tow DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 744 of 1285

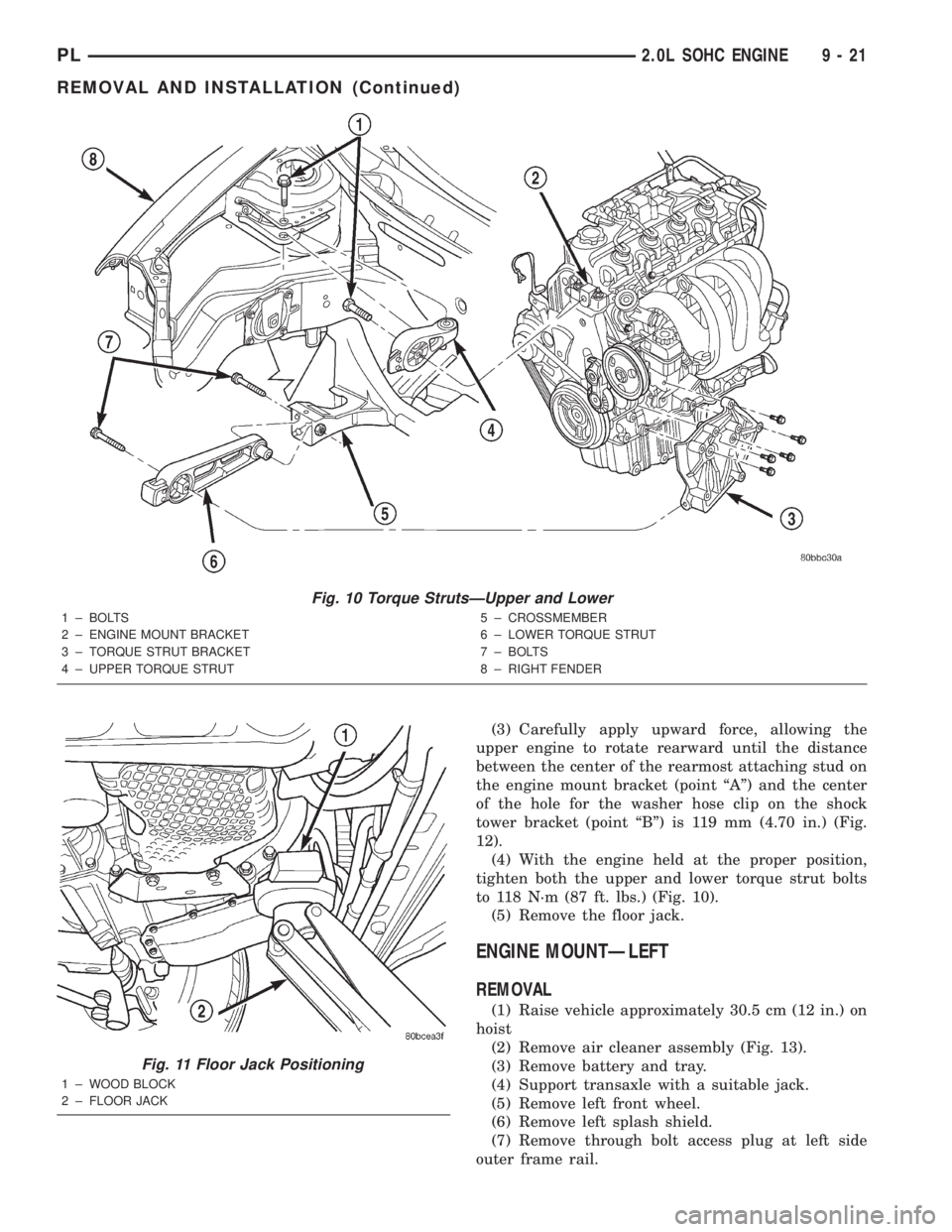

(3) Carefully apply upward force, allowing the

upper engine to rotate rearward until the distance

between the center of the rearmost attaching stud on

the engine mount bracket (point ªAº) and the center

of the hole for the washer hose clip on the shock

tower bracket (point ªBº) is 119 mm (4.70 in.) (Fig.

12).

(4) With the engine held at the proper position,

tighten both the upper and lower torque strut bolts

to 118 N´m (87 ft. lbs.) (Fig. 10).

(5) Remove the floor jack.

ENGINE MOUNTÐLEFT

REMOVAL

(1) Raise vehicle approximately 30.5 cm (12 in.) on

hoist

(2) Remove air cleaner assembly (Fig. 13).

(3) Remove battery and tray.

(4) Support transaxle with a suitable jack.

(5) Remove left front wheel.

(6) Remove left splash shield.

(7) Remove through bolt access plug at left side

outer frame rail.

