warning DODGE NEON 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 158 of 1285

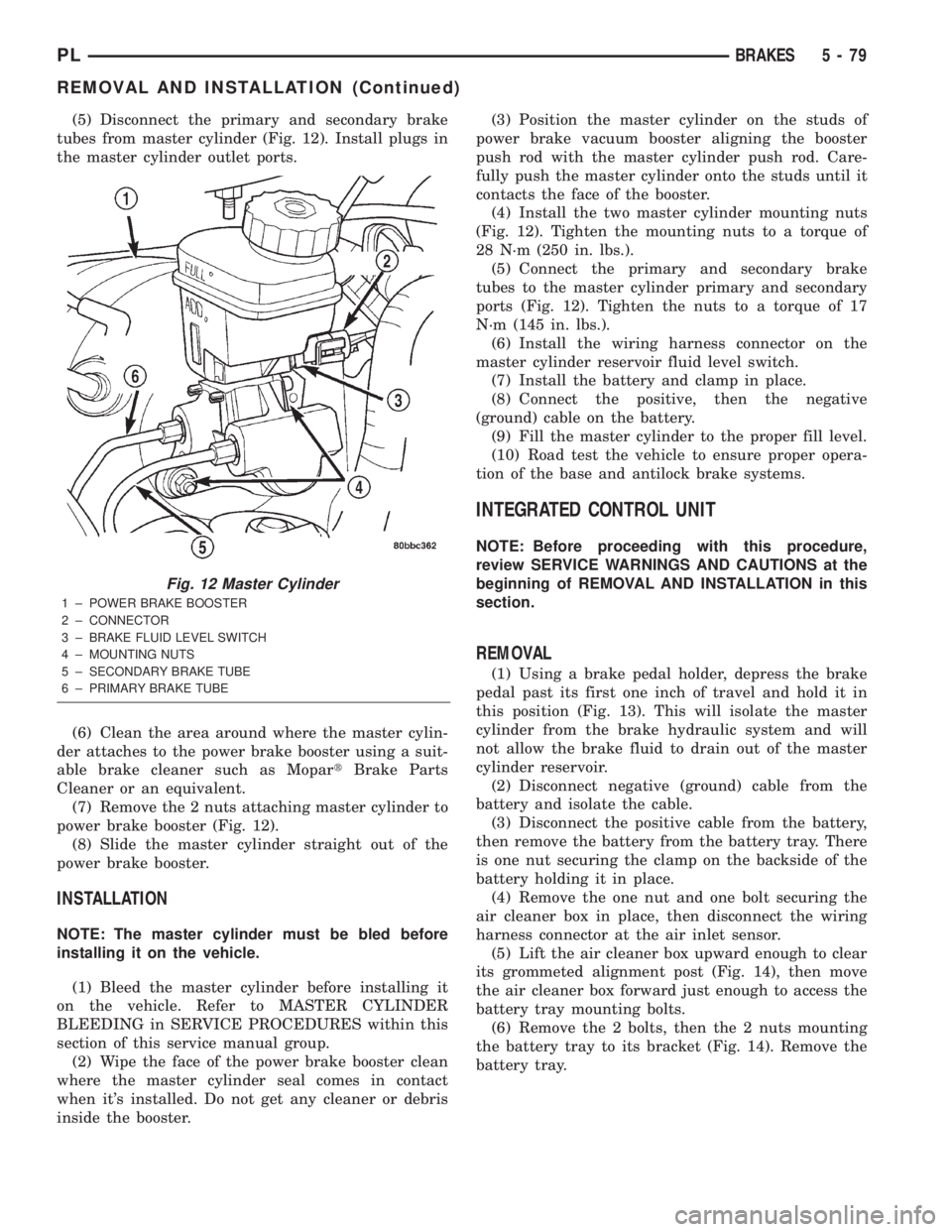

(5) Disconnect the primary and secondary brake

tubes from master cylinder (Fig. 12). Install plugs in

the master cylinder outlet ports.

(6) Clean the area around where the master cylin-

der attaches to the power brake booster using a suit-

able brake cleaner such as MopartBrake Parts

Cleaner or an equivalent.

(7) Remove the 2 nuts attaching master cylinder to

power brake booster (Fig. 12).

(8) Slide the master cylinder straight out of the

power brake booster.

INSTALLATION

NOTE: The master cylinder must be bled before

installing it on the vehicle.

(1) Bleed the master cylinder before installing it

on the vehicle. Refer to MASTER CYLINDER

BLEEDING in SERVICE PROCEDURES within this

section of this service manual group.

(2) Wipe the face of the power brake booster clean

where the master cylinder seal comes in contact

when it's installed. Do not get any cleaner or debris

inside the booster.(3) Position the master cylinder on the studs of

power brake vacuum booster aligning the booster

push rod with the master cylinder push rod. Care-

fully push the master cylinder onto the studs until it

contacts the face of the booster.

(4) Install the two master cylinder mounting nuts

(Fig. 12). Tighten the mounting nuts to a torque of

28 N´m (250 in. lbs.).

(5) Connect the primary and secondary brake

tubes to the master cylinder primary and secondary

ports (Fig. 12). Tighten the nuts to a torque of 17

N´m (145 in. lbs.).

(6) Install the wiring harness connector on the

master cylinder reservoir fluid level switch.

(7) Install the battery and clamp in place.

(8) Connect the positive, then the negative

(ground) cable on the battery.

(9) Fill the master cylinder to the proper fill level.

(10) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

INTEGRATED CONTROL UNIT

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Using a brake pedal holder, depress the brake

pedal past its first one inch of travel and hold it in

this position (Fig. 13). This will isolate the master

cylinder from the brake hydraulic system and will

not allow the brake fluid to drain out of the master

cylinder reservoir.

(2) Disconnect negative (ground) cable from the

battery and isolate the cable.

(3) Disconnect the positive cable from the battery,

then remove the battery from the battery tray. There

is one nut securing the clamp on the backside of the

battery holding it in place.

(4) Remove the one nut and one bolt securing the

air cleaner box in place, then disconnect the wiring

harness connector at the air inlet sensor.

(5) Lift the air cleaner box upward enough to clear

its grommeted alignment post (Fig. 14), then move

the air cleaner box forward just enough to access the

battery tray mounting bolts.

(6) Remove the 2 bolts, then the 2 nuts mounting

the battery tray to its bracket (Fig. 14). Remove the

battery tray.

