ignition DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 757 of 1285

INSPECT CYLINDER HEAD FOR THE FOLLOWING:

NOTE:

²Check oil feed holes for blockage.

²Inspect cylinder head camshaft bearings for

wear, Refer to Cylinder Head, Inspection and Clean-

ing.

²Check camshaft bearing journals for scratches

and worn areas. If light scratches are present, they

may be removed with 400 grit sand paper. If deep

scratches are present, replace the camshaft and

check the cylinder head for damage. Replace the

cylinder head if worn or damaged. Check the lobes

for pitting and wear. If the lobes show signs of

wear, check the corresponding rocker arm roller for

wear or damage. Replace rocker arm/hydraulic lash

adjuster if worn or damaged. If lobes show signs of

pitting on the nose, flank or base circle; replace the

camshaft.

INSTALLATION

(1) Lubricate the camshaft journals with oil and

install camshaftwithoutrocker arm assemblies

installed.

(2) Install camshaft target magnet into the end of

the camshaft. Tighten mounting screw to 3.4 N´m (30

in. lbs.).

(3) Install camshaft position sensor and tighten

mounting screws to 9 N´m (80 in. lbs.).

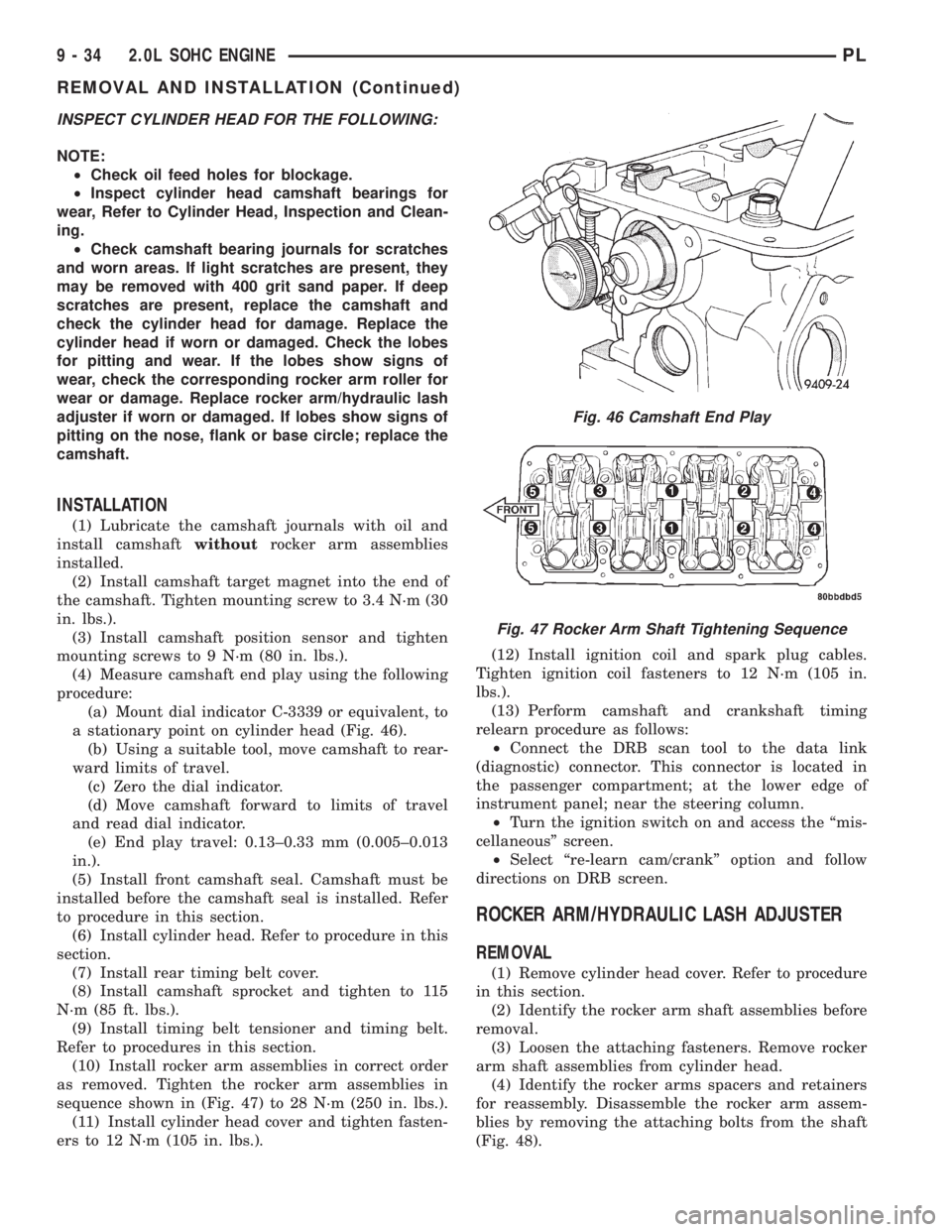

(4) Measure camshaft end play using the following

procedure:

(a) Mount dial indicator C-3339 or equivalent, to

a stationary point on cylinder head (Fig. 46).

(b) Using a suitable tool, move camshaft to rear-

ward limits of travel.

(c) Zero the dial indicator.

(d) Move camshaft forward to limits of travel

and read dial indicator.

(e) End play travel: 0.13±0.33 mm (0.005±0.013

in.).

(5) Install front camshaft seal. Camshaft must be

installed before the camshaft seal is installed. Refer

to procedure in this section.

(6) Install cylinder head. Refer to procedure in this

section.

(7) Install rear timing belt cover.

(8) Install camshaft sprocket and tighten to 115

N´m (85 ft. lbs.).

(9) Install timing belt tensioner and timing belt.

Refer to procedures in this section.

