DODGE NEON 2000 Service Repair Manual

NEON 2000

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56910/w960_56910-0.png

DODGE NEON 2000 Service Repair Manual

Page 1008 of 1285

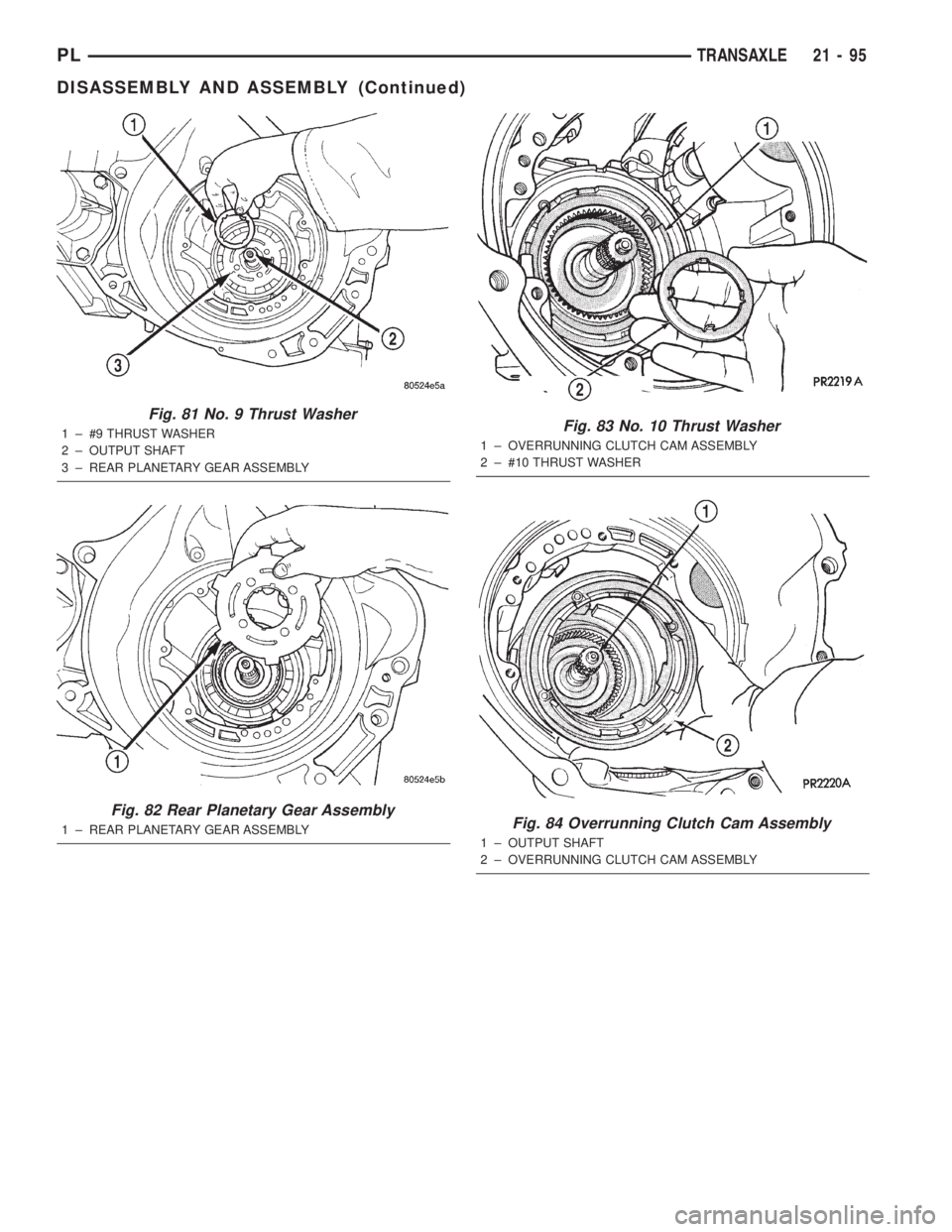

Fig. 81 No. 9 Thrust Washer

1 ± #9 THRUST WASHER

2 ± OUTPUT SHAFT

3 ± REAR PLANETARY GEAR ASSEMBLY

Fig. 82 Rear Planetary Gear Assembly

1 ± REAR PLANETARY GEAR ASSEMBLY

Fig. 83 No. 10 Thrust Washer

1 ± OVERRUNNING CLUTCH CAM ASSEMBLY

2 ± #10 THRUST WASHER