Fig. 12 Master Cylinder

1 ± POWER BRAKE BOOSTER

2 ± CONNECTOR

3 ± BRAKE FLUID LEVEL SWITCH

4 ± MOUNTING NUTS

5 ± SECONDARY BRAKE TUBE

6 ± PRIMARY BRAKE TUBE

PLBRAKES 5 - 79

REMOVAL AND INSTALLATION (Continued)

Page 160 of 1285

(14) Refer to DISASSEMBLY AND ASSEMBLY in

this section of this group for the procedure on sepa-

rating and reattaching the CAB to the HCU.

INSTALLATION

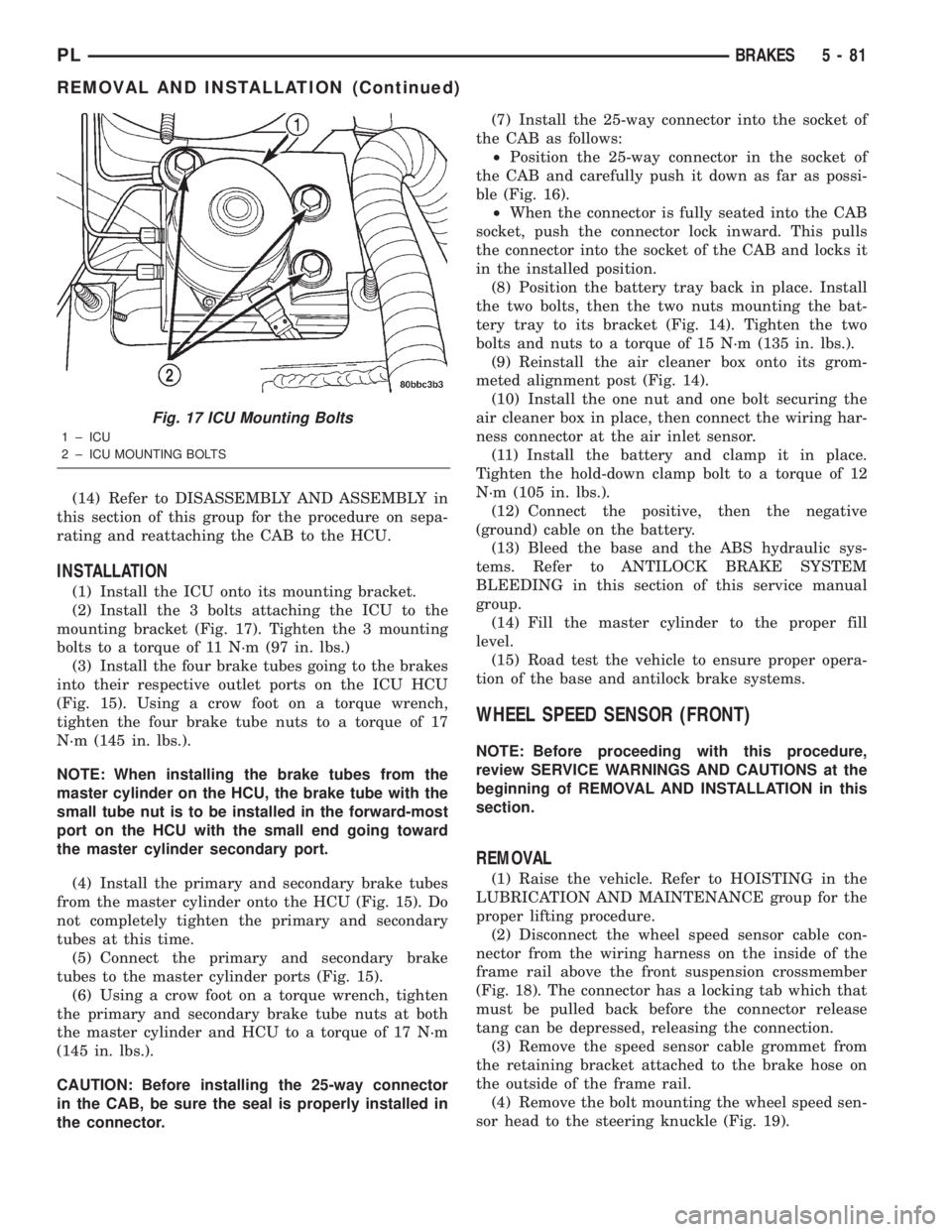

(1) Install the ICU onto its mounting bracket.

(2) Install the 3 bolts attaching the ICU to the

mounting bracket (Fig. 17). Tighten the 3 mounting

bolts to a torque of 11 N´m (97 in. lbs.)

(3) Install the four brake tubes going to the brakes

into their respective outlet ports on the ICU HCU

(Fig. 15). Using a crow foot on a torque wrench,

tighten the four brake tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: When installing the brake tubes from the

master cylinder on the HCU, the brake tube with the

small tube nut is to be installed in the forward-most

port on the HCU with the small end going toward

the master cylinder secondary port.

(4) Install the primary and secondary brake tubes

from the master cylinder onto the HCU (Fig. 15). Do

not completely tighten the primary and secondary

tubes at this time.

(5) Connect the primary and secondary brake

tubes to the master cylinder ports (Fig. 15).

(6) Using a crow foot on a torque wrench, tighten

the primary and secondary brake tube nuts at both

the master cylinder and HCU to a torque of 17 N´m

(145 in. lbs.).

CAUTION: Before installing the 25-way connector

in the CAB, be sure the seal is properly installed in

the connector.(7) Install the 25-way connector into the socket of

the CAB as follows:

²Position the 25-way connector in the socket of

the CAB and carefully push it down as far as possi-

ble (Fig. 16).

²When the connector is fully seated into the CAB

socket, push the connector lock inward. This pulls

the connector into the socket of the CAB and locks it

in the installed position.

(8) Position the battery tray back in place. Install

the two bolts, then the two nuts mounting the bat-

tery tray to its bracket (Fig. 14). Tighten the two

bolts and nuts to a torque of 15 N´m (135 in. lbs.).

(9) Reinstall the air cleaner box onto its grom-

meted alignment post (Fig. 14).

(10) Install the one nut and one bolt securing the

air cleaner box in place, then connect the wiring har-

ness connector at the air inlet sensor.

(11) Install the battery and clamp it in place.

Tighten the hold-down clamp bolt to a torque of 12

N´m (105 in. lbs.).

(12) Connect the positive, then the negative

(ground) cable on the battery.

(13) Bleed the base and the ABS hydraulic sys-

tems. Refer to ANTILOCK BRAKE SYSTEM

BLEEDING in this section of this service manual

group.

(14) Fill the master cylinder to the proper fill

level.

(15) Road test the vehicle to ensure proper opera-

tion of the base and antilock brake systems.

WHEEL SPEED SENSOR (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Disconnect the wheel speed sensor cable con-

nector from the wiring harness on the inside of the

frame rail above the front suspension crossmember

(Fig. 18). The connector has a locking tab which that

must be pulled back before the connector release

tang can be depressed, releasing the connection.

