tow DODGE NEON 2000 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 992 of 1285

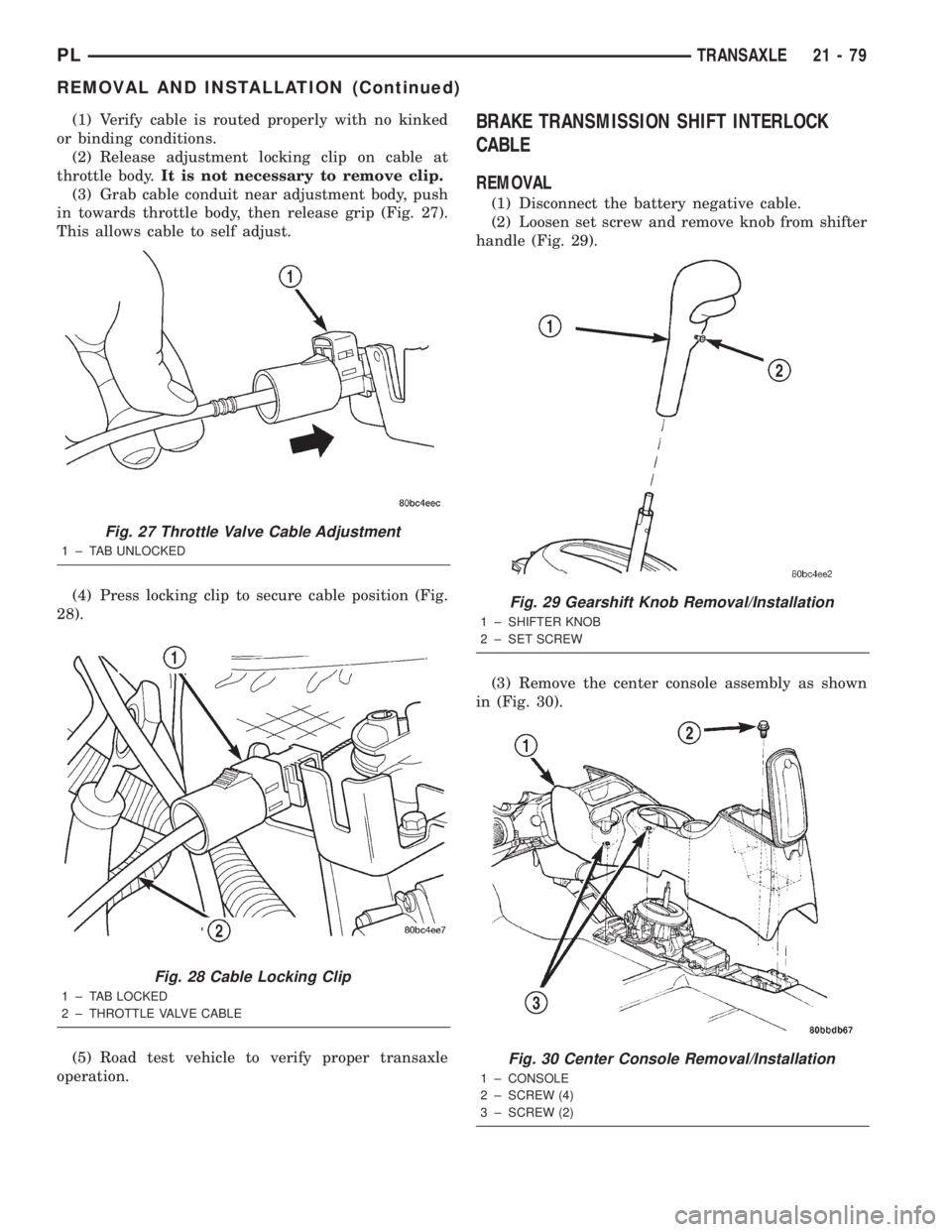

(1) Verify cable is routed properly with no kinked

or binding conditions.

(2) Release adjustment locking clip on cable at

throttle body.It is not necessary to remove clip.

(3) Grab cable conduit near adjustment body, push

in towards throttle body, then release grip (Fig. 27).

This allows cable to self adjust.

(4) Press locking clip to secure cable position (Fig.

28).

(5) Road test vehicle to verify proper transaxle

operation.BRAKE TRANSMISSION SHIFT INTERLOCK

CABLE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Loosen set screw and remove knob from shifter

handle (Fig. 29).

(3) Remove the center console assembly as shown

in (Fig. 30).

Fig. 27 Throttle Valve Cable Adjustment

1 ± TAB UNLOCKED

Fig. 28 Cable Locking Clip

1 ± TAB LOCKED

2 ± THROTTLE VALVE CABLE

Fig. 29 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 30 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

PLTRANSAXLE 21 - 79

REMOVAL AND INSTALLATION (Continued)

