tow DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 829 of 1285

FUEL TUBES/LINES/HOSES AND CLAMPS

OPERATION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes areproperly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

Tighten hose clamps to 3 N´m (25 in. lbs.) torque.

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(5) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(6) Return fuel pump relay to PDC.

(7) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

INJECTOR CONNECTOR

REMOVAL

(1) Disconnect electrical connectors at the fuel

injectors. To remove connector refer to (Fig. 8). Pull

the red colored slider away from injector (1). While

pulling the slider, depress tab (2) and remove connec-

tor (3) from injector. The factory fuel injection wiring

harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, make note of wiring location before removal.

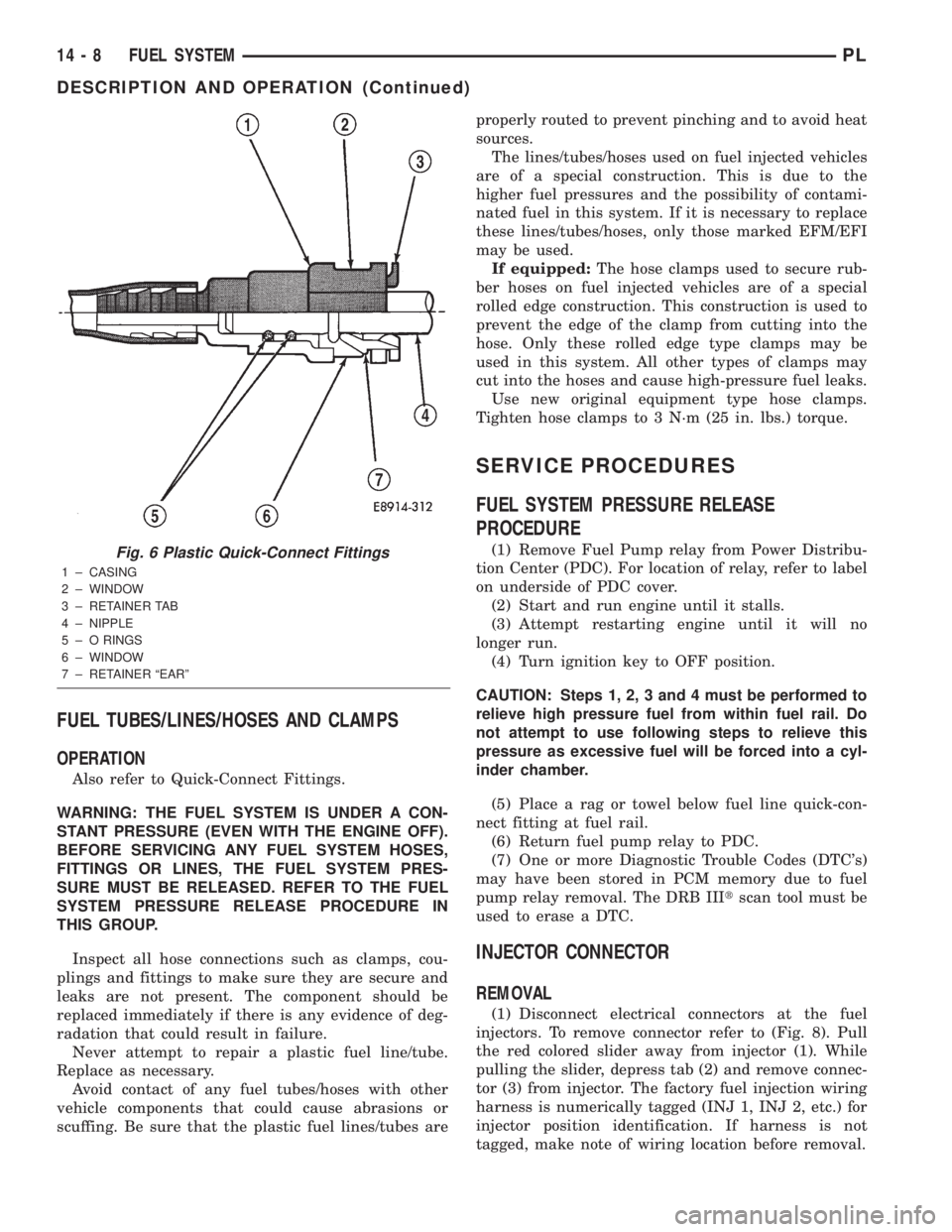

Fig. 6 Plastic Quick-Connect Fittings

1 ± CASING

2 ± WINDOW

3 ± RETAINER TAB

4 ± NIPPLE

5 ± O RINGS

6 ± WINDOW

7 ± RETAINER ªEARº

14 - 8 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 832 of 1285

being serviced. The plastic retainer will remain on

component being serviced after fitting is discon-

nected. The O-rings and spacer will remain in quick-

connect fitting connector body.

(5) Inspect quick-connect fitting body and compo-

nent for damage. Replace as necessary.

CAUTION:

When the quick-connect fitting was dis-

connected, the plastic retainer will remain on the com-

ponent being serviced. If this retainer must be

removed, very carefully release the retainer from the

component with two small screwdrivers. After removal,

inspect the retainer for cracks or any damage.

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Start engine and check for leaks.