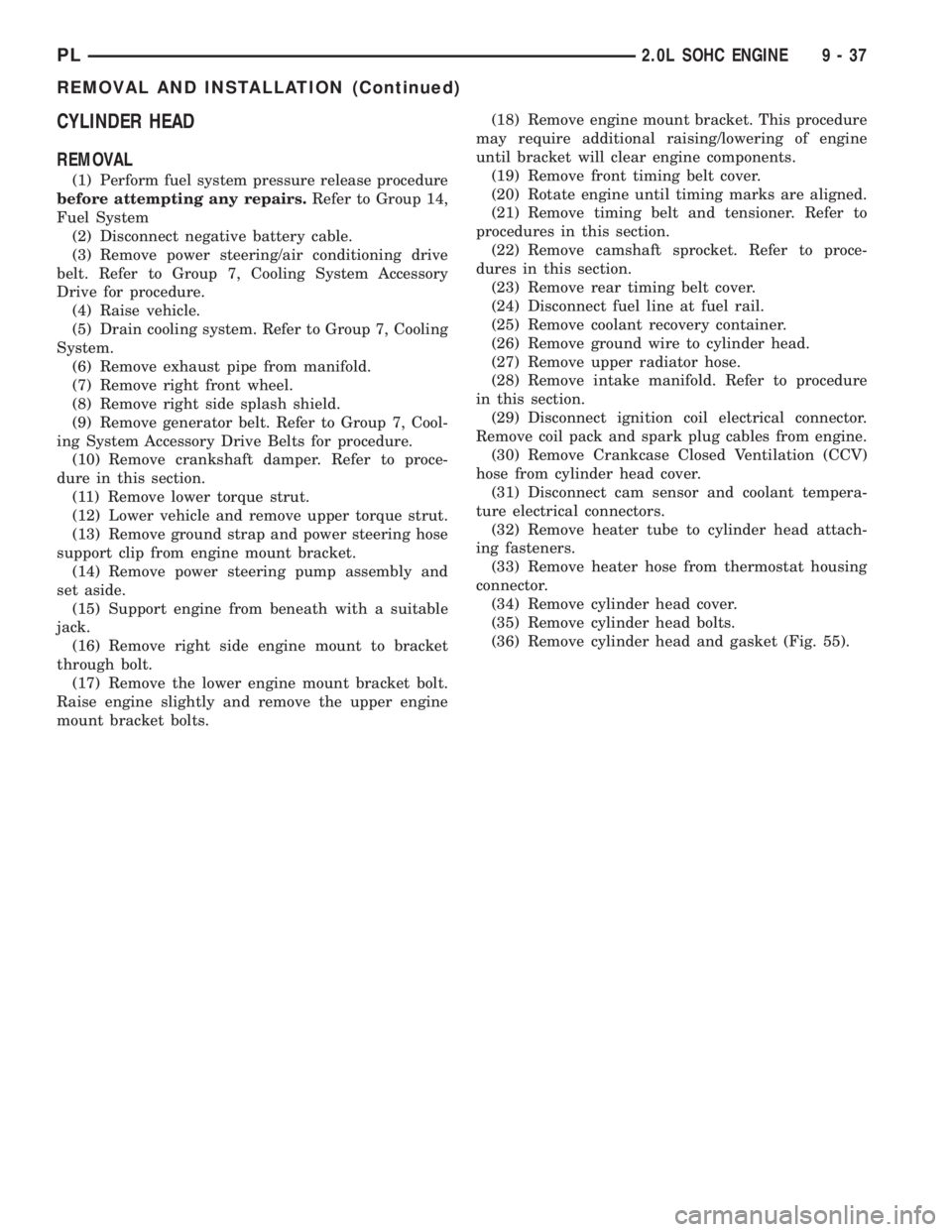

(10) Install rocker arm assemblies in correct order

as removed. Tighten the rocker arm assemblies in

sequence shown in (Fig. 47) to 28 N´m (250 in. lbs.).

(11) Install cylinder head cover and tighten fasten-

ers to 12 N´m (105 in. lbs.).(12) Install ignition coil and spark plug cables.

Tighten ignition coil fasteners to 12 N´m (105 in.

lbs.).

(13) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

ROCKER ARM/HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove cylinder head cover. Refer to procedure

in this section.

(2) Identify the rocker arm shaft assemblies before

removal.

(3) Loosen the attaching fasteners. Remove rocker

arm shaft assemblies from cylinder head.

(4) Identify the rocker arms spacers and retainers

for reassembly. Disassemble the rocker arm assem-

blies by removing the attaching bolts from the shaft

(Fig. 48).

Fig. 46 Camshaft End Play

Fig. 47 Rocker Arm Shaft Tightening Sequence

9 - 34 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 760 of 1285

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Disconnect negative battery cable.

(3) Remove power steering/air conditioning drive

belt. Refer to Group 7, Cooling System Accessory

Drive for procedure.

(4) Raise vehicle.

(5) Drain cooling system. Refer to Group 7, Cooling

System.

(6) Remove exhaust pipe from manifold.

(7) Remove right front wheel.

(8) Remove right side splash shield.

(9) Remove generator belt. Refer to Group 7, Cool-

ing System Accessory Drive Belts for procedure.

(10) Remove crankshaft damper. Refer to proce-

dure in this section.

(11) Remove lower torque strut.

(12) Lower vehicle and remove upper torque strut.

(13) Remove ground strap and power steering hose

support clip from engine mount bracket.

(14) Remove power steering pump assembly and

set aside.

(15) Support engine from beneath with a suitable

jack.

(16) Remove right side engine mount to bracket

through bolt.

(17) Remove the lower engine mount bracket bolt.

Raise engine slightly and remove the upper engine

mount bracket bolts.(18) Remove engine mount bracket. This procedure

may require additional raising/lowering of engine

until bracket will clear engine components.

(19) Remove front timing belt cover.

(20) Rotate engine until timing marks are aligned.

(21) Remove timing belt and tensioner. Refer to

procedures in this section.

(22) Remove camshaft sprocket. Refer to proce-

dures in this section.

(23) Remove rear timing belt cover.

(24) Disconnect fuel line at fuel rail.

(25) Remove coolant recovery container.

(26) Remove ground wire to cylinder head.

(27) Remove upper radiator hose.

(28) Remove intake manifold. Refer to procedure

in this section.

(29) Disconnect ignition coil electrical connector.

Remove coil pack and spark plug cables from engine.

(30) Remove Crankcase Closed Ventilation (CCV)

hose from cylinder head cover.

(31) Disconnect cam sensor and coolant tempera-

ture electrical connectors.

(32) Remove heater tube to cylinder head attach-

ing fasteners.

(33) Remove heater hose from thermostat housing

connector.

(34) Remove cylinder head cover.

(35) Remove cylinder head bolts.

(36) Remove cylinder head and gasket (Fig. 55).

PL2.0L SOHC ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 763 of 1285

(13) Install ignition coil and spark plug cables.

Connect coil electrical connector.

(14) Install intake manifold. Refer to procedure in

this section.

(15) Install upper radiator hose.

(16) Install ground wire to cylinder head.

(17) Install coolant recovery container.

(18) Connect fuel line to fuel rail.

(19) Install rear timing belt cover, camshaft

sprocket, and timing belt tensioner and timing belt.

Refer to procedures in this section.

(20) Install front timing belt cover.

(21) Install engine mount bracket.

(22) Position engine and install right side engine

mount to engine mount bracket bolt. Tighten bolt to

118 N´m (87 ft. lbs.). Remove jack from beneath

engine.

(23) Install power steering pump assembly.

(24) Install power steering hose support clip and

ground strap to engine mount bracket.

