ignition DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 994 of 1285

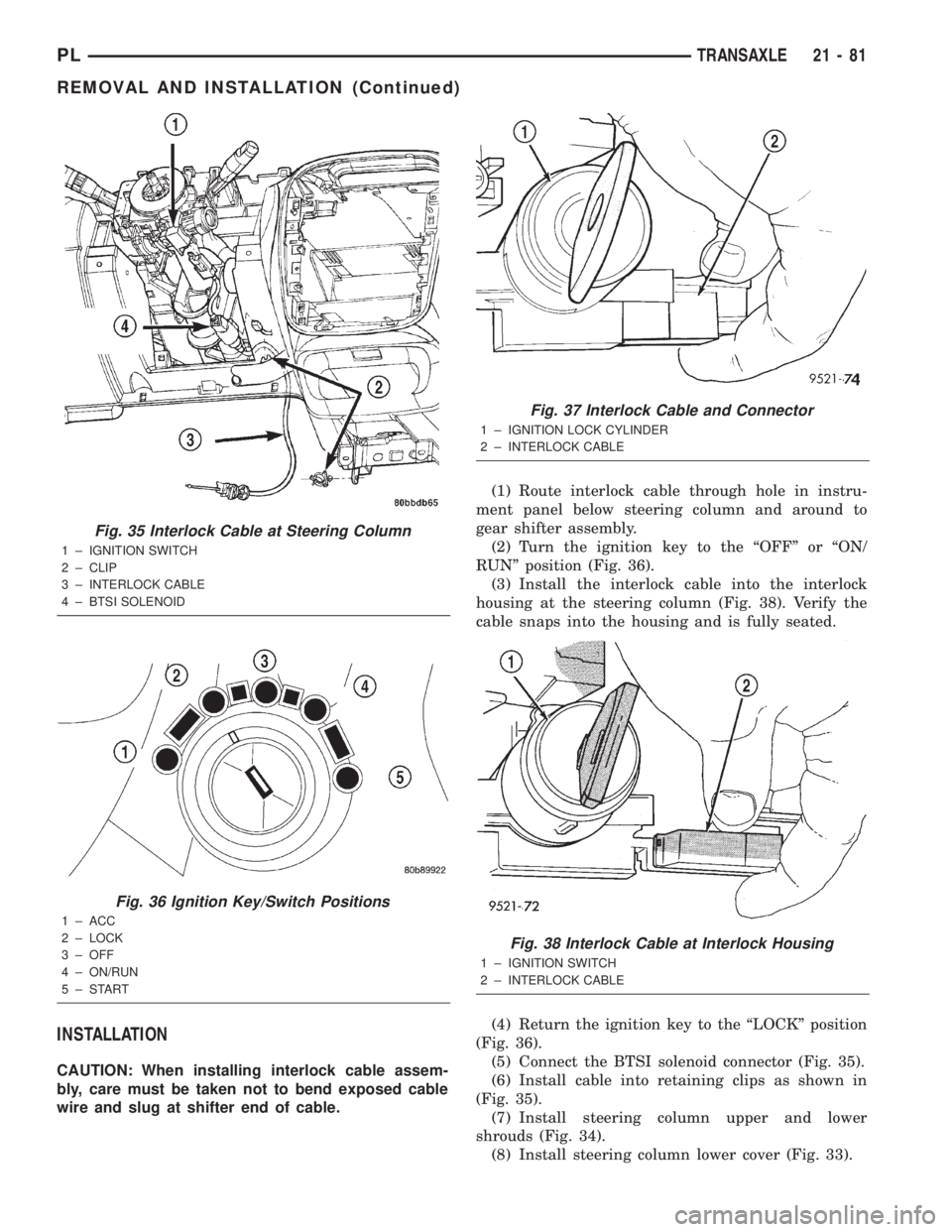

INSTALLATION

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.(1) Route interlock cable through hole in instru-

ment panel below steering column and around to

gear shifter assembly.

(2) Turn the ignition key to the ªOFFº or ªON/

RUNº position (Fig. 36).

(3) Install the interlock cable into the interlock

housing at the steering column (Fig. 38). Verify the

cable snaps into the housing and is fully seated.

(4) Return the ignition key to the ªLOCKº position

(Fig. 36).

(5) Connect the BTSI solenoid connector (Fig. 35).

(6) Install cable into retaining clips as shown in

(Fig. 35).

(7) Install steering column upper and lower

shrouds (Fig. 34).

(8) Install steering column lower cover (Fig. 33).