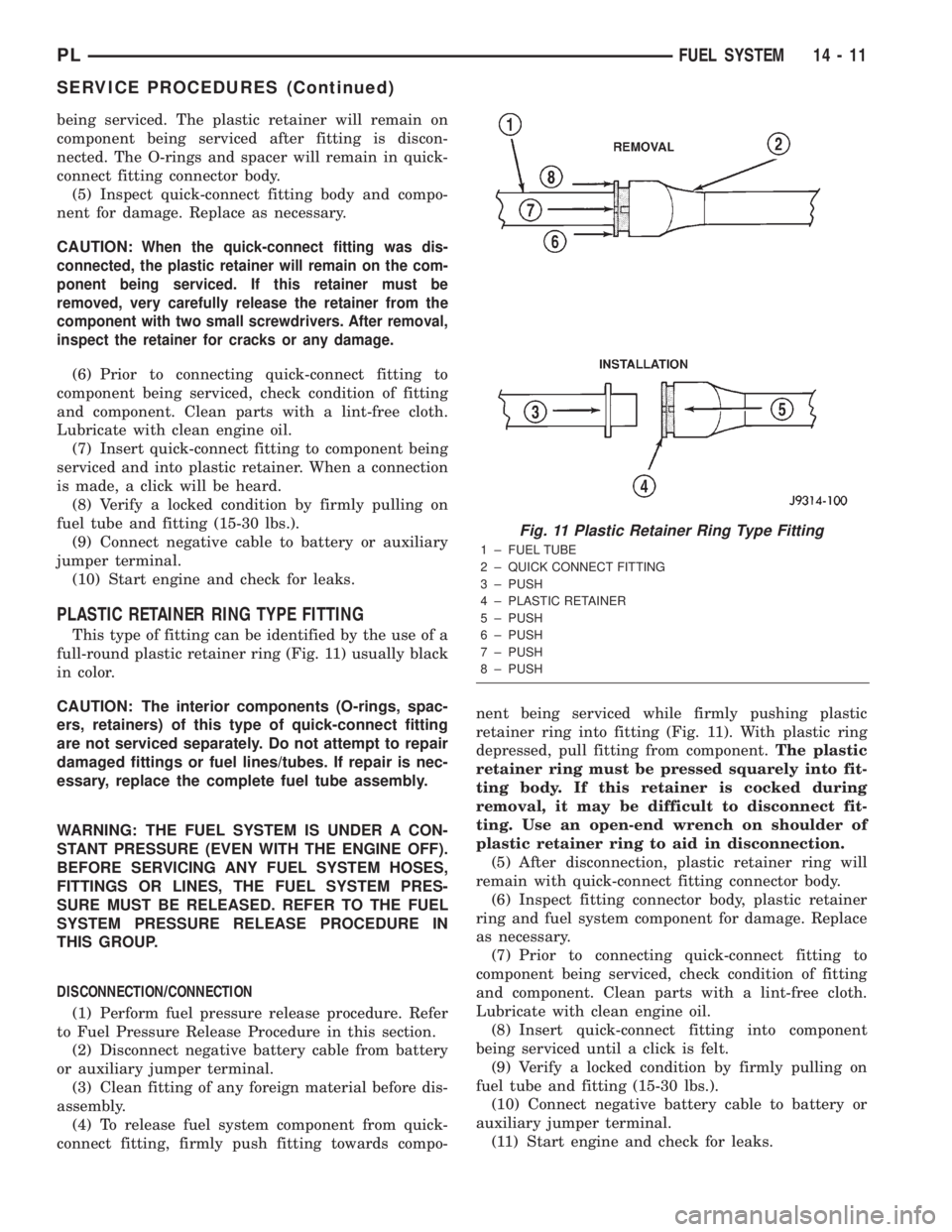

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 11) usually black

in color.

CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-nent being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 11). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.

(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Start engine and check for leaks.

Fig. 11 Plastic Retainer Ring Type Fitting

1 ± FUEL TUBE

2 ± QUICK CONNECT FITTING

3 ± PUSH

4 ± PLASTIC RETAINER

5 ± PUSH

6 ± PUSH

7 ± PUSH

8 ± PUSH

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 868 of 1285

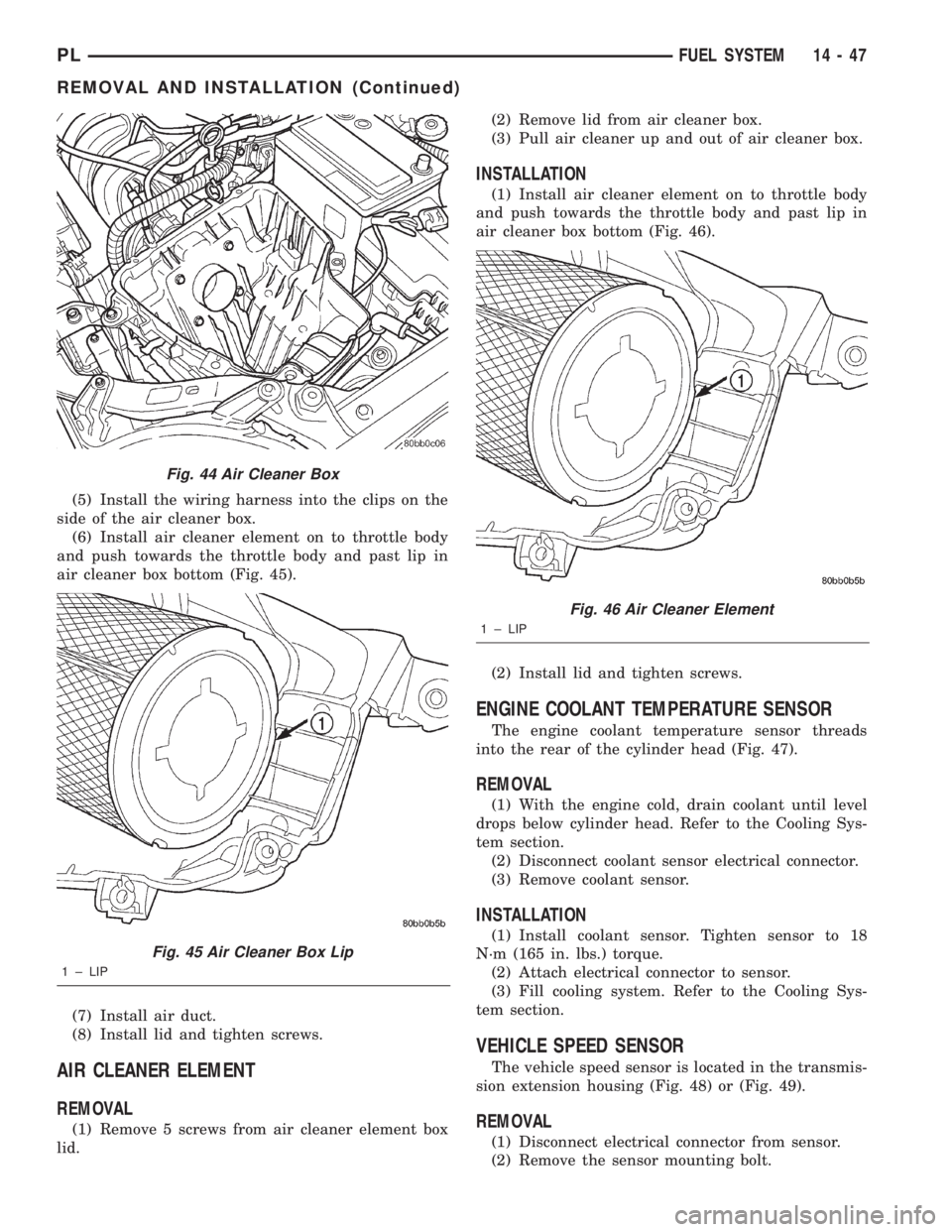

(5) Install the wiring harness into the clips on the

side of the air cleaner box.

(6) Install air cleaner element on to throttle body

and push towards the throttle body and past lip in

air cleaner box bottom (Fig. 45).

(7) Install air duct.

(8) Install lid and tighten screws.

AIR CLEANER ELEMENT

REMOVAL

(1) Remove 5 screws from air cleaner element box

lid.(2) Remove lid from air cleaner box.

(3) Pull air cleaner up and out of air cleaner box.

INSTALLATION

(1) Install air cleaner element on to throttle body

and push towards the throttle body and past lip in

air cleaner box bottom (Fig. 46).

(2) Install lid and tighten screws.

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor threads

into the rear of the cylinder head (Fig. 47).

REMOVAL

(1) With the engine cold, drain coolant until level

drops below cylinder head. Refer to the Cooling Sys-

tem section.

(2) Disconnect coolant sensor electrical connector.

(3) Remove coolant sensor.

INSTALLATION

(1) Install coolant sensor. Tighten sensor to 18

N´m (165 in. lbs.) torque.

(2) Attach electrical connector to sensor.

(3) Fill cooling system. Refer to the Cooling Sys-

tem section.

VEHICLE SPEED SENSOR

The vehicle speed sensor is located in the transmis-

sion extension housing (Fig. 48) or (Fig. 49).

REMOVAL

(1) Disconnect electrical connector from sensor.

(2) Remove the sensor mounting bolt.

