center console DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 661 of 1285

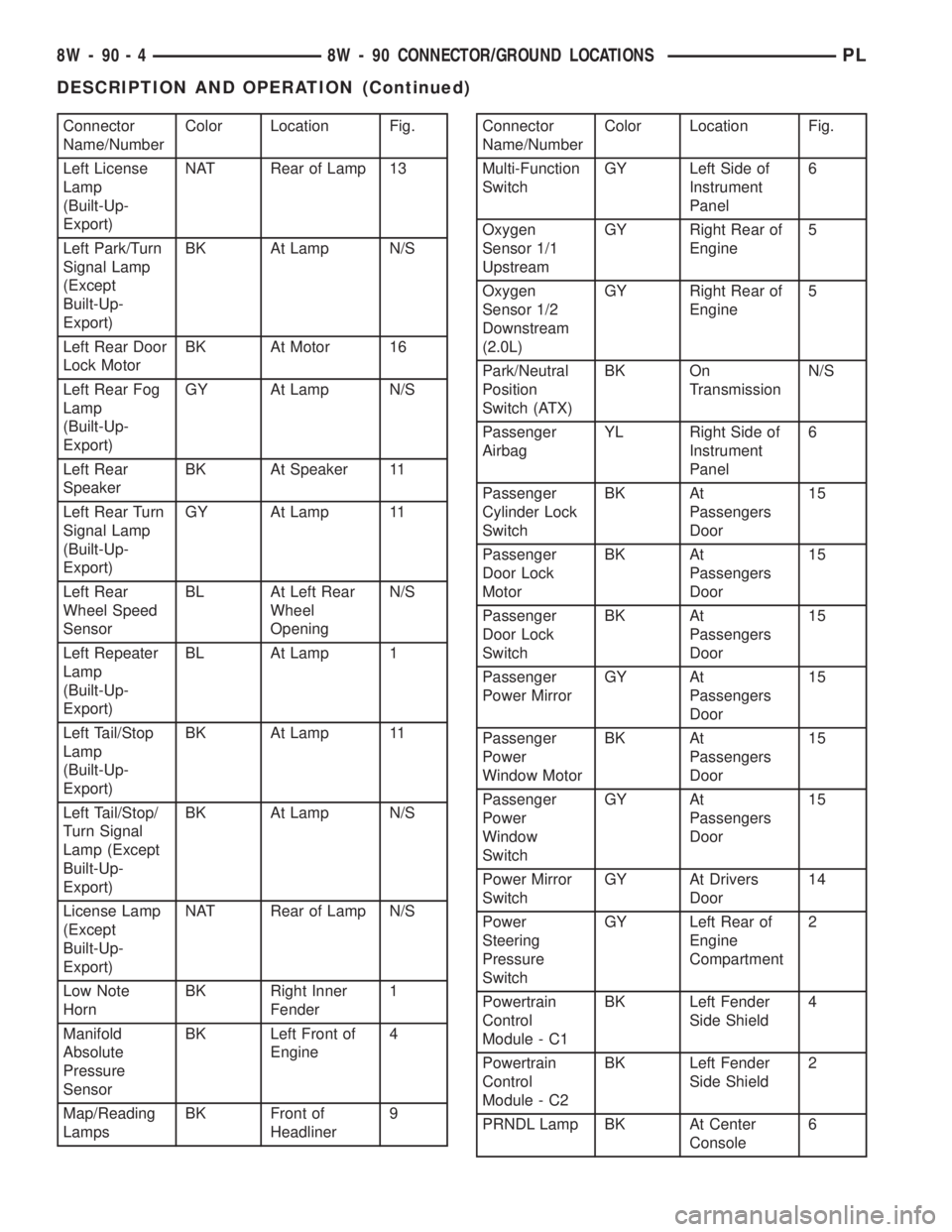

Connector

Name/NumberColor Location Fig.

Left License

Lamp

(Built-Up-

Export)NAT Rear of Lamp 13

Left Park/Turn

Signal Lamp

(Except

Built-Up-

Export)BK At Lamp N/S

Left Rear Door

Lock MotorBK At Motor 16

Left Rear Fog

Lamp

(Built-Up-

Export)GY At Lamp N/S

Left Rear

SpeakerBK At Speaker 11

Left Rear Turn

Signal Lamp

(Built-Up-

Export)GY At Lamp 11

Left Rear

Wheel Speed

SensorBL At Left Rear

Wheel

OpeningN/S

Left Repeater

Lamp

(Built-Up-

Export)BL At Lamp 1

Left Tail/Stop

Lamp

(Built-Up-

Export)BK At Lamp 11

Left Tail/Stop/

Turn Signal

Lamp (Except

Built-Up-

Export)BK At Lamp N/S

License Lamp

(Except

Built-Up-

Export)NAT Rear of Lamp N/S

Low Note

HornBK Right Inner

Fender1

Manifold

Absolute

Pressure

SensorBK Left Front of

Engine4

Map/Reading

LampsBK Front of

Headliner9Connector

Name/NumberColor Location Fig.