Fig. 35 Interlock Cable at Steering Column

1 ± IGNITION SWITCH

2 ± CLIP

3 ± INTERLOCK CABLE

4 ± BTSI SOLENOID

Fig. 36 Ignition Key/Switch Positions

1 ± ACC

2 ± LOCK

3 ± OFF

4 ± ON/RUN

5±START

Fig. 37 Interlock Cable and Connector

1 ± IGNITION LOCK CYLINDER

2 ± INTERLOCK CABLE

Fig. 38 Interlock Cable at Interlock Housing

1 ± IGNITION SWITCH

2 ± INTERLOCK CABLE

PLTRANSAXLE 21 - 81

REMOVAL AND INSTALLATION (Continued)

Page 995 of 1285

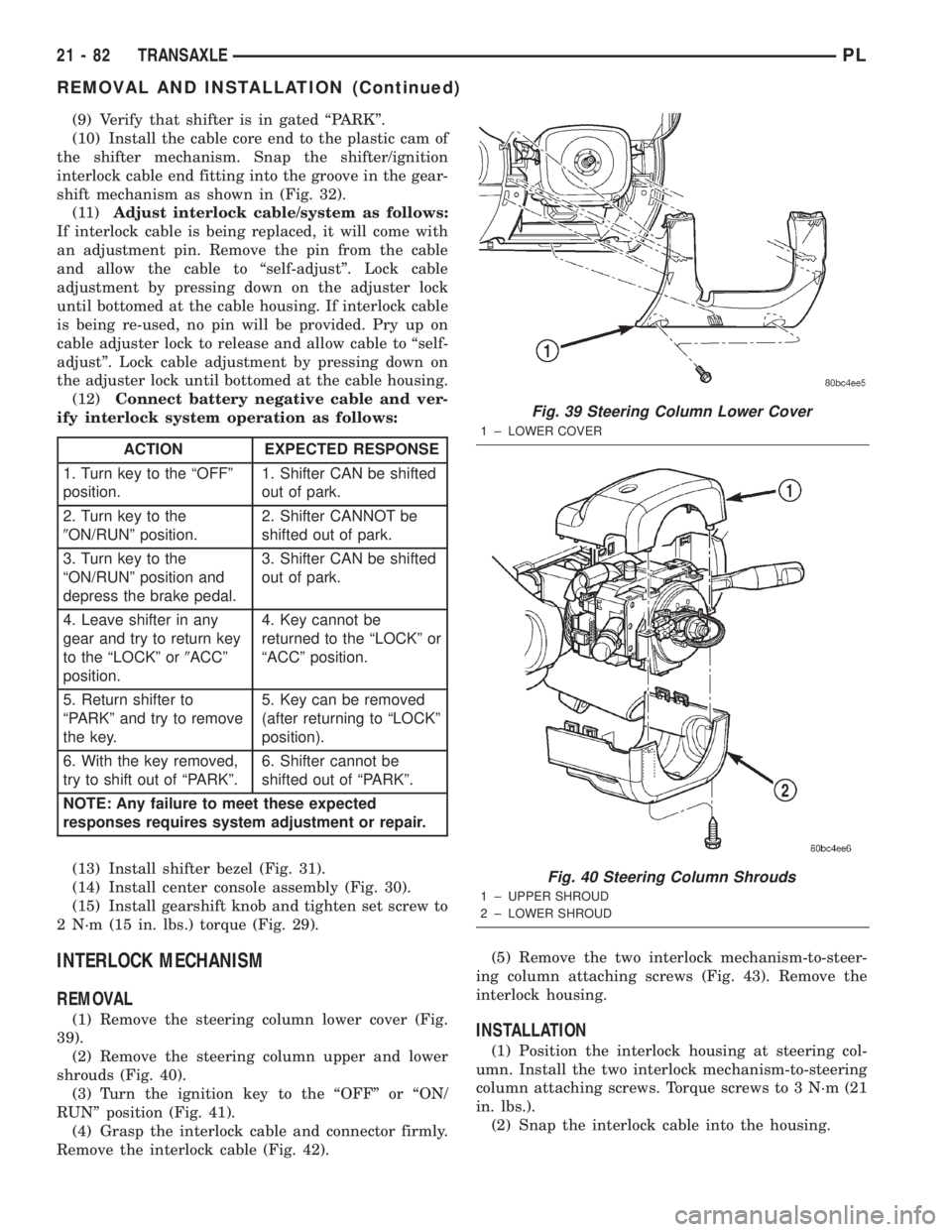

(9) Verify that shifter is in gated ªPARKº.

(10) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism as shown in (Fig. 32).

(11)Adjust interlock cable/system as follows:

If interlock cable is being replaced, it will come with

an adjustment pin. Remove the pin from the cable

and allow the cable to ªself-adjustº. Lock cable

adjustment by pressing down on the adjuster lock

until bottomed at the cable housing. If interlock cable

is being re-used, no pin will be provided. Pry up on

cable adjuster lock to release and allow cable to ªself-

adjustº. Lock cable adjustment by pressing down on

the adjuster lock until bottomed at the cable housing.

(12)Connect battery negative cable and ver-

ify interlock system operation as follows:

(13) Install shifter bezel (Fig. 31).

(14) Install center console assembly (Fig. 30).

(15) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 29).

INTERLOCK MECHANISM

REMOVAL

(1) Remove the steering column lower cover (Fig.

39).

(2) Remove the steering column upper and lower

shrouds (Fig. 40).

(3) Turn the ignition key to the ªOFFº or ªON/

RUNº position (Fig. 41).

(4) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 42).(5) Remove the two interlock mechanism-to-steer-

ing column attaching screws (Fig. 43). Remove the

interlock housing.INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism-to-steering

column attaching screws. Torque screws to 3 N´m (21

in. lbs.).

(2) Snap the interlock cable into the housing.

