tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1038 of 1285

ASSEMBLY

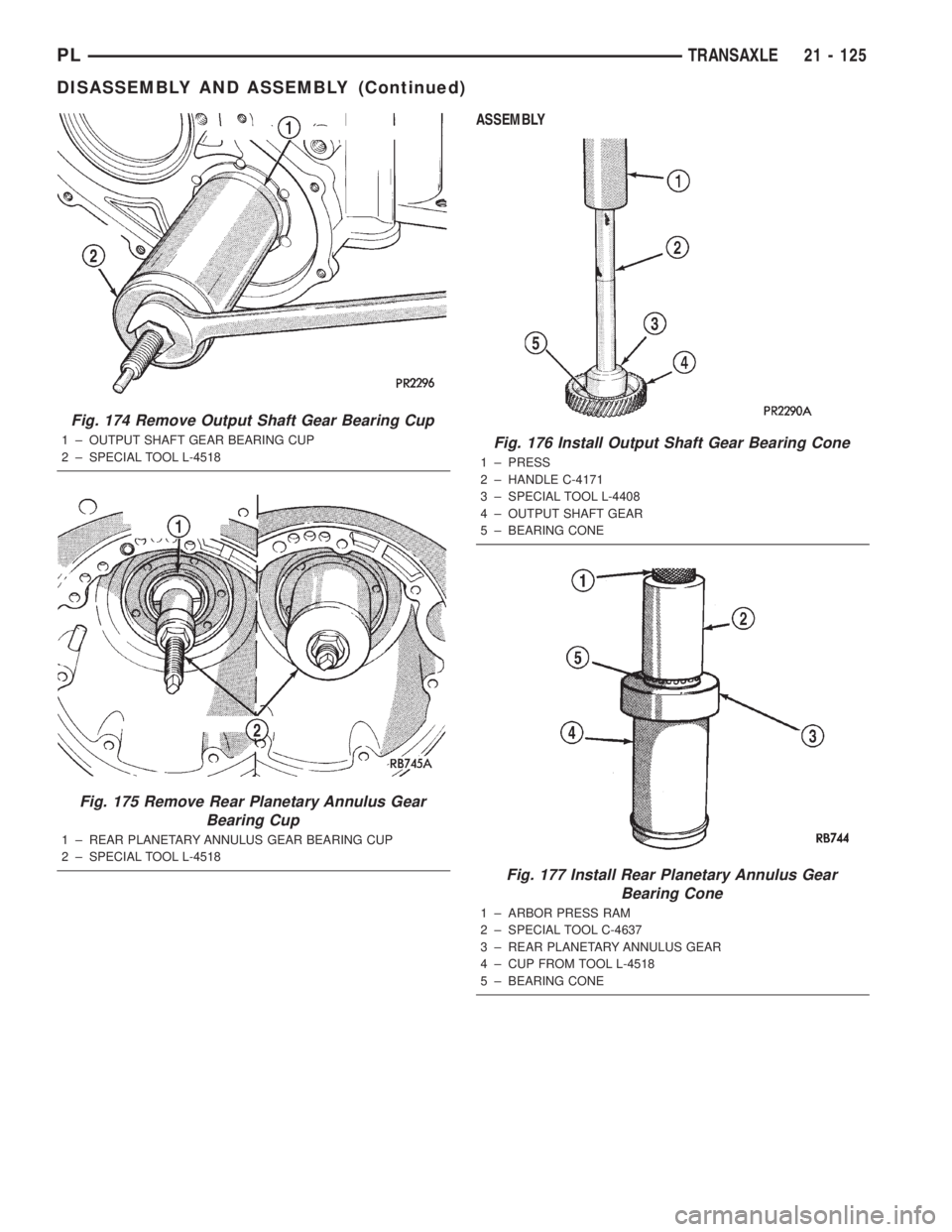

Fig. 174 Remove Output Shaft Gear Bearing Cup

1 ± OUTPUT SHAFT GEAR BEARING CUP

2 ± SPECIAL TOOL L-4518

Fig. 175 Remove Rear Planetary Annulus Gear

Bearing Cup

1 ± REAR PLANETARY ANNULUS GEAR BEARING CUP

2 ± SPECIAL TOOL L-4518

Fig. 176 Install Output Shaft Gear Bearing Cone

1 ± PRESS

2 ± HANDLE C-4171

3 ± SPECIAL TOOL L-4408

4 ± OUTPUT SHAFT GEAR

5 ± BEARING CONE

Fig. 177 Install Rear Planetary Annulus Gear

Bearing Cone

1 ± ARBOR PRESS RAM

2 ± SPECIAL TOOL C-4637

3 ± REAR PLANETARY ANNULUS GEAR

4 ± CUP FROM TOOL L-4518

5 ± BEARING CONE

PLTRANSAXLE 21 - 125

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1039 of 1285

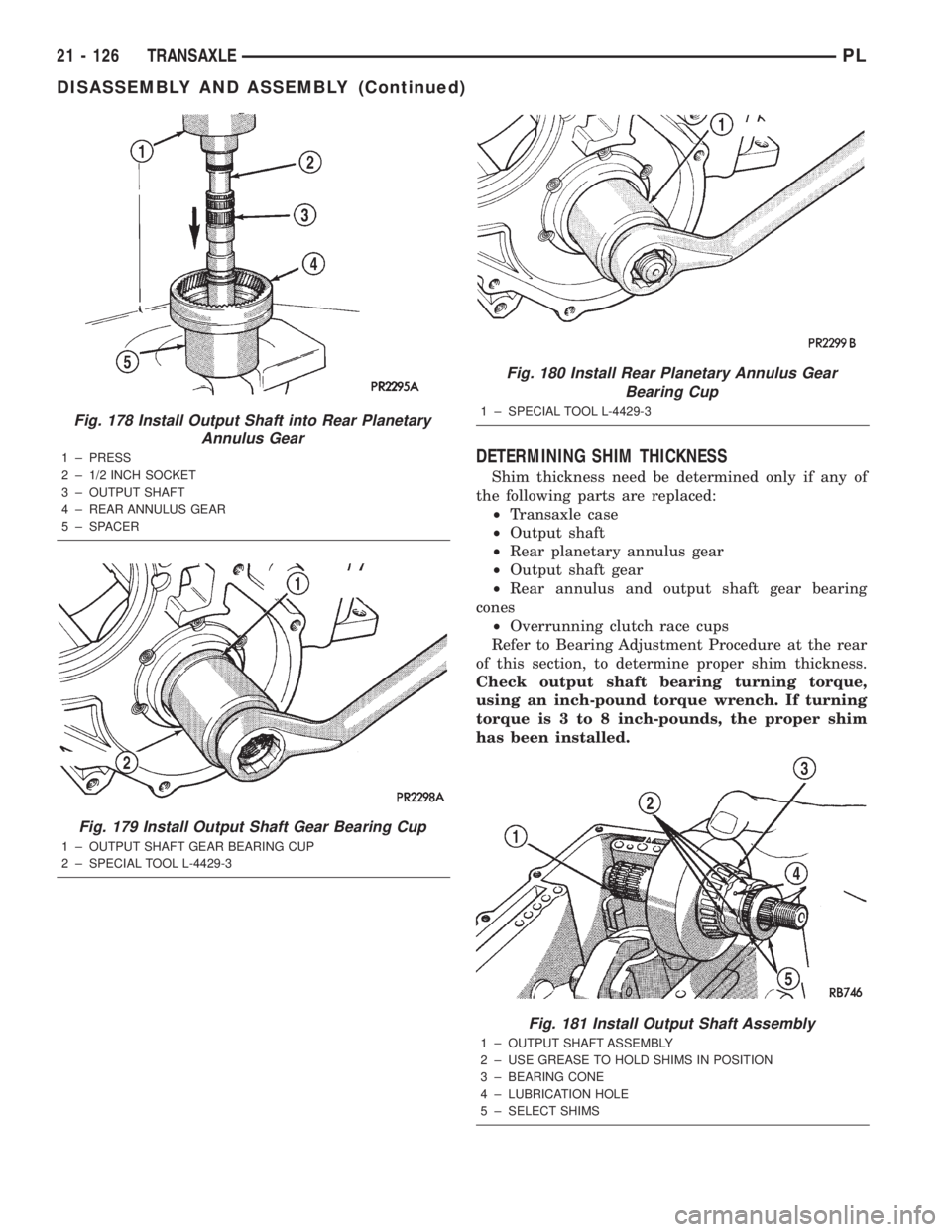

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Output shaft

²Rear planetary annulus gear

²Output shaft gear

²Rear annulus and output shaft gear bearing

cones

²Overrunning clutch race cups

Refer to Bearing Adjustment Procedure at the rear

of this section, to determine proper shim thickness.

Check output shaft bearing turning torque,

using an inch-pound torque wrench. If turning

torque is 3 to 8 inch-pounds, the proper shim

has been installed.