Fig. 44 Air Cleaner Box

Fig. 45 Air Cleaner Box Lip

1 ± LIP

Fig. 46 Air Cleaner Element

1 ± LIP

PLFUEL SYSTEM 14 - 47

REMOVAL AND INSTALLATION (Continued)

Page 875 of 1285

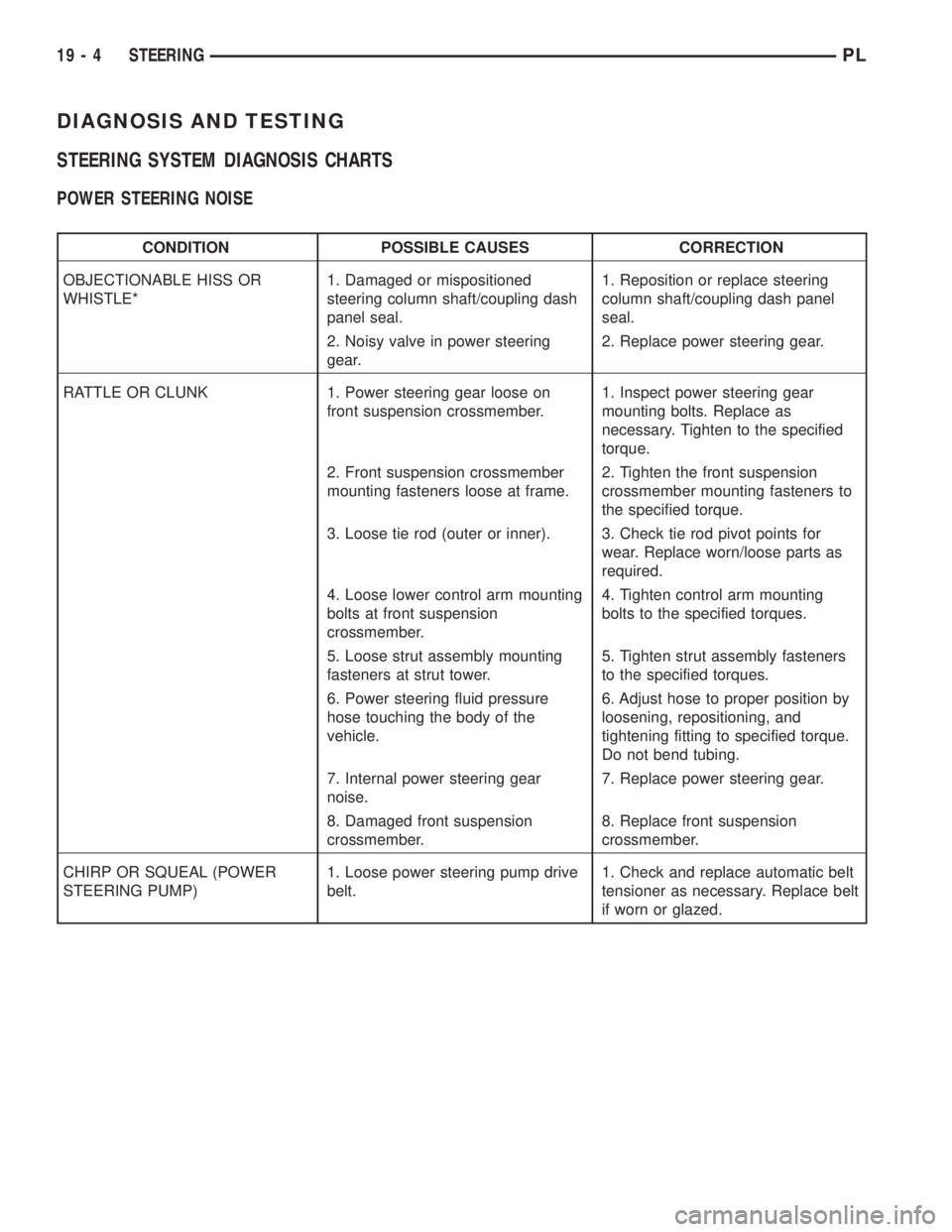

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

POWER STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONABLE HISS OR

WHISTLE*1. Damaged or mispositioned

steering column shaft/coupling dash

panel seal.1. Reposition or replace steering

column shaft/coupling dash panel

seal.

2. Noisy valve in power steering

gear.2. Replace power steering gear.

RATTLE OR CLUNK 1. Power steering gear loose on

front suspension crossmember.1. Inspect power steering gear

mounting bolts. Replace as

necessary. Tighten to the specified

torque.

2. Front suspension crossmember

mounting fasteners loose at frame.2. Tighten the front suspension

crossmember mounting fasteners to

the specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose strut assembly mounting

fasteners at strut tower.5. Tighten strut assembly fasteners

to the specified torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Internal power steering gear

noise.7. Replace power steering gear.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

CHIRP OR SQUEAL (POWER

STEERING PUMP)1. Loose power steering pump drive

belt.1. Check and replace automatic belt

tensioner as necessary. Replace belt

if worn or glazed.