Fig. 10 Torque StrutsÐUpper and Lower

1 ± BOLTS

2 ± ENGINE MOUNT BRACKET

3 ± TORQUE STRUT BRACKET

4 ± UPPER TORQUE STRUT5 ± CROSSMEMBER

6 ± LOWER TORQUE STRUT

7 ± BOLTS

8 ± RIGHT FENDER

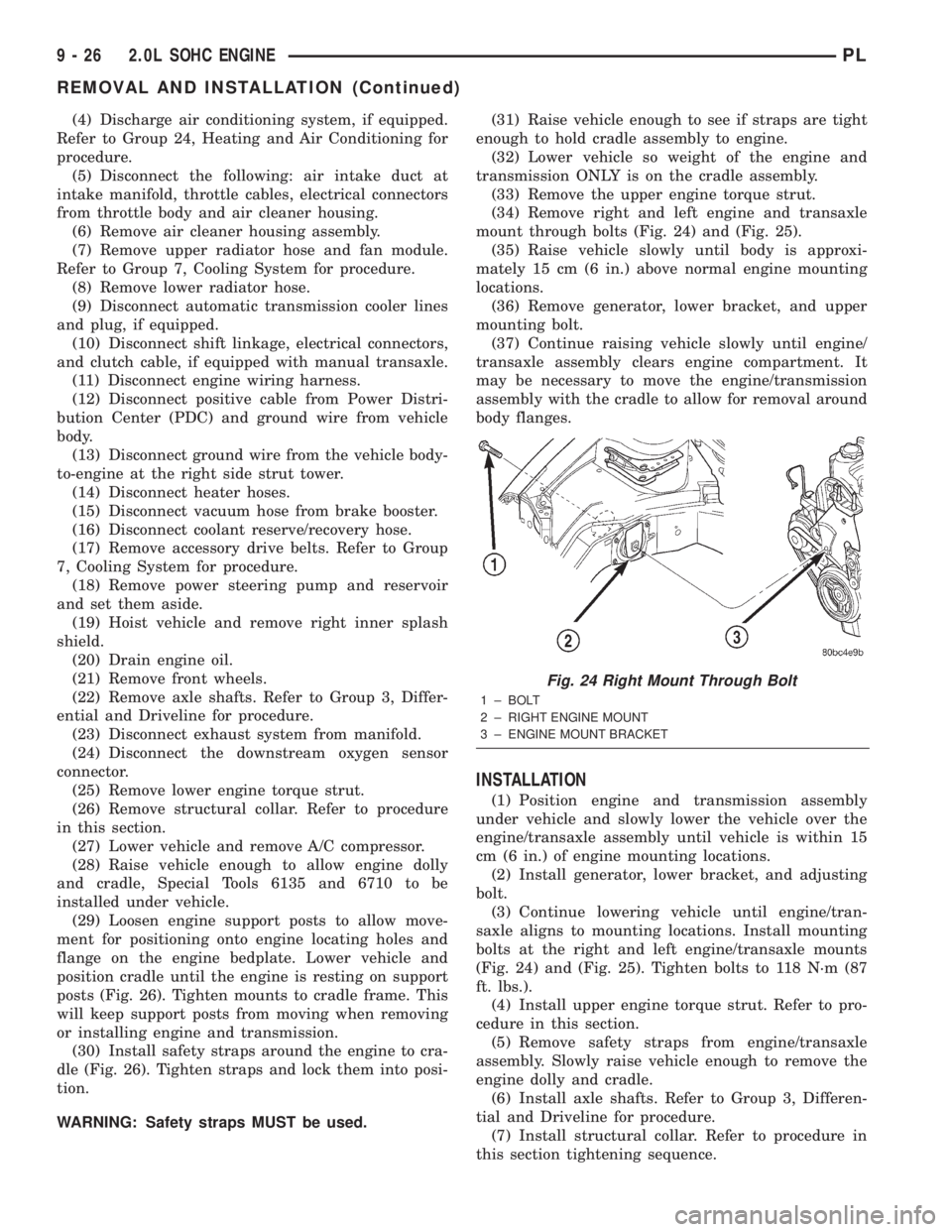

Fig. 11 Floor Jack Positioning

1 ± WOOD BLOCK

2 ± FLOOR JACK

PL2.0L SOHC ENGINE 9 - 21

REMOVAL AND INSTALLATION (Continued)

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

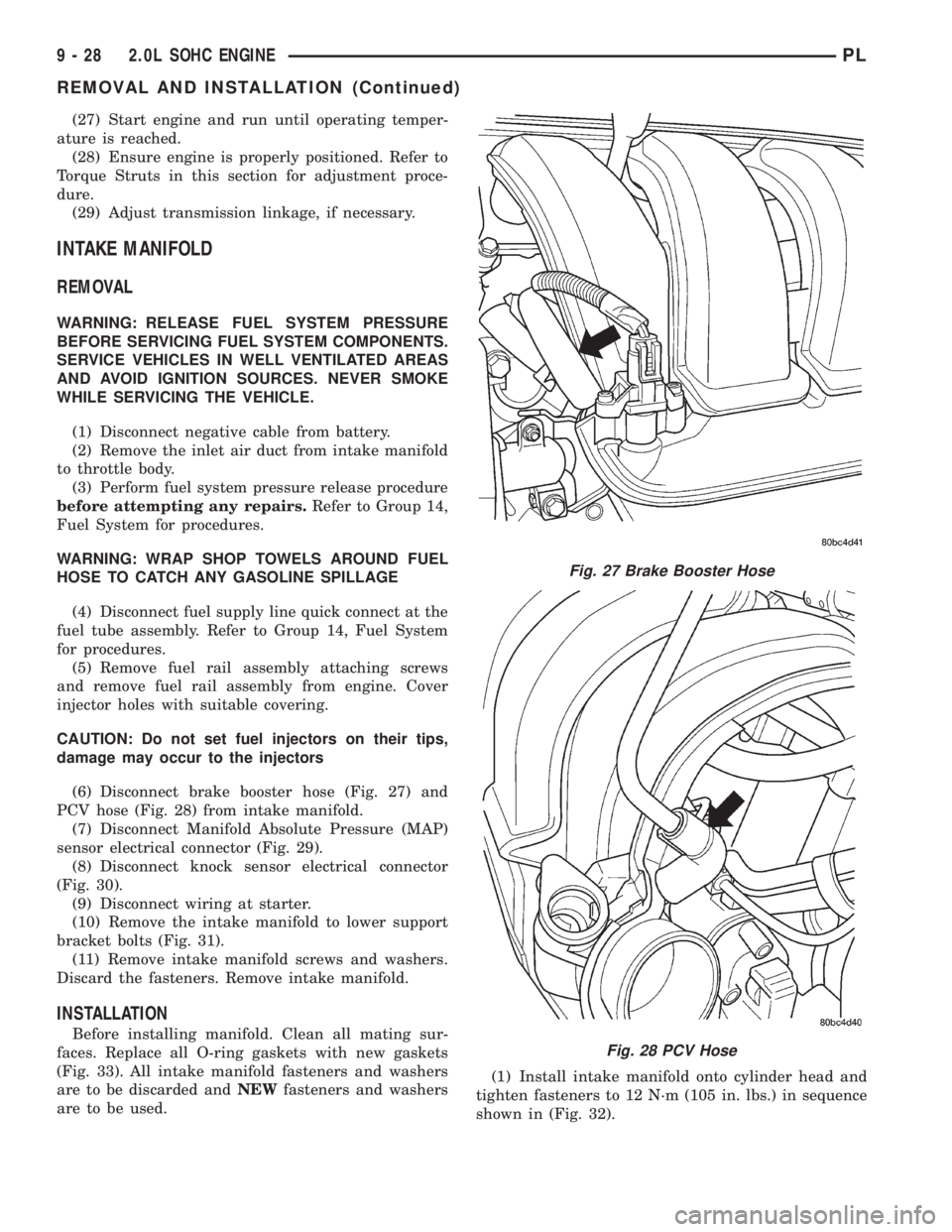

(33) Remove the upper engine torque strut.

(34) Remove right and left engine and transaxle

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 751 of 1285

(27) Start engine and run until operating temper-

ature is reached.

(28) Ensure engine is properly positioned. Refer to

Torque Struts in this section for adjustment proce-

dure.

(29) Adjust transmission linkage, if necessary.

INTAKE MANIFOLD

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove the inlet air duct from intake manifold

to throttle body.

(3) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System for procedures.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSE TO CATCH ANY GASOLINE SPILLAGE

(4) Disconnect fuel supply line quick connect at the

fuel tube assembly. Refer to Group 14, Fuel System

for procedures.

(5) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

(6) Disconnect brake booster hose (Fig. 27) and

PCV hose (Fig. 28) from intake manifold.

(7) Disconnect Manifold Absolute Pressure (MAP)

sensor electrical connector (Fig. 29).