(25) Install upper torque strut.

(26) Raise vehicle.

(27) Install lower torque strut.

(28) Install crankshaft damper.

(29) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Belt for procedure.

(30) Install right side splash shield and front

wheel.

(31) Install exhaust pipe to exhaust manifold

flange.

(32) Lower vehicle and fill cooling system. Refer to

Group 7, Cooling System for procedure.

(33) Connect negative cable to battery.

(34) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

CRANKSHAFT DAMPER

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(2) Raise vehicle on a hoist and remove right inner

splash shield.

(3) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827-A (Fig. 61).

INSTALLATION

(1) Install crankshaft damper using M12±1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792 (Fig. 62).

Fig. 62 Crankshaft DamperÐInstallation

1 ± M12 Ð 1.753150 MM BOLT, WASHER AND THRUST

BEARING FROM SPECIAL TOOL 6792

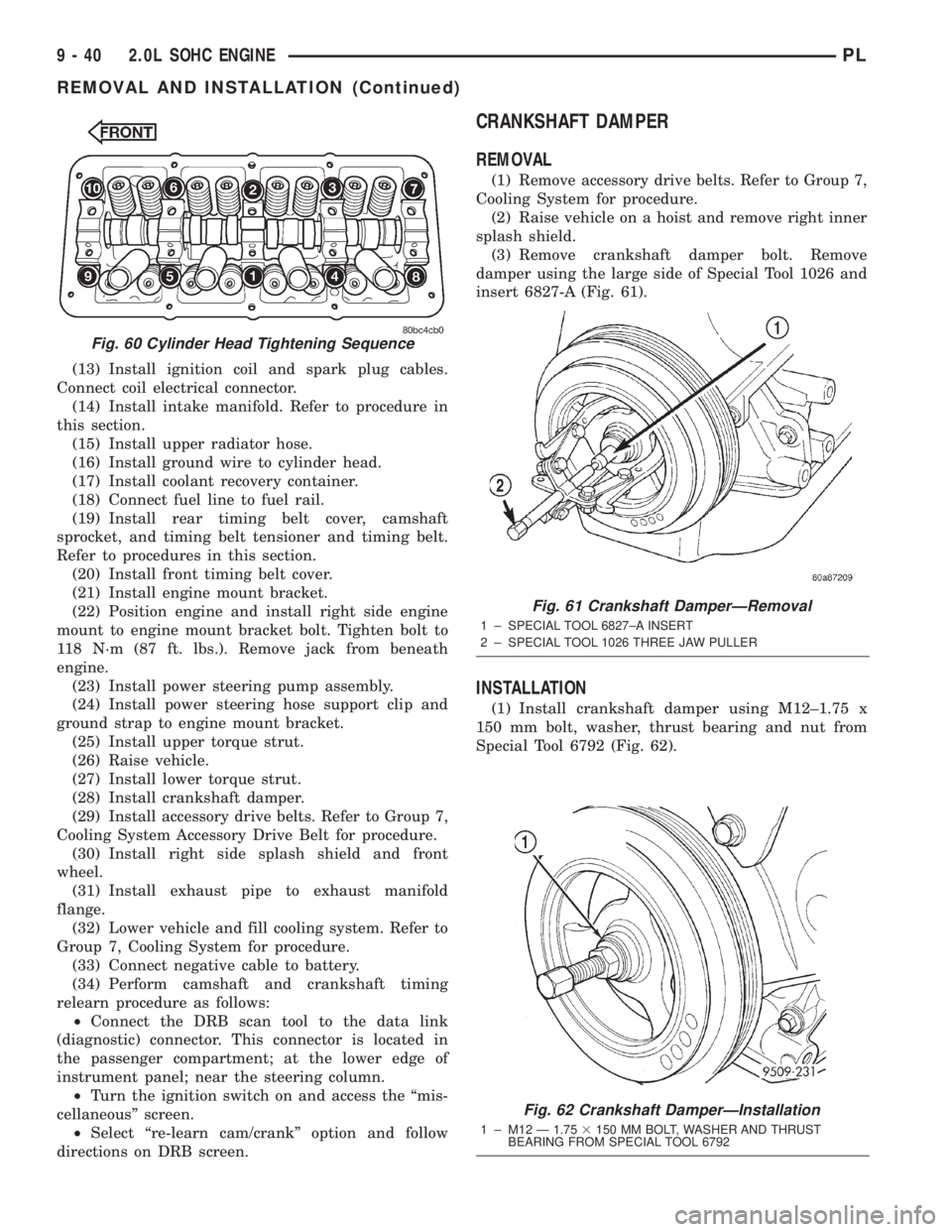

Fig. 60 Cylinder Head Tightening Sequence

Fig. 61 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 6827±A INSERT

2 ± SPECIAL TOOL 1026 THREE JAW PULLER

9 - 40 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 769 of 1285

(10) Install right engine mount to engine mount

bracket through bolt.

(11) Remove jack from under engine.

(12) Install upper torque strut.

(13) Install power steering pump assembly.

(14) Raise vehicle and install lower torque strut.

