warning DODGE NEON 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 82 of 1285

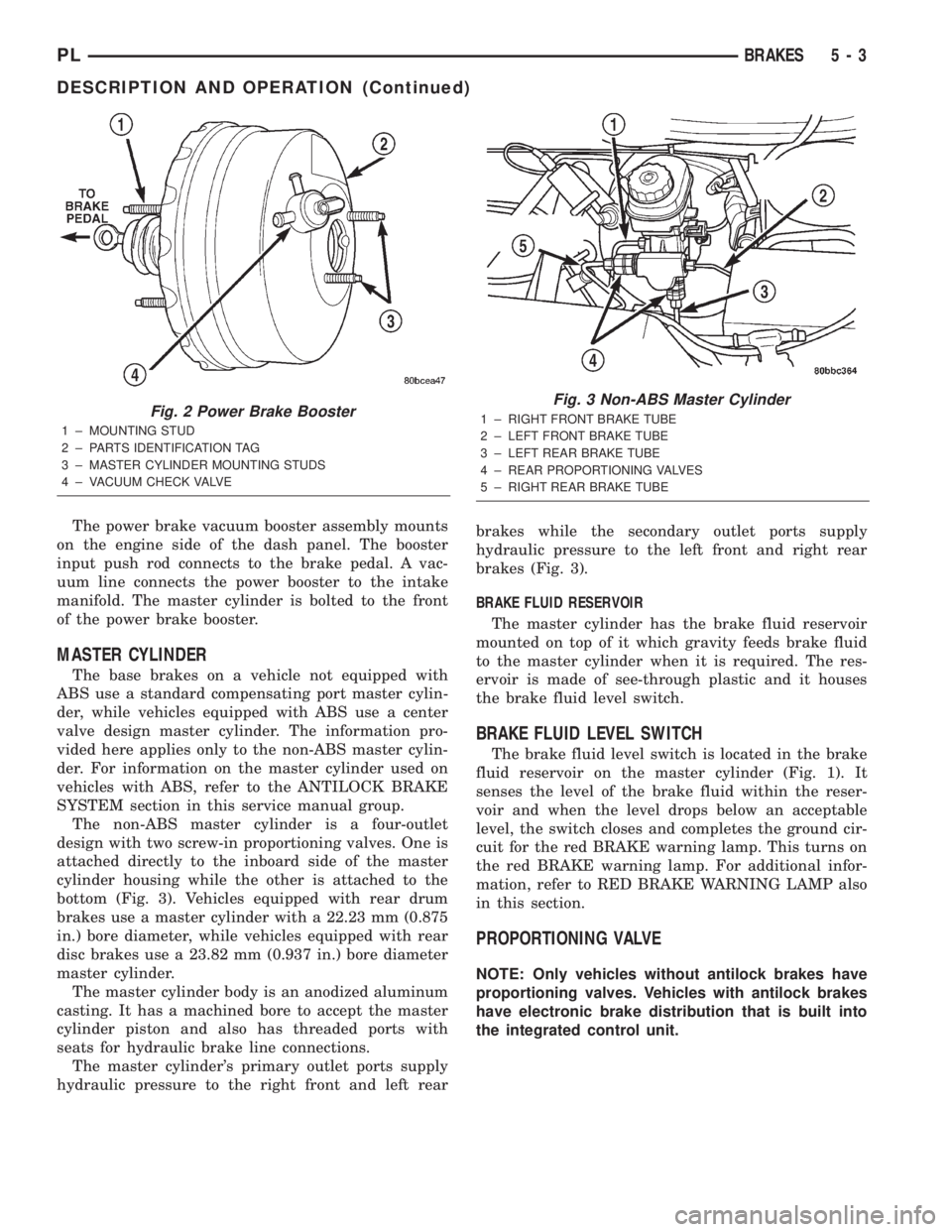

The power brake vacuum booster assembly mounts

on the engine side of the dash panel. The booster

input push rod connects to the brake pedal. A vac-

uum line connects the power booster to the intake

manifold. The master cylinder is bolted to the front

of the power brake booster.

MASTER CYLINDER

The base brakes on a vehicle not equipped with

ABS use a standard compensating port master cylin-

der, while vehicles equipped with ABS use a center

valve design master cylinder. The information pro-

vided here applies only to the non-ABS master cylin-

der. For information on the master cylinder used on

vehicles with ABS, refer to the ANTILOCK BRAKE

SYSTEM section in this service manual group.

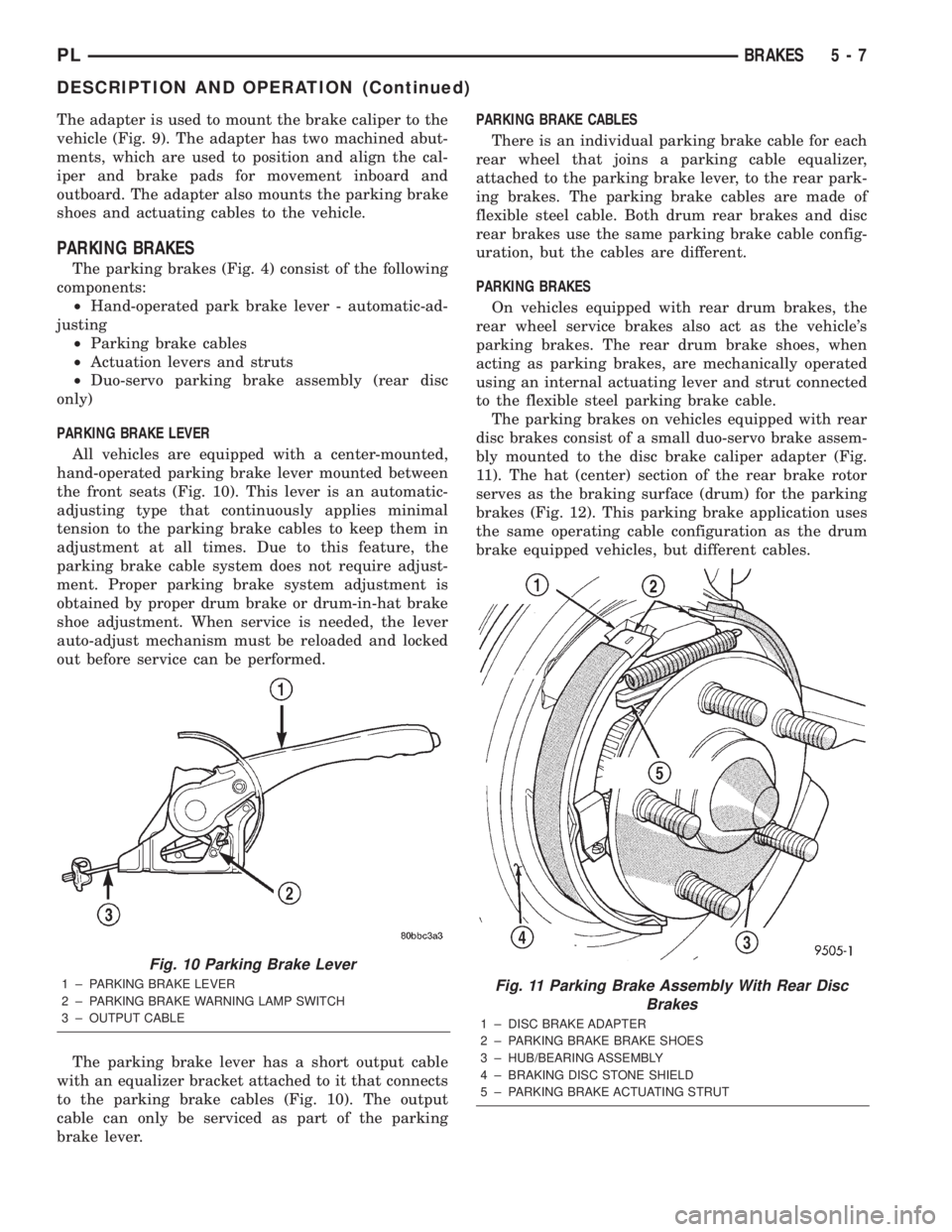

The non-ABS master cylinder is a four-outlet

design with two screw-in proportioning valves. One is

attached directly to the inboard side of the master

cylinder housing while the other is attached to the

bottom (Fig. 3). Vehicles equipped with rear drum

brakes use a master cylinder with a 22.23 mm (0.875

in.) bore diameter, while vehicles equipped with rear

disc brakes use a 23.82 mm (0.937 in.) bore diameter

master cylinder.

