wheel DODGE NEON 2000 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 65 of 1285

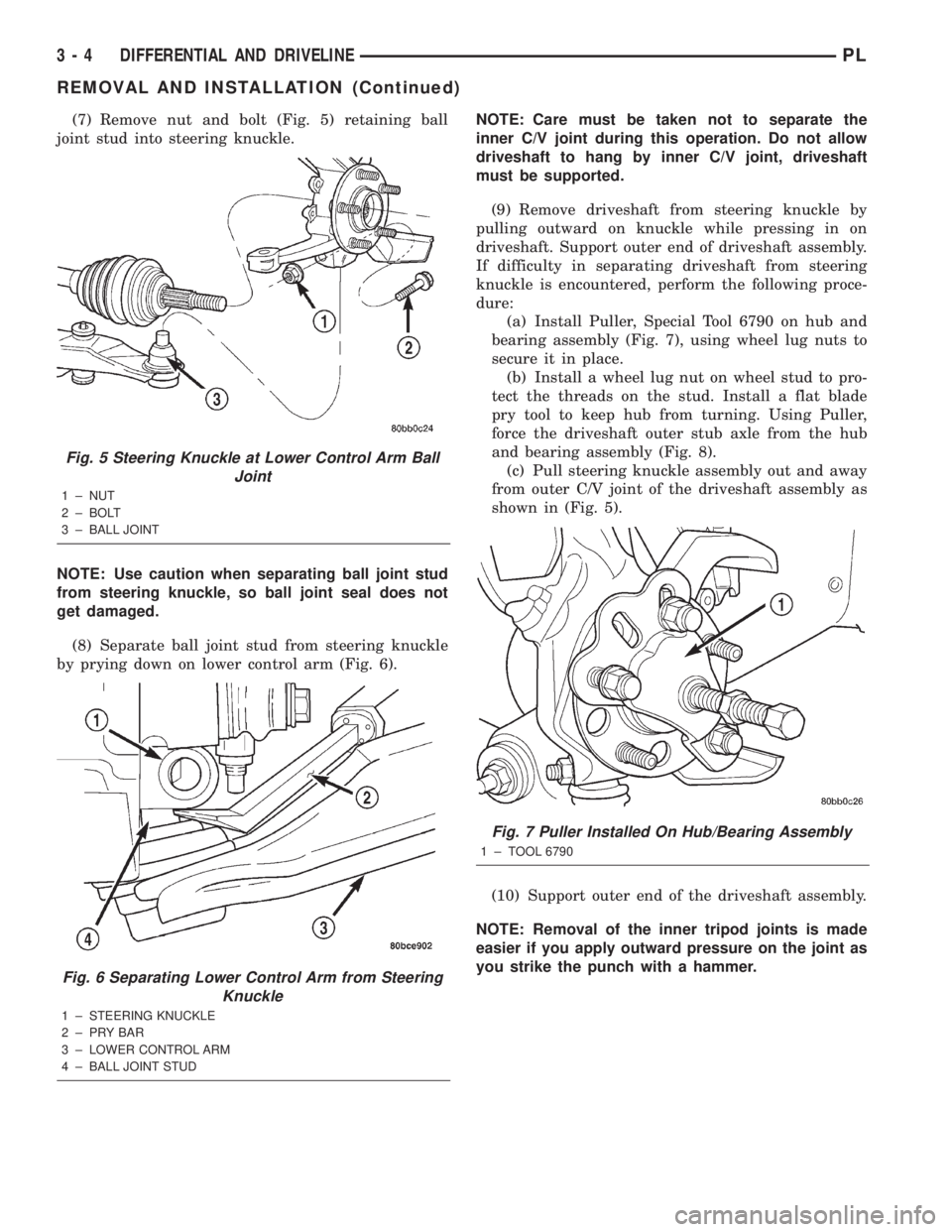

(7) Remove nut and bolt (Fig. 5) retaining ball

joint stud into steering knuckle.

NOTE: Use caution when separating ball joint stud

from steering knuckle, so ball joint seal does not

get damaged.

(8) Separate ball joint stud from steering knuckle

by prying down on lower control arm (Fig. 6).NOTE: Care must be taken not to separate the

inner C/V joint during this operation. Do not allow

driveshaft to hang by inner C/V joint, driveshaft

must be supported.

(9) Remove driveshaft from steering knuckle by

pulling outward on knuckle while pressing in on

driveshaft. Support outer end of driveshaft assembly.

If difficulty in separating driveshaft from steering

knuckle is encountered, perform the following proce-

dure:

(a) Install Puller, Special Tool 6790 on hub and

bearing assembly (Fig. 7), using wheel lug nuts to

secure it in place.

(b) Install a wheel lug nut on wheel stud to pro-

tect the threads on the stud. Install a flat blade

pry tool to keep hub from turning. Using Puller,

force the driveshaft outer stub axle from the hub

and bearing assembly (Fig. 8).

(c) Pull steering knuckle assembly out and away

from outer C/V joint of the driveshaft assembly as

shown in (Fig. 5).

(10) Support outer end of the driveshaft assembly.

NOTE: Removal of the inner tripod joints is made

easier if you apply outward pressure on the joint as

you strike the punch with a hammer.

Fig. 5 Steering Knuckle at Lower Control Arm Ball

Joint

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 6 Separating Lower Control Arm from Steering

Knuckle

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

Fig. 7 Puller Installed On Hub/Bearing Assembly

1 ± TOOL 6790

3 - 4 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 67 of 1285

CAUTION: The driveshaft, when installed, acts as a

bolt and secures the front hub/bearing assembly. If

vehicle is to be supported or moved on its wheels

with a driveshaft removed, install a PROPER±SIZED

BOLT AND NUT through front hub. Tighten bolt and

nut to 203 N´m (150 ft. lbs.). This will ensure that

the hub bearing cannot loosen.

INSTALLATION

(1) Thoroughly clean spline and oil seal sealing

surface, on tripod joint. Lightly lubricate oil seal

sealing surface on tripod joint with fresh clean trans-

mission lubricant.

(2) Holding driveshaft assembly by tripod joint and

interconnecting shaft, install tripod joint into tran-

saxle side gear as far as possible by hand.

(3) Carefully align tripod joint with transaxle side

gears. Then grasp driveshaft interconnecting shaft

and push tripod joint into transaxle side gear until

fully seated.Test that snap ring is fully engaged

with side gear by attempting to remove tripod

joint from transaxle by hand. If snap ring is

fully engaged with side gear, tripod joint will

not be removable by hand.