Multi-Function

SwitchGY Left Side of

Instrument

Panel6

Oxygen

Sensor 1/1

UpstreamGY Right Rear of

Engine5

Oxygen

Sensor 1/2

Downstream

(2.0L)GY Right Rear of

Engine5

Park/Neutral

Position

Switch (ATX)BK On

TransmissionN/S

Passenger

AirbagYL Right Side of

Instrument

Panel6

Passenger

Cylinder Lock

SwitchBK At

Passengers

Door15

Passenger

Door Lock

MotorBK At

Passengers

Door15

Passenger

Door Lock

SwitchBK At

Passengers

Door15

Passenger

Power MirrorGY At

Passengers

Door15

Passenger

Power

Window MotorBK At

Passengers

Door15

Passenger

Power

Window

SwitchGY At

Passengers

Door15

Power Mirror

SwitchGY At Drivers

Door14

Power

Steering

Pressure

SwitchGY Left Rear of

Engine

Compartment2

Powertrain

Control

Module - C1BK Left Fender

Side Shield4

Powertrain

Control

Module - C2BK Left Fender

Side Shield2

PRNDL Lamp BK At Center

Console6

8W - 90 - 4 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 681 of 1285

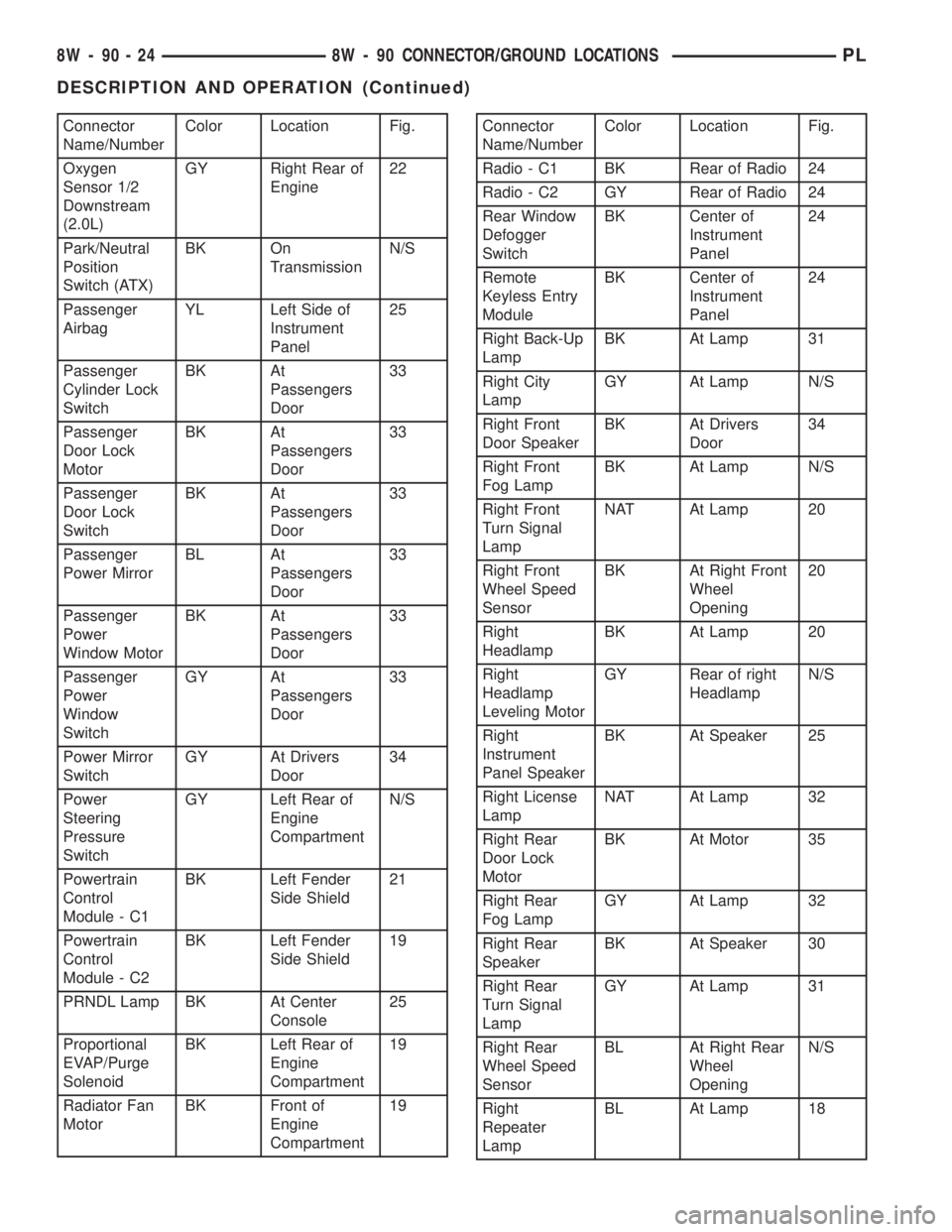

Connector

Name/NumberColor Location Fig.

Oxygen

Sensor 1/2

Downstream

(2.0L)GY Right Rear of

Engine22

Park/Neutral

Position

Switch (ATX)BK On

TransmissionN/S

Passenger

AirbagYL Left Side of

Instrument

Panel25

Passenger

Cylinder Lock

SwitchBK At

Passengers

Door33

Passenger

Door Lock

MotorBK At

Passengers

Door33

Passenger

Door Lock

SwitchBK At

Passengers

Door33

Passenger

Power MirrorBL At

Passengers

Door33

Passenger

Power

Window MotorBK At

Passengers

Door33

Passenger

Power

Window

SwitchGY At

Passengers

Door33

Power Mirror

SwitchGY At Drivers

Door34

Power

Steering

Pressure

SwitchGY Left Rear of

Engine

CompartmentN/S

Powertrain

Control

Module - C1BK Left Fender

Side Shield21

Powertrain

Control

Module - C2BK Left Fender

Side Shield19

PRNDL Lamp BK At Center

Console25

Proportional

EVAP/Purge

SolenoidBK Left Rear of

Engine

Compartment19

Radiator Fan

MotorBK Front of

Engine

Compartment19Connector

Name/NumberColor Location Fig.