(3) Remove the speed sensor cable grommet from

the retaining bracket attached to the brake hose on

the outside of the frame rail.

(4) Remove the bolt mounting the wheel speed sen-

sor head to the steering knuckle (Fig. 19).

Fig. 17 ICU Mounting Bolts

1 ± ICU

2 ± ICU MOUNTING BOLTS

PLBRAKES 5 - 81

REMOVAL AND INSTALLATION (Continued)

Page 162 of 1285

WHEEL SPEED SENSOR (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the tire and wheel assembly from the

vehicle.

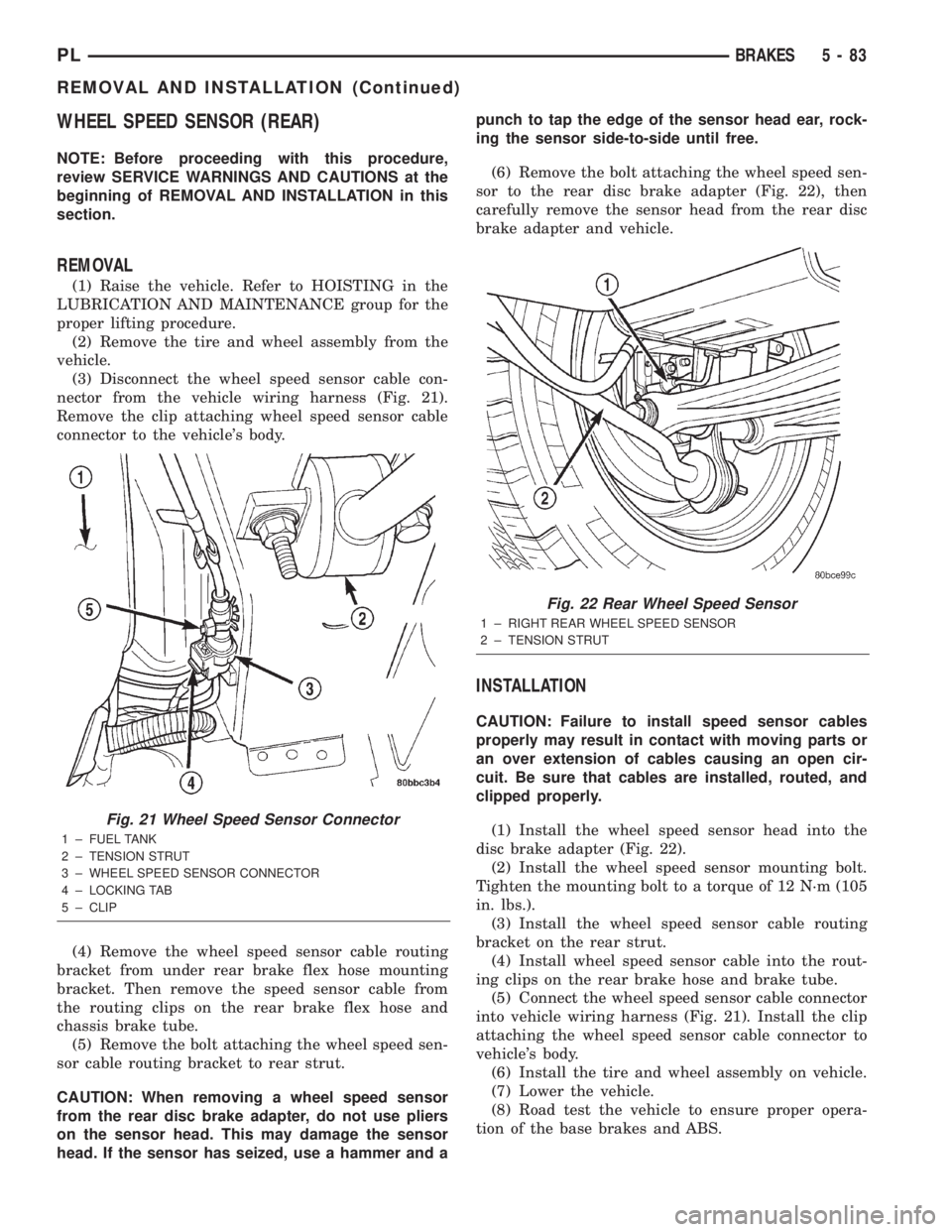

(3) Disconnect the wheel speed sensor cable con-

nector from the vehicle wiring harness (Fig. 21).

Remove the clip attaching wheel speed sensor cable

connector to the vehicle's body.

(4) Remove the wheel speed sensor cable routing

bracket from under rear brake flex hose mounting

bracket. Then remove the speed sensor cable from

the routing clips on the rear brake flex hose and

chassis brake tube.

(5) Remove the bolt attaching the wheel speed sen-

sor cable routing bracket to rear strut.

CAUTION: When removing a wheel speed sensor

from the rear disc brake adapter, do not use pliers

on the sensor head. This may damage the sensor

head. If the sensor has seized, use a hammer and apunch to tap the edge of the sensor head ear, rock-

ing the sensor side-to-side until free.

(6) Remove the bolt attaching the wheel speed sen-

sor to the rear disc brake adapter (Fig. 22), then

carefully remove the sensor head from the rear disc

brake adapter and vehicle.

INSTALLATION

CAUTION: Failure to install speed sensor cables

properly may result in contact with moving parts or

an over extension of cables causing an open cir-

cuit. Be sure that cables are installed, routed, and

clipped properly.

(1) Install the wheel speed sensor head into the

disc brake adapter (Fig. 22).

(2) Install the wheel speed sensor mounting bolt.

Tighten the mounting bolt to a torque of 12 N´m (105

in. lbs.).

(3) Install the wheel speed sensor cable routing

bracket on the rear strut.

(4) Install wheel speed sensor cable into the rout-

ing clips on the rear brake hose and brake tube.

(5) Connect the wheel speed sensor cable connector

into vehicle wiring harness (Fig. 21). Install the clip

attaching the wheel speed sensor cable connector to

vehicle's body.

(6) Install the tire and wheel assembly on vehicle.

(7) Lower the vehicle.

(8) Road test the vehicle to ensure proper opera-

tion of the base brakes and ABS.

