catalytic converter DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 191 of 1285

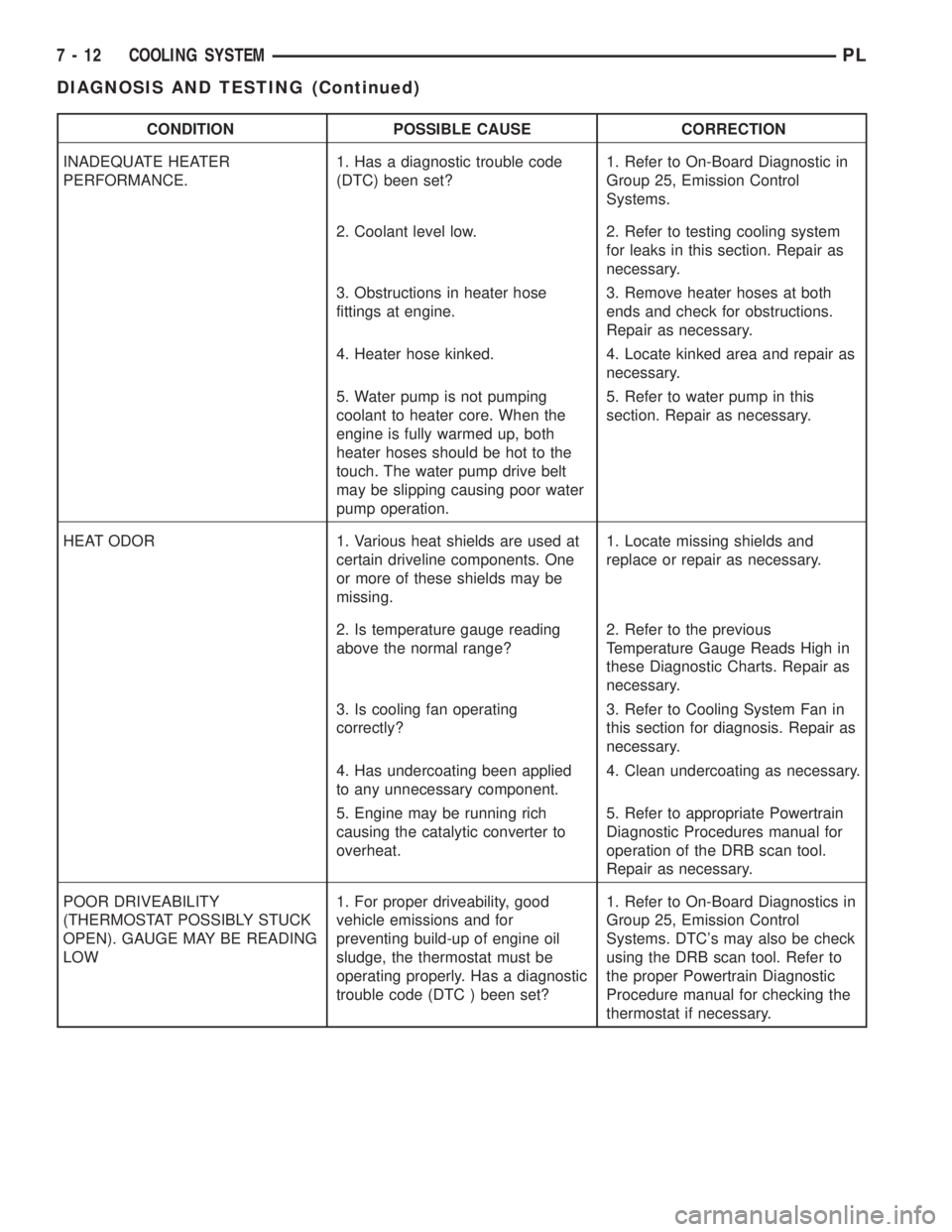

CONDITION POSSIBLE CAUSE CORRECTION

INADEQUATE HEATER

PERFORMANCE.1. Has a diagnostic trouble code

(DTC) been set?1. Refer to On-Board Diagnostic in

Group 25, Emission Control

Systems.