Radio - C1 BK Rear of Radio 24

Radio - C2 GY Rear of Radio 24

Rear Window

Defogger

SwitchBK Center of

Instrument

Panel24

Remote

Keyless Entry

ModuleBK Center of

Instrument

Panel24

Right Back-Up

LampBK At Lamp 31

Right City

LampGY At Lamp N/S

Right Front

Door SpeakerBK At Drivers

Door34

Right Front

Fog LampBK At Lamp N/S

Right Front

Turn Signal

LampNAT At Lamp 20

Right Front

Wheel Speed

SensorBK At Right Front

Wheel

Opening20

Right

HeadlampBK At Lamp 20

Right

Headlamp

Leveling MotorGY Rear of right

HeadlampN/S

Right

Instrument

Panel SpeakerBK At Speaker 25

Right License

LampNAT At Lamp 32

Right Rear

Door Lock

MotorBK At Motor 35

Right Rear

Fog LampGY At Lamp 32

Right Rear

SpeakerBK At Speaker 30

Right Rear

Turn Signal

LampGY At Lamp 31

Right Rear

Wheel Speed

SensorBL At Right Rear

Wheel

OpeningN/S

Right

Repeater

LampBL At Lamp 18

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 918 of 1285

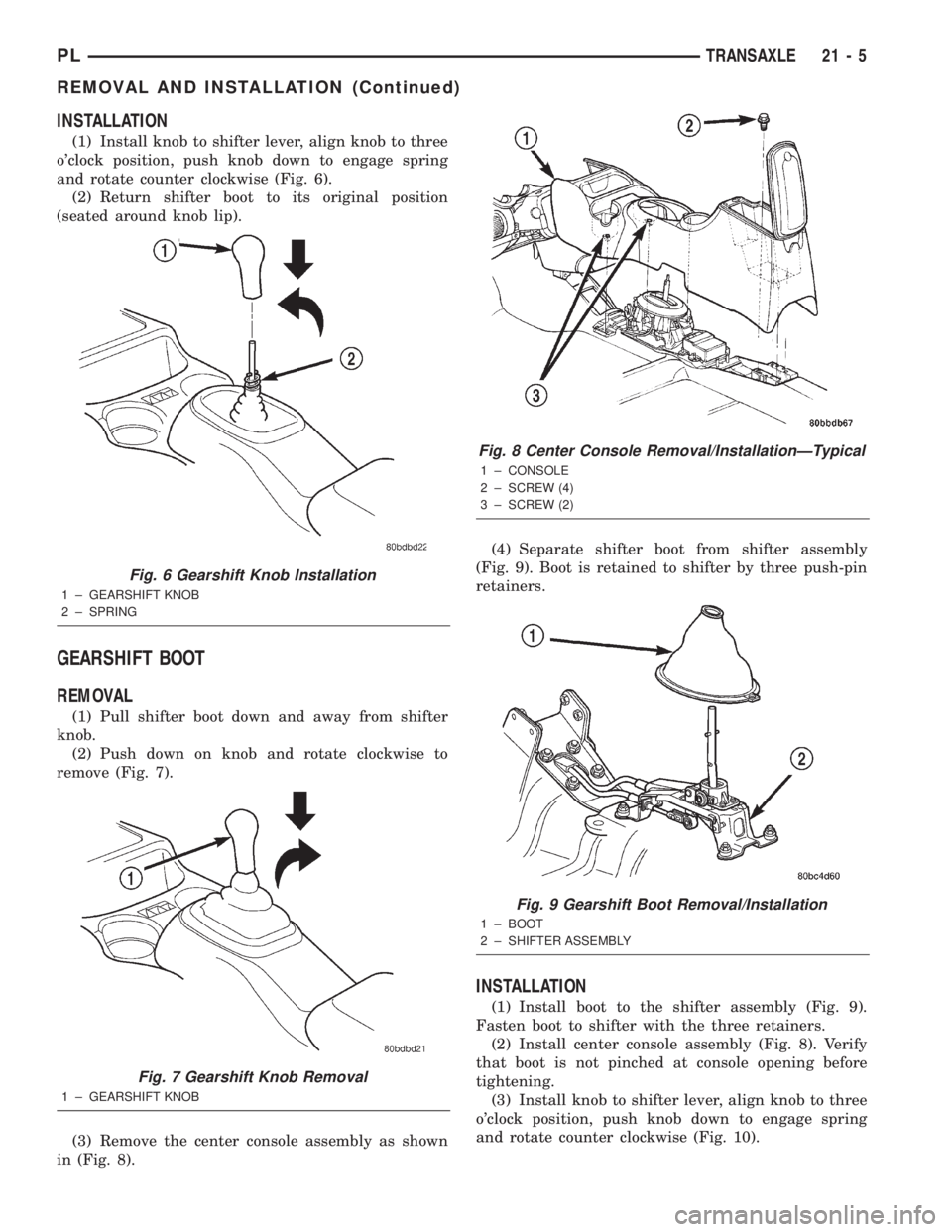

INSTALLATION

(1) Install knob to shifter lever, align knob to three

o'clock position, push knob down to engage spring

and rotate counter clockwise (Fig. 6).

(2) Return shifter boot to its original position

(seated around knob lip).

GEARSHIFT BOOT

REMOVAL

(1) Pull shifter boot down and away from shifter

knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 7).

(3) Remove the center console assembly as shown

in (Fig. 8).(4) Separate shifter boot from shifter assembly

(Fig. 9). Boot is retained to shifter by three push-pin

retainers.

INSTALLATION

(1) Install boot to the shifter assembly (Fig. 9).

Fasten boot to shifter with the three retainers.

(2) Install center console assembly (Fig. 8). Verify

that boot is not pinched at console opening before

tightening.

(3) Install knob to shifter lever, align knob to three

o'clock position, push knob down to engage spring

and rotate counter clockwise (Fig. 10).

Fig. 6 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 7 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

Fig. 8 Center Console Removal/InstallationÐTypical

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

Fig. 9 Gearshift Boot Removal/Installation

1 ± BOOT

2 ± SHIFTER ASSEMBLY

PLTRANSAXLE 21 - 5

REMOVAL AND INSTALLATION (Continued)

Page 919 of 1285

(4) Return shifter boot to its original position

(seated around knob lip).

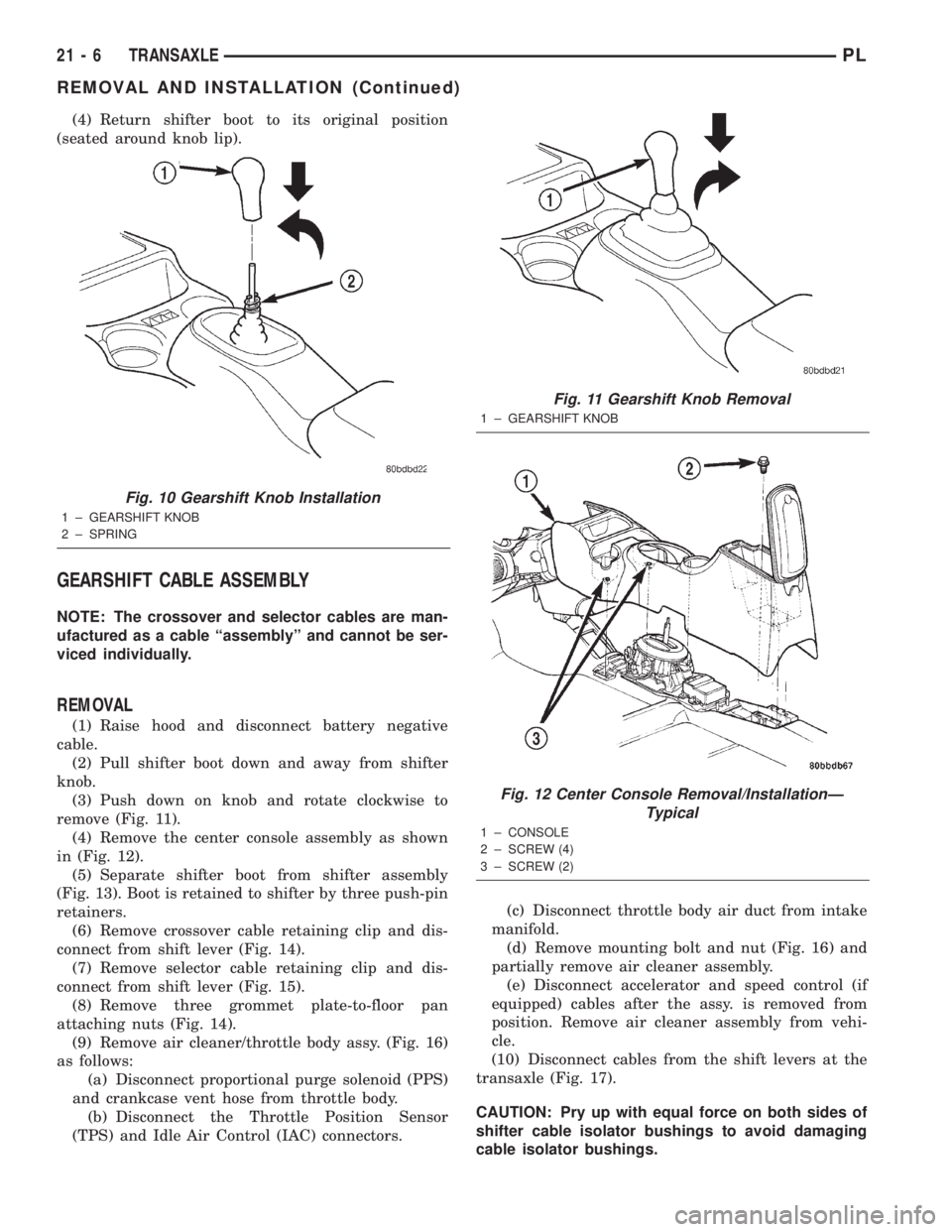

GEARSHIFT CABLE ASSEMBLY

NOTE: The crossover and selector cables are man-

ufactured as a cable ªassemblyº and cannot be ser-

viced individually.