(8) Disconnect knock sensor electrical connector

(Fig. 30).

(9) Disconnect wiring at starter.

(10) Remove the intake manifold to lower support

bracket bolts (Fig. 31).

(11) Remove intake manifold screws and washers.

Discard the fasteners. Remove intake manifold.

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all O-ring gaskets with new gaskets

(Fig. 33). All intake manifold fasteners and washers

are to be discarded andNEWfasteners and washers

are to be used.(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 32).

Fig. 27 Brake Booster Hose

Fig. 28 PCV Hose

9 - 28 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 758 of 1285

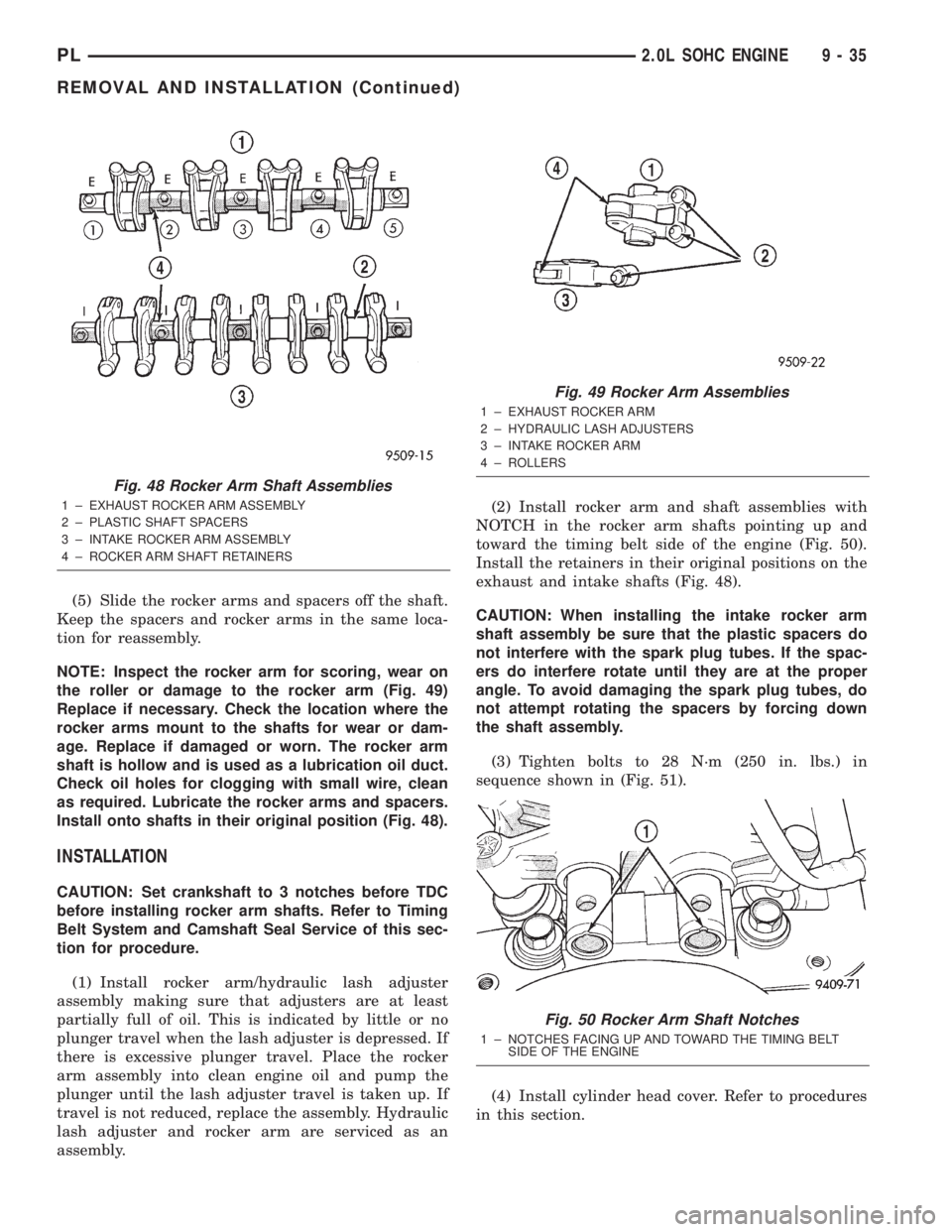

(5) Slide the rocker arms and spacers off the shaft.

Keep the spacers and rocker arms in the same loca-

tion for reassembly.

NOTE: Inspect the rocker arm for scoring, wear on

the roller or damage to the rocker arm (Fig. 49)

Replace if necessary. Check the location where the

rocker arms mount to the shafts for wear or dam-

age. Replace if damaged or worn. The rocker arm

shaft is hollow and is used as a lubrication oil duct.

Check oil holes for clogging with small wire, clean

as required. Lubricate the rocker arms and spacers.

Install onto shafts in their original position (Fig. 48).

INSTALLATION

CAUTION: Set crankshaft to 3 notches before TDC

before installing rocker arm shafts. Refer to Timing

Belt System and Camshaft Seal Service of this sec-

tion for procedure.

(1) Install rocker arm/hydraulic lash adjuster

assembly making sure that adjusters are at least

partially full of oil. This is indicated by little or no

plunger travel when the lash adjuster is depressed. If

there is excessive plunger travel. Place the rocker

arm assembly into clean engine oil and pump the

plunger until the lash adjuster travel is taken up. If

travel is not reduced, replace the assembly. Hydraulic

lash adjuster and rocker arm are serviced as an

assembly.(2) Install rocker arm and shaft assemblies with

NOTCH in the rocker arm shafts pointing up and

toward the timing belt side of the engine (Fig. 50).

Install the retainers in their original positions on the

exhaust and intake shafts (Fig. 48).

CAUTION: When installing the intake rocker arm

shaft assembly be sure that the plastic spacers do

not interfere with the spark plug tubes. If the spac-

ers do interfere rotate until they are at the proper

angle. To avoid damaging the spark plug tubes, do

not attempt rotating the spacers by forcing down

the shaft assembly.

(3) Tighten bolts to 28 N´m (250 in. lbs.) in

sequence shown in (Fig. 51).

(4) Install cylinder head cover. Refer to procedures

in this section.

