tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 998 of 1285

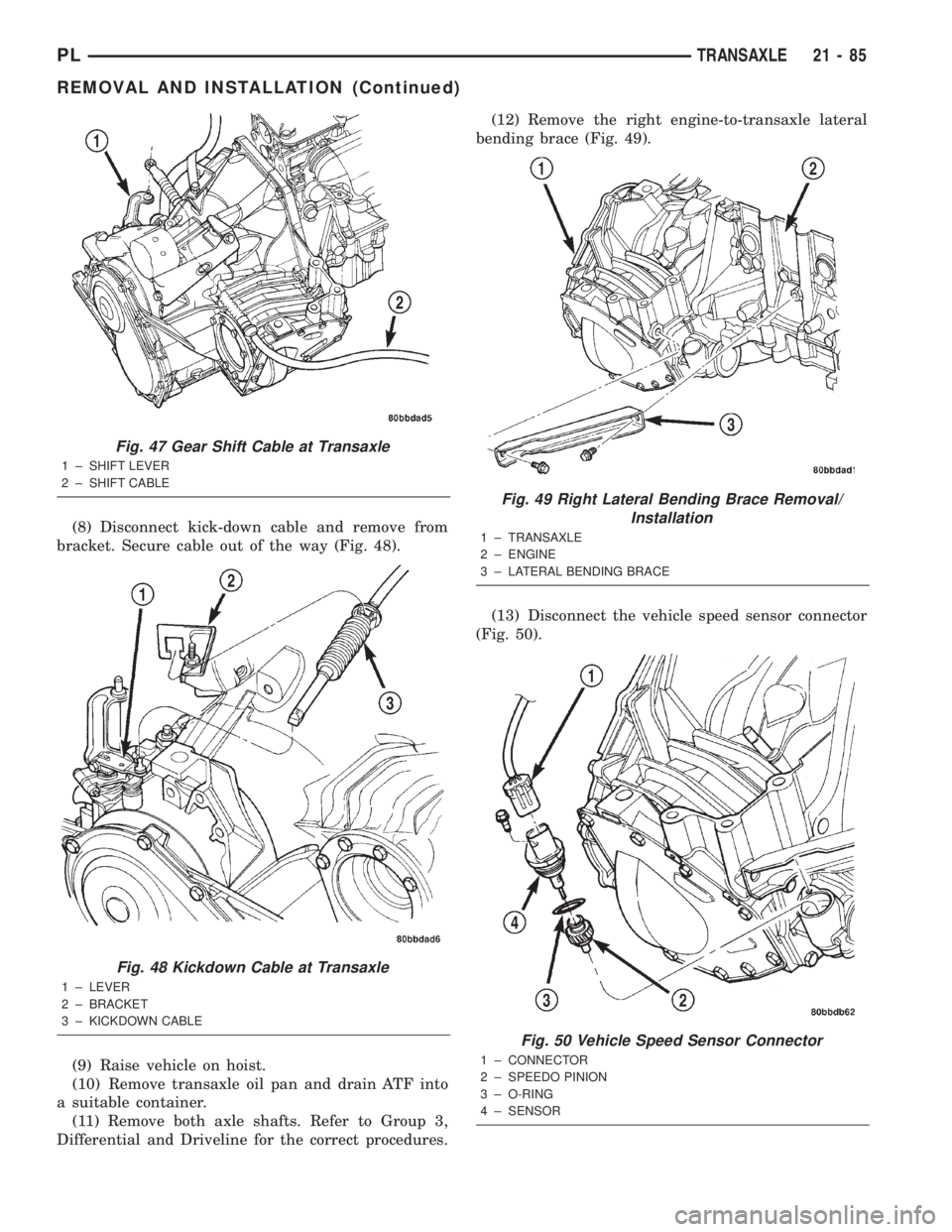

(8) Disconnect kick-down cable and remove from

bracket. Secure cable out of the way (Fig. 48).

(9) Raise vehicle on hoist.

(10) Remove transaxle oil pan and drain ATF into

a suitable container.

(11) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.(12) Remove the right engine-to-transaxle lateral

bending brace (Fig. 49).

(13) Disconnect the vehicle speed sensor connector

(Fig. 50).

Fig. 47 Gear Shift Cable at Transaxle

1 ± SHIFT LEVER

2 ± SHIFT CABLE

Fig. 48 Kickdown Cable at Transaxle

1 ± LEVER

2 ± BRACKET

3 ± KICKDOWN CABLE

Fig. 49 Right Lateral Bending Brace Removal/

Installation

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

Fig. 50 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SPEEDO PINION

3 ± O-RING

4 ± SENSOR

PLTRANSAXLE 21 - 85

REMOVAL AND INSTALLATION (Continued)