2. Coolant level low. 2. Refer to testing cooling system

for leaks in this section. Repair as

necessary.

3. Obstructions in heater hose

fittings at engine.3. Remove heater hoses at both

ends and check for obstructions.

Repair as necessary.

4. Heater hose kinked. 4. Locate kinked area and repair as

necessary.

5. Water pump is not pumping

coolant to heater core. When the

engine is fully warmed up, both

heater hoses should be hot to the

touch. The water pump drive belt

may be slipping causing poor water

pump operation.5. Refer to water pump in this

section. Repair as necessary.

HEAT ODOR 1. Various heat shields are used at

certain driveline components. One

or more of these shields may be

missing.1. Locate missing shields and

replace or repair as necessary.

2. Is temperature gauge reading

above the normal range?2. Refer to the previous

Temperature Gauge Reads High in

these Diagnostic Charts. Repair as

necessary.

3. Is cooling fan operating

correctly?3. Refer to Cooling System Fan in

this section for diagnosis. Repair as

necessary.

4. Has undercoating been applied

to any unnecessary component.4. Clean undercoating as necessary.

5. Engine may be running rich

causing the catalytic converter to

overheat.5. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

POOR DRIVEABILITY

(THERMOSTAT POSSIBLY STUCK

OPEN). GAUGE MAY BE READING

LOW1. For proper driveability, good

vehicle emissions and for

preventing build-up of engine oil

sludge, the thermostat must be

operating properly. Has a diagnostic

trouble code (DTC ) been set?1. Refer to On-Board Diagnostics in

Group 25, Emission Control

Systems. DTC's may also be check

using the DRB scan tool. Refer to

the proper Powertrain Diagnostic

Procedure manual for checking the

thermostat if necessary.

7 - 12 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 798 of 1285

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

EXHAUST SYSTEM........................1

EXHAUST FLEX-JOINT COUPLING............1

CATALYTIC CONVERTER....................1

EXHAUST HEAT SHIELDS..................3

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART.......4

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER..............4CATALYTIC CONVERTER....................7