REMOVAL

(1) Raise hood and disconnect battery negative

cable.

(2) Pull shifter boot down and away from shifter

knob.

(3) Push down on knob and rotate clockwise to

remove (Fig. 11).

(4) Remove the center console assembly as shown

in (Fig. 12).

(5) Separate shifter boot from shifter assembly

(Fig. 13). Boot is retained to shifter by three push-pin

retainers.

(6) Remove crossover cable retaining clip and dis-

connect from shift lever (Fig. 14).

(7) Remove selector cable retaining clip and dis-

connect from shift lever (Fig. 15).

(8) Remove three grommet plate-to-floor pan

attaching nuts (Fig. 14).

(9) Remove air cleaner/throttle body assy. (Fig. 16)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.(c) Disconnect throttle body air duct from intake

manifold.

(d) Remove mounting bolt and nut (Fig. 16) and

partially remove air cleaner assembly.

(e) Disconnect accelerator and speed control (if

equipped) cables after the assy. is removed from

position. Remove air cleaner assembly from vehi-

cle.

(10) Disconnect cables from the shift levers at the

transaxle (Fig. 17).

CAUTION: Pry up with equal force on both sides of

shifter cable isolator bushings to avoid damaging

cable isolator bushings.

Fig. 10 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 11 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

Fig. 12 Center Console Removal/InstallationÐ

Typical

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

21 - 6 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 921 of 1285

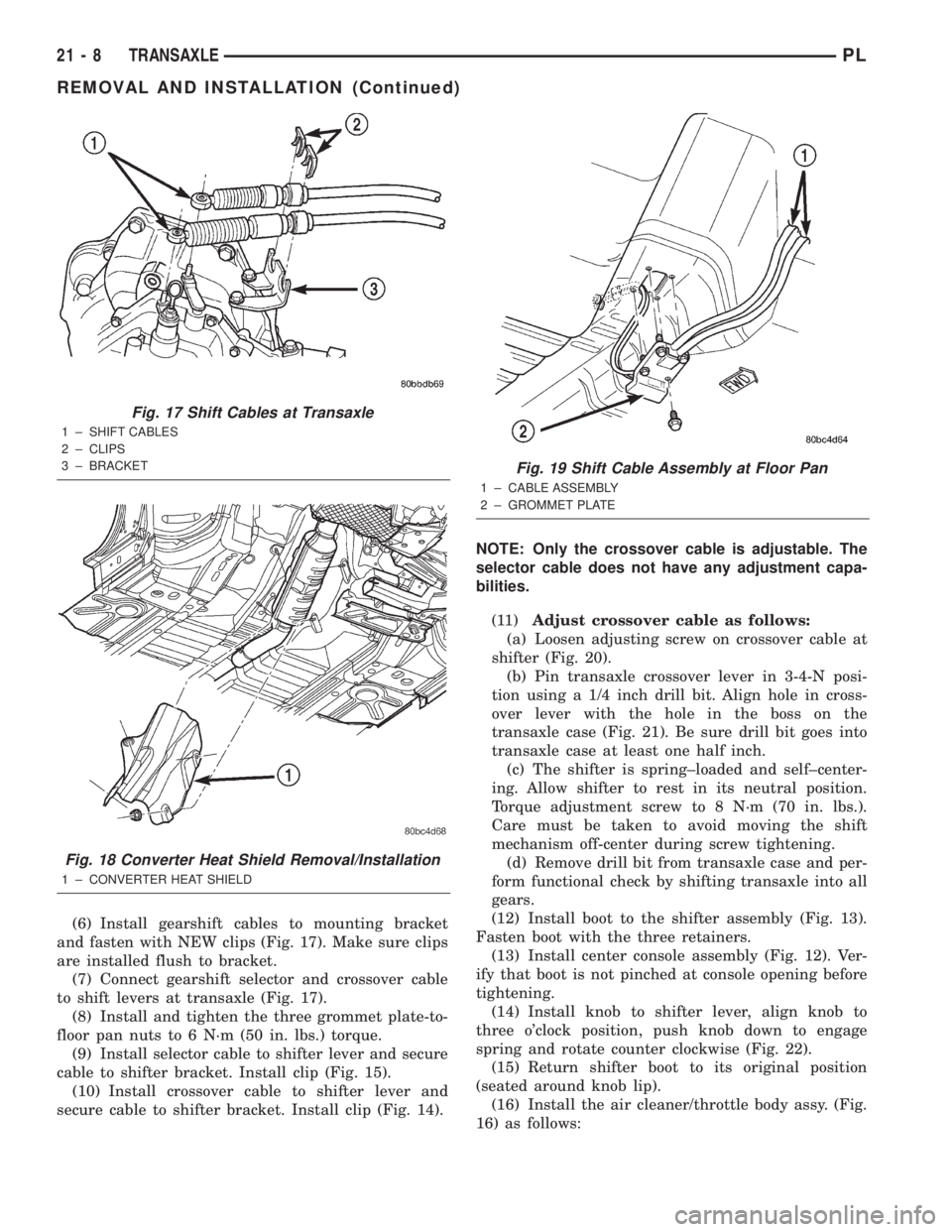

(6) Install gearshift cables to mounting bracket

and fasten with NEW clips (Fig. 17). Make sure clips

are installed flush to bracket.

(7) Connect gearshift selector and crossover cable

to shift levers at transaxle (Fig. 17).

(8) Install and tighten the three grommet plate-to-

floor pan nuts to 6 N´m (50 in. lbs.) torque.

(9) Install selector cable to shifter lever and secure

cable to shifter bracket. Install clip (Fig. 15).

(10) Install crossover cable to shifter lever and

secure cable to shifter bracket. Install clip (Fig. 14).NOTE: Only the crossover cable is adjustable. The

selector cable does not have any adjustment capa-

bilities.

(11)Adjust crossover cable as follows:

(a) Loosen adjusting screw on crossover cable at

shifter (Fig. 20).

(b) Pin transaxle crossover lever in 3-4-N posi-

tion using a 1/4 inch drill bit. Align hole in cross-

over lever with the hole in the boss on the

transaxle case (Fig. 21). Be sure drill bit goes into

transaxle case at least one half inch.