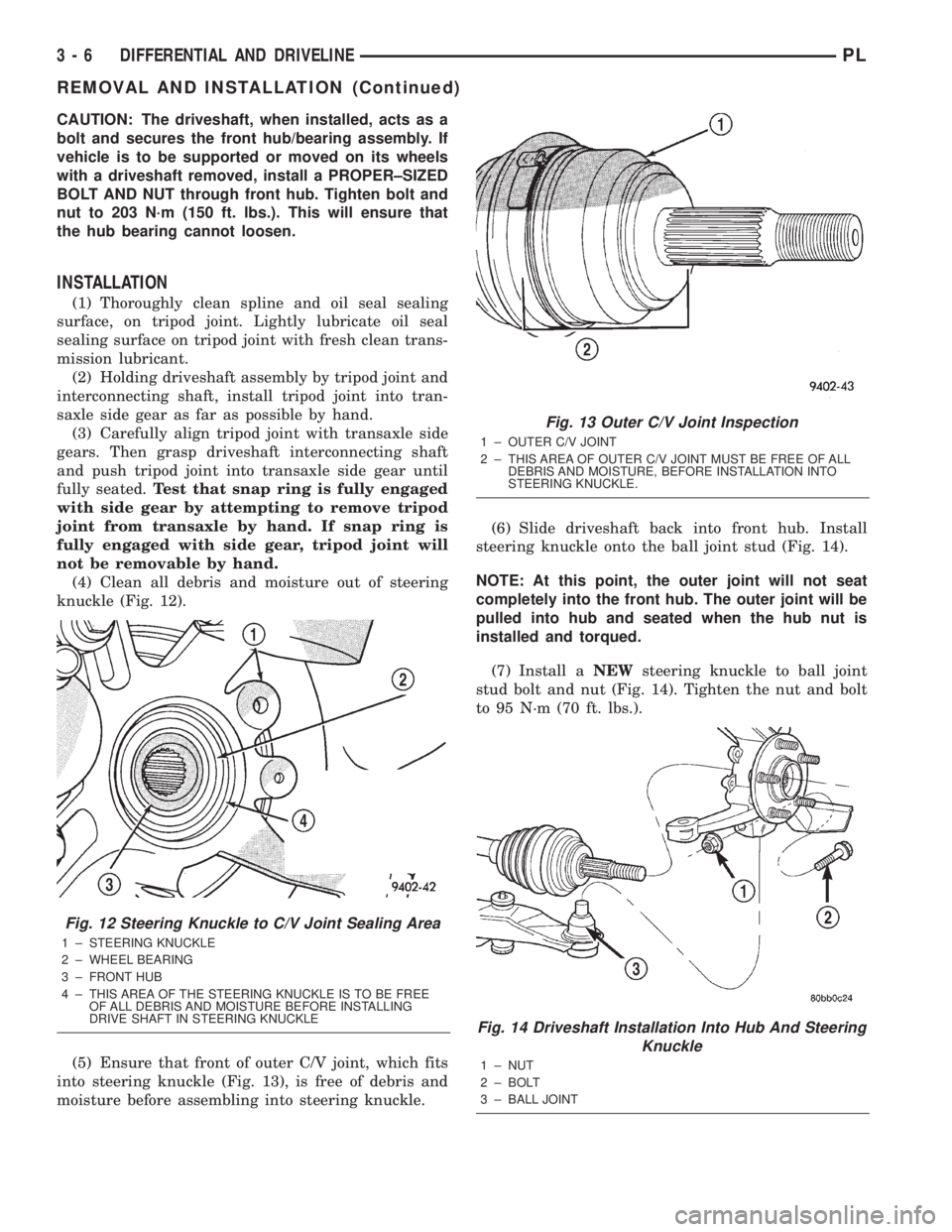

(4) Clean all debris and moisture out of steering

knuckle (Fig. 12).

(5) Ensure that front of outer C/V joint, which fits

into steering knuckle (Fig. 13), is free of debris and

moisture before assembling into steering knuckle.(6) Slide driveshaft back into front hub. Install

steering knuckle onto the ball joint stud (Fig. 14).

NOTE: At this point, the outer joint will not seat

completely into the front hub. The outer joint will be

pulled into hub and seated when the hub nut is

installed and torqued.

(7) Install aNEWsteering knuckle to ball joint

stud bolt and nut (Fig. 14). Tighten the nut and bolt

to 95 N´m (70 ft. lbs.).

Fig. 12 Steering Knuckle to C/V Joint Sealing Area

1 ± STEERING KNUCKLE

2 ± WHEEL BEARING

3 ± FRONT HUB

4 ± THIS AREA OF THE STEERING KNUCKLE IS TO BE FREE

OF ALL DEBRIS AND MOISTURE BEFORE INSTALLING

DRIVE SHAFT IN STEERING KNUCKLE

Fig. 13 Outer C/V Joint Inspection

1 ± OUTER C/V JOINT

2 ± THIS AREA OF OUTER C/V JOINT MUST BE FREE OF ALL

DEBRIS AND MOISTURE, BEFORE INSTALLATION INTO

STEERING KNUCKLE.