Page 999 of 1285

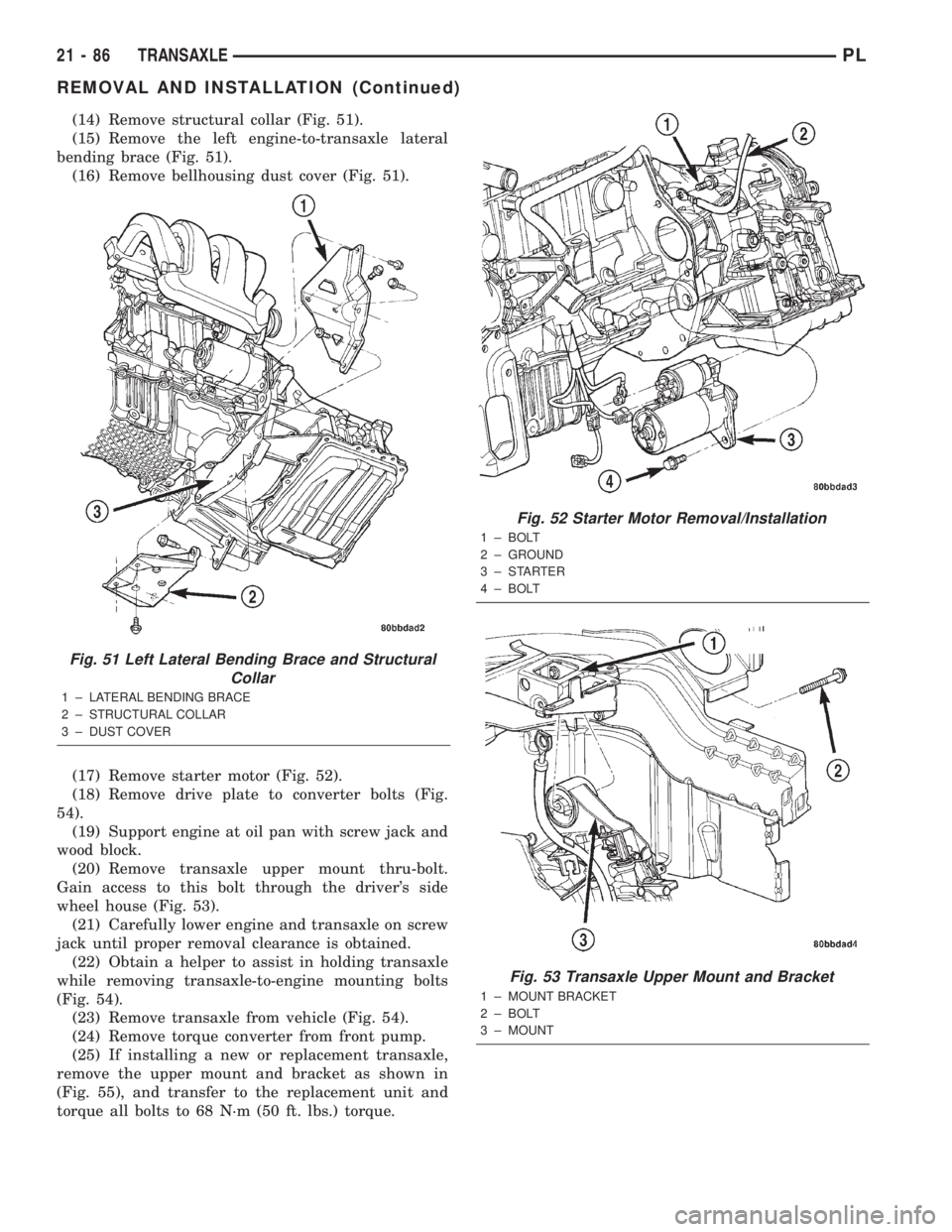

(14) Remove structural collar (Fig. 51).

(15) Remove the left engine-to-transaxle lateral

bending brace (Fig. 51).

(16) Remove bellhousing dust cover (Fig. 51).

(17) Remove starter motor (Fig. 52).

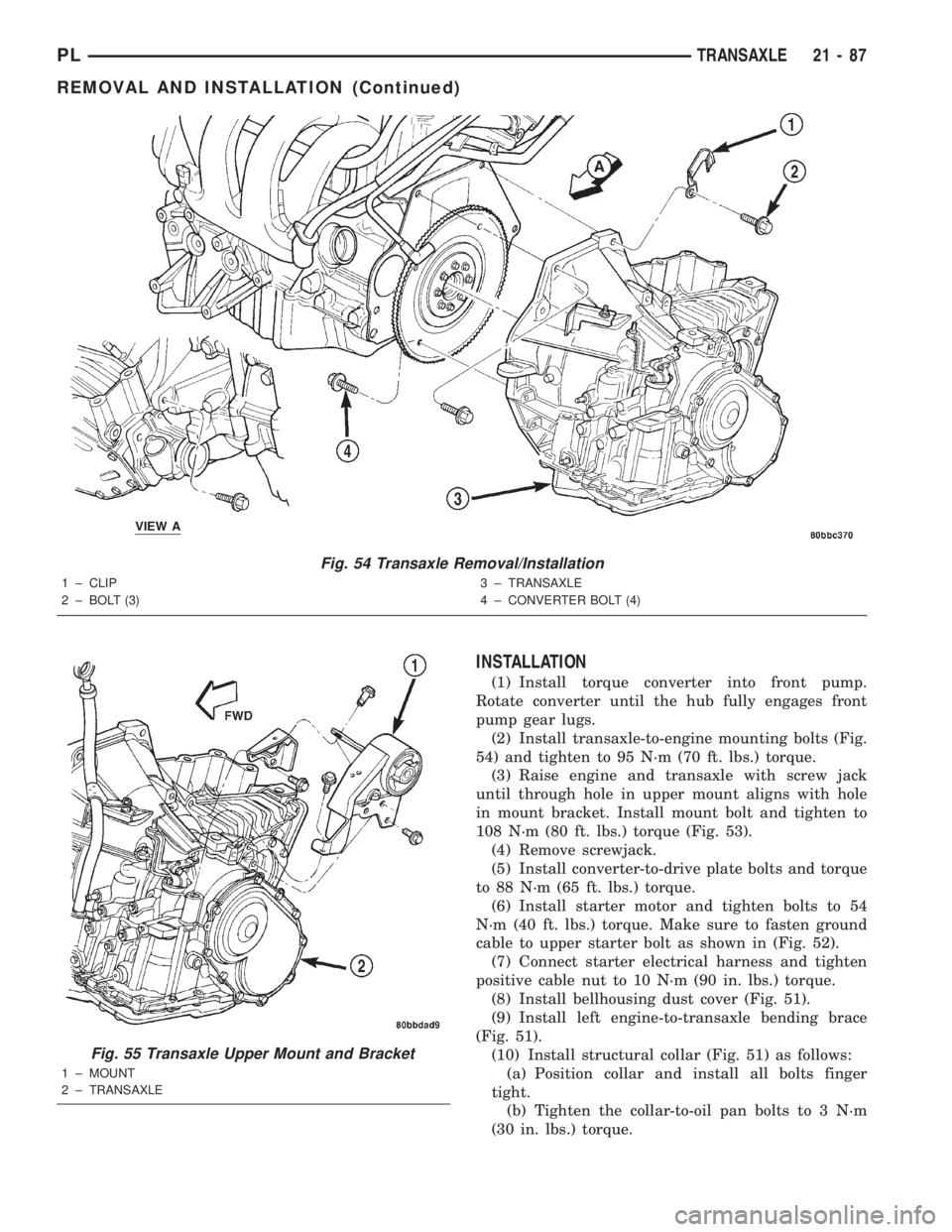

(18) Remove drive plate to converter bolts (Fig.