19 - 4 STEERINGPL

Page 883 of 1285

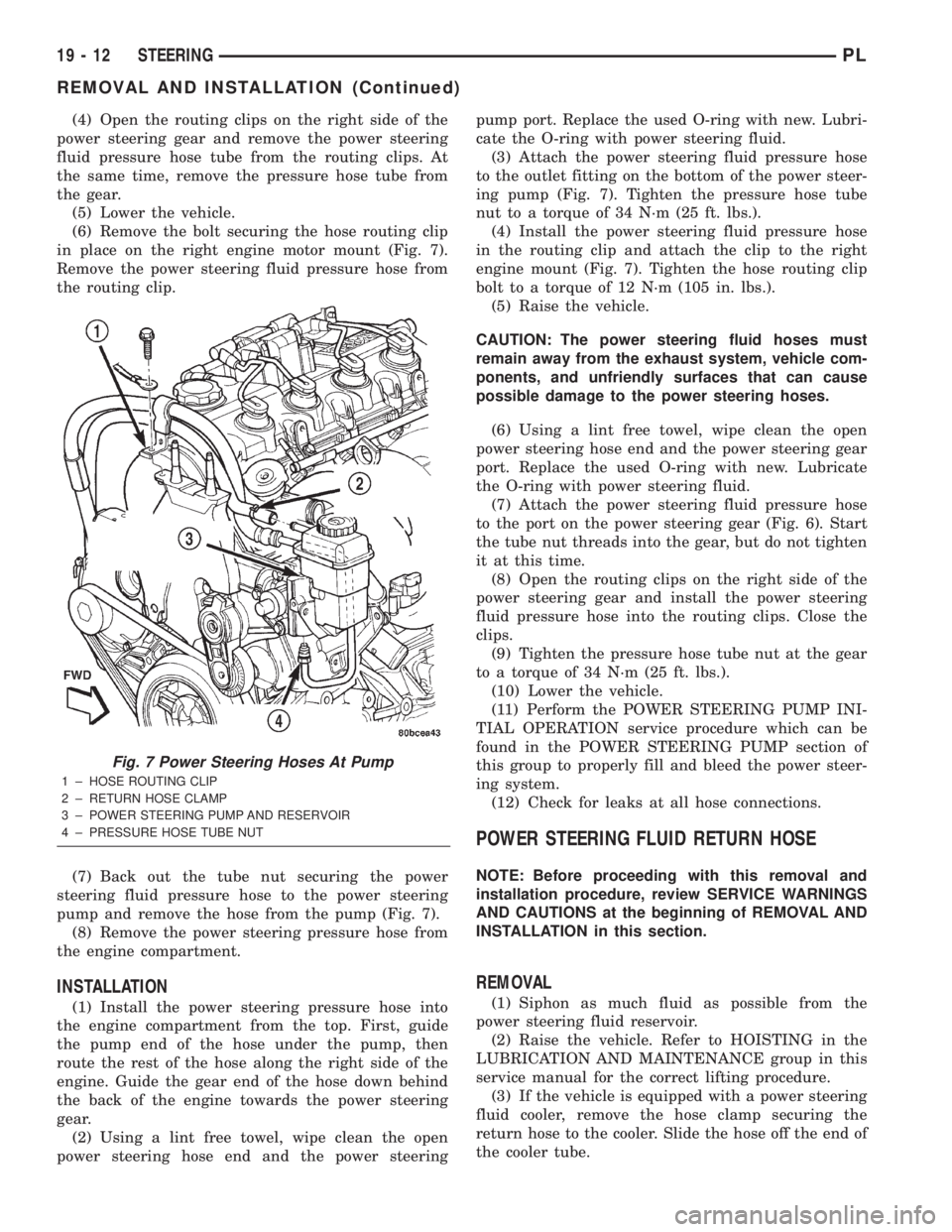

(4) Open the routing clips on the right side of the

power steering gear and remove the power steering

fluid pressure hose tube from the routing clips. At

the same time, remove the pressure hose tube from

the gear.

(5) Lower the vehicle.

(6) Remove the bolt securing the hose routing clip

in place on the right engine motor mount (Fig. 7).

Remove the power steering fluid pressure hose from

the routing clip.

(7) Back out the tube nut securing the power

steering fluid pressure hose to the power steering

pump and remove the hose from the pump (Fig. 7).

(8) Remove the power steering pressure hose from

the engine compartment.

INSTALLATION

(1) Install the power steering pressure hose into

the engine compartment from the top. First, guide

the pump end of the hose under the pump, then

route the rest of the hose along the right side of the

engine. Guide the gear end of the hose down behind

the back of the engine towards the power steering

gear.

(2) Using a lint free towel, wipe clean the open

power steering hose end and the power steeringpump port. Replace the used O-ring with new. Lubri-

cate the O-ring with power steering fluid.

(3) Attach the power steering fluid pressure hose

to the outlet fitting on the bottom of the power steer-

ing pump (Fig. 7). Tighten the pressure hose tube

nut to a torque of 34 N´m (25 ft. lbs.).

(4) Install the power steering fluid pressure hose

in the routing clip and attach the clip to the right

engine mount (Fig. 7). Tighten the hose routing clip

bolt to a torque of 12 N´m (105 in. lbs.).

(5) Raise the vehicle.

CAUTION: The power steering fluid hoses must

remain away from the exhaust system, vehicle com-

ponents, and unfriendly surfaces that can cause

possible damage to the power steering hoses.

(6) Using a lint free towel, wipe clean the open

power steering hose end and the power steering gear

port. Replace the used O-ring with new. Lubricate

the O-ring with power steering fluid.

(7) Attach the power steering fluid pressure hose

to the port on the power steering gear (Fig. 6). Start

the tube nut threads into the gear, but do not tighten

it at this time.

(8) Open the routing clips on the right side of the

power steering gear and install the power steering

fluid pressure hose into the routing clips. Close the

clips.

(9) Tighten the pressure hose tube nut at the gear

to a torque of 34 N´m (25 ft. lbs.).

(10) Lower the vehicle.

(11) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(12) Check for leaks at all hose connections.

POWER STEERING FLUID RETURN HOSE

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) If the vehicle is equipped with a power steering

fluid cooler, remove the hose clamp securing the

return hose to the cooler. Slide the hose off the end of

the cooler tube.

Fig. 7 Power Steering Hoses At Pump

1 ± HOSE ROUTING CLIP

2 ± RETURN HOSE CLAMP

3 ± POWER STEERING PUMP AND RESERVOIR

4 ± PRESSURE HOSE TUBE NUT

19 - 12 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 884 of 1285

(4) If the vehicle is not equipped with a power

steering fluid cooler:

²Remove the hose clamp securing the return hose

to the steel fitting in the outlet port on the power

steering gear (Fig. 6).

²Slide the hose off the end of the steel fitting.

²Pull the hose loose from the C-clamps on the two

routing clips located on the front of the steering gear

(Fig. 6).

(5) Lower the vehicle.

(6) Remove the bolt securing the hose routing clip

in place on the right engine mount (Fig. 7). Remove

the power steering fluid return hose from the routing

clip.

(7) Remove the hose clamp securing the return

hose to the power steering fluid reservoir (Fig. 7).

Slide the hose off the end of the reservoir fitting.

(8) Remove the power steering return hose from

the engine compartment.

INSTALLATION

(1) Slide a hose clamp onto the power steering

pump end of the hose far enough to clear the fitting

on the power steering fluid reservoir once the hose is

installed.

(2) Install the power steering return hose into the

engine compartment from the top. First, guide the

pump end of the hose onto the fitting on the power

steering fluid reservoir, then route the rest of the

hose along the right side of the engine (Fig. 7). Guide

the gear end of the hose down behind the back of the

engine towards the power steering gear.

(3) Expand the hose clamp and slide it onto the

fluid reservoir fitting. Secure the clamp once it is

past the bead formed into the fluid reservoir fitting.

(4) Install the power steering fluid return hose in

the hose routing clip and attach the clip to the right

engine mount (Fig. 7). Tighten the hose routing clip

bolt to a torque of 12 N´m (105 in. lbs.).

(5) Raise the vehicle.

CAUTION: The power steering fluid hoses must

remain away from the exhaust system, vehicle com-

ponents, and unfriendly surfaces that can cause

possible damage to the power steering hoses.

(6) Using a lint free towel, wipe clean the open

power steering hose end and the power steering gear

port fitting or power steering fluid cooler port.

(7) Install a hose clamp onto the end of the hose

far enough to clear the fitting on the steering gear or

cooler once the hose is installed.

(8) If the vehicle is equipped with a power steering

fluid cooler, slide the hose onto the end of the cooler

tube. Install the hose clamp past the bead formed

into the cooler tube and secure in place.(9) If the vehicle is not equipped with a power

steering fluid cooler:

²Slide the hose onto the end of the steel fitting in

the steering gear outlet port (Fig. 6).

²Install the hose clamp past the bead formed into

the steel fitting and secure in place.

²Align and attach the hose to the C-clamps on

the two routing clips located on the front of the steer-

ing gear (Fig. 6).

(10) Lower the vehicle.

(11) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(12) Check for leaks at all hose connections.

POWER STEERING FLUID COOLER

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

(1) Siphon as much fluid as possible from the

power steering fluid reservoir.

(2) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

(3) Remove the hose clamp, attaching the power

steering fluid return hose to the power steering fluid

cooler. Remove the return hose from the cooler.

(4) Remove the hose clamp attaching the power

steering cooler fluid hose to the steel fitting in the

power steering gear outlet port (Fig. 8).

(5) Remove the two screws securing the cooler to

the front suspension crossmember. They are located

behind the cooler. They can be accessed from above.

(6) Open the routing clip on the right front of the

power steering gear housing and remove the cooler

tube from it.

(7) Remove the cooler from the vehicle.