The master cylinder body is an anodized aluminum

casting. It has a machined bore to accept the master

cylinder piston and also has threaded ports with

seats for hydraulic brake line connections.

The master cylinder's primary outlet ports supply

hydraulic pressure to the right front and left rearbrakes while the secondary outlet ports supply

hydraulic pressure to the left front and right rear

brakes (Fig. 3).

BRAKE FLUID RESERVOIR

The master cylinder has the brake fluid reservoir

mounted on top of it which gravity feeds brake fluid

to the master cylinder when it is required. The res-

ervoir is made of see-through plastic and it houses

the brake fluid level switch.

BRAKE FLUID LEVEL SWITCH

The brake fluid level switch is located in the brake

fluid reservoir on the master cylinder (Fig. 1). It

senses the level of the brake fluid within the reser-

voir and when the level drops below an acceptable

level, the switch closes and completes the ground cir-

cuit for the red BRAKE warning lamp. This turns on

the red BRAKE warning lamp. For additional infor-

mation, refer to RED BRAKE WARNING LAMP also

in this section.

PROPORTIONING VALVE

NOTE: Only vehicles without antilock brakes have

proportioning valves. Vehicles with antilock brakes

have electronic brake distribution that is built into

the integrated control unit.

Fig. 2 Power Brake Booster

1 ± MOUNTING STUD

2 ± PARTS IDENTIFICATION TAG

3 ± MASTER CYLINDER MOUNTING STUDS

4 ± VACUUM CHECK VALVE

Fig. 3 Non-ABS Master Cylinder

1 ± RIGHT FRONT BRAKE TUBE

2 ± LEFT FRONT BRAKE TUBE

3 ± LEFT REAR BRAKE TUBE

4 ± REAR PROPORTIONING VALVES

5 ± RIGHT REAR BRAKE TUBE

PLBRAKES 5 - 3

DESCRIPTION AND OPERATION (Continued)

Page 86 of 1285

The adapter is used to mount the brake caliper to the

vehicle (Fig. 9). The adapter has two machined abut-

ments, which are used to position and align the cal-

iper and brake pads for movement inboard and

outboard. The adapter also mounts the parking brake

shoes and actuating cables to the vehicle.

PARKING BRAKES

The parking brakes (Fig. 4) consist of the following

components:

²Hand-operated park brake lever - automatic-ad-

justing

²Parking brake cables

²Actuation levers and struts

²Duo-servo parking brake assembly (rear disc

only)

PARKING BRAKE LEVER

All vehicles are equipped with a center-mounted,

hand-operated parking brake lever mounted between

the front seats (Fig. 10). This lever is an automatic-

adjusting type that continuously applies minimal

tension to the parking brake cables to keep them in

adjustment at all times. Due to this feature, the

parking brake cable system does not require adjust-

ment. Proper parking brake system adjustment is

obtained by proper drum brake or drum-in-hat brake

shoe adjustment. When service is needed, the lever

auto-adjust mechanism must be reloaded and locked

out before service can be performed.

The parking brake lever has a short output cable

with an equalizer bracket attached to it that connects

to the parking brake cables (Fig. 10). The output

cable can only be serviced as part of the parking

brake lever.PARKING BRAKE CABLES

There is an individual parking brake cable for each

rear wheel that joins a parking cable equalizer,

attached to the parking brake lever, to the rear park-

ing brakes. The parking brake cables are made of

flexible steel cable. Both drum rear brakes and disc

rear brakes use the same parking brake cable config-

uration, but the cables are different.

PARKING BRAKES

On vehicles equipped with rear drum brakes, the

rear wheel service brakes also act as the vehicle's

parking brakes. The rear drum brake shoes, when

acting as parking brakes, are mechanically operated

using an internal actuating lever and strut connected

to the flexible steel parking brake cable.

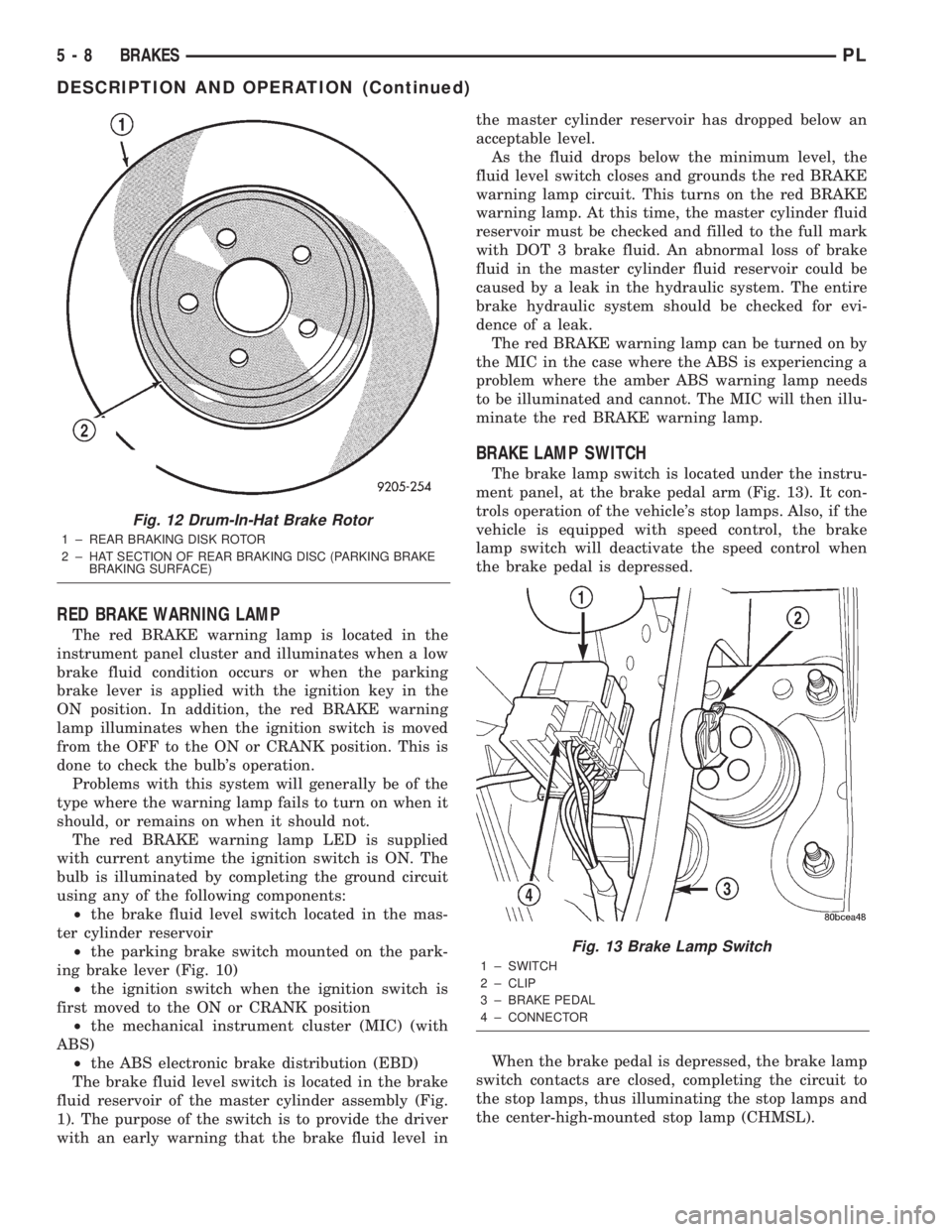

The parking brakes on vehicles equipped with rear

disc brakes consist of a small duo-servo brake assem-

bly mounted to the disc brake caliper adapter (Fig.

11). The hat (center) section of the rear brake rotor

serves as the braking surface (drum) for the parking

brakes (Fig. 12). This parking brake application uses

the same operating cable configuration as the drum

brake equipped vehicles, but different cables.