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

Fig. 39 Steering Column Lower Cover

1 ± LOWER COVER

Fig. 40 Steering Column Shrouds

1 ± UPPER SHROUD

2 ± LOWER SHROUD

21 - 82 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 996 of 1285

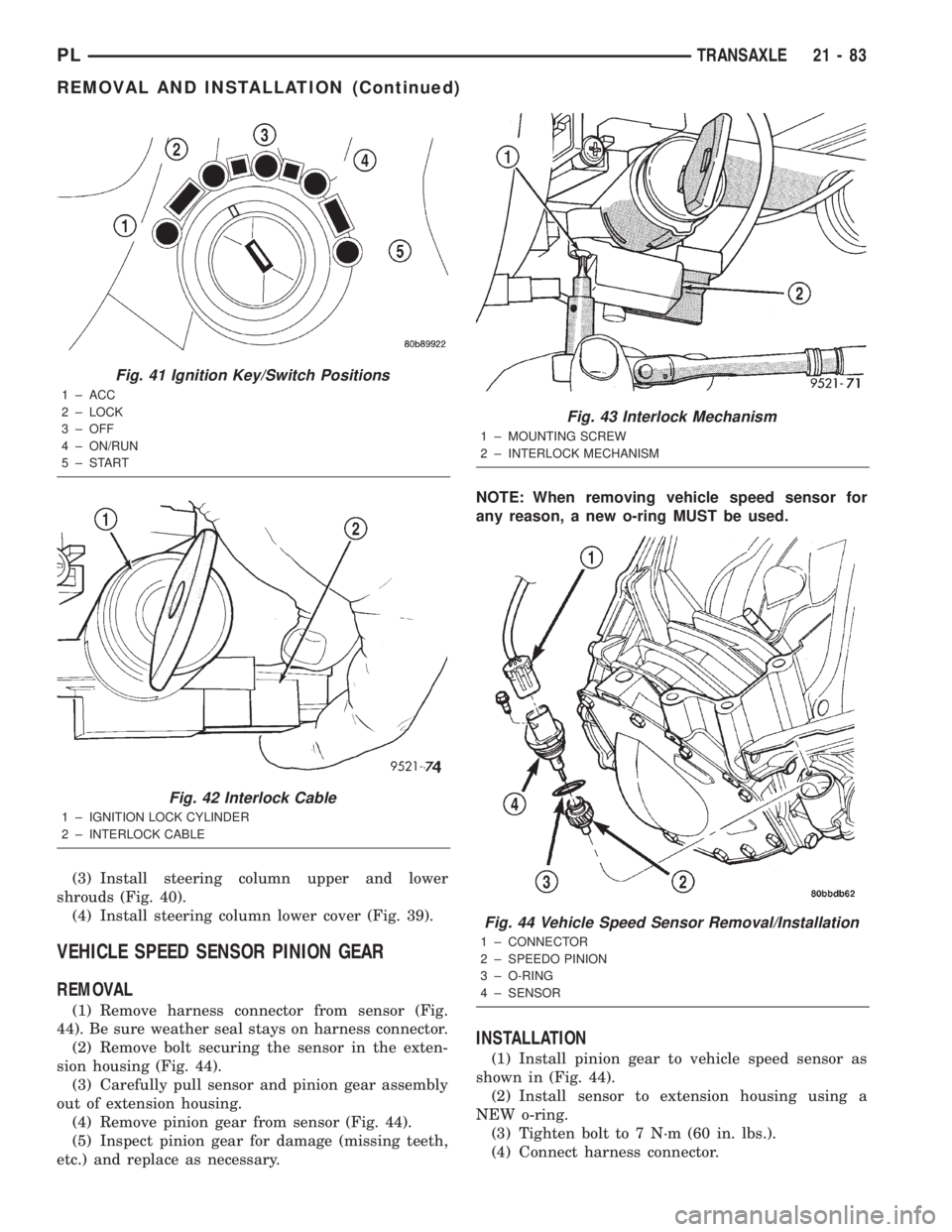

(3) Install steering column upper and lower

shrouds (Fig. 40).

(4) Install steering column lower cover (Fig. 39).

VEHICLE SPEED SENSOR PINION GEAR

REMOVAL

(1) Remove harness connector from sensor (Fig.

44). Be sure weather seal stays on harness connector.

(2) Remove bolt securing the sensor in the exten-

sion housing (Fig. 44).

(3) Carefully pull sensor and pinion gear assembly

out of extension housing.

(4) Remove pinion gear from sensor (Fig. 44).

(5) Inspect pinion gear for damage (missing teeth,

etc.) and replace as necessary.NOTE: When removing vehicle speed sensor for

any reason, a new o-ring MUST be used.

INSTALLATION

(1) Install pinion gear to vehicle speed sensor as

shown in (Fig. 44).

(2) Install sensor to extension housing using a

NEW o-ring.

(3) Tighten bolt to 7 N´m (60 in. lbs.).

(4) Connect harness connector.