Fig. 178 Install Output Shaft into Rear Planetary

Annulus Gear

1 ± PRESS

2 ± 1/2 INCH SOCKET

3 ± OUTPUT SHAFT

4 ± REAR ANNULUS GEAR

5 ± SPACER

Fig. 179 Install Output Shaft Gear Bearing Cup

1 ± OUTPUT SHAFT GEAR BEARING CUP

2 ± SPECIAL TOOL L-4429-3

Fig. 180 Install Rear Planetary Annulus Gear

Bearing Cup

1 ± SPECIAL TOOL L-4429-3

Fig. 181 Install Output Shaft Assembly

1 ± OUTPUT SHAFT ASSEMBLY

2 ± USE GREASE TO HOLD SHIMS IN POSITION

3 ± BEARING CONE

4 ± LUBRICATION HOLE

5 ± SELECT SHIMS

21 - 126 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1040 of 1285

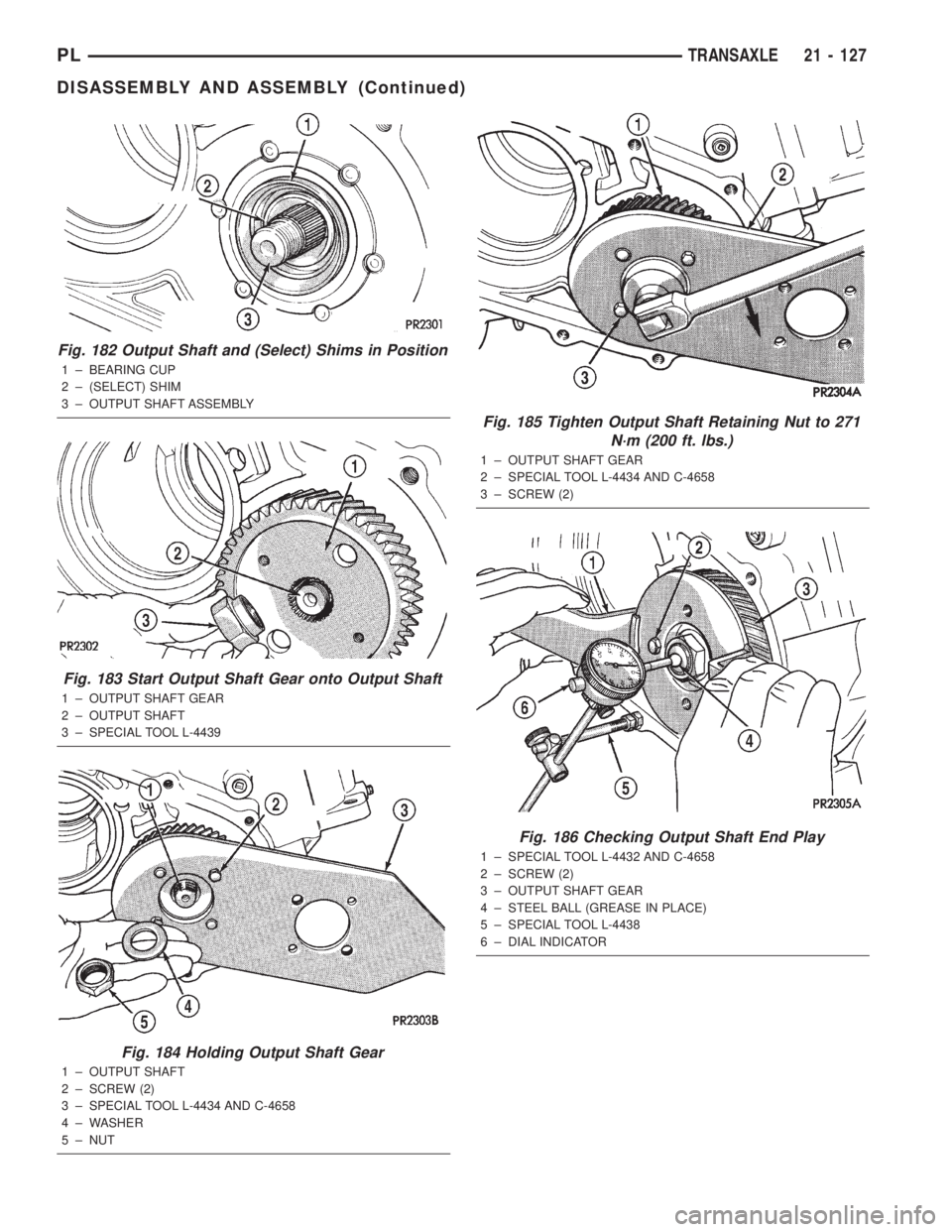

Fig. 182 Output Shaft and (Select) Shims in Position

1 ± BEARING CUP

2 ± (SELECT) SHIM

3 ± OUTPUT SHAFT ASSEMBLY

Fig. 183 Start Output Shaft Gear onto Output Shaft

1 ± OUTPUT SHAFT GEAR