CLEANING AND INSPECTION

EXHAUST SYSTEM........................8

ADJUSTMENTS

EXHAUST SYSTEM ALIGNMENT.............8

SPECIFICATIONS

TORQUE SPECIFICATION CHART.............8

DESCRIPTION AND OPERATION

EXHAUST SYSTEM

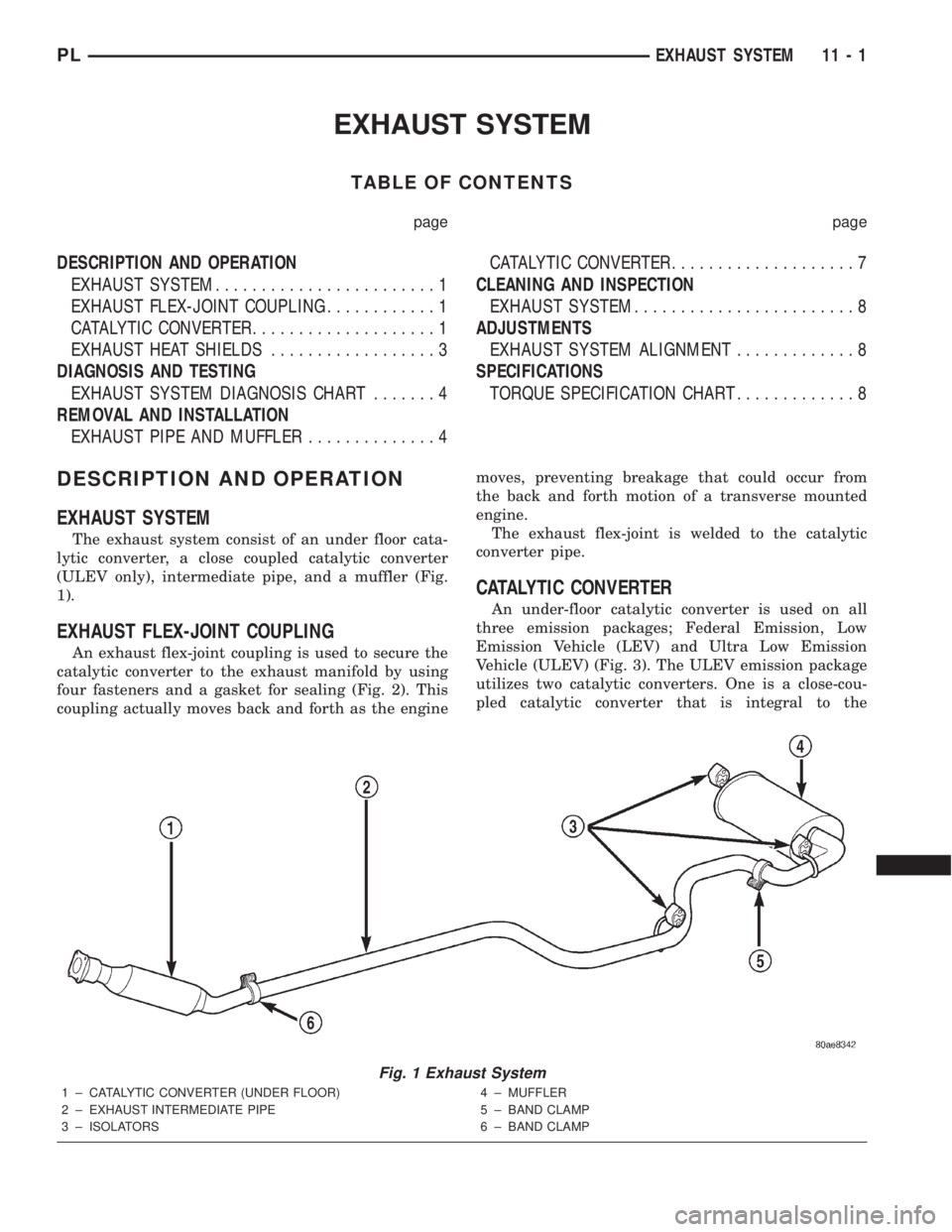

The exhaust system consist of an under floor cata-

lytic converter, a close coupled catalytic converter

(ULEV only), intermediate pipe, and a muffler (Fig.

1).

EXHAUST FLEX-JOINT COUPLING

An exhaust flex-joint coupling is used to secure the

catalytic converter to the exhaust manifold by using

four fasteners and a gasket for sealing (Fig. 2). This

coupling actually moves back and forth as the enginemoves, preventing breakage that could occur from

the back and forth motion of a transverse mounted

engine.

The exhaust flex-joint is welded to the catalytic

converter pipe.