54).

(19) Support engine at oil pan with screw jack and

wood block.

(20) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 53).

(21) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(22) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 54).

(23) Remove transaxle from vehicle (Fig. 54).

(24) Remove torque converter from front pump.

(25) If installing a new or replacement transaxle,

remove the upper mount and bracket as shown in

(Fig. 55), and transfer to the replacement unit and

torque all bolts to 68 N´m (50 ft. lbs.) torque.

Fig. 51 Left Lateral Bending Brace and Structural

Collar

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 52 Starter Motor Removal/Installation

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 53 Transaxle Upper Mount and Bracket

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 86 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1000 of 1285

INSTALLATION

(1) Install torque converter into front pump.

Rotate converter until the hub fully engages front

pump gear lugs.

(2) Install transaxle-to-engine mounting bolts (Fig.

54) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 53).

(4) Remove screwjack.

(5) Install converter-to-drive plate bolts and torque

to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 52).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 51).

(9) Install left engine-to-transaxle bending brace

(Fig. 51).

(10) Install structural collar (Fig. 51) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

Fig. 54 Transaxle Removal/Installation

1 ± CLIP

2 ± BOLT (3)3 ± TRANSAXLE

4 ± CONVERTER BOLT (4)

Fig. 55 Transaxle Upper Mount and Bracket

1 ± MOUNT

2 ± TRANSAXLE

PLTRANSAXLE 21 - 87

REMOVAL AND INSTALLATION (Continued)

Page 1001 of 1285

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(12) Connect vehicle speed sensor connector (Fig.

50).

(13) Install right lateral bending brace and tighten

bolts to 81 N´m (60 ft. lbs.) torque.

(14) Lower vehicle.

(15) Connect transaxle cooler lines and tighten

clamps (Fig. 46).

(16) Connect torque converter clutch solenoid and

neutral safety/back-up lamp switch connectors.

(17) Install transaxle dipstick tube.

(18) Install gear shift cable to bracket and connect

to shift lever (Fig. 47).

(19) Install transaxle kickdown cable to bracket

and lever as shown in (Fig. 48).

(20) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

(21) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator, transaxle kickdown,

and speed control (if equipped) cables to the air

cleaner/throttle body assy.

(b) Install assy into position and tighten fasten-

ers to 14 N´m (120 in. lbs.) torque.

(c) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(d) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(22) Fill transaxle with a suitable amount of

ATF+4.

(23) Road test vehicle.

(24) Check for leaks, inspect fluid level, and adjust

as necessary.

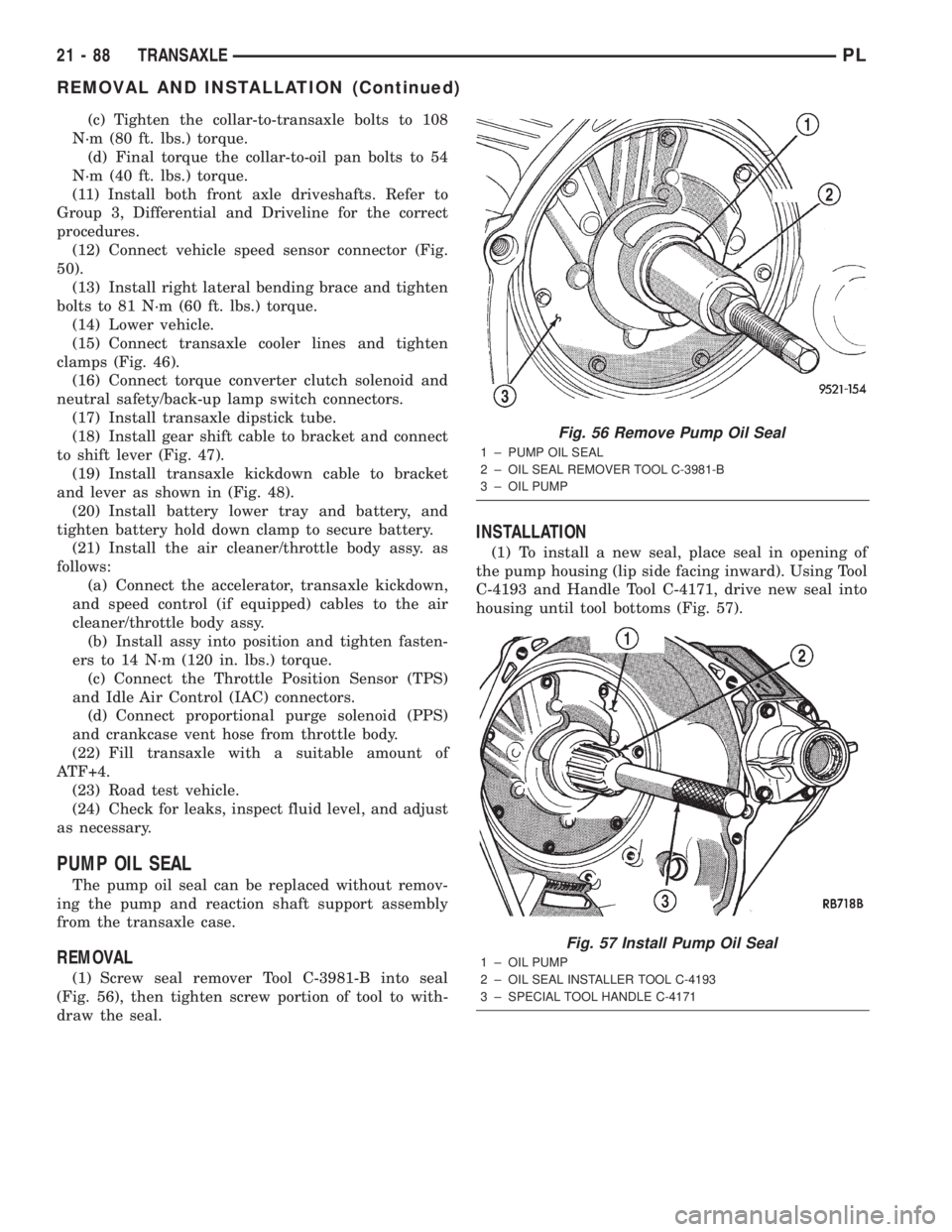

PUMP OIL SEAL

The pump oil seal can be replaced without remov-

ing the pump and reaction shaft support assembly

from the transaxle case.