Fig. 84 Overrunning Clutch Cam Assembly

1 ± OUTPUT SHAFT

2 ± OVERRUNNING CLUTCH CAM ASSEMBLY

PLTRANSAXLE 21 - 95

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1009 of 1285

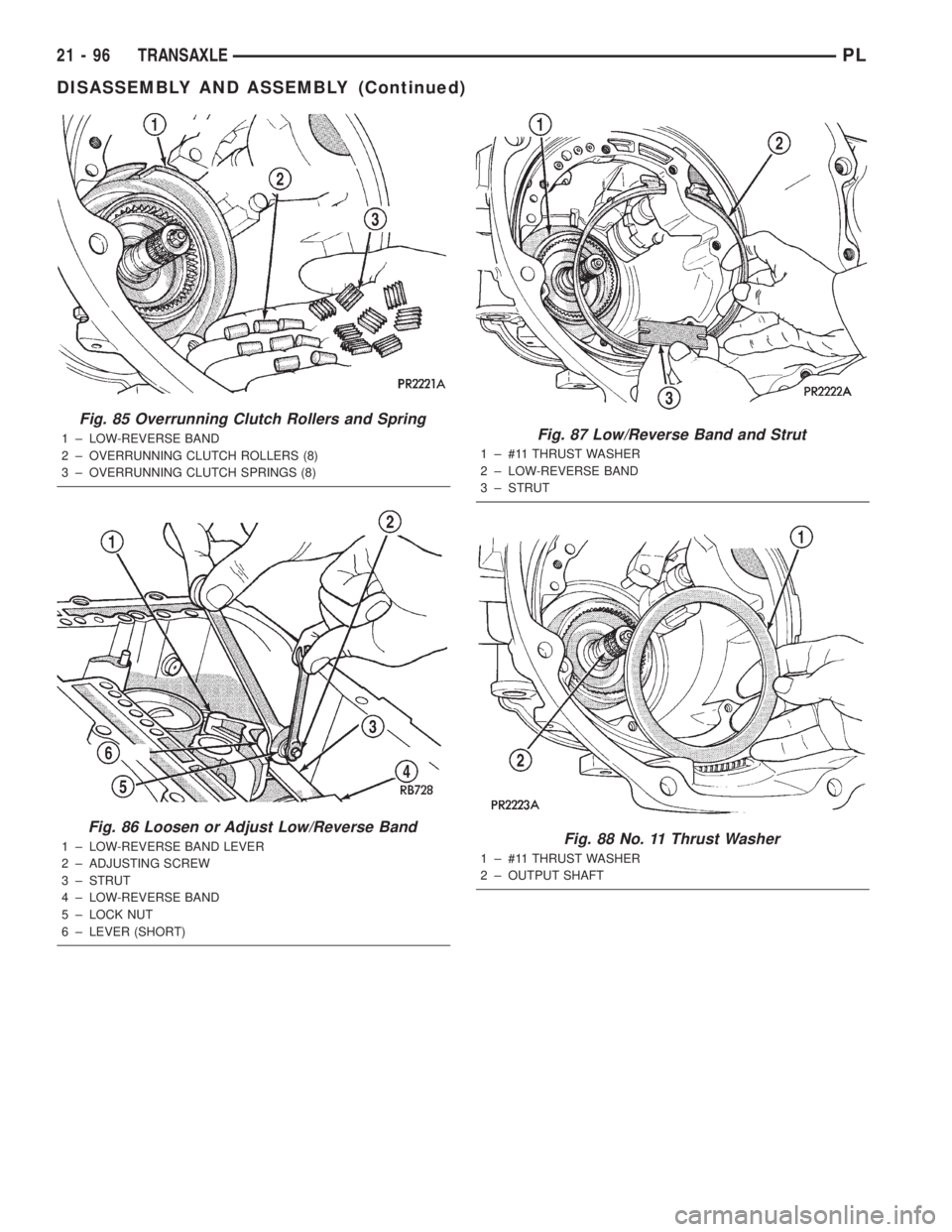

Fig. 85 Overrunning Clutch Rollers and Spring

1 ± LOW-REVERSE BAND

2 ± OVERRUNNING CLUTCH ROLLERS (8)

3 ± OVERRUNNING CLUTCH SPRINGS (8)

Fig. 86 Loosen or Adjust Low/Reverse Band

1 ± LOW-REVERSE BAND LEVER

2 ± ADJUSTING SCREW

3 ± STRUT

4 ± LOW-REVERSE BAND

5 ± LOCK NUT

6 ± LEVER (SHORT)