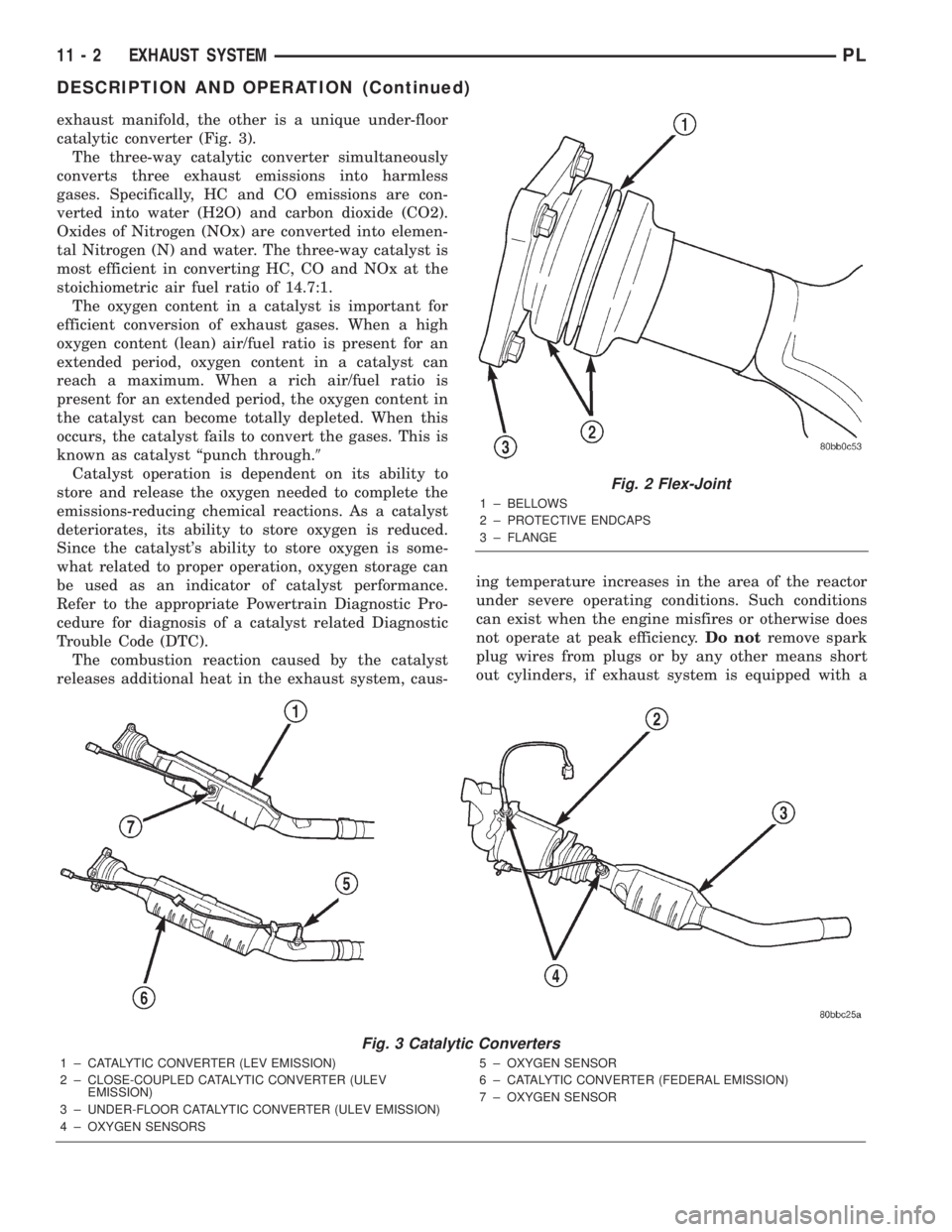

CATALYTIC CONVERTER

An under-floor catalytic converter is used on all

three emission packages; Federal Emission, Low

Emission Vehicle (LEV) and Ultra Low Emission

Vehicle (ULEV) (Fig. 3). The ULEV emission package

utilizes two catalytic converters. One is a close-cou-

pled catalytic converter that is integral to the

Fig. 1 Exhaust System

1 ± CATALYTIC CONVERTER (UNDER FLOOR)

2 ± EXHAUST INTERMEDIATE PIPE

3 ± ISOLATORS4 ± MUFFLER

5 ± BAND CLAMP

6 ± BAND CLAMP

PLEXHAUST SYSTEM 11 - 1

Page 799 of 1285

exhaust manifold, the other is a unique under-floor

catalytic converter (Fig. 3).

The three-way catalytic converter simultaneously

converts three exhaust emissions into harmless

gases. Specifically, HC and CO emissions are con-

verted into water (H2O) and carbon dioxide (CO2).

Oxides of Nitrogen (NOx) are converted into elemen-

tal Nitrogen (N) and water. The three-way catalyst is

most efficient in converting HC, CO and NOx at the

stoichiometric air fuel ratio of 14.7:1.

The oxygen content in a catalyst is important for

efficient conversion of exhaust gases. When a high

oxygen content (lean) air/fuel ratio is present for an

extended period, oxygen content in a catalyst can

reach a maximum. When a rich air/fuel ratio is

present for an extended period, the oxygen content in

the catalyst can become totally depleted. When this

occurs, the catalyst fails to convert the gases. This is

known as catalyst ªpunch through.9

Catalyst operation is dependent on its ability to

store and release the oxygen needed to complete the

emissions-reducing chemical reactions. As a catalyst

deteriorates, its ability to store oxygen is reduced.