Fig. 21 Wheel Speed Sensor Connector

1 ± FUEL TANK

2 ± TENSION STRUT

3 ± WHEEL SPEED SENSOR CONNECTOR

4 ± LOCKING TAB

5 ± CLIP

Fig. 22 Rear Wheel Speed Sensor

1 ± RIGHT REAR WHEEL SPEED SENSOR

2 ± TENSION STRUT

PLBRAKES 5 - 83

REMOVAL AND INSTALLATION (Continued)

Page 184 of 1285

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE WORKING ON VEHI-

CLE. RELIEVE PRESSURE BY PLACING A SHOP

TOWEL OVER THE CAP AND WITHOUT PUSHING

DOWN ROTATE IT COUNTERCLOCKWISE TO THE

FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

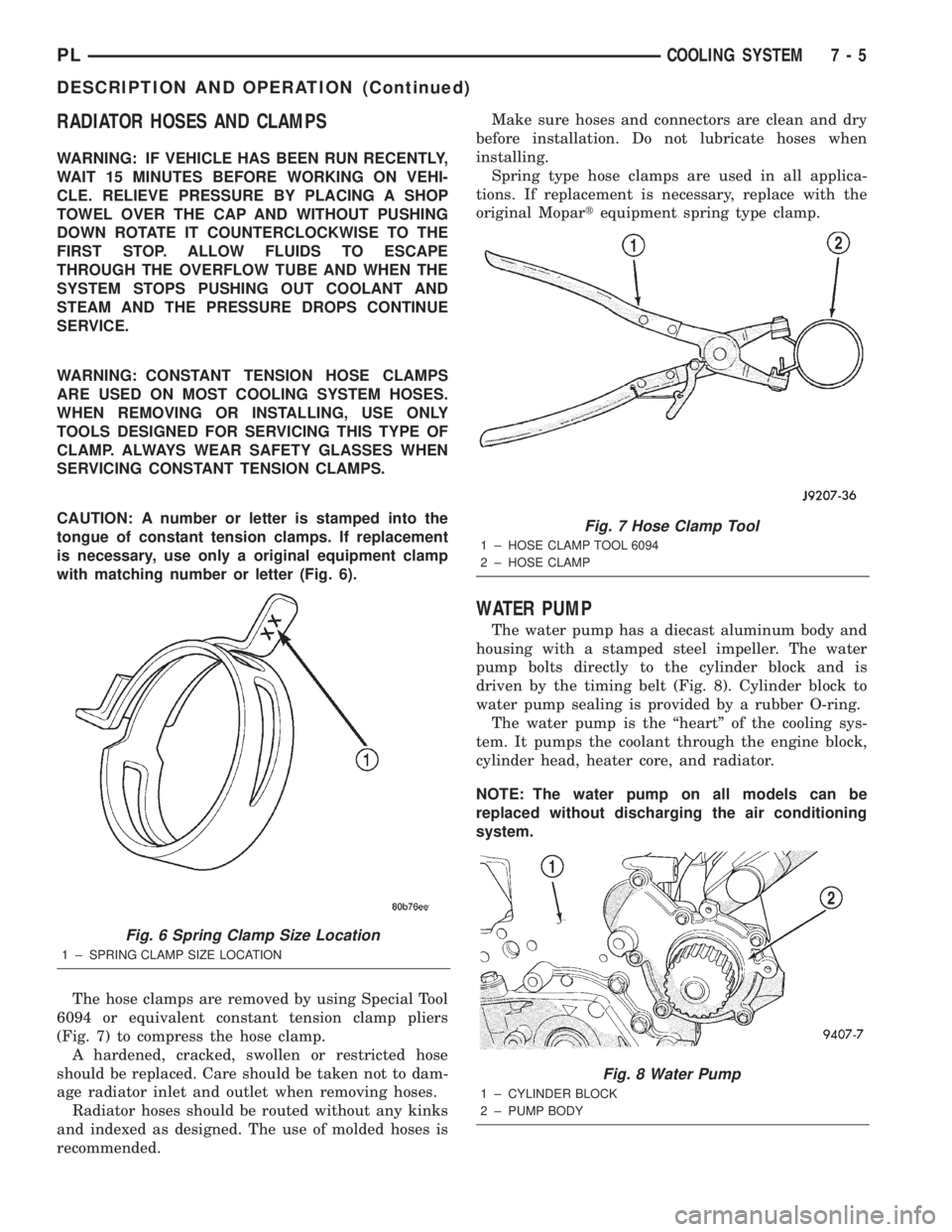

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 6).

The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 7) to compress the hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Care should be taken not to dam-

age radiator inlet and outlet when removing hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.Make sure hoses and connectors are clean and dry

before installation. Do not lubricate hoses when

installing.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary, replace with the

original Mopartequipment spring type clamp.

WATER PUMP

The water pump has a diecast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the cylinder block and is

driven by the timing belt (Fig. 8). Cylinder block to

water pump sealing is provided by a rubber O-ring.

The water pump is the ªheartº of the cooling sys-

tem. It pumps the coolant through the engine block,

cylinder head, heater core, and radiator.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

Fig. 6 Spring Clamp Size Location

1 ± SPRING CLAMP SIZE LOCATION

Fig. 7 Hose Clamp Tool

1 ± HOSE CLAMP TOOL 6094

2 ± HOSE CLAMP

Fig. 8 Water Pump

1 ± CYLINDER BLOCK

2 ± PUMP BODY

PLCOOLING SYSTEM 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 186 of 1285

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open engine thermostat?1. Refer to On Board Diagnostic in

Group 25. Replace thermostat, if

necessary. If a (DTC) has not been

set, the problem may be with the

temperature gauge.

2. Is the temperature gauge (if

equipped) connected to the

temperature gauge coolant sensor

on the engine?2. Check the connector at the

engine coolant sensor. Refer to

Group 8E. Repair as necessary.

3. Is the temperature gauge (if

equipped) operating OK?3. Check Gauge operation. Refer to

Group 8E. Repair as necessary.

4. Coolant level low during cold

ambient temperature, accompanied

by poor heater performance.4. Check coolant level in the coolant

recovery/reserve container and the

radiator. Inspect the system for

leaks. Repair as necessary. Refer to

WARNINGS in this section before

removing pressure cap.

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM.1. Trailer being towed, a steep hill

being climbed, vehicle being

operated in slow moving traffic, or

engine idling during high ambient

(outside) temperatures with air

conditioning on. High altitudes

Could aggravate these conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and drive the vehicle

without any of the previous

conditions. Observe the temperature

gauge the gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause of the

overheating and repair. Refer to

POSSIBLE CAUSES in this section.

2. Is temperature gauge (if

equipped) reading correctly?2. Check gauge. Refer to Group 8E.

Repair as necessary.

3. Is temperature warning lamp (if

equipped) illuminating

unnecessarily?3. Check warning lamp operation.

Refer to Group 8E. Repair as

necessary.