Page 1049 of 1285

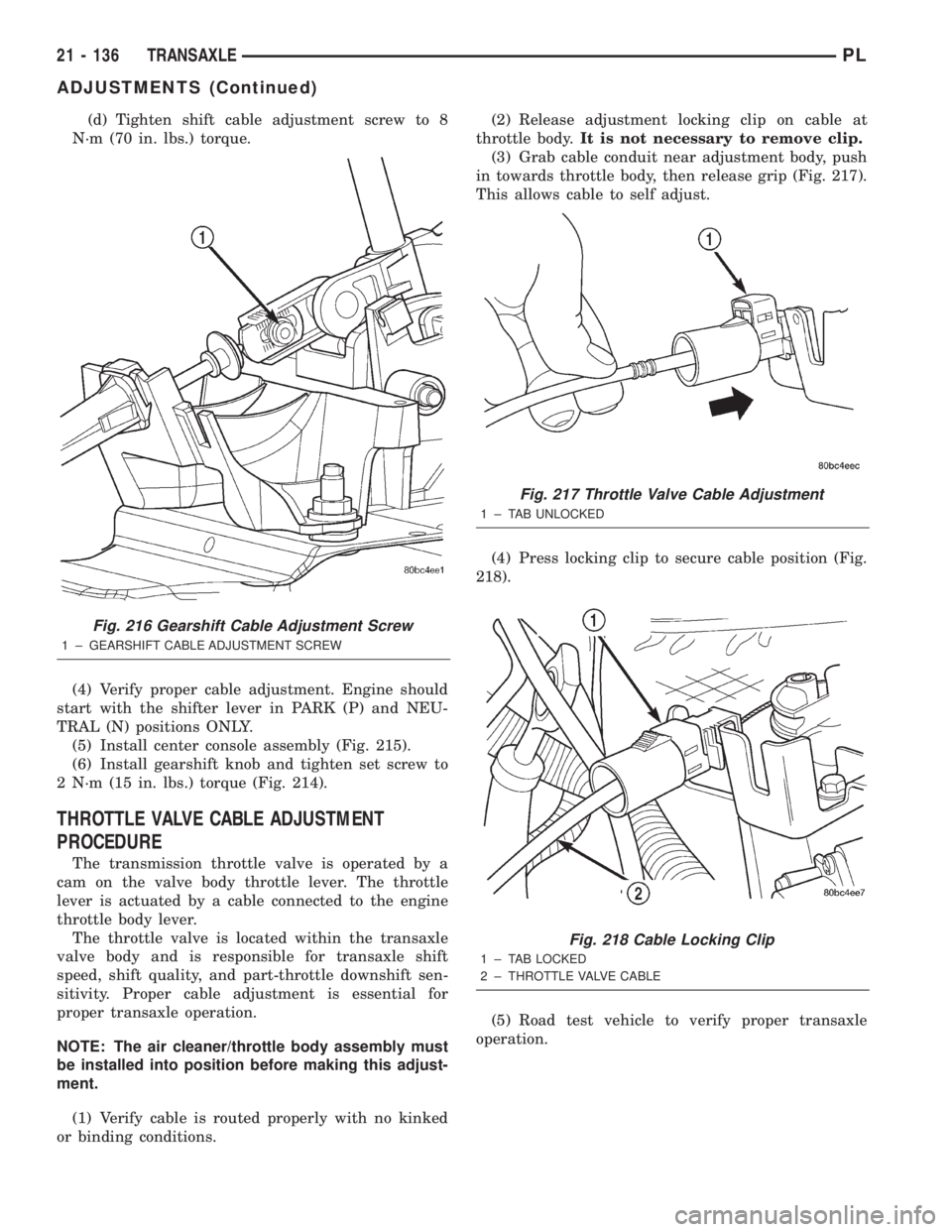

(d) Tighten shift cable adjustment screw to 8

N´m (70 in. lbs.) torque.

(4) Verify proper cable adjustment. Engine should

start with the shifter lever in PARK (P) and NEU-

TRAL (N) positions ONLY.

(5) Install center console assembly (Fig. 215).

(6) Install gearshift knob and tighten set screw to

2 N´m (15 in. lbs.) torque (Fig. 214).

THROTTLE VALVE CABLE ADJUSTMENT

PROCEDURE

The transmission throttle valve is operated by a

cam on the valve body throttle lever. The throttle

lever is actuated by a cable connected to the engine

throttle body lever.

The throttle valve is located within the transaxle

valve body and is responsible for transaxle shift

speed, shift quality, and part-throttle downshift sen-

sitivity. Proper cable adjustment is essential for

proper transaxle operation.

NOTE: The air cleaner/throttle body assembly must

be installed into position before making this adjust-

ment.

(1) Verify cable is routed properly with no kinked

or binding conditions.(2) Release adjustment locking clip on cable at

throttle body.It is not necessary to remove clip.

(3) Grab cable conduit near adjustment body, push

in towards throttle body, then release grip (Fig. 217).

This allows cable to self adjust.

(4) Press locking clip to secure cable position (Fig.

218).

(5) Road test vehicle to verify proper transaxle

operation.