INSTALLATION

(1) Slide a hose clamp onto the end of the power

steering cooler fluid hose far enough to clear the steel

fitting on the power steering gear once the hose is

installed.

(2) Slide the hose (with cooler attached) onto the

fitting on the steering gear, then align the tube on

back of the cooler with the open routing clip on the

right front of the power steering gear housing, and

snap it into place. Close the clip.

PLSTEERING 19 - 13

REMOVAL AND INSTALLATION (Continued)

Page 890 of 1285

SORY DRIVE BELTS in the COOLING SYSTEM

service manual group for the required removal and

installation procedure.

(6) Using a lint free towel, wipe clean all open

power steering hose ends and power steering pump

fittings.

(7) Install a new O-ring on the end of the power

steering pressure hose. Lubricate the O-ring using

clean power steering fluid.

(8) Attach the power steering fluid pressure hose

to the pressure fitting on the lower end of the power

steering pump (Fig. 2). Thread the tube nut securing

the power steering fluid pressure hose into the power

steering pump pressure fitting. Tighten the tube nut

to at torque of 34 N´m (25 ft. lbs.).

(9) Slide the power steering fluid return hose onto

the fluid reservoir fitting (Fig. 2). Position the hose

clamp so it is installed on the hose past the bead

formed into the fluid reservoir fitting.

(10) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure found in this

section of this group to properly fill and bleed the

power steering system.

(11) Check for leaks.

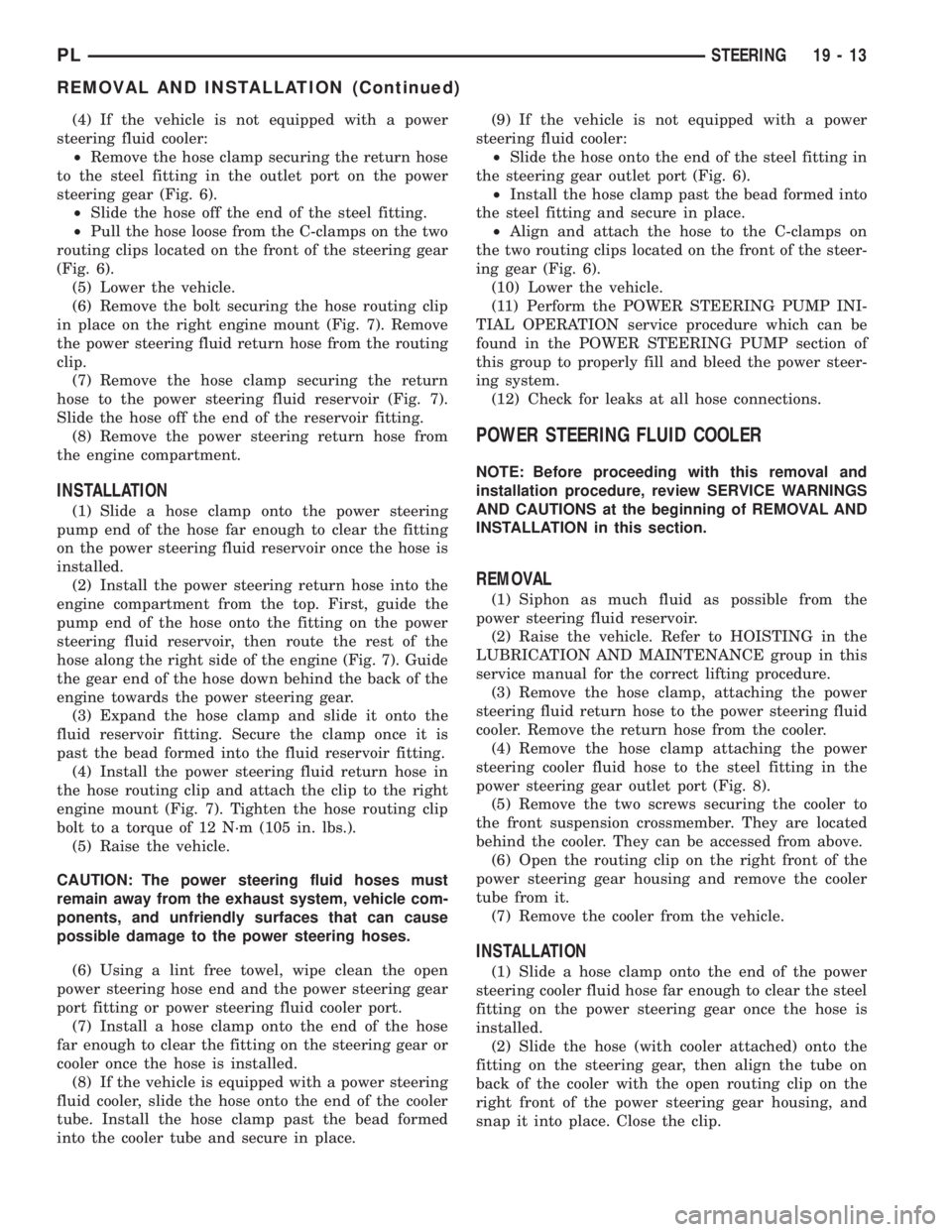

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP (PULLEY)

The only serviceable part of the power steering

pump is the pulley. The following procedure is for the

removal and installation of the pulley from the

pump.

The power steering pump must be removed from

the vehicle for power steering pump pulley service.

Refer to POWER STEERING PUMP in REMOVAL

AND INSTALLATION for the required procedure.

CAUTION: Use care when removing and installing

the power steering pump pulley. It is made of plas-

tic composite, except for the center shank. The spe-

cial tools are to be used in the shank area only as

described in the following procedure.

DISASSEMBLY

CAUTION: Do not hammer on the power steering

pump pulley or shaft to remove the power steering

pump pulley. This will damage the pulley and the

power steering pump.

(1) Install Puller, Special Tool C-4333, or an equiv-

alent, on the steering pump pulley as shown (Fig. 5).

Tighten the puller screw drive and remove the pulley

from the power steering pump shaft.NOTE: Replace the power steering pump pulley if it

is cracked or loose.

(2) Remove the puller from the power steering

pump pulley.