Fig. 10 Parking Brake Lever

1 ± PARKING BRAKE LEVER

2 ± PARKING BRAKE WARNING LAMP SWITCH

3 ± OUTPUT CABLEFig. 11 Parking Brake Assembly With Rear Disc

Brakes

1 ± DISC BRAKE ADAPTER

2 ± PARKING BRAKE BRAKE SHOES

3 ± HUB/BEARING ASSEMBLY

4 ± BRAKING DISC STONE SHIELD

5 ± PARKING BRAKE ACTUATING STRUT

PLBRAKES 5 - 7

DESCRIPTION AND OPERATION (Continued)

Page 87 of 1285

RED BRAKE WARNING LAMP

The red BRAKE warning lamp is located in the

instrument panel cluster and illuminates when a low

brake fluid condition occurs or when the parking

brake lever is applied with the ignition key in the

ON position. In addition, the red BRAKE warning

lamp illuminates when the ignition switch is moved

from the OFF to the ON or CRANK position. This is

done to check the bulb's operation.

Problems with this system will generally be of the

type where the warning lamp fails to turn on when it

should, or remains on when it should not.

The red BRAKE warning lamp LED is supplied

with current anytime the ignition switch is ON. The

bulb is illuminated by completing the ground circuit

using any of the following components:

²the brake fluid level switch located in the mas-

ter cylinder reservoir

²the parking brake switch mounted on the park-

ing brake lever (Fig. 10)

²the ignition switch when the ignition switch is

first moved to the ON or CRANK position

²the mechanical instrument cluster (MIC) (with

ABS)

²the ABS electronic brake distribution (EBD)

The brake fluid level switch is located in the brake

fluid reservoir of the master cylinder assembly (Fig.

1). The purpose of the switch is to provide the driver

with an early warning that the brake fluid level inthe master cylinder reservoir has dropped below an

acceptable level.

As the fluid drops below the minimum level, the

fluid level switch closes and grounds the red BRAKE

warning lamp circuit. This turns on the red BRAKE

warning lamp. At this time, the master cylinder fluid

reservoir must be checked and filled to the full mark

with DOT 3 brake fluid. An abnormal loss of brake

fluid in the master cylinder fluid reservoir could be

caused by a leak in the hydraulic system. The entire

brake hydraulic system should be checked for evi-

dence of a leak.

The red BRAKE warning lamp can be turned on by

the MIC in the case where the ABS is experiencing a

problem where the amber ABS warning lamp needs

to be illuminated and cannot. The MIC will then illu-

minate the red BRAKE warning lamp.

BRAKE LAMP SWITCH

The brake lamp switch is located under the instru-

ment panel, at the brake pedal arm (Fig. 13). It con-

trols operation of the vehicle's stop lamps. Also, if the

vehicle is equipped with speed control, the brake

lamp switch will deactivate the speed control when

the brake pedal is depressed.

When the brake pedal is depressed, the brake lamp

switch contacts are closed, completing the circuit to

the stop lamps, thus illuminating the stop lamps and

the center-high-mounted stop lamp (CHMSL).

Fig. 12 Drum-In-Hat Brake Rotor

1 ± REAR BRAKING DISK ROTOR

2 ± HAT SECTION OF REAR BRAKING DISC (PARKING BRAKE

BRAKING SURFACE)

Fig. 13 Brake Lamp Switch

1 ± SWITCH

2 ± CLIP

3 ± BRAKE PEDAL

4 ± CONNECTOR

5 - 8 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 88 of 1285

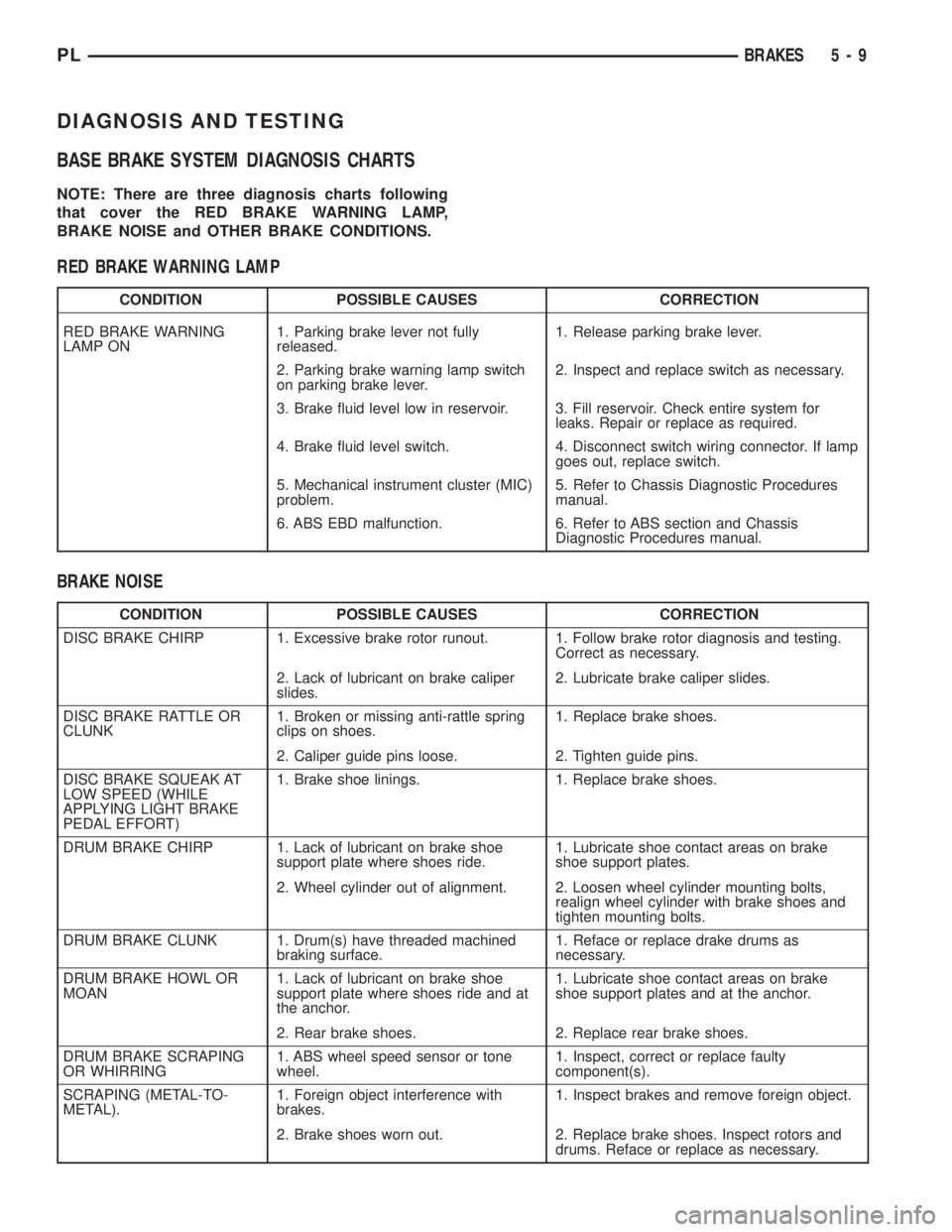

DIAGNOSIS AND TESTING

BASE BRAKE SYSTEM DIAGNOSIS CHARTS

NOTE: There are three diagnosis charts following

that cover the RED BRAKE WARNING LAMP,

BRAKE NOISE and OTHER BRAKE CONDITIONS.

RED BRAKE WARNING LAMP

CONDITION POSSIBLE CAUSES CORRECTION

RED BRAKE WARNING

LAMP ON1. Parking brake lever not fully

released.1. Release parking brake lever.

2. Parking brake warning lamp switch

on parking brake lever.2. Inspect and replace switch as necessary.

3. Brake fluid level low in reservoir. 3. Fill reservoir. Check entire system for

leaks. Repair or replace as required.

4. Brake fluid level switch. 4. Disconnect switch wiring connector. If lamp

goes out, replace switch.

5. Mechanical instrument cluster (MIC)

problem.5. Refer to Chassis Diagnostic Procedures

manual.