4. Coolant low in recovery/reserve

container and radiator?4. Check for coolant leaks and

repair as necessary. Refer to

Checking Cooling System for Leaks

in this section.

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following step 6.5. Tighten cap.

PLCOOLING SYSTEM 7 - 7

Page 187 of 1285

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM. (CONT.)6. Poor seals at radiator cap. 6. (a) Check condition of cap and

cap seals. Refer to Radiator cap

Inspection. Replace cap if

necessary.

(b) Check condition of filler neck. If

neck is bent or damaged, replace

neck.

7. Coolant level low in radiator, but

not in coolant recovery/reserve

container. This indicates the

radiator is not drawing coolant from

the coolant recovery/reserve

container as the engine cools. As

the engine cools, a vacuum is

formed inside the cooling system. If

the radiator cap seals are defective,

or the cooling system has a leak, a

vacuum cannot be formed.7. (a) Check condition of radiator

cap and cap seals. Replace cap if

necessary.

(b) Check condition of filler neck.

Replace if damaged.

(c) Check condition of hose from

filler neck to coolant container. It

should be tight at both ends without

any kinks or tears. Replace hose as

necessary.

(d) Check coolant recovery/reserve

container and hose for blockage.

Repair as necessary.

8. Freeze point of coolant not

correct. Mixture ratio may be too

rich.8. Check coolant concentration.

Refer to Coolant Concentration

Testing in this section. Adjust

glycol-to-water ration as required.

9. Coolant not flowing through

system.9. Check for coolant flow at filler

neck with some coolant removed,

engine warm, and thermostat open.

Coolant should be observed flowing

through filler neck. If flow is not

observed, determine reason for lack

of flow and repair as necessary.

10. Radiator or A/C condenser fins

are dirty or clogged.10. Clean obstruction from fins.

11. Radiator core is plugged or

corroded.11. Replace or re-core radiator.

12. Fuel or ignition system

problems.12. Refer to Fuel and Ignition

System groups for diagnosis. Also

refer to the appropriate Powertrain

Diagnostic Procedure manual.

13. Dragging Brakes. 13. Inspect brake system and repair

as necessary. Refer to Group 5,

Brakes for diagnosis.

14 Bug screen or other aftermarket

accessory is being used causing

reduced air flow.14. Remove bug screen or

accessory.

15. Thermostat partially or

completely closed. This is more

prevalent on high mileage vehicles.15. Check thermostat operation and

replace as necessary. Refer to

thermostat in this section for

procedure.

7 - 8 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 194 of 1285

WATER PUMP DIAGNOSIS

A quick flow test to tell whether or not the pump is

working is to see if the heater warms properly. A

defective pump will not be able to circulate heated

coolant through the long heater hose.

Another flow test to help determine pump opera-

tion:

WARNING: DO NOT remove radiator cap if the cool-

ing system is hot or under pressure.

(1) Remove cooling system pressure cap.

(2) Remove a small amount of coolant from the

system.

(3) Start the engine and warm up until thermostat

opens.

(4) With the thermostat open and coolant level low,

visually inspect for coolant flow. If flow is present,

the water pump is pumping coolant through the sys-

tem.

COOLING SYSTEM FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedures:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP WITH THE SYSTEM HOT AND

UNDER PRESSURE BECAUSE SERIOUS BURNS

FROM COOLANT CAN OCCUR.

(2) Remove pressure cap when engine is cold,

remove small amount of coolant Idle engine until

thermostat opens, you should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap.

ELECTRIC FAN MOTOR TEST

Refer to Powertrain Diagnostic Manual for proce-

dure.

COOLANT CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37ÉC

(-34ÉF) to -59ÉC (-50ÉF). The use of a hydrometer or a

refractometer can be used to test coolant concentra-

tion.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, andhigher the freeze protection (up to a maximum of

70% by volume glycol).

A refractometer will test the amount of glycol in a

coolant mixture by measuring the amount a beam of

light bends as it passes through the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is only

recommended for limited usage. Refer to appropriate

Technical Service Bulletin(s) regarding use of propy-

lene glycol based coolants.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

Because ethylene glycol and propylene glycol do

not have the same specific gravities, the use of a

hydrometer will be inaccurate. Therefore, Special

Tool 8286 refractometer, is recommended when test-

ing either ethylene or propylene glycol coolants.