Since the catalyst's ability to store oxygen is some-

what related to proper operation, oxygen storage can

be used as an indicator of catalyst performance.

Refer to the appropriate Powertrain Diagnostic Pro-

cedure for diagnosis of a catalyst related Diagnostic

Trouble Code (DTC).

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system, caus-ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders, if exhaust system is equipped with a

Fig. 2 Flex-Joint

1 ± BELLOWS

2 ± PROTECTIVE ENDCAPS

3 ± FLANGE

Fig. 3 Catalytic Converters

1 ± CATALYTIC CONVERTER (LEV EMISSION)

2 ± CLOSE-COUPLED CATALYTIC CONVERTER (ULEV

EMISSION)

3 ± UNDER-FLOOR CATALYTIC CONVERTER (ULEV EMISSION)

4 ± OXYGEN SENSORS5 ± OXYGEN SENSOR

6 ± CATALYTIC CONVERTER (FEDERAL EMISSION)

7 ± OXYGEN SENSOR

11 - 2 EXHAUST SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 800 of 1285

catalytic converter. Failure of the catalytic converter

can occur due to temperature increases caused by

unburned fuel passing through the converter. This

deterioration of the catalyst core can result in exces-

sively high emission levels, noise complaints, and

exhaust restrictions.

The use of catalysts also involves some non-auto-

motive problems. Unleaded gasoline must be used to

avoid poisoning the catalyst core. Do not allow engine

to operate above 1200 RPM in neutral for extended

periods over 5 minutes. This condition may result in

excessive exhaust system/floor pan temperatures

because of no air movement under the vehicle.

There is no regularly scheduled maintenance on

any DaimlerChrysler catalytic converter. If damaged,

the converter must be replaced.

CAUTION: Due to exterior physical similarities of

some catalytic converters with pipe assemblies,

extreme care should be taken with replacement

parts.