Fig. 14 Driveshaft Installation Into Hub And Steering

Knuckle

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

3 - 6 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 68 of 1285

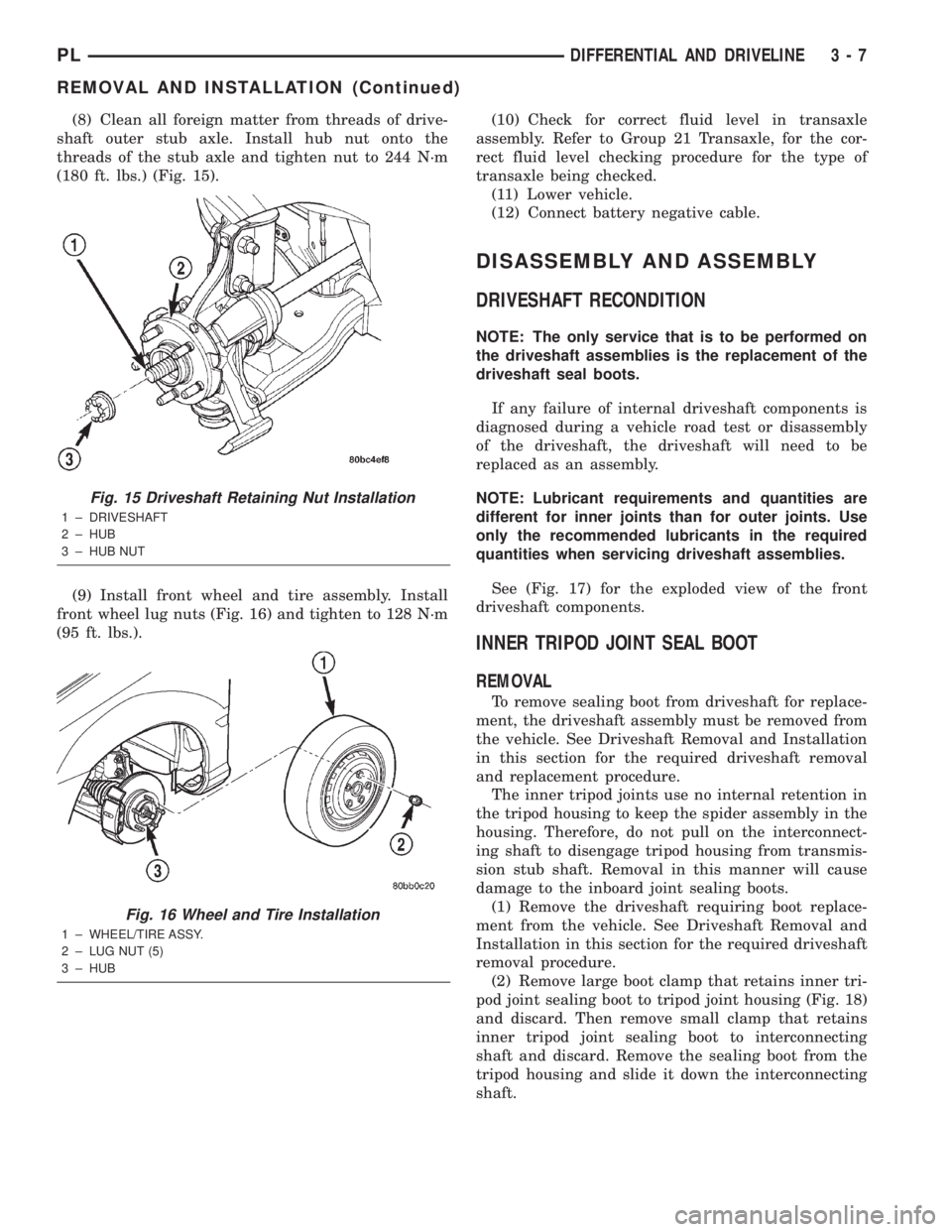

(8) Clean all foreign matter from threads of drive-

shaft outer stub axle. Install hub nut onto the

threads of the stub axle and tighten nut to 244 N´m

(180 ft. lbs.) (Fig. 15).

(9) Install front wheel and tire assembly. Install

front wheel lug nuts (Fig. 16) and tighten to 128 N´m

(95 ft. lbs.).(10) Check for correct fluid level in transaxle

assembly. Refer to Group 21 Transaxle, for the cor-

rect fluid level checking procedure for the type of

transaxle being checked.

(11) Lower vehicle.

(12) Connect battery negative cable.

DISASSEMBLY AND ASSEMBLY

DRIVESHAFT RECONDITION

NOTE: The only service that is to be performed on

the driveshaft assemblies is the replacement of the

driveshaft seal boots.

If any failure of internal driveshaft components is

diagnosed during a vehicle road test or disassembly

of the driveshaft, the driveshaft will need to be

replaced as an assembly.

NOTE: Lubricant requirements and quantities are

different for inner joints than for outer joints. Use

only the recommended lubricants in the required

quantities when servicing driveshaft assemblies.

See (Fig. 17) for the exploded view of the front

driveshaft components.

INNER TRIPOD JOINT SEAL BOOT

REMOVAL

To remove sealing boot from driveshaft for replace-

ment, the driveshaft assembly must be removed from

the vehicle. See Driveshaft Removal and Installation

in this section for the required driveshaft removal

and replacement procedure.

The inner tripod joints use no internal retention in

the tripod housing to keep the spider assembly in the

housing. Therefore, do not pull on the interconnect-

ing shaft to disengage tripod housing from transmis-

sion stub shaft. Removal in this manner will cause

damage to the inboard joint sealing boots.

(1) Remove the driveshaft requiring boot replace-

ment from the vehicle. See Driveshaft Removal and

Installation in this section for the required driveshaft

removal procedure.

(2) Remove large boot clamp that retains inner tri-

pod joint sealing boot to tripod joint housing (Fig. 18)

and discard. Then remove small clamp that retains

inner tripod joint sealing boot to interconnecting

shaft and discard. Remove the sealing boot from the

tripod housing and slide it down the interconnecting

shaft.

Fig. 15 Driveshaft Retaining Nut Installation

1 ± DRIVESHAFT

2 ± HUB

3 ± HUB NUT

Fig. 16 Wheel and Tire Installation

1 ± WHEEL/TIRE ASSY.

2 ± LUG NUT (5)

3 ± HUB

PLDIFFERENTIAL AND DRIVELINE 3 - 7

REMOVAL AND INSTALLATION (Continued)

Page 78 of 1285

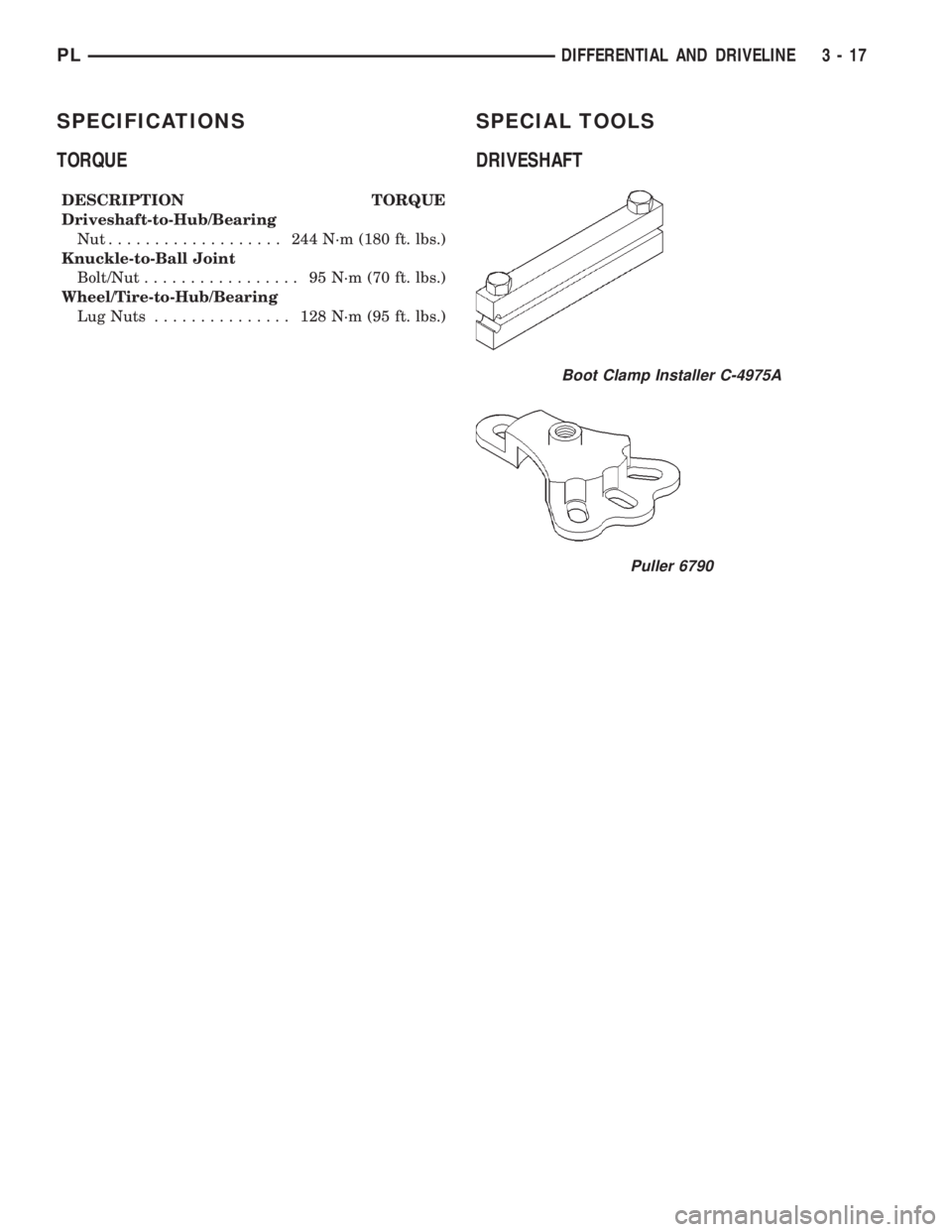

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Driveshaft-to-Hub/Bearing

Nut................... 244N´m(180 ft. lbs.)