(c) The shifter is spring±loaded and self±center-

ing. Allow shifter to rest in its neutral position.

Torque adjustment screw to 8 N´m (70 in. lbs.).

Care must be taken to avoid moving the shift

mechanism off-center during screw tightening.

(d) Remove drill bit from transaxle case and per-

form functional check by shifting transaxle into all

gears.

(12) Install boot to the shifter assembly (Fig. 13).

Fasten boot with the three retainers.

(13) Install center console assembly (Fig. 12). Ver-

ify that boot is not pinched at console opening before

tightening.

(14) Install knob to shifter lever, align knob to

three o'clock position, push knob down to engage

spring and rotate counter clockwise (Fig. 22).

(15) Return shifter boot to its original position

(seated around knob lip).

(16) Install the air cleaner/throttle body assy. (Fig.

16) as follows:

Fig. 17 Shift Cables at Transaxle

1 ± SHIFT CABLES

2 ± CLIPS

3 ± BRACKET

Fig. 18 Converter Heat Shield Removal/Installation

1 ± CONVERTER HEAT SHIELD

Fig. 19 Shift Cable Assembly at Floor Pan

1 ± CABLE ASSEMBLY

2 ± GROMMET PLATE

21 - 8 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 923 of 1285

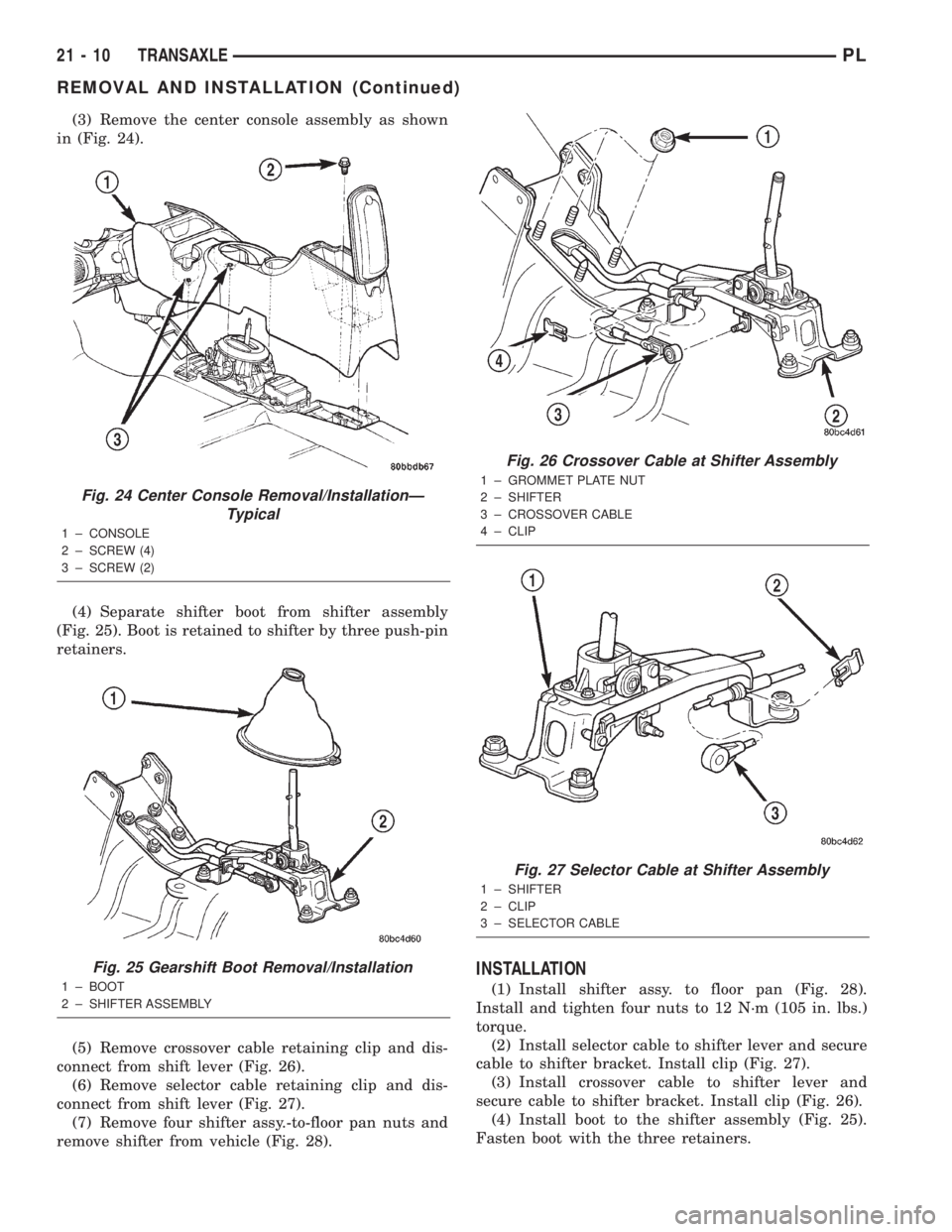

(3) Remove the center console assembly as shown

in (Fig. 24).

(4) Separate shifter boot from shifter assembly

(Fig. 25). Boot is retained to shifter by three push-pin

retainers.

(5) Remove crossover cable retaining clip and dis-

connect from shift lever (Fig. 26).

(6) Remove selector cable retaining clip and dis-

connect from shift lever (Fig. 27).

(7) Remove four shifter assy.-to-floor pan nuts and

remove shifter from vehicle (Fig. 28).

INSTALLATION

(1) Install shifter assy. to floor pan (Fig. 28).

Install and tighten four nuts to 12 N´m (105 in. lbs.)

torque.

(2) Install selector cable to shifter lever and secure

cable to shifter bracket. Install clip (Fig. 27).

(3) Install crossover cable to shifter lever and

secure cable to shifter bracket. Install clip (Fig. 26).

(4) Install boot to the shifter assembly (Fig. 25).

Fasten boot with the three retainers.