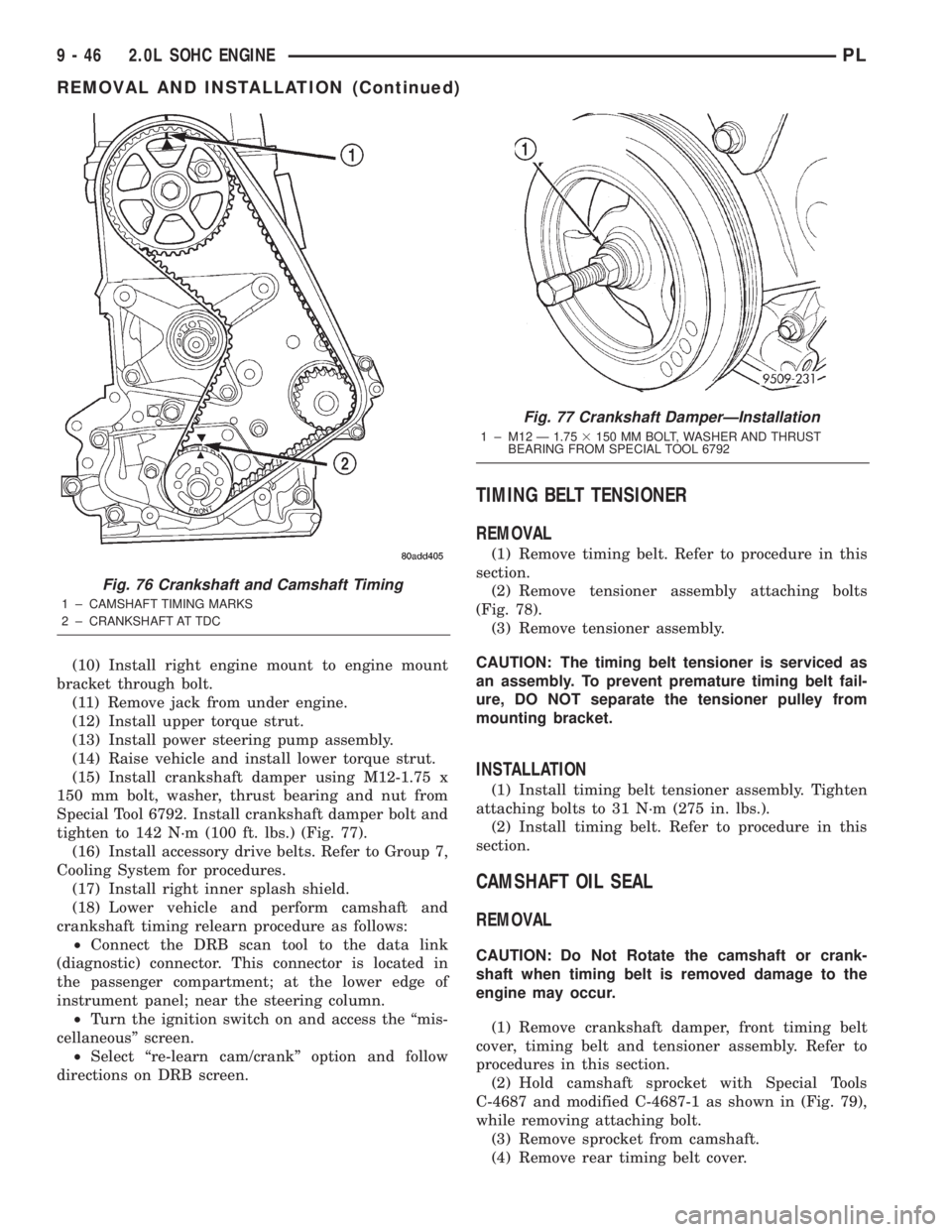

(15) Install crankshaft damper using M12-1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (100 ft. lbs.) (Fig. 77).

(16) Install accessory drive belts. Refer to Group 7,

Cooling System for procedures.

(17) Install right inner splash shield.

(18) Lower vehicle and perform camshaft and

crankshaft timing relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

TIMING BELT TENSIONER

REMOVAL

(1) Remove timing belt. Refer to procedure in this

section.

(2) Remove tensioner assembly attaching bolts

(Fig. 78).

(3) Remove tensioner assembly.

CAUTION: The timing belt tensioner is serviced as

an assembly. To prevent premature timing belt fail-

ure, DO NOT separate the tensioner pulley from

mounting bracket.

INSTALLATION

(1) Install timing belt tensioner assembly. Tighten

attaching bolts to 31 N´m (275 in. lbs.).

(2) Install timing belt. Refer to procedure in this

section.

CAMSHAFT OIL SEAL

REMOVAL

CAUTION: Do Not Rotate the camshaft or crank-

shaft when timing belt is removed damage to the

engine may occur.

(1) Remove crankshaft damper, front timing belt

cover, timing belt and tensioner assembly. Refer to

procedures in this section.

(2) Hold camshaft sprocket with Special Tools

C-4687 and modified C-4687-1 as shown in (Fig. 79),

while removing attaching bolt.

(3) Remove sprocket from camshaft.

(4) Remove rear timing belt cover.

Fig. 76 Crankshaft and Camshaft Timing

1 ± CAMSHAFT TIMING MARKS

2 ± CRANKSHAFT AT TDC

Fig. 77 Crankshaft DamperÐInstallation

1 ± M12 Ð 1.753150 MM BOLT, WASHER AND THRUST

BEARING FROM SPECIAL TOOL 6792

9 - 46 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 778 of 1285

(17) Install rear timing belt cover and camshaft

sprocket.

(18) Install crankshaft sprocket, timing belt ten-

sioner, timing belt, and cover.

(19) Install front engine mount bracket.

(20) Remove engine from repair stand and position

on Special Tools 6135 and 6710 Engine Dolly and

Cradle. Install safety straps around the engine to

cradle and tighten and lock them into position.

(21) Install crankshaft rear oil seal. Refer to proce-

dure in this section.

(22) Install drive plate/flywheel. Apply Mopart

Lock & Seal Adhesive to bolt threads and tighten to

95 N´m (70 ft. lbs.).

(23) Install transaxle to engine.

(24) Install structural collar. Refer to procedure in

this section.

(25) Install engine assembly. Refer to procedure in

this section.