Fig. 216 Gearshift Cable Adjustment Screw

1 ± GEARSHIFT CABLE ADJUSTMENT SCREW

Fig. 217 Throttle Valve Cable Adjustment

1 ± TAB UNLOCKED

Fig. 218 Cable Locking Clip

1 ± TAB LOCKED

2 ± THROTTLE VALVE CABLE

21 - 136 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1144 of 1285

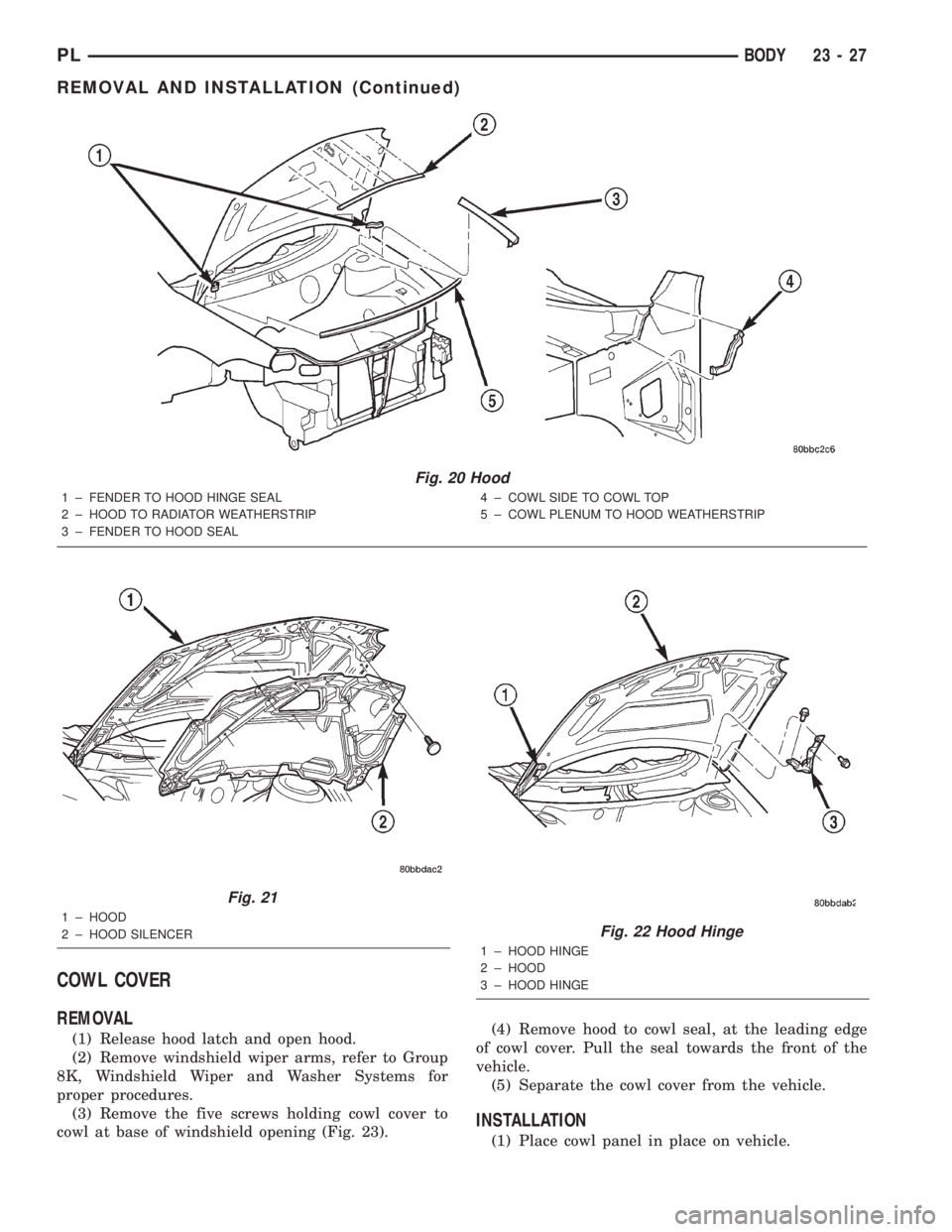

COWL COVER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems for

proper procedures.

(3) Remove the five screws holding cowl cover to

cowl at base of windshield opening (Fig. 23).(4) Remove hood to cowl seal, at the leading edge

of cowl cover. Pull the seal towards the front of the

vehicle.

(5) Separate the cowl cover from the vehicle.

INSTALLATION

(1) Place cowl panel in place on vehicle.

Fig. 20 Hood

1 ± FENDER TO HOOD HINGE SEAL

2 ± HOOD TO RADIATOR WEATHERSTRIP

3 ± FENDER TO HOOD SEAL4 ± COWL SIDE TO COWL TOP

5 ± COWL PLENUM TO HOOD WEATHERSTRIP

Fig. 21

1 ± HOOD

2 ± HOOD SILENCERFig. 22 Hood Hinge

1 ± HOOD HINGE

2 ± HOOD

3 ± HOOD HINGE

PLBODY 23 - 27

REMOVAL AND INSTALLATION (Continued)