2 ± OUTPUT SHAFT

3 ± SPECIAL TOOL L-4439

Fig. 184 Holding Output Shaft Gear

1 ± OUTPUT SHAFT

2 ± SCREW (2)

3 ± SPECIAL TOOL L-4434 AND C-4658

4 ± WASHER

5 ± NUT

Fig. 185 Tighten Output Shaft Retaining Nut to 271

N´m (200 ft. lbs.)

1 ± OUTPUT SHAFT GEAR

2 ± SPECIAL TOOL L-4434 AND C-4658

3 ± SCREW (2)

Fig. 186 Checking Output Shaft End Play

1 ± SPECIAL TOOL L-4432 AND C-4658

2 ± SCREW (2)

3 ± OUTPUT SHAFT GEAR

4 ± STEEL BALL (GREASE IN PLACE)

5 ± SPECIAL TOOL L-4438

6 ± DIAL INDICATOR

PLTRANSAXLE 21 - 127

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1041 of 1285

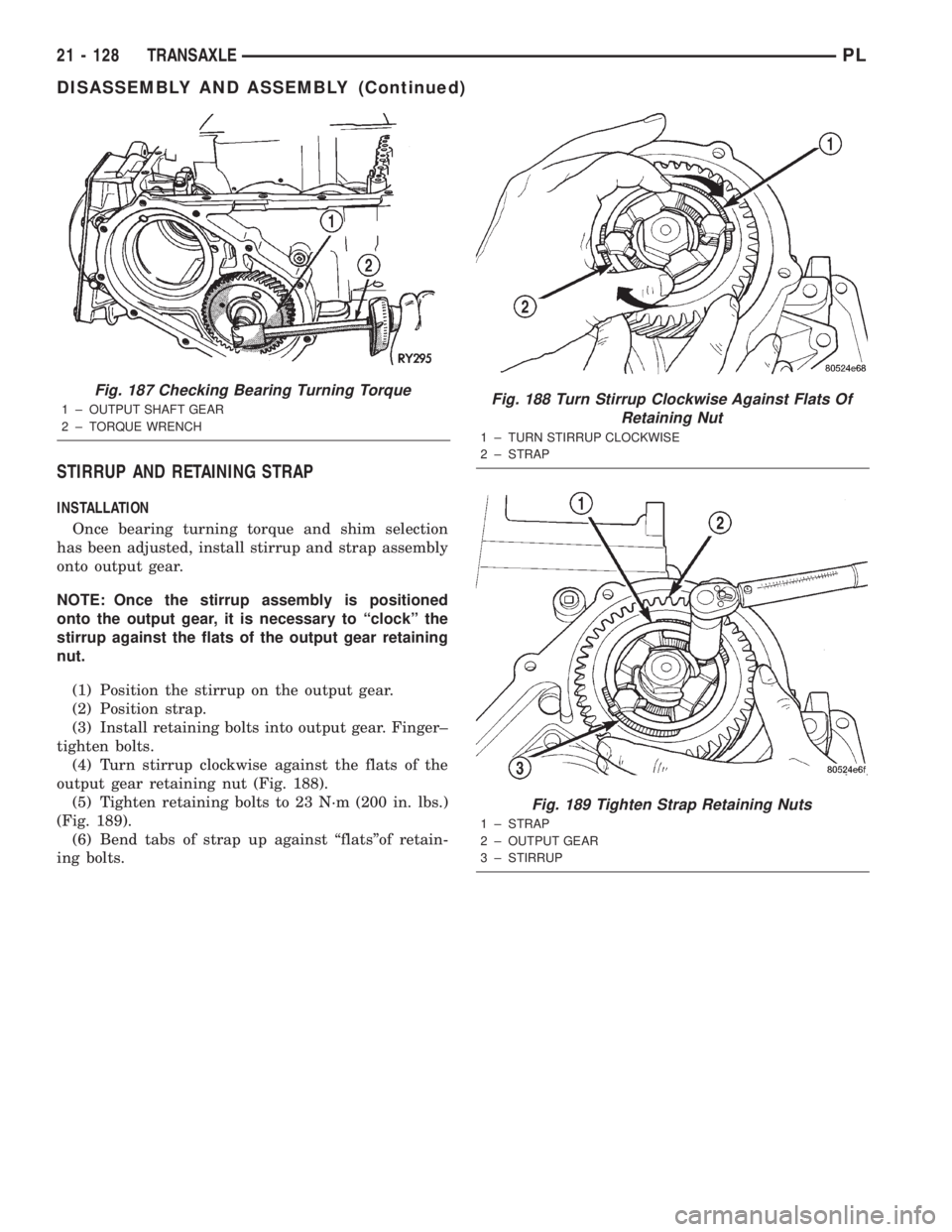

STIRRUP AND RETAINING STRAP

INSTALLATION

Once bearing turning torque and shim selection

has been adjusted, install stirrup and strap assembly

onto output gear.