Knuckle-to-Ball Joint

Bolt/Nut................. 95N´m(70ft.lbs.)

Wheel/Tire-to-Hub/Bearing

Lug Nuts............... 128N´m(95ft.lbs.)

SPECIAL TOOLS

DRIVESHAFT

Boot Clamp Installer C-4975A

Puller 6790

PLDIFFERENTIAL AND DRIVELINE 3 - 17

Page 80 of 1285

BRAKES

TABLE OF CONTENTS

page page

BASE BRAKE SYSTEM...................... 1ANTILOCK BRAKE SYSTEM................. 65

BASE BRAKE SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

BASE BRAKE SYSTEM OPERATION...........2

BASE BRAKE SYSTEM COMPONENTS.........2

DIAGNOSIS AND TESTING

BASE BRAKE SYSTEM DIAGNOSIS CHARTS....9

POWER BRAKE BOOSTER.................11

DRUM BRAKE AUTOMATIC ADJUSTER........12

BRAKE ROTOR..........................12

BRAKE DRUM...........................15

PROPORTIONING VALVE..................15

BRAKE FLUID CONTAMINATION.............17

SERVICE PROCEDURES

BRAKE FLUID LEVEL CHECKING............17

BASE BRAKE BLEEDING...................17

MASTER CYLINDER BLEEDING.............19

BRAKE TUBE REPAIR.....................19

BRAKE ROTOR MACHINING................21

BRAKE DRUM MACHINING.................22

PARKING BRAKE AUTOMATIC ADJUSTER

LOCK OUT............................22

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........23

BRAKE PEDAL...........................24

BRAKE LAMP SWITCH....................27

MASTER CYLINDER......................28

BRAKE FLUID RESERVOIR.................29

BRAKE FLUID LEVEL SWITCH..............30

POWER BRAKE BOOSTER.................30

PROPORTIONING VALVE..................32

BRAKES TUBES AND HOSES...............33

DISC BRAKE CALIPER (FRONT).............33

DISC BRAKE SHOES (FRONT)..............35BRAKE ROTOR (FRONT)...................37

DISC BRAKE CALIPER (REAR)..............38

DISC BRAKE SHOES (REAR)...............39

BRAKE ROTOR (REAR)....................41

DRUM BRAKE WHEEL CYLINDER (REAR).....41

DRUM BRAKE SHOES (REAR)..............43

BRAKE DRUM (REAR).....................45

DRUM BRAKE SHOE SUPPORT PLATE

(REAR)...............................46

PARKING BRAKE LEVER...................48

PARKING BRAKE CABLE (REAR)............49

PARKING BRAKE SHOES (REAR DISC

BRAKE)...............................53

DISASSEMBLY AND ASSEMBLY

DISC BRAKE CALIPER (FRONT AND REAR)....55

CLEANING AND INSPECTION

BRAKE TUBES AND HOSES................59

DISC BRAKES (FRONT)....................59

DISC BRAKES (REAR).....................60

DRUM BRAKES (REAR)....................60

ADJUSTMENTS

BRAKE LAMP SWITCH....................61

DRUM BRAKE SHOES.....................61

PARKING BRAKE SHOES (REAR DISC

BRAKES).............................62

SPECIFICATIONS

BRAKE FLUID...........................63

BRAKE ACTUATION SYSTEM...............63

BRAKE FASTENER TORQUE

SPECIFICATIONS.......................63

SPECIAL TOOLS

BASE BRAKE SYSTEM....................64

PLBRAKES 5 - 1

Page 81 of 1285

DESCRIPTION AND OPERATION

BASE BRAKE SYSTEM OPERATION

When a vehicle needs to be stopped, the driver

applies the brake pedal. The brake pedal pushes the

input rod of the power brake booster into the booster.

The booster uses vacuum to ease pedal effort as force

is transferred through the booster to the master cyl-

inder. The booster's output rod pushes in the master

cylinder's primary and secondary pistons applying

hydraulic pressure through the chassis brake tubes

and proportioning valves (rear only) to the brakes at

each tire and wheel assembly.

Front disc brakes control the braking of the front

wheels; rear braking is controlled by rear drum

brakes as standard equipment. Rear disc brakes and

an antilock brake system (ABS) with traction control

are optional.

The hydraulic brake system is diagonally split on

both the non-antilock and antilock braking systems.

This means the left front and right rear brakes are

on one hydraulic circuit and the right front and left

rear are on the other.

Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20e.

This system shares most base brake hardware used

on vehicles without ABS. A vehicle equipped with

ABS, however, uses a different master cylinder and

brake tubes. Also included in the ABS system is an

integrated control unit (ICU) and four wheel speed

sensors. These components are described in detail in

the ANTILOCK BRAKE SYSTEM section in this

group of the service manual. All vehicles with ABS

come standard with four-wheel-disc brakes and trac-

tion control.

The parking brakes are hand-operated. When

applied, the parking brake lever pulls on cables that

actuate brake shoes at each rear wheel. The parking

brake lever has an automatic adjusting feature that

takes up any excessive slack in the parking brake

cable system.

BASE BRAKE SYSTEM COMPONENTS

BRAKE PEDAL

A suspended-type brake pedal is used on this vehi-

cle. The pedal pivots on a shaft mounted in the pedal

support bracket under the instrument panel. The

pedal connects to the power brake booster input rod

and pushes it in when the pedal is applied.

The brake pedal and it's pad are serviceable sepa-

rately.