Fig. 24 Center Console Removal/InstallationÐ

Typical

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

Fig. 25 Gearshift Boot Removal/Installation

1 ± BOOT

2 ± SHIFTER ASSEMBLY

Fig. 26 Crossover Cable at Shifter Assembly

1 ± GROMMET PLATE NUT

2 ± SHIFTER

3 ± CROSSOVER CABLE

4 ± CLIP

Fig. 27 Selector Cable at Shifter Assembly

1 ± SHIFTER

2 ± CLIP

3 ± SELECTOR CABLE

21 - 10 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 924 of 1285

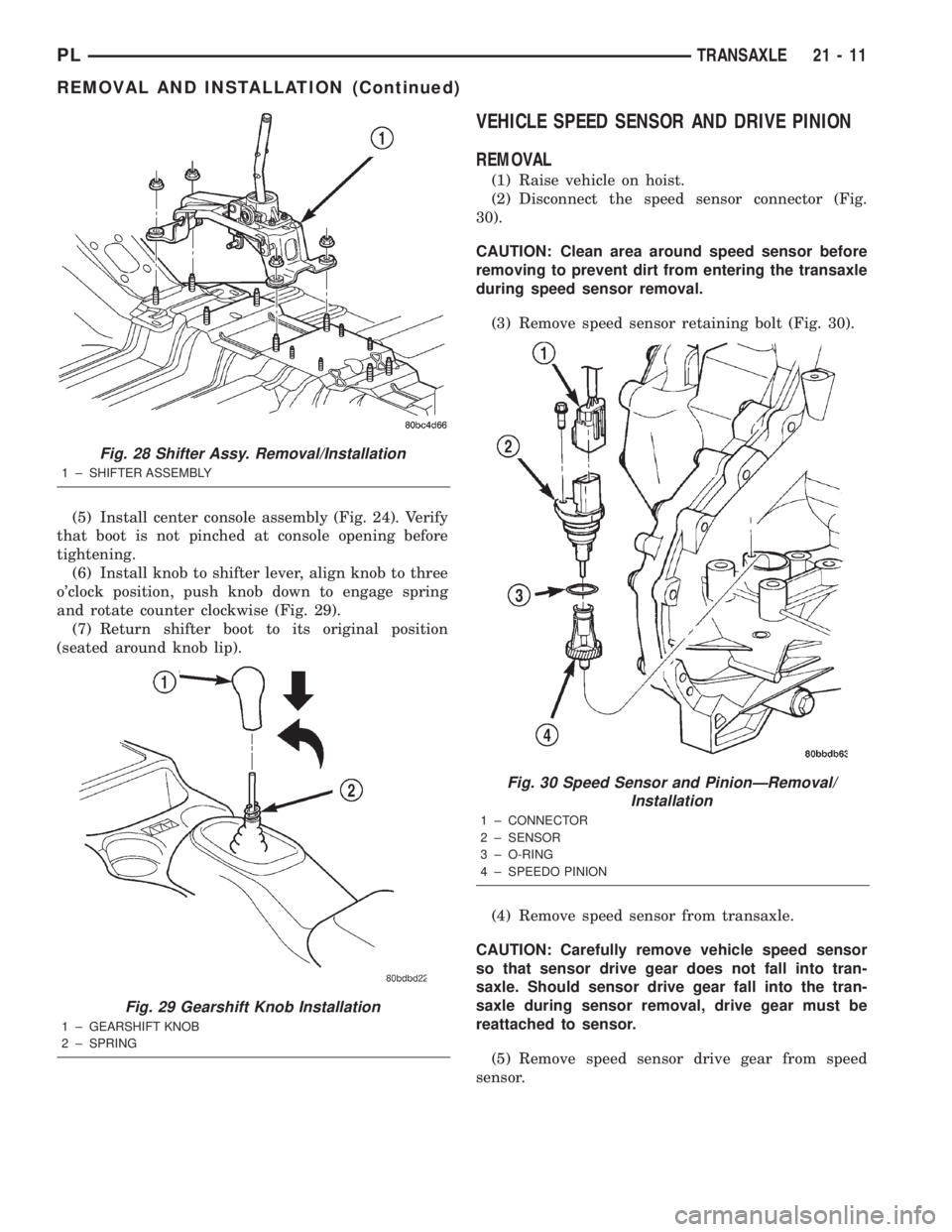

(5) Install center console assembly (Fig. 24). Verify

that boot is not pinched at console opening before

tightening.

(6) Install knob to shifter lever, align knob to three

o'clock position, push knob down to engage spring

and rotate counter clockwise (Fig. 29).

(7) Return shifter boot to its original position

(seated around knob lip).

VEHICLE SPEED SENSOR AND DRIVE PINION

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect the speed sensor connector (Fig.

30).

CAUTION: Clean area around speed sensor before

removing to prevent dirt from entering the transaxle

during speed sensor removal.

(3) Remove speed sensor retaining bolt (Fig. 30).

(4) Remove speed sensor from transaxle.

CAUTION: Carefully remove vehicle speed sensor

so that sensor drive gear does not fall into tran-

saxle. Should sensor drive gear fall into the tran-

saxle during sensor removal, drive gear must be

reattached to sensor.

(5) Remove speed sensor drive gear from speed

sensor.

Fig. 28 Shifter Assy. Removal/Installation

1 ± SHIFTER ASSEMBLY

Fig. 29 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

Fig. 30 Speed Sensor and PinionÐRemoval/

Installation

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

PLTRANSAXLE 21 - 11

REMOVAL AND INSTALLATION (Continued)