REMOVAL

(1) Screw seal remover Tool C-3981-B into seal

(Fig. 56), then tighten screw portion of tool to with-

draw the seal.

INSTALLATION

(1) To install a new seal, place seal in opening of

the pump housing (lip side facing inward). Using Tool

C-4193 and Handle Tool C-4171, drive new seal into

housing until tool bottoms (Fig. 57).

Fig. 56 Remove Pump Oil Seal

1 ± PUMP OIL SEAL

2 ± OIL SEAL REMOVER TOOL C-3981-B

3 ± OIL PUMP

Fig. 57 Install Pump Oil Seal

1 ± OIL PUMP

2 ± OIL SEAL INSTALLER TOOL C-4193

3 ± SPECIAL TOOL HANDLE C-4171

21 - 88 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1002 of 1285

DISASSEMBLY AND ASSEMBLY

TRANSAXLE

DISASSEMBLY

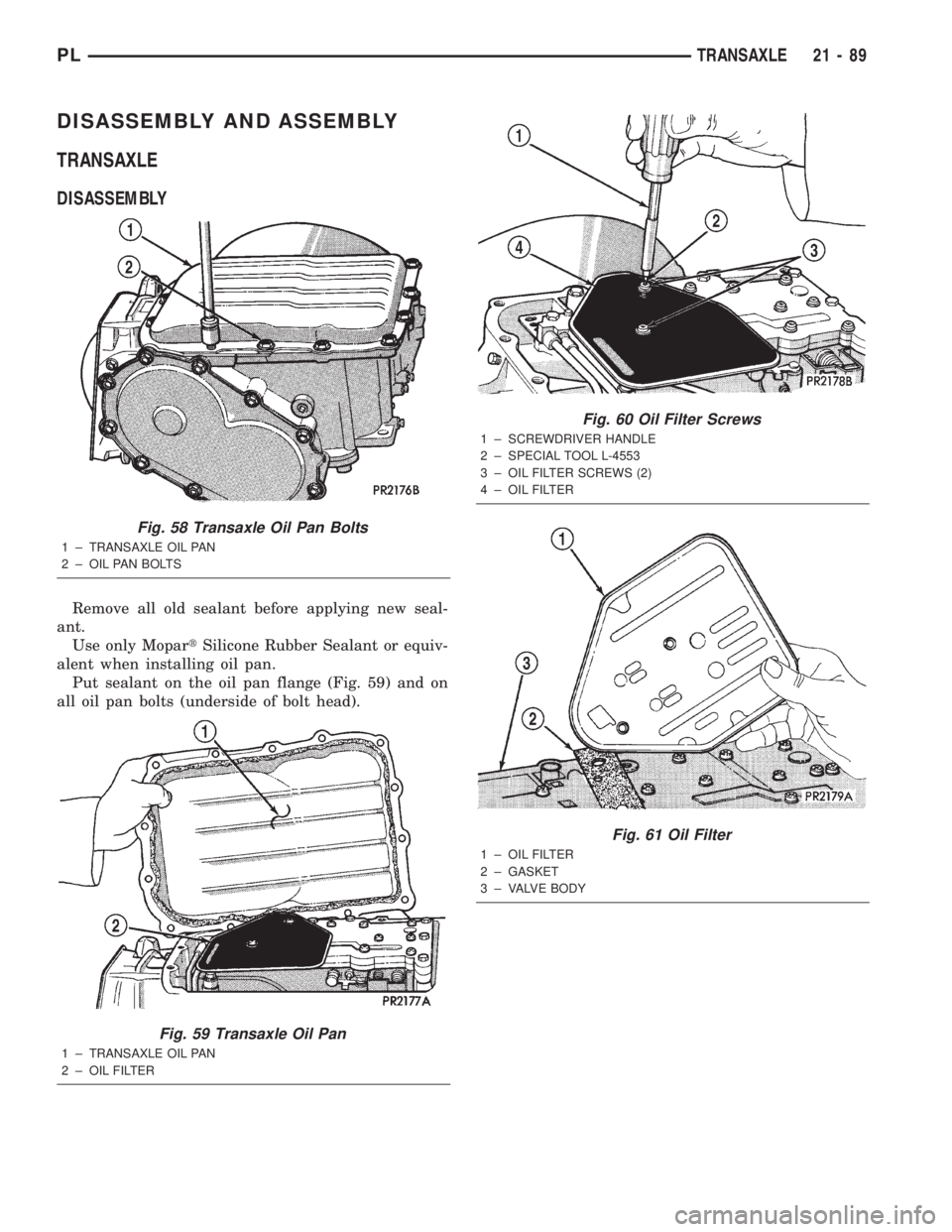

Remove all old sealant before applying new seal-

ant.

Use only MopartSilicone Rubber Sealant or equiv-

alent when installing oil pan.

Put sealant on the oil pan flange (Fig. 59) and on

all oil pan bolts (underside of bolt head).