Fig. 48 Rocker Arm Shaft Assemblies

1 ± EXHAUST ROCKER ARM ASSEMBLY

2 ± PLASTIC SHAFT SPACERS

3 ± INTAKE ROCKER ARM ASSEMBLY

4 ± ROCKER ARM SHAFT RETAINERS

Fig. 49 Rocker Arm Assemblies

1 ± EXHAUST ROCKER ARM

2 ± HYDRAULIC LASH ADJUSTERS

3 ± INTAKE ROCKER ARM

4 ± ROLLERS

Fig. 50 Rocker Arm Shaft Notches

1 ± NOTCHES FACING UP AND TOWARD THE TIMING BELT

SIDE OF THE ENGINE

PL2.0L SOHC ENGINE 9 - 35

REMOVAL AND INSTALLATION (Continued)

Page 772 of 1285

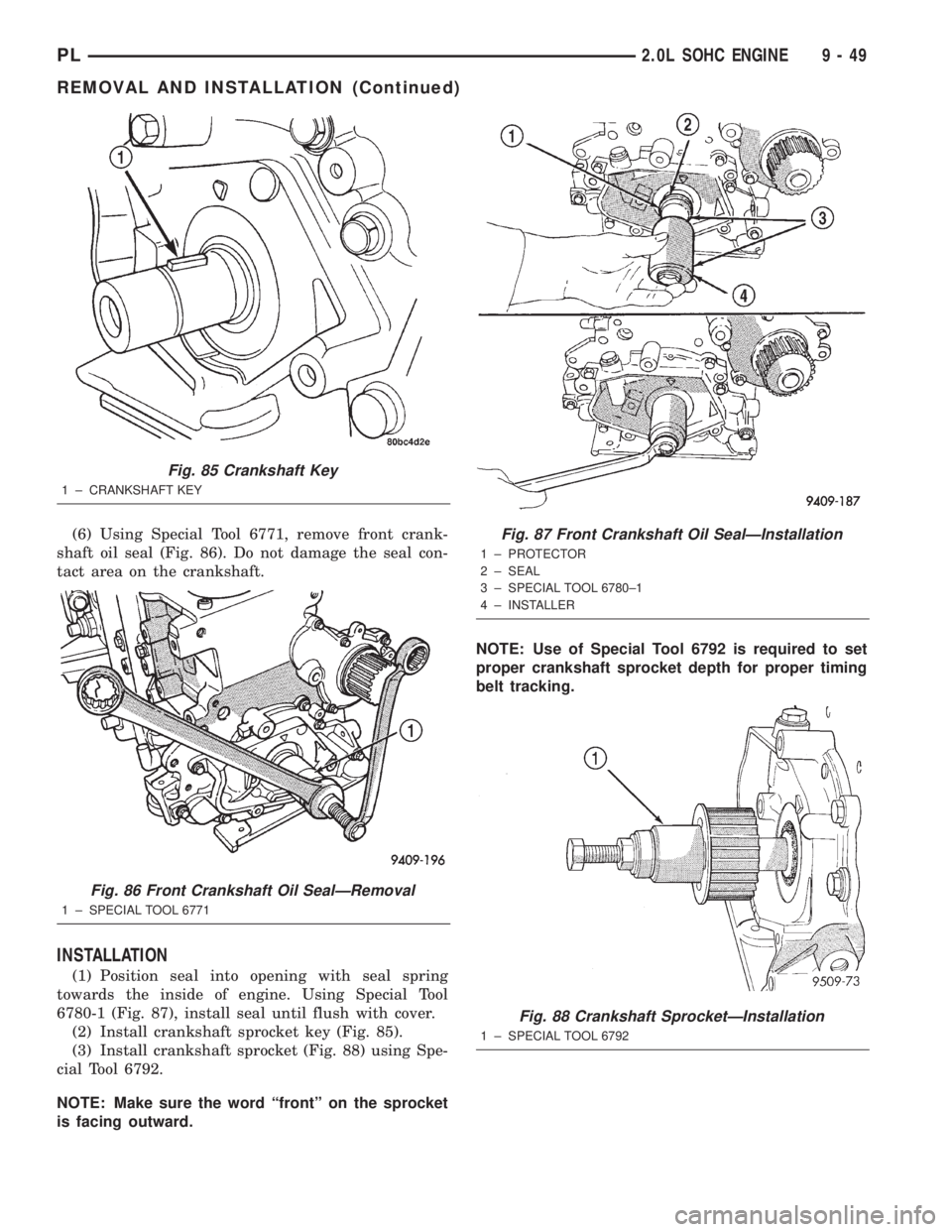

(6) Using Special Tool 6771, remove front crank-

shaft oil seal (Fig. 86). Do not damage the seal con-

tact area on the crankshaft.

INSTALLATION

(1) Position seal into opening with seal spring

towards the inside of engine. Using Special Tool

6780-1 (Fig. 87), install seal until flush with cover.

(2) Install crankshaft sprocket key (Fig. 85).

(3) Install crankshaft sprocket (Fig. 88) using Spe-

cial Tool 6792.

NOTE: Make sure the word ªfrontº on the sprocket

is facing outward.NOTE: Use of Special Tool 6792 is required to set

proper crankshaft sprocket depth for proper timing

belt tracking.

Fig. 85 Crankshaft Key

1 ± CRANKSHAFT KEY

Fig. 86 Front Crankshaft Oil SealÐRemoval

1 ± SPECIAL TOOL 6771

Fig. 87 Front Crankshaft Oil SealÐInstallation

1 ± PROTECTOR

2 ± SEAL

3 ± SPECIAL TOOL 6780±1

4 ± INSTALLER

Fig. 88 Crankshaft SprocketÐInstallation

1 ± SPECIAL TOOL 6792

PL2.0L SOHC ENGINE 9 - 49

REMOVAL AND INSTALLATION (Continued)

Page 773 of 1285

(4) Install timing belt and cover. Refer to proce-

dures in this section.

(5) Install crankshaft damper. Refer to procedure

in this section.