Fig. 87 Low/Reverse Band and Strut

1 ± #11 THRUST WASHER

2 ± LOW-REVERSE BAND

3 ± STRUT

Fig. 88 No. 11 Thrust Washer

1 ± #11 THRUST WASHER

2 ± OUTPUT SHAFT

21 - 96 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1010 of 1285

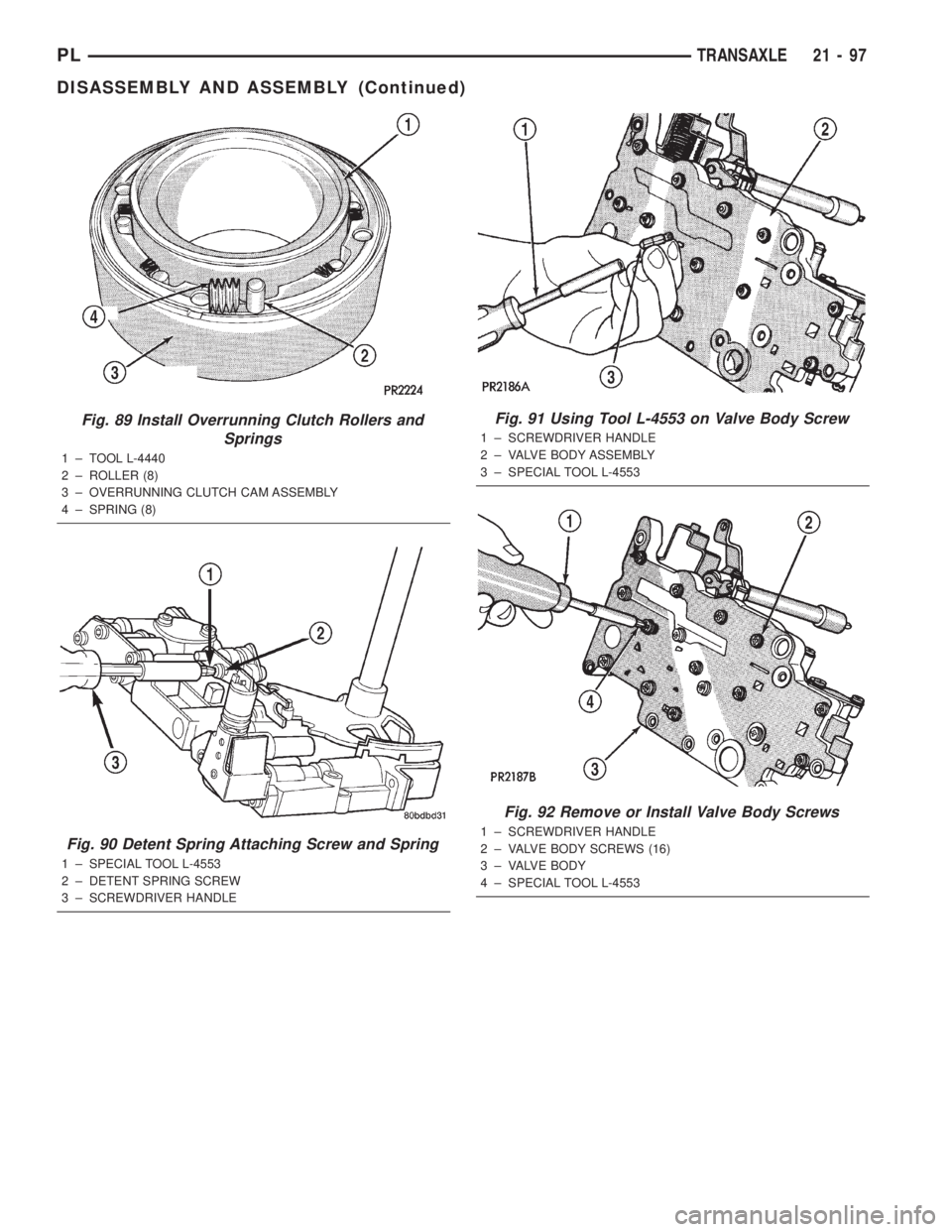

Fig. 89 Install Overrunning Clutch Rollers and

Springs

1 ± TOOL L-4440

2 ± ROLLER (8)

3 ± OVERRUNNING CLUTCH CAM ASSEMBLY

4 ± SPRING (8)

Fig. 90 Detent Spring Attaching Screw and Spring

1 ± SPECIAL TOOL L-4553

2 ± DETENT SPRING SCREW

3 ± SCREWDRIVER HANDLE

Fig. 91 Using Tool L-4553 on Valve Body Screw

1 ± SCREWDRIVER HANDLE

2 ± VALVE BODY ASSEMBLY

3 ± SPECIAL TOOL L-4553

Fig. 92 Remove or Install Valve Body Screws

1 ± SCREWDRIVER HANDLE

2 ± VALVE BODY SCREWS (16)