Fig. 58 Transaxle Oil Pan Bolts

1 ± TRANSAXLE OIL PAN

2 ± OIL PAN BOLTS

Fig. 59 Transaxle Oil Pan

1 ± TRANSAXLE OIL PAN

2 ± OIL FILTER

Fig. 60 Oil Filter Screws

1 ± SCREWDRIVER HANDLE

2 ± SPECIAL TOOL L-4553

3 ± OIL FILTER SCREWS (2)

4 ± OIL FILTER

Fig. 61 Oil Filter

1 ± OIL FILTER

2 ± GASKET

3 ± VALVE BODY

PLTRANSAXLE 21 - 89

Page 1003 of 1285

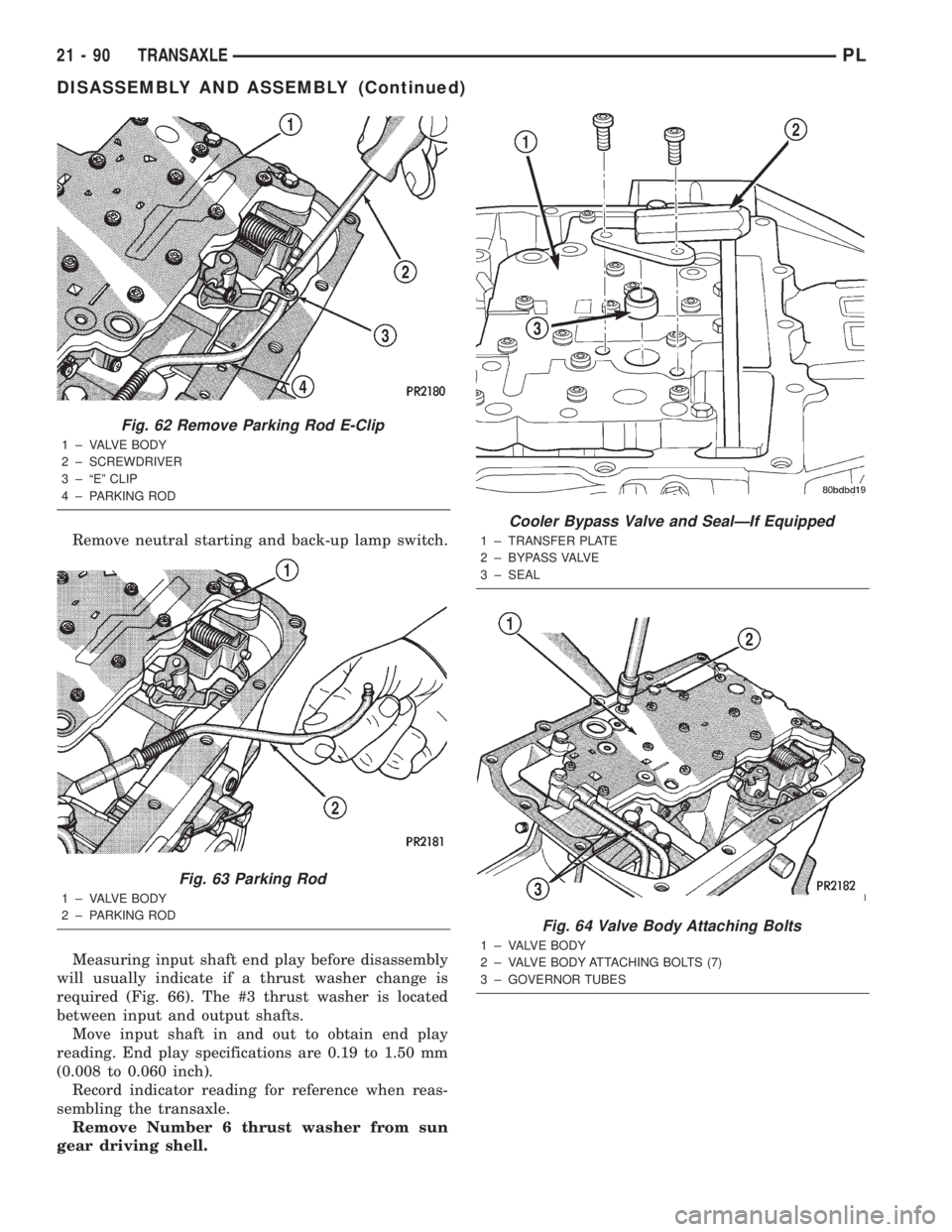

Remove neutral starting and back-up lamp switch.

Measuring input shaft end play before disassembly

will usually indicate if a thrust washer change is

required (Fig. 66). The #3 thrust washer is located

between input and output shafts.

Move input shaft in and out to obtain end play

reading. End play specifications are 0.19 to 1.50 mm

(0.008 to 0.060 inch).

Record indicator reading for reference when reas-

sembling the transaxle.

Remove Number 6 thrust washer from sun

gear driving shell.

Fig. 62 Remove Parking Rod E-Clip

1 ± VALVE BODY

2 ± SCREWDRIVER

3 ± ªEº CLIP

4 ± PARKING ROD

Fig. 63 Parking Rod

1 ± VALVE BODY

2 ± PARKING ROD

Cooler Bypass Valve and SealÐIf Equipped

1 ± TRANSFER PLATE

2 ± BYPASS VALVE

3 ± SEAL

Fig. 64 Valve Body Attaching Bolts

1 ± VALVE BODY

2 ± VALVE BODY ATTACHING BOLTS (7)