Page 1173 of 1285

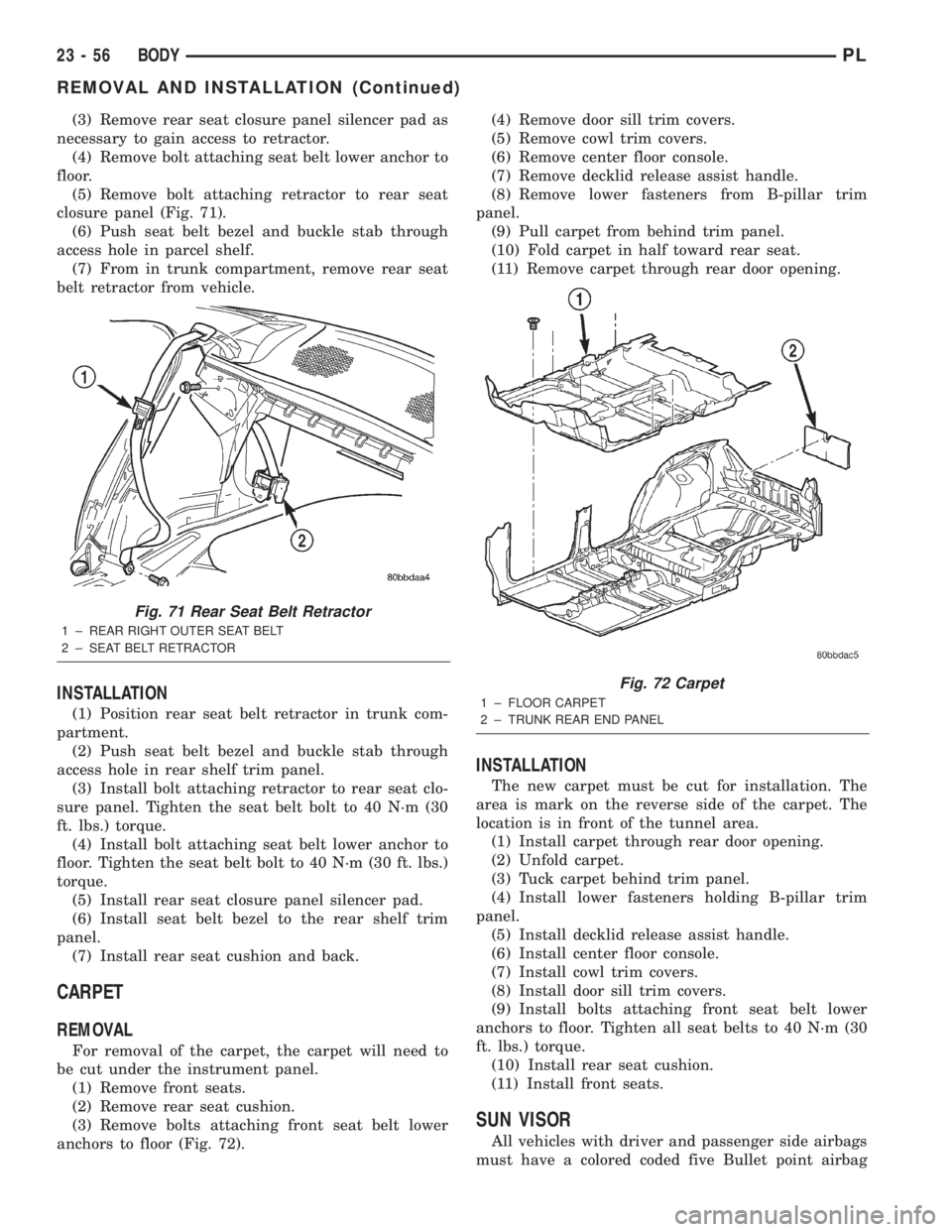

(3) Remove rear seat closure panel silencer pad as

necessary to gain access to retractor.

(4) Remove bolt attaching seat belt lower anchor to

floor.

(5) Remove bolt attaching retractor to rear seat

closure panel (Fig. 71).

(6) Push seat belt bezel and buckle stab through

access hole in parcel shelf.

(7) From in trunk compartment, remove rear seat

belt retractor from vehicle.

INSTALLATION

(1) Position rear seat belt retractor in trunk com-

partment.

(2) Push seat belt bezel and buckle stab through

access hole in rear shelf trim panel.

(3) Install bolt attaching retractor to rear seat clo-

sure panel. Tighten the seat belt bolt to 40 N´m (30

ft. lbs.) torque.

(4) Install bolt attaching seat belt lower anchor to

floor. Tighten the seat belt bolt to 40 N´m (30 ft. lbs.)

torque.

(5) Install rear seat closure panel silencer pad.

(6) Install seat belt bezel to the rear shelf trim

panel.

(7) Install rear seat cushion and back.

CARPET

REMOVAL

For removal of the carpet, the carpet will need to

be cut under the instrument panel.

(1) Remove front seats.

(2) Remove rear seat cushion.

(3) Remove bolts attaching front seat belt lower

anchors to floor (Fig. 72).(4) Remove door sill trim covers.

(5) Remove cowl trim covers.

(6) Remove center floor console.

(7) Remove decklid release assist handle.

(8) Remove lower fasteners from B-pillar trim

panel.

(9) Pull carpet from behind trim panel.

(10) Fold carpet in half toward rear seat.

(11) Remove carpet through rear door opening.

INSTALLATION

The new carpet must be cut for installation. The

area is mark on the reverse side of the carpet. The

location is in front of the tunnel area.

(1) Install carpet through rear door opening.

(2) Unfold carpet.

(3) Tuck carpet behind trim panel.

(4) Install lower fasteners holding B-pillar trim

panel.

(5) Install decklid release assist handle.

(6) Install center floor console.

(7) Install cowl trim covers.

(8) Install door sill trim covers.

(9) Install bolts attaching front seat belt lower

anchors to floor. Tighten all seat belts to 40 N´m (30

ft. lbs.) torque.

(10) Install rear seat cushion.

(11) Install front seats.