Fig. 41 Ignition Key/Switch Positions

1 ± ACC

2 ± LOCK

3 ± OFF

4 ± ON/RUN

5±START

Fig. 42 Interlock Cable

1 ± IGNITION LOCK CYLINDER

2 ± INTERLOCK CABLE

Fig. 43 Interlock Mechanism

1 ± MOUNTING SCREW

2 ± INTERLOCK MECHANISM

Fig. 44 Vehicle Speed Sensor Removal/Installation

1 ± CONNECTOR

2 ± SPEEDO PINION

3 ± O-RING

4 ± SENSOR

PLTRANSAXLE 21 - 83

REMOVAL AND INSTALLATION (Continued)

Page 1088 of 1285

EMISSION CONTROL SYSTEMS

TABLE OF CONTENTS

page page

ON-BOARD DIAGNOSTICS................... 1 EVAPORATIVE EMISSION CONTROLS......... 25

ON-BOARD DIAGNOSTICS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

SYSTEM DESCRIPTION....................1

TASK MANAGER..........................2

MALFUNCTION INDICATOR LAMP (MIL)........5

DRB III STATE DISPLAY TEST MODE..........5

DRB III CIRCUIT ACTUATION TEST MODE......5

DIAGNOSTIC TROUBLE CODES..............5

DIAGNOSTIC TROUBLE CODE

DESCRIPTIONS.........................6MONITORED SYSTEMS....................15

TRIP DEFINITION........................19

MONITORED COMPONENT.................19

NON-MONITORED CIRCUITS...............23

HIGH AND LOW LIMITS....................24

LOAD VALUE............................24

DESCRIPTION AND OPERATION

SYSTEM DESCRIPTION

DESCRIPTION

OBD II requires that vehicles falling under OBD II

guidelines utilize the following system monitors:

²Comprehensive Component Monitor (inputs/out-

puts for powertrain management that affect emis-

sions, but do not have a specific major monitor)

²Fuel Control Monitor (fuel compensation

required to maintain stoichiometric ratio rich/lean)

²Misfire Monitor (change in crankshaft speed)

²Oxygen Sensor Heater Monitor (response and

performance of oxygen sensors)

²Catalyst Monitor (Performance and efficiency of

catalyst)

²Evaporative Emissions Monitor (performance of

and leaks from EVAP system)

²Exhaust Gas Recirculation Monitor (flow perfor-

mance of EGR system)

The software was rewritten to enable the PCM to

carry out the responsibilities to meet these required

guidelines. The PCM now contains a Task Manager.

OPERATION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PLEMISSION CONTROL SYSTEMS 25 - 1

Page 1093 of 1285

OPERATION

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located inthe passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

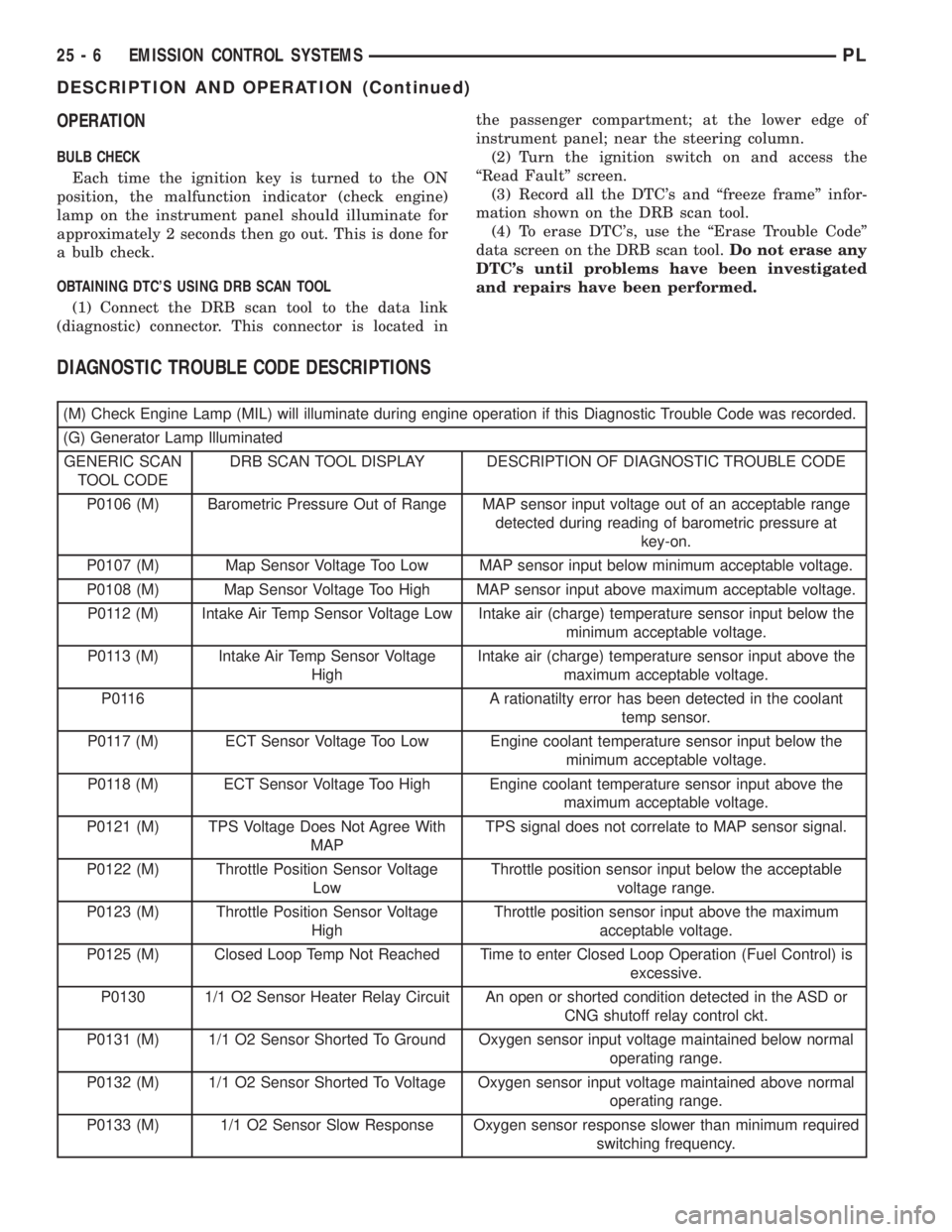

DIAGNOSTIC TROUBLE CODE DESCRIPTIONS

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0106 (M) Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at