(6) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

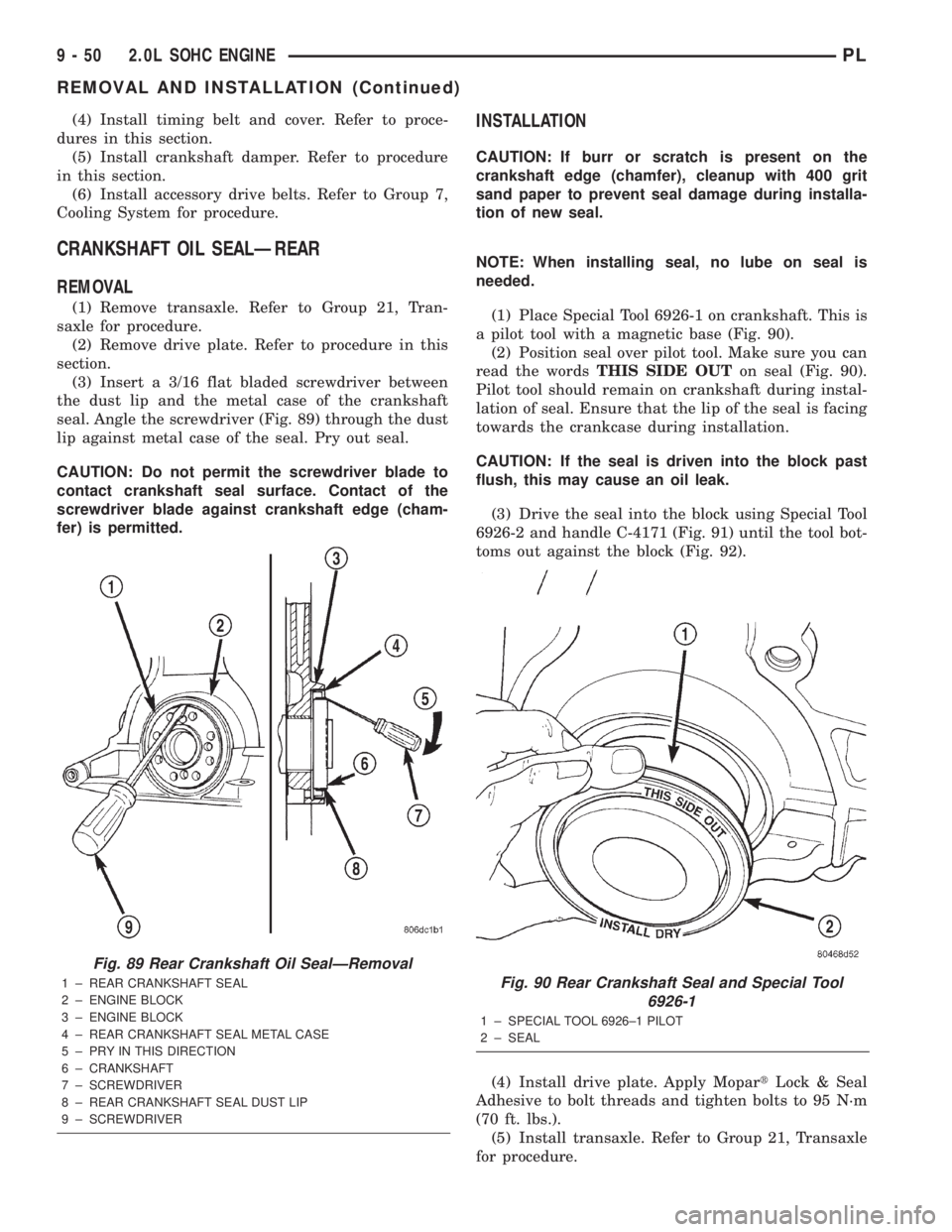

CRANKSHAFT OIL SEALÐREAR

REMOVAL

(1) Remove transaxle. Refer to Group 21, Tran-

saxle for procedure.

(2) Remove drive plate. Refer to procedure in this

section.

(3) Insert a 3/16 flat bladed screwdriver between

the dust lip and the metal case of the crankshaft

seal. Angle the screwdriver (Fig. 89) through the dust

lip against metal case of the seal. Pry out seal.

CAUTION: Do not permit the screwdriver blade to

contact crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

NOTE: When installing seal, no lube on seal is

needed.

(1) Place Special Tool 6926-1 on crankshaft. This is

a pilot tool with a magnetic base (Fig. 90).

(2) Position seal over pilot tool. Make sure you can

read the wordsTHIS SIDE OUTon seal (Fig. 90).

Pilot tool should remain on crankshaft during instal-

lation of seal. Ensure that the lip of the seal is facing

towards the crankcase during installation.

CAUTION: If the seal is driven into the block past

flush, this may cause an oil leak.

(3) Drive the seal into the block using Special Tool

6926-2 and handle C-4171 (Fig. 91) until the tool bot-

toms out against the block (Fig. 92).

(4) Install drive plate. Apply MopartLock & Seal

Adhesive to bolt threads and tighten bolts to 95 N´m

(70 ft. lbs.).

(5) Install transaxle. Refer to Group 21, Transaxle

for procedure.

Fig. 89 Rear Crankshaft Oil SealÐRemoval

1 ± REAR CRANKSHAFT SEAL

2 ± ENGINE BLOCK

3 ± ENGINE BLOCK

4 ± REAR CRANKSHAFT SEAL METAL CASE

5 ± PRY IN THIS DIRECTION

6 ± CRANKSHAFT

7 ± SCREWDRIVER

8 ± REAR CRANKSHAFT SEAL DUST LIP

9 ± SCREWDRIVERFig. 90 Rear Crankshaft Seal and Special Tool

6926-1

1 ± SPECIAL TOOL 6926±1 PILOT

2 ± SEAL

9 - 50 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 781 of 1285

(4) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 108). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(5) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(6) Remove connecting rod cap bolts.Do not use

old bolts if reinstalling connecting rod.

(7) To protect crankshaft journal and fractured rod

surfaces, install Special Tool 8189, connecting rod

guides onto connecting rod (Fig. 110). Carefully push

each piston and rod assembly out of cylinder bore.

CAUTION: Care must be taken not to damage the

fractured rod and cap joint surfaces, as engine

damage many occur.

(8) Remove Special Tool 8189, connecting rod

guides and re-install bearing cap on the mating rod.

NOTE: Piston and rods are serviced as an assem-

bly.