6. ABS EBD malfunction. 6. Refer to ABS section and Chassis

Diagnostic Procedures manual.

BRAKE NOISE

CONDITION POSSIBLE CAUSES CORRECTION

DISC BRAKE CHIRP 1. Excessive brake rotor runout. 1. Follow brake rotor diagnosis and testing.

Correct as necessary.

2. Lack of lubricant on brake caliper

slides.2. Lubricate brake caliper slides.

DISC BRAKE RATTLE OR

CLUNK1. Broken or missing anti-rattle spring

clips on shoes.1. Replace brake shoes.

2. Caliper guide pins loose. 2. Tighten guide pins.

DISC BRAKE SQUEAK AT

LOW SPEED (WHILE

APPLYING LIGHT BRAKE

PEDAL EFFORT)1. Brake shoe linings. 1. Replace brake shoes.

DRUM BRAKE CHIRP 1. Lack of lubricant on brake shoe

support plate where shoes ride.1. Lubricate shoe contact areas on brake

shoe support plates.

2. Wheel cylinder out of alignment. 2. Loosen wheel cylinder mounting bolts,

realign wheel cylinder with brake shoes and

tighten mounting bolts.

DRUM BRAKE CLUNK 1. Drum(s) have threaded machined

braking surface.1. Reface or replace drake drums as

necessary.

DRUM BRAKE HOWL OR

MOAN1. Lack of lubricant on brake shoe

support plate where shoes ride and at

the anchor.1. Lubricate shoe contact areas on brake

shoe support plates and at the anchor.

2. Rear brake shoes. 2. Replace rear brake shoes.

DRUM BRAKE SCRAPING

OR WHIRRING1. ABS wheel speed sensor or tone

wheel.1. Inspect, correct or replace faulty

component(s).

SCRAPING (METAL-TO-

METAL).1. Foreign object interference with

brakes.1. Inspect brakes and remove foreign object.

2. Brake shoes worn out. 2. Replace brake shoes. Inspect rotors and

drums. Reface or replace as necessary.

PLBRAKES 5 - 9

Page 101 of 1285

BRAKE ROTOR LIMITS

Braking Rotor Rotor ThicknessMinimum

Rotor

ThicknessRotor

Thickness

VariationRotor Run

Out*Rotor Micro

Finish

Front Rotor21.87±22.13 mm

0.861-0.871 in.20.4 mm

0.803 in.0.013 mm

0.0005 in.0.08 mm

0.003 in.15-80 RMS

Rear Rotor8.75±9.25 mm

0.344 -0.364 in.7.25 mm

0.285 in.0.013 mm

0.0005 in.0.08 mm

0.003 in.15-80 RMS

* TIR Total Indicator Reading (Measured On Vehicle)

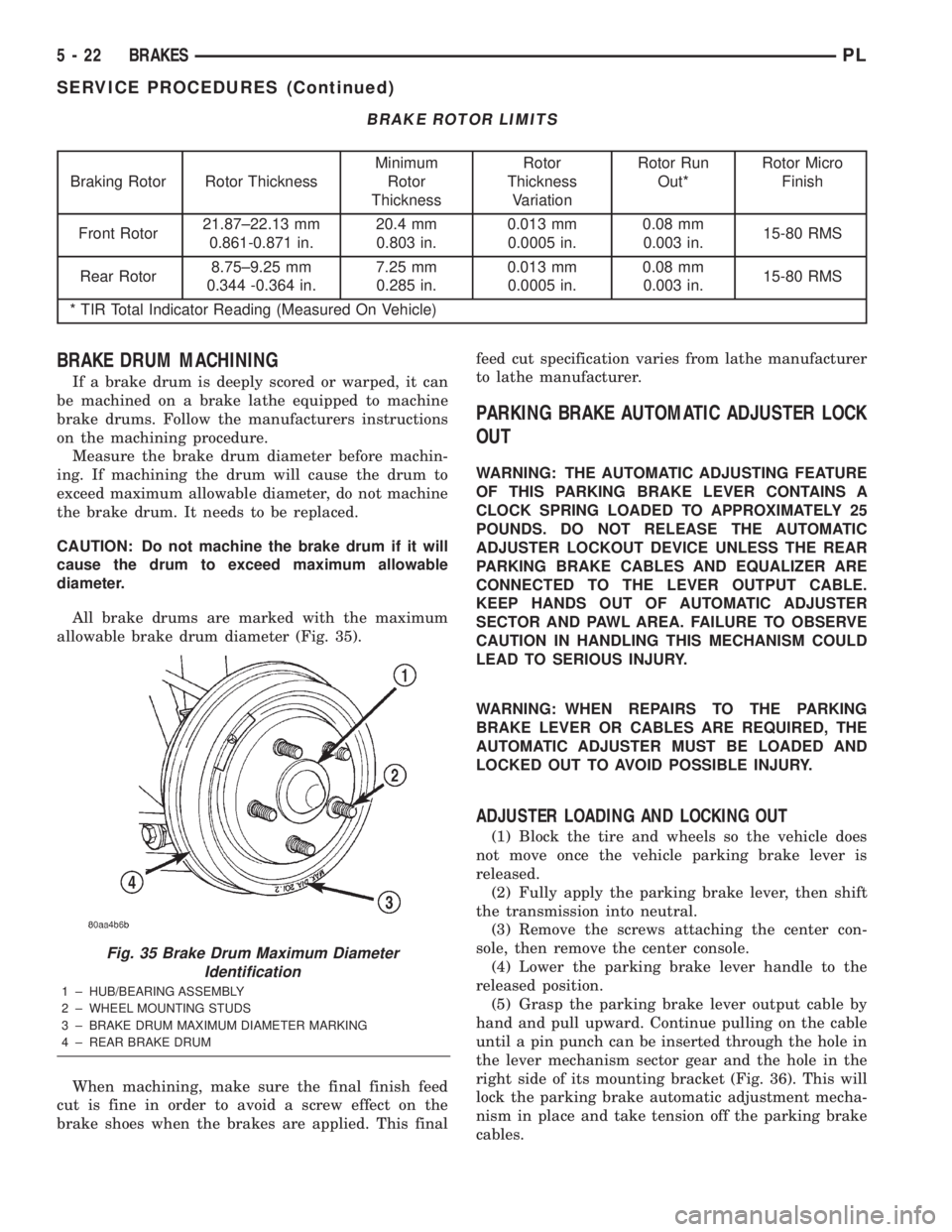

BRAKE DRUM MACHINING

If a brake drum is deeply scored or warped, it can

be machined on a brake lathe equipped to machine

brake drums. Follow the manufacturers instructions

on the machining procedure.

Measure the brake drum diameter before machin-

ing. If machining the drum will cause the drum to

exceed maximum allowable diameter, do not machine

the brake drum. It needs to be replaced.

CAUTION: Do not machine the brake drum if it will

cause the drum to exceed maximum allowable

diameter.

All brake drums are marked with the maximum

allowable brake drum diameter (Fig. 35).

When machining, make sure the final finish feed

cut is fine in order to avoid a screw effect on the

brake shoes when the brakes are applied. This finalfeed cut specification varies from lathe manufacturer

to lathe manufacturer.

PARKING BRAKE AUTOMATIC ADJUSTER LOCK

OUT

WARNING: THE AUTOMATIC ADJUSTING FEATURE

OF THIS PARKING BRAKE LEVER CONTAINS A

CLOCK SPRING LOADED TO APPROXIMATELY 25

POUNDS. DO NOT RELEASE THE AUTOMATIC

ADJUSTER LOCKOUT DEVICE UNLESS THE REAR

PARKING BRAKE CABLES AND EQUALIZER ARE

CONNECTED TO THE LEVER OUTPUT CABLE.

KEEP HANDS OUT OF AUTOMATIC ADJUSTER

SECTOR AND PAWL AREA. FAILURE TO OBSERVE

CAUTION IN HANDLING THIS MECHANISM COULD

LEAD TO SERIOUS INJURY.

WARNING: WHEN REPAIRS TO THE PARKING

BRAKE LEVER OR CABLES ARE REQUIRED, THE

AUTOMATIC ADJUSTER MUST BE LOADED AND

LOCKED OUT TO AVOID POSSIBLE INJURY.