SUN VISOR

All vehicles with driver and passenger side airbags

must have a colored coded five Bullet point airbag

Fig. 71 Rear Seat Belt Retractor

1 ± REAR RIGHT OUTER SEAT BELT

2 ± SEAT BELT RETRACTOR

Fig. 72 Carpet

1 ± FLOOR CARPET

2 ± TRUNK REAR END PANEL

23 - 56 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1194 of 1285

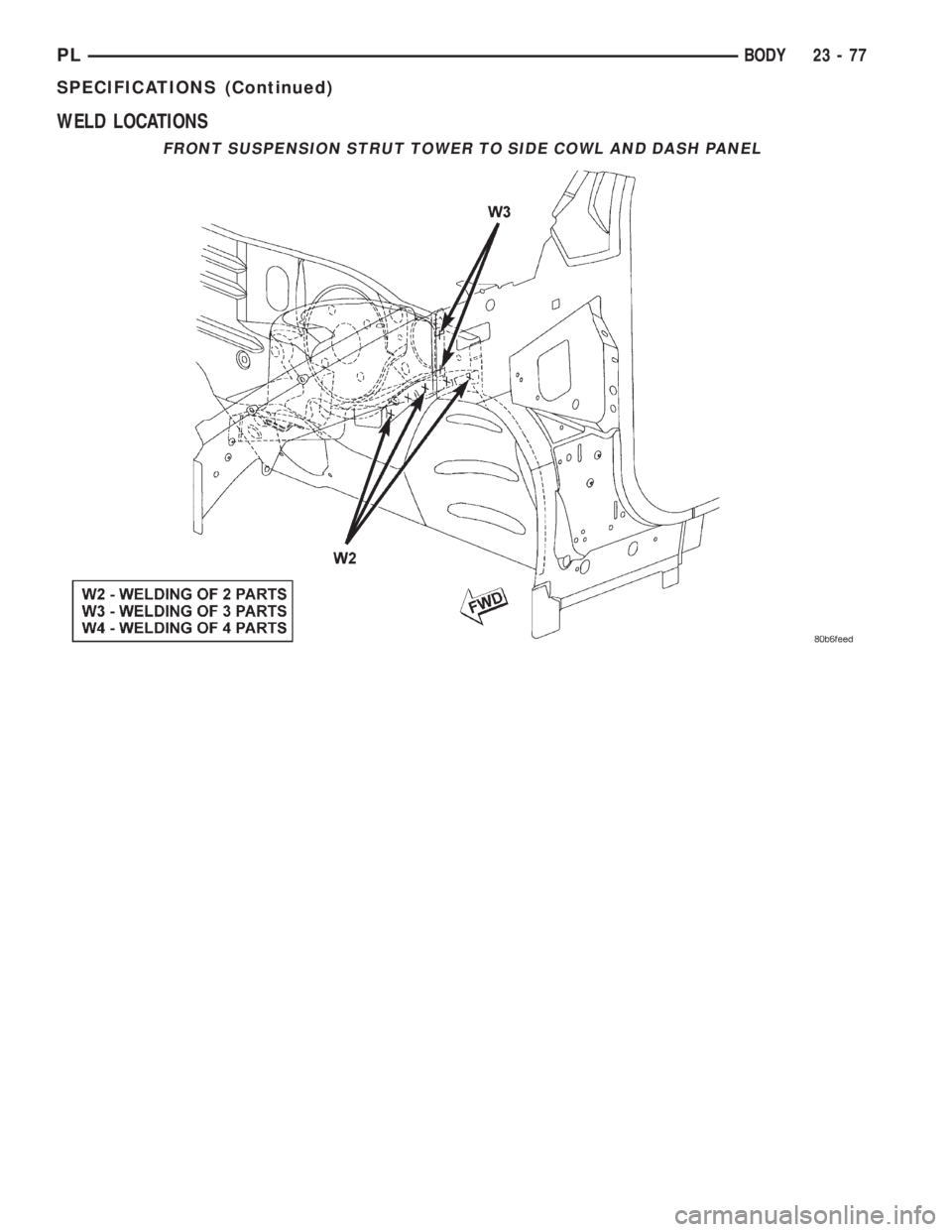

WELD LOCATIONS

FRONT SUSPENSION STRUT TOWER TO SIDE COWL AND DASH PANEL

PLBODY 23 - 77

SPECIFICATIONS (Continued)

Page 1195 of 1285

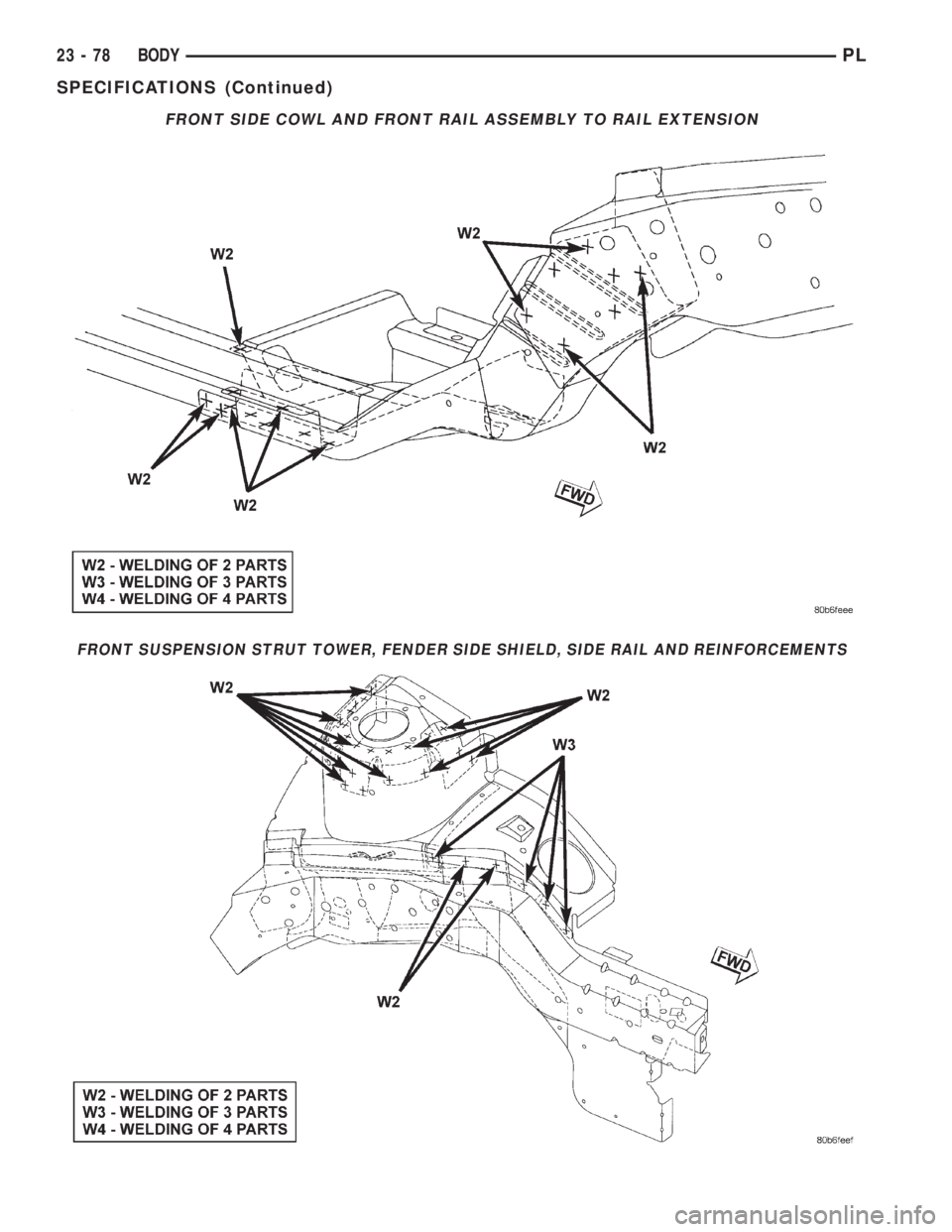

FRONT SIDE COWL AND FRONT RAIL ASSEMBLY TO RAIL EXTENSION

FRONT SUSPENSION STRUT TOWER, FENDER SIDE SHIELD, SIDE RAIL AND REINFORCEMENTS

23 - 78 BODYPL

SPECIFICATIONS (Continued)

