tube from the proportion-

ing valve requiring removal (Fig. 54).

(3) Unscrew the Proportioning valve from the mas-

ter cylinder.

Fig. 53 Brake Pedal Holder

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

Fig. 54 Proportioning Valves On Master Cylinder

1 ± RIGHT FRONT BRAKE TUBE

2 ± LEFT FRONT BRAKE TUBE

3 ± LEFT REAR BRAKE TUBE

4 ± REAR PROPORTIONING VALVES

5 ± RIGHT REAR BRAKE TUBE

5 - 32 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 112 of 1285

INSTALLATION

(1) Lubricate the O-ring on the proportioning

valve. Make sure the O-ring on the proportioning

valve is new.

(2) Install the proportioning valve in its master

cylinder port. Tighten the proportioning valve to a

torque of 40 N´m (30 ft. lbs.).

(3) Connect the brake tube to the proportioning

valve (Fig. 54). Tighten the tube nut to a torque of 17

N´m (145 in. lbs.).

(4) Remove the brake pedal holder (Fig. 53).

(5) Bleed the affected brake line. See BASE

BRAKE BLEEDING in the SERVICE PROCE-

DURES section in this service manual group.

(6) Road test the vehicle to ensure proper opera-

tion of the brakes.

BRAKES TUBES AND HOSES

NOTE: Brake hoses for each brake are unique and

are not interchangeable.

Always use Mopartreplacement brake hoses to

ensure quality, correct length and superior fatigue

life. Care should be taken to make sure that the tube

and hose mating surfaces are clean and free from

nicks and burrs.

Use new copper seal washers on all connections

using banjo bolts and tighten all the fittings to their

specified torques.

Follow the procedures in the next three paragraphs

to reduce the potential for twisting the brake hose

during installation.

The flexible front hydraulic brake hose should

always be installed on the vehicle by first attaching

the banjo fitting to the disc brake caliper. Attach the

hose to the brake tubing before attaching it to the

front frame rail. Tighten all brake line fittings to the

specified torque.

On vehicles equipped with rear drum brakes,

loosely install the rear brake hose to the wheel cylin-

der first, then bolt the intermediate routing bracket

to the strut. Next, loosely install the hose to the steel

tube coming from the master cylinder. Attach the

hose bracket to the body. Finally, tighten the tube

nuts at each end of the brake hose.

On vehicles equipped with rear disc brakes, attach

the brake hose banjo fitting to the caliper first, then

loosely install the hose to the steel tube coming from

the master cylinder. Next, attach the brake hose

bracket to the body. Finally, tighten the tube nut at

the each of the end of the brake hose connecting to

the steel tube coming from the master cylinder.Only double wall 4.75 mm (3/16 in.) steel brake

line tubing with Nygal coating should be used for

replacement along with its special tube nuts. Care

must be taken when replacing brake tubing; to be

sure, use the proper bending and flaring tools, and

procedures to avoid kinking. Do not route the tubes

against sharp edges, moving components, or into hot

areas. All tubes should be properly attached with the

recommended retaining clips.

DISC BRAKE CALIPER (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Using a brake pedal holding tool as shown (Fig.

55), depress the brake pedal past its first one inch of

travel and hold it in this position. This will isolate

the master cylinder from the brake hydraulic system

and will not allow the brake fluid to drain out of the

master cylinder reservoir when the lines are opened.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(3) Remove the front tire and wheel assembly.

Fig. 55 Brake Pedal Holding Tool

1 ± CLUTCH PEDAL (IF EQUIPPED WITH MANUAL TRANSAXLE)

2 ± THROTTLE PEDAL

3 ± BRAKE PEDAL HOLDING TOOL

4 ± STEERING WHEEL

5 ± DRIVER'S SEAT

6 ± BRAKE PEDAL

PLBRAKES 5 - 33

REMOVAL AND INSTALLATION (Continued)