ADJUSTER LOADING AND LOCKING OUT

(1) Block the tire and wheels so the vehicle does

not move once the vehicle parking brake lever is

released.

(2) Fully apply the parking brake lever, then shift

the transmission into neutral.

(3) Remove the screws attaching the center con-

sole, then remove the center console.

(4) Lower the parking brake lever handle to the

released position.

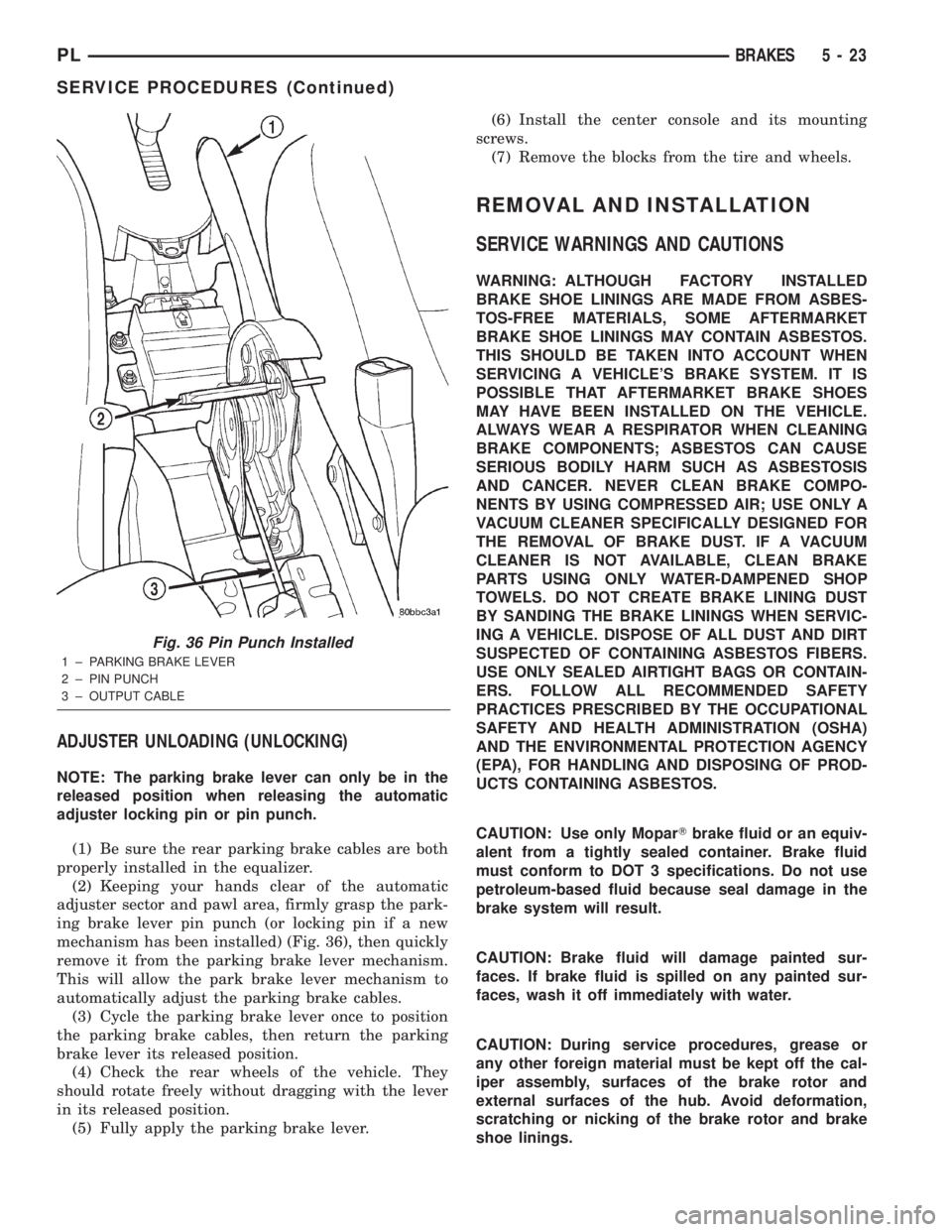

(5) Grasp the parking brake lever output cable by

hand and pull upward. Continue pulling on the cable

until a pin punch can be inserted through the hole in

the lever mechanism sector gear and the hole in the

right side of its mounting bracket (Fig. 36). This will

lock the parking brake automatic adjustment mecha-

nism in place and take tension off the parking brake

cables.

Fig. 35 Brake Drum Maximum Diameter

Identification

1 ± HUB/BEARING ASSEMBLY

2 ± WHEEL MOUNTING STUDS

3 ± BRAKE DRUM MAXIMUM DIAMETER MARKING

4 ± REAR BRAKE DRUM

5 - 22 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 102 of 1285

ADJUSTER UNLOADING (UNLOCKING)

NOTE: The parking brake lever can only be in the

released position when releasing the automatic

adjuster locking pin or pin punch.

(1) Be sure the rear parking brake cables are both

properly installed in the equalizer.

(2) Keeping your hands clear of the automatic

adjuster sector and pawl area, firmly grasp the park-

ing brake lever pin punch (or locking pin if a new

mechanism has been installed) (Fig. 36), then quickly

remove it from the parking brake lever mechanism.

This will allow the park brake lever mechanism to

automatically adjust the parking brake cables.

(3) Cycle the parking brake lever once to position

the parking brake cables, then return the parking

brake lever its released position.

(4) Check the rear wheels of the vehicle. They

should rotate freely without dragging with the lever

in its released position.

(5) Fully apply the parking brake lever.(6) Install the center console and its mounting

screws.

(7) Remove the blocks from the tire and wheels.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: ALTHOUGH FACTORY INSTALLED

BRAKE SHOE LININGS ARE MADE FROM ASBES-

TOS-FREE MATERIALS, SOME AFTERMARKET

BRAKE SHOE LININGS MAY CONTAIN ASBESTOS.

THIS SHOULD BE TAKEN INTO ACCOUNT WHEN

SERVICING A VEHICLE'S BRAKE SYSTEM. IT IS

POSSIBLE THAT AFTERMARKET BRAKE SHOES

MAY HAVE BEEN INSTALLED ON THE VEHICLE.

ALWAYS WEAR A RESPIRATOR WHEN CLEANING

BRAKE COMPONENTS; ASBESTOS CAN CAUSE

SERIOUS BODILY HARM SUCH AS ASBESTOSIS

AND CANCER. NEVER CLEAN BRAKE COMPO-

NENTS BY USING COMPRESSED AIR; USE ONLY A

VACUUM CLEANER SPECIFICALLY DESIGNED FOR

THE REMOVAL OF BRAKE DUST. IF A VACUUM

CLEANER IS NOT AVAILABLE, CLEAN BRAKE

PARTS USING ONLY WATER-DAMPENED SHOP

TOWELS. DO NOT CREATE BRAKE LINING DUST

BY SANDING THE BRAKE LININGS WHEN SERVIC-

ING A VEHICLE. DISPOSE OF ALL DUST AND DIRT

SUSPECTED OF CONTAINING ASBESTOS FIBERS.

USE ONLY SEALED AIRTIGHT BAGS OR CONTAIN-

ERS. FOLLOW ALL RECOMMENDED SAFETY

PRACTICES PRESCRIBED BY THE OCCUPATIONAL

SAFETY AND HEALTH ADMINISTRATION (OSHA)

AND THE ENVIRONMENTAL PROTECTION AGENCY

(EPA), FOR HANDLING AND DISPOSING OF PROD-

UCTS CONTAINING ASBESTOS.

CAUTION: Use only MoparTbrake fluid or an equiv-

alent from a tightly sealed container. Brake fluid

must conform to DOT 3 specifications. Do not use

petroleum-based fluid because seal damage in the

brake system will result.

CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash it off immediately with water.

CAUTION: During service procedures, grease or

any other foreign material must be kept off the cal-

iper assembly, surfaces of the brake rotor and

external surfaces of the hub. Avoid deformation,

scratching or nicking of the brake rotor and brake

shoe linings.