(26) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

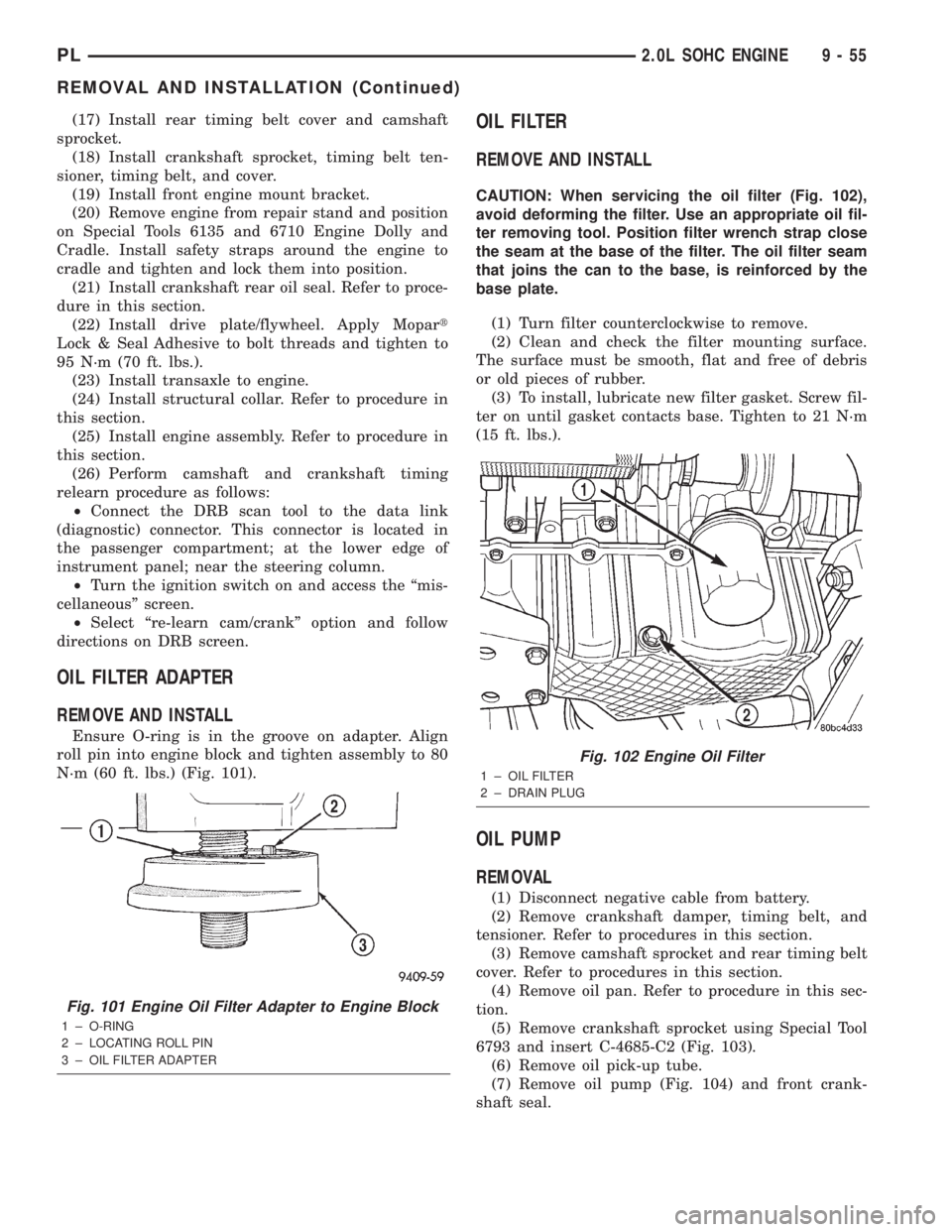

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 101).

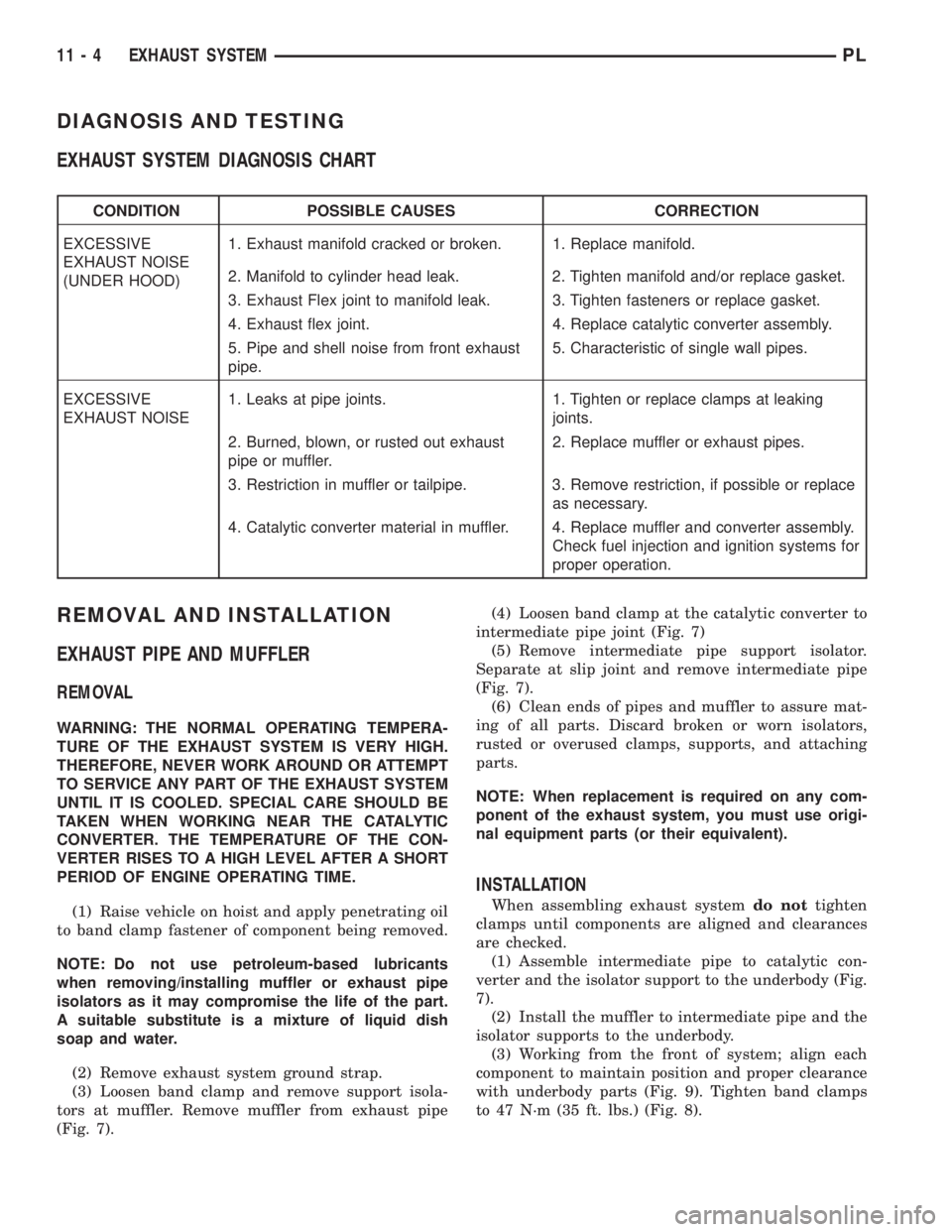

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 102),

avoid deforming the filter. Use an appropriate oil fil-

ter removing tool. Position filter wrench strap close

the seam at the base of the filter. The oil filter seam

that joins the can to the base, is reinforced by the

base plate.

(1) Turn filter counterclockwise to remove.

(2) Clean and check the filter mounting surface.

The surface must be smooth, flat and free of debris

or old pieces of rubber.

(3) To install, lubricate new filter gasket. Screw fil-

ter on until gasket contacts base. Tighten to 21 N´m

(15 ft. lbs.).

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove crankshaft damper, timing belt, and

tensioner. Refer to procedures in this section.

(3) Remove camshaft sprocket and rear timing belt

cover. Refer to procedures in this section.

(4) Remove oil pan. Refer to procedure in this sec-

tion.

(5) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 103).

(6) Remove oil pick-up tube.

(7) Remove oil pump (Fig. 104) and front crank-

shaft seal.