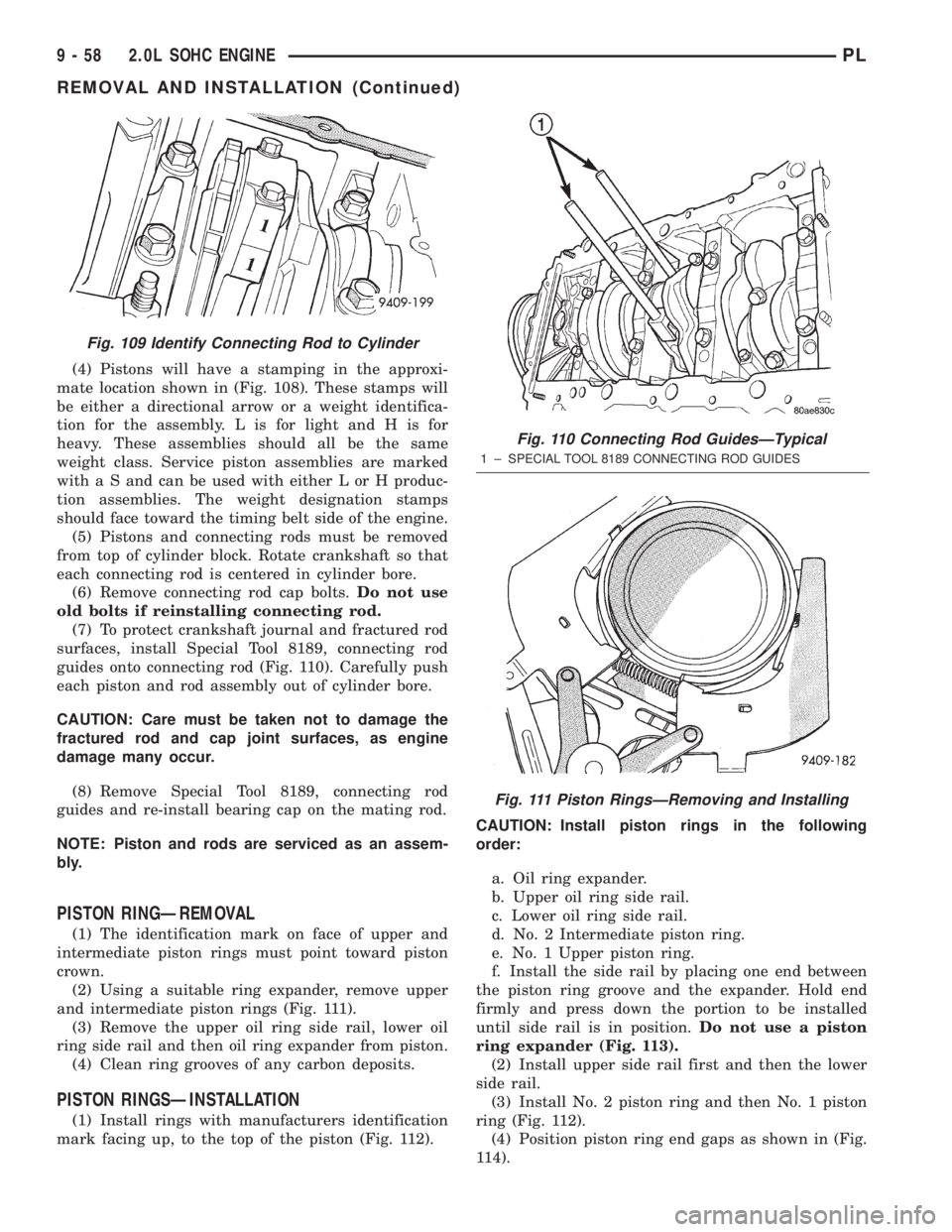

PISTON RINGÐREMOVAL

(1) The identification mark on face of upper and

intermediate piston rings must point toward piston

crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 111).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers identification

mark facing up, to the top of the piston (Fig. 112).CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

c. Lower oil ring side rail.

d. No. 2 Intermediate piston ring.

e. No. 1 Upper piston ring.

f. Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position.Do not use a piston

ring expander (Fig. 113).

(2) Install upper side rail first and then the lower

side rail.

(3) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 112).

(4) Position piston ring end gaps as shown in (Fig.

114).

Fig. 109 Identify Connecting Rod to Cylinder

Fig. 110 Connecting Rod GuidesÐTypical

1 ± SPECIAL TOOL 8189 CONNECTING ROD GUIDES

Fig. 111 Piston RingsÐRemoving and Installing

9 - 58 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 782 of 1285

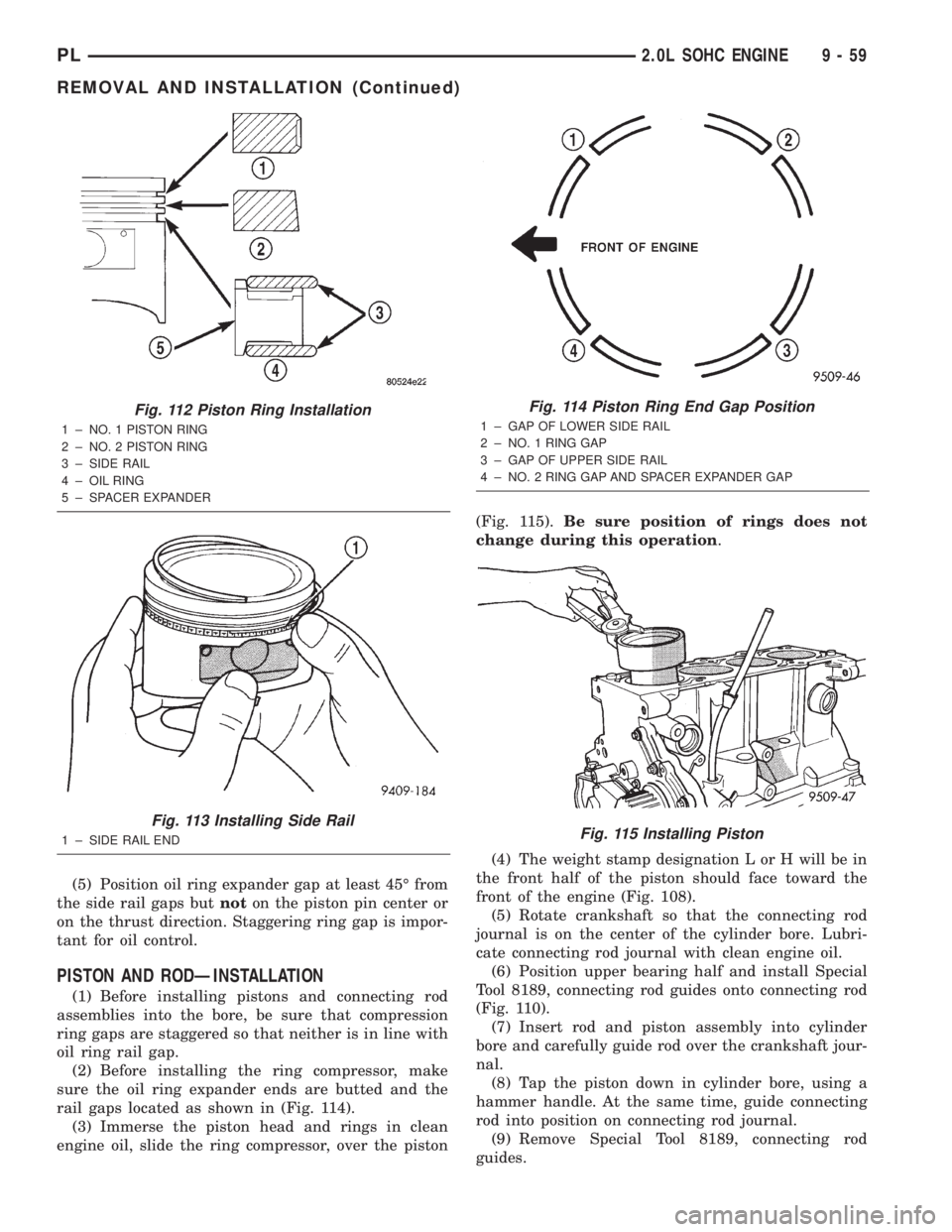

(5) Position oil ring expander gap at least 45É from

the side rail gaps butnoton the piston pin center or

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

PISTON AND RODÐINSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 114).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston(Fig. 115).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine (Fig. 108).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Lubri-

cate connecting rod journal with clean engine oil.