Fig. 36 Pin Punch Installed

1 ± PARKING BRAKE LEVER

2 ± PIN PUNCH

3 ± OUTPUT CABLE

PLBRAKES 5 - 23

SERVICE PROCEDURES (Continued)

Page 103 of 1285

BRAKE PEDAL

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

WITH AUTOMATIC TRANSAXLE

REMOVAL

(1) Disconnect and isolate the battery negative

cable from its post on the battery.

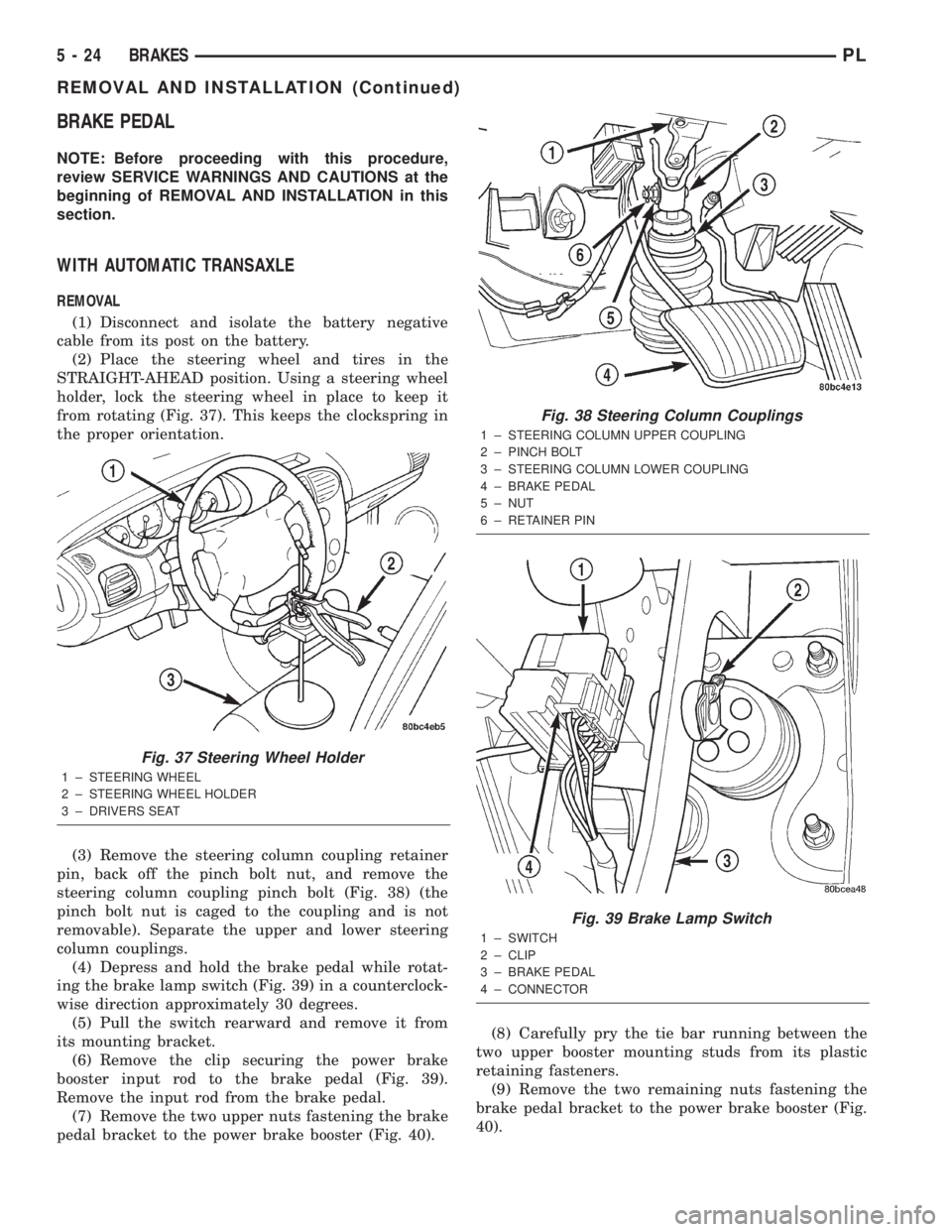

(2) Place the steering wheel and tires in the

STRAIGHT-AHEAD position. Using a steering wheel

holder, lock the steering wheel in place to keep it

from rotating (Fig. 37). This keeps the clockspring in

the proper orientation.

(3) Remove the steering column coupling retainer

pin, back off the pinch bolt nut, and remove the

steering column coupling pinch bolt (Fig. 38) (the

pinch bolt nut is caged to the coupling and is not

removable). Separate the upper and lower steering

column couplings.

(4) Depress and hold the brake pedal while rotat-

ing the brake lamp switch (Fig. 39) in a counterclock-

wise direction approximately 30 degrees.

(5) Pull the switch rearward and remove it from

its mounting bracket.

(6) Remove the clip securing the power brake

booster input rod to the brake pedal (Fig. 39).

Remove the input rod from the brake pedal.

(7) Remove the two upper nuts fastening the brake

pedal bracket to the power brake booster (Fig. 40).(8) Carefully pry the tie bar running between the

two upper booster mounting studs from its plastic

retaining fasteners.

(9) Remove the two remaining nuts fastening the

brake pedal bracket to the power brake booster (Fig.

40).

Fig. 37 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 38 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 39 Brake Lamp Switch

1 ± SWITCH

2 ± CLIP

3 ± BRAKE PEDAL

4 ± CONNECTOR

5 - 24 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 107 of 1285

(4) Gently pull back on the brake pedal until the

pedal stops moving. This will ratchet the switch

plunger backward to the correct adjustment position.

(5) Check the stop lamps to verify they are operat-

ing properly and not staying on when the pedal is in

the released position.

MASTER CYLINDER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal while the engine is not running until a

firm brake pedal is achieved.

(1) With the engine not running, pump the brake

pedal 4-5 strokes until the pedal feel is firm.