Page 1200 of 1285

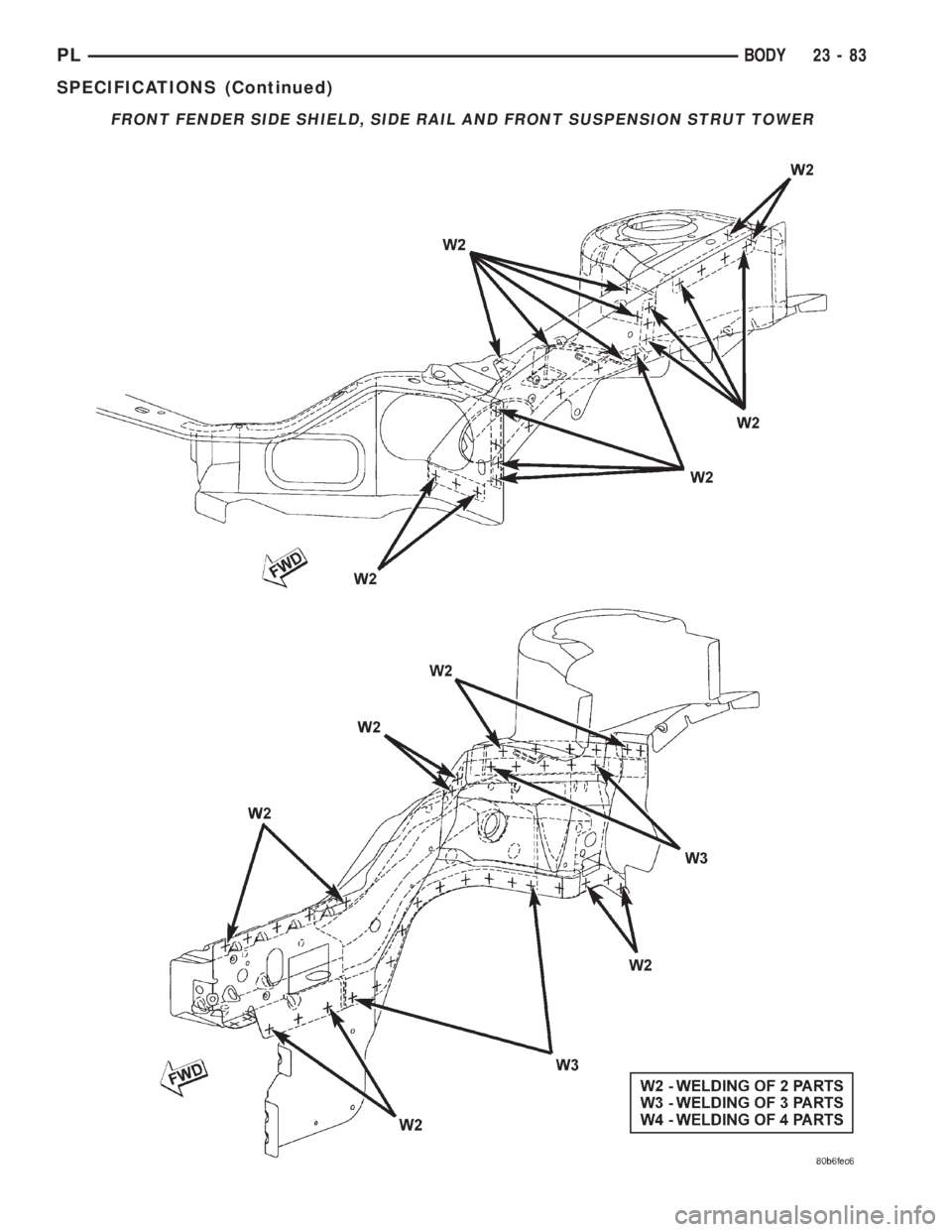

FRONT FENDER SIDE SHIELD, SIDE RAIL AND FRONT SUSPENSION STRUT TOWER

PLBODY 23 - 83

SPECIFICATIONS (Continued)

Page 1250 of 1285

Then allow the system to evacuate an additional 10

minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

(4) The refrigerant system is prepared to be

charged with refrigerant.

R-134a REFRIGERANT

This vehicle uses a refrigerant called R-134a. It is

a non-toxic, non-flammable, clear colorless liquefied

gas.

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 in a R-134a system could cause

compressor failure, refrigerant oil to sludge and/or

poor performance.Never add any other type of

refrigerant to a system designed to use R-134a

refrigerant. System failure will occur.

The high pressure service port is located on the

ffilter/drier. The low pressure service port is located

on the suction line near the strut tower.