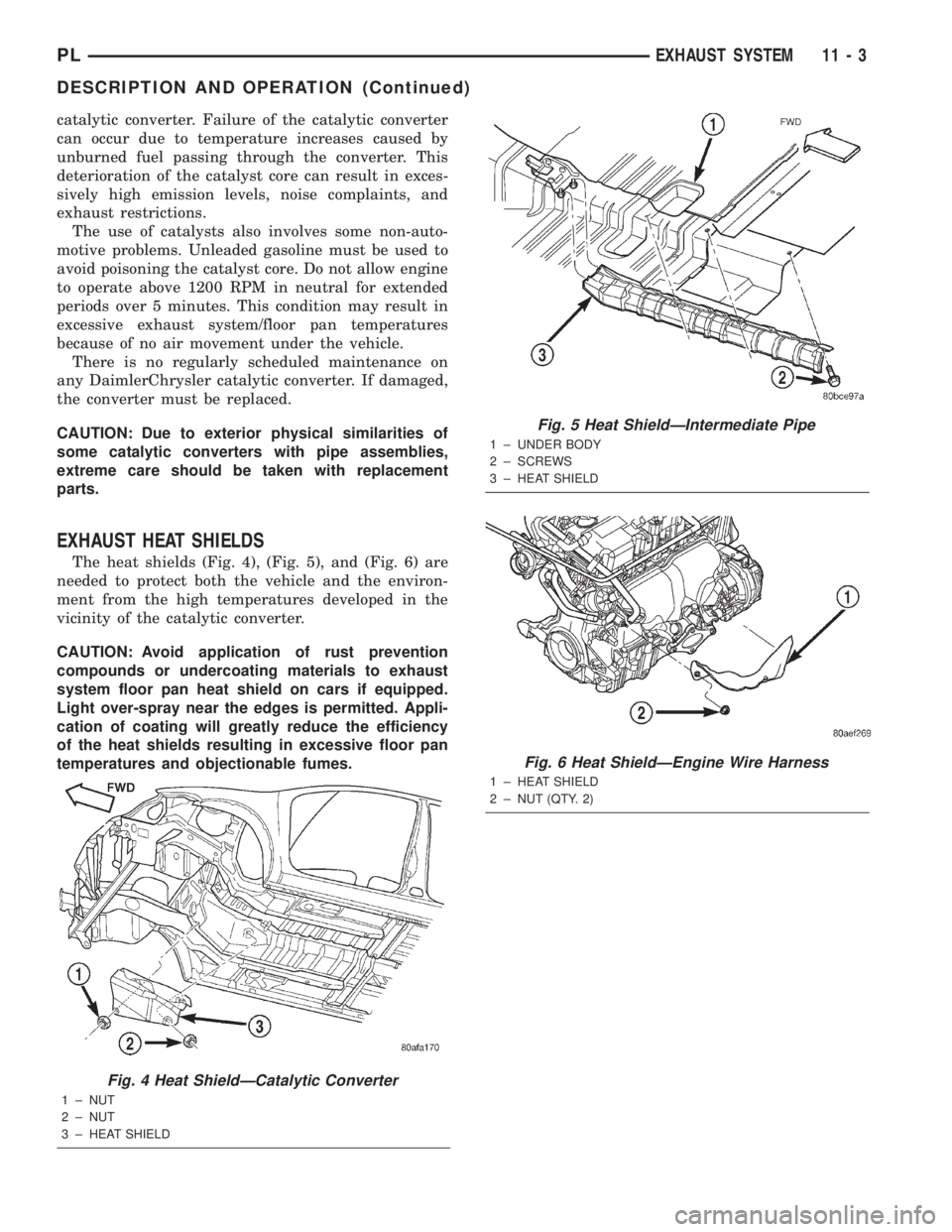

EXHAUST HEAT SHIELDS

The heat shields (Fig. 4), (Fig. 5), and (Fig. 6) are

needed to protect both the vehicle and the environ-

ment from the high temperatures developed in the

vicinity of the catalytic converter.

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan heat shield on cars if equipped.

Light over-spray near the edges is permitted. Appli-

cation of coating will greatly reduce the efficiency

of the heat shields resulting in excessive floor pan

temperatures and objectionable fumes.

Fig. 4 Heat ShieldÐCatalytic Converter

1 ± NUT

2 ± NUT

3 ± HEAT SHIELD

Fig. 5 Heat ShieldÐIntermediate Pipe

1 ± UNDER BODY

2 ± SCREWS

3 ± HEAT SHIELD

Fig. 6 Heat ShieldÐEngine Wire Harness

1 ± HEAT SHIELD

2 ± NUT (QTY. 2)

PLEXHAUST SYSTEM 11 - 3

DESCRIPTION AND OPERATION (Continued)

Page 801 of 1285

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE

EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. Exhaust Flex joint to manifold leak. 3. Tighten fasteners or replace gasket.

4. Exhaust flex joint. 4. Replace catalytic converter assembly.

5. Pipe and shell noise from front exhaust

pipe.5. Characteristic of single wall pipes.

EXCESSIVE

EXHAUST NOISE1. Leaks at pipe joints. 1. Tighten or replace clamps at leaking

joints.

2. Burned, blown, or rusted out exhaust

pipe or muffler.2. Replace muffler or exhaust pipes.

3. Restriction in muffler or tailpipe. 3. Remove restriction, if possible or replace

as necessary.

4. Catalytic converter material in muffler. 4. Replace muffler and converter assembly.

Check fuel injection and ignition systems for

proper operation.

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATING TIME.

(1) Raise vehicle on hoist and apply penetrating oil

to band clamp fastener of component being removed.

NOTE: Do not use petroleum-based lubricants

when removing/installing muffler or exhaust pipe

isolators as it may compromise the life of the part.

A suitable substitute is a mixture of liquid dish

soap and water.

(2) Remove exhaust system ground strap.