Page 962 of 1285

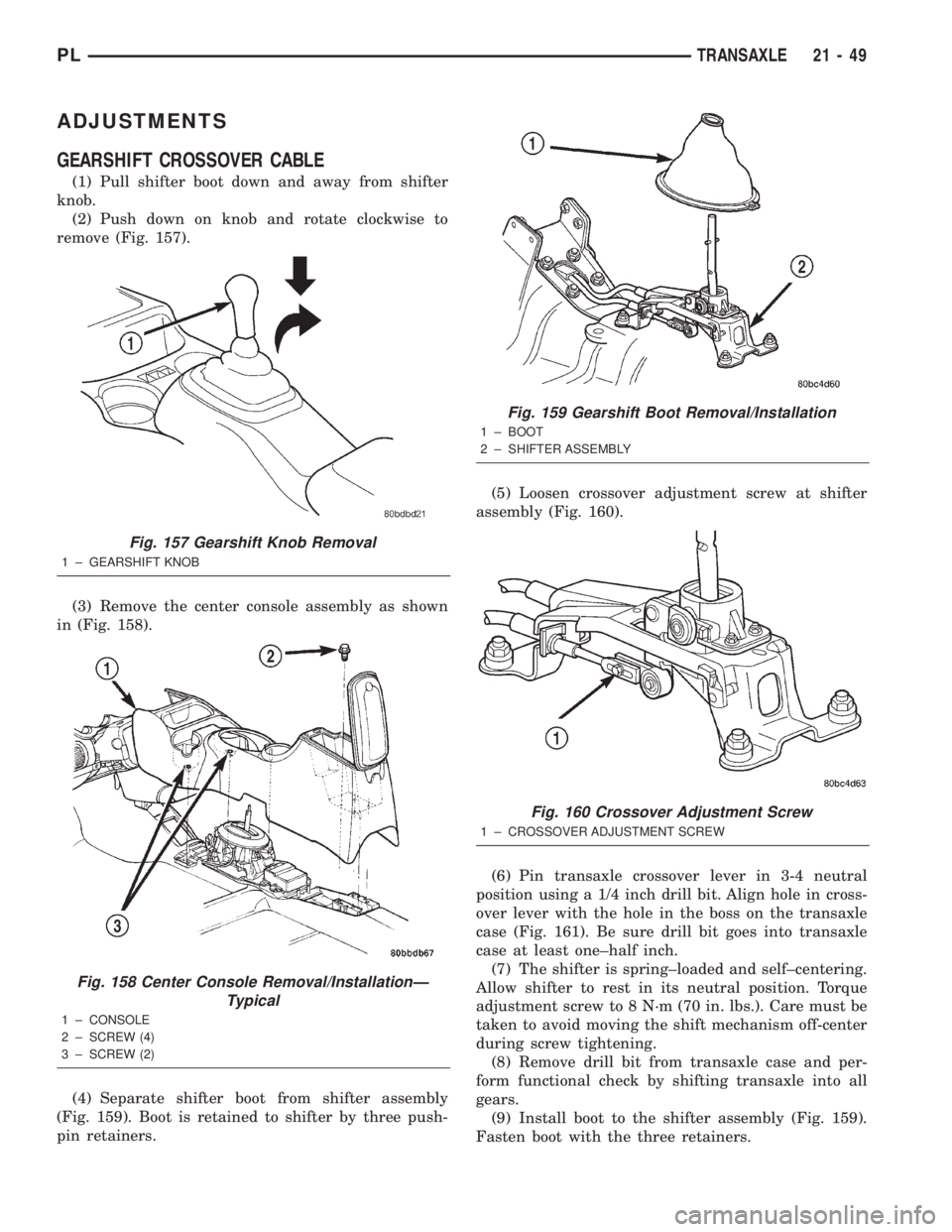

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE

(1) Pull shifter boot down and away from shifter

knob.

(2) Push down on knob and rotate clockwise to

remove (Fig. 157).

(3) Remove the center console assembly as shown

in (Fig. 158).

(4) Separate shifter boot from shifter assembly

(Fig. 159). Boot is retained to shifter by three push-

pin retainers.(5) Loosen crossover adjustment screw at shifter

assembly (Fig. 160).

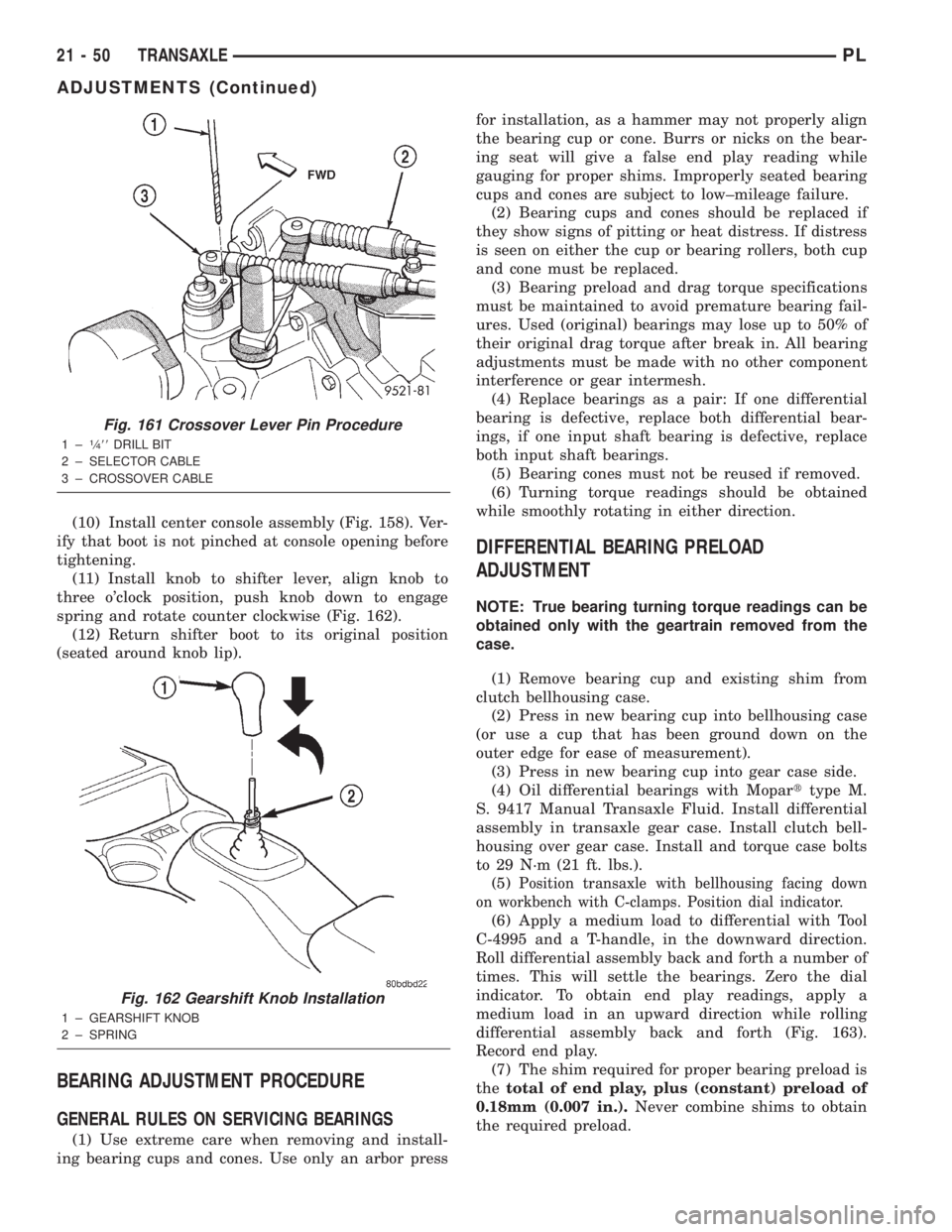

(6) Pin transaxle crossover lever in 3-4 neutral

position using a 1/4 inch drill bit. Align hole in cross-

over lever with the hole in the boss on the transaxle

case (Fig. 161). Be sure drill bit goes into transaxle

case at least one±half inch.

(7) The shifter is spring±loaded and self±centering.

Allow shifter to rest in its neutral position. Torque

adjustment screw to 8 N´m (70 in. lbs.). Care must be

taken to avoid moving the shift mechanism off-center

during screw tightening.

(8) Remove drill bit from transaxle case and per-

form functional check by shifting transaxle into all

gears.

(9) Install boot to the shifter assembly (Fig. 159).

Fasten boot with the three retainers.

Fig. 157 Gearshift Knob Removal

1 ± GEARSHIFT KNOB

Fig. 158 Center Console Removal/InstallationÐ

Typical

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

Fig. 159 Gearshift Boot Removal/Installation

1 ± BOOT

2 ± SHIFTER ASSEMBLY

Fig. 160 Crossover Adjustment Screw

1 ± CROSSOVER ADJUSTMENT SCREW

PLTRANSAXLE 21 - 49

Page 963 of 1285

(10) Install center console assembly (Fig. 158). Ver-

ify that boot is not pinched at console opening before

tightening.