3 ± VALVE BODY

4 ± SPECIAL TOOL L-4553

PLTRANSAXLE 21 - 97

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1011 of 1285

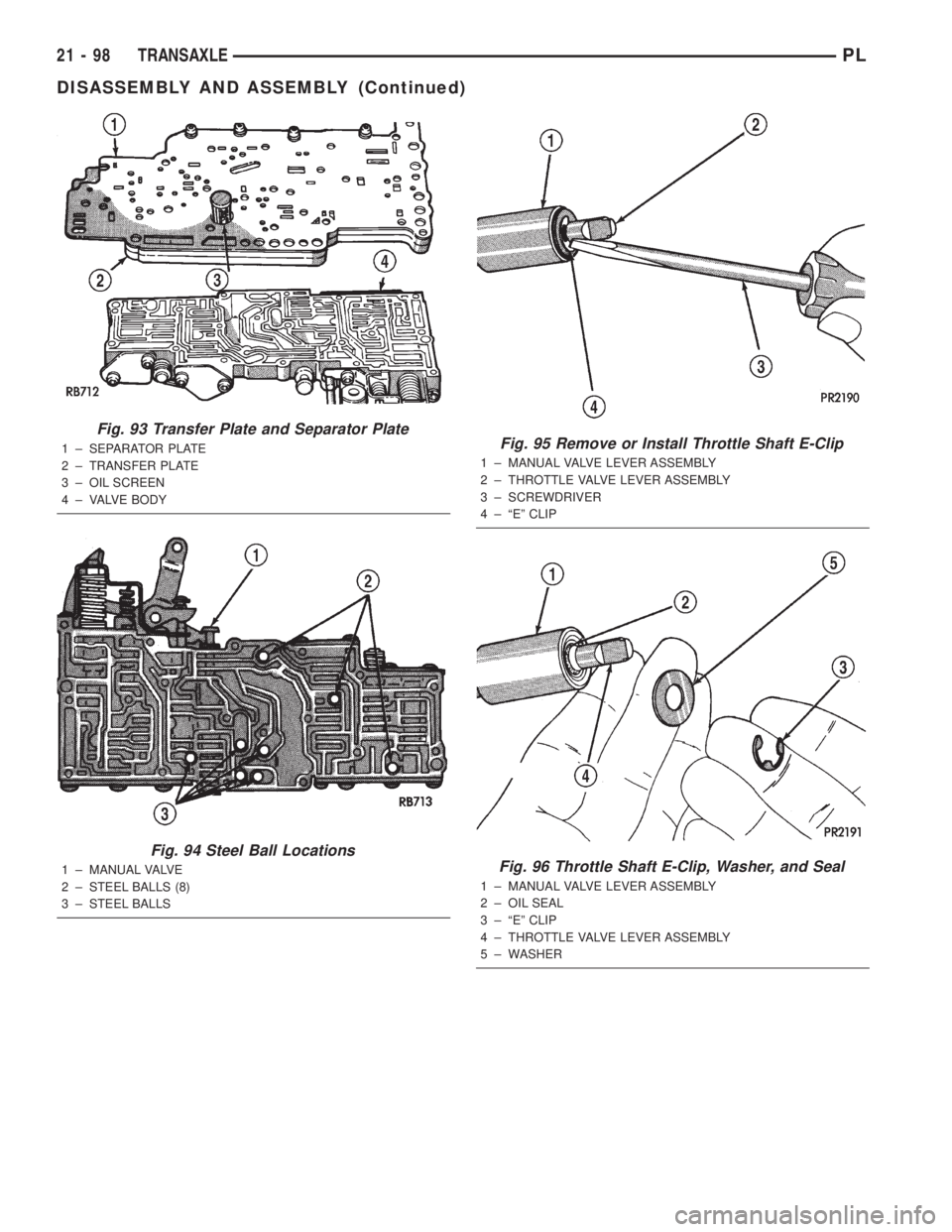

Fig. 93 Transfer Plate and Separator Plate

1 ± SEPARATOR PLATE

2 ± TRANSFER PLATE

3 ± OIL SCREEN

4 ± VALVE BODY

Fig. 94 Steel Ball Locations

1 ± MANUAL VALVE

2 ± STEEL BALLS (8)