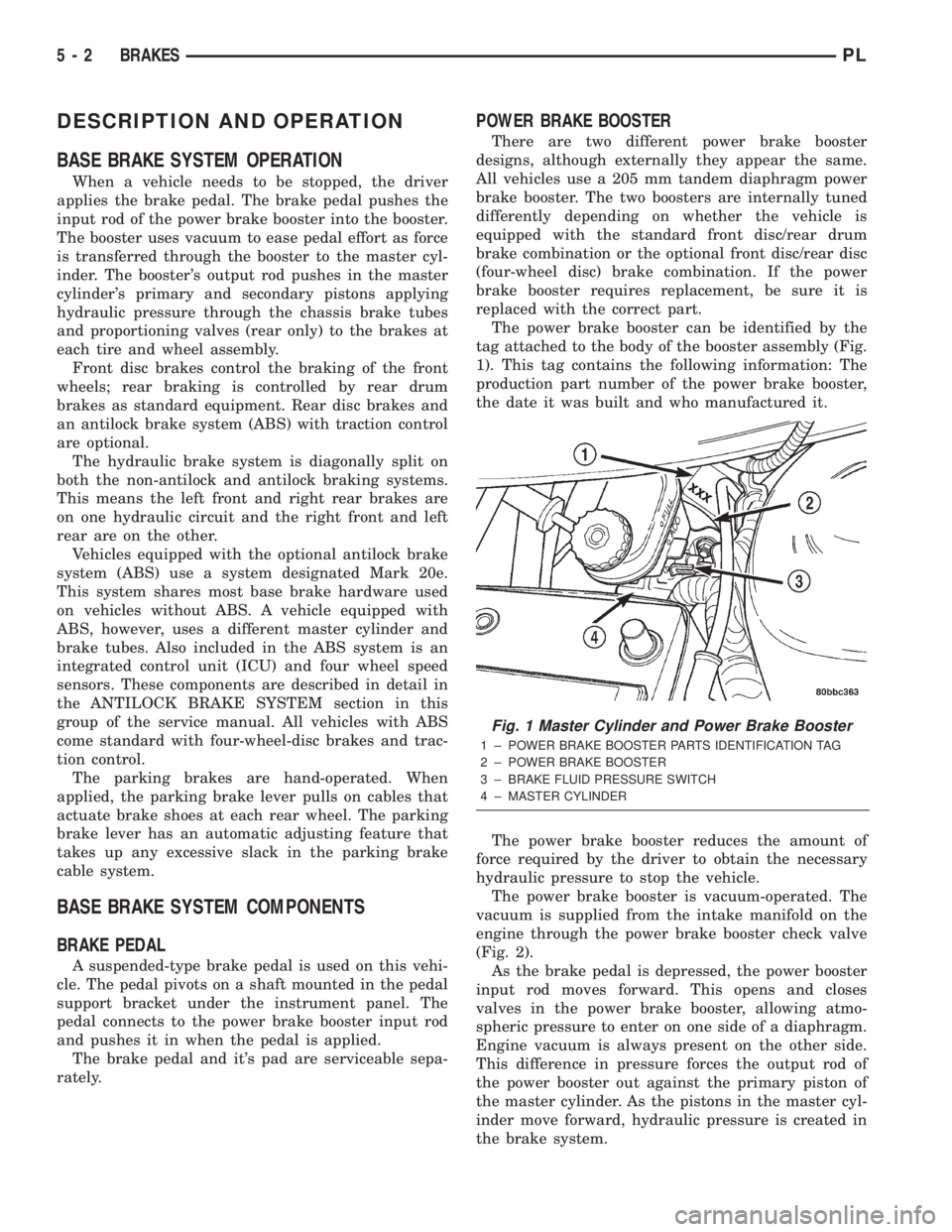

POWER BRAKE BOOSTER

There are two different power brake booster

designs, although externally they appear the same.

All vehicles use a 205 mm tandem diaphragm power

brake booster. The two boosters are internally tuned

differently depending on whether the vehicle is

equipped with the standard front disc/rear drum

brake combination or the optional front disc/rear disc

(four-wheel disc) brake combination. If the power

brake booster requires replacement, be sure it is

replaced with the correct part.

The power brake booster can be identified by the

tag attached to the body of the booster assembly (Fig.

1). This tag contains the following information: The

production part number of the power brake booster,

the date it was built and who manufactured it.

The power brake booster reduces the amount of

force required by the driver to obtain the necessary

hydraulic pressure to stop the vehicle.

The power brake booster is vacuum-operated. The

vacuum is supplied from the intake manifold on the

engine through the power brake booster check valve

(Fig. 2).

As the brake pedal is depressed, the power booster

input rod moves forward. This opens and closes

valves in the power brake booster, allowing atmo-

spheric pressure to enter on one side of a diaphragm.

Engine vacuum is always present on the other side.

This difference in pressure forces the output rod of

the power booster out against the primary piston of

the master cylinder. As the pistons in the master cyl-

inder move forward, hydraulic pressure is created in

the brake system.

Fig. 1 Master Cylinder and Power Brake Booster

1 ± POWER BRAKE BOOSTER PARTS IDENTIFICATION TAG

2 ± POWER BRAKE BOOSTER

3 ± BRAKE FLUID PRESSURE SWITCH

4 ± MASTER CYLINDER

5 - 2 BRAKESPL

Page 83 of 1285

Proportioning valves balance front to rear braking

by controlling the brake fluid hydraulic pressure to

the rear brakes. Under light pedal application, the

proportioning valve allows normal fluid flow to the

rear brakes. Under higher pedal effort, the valve

reduces fluid pressure to the rear brakes.

The non-antilock master cylinder is a four-outlet

design with two screw-in proportioning valves

attached directly to the master cylinder housing (Fig.

3). One proportioning valve controls each rear brake.

BRAKE TUBES AND HOSES

The purpose of the brake tubes and flex hoses is to

transfer the pressurized brake fluid developed by the

master cylinder to the brakes at each wheel of the

vehicle. The flex hoses connect the chassis brake

tubes, which are mounted to the vehicle's underbody,

to the brake at each wheel, allowing for movement of

the vehicle's suspension. The brake tubes are steel

with a corrosion-resistant nylon coating applied to

the external surfaces. The flex hoses are made of

reinforced rubber.