key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage

HighIntake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 A rationatilty error has been detected in the coolant

temp sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the

minimum acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0122 (M) Throttle Position Sensor Voltage

LowThrottle position sensor input below the acceptable

voltage range.

P0123 (M) Throttle Position Sensor Voltage

HighThrottle position sensor input above the maximum

acceptable voltage.

P0125 (M) Closed Loop Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0130 1/1 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or

CNG shutoff relay control ckt.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

25 - 6 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1096 of 1285

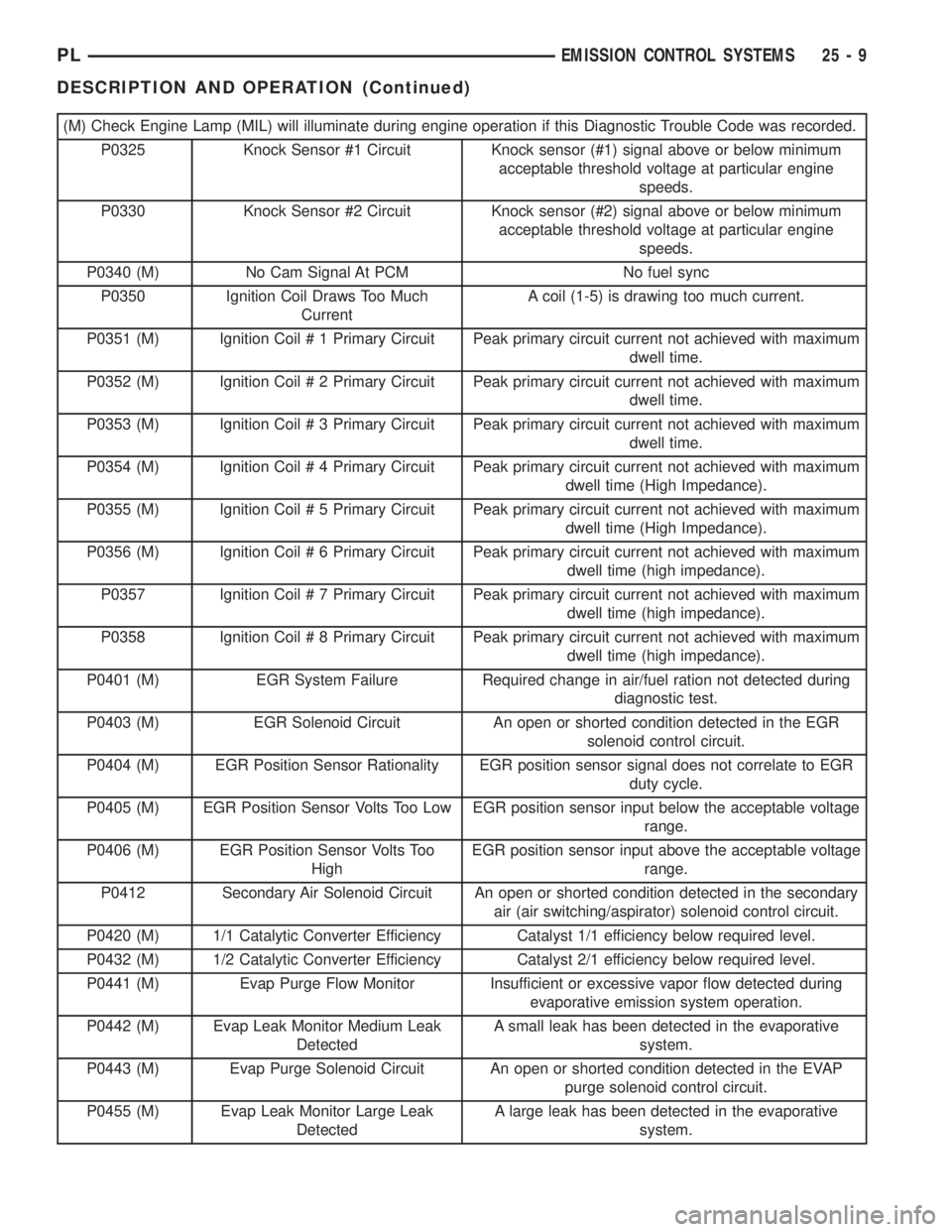

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0325 Knock Sensor #1 Circuit Knock sensor (#1) signal above or below minimum

acceptable threshold voltage at particular engine

speeds.

P0330 Knock Sensor #2 Circuit Knock sensor (#2) signal above or below minimum

acceptable threshold voltage at particular engine

speeds.