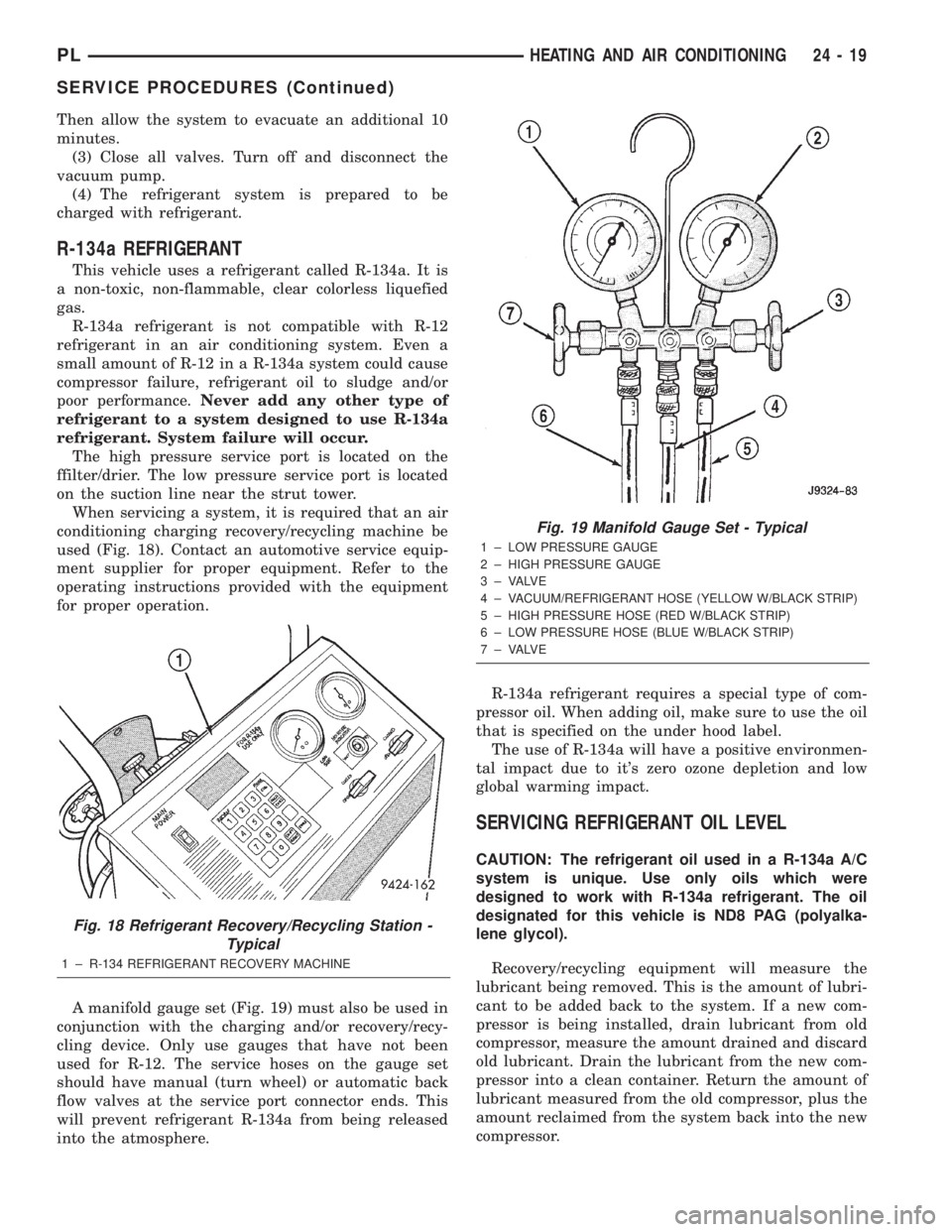

When servicing a system, it is required that an air

conditioning charging recovery/recycling machine be

used (Fig. 18). Contact an automotive service equip-

ment supplier for proper equipment. Refer to the

operating instructions provided with the equipment

for proper operation.

A manifold gauge set (Fig. 19) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. Only use gauges that have not been

used for R-12. The service hoses on the gauge set

should have manual (turn wheel) or automatic back

flow valves at the service port connector ends. This

will prevent refrigerant R-134a from being released

into the atmosphere.R-134a refrigerant requires a special type of com-

pressor oil. When adding oil, make sure to use the oil

that is specified on the under hood label.

The use of R-134a will have a positive environmen-

tal impact due to it's zero ozone depletion and low

global warming impact.

SERVICING REFRIGERANT OIL LEVEL

CAUTION: The refrigerant oil used in a R-134a A/C

system is unique. Use only oils which were

designed to work with R-134a refrigerant. The oil

designated for this vehicle is ND8 PAG (polyalka-

lene glycol).

Recovery/recycling equipment will measure the

lubricant being removed. This is the amount of lubri-

cant to be added back to the system. If a new com-

pressor is being installed, drain lubricant from old

compressor, measure the amount drained and discard

old lubricant. Drain the lubricant from the new com-

pressor into a clean container. Return the amount of

lubricant measured from the old compressor, plus the

amount reclaimed from the system back into the new

compressor.

Fig. 18 Refrigerant Recovery/Recycling Station -

Typical

1 ± R-134 REFRIGERANT RECOVERY MACHINE

Fig. 19 Manifold Gauge Set - Typical

1 ± LOW PRESSURE GAUGE

2 ± HIGH PRESSURE GAUGE

3 ± VALVE

4 ± VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK STRIP)

5 ± HIGH PRESSURE HOSE (RED W/BLACK STRIP)

6 ± LOW PRESSURE HOSE (BLUE W/BLACK STRIP)

7 ± VALVE

PLHEATING AND AIR CONDITIONING 24 - 19

SERVICE PROCEDURES (Continued)