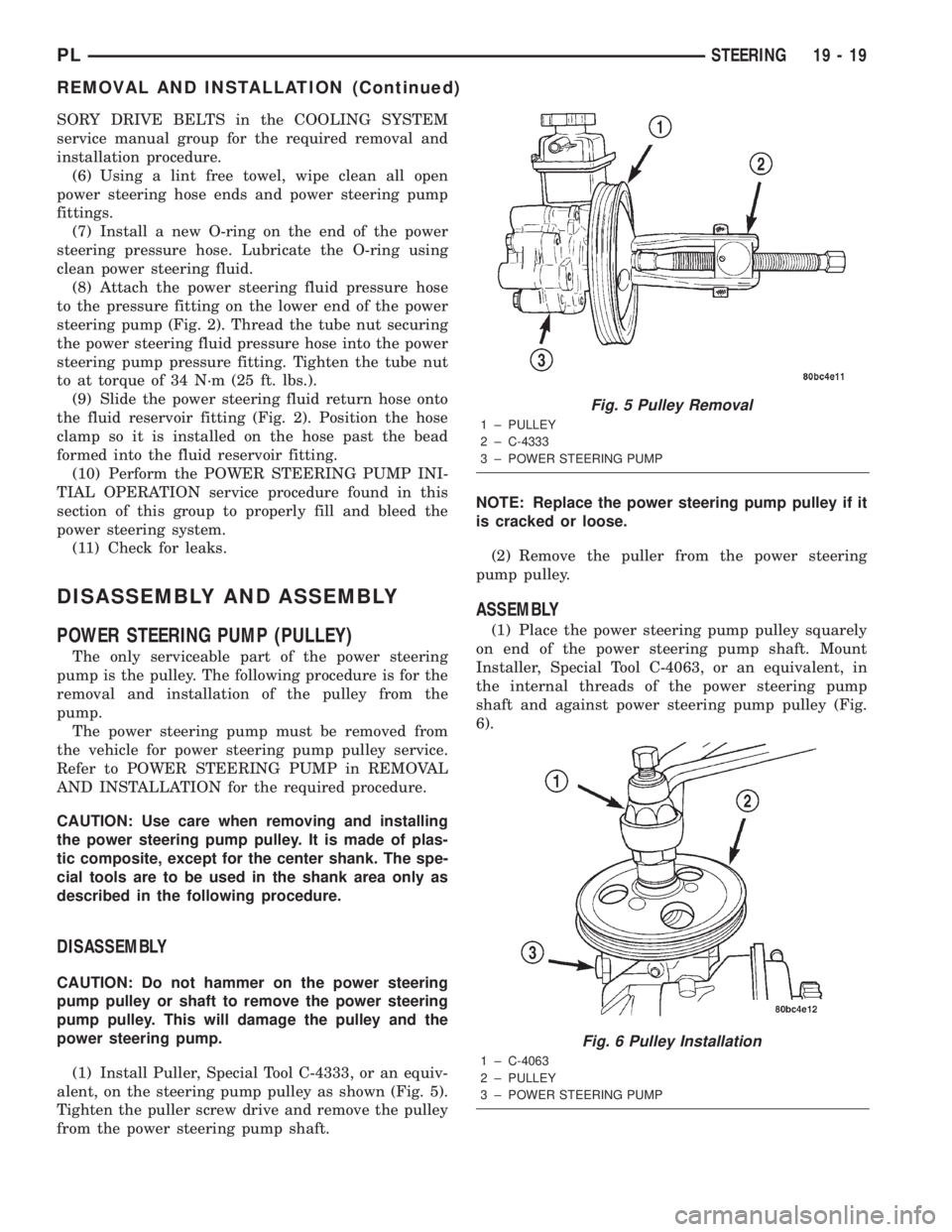

ASSEMBLY

(1) Place the power steering pump pulley squarely

on end of the power steering pump shaft. Mount

Installer, Special Tool C-4063, or an equivalent, in

the internal threads of the power steering pump

shaft and against power steering pump pulley (Fig.

6).

Fig. 5 Pulley Removal

1 ± PULLEY

2 ± C-4333

3 ± POWER STEERING PUMP

Fig. 6 Pulley Installation

1 ± C-4063

2 ± PULLEY

3 ± POWER STEERING PUMP

PLSTEERING 19 - 19

REMOVAL AND INSTALLATION (Continued)

Page 897 of 1285

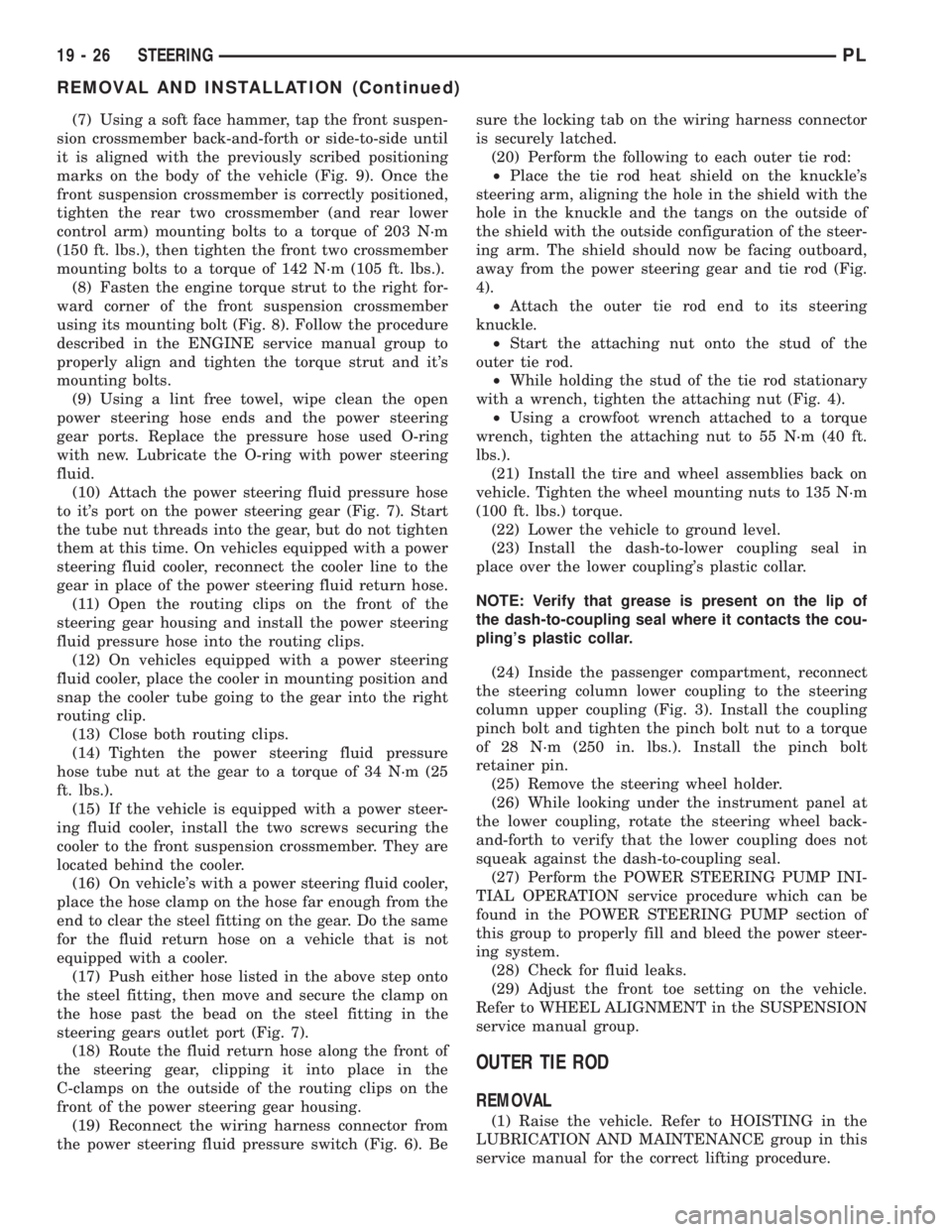

(7) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 9). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember (and rear lower

control arm) mounting bolts to a torque of 203 N´m

(150 ft. lbs.), then tighten the front two crossmember

mounting bolts to a torque of 142 N´m (105 ft. lbs.).

(8) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 8). Follow the procedure

described in the ENGINE service manual group to

properly align and tighten the torque strut and it's

mounting bolts.

(9) Using a lint free towel, wipe clean the open

power steering hose ends and the power steering

gear ports. Replace the pressure hose used O-ring

with new. Lubricate the O-ring with power steering

fluid.