3 ± STEEL BALLS

Fig. 95 Remove or Install Throttle Shaft E-Clip

1 ± MANUAL VALVE LEVER ASSEMBLY

2 ± THROTTLE VALVE LEVER ASSEMBLY

3 ± SCREWDRIVER

4 ± ªEº CLIP

Fig. 96 Throttle Shaft E-Clip, Washer, and Seal

1 ± MANUAL VALVE LEVER ASSEMBLY

2 ± OIL SEAL

3 ± ªEº CLIP

4 ± THROTTLE VALVE LEVER ASSEMBLY

5 ± WASHER

21 - 98 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1012 of 1285

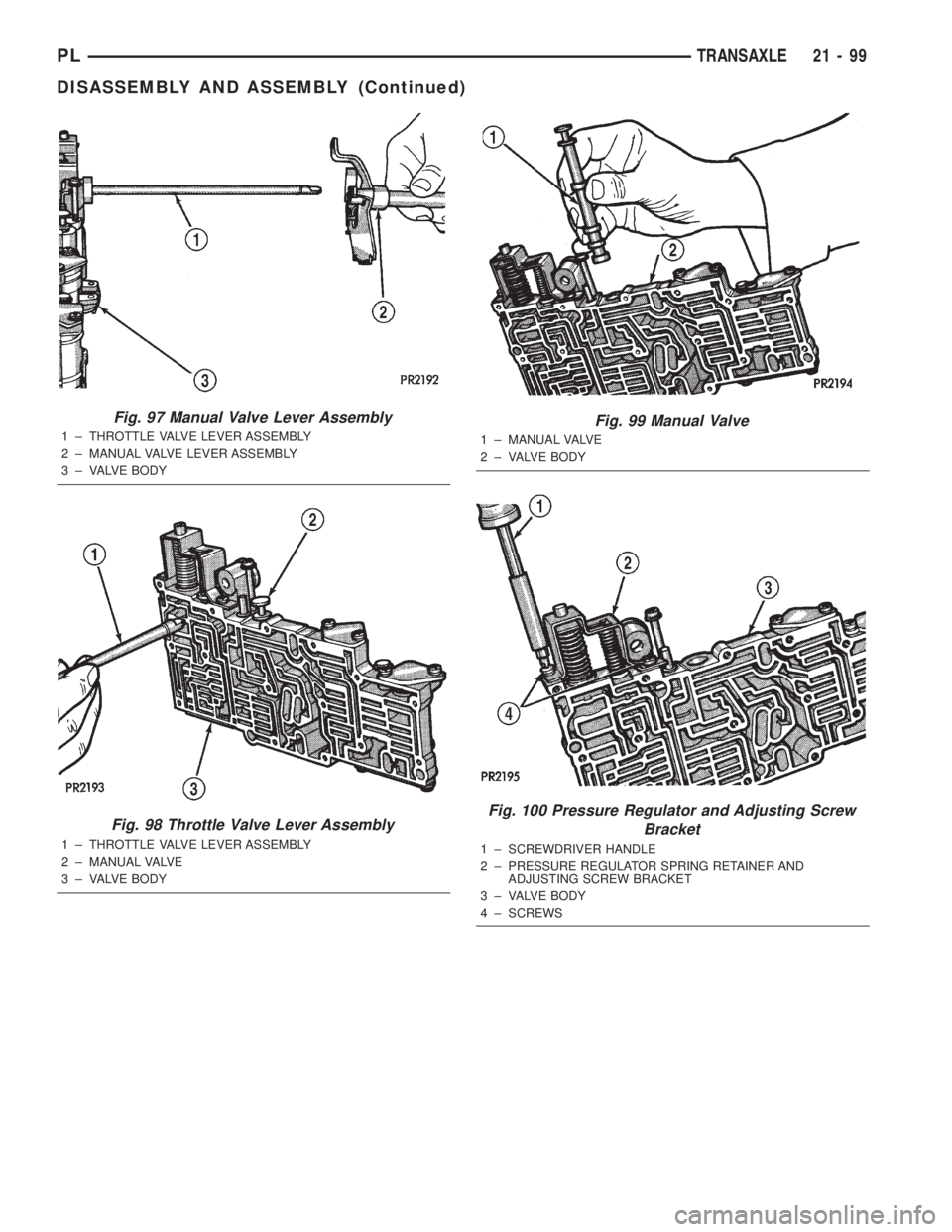

Fig. 97 Manual Valve Lever Assembly

1 ± THROTTLE VALVE LEVER ASSEMBLY

2 ± MANUAL VALVE LEVER ASSEMBLY

3 ± VALVE BODY

Fig. 98 Throttle Valve Lever Assembly

1 ± THROTTLE VALVE LEVER ASSEMBLY

2 ± MANUAL VALVE

3 ± VALVE BODY

Fig. 99 Manual Valve

1 ± MANUAL VALVE

2 ± VALVE BODY