Fig. 101 Engine Oil Filter Adapter to Engine Block

1 ± O-RING

2 ± LOCATING ROLL PIN

3 ± OIL FILTER ADAPTER

Fig. 102 Engine Oil Filter

1 ± OIL FILTER

2 ± DRAIN PLUG

PL2.0L SOHC ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 801 of 1285

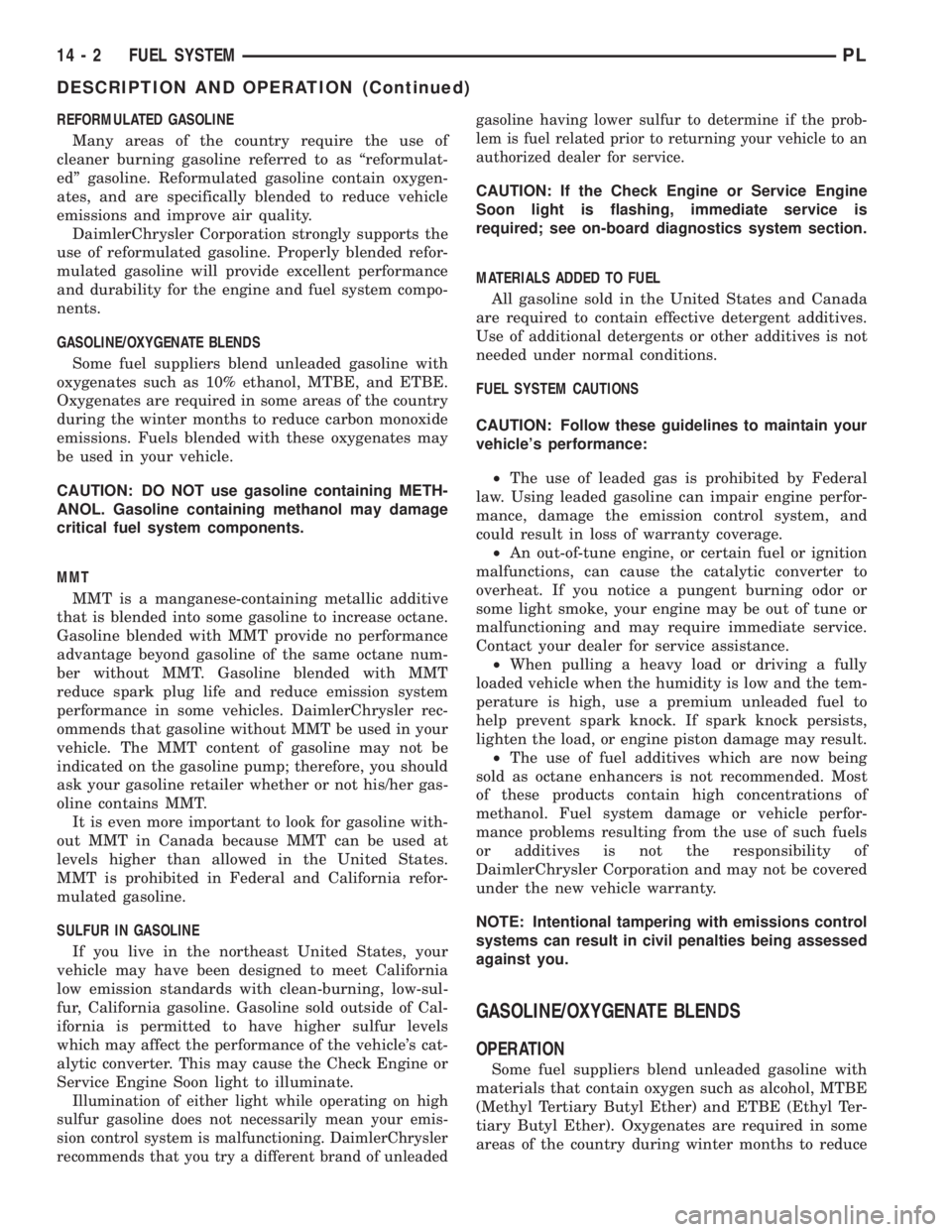

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE

EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. Exhaust Flex joint to manifold leak. 3. Tighten fasteners or replace gasket.

4. Exhaust flex joint. 4. Replace catalytic converter assembly.

5. Pipe and shell noise from front exhaust

pipe.5. Characteristic of single wall pipes.

EXCESSIVE

EXHAUST NOISE1. Leaks at pipe joints. 1. Tighten or replace clamps at leaking

joints.

2. Burned, blown, or rusted out exhaust

pipe or muffler.2. Replace muffler or exhaust pipes.

3. Restriction in muffler or tailpipe. 3. Remove restriction, if possible or replace

as necessary.

4. Catalytic converter material in muffler. 4. Replace muffler and converter assembly.

Check fuel injection and ignition systems for

proper operation.

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATING TIME.

(1) Raise vehicle on hoist and apply penetrating oil

to band clamp fastener of component being removed.

NOTE: Do not use petroleum-based lubricants

when removing/installing muffler or exhaust pipe

isolators as it may compromise the life of the part.

A suitable substitute is a mixture of liquid dish

soap and water.

(2) Remove exhaust system ground strap.

(3) Loosen band clamp and remove support isola-

tors at muffler. Remove muffler from exhaust pipe

(Fig. 7).(4) Loosen band clamp at the catalytic converter to

intermediate pipe joint (Fig. 7)

(5) Remove intermediate pipe support isolator.

Separate at slip joint and remove intermediate pipe

(Fig. 7).

(6) Clean ends of pipes and muffler to assure mat-

ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble intermediate pipe to catalytic con-

verter and the isolator support to the underbody (Fig.

7).

(2) Install the muffler to intermediate pipe and the

isolator supports to the underbody.

(3) Working from the front of system; align each

component to maintain position and proper clearance

with underbody parts (Fig. 9). Tighten band clamps

to 47 N´m (35 ft. lbs.) (Fig. 8).

11 - 4 EXHAUST SYSTEMPL

Page 823 of 1285

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

DaimlerChrysler Corporation strongly supports the

use of reformulated gasoline. Properly blended refor-

mulated gasoline will provide excellent performance

and durability for the engine and fuel system compo-

nents.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane num-

ber without MMT. Gasoline blended with MMT

reduce spark plug life and reduce emission system

performance in some vehicles. DaimlerChrysler rec-

ommends that gasoline without MMT be used in your

vehicle. The MMT content of gasoline may not be

indicated on the gasoline pump; therefore, you should

ask your gasoline retailer whether or not his/her gas-

oline contains MMT.

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used at

levels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with clean-burning, low-sul-

fur, California gasoline. Gasoline sold outside of Cal-

ifornia is permitted to have higher sulfur levels

which may affect the performance of the vehicle's cat-

alytic converter. This may cause the Check Engine or

Service Engine Soon light to illuminate.

Illumination of either light while operating on high

sulfur gasoline does not necessarily mean your emis-

sion control system is malfunctioning. DaimlerChrysler

recommends that you try a different brand of unleadedgasoline having lower sulfur to determine if the prob-

lem is fuel related prior to returning your vehicle to an

authorized dealer for service.