(10) Attach the power steering fluid pressure hose

to it's port on the power steering gear (Fig. 7). Start

the tube nut threads into the gear, but do not tighten

them at this time. On vehicles equipped with a power

steering fluid cooler, reconnect the cooler line to the

gear in place of the power steering fluid return hose.

(11) Open the routing clips on the front of the

steering gear housing and install the power steering

fluid pressure hose into the routing clips.

(12) On vehicles equipped with a power steering

fluid cooler, place the cooler in mounting position and

snap the cooler tube going to the gear into the right

routing clip.

(13) Close both routing clips.

(14) Tighten the power steering fluid pressure

hose tube nut at the gear to a torque of 34 N´m (25

ft. lbs.).

(15) If the vehicle is equipped with a power steer-

ing fluid cooler, install the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler.

(16) On vehicle's with a power steering fluid cooler,

place the hose clamp on the hose far enough from the

end to clear the steel fitting on the gear. Do the same

for the fluid return hose on a vehicle that is not

equipped with a cooler.

(17) Push either hose listed in the above step onto

the steel fitting, then move and secure the clamp on

the hose past the bead on the steel fitting in the

steering gears outlet port (Fig. 7).

(18) Route the fluid return hose along the front of

the steering gear, clipping it into place in the

C-clamps on the outside of the routing clips on the

front of the power steering gear housing.

(19) Reconnect the wiring harness connector from

the power steering fluid pressure switch (Fig. 6). Besure the locking tab on the wiring harness connector

is securely latched.

(20) Perform the following to each outer tie rod:

²Place the tie rod heat shield on the knuckle's

steering arm, aligning the hole in the shield with the

hole in the knuckle and the tangs on the outside of

the shield with the outside configuration of the steer-

ing arm. The shield should now be facing outboard,

away from the power steering gear and tie rod (Fig.

4).

²Attach the outer tie rod end to its steering

knuckle.

²Start the attaching nut onto the stud of the

outer tie rod.

²While holding the stud of the tie rod stationary

with a wrench, tighten the attaching nut (Fig. 4).

²Using a crowfoot wrench attached to a torque

wrench, tighten the attaching nut to 55 N´m (40 ft.

lbs.).

(21) Install the tire and wheel assemblies back on

vehicle. Tighten the wheel mounting nuts to 135 N´m

(100 ft. lbs.) torque.

(22) Lower the vehicle to ground level.

(23) Install the dash-to-lower coupling seal in

place over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(24) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 3). Install the coupling

pinch bolt and tighten the pinch bolt nut to a torque

of 28 N´m (250 in. lbs.). Install the pinch bolt

retainer pin.

(25) Remove the steering wheel holder.

(26) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

(27) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(28) Check for fluid leaks.

(29) Adjust the front toe setting on the vehicle.

Refer to WHEEL ALIGNMENT in the SUSPENSION

service manual group.

OUTER TIE ROD

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

19 - 26 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 954 of 1285

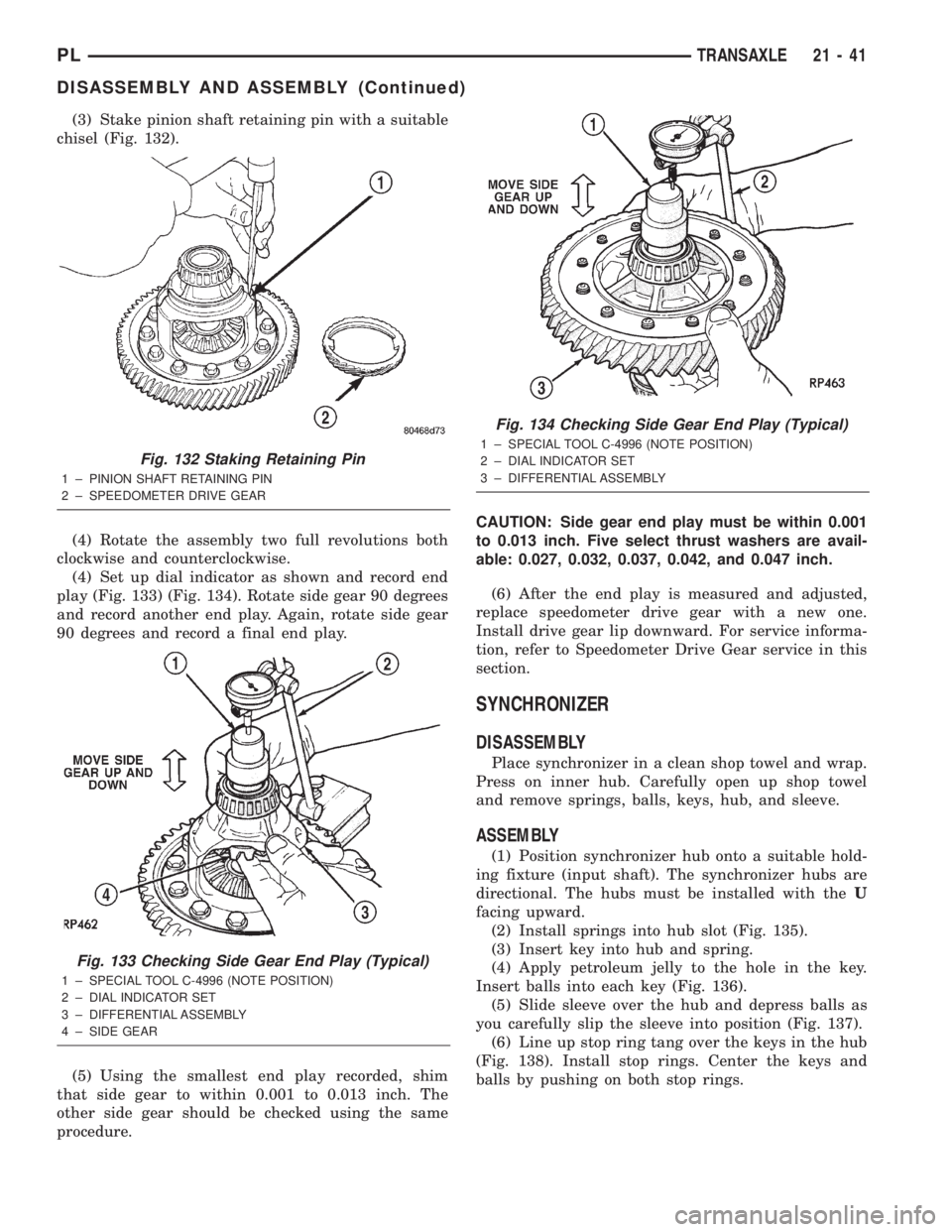

(3) Stake pinion shaft retaining pin with a suitable

chisel (Fig. 132).

(4) Rotate the assembly two full revolutions both

clockwise and counterclockwise.

(4) Set up dial indicator as shown and record end

play (Fig. 133) (Fig. 134). Rotate side gear 90 degrees

and record another end play. Again, rotate side gear

90 degrees and record a final end play.

(5) Using the smallest end play recorded, shim

that side gear to within 0.001 to 0.013 inch. The

other side gear should be checked using the same

procedure.CAUTION: Side gear end play must be within 0.001

to 0.013 inch. Five select thrust washers are avail-

able: 0.027, 0.032, 0.037, 0.042, and 0.047 inch.

(6) After the end play is measured and adjusted,

replace speedometer drive gear with a new one.