P0340 (M) No Cam Signal At PCM No fuel sync

P0350 Ignition Coil Draws Too Much

CurrentA coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil # 1 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil # 2 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil # 3 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil # 4 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil # 5 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil # 6 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 Ignition Coil # 7 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 Ignition Coil # 8 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0401 (M) EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 (M) EGR Solenoid Circuit An open or shorted condition detected in the EGR

solenoid control circuit.

P0404 (M) EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR

duty cycle.

P0405 (M) EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

P0406 (M) EGR Position Sensor Volts Too

HighEGR position sensor input above the acceptable voltage

range.

P0412 Secondary Air Solenoid Circuit An open or shorted condition detected in the secondary

air (air switching/aspirator) solenoid control circuit.

P0420 (M) 1/1 Catalytic Converter Efficiency Catalyst 1/1 efficiency below required level.

P0432 (M) 1/2 Catalytic Converter Efficiency Catalyst 2/1 efficiency below required level.

P0441 (M) Evap Purge Flow Monitor Insufficient or excessive vapor flow detected during

evaporative emission system operation.

P0442 (M) Evap Leak Monitor Medium Leak

DetectedA small leak has been detected in the evaporative

system.

P0443 (M) Evap Purge Solenoid Circuit An open or shorted condition detected in the EVAP

purge solenoid control circuit.

P0455 (M) Evap Leak Monitor Large Leak

DetectedA large leak has been detected in the evaporative

system.

PLEMISSION CONTROL SYSTEMS 25 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1102 of 1285

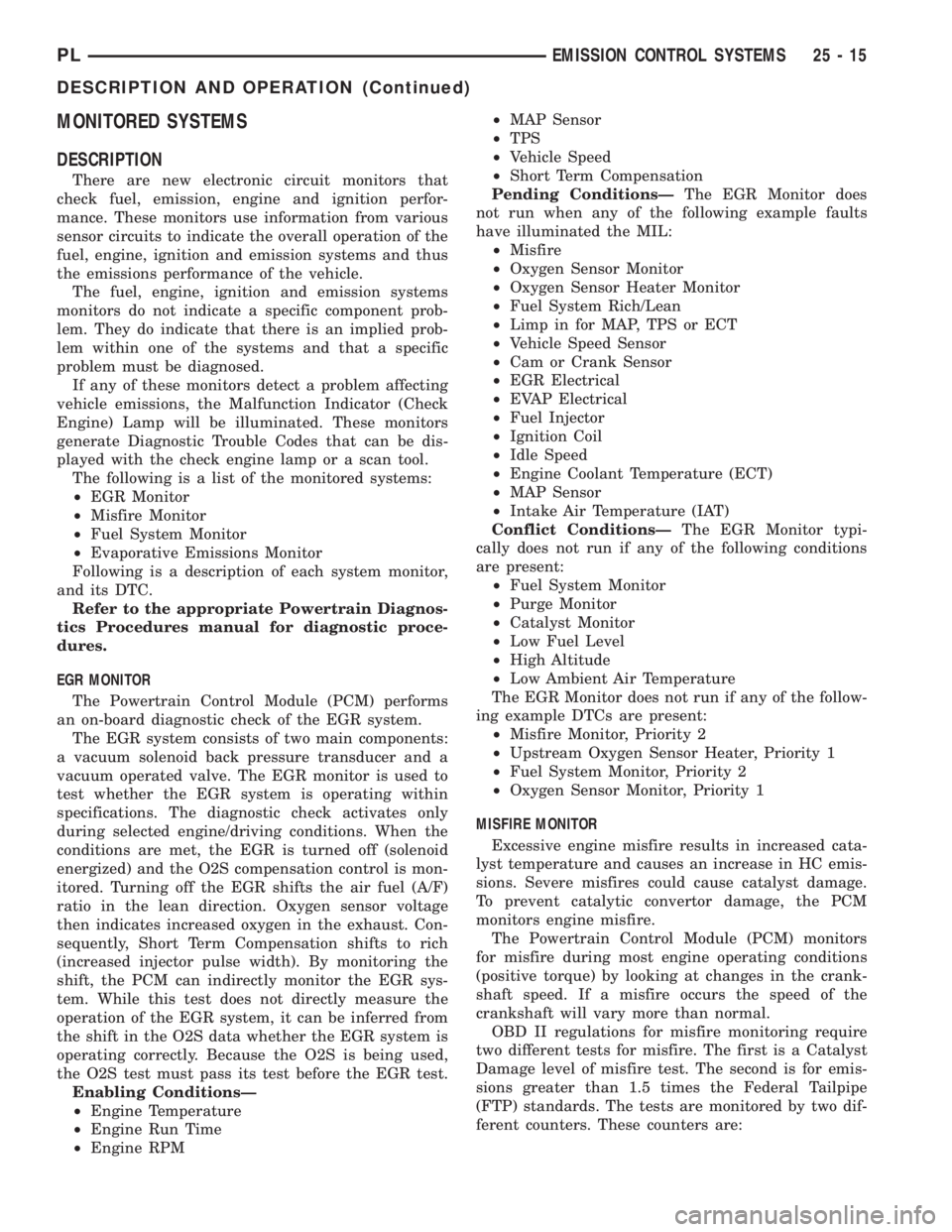

MONITORED SYSTEMS

DESCRIPTION

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the monitored systems:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Evaporative Emissions Monitor