NOTE: Once the stirrup assembly is positioned

onto the output gear, it is necessary to ªclockº the

stirrup against the flats of the output gear retaining

nut.

(1) Position the stirrup on the output gear.

(2) Position strap.

(3) Install retaining bolts into output gear. Finger±

tighten bolts.

(4) Turn stirrup clockwise against the flats of the

output gear retaining nut (Fig. 188).

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.)

(Fig. 189).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

Fig. 187 Checking Bearing Turning Torque

1 ± OUTPUT SHAFT GEAR

2 ± TORQUE WRENCHFig. 188 Turn Stirrup Clockwise Against Flats Of

Retaining Nut

1 ± TURN STIRRUP CLOCKWISE

2 ± STRAP

Fig. 189 Tighten Strap Retaining Nuts

1 ± STRAP

2 ± OUTPUT GEAR

3 ± STIRRUP

21 - 128 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1042 of 1285

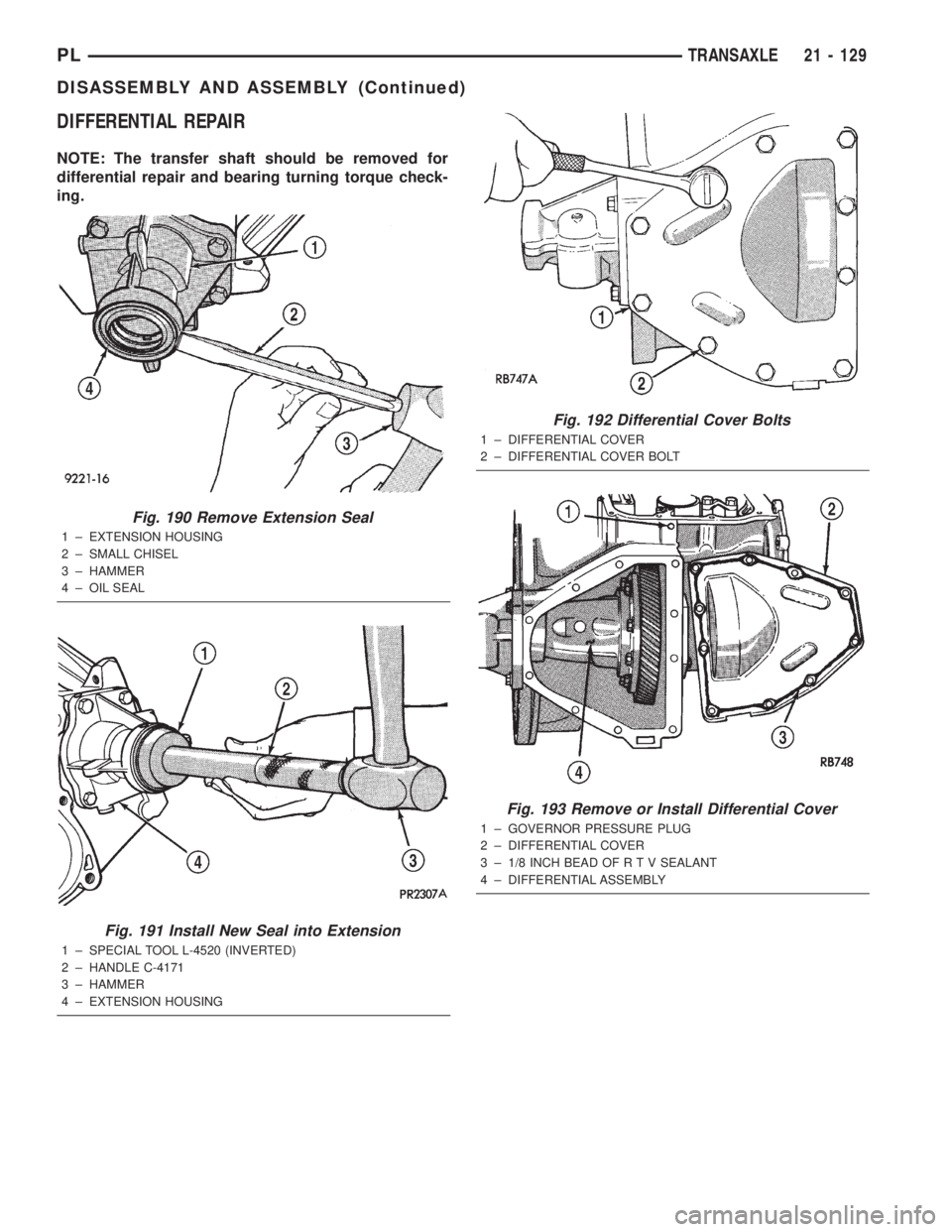

DIFFERENTIAL REPAIR

NOTE: The transfer shaft should be removed for

differential repair and bearing turning torque check-

ing.