(6) Position upper bearing half and install Special

Tool 8189, connecting rod guides onto connecting rod

(Fig. 110).

(7) Insert rod and piston assembly into cylinder

bore and carefully guide rod over the crankshaft jour-

nal.

(8) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(9) Remove Special Tool 8189, connecting rod

guides.

Fig. 112 Piston Ring Installation

1 ± NO. 1 PISTON RING

2 ± NO. 2 PISTON RING

3 ± SIDE RAIL

4 ± OIL RING

5 ± SPACER EXPANDER

Fig. 113 Installing Side Rail

1 ± SIDE RAIL END

Fig. 114 Piston Ring End Gap Position

1 ± GAP OF LOWER SIDE RAIL

2 ± NO. 1 RING GAP

3 ± GAP OF UPPER SIDE RAIL

4 ± NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 115 Installing Piston

PL2.0L SOHC ENGINE 9 - 59

REMOVAL AND INSTALLATION (Continued)

Page 789 of 1285

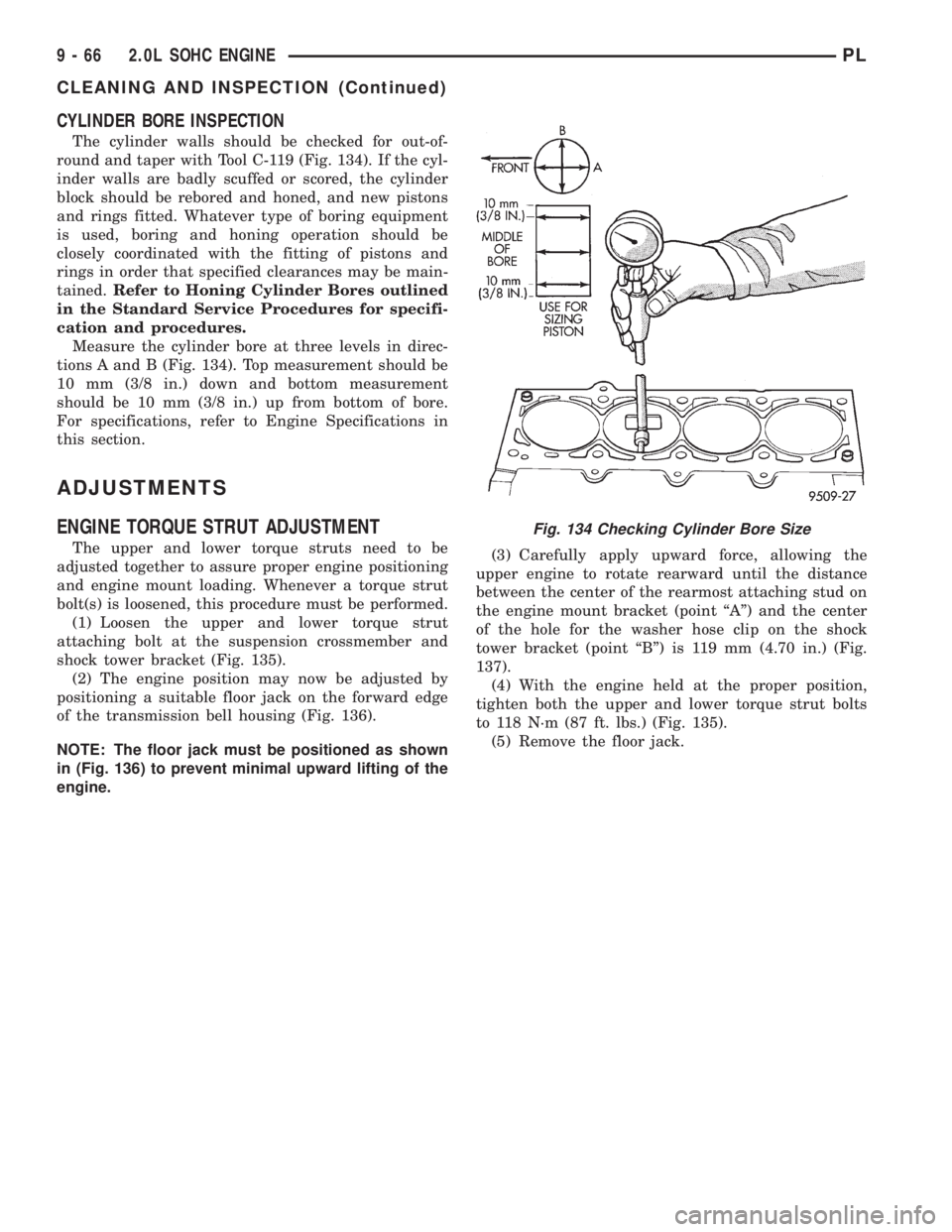

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 134). If the cyl-

inder walls are badly scuffed or scored, the cylinder

block should be rebored and honed, and new pistons

and rings fitted. Whatever type of boring equipment

is used, boring and honing operation should be

closely coordinated with the fitting of pistons and

rings in order that specified clearances may be main-

tained.Refer to Honing Cylinder Bores outlined

in the Standard Service Procedures for specifi-

cation and procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 134). Top measurement should be

10 mm (3/8 in.) down and bottom measurement

should be 10 mm (3/8 in.) up from bottom of bore.

For specifications, refer to Engine Specifications in

this section.

ADJUSTMENTS

ENGINE TORQUE STRUT ADJUSTMENT

The upper and lower torque struts need to be

adjusted together to assure proper engine positioning

and engine mount loading. Whenever a torque strut

bolt(s) is loosened, this procedure must be performed.

(1) Loosen the upper and lower torque strut

attaching bolt at the suspension crossmember and

shock tower bracket (Fig. 135).

(2) The engine position may now be adjusted by

positioning a suitable floor jack on the forward edge

of the transmission bell housing (Fig. 136).

NOTE: The floor jack must be positioned as shown

in (Fig. 136) to prevent minimal upward lifting of the

engine.(3) Carefully apply upward force, allowing the

upper engine to rotate rearward until the distance

between the center of the rearmost attaching stud on

the engine mount bracket (point ªAº) and the center

of the hole for the washer hose clip on the shock

tower bracket (point ªBº) is 119 mm (4.70 in.) (Fig.

137).

(4) With the engine held at the proper position,

tighten both the upper and lower torque strut bolts

to 118 N´m (87 ft. lbs.) (Fig. 135).

(5) Remove the floor jack.

Fig. 134 Checking Cylinder Bore Size

9 - 66 2.0L SOHC ENGINEPL

CLEANING AND INSPECTION (Continued)

Page 813 of 1285

(3) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 5). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-

mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(4) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 6). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(5) Tighten the lower control arm front pivot bolts

to a torque of 163 N´m (120 ft. lbs.).