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

EGR MONITOR

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR system consists of two main components:

a vacuum solenoid back pressure transducer and a

vacuum operated valve. The EGR monitor is used to

test whether the EGR system is operating within

specifications. The diagnostic check activates only

during selected engine/driving conditions. When the

conditions are met, the EGR is turned off (solenoid

energized) and the O2S compensation control is mon-

itored. Turning off the EGR shifts the air fuel (A/F)

ratio in the lean direction. Oxygen sensor voltage

then indicates increased oxygen in the exhaust. Con-

sequently, Short Term Compensation shifts to rich

(increased injector pulse width). By monitoring the

shift, the PCM can indirectly monitor the EGR sys-

tem. While this test does not directly measure the

operation of the EGR system, it can be inferred from

the shift in the O2S data whether the EGR system is

operating correctly. Because the O2S is being used,

the O2S test must pass its test before the EGR test.

Enabling ConditionsÐ

²Engine Temperature

²Engine Run Time

²Engine RPM²MAP Sensor

²TPS

²Vehicle Speed

²Short Term Compensation

Pending ConditionsÐThe EGR Monitor does

not run when any of the following example faults

have illuminated the MIL:

²Misfire

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Fuel System Rich/Lean

²Limp in for MAP, TPS or ECT

²Vehicle Speed Sensor

²Cam or Crank Sensor

²EGR Electrical

²EVAP Electrical

²Fuel Injector

²Ignition Coil

²Idle Speed

²Engine Coolant Temperature (ECT)

²MAP Sensor

²Intake Air Temperature (IAT)

Conflict ConditionsÐThe EGR Monitor typi-

cally does not run if any of the following conditions

are present:

²Fuel System Monitor

²Purge Monitor

²Catalyst Monitor

²Low Fuel Level

²High Altitude

²Low Ambient Air Temperature

The EGR Monitor does not run if any of the follow-

ing example DTCs are present:

²Misfire Monitor, Priority 2

²Upstream Oxygen Sensor Heater, Priority 1

²Fuel System Monitor, Priority 2

²Oxygen Sensor Monitor, Priority 1

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

OBD II regulations for misfire monitoring require

two different tests for misfire. The first is a Catalyst

Damage level of misfire test. The second is for emis-

sions greater than 1.5 times the Federal Tailpipe

(FTP) standards. The tests are monitored by two dif-

ferent counters. These counters are:

PLEMISSION CONTROL SYSTEMS 25 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1104 of 1285