CAUTION: If the Check Engine or Service Engine

Soon light is flashing, immediate service is

required; see on-board diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of

DaimlerChrysler Corporation and may not be covered

under the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

GASOLINE/OXYGENATE BLENDS

OPERATION

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

14 - 2 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 829 of 1285

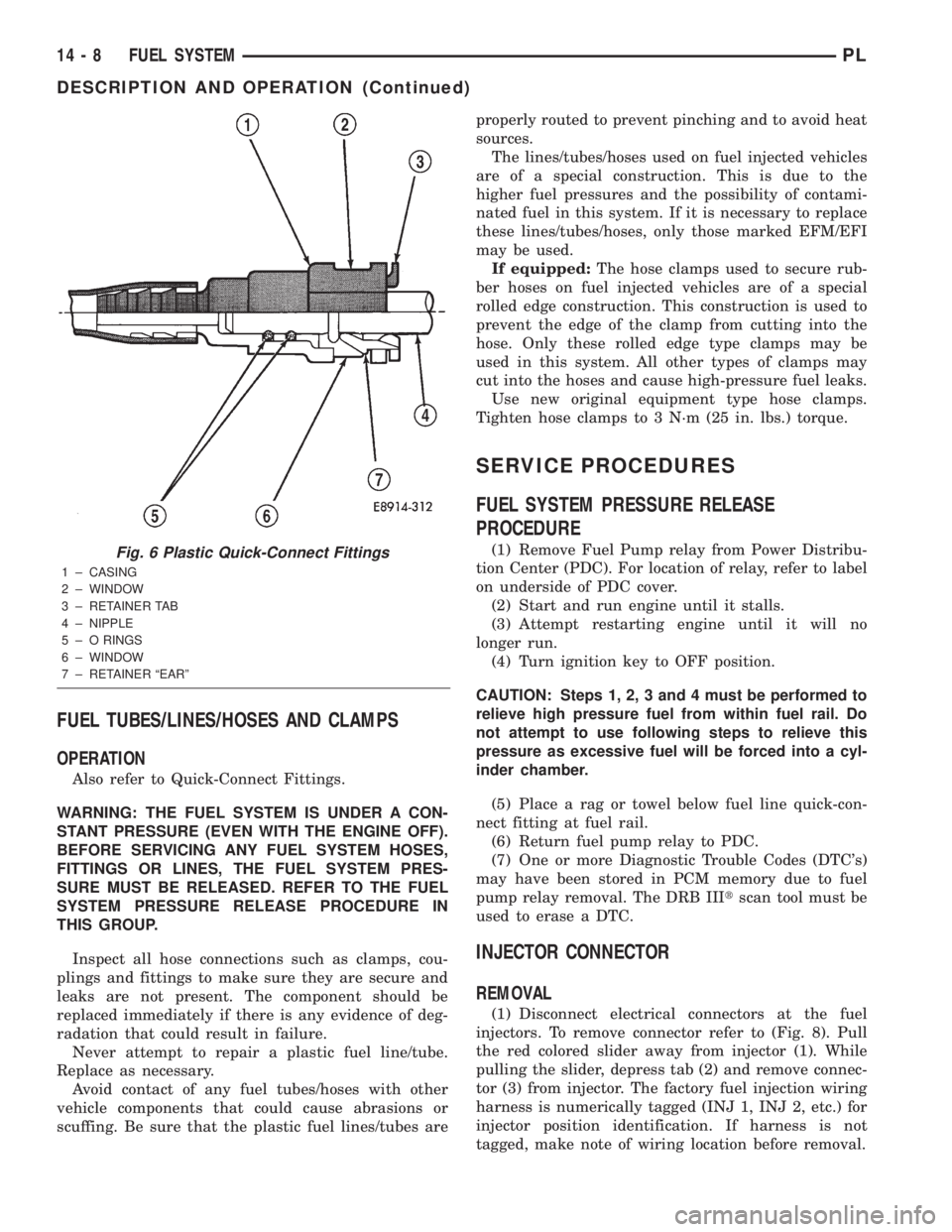

FUEL TUBES/LINES/HOSES AND CLAMPS

OPERATION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes areproperly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

Tighten hose clamps to 3 N´m (25 in. lbs.) torque.

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(5) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(6) Return fuel pump relay to PDC.