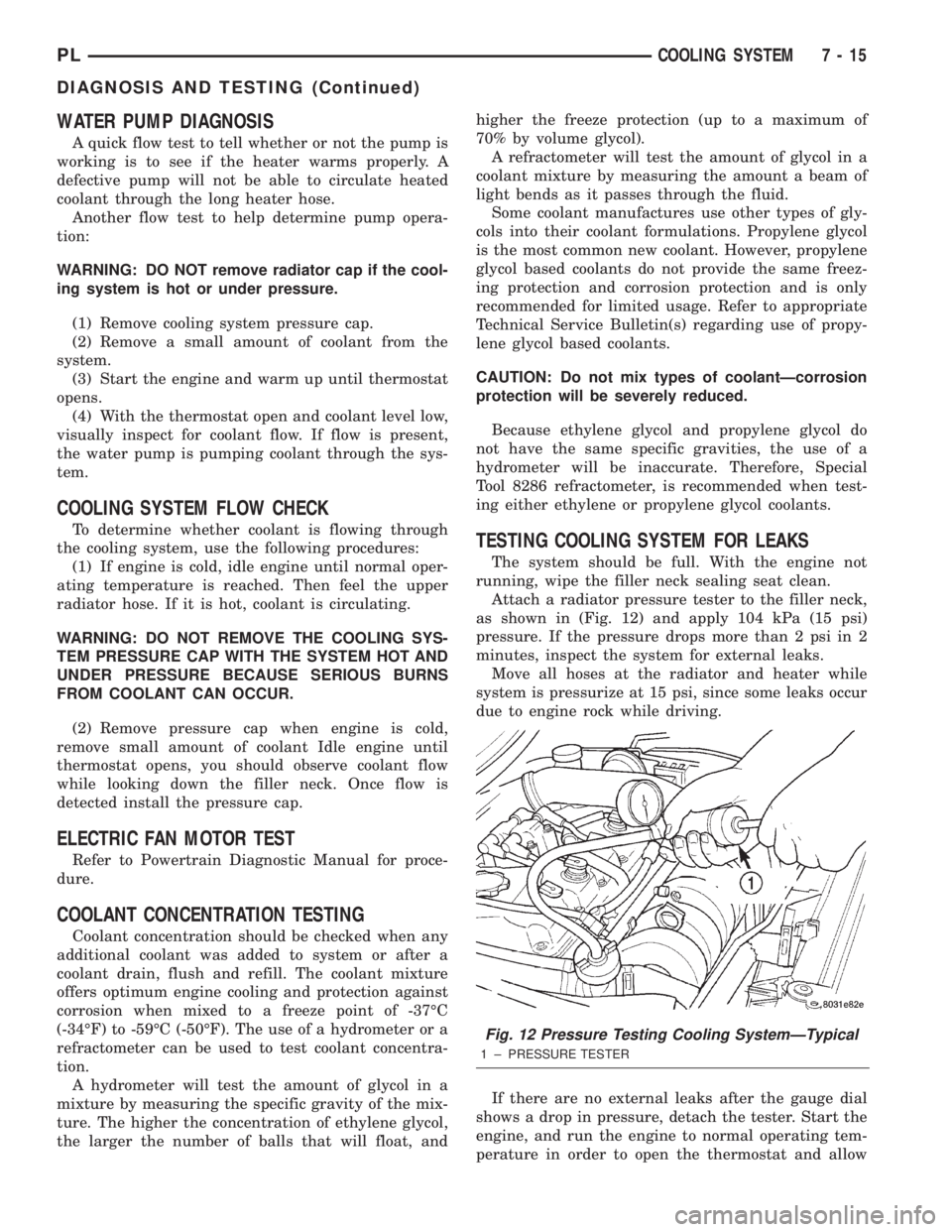

TESTING COOLING SYSTEM FOR LEAKS

The system should be full. With the engine not

running, wipe the filler neck sealing seat clean.

Attach a radiator pressure tester to the filler neck,

as shown in (Fig. 12) and apply 104 kPa (15 psi)

pressure. If the pressure drops more than 2 psi in 2

minutes, inspect the system for external leaks.

Move all hoses at the radiator and heater while

system is pressurize at 15 psi, since some leaks occur

due to engine rock while driving.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start the

engine, and run the engine to normal operating tem-

perature in order to open the thermostat and allow

Fig. 12 Pressure Testing Cooling SystemÐTypical

1 ± PRESSURE TESTER

PLCOOLING SYSTEM 7 - 15

DIAGNOSIS AND TESTING (Continued)

Page 195 of 1285

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH THE PRESSURE TESTER IN

PLACE PRESSURE BUILDS UP QUICKLY. ANY

EXCESSIVE PRESSURE BUILD-UP DUE TO CON-

TINUOUS ENGINE OPERATION MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block,

or cracked cylinder head.

There may be internal leaks, which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil, it indicates an inter-

nal leak in the engine. If there is an internal leak,

the engine must be disassembled for repair.

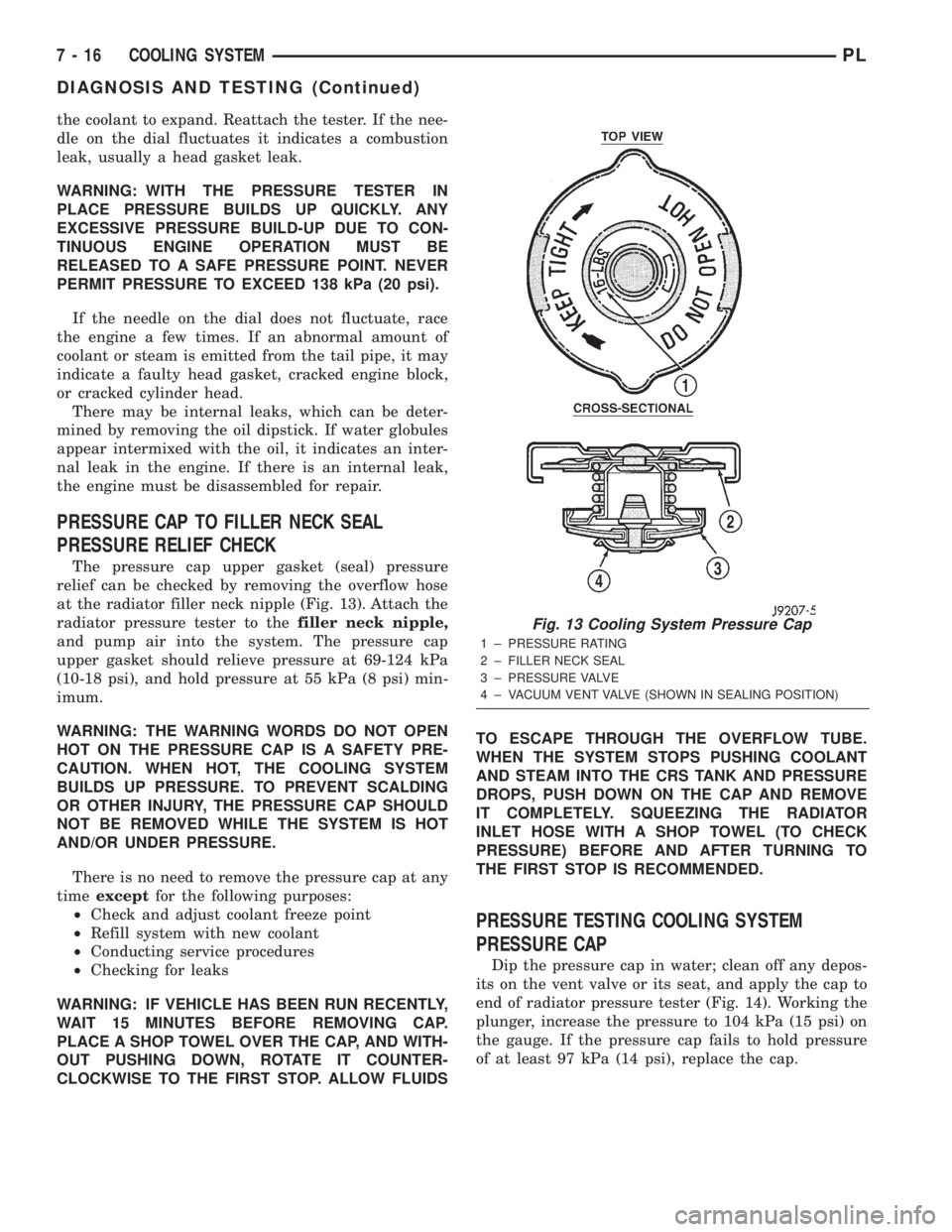

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 13). Attach the

radiator pressure tester to thefiller neck nipple,

and pump air into the system. The pressure cap

upper gasket should relieve pressure at 69-124 kPa

(10-18 psi), and hold pressure at 55 kPa (8 psi) min-

imum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE PRESSURE CAP IS A SAFETY PRE-

CAUTION. WHEN HOT, THE COOLING SYSTEM

BUILDS UP PRESSURE. TO PREVENT SCALDING

OR OTHER INJURY, THE PRESSURE CAP SHOULD

NOT BE REMOVED WHILE THE SYSTEM IS HOT

AND/OR UNDER PRESSURE.