Fig. 190 Remove Extension Seal

1 ± EXTENSION HOUSING

2 ± SMALL CHISEL

3 ± HAMMER

4 ± OIL SEAL

Fig. 191 Install New Seal into Extension

1 ± SPECIAL TOOL L-4520 (INVERTED)

2 ± HANDLE C-4171

3 ± HAMMER

4 ± EXTENSION HOUSING

Fig. 192 Differential Cover Bolts

1 ± DIFFERENTIAL COVER

2 ± DIFFERENTIAL COVER BOLT

Fig. 193 Remove or Install Differential Cover

1 ± GOVERNOR PRESSURE PLUG

2 ± DIFFERENTIAL COVER

3 ± 1/8 INCH BEAD OF R T V SEALANT

4 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 129

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1043 of 1285

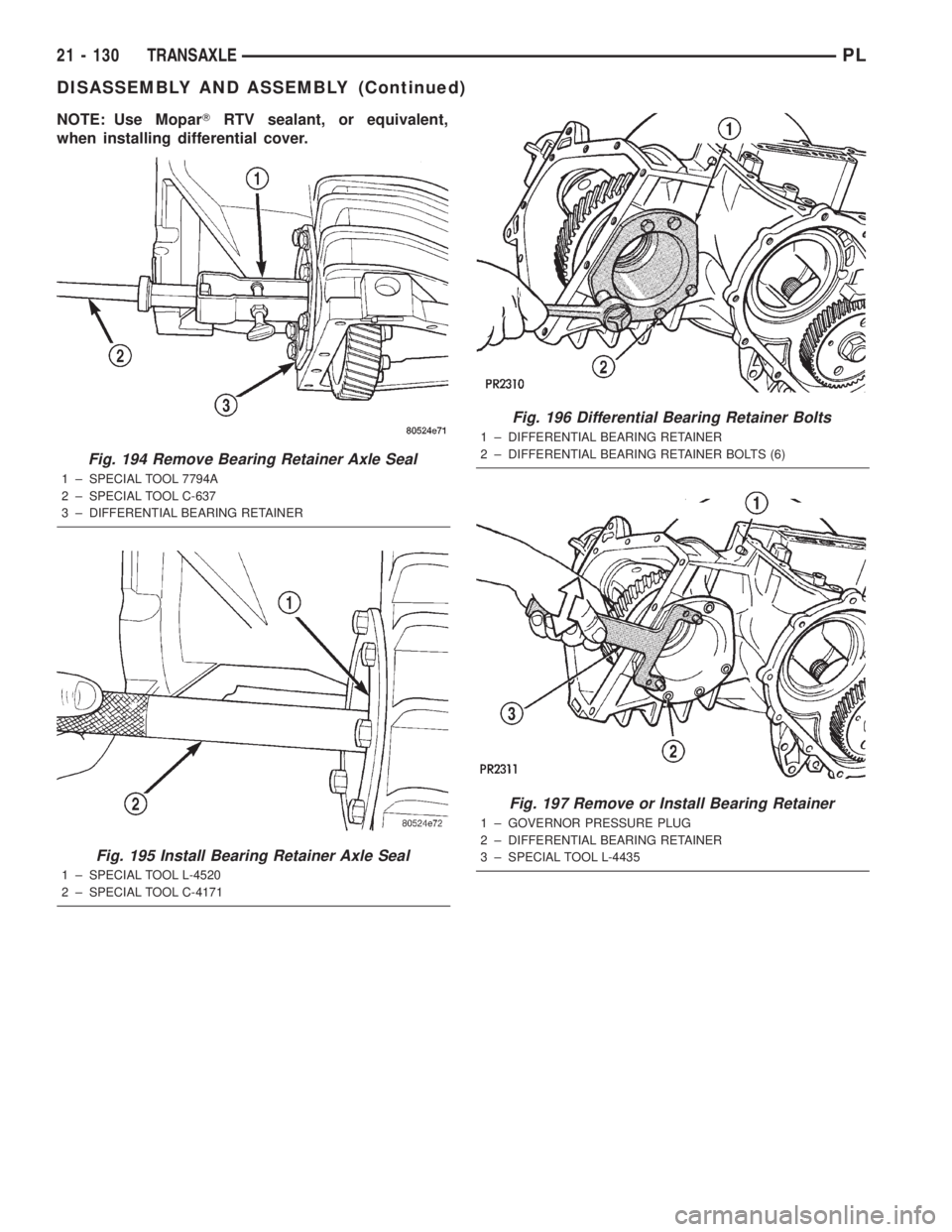

NOTE: Use MoparTRTV sealant, or equivalent,

when installing differential cover.

Fig. 194 Remove Bearing Retainer Axle Seal

1 ± SPECIAL TOOL 7794A

2 ± SPECIAL TOOL C-637

3 ± DIFFERENTIAL BEARING RETAINER

Fig. 195 Install Bearing Retainer Axle Seal

1 ± SPECIAL TOOL L-4520

2 ± SPECIAL TOOL C-4171

Fig. 196 Differential Bearing Retainer Bolts

1 ± DIFFERENTIAL BEARING RETAINER

2 ± DIFFERENTIAL BEARING RETAINER BOLTS (6)