(7) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

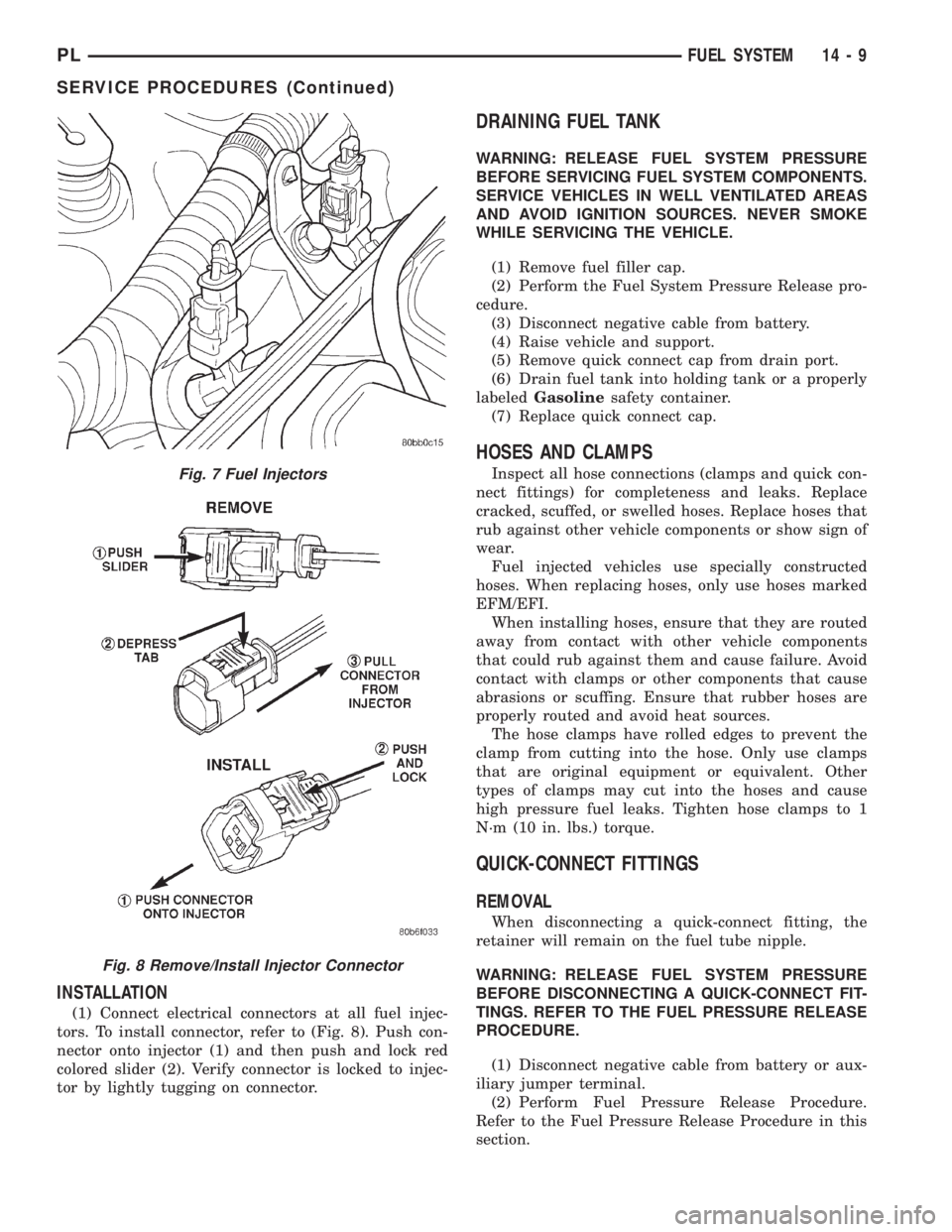

INJECTOR CONNECTOR

REMOVAL

(1) Disconnect electrical connectors at the fuel

injectors. To remove connector refer to (Fig. 8). Pull

the red colored slider away from injector (1). While

pulling the slider, depress tab (2) and remove connec-

tor (3) from injector. The factory fuel injection wiring

harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, make note of wiring location before removal.

Fig. 6 Plastic Quick-Connect Fittings

1 ± CASING

2 ± WINDOW

3 ± RETAINER TAB

4 ± NIPPLE

5 ± O RINGS

6 ± WINDOW

7 ± RETAINER ªEARº

14 - 8 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 830 of 1285

INSTALLATION

(1) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 8). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

DRAINING FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle and support.

(5) Remove quick connect cap from drain port.

(6) Drain fuel tank into holding tank or a properly

labeledGasolinesafety container.

(7) Replace quick connect cap.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

Fig. 7 Fuel Injectors

Fig. 8 Remove/Install Injector Connector

PLFUEL SYSTEM 14 - 9

SERVICE PROCEDURES (Continued)

Page 831 of 1285

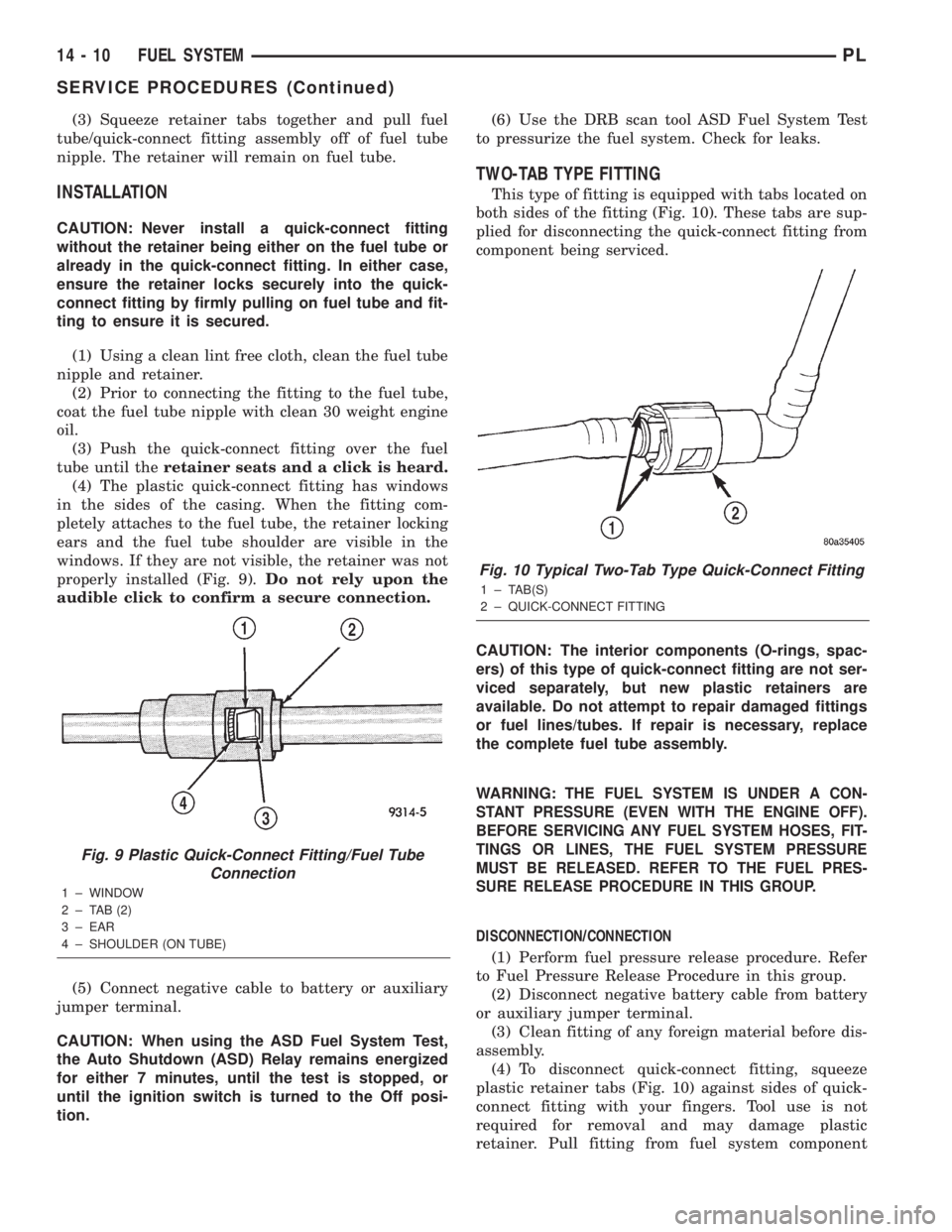

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 9).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 10). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

WARNING:

THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES, FIT-

TINGS OR LINES, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 10) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

Fig. 9 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 ± WINDOW

2 ± TAB (2)

3 ± EAR

4 ± SHOULDER (ON TUBE)

Fig. 10 Typical Two-Tab Type Quick-Connect Fitting

1 ± TAB(S)

2 ± QUICK-CONNECT FITTING

14 - 10 FUEL SYSTEMPL

SERVICE PROCEDURES (Continued)