Fig. 100 Pressure Regulator and Adjusting Screw

Bracket

1 ± SCREWDRIVER HANDLE

2 ± PRESSURE REGULATOR SPRING RETAINER AND

ADJUSTING SCREW BRACKET

3 ± VALVE BODY

4 ± SCREWS

PLTRANSAXLE 21 - 99

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1013 of 1285

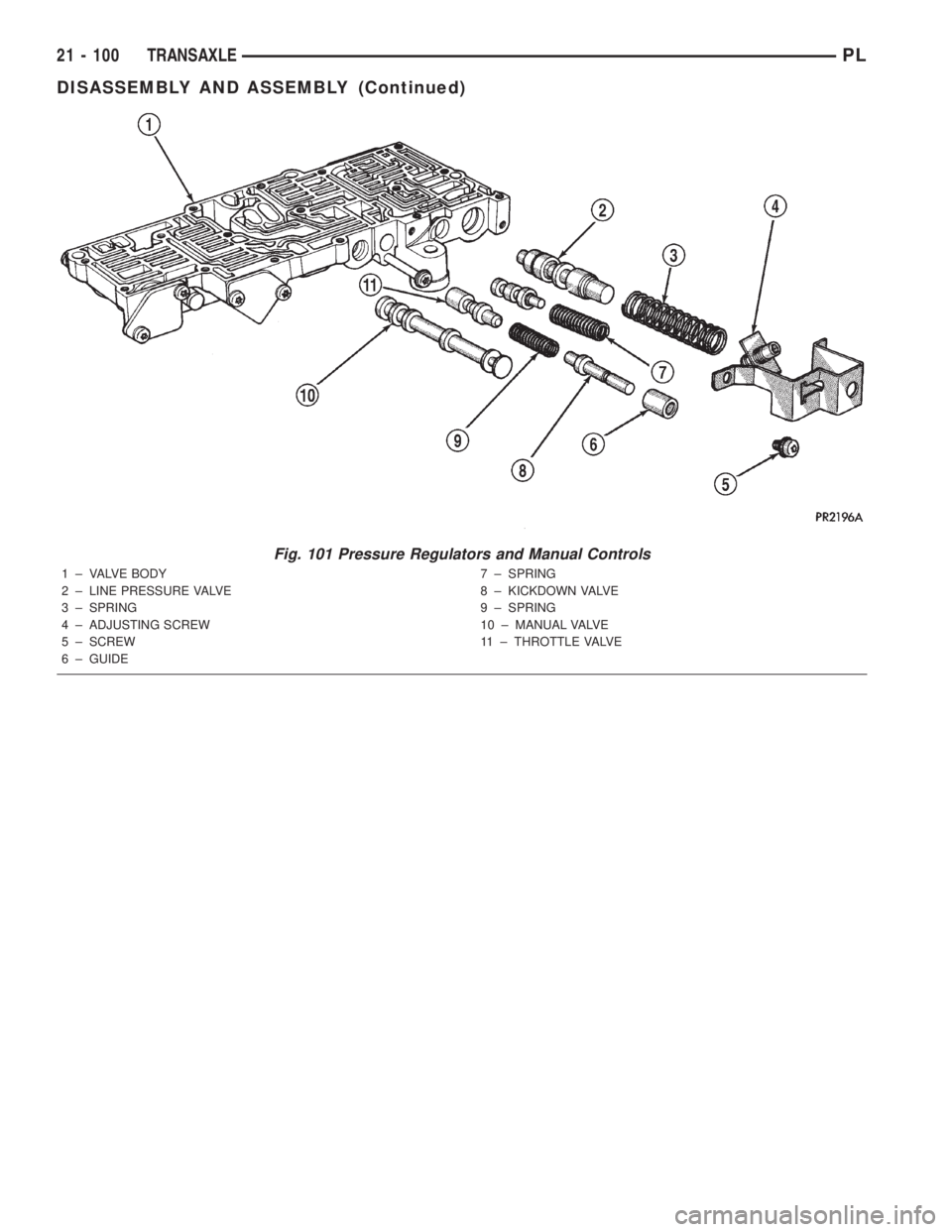

Fig. 101 Pressure Regulators and Manual Controls

1 ± VALVE BODY

2 ± LINE PRESSURE VALVE

3 ± SPRING

4 ± ADJUSTING SCREW

5 ± SCREW

6 ± GUIDE7 ± SPRING

8 ± KICKDOWN VALVE

9 ± SPRING

10 ± MANUAL VALVE

11 ± THROTTLE VALVE

21 - 100 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1014 of 1285

Fig. 102 Governor Plugs

1 ± SHUTTLE VALVE SECONDARY SPRING

2 ± SHUTTLE VALVE

3 ± 1-2 SHIFT VALVE GOVERNOR PLUG

4 ± END COVER5 ± SCREW (4)