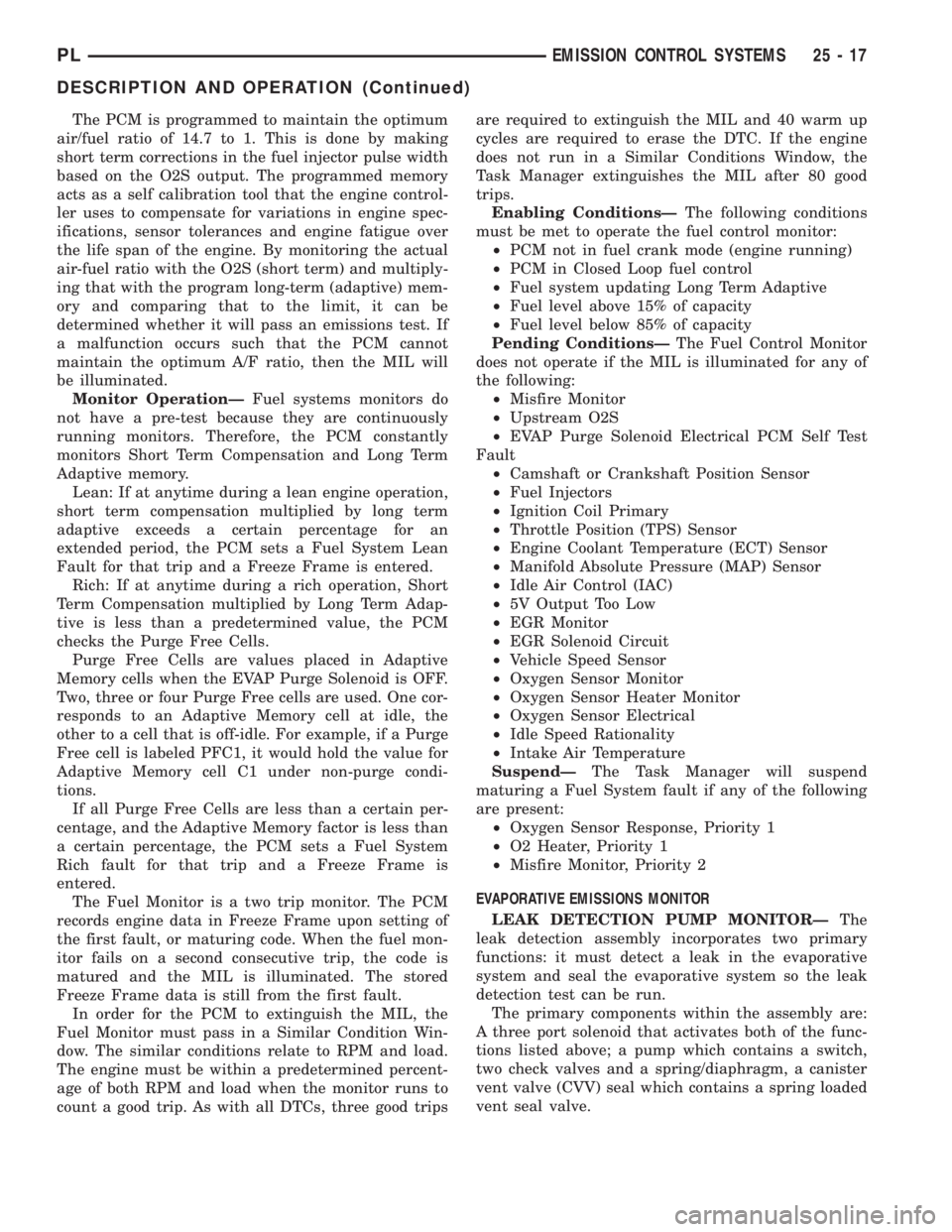

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S output. The programmed memory

acts as a self calibration tool that the engine control-

ler uses to compensate for variations in engine spec-

ifications, sensor tolerances and engine fatigue over

the life span of the engine. By monitoring the actual

air-fuel ratio with the O2S (short term) and multiply-

ing that with the program long-term (adaptive) mem-

ory and comparing that to the limit, it can be

determined whether it will pass an emissions test. If

a malfunction occurs such that the PCM cannot

maintain the optimum A/F ratio, then the MIL will

be illuminated.

Monitor OperationÐFuel systems monitors do

not have a pre-test because they are continuously

running monitors. Therefore, the PCM constantly

monitors Short Term Compensation and Long Term

Adaptive memory.

Lean: If at anytime during a lean engine operation,

short term compensation multiplied by long term

adaptive exceeds a certain percentage for an

extended period, the PCM sets a Fuel System Lean

Fault for that trip and a Freeze Frame is entered.

Rich: If at anytime during a rich operation, Short

Term Compensation multiplied by Long Term Adap-

tive is less than a predetermined value, the PCM

checks the Purge Free Cells.

Purge Free Cells are values placed in Adaptive

Memory cells when the EVAP Purge Solenoid is OFF.

Two, three or four Purge Free cells are used. One cor-

responds to an Adaptive Memory cell at idle, the

other to a cell that is off-idle. For example, if a Purge

Free cell is labeled PFC1, it would hold the value for

Adaptive Memory cell C1 under non-purge condi-

tions.

If all Purge Free Cells are less than a certain per-

centage, and the Adaptive Memory factor is less than

a certain percentage, the PCM sets a Fuel System

Rich fault for that trip and a Freeze Frame is

entered.

The Fuel Monitor is a two trip monitor. The PCM

records engine data in Freeze Frame upon setting of

the first fault, or maturing code. When the fuel mon-

itor fails on a second consecutive trip, the code is

matured and the MIL is illuminated. The stored

Freeze Frame data is still from the first fault.

In order for the PCM to extinguish the MIL, the

Fuel Monitor must pass in a Similar Condition Win-

dow. The similar conditions relate to RPM and load.

The engine must be within a predetermined percent-

age of both RPM and load when the monitor runs to

count a good trip. As with all DTCs, three good tripsare required to extinguish the MIL and 40 warm up

cycles are required to erase the DTC. If the engine

does not run in a Similar Conditions Window, the

Task Manager extinguishes the MIL after 80 good

trips.

Enabling ConditionsÐThe following conditions

must be met to operate the fuel control monitor:

²PCM not in fuel crank mode (engine running)

²PCM in Closed Loop fuel control

²Fuel system updating Long Term Adaptive

²Fuel level above 15% of capacity

²Fuel level below 85% of capacity

Pending ConditionsÐThe Fuel Control Monitor

does not operate if the MIL is illuminated for any of

the following:

²Misfire Monitor

²Upstream O2S

²EVAP Purge Solenoid Electrical PCM Self Test

Fault

²Camshaft or Crankshaft Position Sensor

²Fuel Injectors

²Ignition Coil Primary

²Throttle Position (TPS) Sensor

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Idle Air Control (IAC)

²5V Output Too Low

²EGR Monitor

²EGR Solenoid Circuit

²Vehicle Speed Sensor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Oxygen Sensor Electrical

²Idle Speed Rationality

²Intake Air Temperature

SuspendÐThe Task Manager will suspend

maturing a Fuel System fault if any of the following

are present:

²Oxygen Sensor Response, Priority 1

²O2 Heater, Priority 1

²Misfire Monitor, Priority 2

EVAPORATIVE EMISSIONS MONITOR

LEAK DETECTION PUMP MONITORÐThe

leak detection assembly incorporates two primary

functions: it must detect a leak in the evaporative

system and seal the evaporative system so the leak

detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

PLEMISSION CONTROL SYSTEMS 25 - 17

DESCRIPTION AND OPERATION (Continued)

Page 1107 of 1285

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1108 of 1285

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure

²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Monitor if over-

lapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault isrepaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

an The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

PLEMISSION CONTROL SYSTEMS 25 - 21

DESCRIPTION AND OPERATION (Continued)