3 ± GOVERNOR TUBES

21 - 90 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1004 of 1285

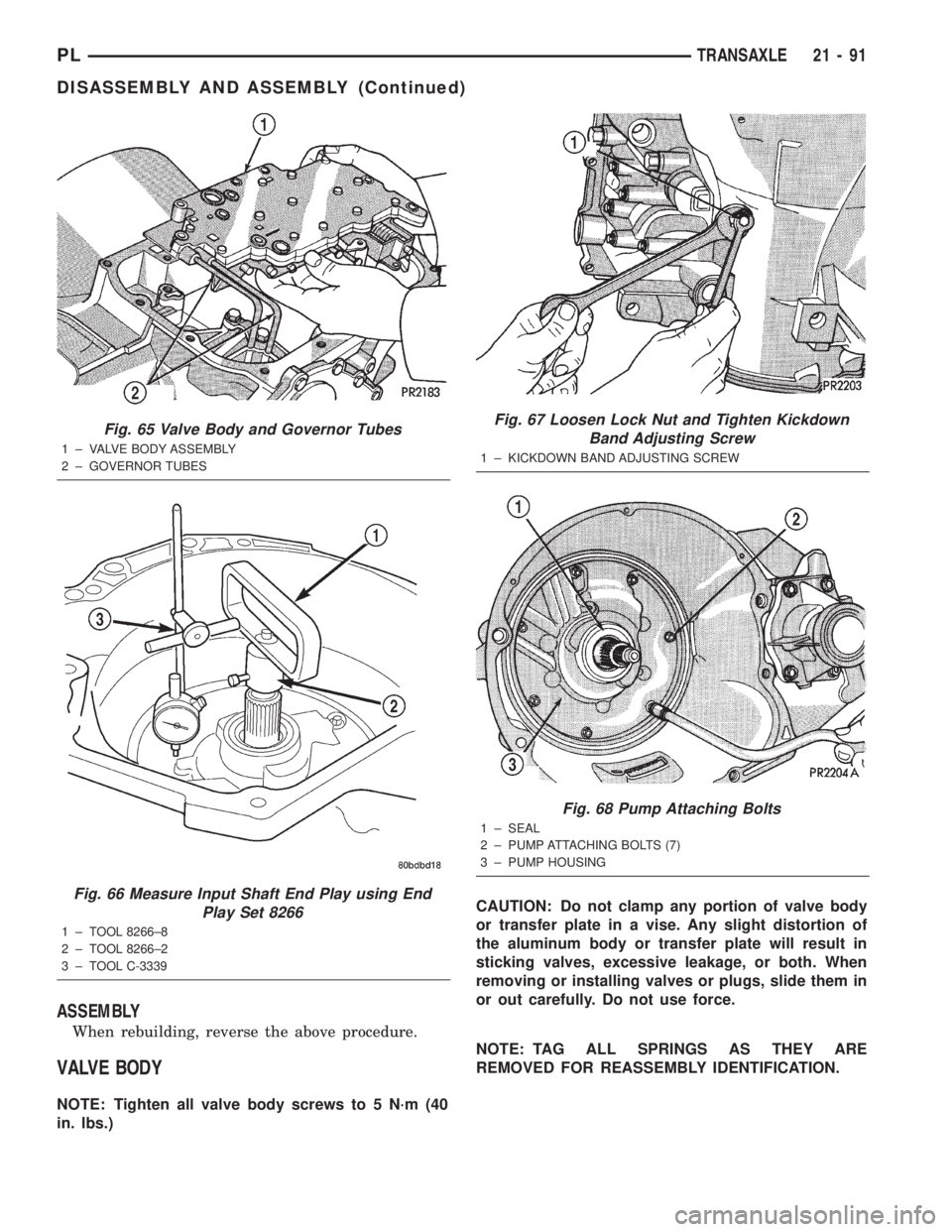

ASSEMBLY

When rebuilding, reverse the above procedure.

VALVE BODY

NOTE: Tighten all valve body screws to 5 N´m (40

in. lbs.)CAUTION: Do not clamp any portion of valve body

or transfer plate in a vise. Any slight distortion of

the aluminum body or transfer plate will result in

sticking valves, excessive leakage, or both. When

removing or installing valves or plugs, slide them in

or out carefully. Do not use force.

NOTE: TAG ALL SPRINGS AS THEY ARE

REMOVED FOR REASSEMBLY IDENTIFICATION.

Fig. 65 Valve Body and Governor Tubes

1 ± VALVE BODY ASSEMBLY

2 ± GOVERNOR TUBES

Fig. 66 Measure Input Shaft End Play using End

Play Set 8266

1 ± TOOL 8266±8

2 ± TOOL 8266±2

3 ± TOOL C-3339

Fig. 67 Loosen Lock Nut and Tighten Kickdown

Band Adjusting Screw

1 ± KICKDOWN BAND ADJUSTING SCREW

Fig. 68 Pump Attaching Bolts

1 ± SEAL

2 ± PUMP ATTACHING BOLTS (7)