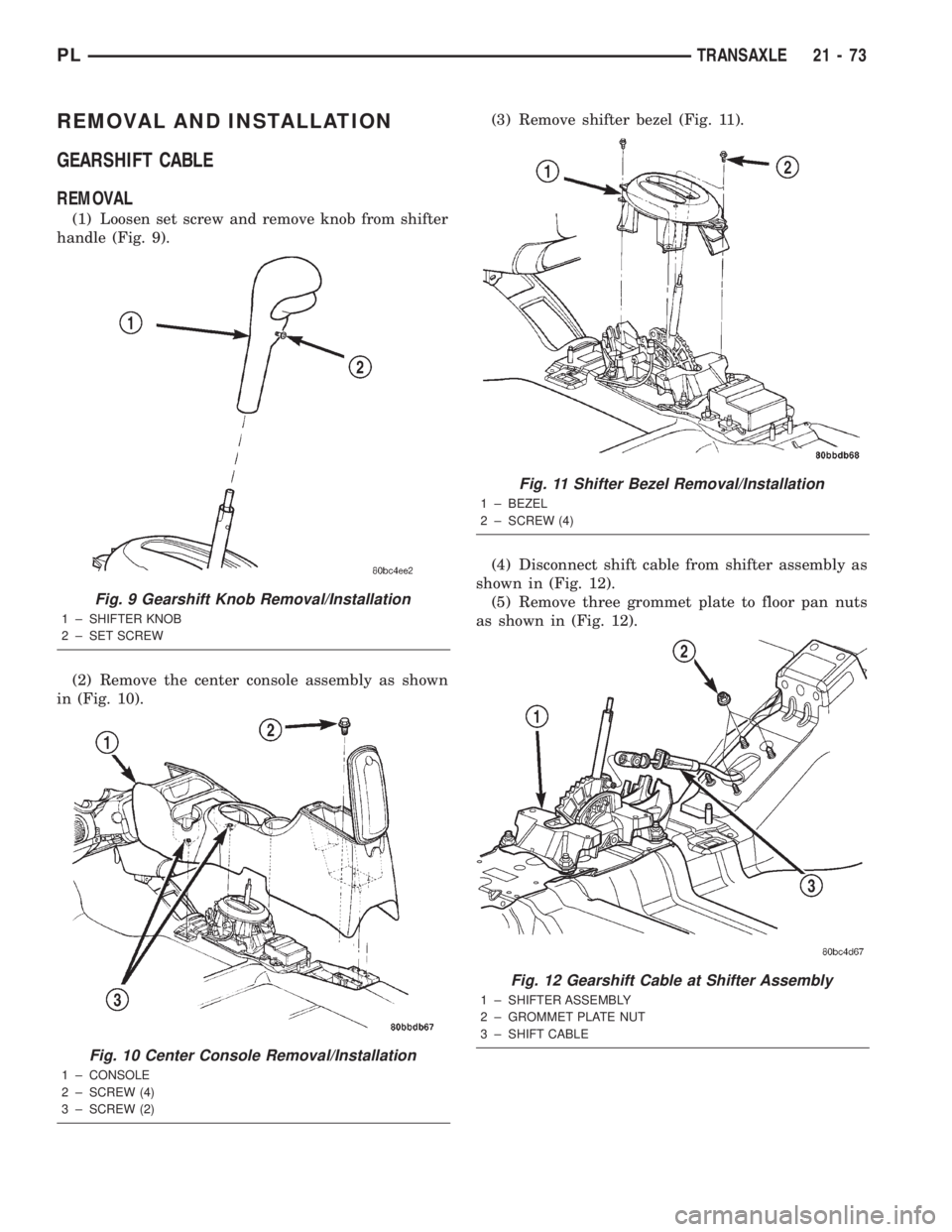

(11) Install knob to shifter lever, align knob to

three o'clock position, push knob down to engage

spring and rotate counter clockwise (Fig. 162).

(12) Return shifter boot to its original position

(seated around knob lip).

BEARING ADJUSTMENT PROCEDURE

GENERAL RULES ON SERVICING BEARINGS

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor pressfor installation, as a hammer may not properly align

the bearing cup or cone. Burrs or nicks on the bear-

ing seat will give a false end play reading while

gauging for proper shims. Improperly seated bearing

cups and cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.

(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

their original drag torque after break in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings, if one input shaft bearing is defective, replace

both input shaft bearings.

(5) Bearing cones must not be reused if removed.

(6) Turning torque readings should be obtained

while smoothly rotating in either direction.

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT

NOTE: True bearing turning torque readings can be

obtained only with the geartrain removed from the

case.

(1) Remove bearing cup and existing shim from

clutch bellhousing case.

(2) Press in new bearing cup into bellhousing case

(or use a cup that has been ground down on the

outer edge for ease of measurement).

(3) Press in new bearing cup into gear case side.

(4) Oil differential bearings with Moparttype M.

S. 9417 Manual Transaxle Fluid. Install differential

assembly in transaxle gear case. Install clutch bell-

housing over gear case. Install and torque case bolts

to 29 N´m (21 ft. lbs.).

(5)

Position transaxle with bellhousing facing down

on workbench with C-clamps. Position dial indicator.

(6) Apply a medium load to differential with Tool

C-4995 and a T-handle, in the downward direction.

Roll differential assembly back and forth a number of

times. This will settle the bearings. Zero the dial

indicator. To obtain end play readings, apply a

medium load in an upward direction while rolling

differential assembly back and forth (Fig. 163).

Record end play.

(7) The shim required for proper bearing preload is

thetotal of end play, plus (constant) preload of

0.18mm (0.007 in.).Never combine shims to obtain

the required preload.

Fig. 161 Crossover Lever Pin Procedure

1±1¤488DRILL BIT

2 ± SELECTOR CABLE

3 ± CROSSOVER CABLE

Fig. 162 Gearshift Knob Installation

1 ± GEARSHIFT KNOB

2 ± SPRING

21 - 50 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 986 of 1285

REMOVAL AND INSTALLATION

GEARSHIFT CABLE

REMOVAL

(1) Loosen set screw and remove knob from shifter

handle (Fig. 9).

(2) Remove the center console assembly as shown

in (Fig. 10).(3) Remove shifter bezel (Fig. 11).

(4) Disconnect shift cable from shifter assembly as

shown in (Fig. 12).

(5) Remove three grommet plate to floor pan nuts

as shown in (Fig. 12).

Fig. 9 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 10 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

Fig. 11 Shifter Bezel Removal/Installation

1 ± BEZEL

2 ± SCREW (4)

Fig. 12 Gearshift Cable at Shifter Assembly

1 ± SHIFTER ASSEMBLY

2 ± GROMMET PLATE NUT

3 ± SHIFT CABLE

PLTRANSAXLE 21 - 73