(2) Disconnect the negative (ground) cable from

the battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

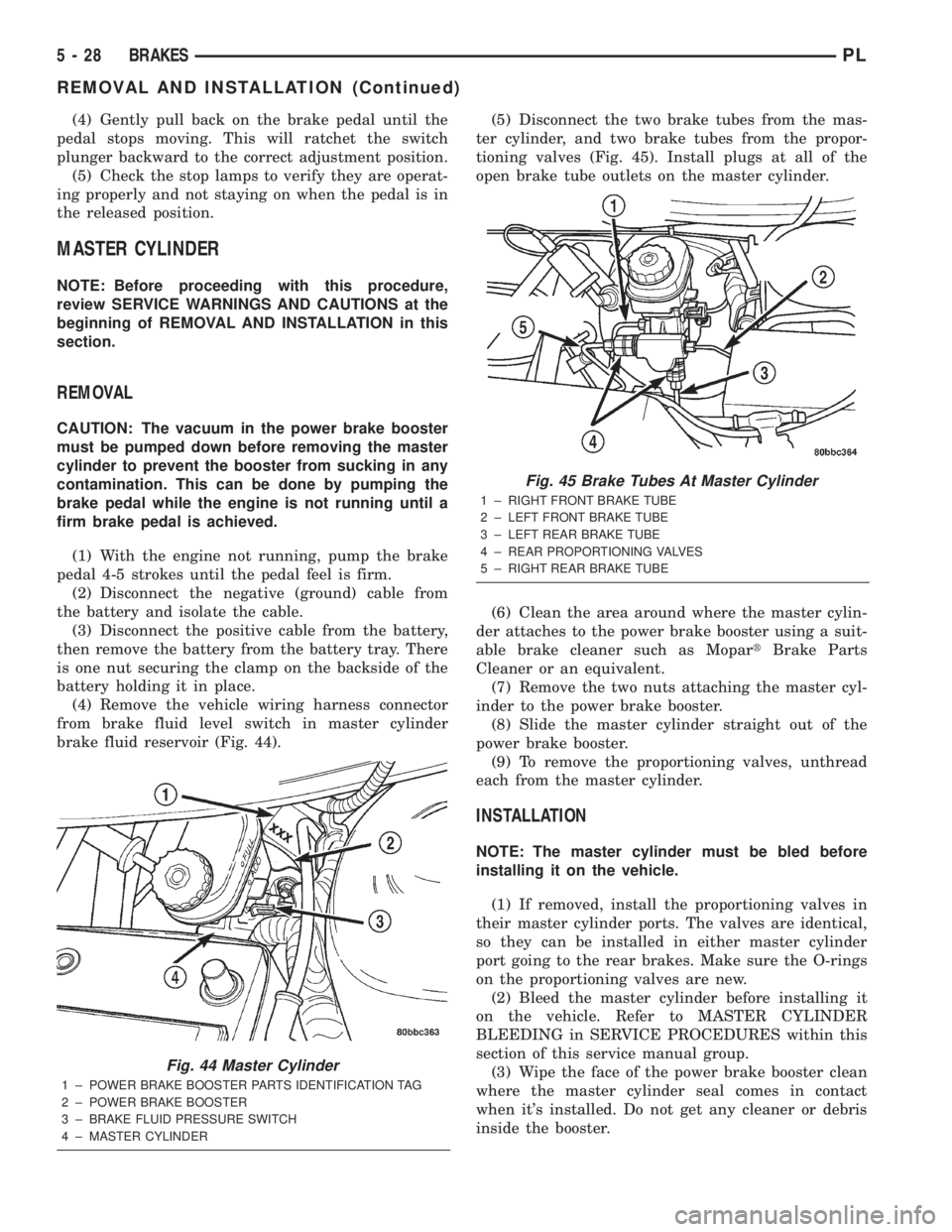

(4) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).(5) Disconnect the two brake tubes from the mas-

ter cylinder, and two brake tubes from the propor-

tioning valves (Fig. 45). Install plugs at all of the

open brake tube outlets on the master cylinder.

(6) Clean the area around where the master cylin-

der attaches to the power brake booster using a suit-

able brake cleaner such as MopartBrake Parts

Cleaner or an equivalent.

(7) Remove the two nuts attaching the master cyl-

inder to the power brake booster.

(8) Slide the master cylinder straight out of the

power brake booster.

(9) To remove the proportioning valves, unthread

each from the master cylinder.

INSTALLATION

NOTE: The master cylinder must be bled before

installing it on the vehicle.

(1) If removed, install the proportioning valves in

their master cylinder ports. The valves are identical,

so they can be installed in either master cylinder

port going to the rear brakes. Make sure the O-rings

on the proportioning valves are new.

(2) Bleed the master cylinder before installing it

on the vehicle. Refer to MASTER CYLINDER

BLEEDING in SERVICE PROCEDURES within this

section of this service manual group.

(3) Wipe the face of the power brake booster clean

where the master cylinder seal comes in contact

when it's installed. Do not get any cleaner or debris

inside the booster.

Fig. 44 Master Cylinder

1 ± POWER BRAKE BOOSTER PARTS IDENTIFICATION TAG

2 ± POWER BRAKE BOOSTER

3 ± BRAKE FLUID PRESSURE SWITCH

4 ± MASTER CYLINDER

Fig. 45 Brake Tubes At Master Cylinder

1 ± RIGHT FRONT BRAKE TUBE

2 ± LEFT FRONT BRAKE TUBE

3 ± LEFT REAR BRAKE TUBE

4 ± REAR PROPORTIONING VALVES

5 ± RIGHT REAR BRAKE TUBE

5 - 28 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 108 of 1285

(4) Position the master cylinder on the studs of the

power brake booster, aligning the push rod of the

power brake booster with master cylinder piston

push rod. Carefully push the master cylinder onto

the studs until it contacts the face of the booster.

(5) Install the two master cylinder mounting nuts

and tighten each to a torque of 28 N´m (250 in. lbs.).

(6) Connect the four brake tubes to the master cyl-

inder and proportioning valve ports (Fig. 45). Tighten

all tube nuts to a torque of 17 N´m (145 in. lbs.).

(7) Connect the brake fluid level switch wiring

connector.

(8) Install the battery and clamp it in place.

(9) Connect the positive, then the negative

(ground) cable on the battery.

(10) Fill the master cylinder to the proper level.

(11) Road test the vehicle to ensure proper opera-

tion of the brakes.

BRAKE FLUID RESERVOIR

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

NOTE: The master cylinder does not need to be

removed from the power brake booster for removal

and installation of the brake fluid reservoir.

REMOVAL

(1) Clean the master cylinder housing and brake

fluid reservoir exterior surfaces.

(2) Remove the brake fluid reservoir cap. Using a

clean syringe or siphoning tool, empty as much brake

fluid as possible from the reservoir.

(3) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).

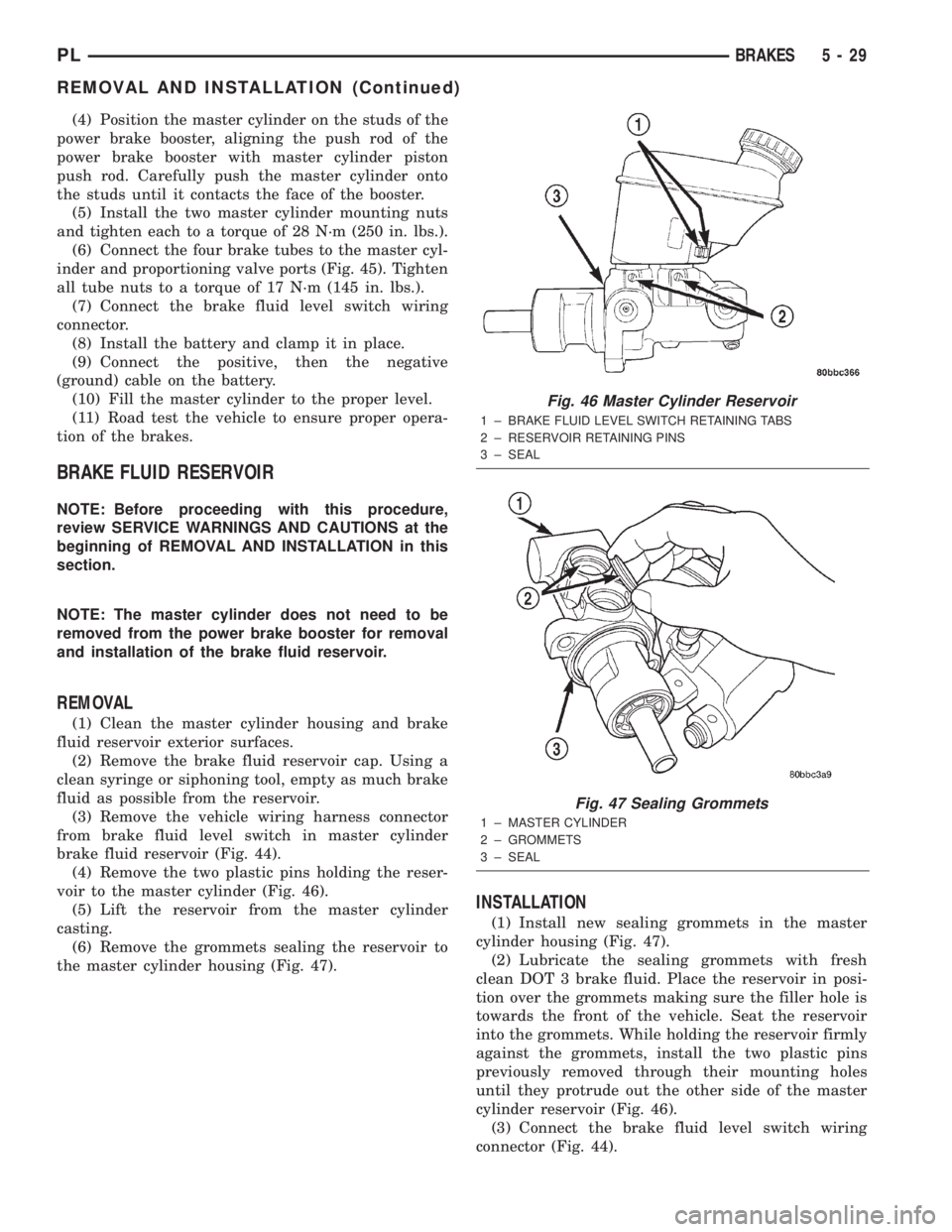

(4) Remove the two plastic pins holding the reser-

voir to the master cylinder (Fig. 46).