3 ± PUMP HOUSING

PLTRANSAXLE 21 - 91

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1005 of 1285

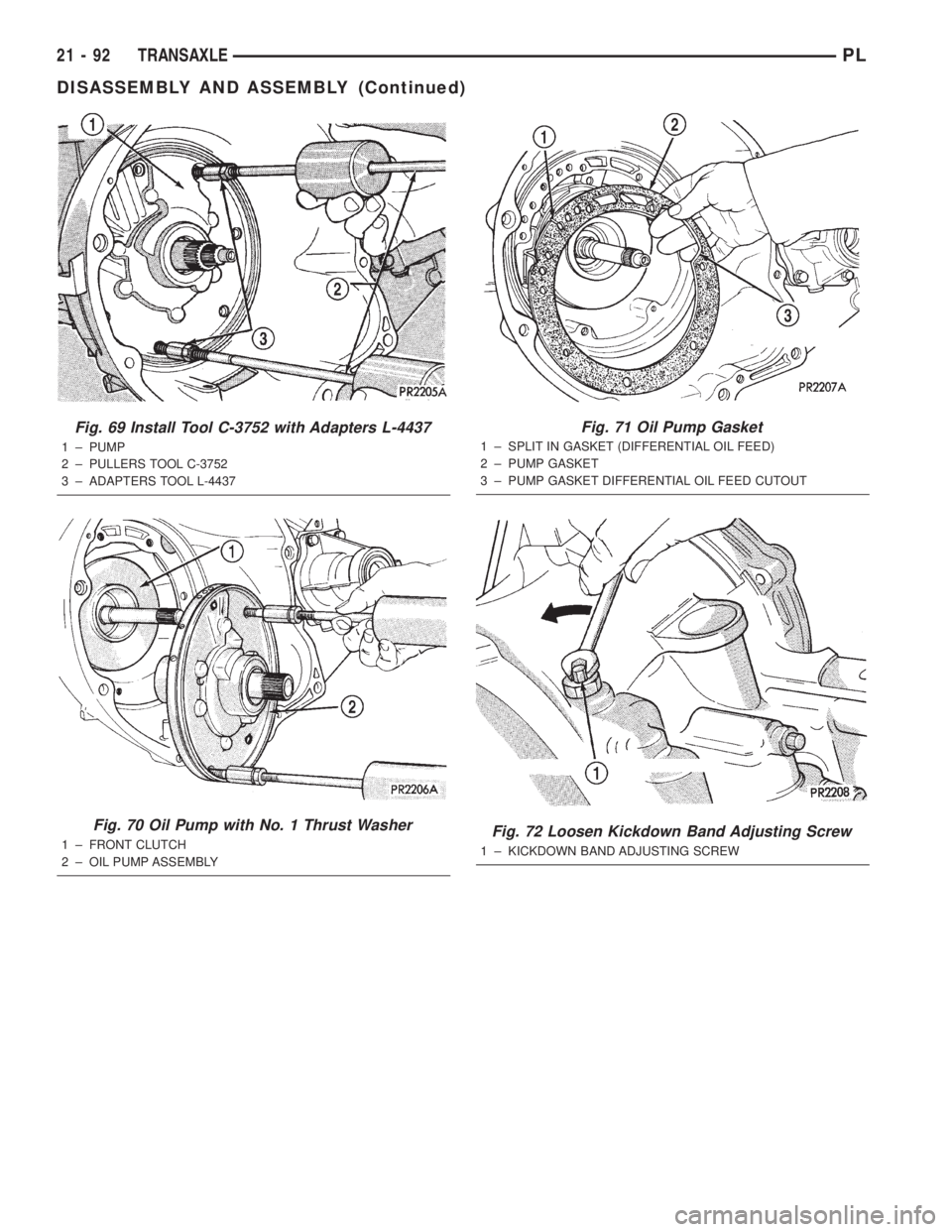

Fig. 69 Install Tool C-3752 with Adapters L-4437

1 ± PUMP

2 ± PULLERS TOOL C-3752

3 ± ADAPTERS TOOL L-4437

Fig. 70 Oil Pump with No. 1 Thrust Washer

1 ± FRONT CLUTCH

2 ± OIL PUMP ASSEMBLY

Fig. 71 Oil Pump Gasket

1 ± SPLIT IN GASKET (DIFFERENTIAL OIL FEED)