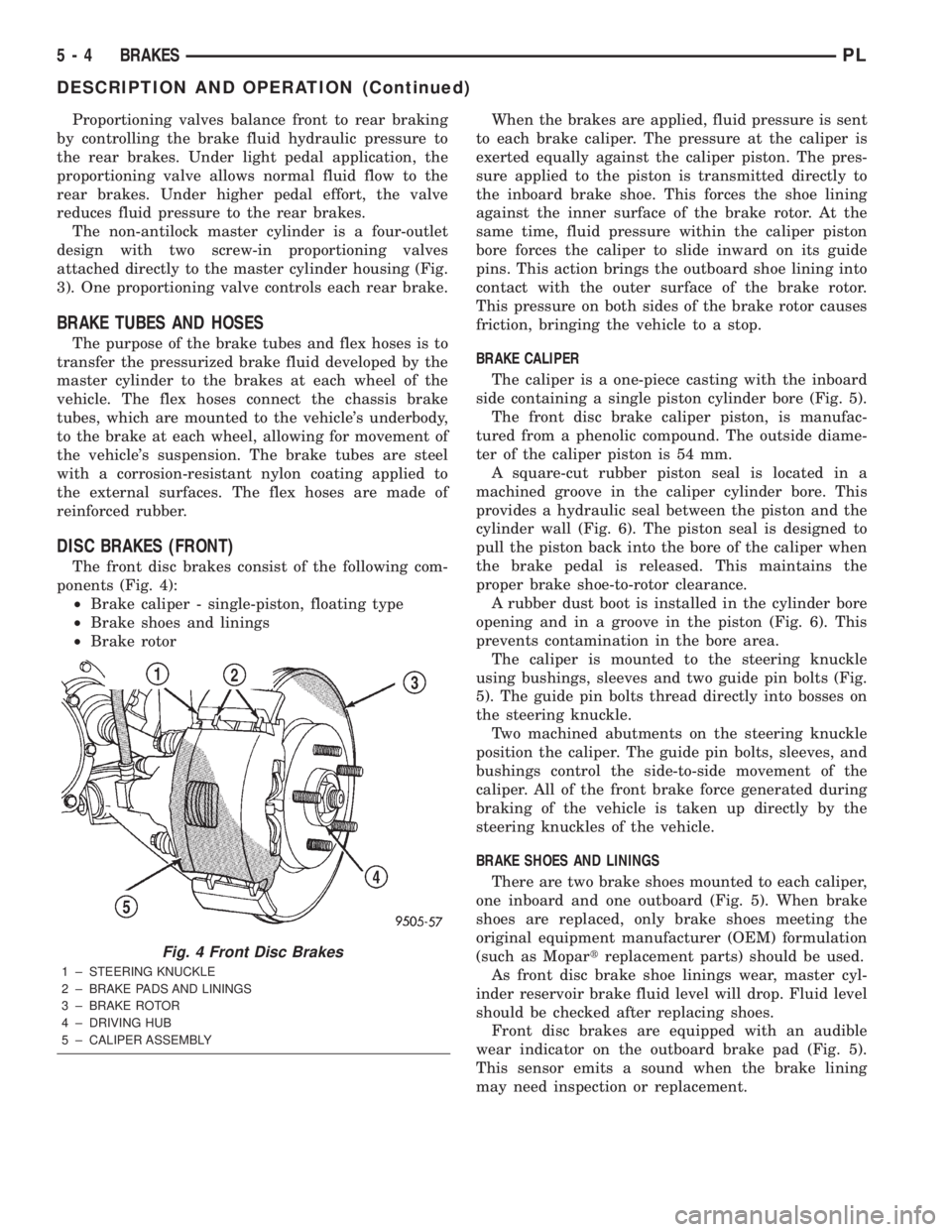

DISC BRAKES (FRONT)

The front disc brakes consist of the following com-

ponents (Fig. 4):

²Brake caliper - single-piston, floating type

²Brake shoes and linings

²Brake rotorWhen the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

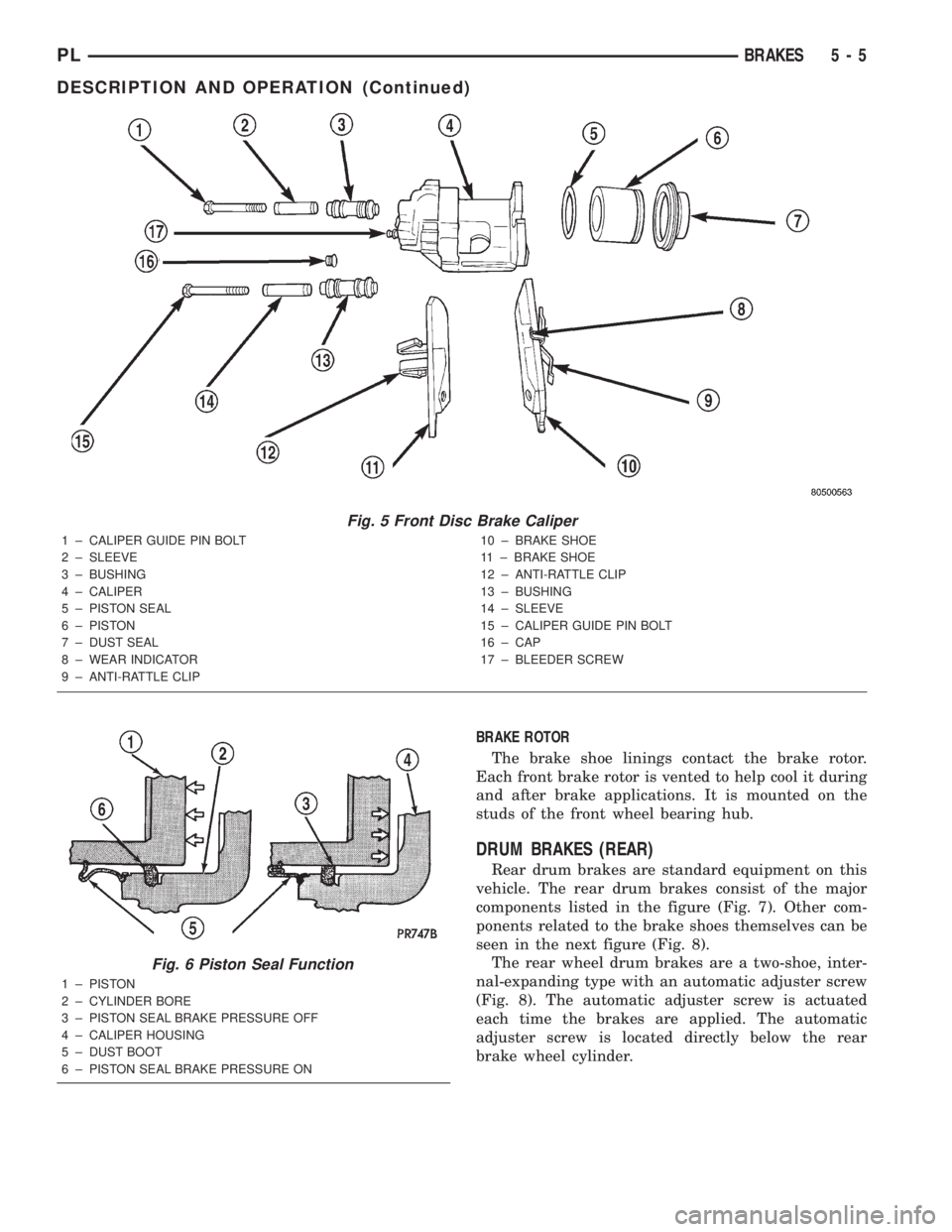

BRAKE CALIPER

The caliper is a one-piece casting with the inboard

side containing a single piston cylinder bore (Fig. 5).

The front disc brake caliper piston, is manufac-

tured from a phenolic compound. The outside diame-

ter of the caliper piston is 54 mm.

A square-cut rubber piston seal is located in a

machined groove in the caliper cylinder bore. This

provides a hydraulic seal between the piston and the

cylinder wall (Fig. 6). The piston seal is designed to

pull the piston back into the bore of the caliper when

the brake pedal is released. This maintains the

proper brake shoe-to-rotor clearance.

A rubber dust boot is installed in the cylinder bore

opening and in a groove in the piston (Fig. 6). This

prevents contamination in the bore area.

The caliper is mounted to the steering knuckle

using bushings, sleeves and two guide pin bolts (Fig.

5). The guide pin bolts thread directly into bosses on

the steering knuckle.

Two machined abutments on the steering knuckle

position the caliper. The guide pin bolts, sleeves, and

bushings control the side-to-side movement of the

caliper. All of the front brake force generated during

braking of the vehicle is taken up directly by the

steering knuckles of the vehicle.

BRAKE SHOES AND LININGS

There are two brake shoes mounted to each caliper,

one inboard and one outboard (Fig. 5). When brake

shoes are replaced, only brake shoes meeting the

original equipment manufacturer (OEM) formulation

(such as Mopartreplacement parts) should be used.

As front disc brake shoe linings wear, master cyl-

inder reservoir brake fluid level will drop. Fluid level

should be checked after replacing shoes.

Front disc brakes are equipped with an audible

wear indicator on the outboard brake pad (Fig. 5).

This sensor emits a sound when the brake lining

may need inspection or replacement.

Fig. 4 Front Disc Brakes

1 ± STEERING KNUCKLE

2 ± BRAKE PADS AND LININGS

3 ± BRAKE ROTOR

4 ± DRIVING HUB

5 ± CALIPER ASSEMBLY

5 - 4 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 84 of 1285

BRAKE ROTOR

The brake shoe linings contact the brake rotor.