There is no need to remove the pressure cap at any

timeexceptfor the following purposes:

²Check and adjust coolant freeze point

²Refill system with new coolant

²Conducting service procedures

²Checking for leaks

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP.

PLACE A SHOP TOWEL OVER THE CAP, AND WITH-

OUT PUSHING DOWN, ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDSTO ESCAPE THROUGH THE OVERFLOW TUBE.

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS, PUSH DOWN ON THE CAP AND REMOVE

IT COMPLETELY. SQUEEZING THE RADIATOR

INLET HOSE WITH A SHOP TOWEL (TO CHECK

PRESSURE) BEFORE AND AFTER TURNING TO

THE FIRST STOP IS RECOMMENDED.

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water; clean off any depos-

its on the vent valve or its seat, and apply the cap to

end of radiator pressure tester (Fig. 14). Working the

plunger, increase the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the cap.

Fig. 13 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

7 - 16 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 200 of 1285

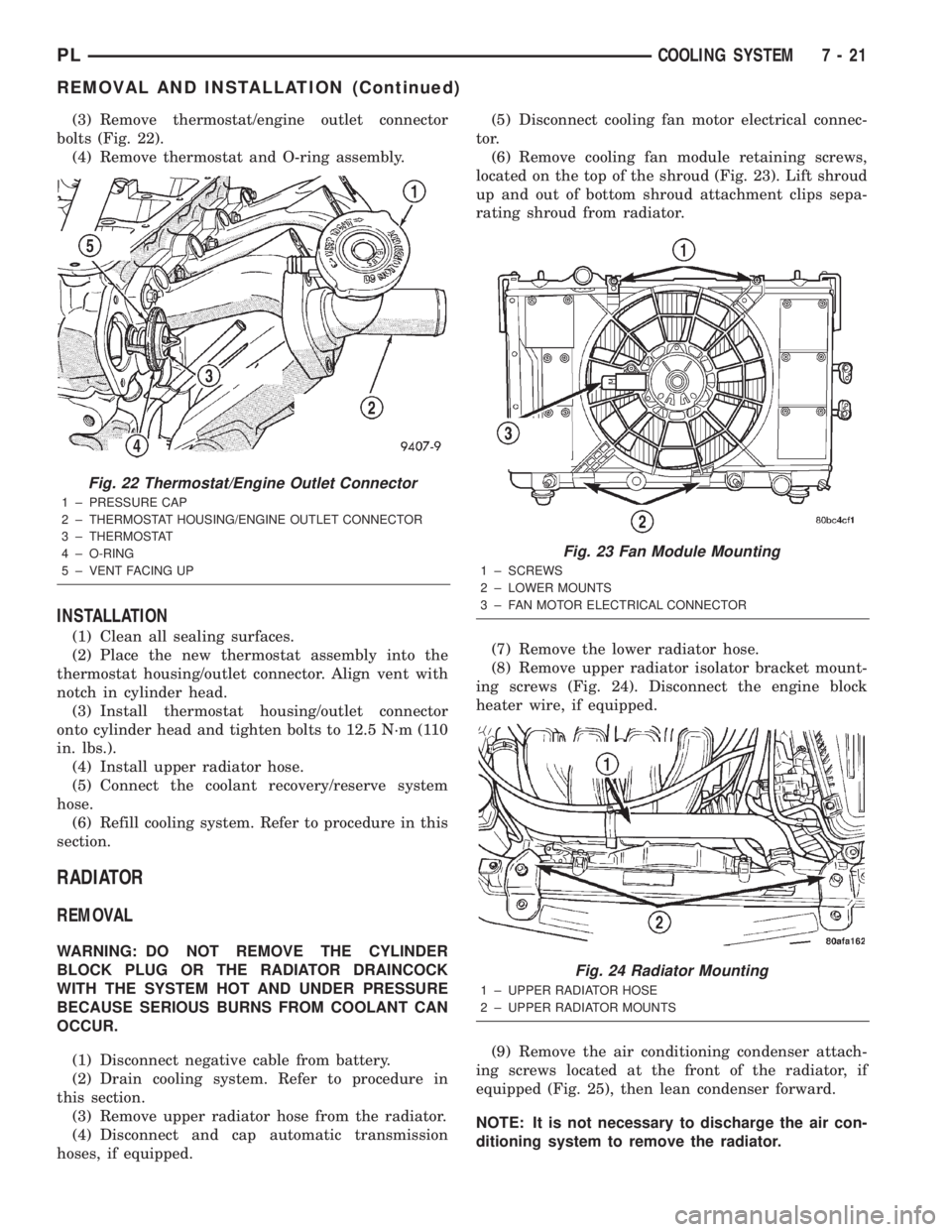

(3) Remove thermostat/engine outlet connector

bolts (Fig. 22).

(4) Remove thermostat and O-ring assembly.

INSTALLATION

(1) Clean all sealing surfaces.

(2) Place the new thermostat assembly into the

thermostat housing/outlet connector. Align vent with

notch in cylinder head.

(3) Install thermostat housing/outlet connector

onto cylinder head and tighten bolts to 12.5 N´m (110

in. lbs.).

(4) Install upper radiator hose.

(5) Connect the coolant recovery/reserve system

hose.

(6) Refill cooling system. Refer to procedure in this

section.

RADIATOR

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain cooling system. Refer to procedure in

this section.

(3) Remove upper radiator hose from the radiator.