Fig. 197 Remove or Install Bearing Retainer

1 ± GOVERNOR PRESSURE PLUG

2 ± DIFFERENTIAL BEARING RETAINER

3 ± SPECIAL TOOL L-4435

21 - 130 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1044 of 1285

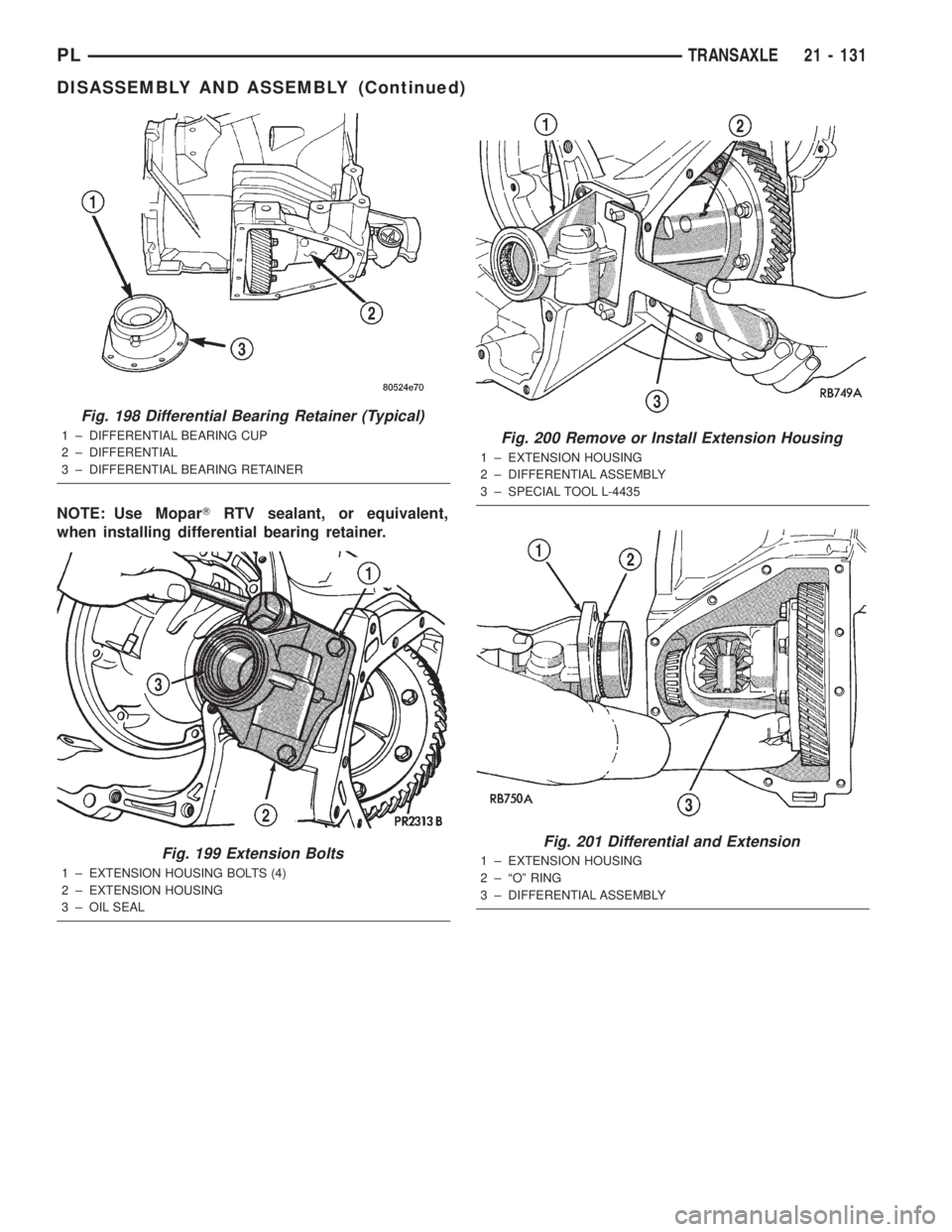

NOTE: Use MoparTRTV sealant, or equivalent,

when installing differential bearing retainer.

Fig. 198 Differential Bearing Retainer (Typical)

1 ± DIFFERENTIAL BEARING CUP

2 ± DIFFERENTIAL

3 ± DIFFERENTIAL BEARING RETAINER

Fig. 199 Extension Bolts

1 ± EXTENSION HOUSING BOLTS (4)

2 ± EXTENSION HOUSING

3 ± OIL SEAL

Fig. 200 Remove or Install Extension Housing

1 ± EXTENSION HOUSING

2 ± DIFFERENTIAL ASSEMBLY

3 ± SPECIAL TOOL L-4435

Fig. 201 Differential and Extension

1 ± EXTENSION HOUSING

2 ± ªOº RING

3 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 131

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1045 of 1285

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

Use MopartSilicone Rubber Adhesive Sealant, or

equivalent, when installing extension housing.