Each front brake rotor is vented to help cool it during

and after brake applications. It is mounted on the

studs of the front wheel bearing hub.

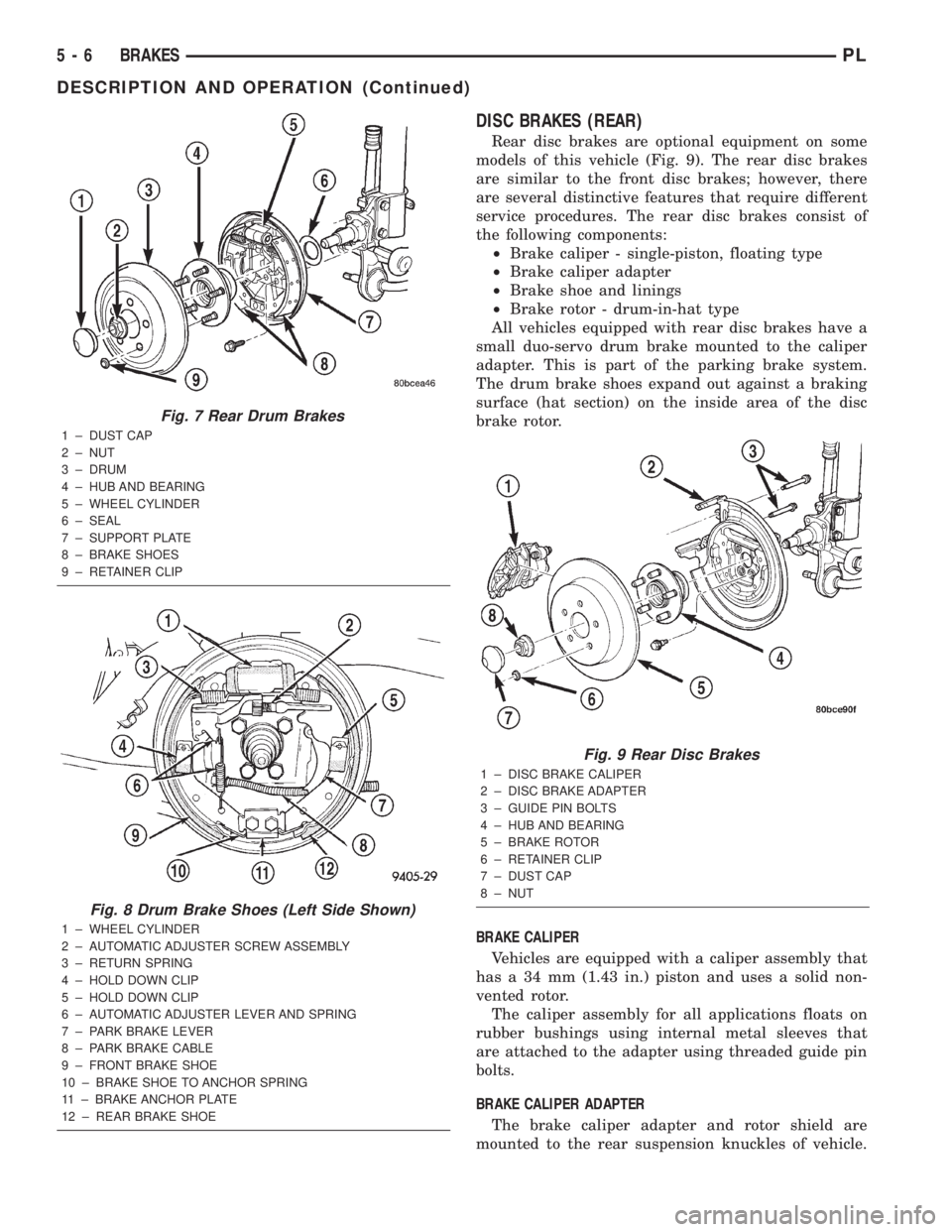

DRUM BRAKES (REAR)

Rear drum brakes are standard equipment on this

vehicle. The rear drum brakes consist of the major

components listed in the figure (Fig. 7). Other com-

ponents related to the brake shoes themselves can be

seen in the next figure (Fig. 8).

The rear wheel drum brakes are a two-shoe, inter-

nal-expanding type with an automatic adjuster screw

(Fig. 8). The automatic adjuster screw is actuated

each time the brakes are applied. The automatic

adjuster screw is located directly below the rear

brake wheel cylinder.

Fig. 5 Front Disc Brake Caliper

1 ± CALIPER GUIDE PIN BOLT

2 ± SLEEVE

3 ± BUSHING

4 ± CALIPER

5 ± PISTON SEAL

6 ± PISTON

7 ± DUST SEAL

8 ± WEAR INDICATOR

9 ± ANTI-RATTLE CLIP10 ± BRAKE SHOE

11 ± BRAKE SHOE

12 ± ANTI-RATTLE CLIP

13 ± BUSHING

14 ± SLEEVE

15 ± CALIPER GUIDE PIN BOLT

16 ± CAP

17 ± BLEEDER SCREW

Fig. 6 Piston Seal Function

1 ± PISTON

2 ± CYLINDER BORE

3 ± PISTON SEAL BRAKE PRESSURE OFF

4 ± CALIPER HOUSING

5 ± DUST BOOT

6 ± PISTON SEAL BRAKE PRESSURE ON

PLBRAKES 5 - 5

DESCRIPTION AND OPERATION (Continued)