Install drive gear lip downward. For service informa-

tion, refer to Speedometer Drive Gear service in this

section.

SYNCHRONIZER

DISASSEMBLY

Place synchronizer in a clean shop towel and wrap.

Press on inner hub. Carefully open up shop towel

and remove springs, balls, keys, hub, and sleeve.

ASSEMBLY

(1) Position synchronizer hub onto a suitable hold-

ing fixture (input shaft). The synchronizer hubs are

directional. The hubs must be installed with theU

facing upward.

(2) Install springs into hub slot (Fig. 135).

(3) Insert key into hub and spring.

(4) Apply petroleum jelly to the hole in the key.

Insert balls into each key (Fig. 136).

(5) Slide sleeve over the hub and depress balls as

you carefully slip the sleeve into position (Fig. 137).

(6) Line up stop ring tang over the keys in the hub

(Fig. 138). Install stop rings. Center the keys and

balls by pushing on both stop rings.

Fig. 132 Staking Retaining Pin

1 ± PINION SHAFT RETAINING PIN

2 ± SPEEDOMETER DRIVE GEAR

Fig. 133 Checking Side Gear End Play (Typical)

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

4 ± SIDE GEAR

Fig. 134 Checking Side Gear End Play (Typical)

1 ± SPECIAL TOOL C-4996 (NOTE POSITION)

2 ± DIAL INDICATOR SET

3 ± DIFFERENTIAL ASSEMBLY

PLTRANSAXLE 21 - 41

DISASSEMBLY AND ASSEMBLY (Continued)

Page 961 of 1285

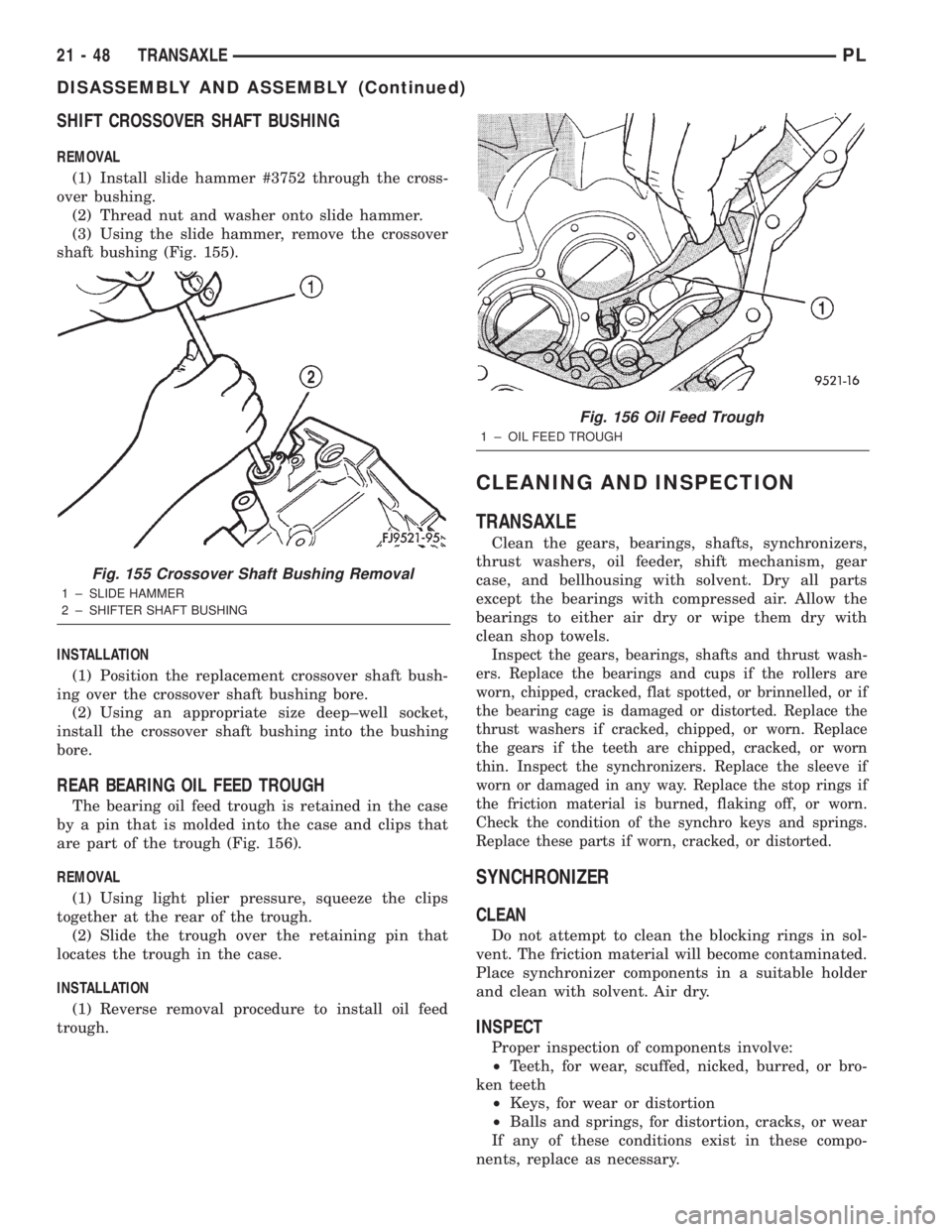

SHIFT CROSSOVER SHAFT BUSHING

REMOVAL

(1) Install slide hammer #3752 through the cross-

over bushing.

(2) Thread nut and washer onto slide hammer.

(3) Using the slide hammer, remove the crossover

shaft bushing (Fig. 155).

INSTALLATION

(1) Position the replacement crossover shaft bush-

ing over the crossover shaft bushing bore.

(2) Using an appropriate size deep±well socket,

install the crossover shaft bushing into the bushing

bore.

REAR BEARING OIL FEED TROUGH

The bearing oil feed trough is retained in the case

by a pin that is molded into the case and clips that

are part of the trough (Fig. 156).

REMOVAL

(1) Using light plier pressure, squeeze the clips

together at the rear of the trough.

(2) Slide the trough over the retaining pin that

locates the trough in the case.

INSTALLATION

(1) Reverse removal procedure to install oil feed

trough.

CLEANING AND INSPECTION

TRANSAXLE

Clean the gears, bearings, shafts, synchronizers,

thrust washers, oil feeder, shift mechanism, gear

case, and bellhousing with solvent. Dry all parts

except the bearings with compressed air. Allow the

bearings to either air dry or wipe them dry with

clean shop towels.

Inspect the gears, bearings, shafts and thrust wash-

ers. Replace the bearings and cups if the rollers are

worn, chipped, cracked, flat spotted, or brinnelled, or if

the bearing cage is damaged or distorted. Replace the

thrust washers if cracked, chipped, or worn. Replace

the gears if the teeth are chipped, cracked, or worn

thin. Inspect the synchronizers. Replace the sleeve if

worn or damaged in any way. Replace the stop rings if

the friction material is burned, flaking off, or worn.

Check the condition of the synchro keys and springs.

Replace these parts if worn, cracked, or distorted.

SYNCHRONIZER

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

Fig. 155 Crossover Shaft Bushing Removal

1 ± SLIDE HAMMER

2 ± SHIFTER SHAFT BUSHING

Fig. 156 Oil Feed Trough

1 ± OIL FEED TROUGH

21 - 48 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)