(4) Disconnect and cap automatic transmission

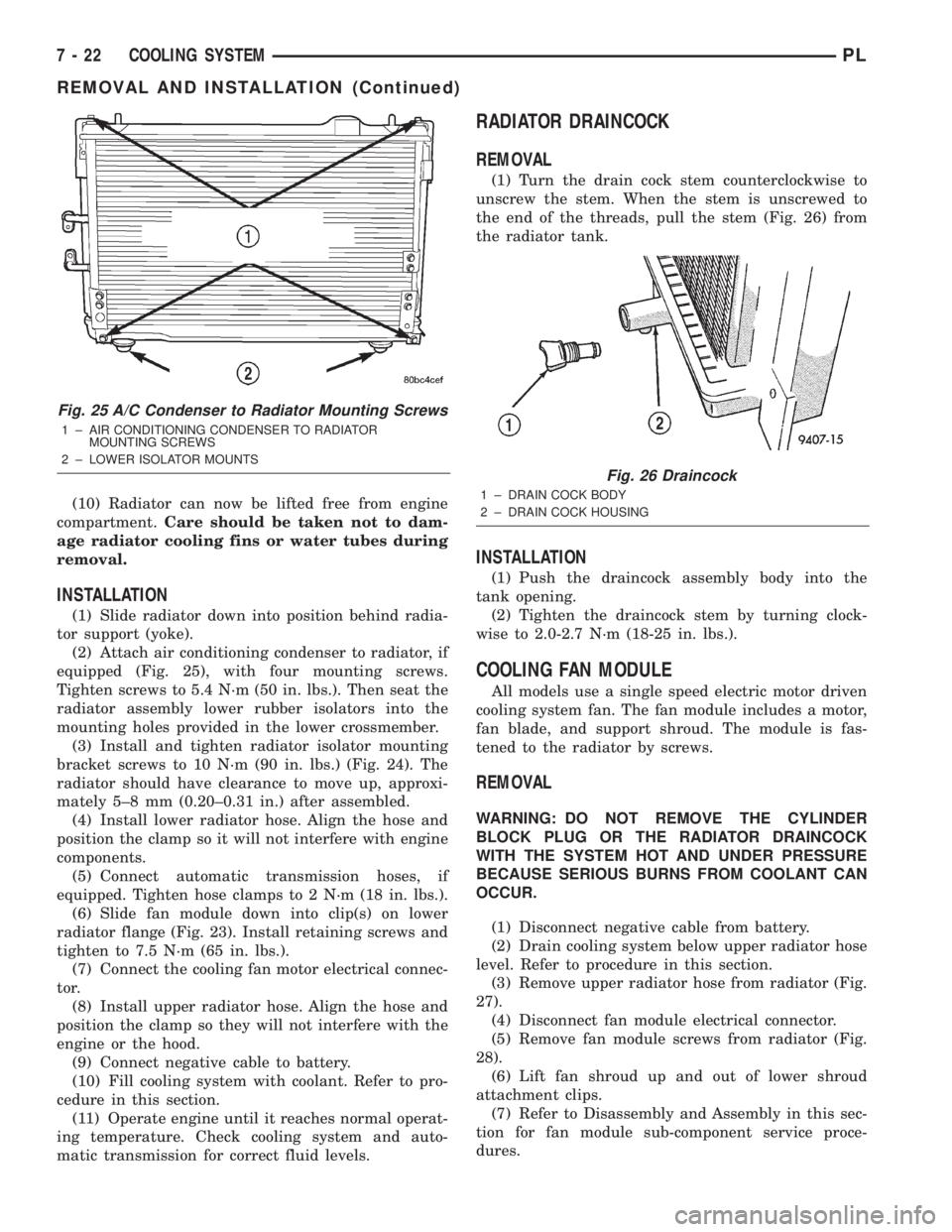

hoses, if equipped.(5) Disconnect cooling fan motor electrical connec-

tor.

(6) Remove cooling fan module retaining screws,

located on the top of the shroud (Fig. 23). Lift shroud

up and out of bottom shroud attachment clips sepa-

rating shroud from radiator.

(7) Remove the lower radiator hose.

(8) Remove upper radiator isolator bracket mount-

ing screws (Fig. 24). Disconnect the engine block

heater wire, if equipped.

(9) Remove the air conditioning condenser attach-

ing screws located at the front of the radiator, if

equipped (Fig. 25), then lean condenser forward.

NOTE: It is not necessary to discharge the air con-

ditioning system to remove the radiator.

Fig. 22 Thermostat/Engine Outlet Connector

1 ± PRESSURE CAP

2 ± THERMOSTAT HOUSING/ENGINE OUTLET CONNECTOR

3 ± THERMOSTAT

4 ± O-RING

5 ± VENT FACING UP

Fig. 23 Fan Module Mounting

1 ± SCREWS

2 ± LOWER MOUNTS

3 ± FAN MOTOR ELECTRICAL CONNECTOR

Fig. 24 Radiator Mounting

1 ± UPPER RADIATOR HOSE

2 ± UPPER RADIATOR MOUNTS

PLCOOLING SYSTEM 7 - 21

REMOVAL AND INSTALLATION (Continued)

Page 201 of 1285

(10) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

INSTALLATION

(1) Slide radiator down into position behind radia-

tor support (yoke).

(2) Attach air conditioning condenser to radiator, if

equipped (Fig. 25), with four mounting screws.

Tighten screws to 5.4 N´m (50 in. lbs.). Then seat the

radiator assembly lower rubber isolators into the

mounting holes provided in the lower crossmember.

(3) Install and tighten radiator isolator mounting

bracket screws to 10 N´m (90 in. lbs.) (Fig. 24). The

radiator should have clearance to move up, approxi-

mately 5±8 mm (0.20±0.31 in.) after assembled.

(4) Install lower radiator hose. Align the hose and

position the clamp so it will not interfere with engine

components.

(5) Connect automatic transmission hoses, if

equipped. Tighten hose clamps to 2 N´m (18 in. lbs.).

(6) Slide fan module down into clip(s) on lower

radiator flange (Fig. 23). Install retaining screws and

tighten to 7.5 N´m (65 in. lbs.).

(7) Connect the cooling fan motor electrical connec-

tor.

(8) Install upper radiator hose. Align the hose and

position the clamp so they will not interfere with the

engine or the hood.

(9) Connect negative cable to battery.

(10) Fill cooling system with coolant. Refer to pro-

cedure in this section.

(11) Operate engine until it reaches normal operat-

ing temperature. Check cooling system and auto-

matic transmission for correct fluid levels.

RADIATOR DRAINCOCK

REMOVAL

(1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 26) from

the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening.

(2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N´m (18-25 in. lbs.).

COOLING FAN MODULE

All models use a single speed electric motor driven

cooling system fan. The fan module includes a motor,

fan blade, and support shroud. The module is fas-

tened to the radiator by screws.

REMOVAL

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain cooling system below upper radiator hose

level. Refer to procedure in this section.

(3) Remove upper radiator hose from radiator (Fig.

27).

(4) Disconnect fan module electrical connector.

(5) Remove fan module screws from radiator (Fig.

28).

(6) Lift fan shroud up and out of lower shroud

attachment clips.

(7) Refer to Disassembly and Assembly in this sec-

tion for fan module sub-component service proce-

dures.

Fig. 25 A/C Condenser to Radiator Mounting Screws

1 ± AIR CONDITIONING CONDENSER TO RADIATOR

MOUNTING SCREWS

2 ± LOWER ISOLATOR MOUNTS

Fig. 26 Draincock

1 ± DRAIN COCK BODY

2 ± DRAIN COCK HOUSING

7 - 22 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)