(6) Attach the steering gear to the front suspen-

sion crossmember (Fig. 4). Install the four power

steering gear mounting bolts. Tighten the mounting

bolts to a torque of 61 N´m (45 ft. lbs.).

(7) Remove the wire or cord suspending the power

steering gear to the underbody.

(8) If the vehicle is equipped with a power steering

fluid cooler, install the two screws securing the cooler

to the front suspension crossmember. They are

located behind the cooler.

(9)

Install each ball joint stud into the steering

knuckle aligning the bolt hole in the knuckle boss with

the notch formed in the side of the ball joint stud.

(10) Install a new ball joint stud pinch bolt and

nut (Fig. 2). Tighten the nut to a torque of 95 N´m

(70 ft. lbs.).

(11) Fasten the engine torque strut to the right

forward corner of the front suspension crossmember

using its mounting bolt (Fig. 5). Follow the procedure

described in the ENGINE service manual group to

properly align and tighten the torque strut and it's

mounting bolts.

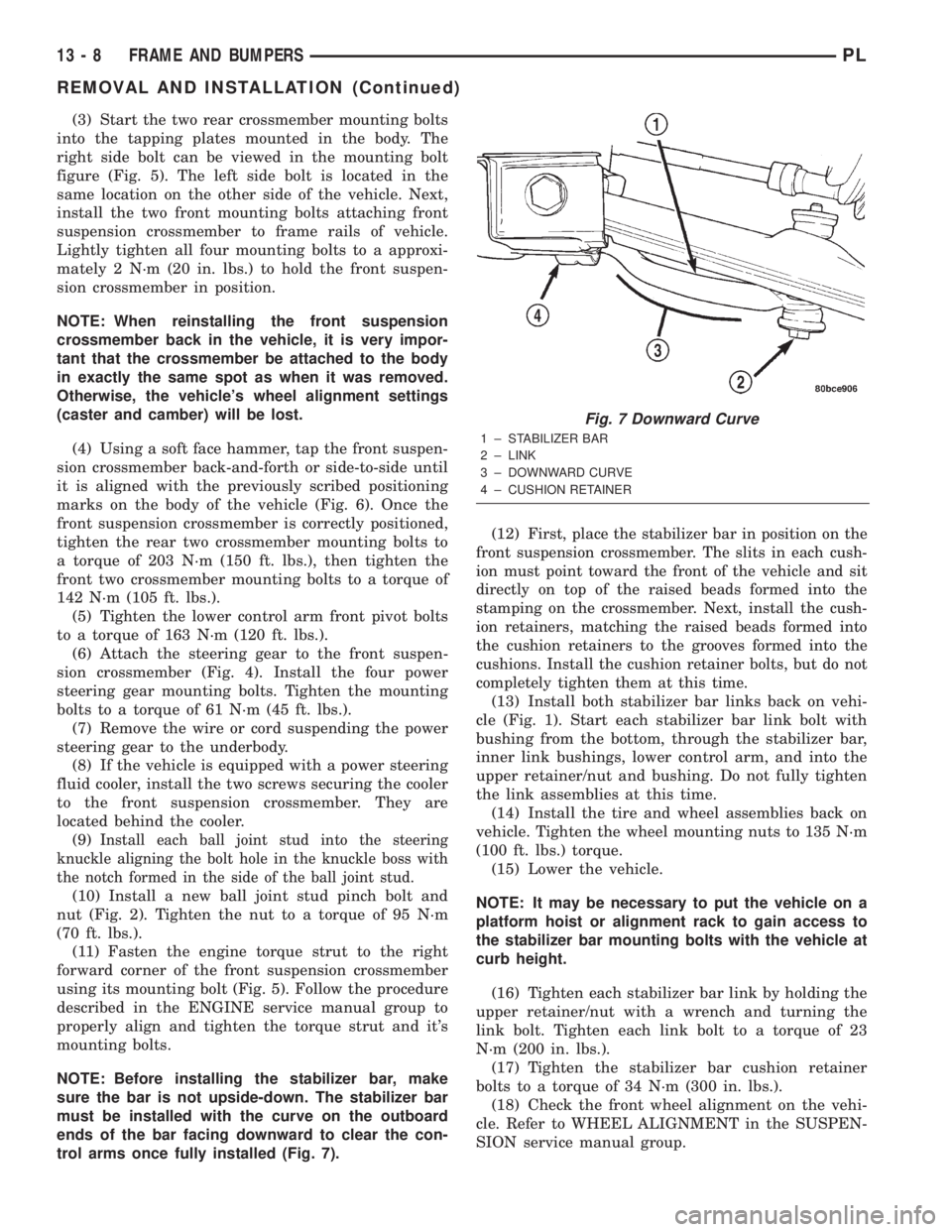

NOTE: Before installing the stabilizer bar, make

sure the bar is not upside-down. The stabilizer bar

must be installed with the curve on the outboard

ends of the bar facing downward to clear the con-

trol arms once fully installed (Fig. 7).(12)

First, place the stabilizer bar in position on the

front suspension crossmember. The slits in each cush-

ion must point toward the front of the vehicle and sit

directly on top of the raised beads formed into the

stamping on the crossmember. Next, install the cush-

ion retainers, matching the raised beads formed into

the cushion retainers to the grooves formed into the

cushions. Install the cushion retainer bolts, but do not

completely tighten them at this time.

(13) Install both stabilizer bar links back on vehi-

cle (Fig. 1). Start each stabilizer bar link bolt with

bushing from the bottom, through the stabilizer bar,

inner link bushings, lower control arm, and into the

upper retainer/nut and bushing. Do not fully tighten

the link assemblies at this time.

(14) Install the tire and wheel assemblies back on

vehicle. Tighten the wheel mounting nuts to 135 N´m

(100 ft. lbs.) torque.

(15) Lower the vehicle.

NOTE: It may be necessary to put the vehicle on a

platform hoist or alignment rack to gain access to

the stabilizer bar mounting bolts with the vehicle at

curb height.

(16) Tighten each stabilizer bar link by holding the

upper retainer/nut with a wrench and turning the

link bolt. Tighten each link bolt to a torque of 23

N´m (200 in. lbs.).

(17) Tighten the stabilizer bar cushion retainer

bolts to a torque of 34 N´m (300 in. lbs.).

(18) Check the front wheel alignment on the vehi-

cle. Refer to WHEEL ALIGNMENT in the SUSPEN-

SION service manual group.

Fig. 7 Downward Curve

1 ± STABILIZER BAR

2 ± LINK

3 ± DOWNWARD CURVE

4 ± CUSHION RETAINER

13 - 8 FRAME AND BUMPERSPL

REMOVAL AND INSTALLATION (Continued)