Page 85 of 1285

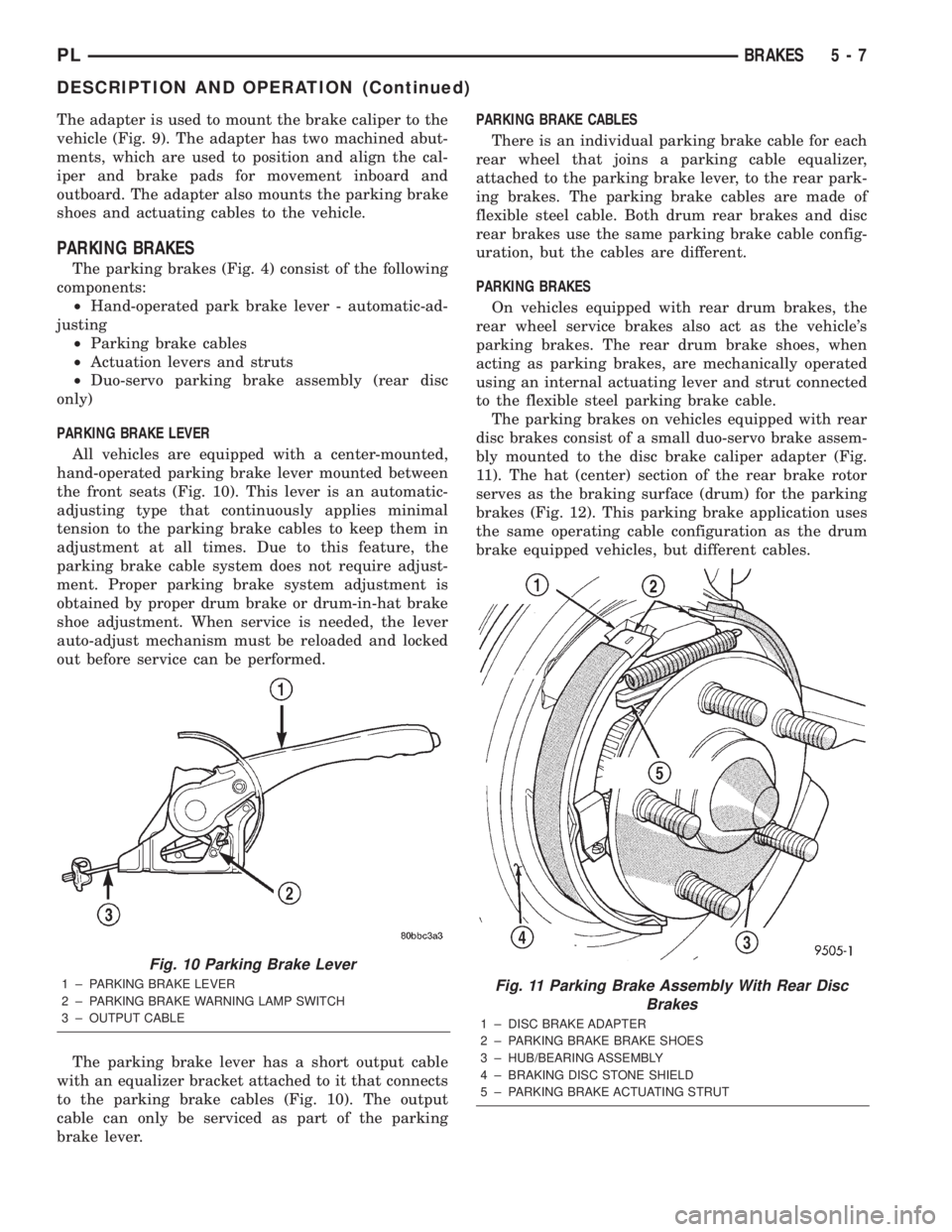

DISC BRAKES (REAR)

Rear disc brakes are optional equipment on some

models of this vehicle (Fig. 9). The rear disc brakes

are similar to the front disc brakes; however, there

are several distinctive features that require different

service procedures. The rear disc brakes consist of

the following components:

²Brake caliper - single-piston, floating type

²Brake caliper adapter

²Brake shoe and linings

²Brake rotor - drum-in-hat type

All vehicles equipped with rear disc brakes have a

small duo-servo drum brake mounted to the caliper

adapter. This is part of the parking brake system.

The drum brake shoes expand out against a braking

surface (hat section) on the inside area of the disc

brake rotor.

BRAKE CALIPER

Vehicles are equipped with a caliper assembly that

has a 34 mm (1.43 in.) piston and uses a solid non-

vented rotor.

The caliper assembly for all applications floats on

rubber bushings using internal metal sleeves that

are attached to the adapter using threaded guide pin

bolts.

BRAKE CALIPER ADAPTER

The brake caliper adapter and rotor shield are

mounted to the rear suspension knuckles of vehicle.

Fig. 7 Rear Drum Brakes

1 ± DUST CAP

2 ± NUT

3 ± DRUM

4 ± HUB AND BEARING

5 ± WHEEL CYLINDER

6 ± SEAL

7 ± SUPPORT PLATE

8 ± BRAKE SHOES

9 ± RETAINER CLIP

Fig. 8 Drum Brake Shoes (Left Side Shown)

1 ± WHEEL CYLINDER

2 ± AUTOMATIC ADJUSTER SCREW ASSEMBLY

3 ± RETURN SPRING

4 ± HOLD DOWN CLIP

5 ± HOLD DOWN CLIP

6 ± AUTOMATIC ADJUSTER LEVER AND SPRING

7 ± PARK BRAKE LEVER

8 ± PARK BRAKE CABLE

9 ± FRONT BRAKE SHOE

10 ± BRAKE SHOE TO ANCHOR SPRING

11 ± BRAKE ANCHOR PLATE

12 ± REAR BRAKE SHOE

Fig. 9 Rear Disc Brakes

1 ± DISC BRAKE CALIPER

2 ± DISC BRAKE ADAPTER

3 ± GUIDE PIN BOLTS

4 ± HUB AND BEARING

5 ± BRAKE ROTOR

6 ± RETAINER CLIP

7 ± DUST CAP

8 ± NUT

5 - 6 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 86 of 1285

The adapter is used to mount the brake caliper to the

vehicle (Fig. 9). The adapter has two machined abut-

ments, which are used to position and align the cal-

iper and brake pads for movement inboard and

outboard. The adapter also mounts the parking brake

shoes and actuating cables to the vehicle.

PARKING BRAKES

The parking brakes (Fig. 4) consist of the following

components:

²Hand-operated park brake lever - automatic-ad-

justing

²Parking brake cables

²Actuation levers and struts

²Duo-servo parking brake assembly (rear disc

only)

PARKING BRAKE LEVER

All vehicles are equipped with a center-mounted,

hand-operated parking brake lever mounted between

the front seats (Fig. 10). This lever is an automatic-

adjusting type that continuously applies minimal

tension to the parking brake cables to keep them in

adjustment at all times. Due to this feature, the

parking brake cable system does not require adjust-

ment. Proper parking brake system adjustment is

obtained by proper drum brake or drum-in-hat brake

shoe adjustment. When service is needed, the lever

auto-adjust mechanism must be reloaded and locked

out before service can be performed.

The parking brake lever has a short output cable

with an equalizer bracket attached to it that connects

to the parking brake cables (Fig. 10). The output

cable can only be serviced as part of the parking

brake lever.PARKING BRAKE CABLES

There is an individual parking brake cable for each

rear wheel that joins a parking cable equalizer,

attached to the parking brake lever, to the rear park-

ing brakes. The parking brake cables are made of

flexible steel cable. Both drum rear brakes and disc

rear brakes use the same parking brake cable config-

uration, but the cables are different.

PARKING BRAKES

On vehicles equipped with rear drum brakes, the

rear wheel service brakes also act as the vehicle's

parking brakes. The rear drum brake shoes, when

acting as parking brakes, are mechanically operated

using an internal actuating lever and strut connected

to the flexible steel parking brake cable.

The parking brakes on vehicles equipped with rear

disc brakes consist of a small duo-servo brake assem-

bly mounted to the disc brake caliper adapter (Fig.

11). The hat (center) section of the rear brake rotor

serves as the braking surface (drum) for the parking

brakes (Fig. 12). This parking brake application uses

the same operating cable configuration as the drum

brake equipped vehicles, but different cables.

Fig. 10 Parking Brake Lever

1 ± PARKING BRAKE LEVER

2 ± PARKING BRAKE WARNING LAMP SWITCH

3 ± OUTPUT CABLEFig. 11 Parking Brake Assembly With Rear Disc

Brakes

1 ± DISC BRAKE ADAPTER

2 ± PARKING BRAKE BRAKE SHOES

3 ± HUB/BEARING ASSEMBLY

4 ± BRAKING DISC STONE SHIELD

5 ± PARKING BRAKE ACTUATING STRUT

PLBRAKES 5 - 7

DESCRIPTION AND OPERATION (Continued)