2 ± PUMP GASKET

3 ± PUMP GASKET DIFFERENTIAL OIL FEED CUTOUT

Fig. 72 Loosen Kickdown Band Adjusting Screw

1 ± KICKDOWN BAND ADJUSTING SCREW

21 - 92 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1006 of 1285

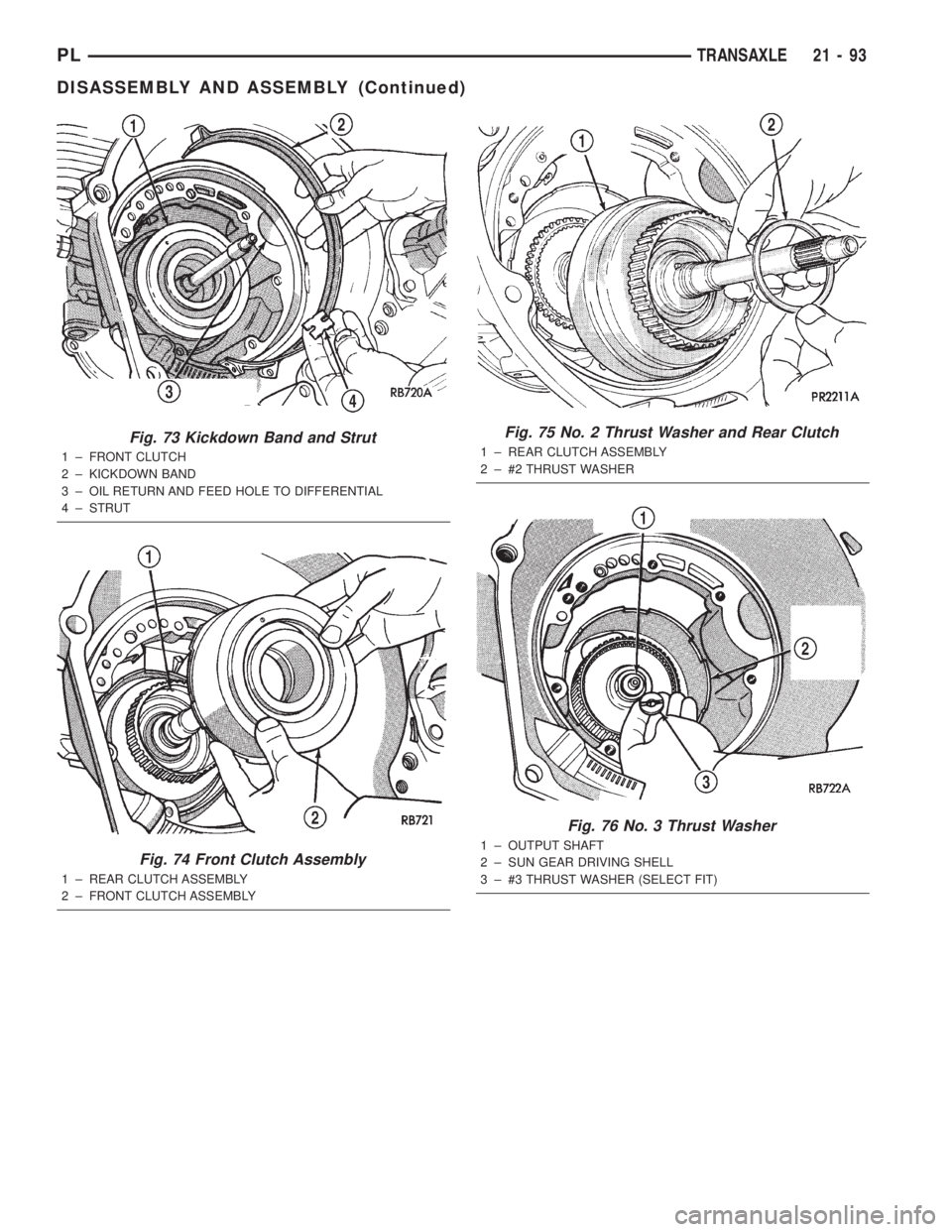

Fig. 73 Kickdown Band and Strut

1 ± FRONT CLUTCH

2 ± KICKDOWN BAND

3 ± OIL RETURN AND FEED HOLE TO DIFFERENTIAL

4 ± STRUT

Fig. 74 Front Clutch Assembly

1 ± REAR CLUTCH ASSEMBLY

2 ± FRONT CLUTCH ASSEMBLY

Fig. 75 No. 2 Thrust Washer and Rear Clutch

1 ± REAR CLUTCH ASSEMBLY

2 ± #2 THRUST WASHER

Fig. 76 No. 3 Thrust Washer

1 ± OUTPUT SHAFT

2 ± SUN GEAR DRIVING SHELL

3 ± #3 THRUST WASHER (SELECT FIT)

PLTRANSAXLE 21 - 93

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1007 of 1285

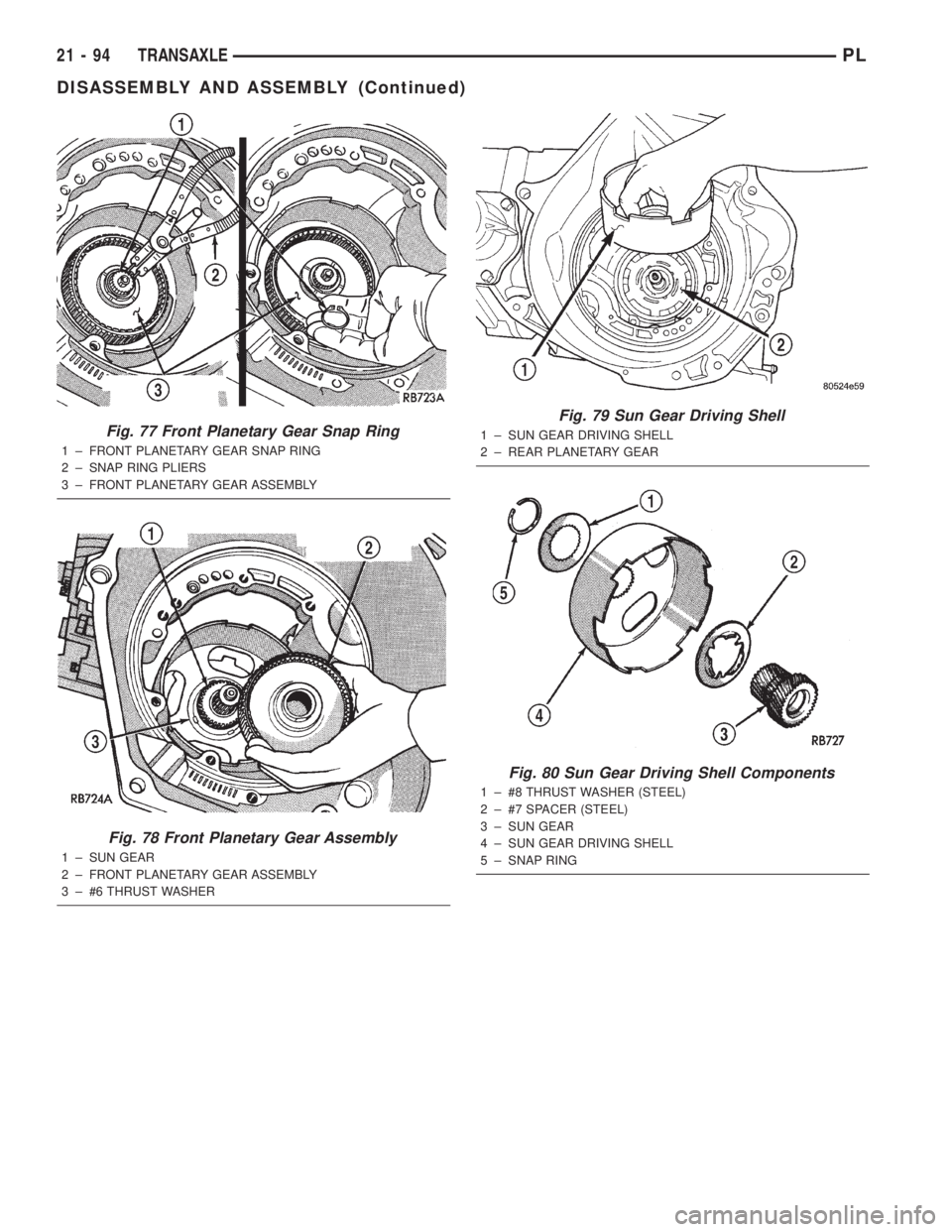

Fig. 77 Front Planetary Gear Snap Ring

1 ± FRONT PLANETARY GEAR SNAP RING

2 ± SNAP RING PLIERS

3 ± FRONT PLANETARY GEAR ASSEMBLY

Fig. 78 Front Planetary Gear Assembly

1 ± SUN GEAR

2 ± FRONT PLANETARY GEAR ASSEMBLY

3 ± #6 THRUST WASHER

Fig. 79 Sun Gear Driving Shell

1 ± SUN GEAR DRIVING SHELL

2 ± REAR PLANETARY GEAR

Fig. 80 Sun Gear Driving Shell Components

1 ± #8 THRUST WASHER (STEEL)

2 ± #7 SPACER (STEEL)

3 ± SUN GEAR

4 ± SUN GEAR DRIVING SHELL

5 ± SNAP RING

21 - 94 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)