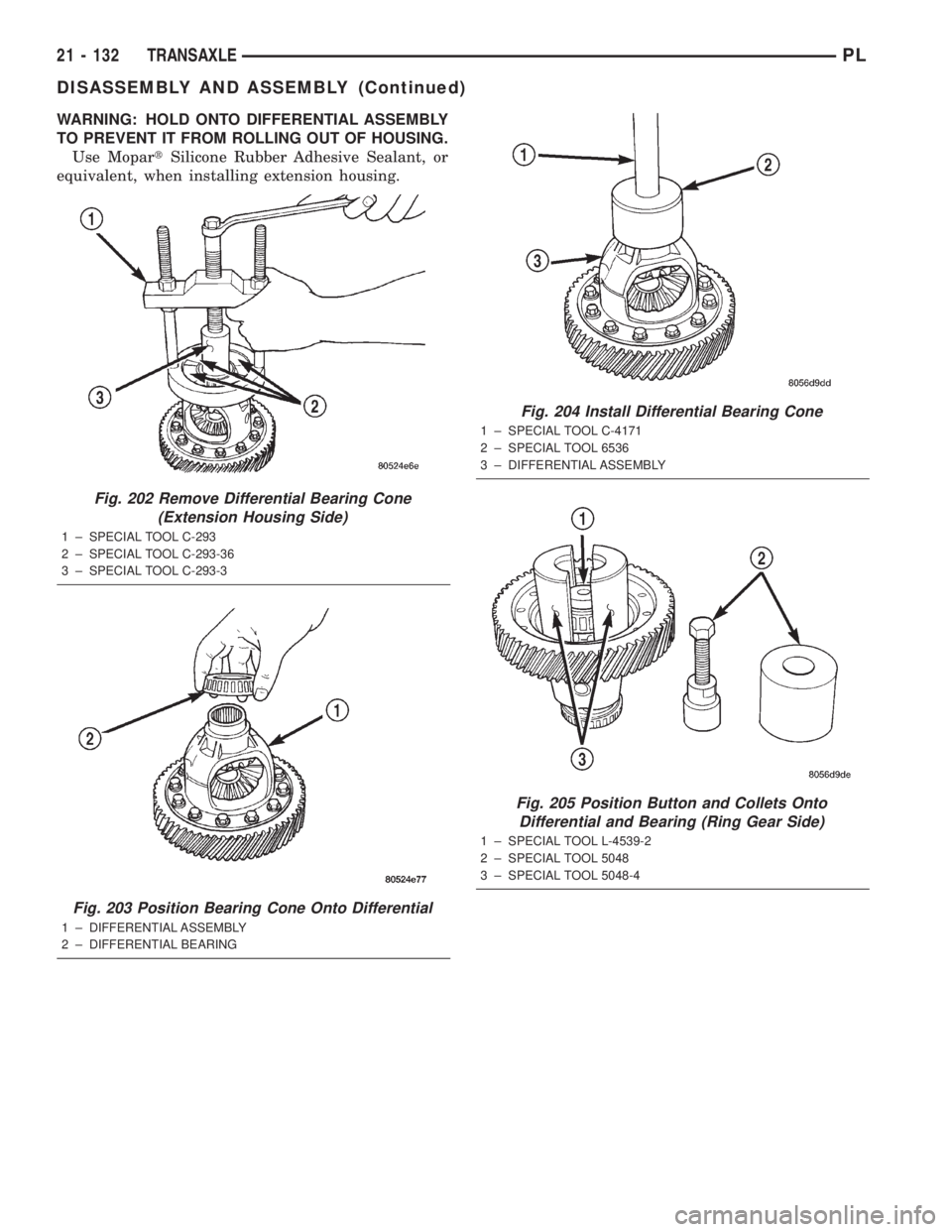

Fig. 202 Remove Differential Bearing Cone

(Extension Housing Side)

1 ± SPECIAL TOOL C-293

2 ± SPECIAL TOOL C-293-36

3 ± SPECIAL TOOL C-293-3

Fig. 203 Position Bearing Cone Onto Differential

1 ± DIFFERENTIAL ASSEMBLY

2 ± DIFFERENTIAL BEARING

Fig. 204 Install Differential Bearing Cone

1 ± SPECIAL TOOL C-4171

2 ± SPECIAL TOOL 6536

3 ± DIFFERENTIAL ASSEMBLY

Fig. 205 Position Button and Collets Onto

Differential and Bearing (Ring Gear Side)

1 ± SPECIAL TOOL L-4539-2

2 ± SPECIAL TOOL 5048

3 ± SPECIAL TOOL 5048-4

21 - 132 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1046 of 1285

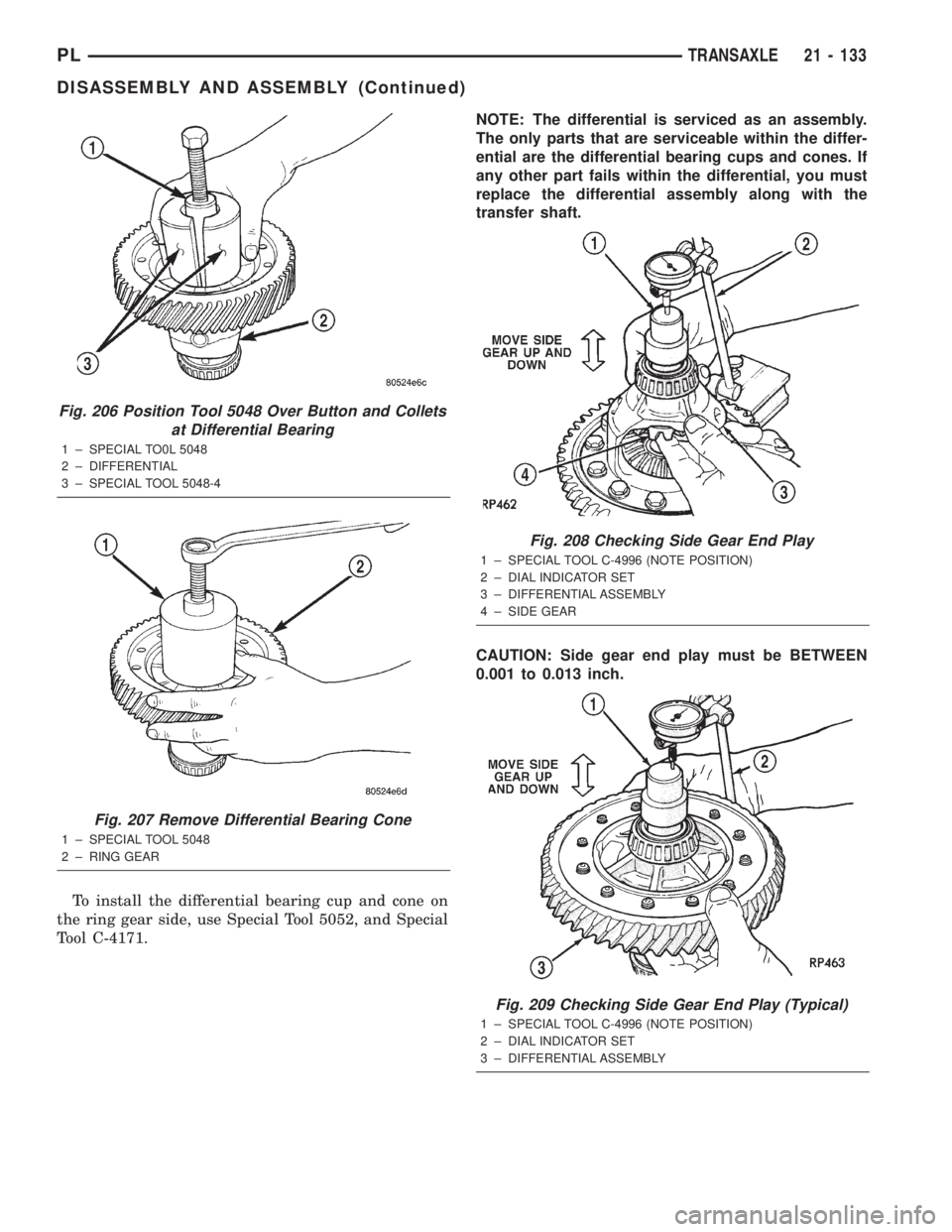

To install the differential bearing cup and cone on

the ring gear side, use Special Tool 5052, and Special

Tool C-4171.NOTE: The differential is serviced as an assembly.