6 ± END COVER

7 ± 2-3 SHIFT VALVE GOVERNOR PLUG

8 ± E-CLIP

PLTRANSAXLE 21 - 101

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1015 of 1285

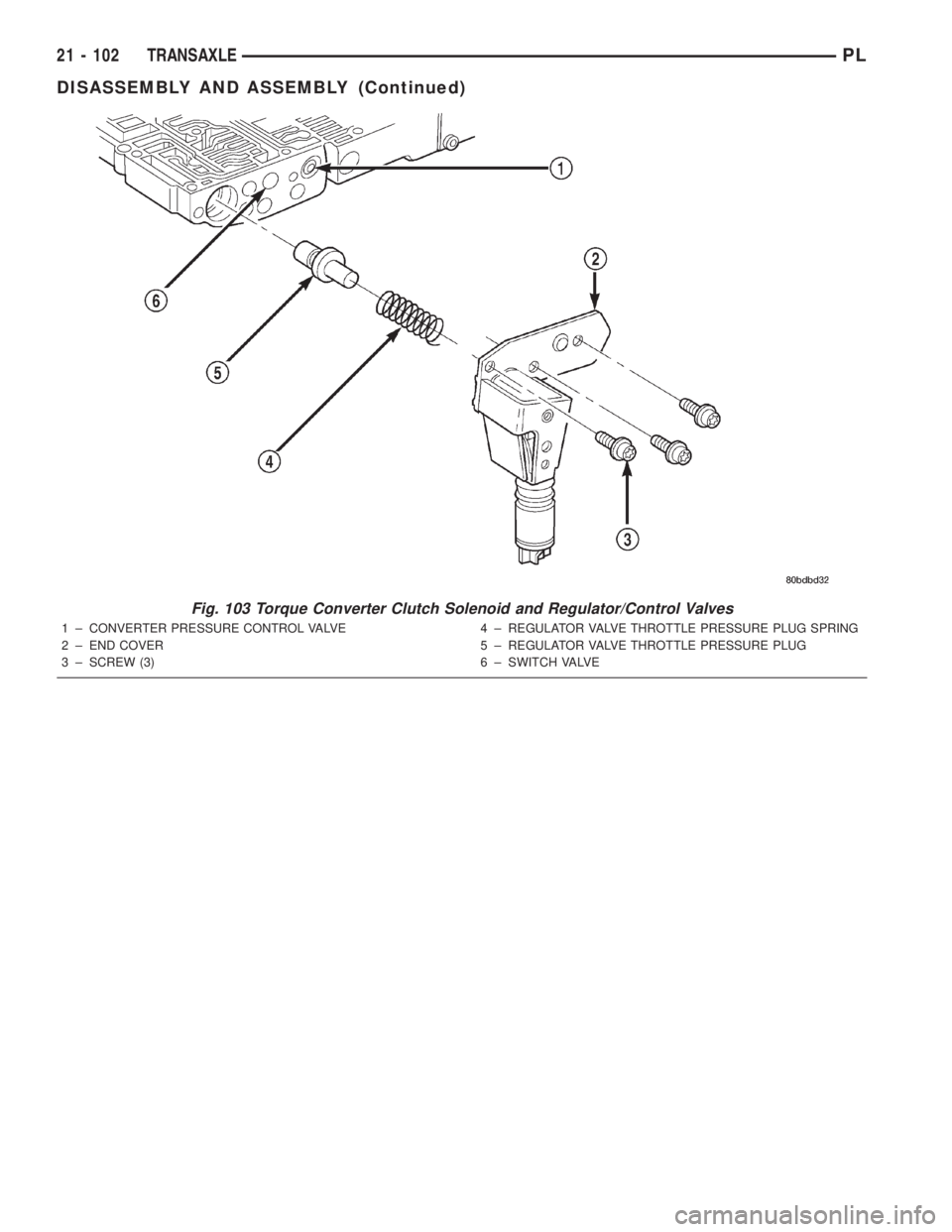

Fig. 103 Torque Converter Clutch Solenoid and Regulator/Control Valves

1 ± CONVERTER PRESSURE CONTROL VALVE

2 ± END COVER

3 ± SCREW (3)4 ± REGULATOR VALVE THROTTLE PRESSURE PLUG SPRING

5 ± REGULATOR VALVE THROTTLE PRESSURE PLUG

6 ± SWITCH VALVE

21 - 102 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1016 of 1285

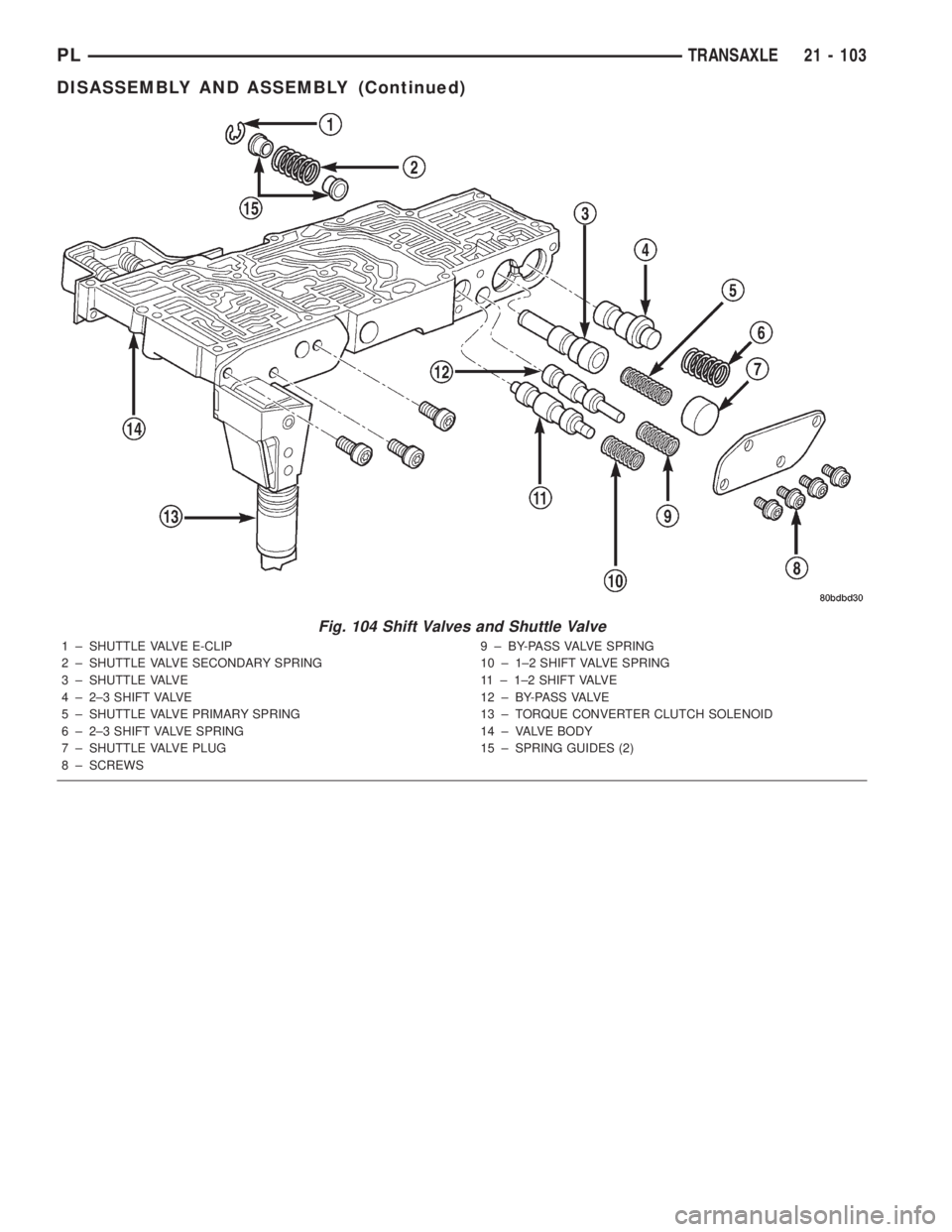

Fig. 104 Shift Valves and Shuttle Valve

1 ± SHUTTLE VALVE E-CLIP

2 ± SHUTTLE VALVE SECONDARY SPRING

3 ± SHUTTLE VALVE

4 ± 2±3 SHIFT VALVE

5 ± SHUTTLE VALVE PRIMARY SPRING

6 ± 2±3 SHIFT VALVE SPRING

7 ± SHUTTLE VALVE PLUG

8 ± SCREWS9 ± BY-PASS VALVE SPRING

10 ± 1±2 SHIFT VALVE SPRING

11 ± 1±2 SHIFT VALVE

1 2 ± B Y- PA S S VA LV E

13 ± TORQUE CONVERTER CLUTCH SOLENOID

14 ± VALVE BODY

15 ± SPRING GUIDES (2)