(5) Lift the reservoir from the master cylinder

casting.

(6) Remove the grommets sealing the reservoir to

the master cylinder housing (Fig. 47).

INSTALLATION

(1) Install new sealing grommets in the master

cylinder housing (Fig. 47).

(2) Lubricate the sealing grommets with fresh

clean DOT 3 brake fluid. Place the reservoir in posi-

tion over the grommets making sure the filler hole is

towards the front of the vehicle. Seat the reservoir

into the grommets. While holding the reservoir firmly

against the grommets, install the two plastic pins

previously removed through their mounting holes

until they protrude out the other side of the master

cylinder reservoir (Fig. 46).

(3) Connect the brake fluid level switch wiring

connector (Fig. 44).

Fig. 46 Master Cylinder Reservoir

1 ± BRAKE FLUID LEVEL SWITCH RETAINING TABS

2 ± RESERVOIR RETAINING PINS

3 ± SEAL

Fig. 47 Sealing Grommets

1 ± MASTER CYLINDER

2 ± GROMMETS

3 ± SEAL

PLBRAKES 5 - 29

REMOVAL AND INSTALLATION (Continued)

Page 109 of 1285

(4) Fill the reservoir with fresh clean DOT 3 brake

fluid. Refer to BRAKE FLUID LEVEL CHECKING

in the SERVICE PROCEDURES section in this sec-

tion of this service manual group.

BRAKE FLUID LEVEL SWITCH

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Remove the vehicle wiring harness connector

from brake fluid level switch in master cylinder

brake fluid reservoir (Fig. 44).

(2) Push together the retaining tabs holding the

brake fluid level switch in place in the brake fluid

reservoir (Fig. 46).

(3) Pull the brake fluid level switch out the other

side of the reservoir.

INSTALLATION

(1) Align the brake fluid level switch with its

mounting hole on the left side of the master cylinder

brake fluid reservoir. Push the switch into the fluid

reservoir until the switch retaining tabs are

expanded on the other side of the reservoir, locking it

in place (Fig. 46).

(2) Connect the brake fluid level switch wiring

connector (Fig. 44).

POWER BRAKE BOOSTER

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Disconnect negative (ground) cable from the

battery and isolate the cable.

(2) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

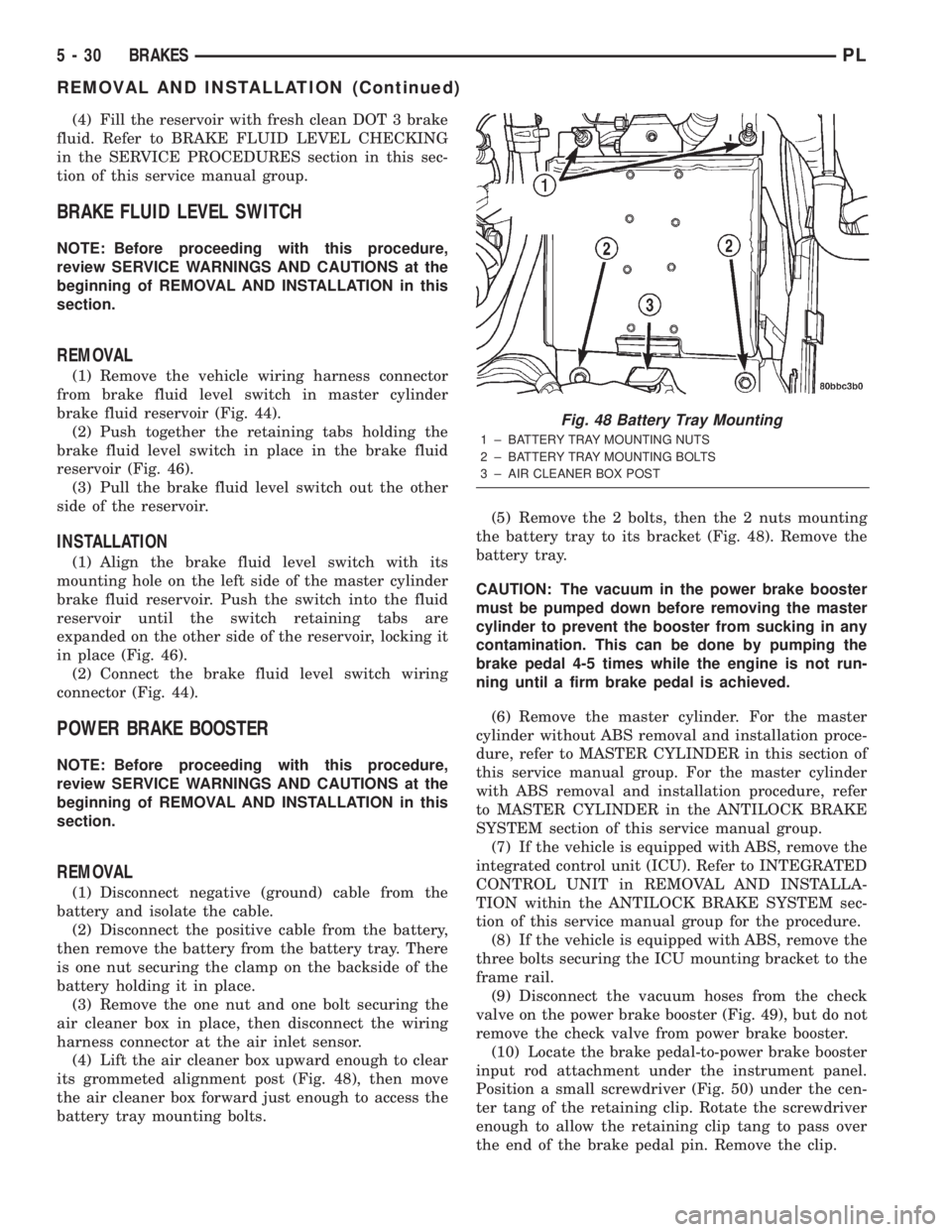

(3) Remove the one nut and one bolt securing the

air cleaner box in place, then disconnect the wiring

harness connector at the air inlet sensor.

(4) Lift the air cleaner box upward enough to clear

its grommeted alignment post (Fig. 48), then move

the air cleaner box forward just enough to access the

battery tray mounting bolts.(5) Remove the 2 bolts, then the 2 nuts mounting

the battery tray to its bracket (Fig. 48). Remove the

battery tray.

CAUTION: The vacuum in the power brake booster

must be pumped down before removing the master

cylinder to prevent the booster from sucking in any

contamination. This can be done by pumping the

brake pedal 4-5 times while the engine is not run-

ning until a firm brake pedal is achieved.

(6) Remove the master cylinder. For the master

cylinder without ABS removal and installation proce-

dure, refer to MASTER CYLINDER in this section of

this service manual group. For the master cylinder

with ABS removal and installation procedure, refer

to MASTER CYLINDER in the ANTILOCK BRAKE

SYSTEM section of this service manual group.

(7) If the vehicle is equipped with ABS, remove the

integrated control unit (ICU). Refer to INTEGRATED

CONTROL UNIT in REMOVAL AND INSTALLA-

TION within the ANTILOCK BRAKE SYSTEM sec-

tion of this service manual group for the procedure.

(8) If the vehicle is equipped with ABS, remove the

three bolts securing the ICU mounting bracket to the

frame rail.

(9) Disconnect the vacuum hoses from the check

valve on the power brake booster (Fig. 49), but do not

remove the check valve from power brake booster.

(10) Locate the brake pedal-to-power brake booster

input rod attachment under the instrument panel.

Position a small screwdriver (Fig. 50) under the cen-

ter tang of the retaining clip. Rotate the screwdriver

enough to allow the retaining clip tang to pass over

the end of the brake pedal pin. Remove the clip.

Fig. 48 Battery Tray Mounting

1 ± BATTERY TRAY MOUNTING NUTS

2 ± BATTERY TRAY MOUNTING BOLTS

3 ± AIR CLEANER BOX POST

5 - 30 BRAKESPL

REMOVAL AND INSTALLATION (Continued)