The only parts that are serviceable within the differ-

ential are the differential bearing cups and cones. If

any other part fails within the differential, you must

replace the differential assembly along with the

transfer shaft.

CAUTION: Side gear end play must be BETWEEN

0.001 to 0.013 inch.

Fig. 206 Position Tool 5048 Over Button and Collets

at Differential Bearing

1 ± SPECIAL TO0L 5048

2 ± DIFFERENTIAL

3 ± SPECIAL TOOL 5048-4

Fig. 207 Remove Differential Bearing Cone

1 ± SPECIAL TOOL 5048

2 ± RING GEAR

Fig. 208 Checking Side Gear End Play

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

4 ± SIDE GEAR

Fig. 209 Checking Side Gear End Play (Typical)

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 133

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1047 of 1285

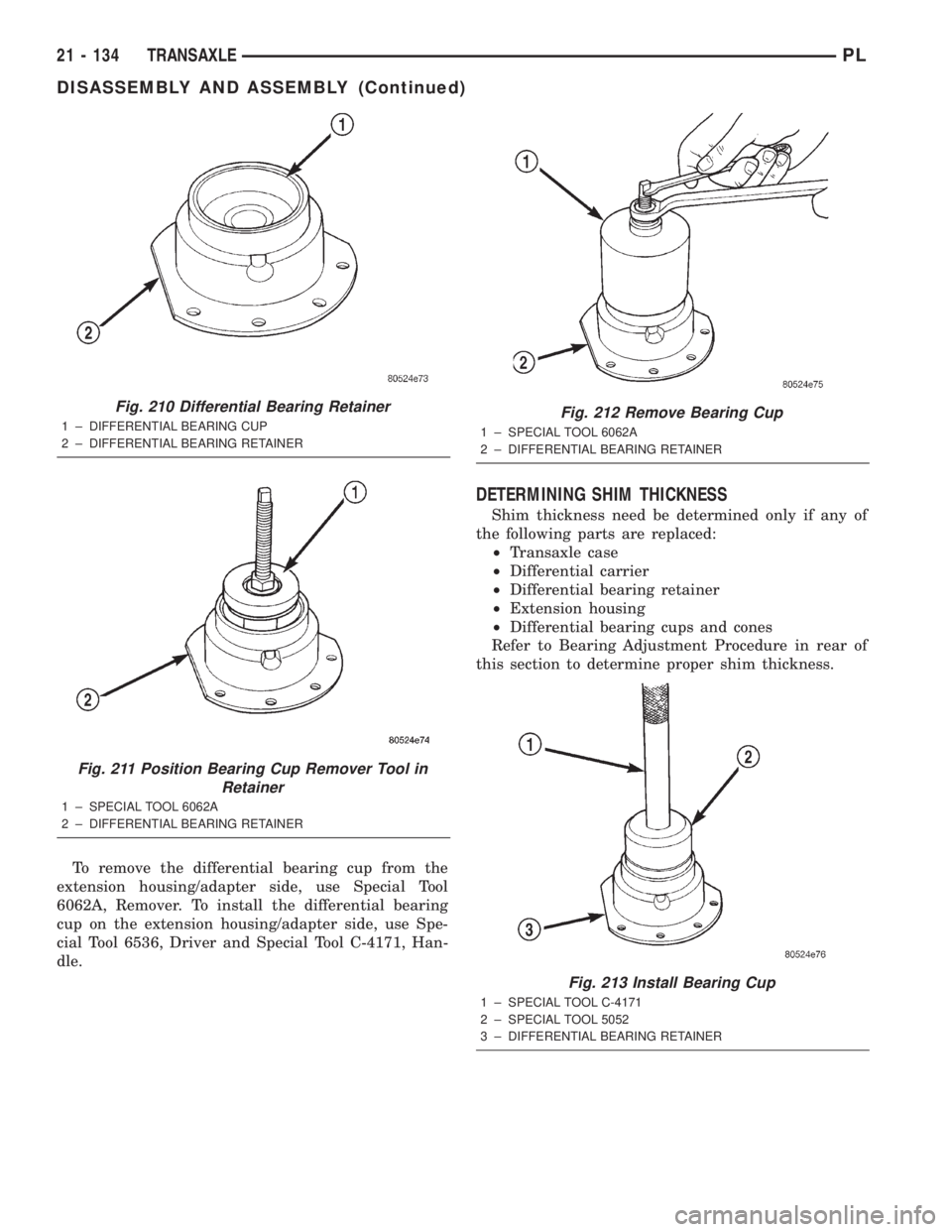

To remove the differential bearing cup from the

extension housing/adapter side, use Special Tool

6062A, Remover. To install the differential bearing

cup on the extension housing/adapter side, use Spe-

cial Tool 6536, Driver and Special Tool C-4171, Han-

dle.

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Differential carrier

²Differential bearing retainer

²Extension housing

²Differential bearing cups and cones

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.

Fig. 210 Differential Bearing Retainer

1 ± DIFFERENTIAL BEARING CUP

2 ± DIFFERENTIAL BEARING RETAINER

Fig. 211 Position Bearing Cup Remover Tool in

Retainer

1 ± SPECIAL TOOL 6062A

2 ± DIFFERENTIAL BEARING RETAINER

Fig. 212 Remove Bearing Cup

1 ± SPECIAL TOOL 6062A

2 ± DIFFERENTIAL BEARING RETAINER

Fig. 213 Install Bearing Cup

1 ± SPECIAL TOOL C-4171

2 ± SPECIAL TOOL 5052

3 ± DIFFERENTIAL BEARING RETAINER

21 - 134 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)