Page 1259 of 1285

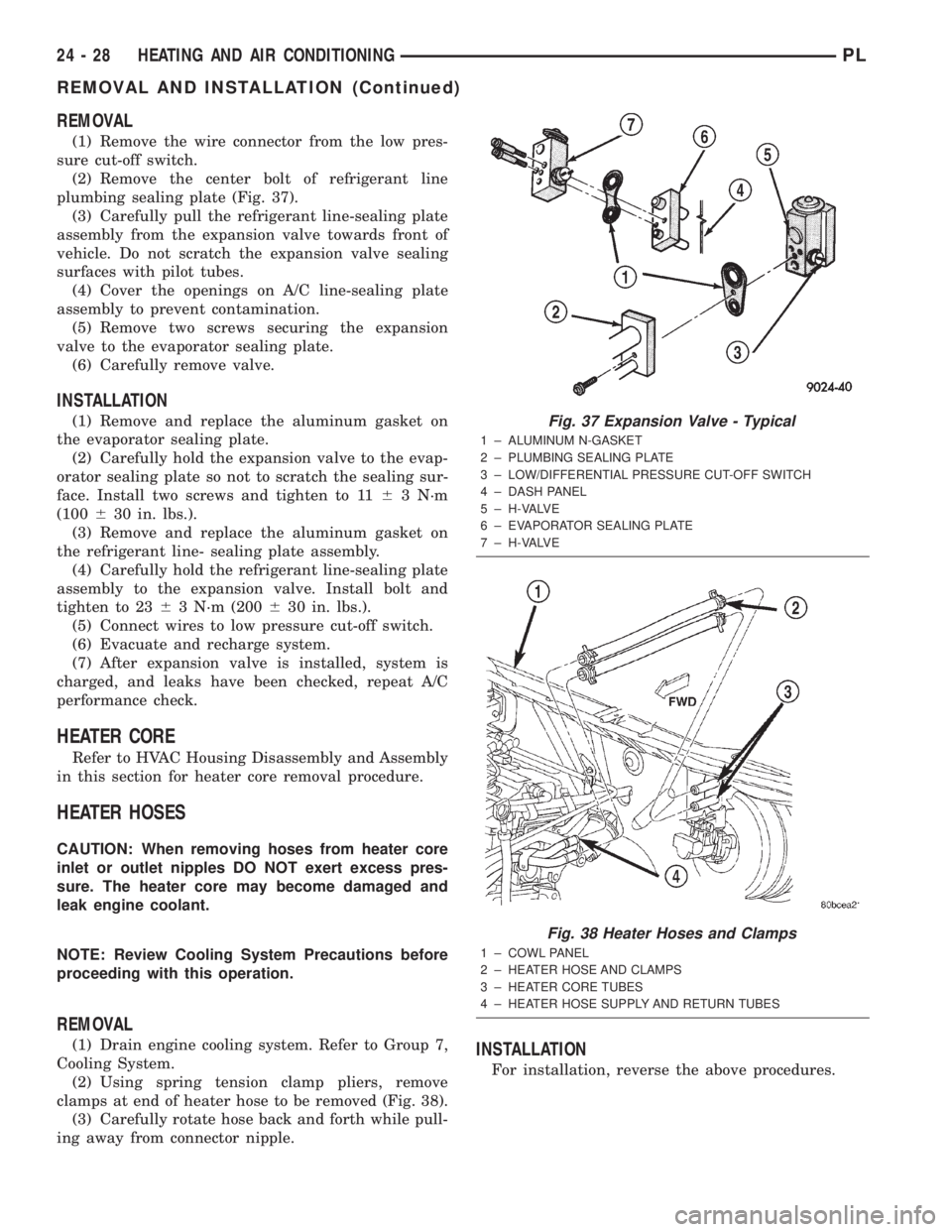

REMOVAL

(1) Remove the wire connector from the low pres-

sure cut-off switch.

(2) Remove the center bolt of refrigerant line

plumbing sealing plate (Fig. 37).

(3) Carefully pull the refrigerant line-sealing plate

assembly from the expansion valve towards front of

vehicle. Do not scratch the expansion valve sealing

surfaces with pilot tubes.

(4) Cover the openings on A/C line-sealing plate

assembly to prevent contamination.

(5) Remove two screws securing the expansion

valve to the evaporator sealing plate.

(6) Carefully remove valve.

INSTALLATION

(1) Remove and replace the aluminum gasket on

the evaporator sealing plate.

(2) Carefully hold the expansion valve to the evap-

orator sealing plate so not to scratch the sealing sur-

face. Install two screws and tighten to 1163 N´m

(100630 in. lbs.).

(3) Remove and replace the aluminum gasket on

the refrigerant line- sealing plate assembly.

(4) Carefully hold the refrigerant line-sealing plate

assembly to the expansion valve. Install bolt and

tighten to 2363 N´m (200630 in. lbs.).

(5) Connect wires to low pressure cut-off switch.

(6) Evacuate and recharge system.

(7) After expansion valve is installed, system is

charged, and leaks have been checked, repeat A/C

performance check.

HEATER CORE

Refer to HVAC Housing Disassembly and Assembly

in this section for heater core removal procedure.

HEATER HOSES

CAUTION: When removing hoses from heater core

inlet or outlet nipples DO NOT exert excess pres-

sure. The heater core may become damaged and

leak engine coolant.

NOTE: Review Cooling System Precautions before

proceeding with this operation.

REMOVAL

(1) Drain engine cooling system. Refer to Group 7,

Cooling System.

(2) Using spring tension clamp pliers, remove

clamps at end of heater hose to be removed (Fig. 38).

(3) Carefully rotate hose back and forth while pull-

ing away from connector nipple.INSTALLATION

For installation, reverse the above procedures.

Fig. 37 Expansion Valve - Typical

1 ± ALUMINUM N-GASKET

2 ± PLUMBING SEALING PLATE

3 ± LOW/DIFFERENTIAL PRESSURE CUT-OFF SWITCH

4 ± DASH PANEL

5 ± H-VALVE

6 ± EVAPORATOR SEALING PLATE

7 ± H-VALVE

Fig. 38 Heater Hoses and Clamps

1 ± COWL PANEL

2 ± HEATER HOSE AND CLAMPS

3 ± HEATER CORE TUBES

4 ± HEATER HOSE SUPPLY AND RETURN TUBES

24 - 28 HEATING AND AIR CONDITIONINGPL

REMOVAL AND INSTALLATION (Continued)