PLTRANSAXLE 21 - 103

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1017 of 1285

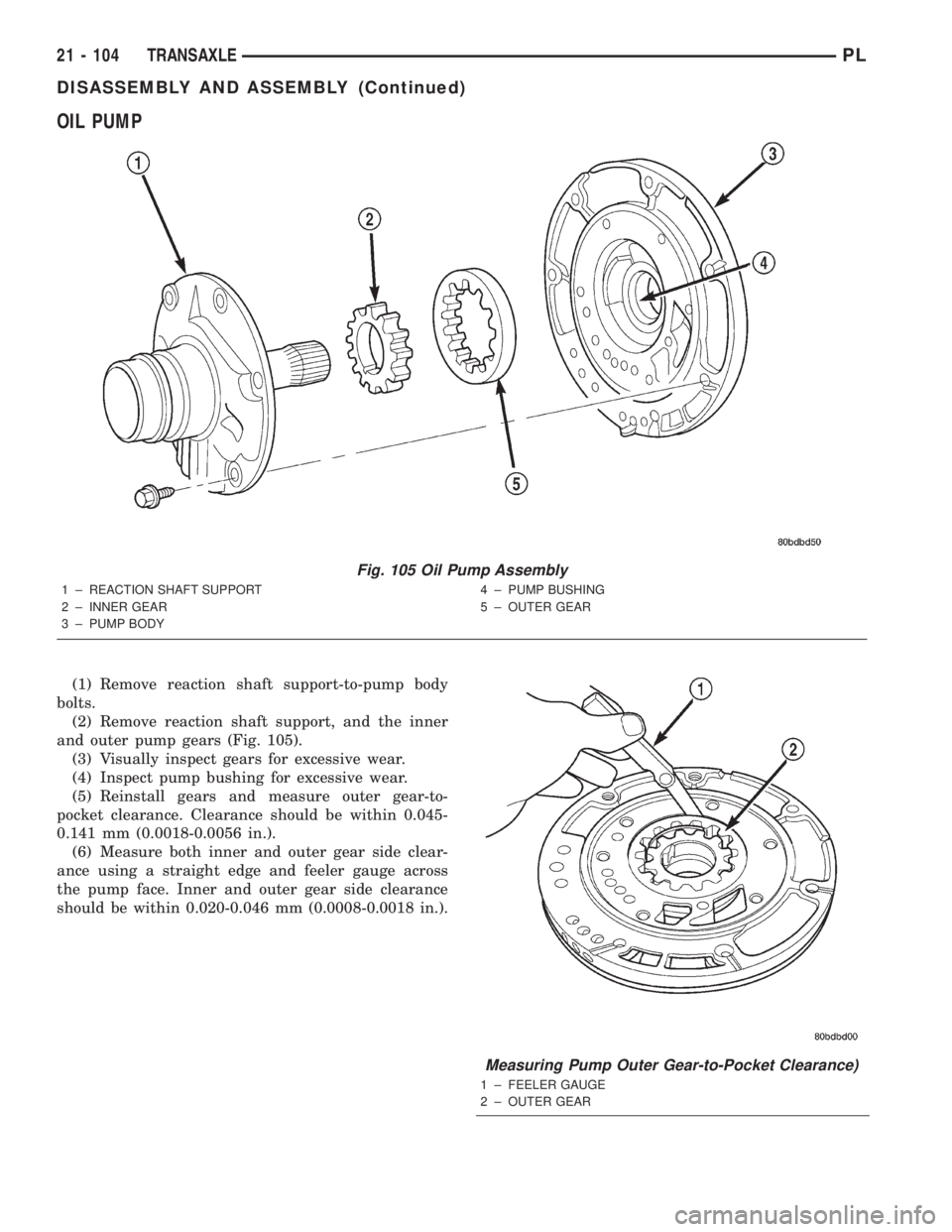

OIL PUMP

(1) Remove reaction shaft support-to-pump body

bolts.

(2) Remove reaction shaft support, and the inner

and outer pump gears (Fig. 105).

(3) Visually inspect gears for excessive wear.

(4) Inspect pump bushing for excessive wear.

(5) Reinstall gears and measure outer gear-to-

pocket clearance. Clearance should be within 0.045-

0.141 mm (0.0018-0.0056 in.).

(6) Measure both inner and outer gear side clear-

ance using a straight edge and feeler gauge across

the pump face. Inner and outer gear side clearance

should be within 0.020-0.046 mm (0.0008-0.0018 in.).

Fig. 105 Oil Pump Assembly

1 ± REACTION SHAFT SUPPORT

2 ± INNER GEAR

3 ± PUMP BODY4 ± PUMP BUSHING

5 ± OUTER GEAR

Measuring Pump Outer Gear-to-Pocket Clearance)

1 ± FEELER GAUGE

2 ± OUTER GEAR

21 - 104 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)