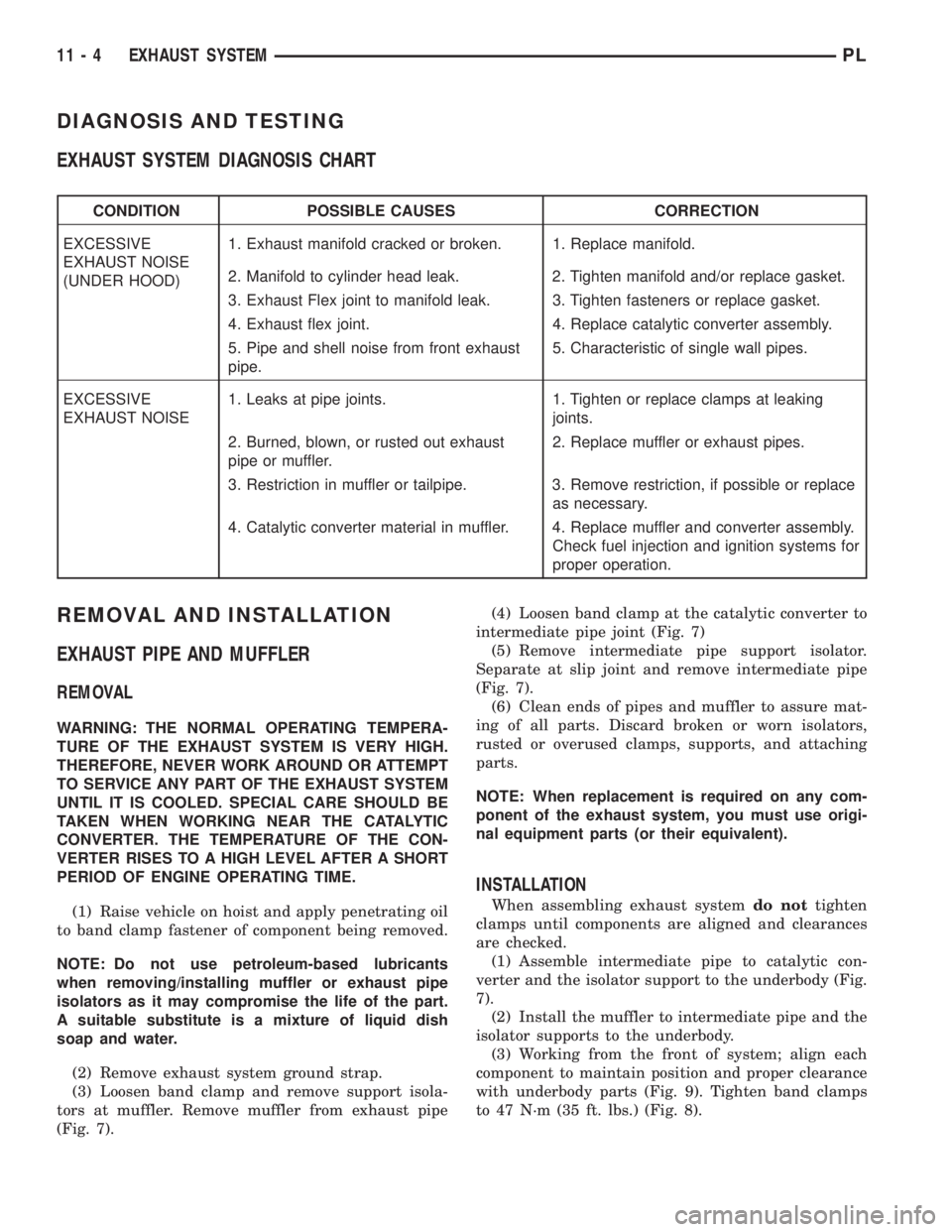

(3) Loosen band clamp and remove support isola-

tors at muffler. Remove muffler from exhaust pipe

(Fig. 7).(4) Loosen band clamp at the catalytic converter to

intermediate pipe joint (Fig. 7)

(5) Remove intermediate pipe support isolator.

Separate at slip joint and remove intermediate pipe

(Fig. 7).

(6) Clean ends of pipes and muffler to assure mat-

ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble intermediate pipe to catalytic con-

verter and the isolator support to the underbody (Fig.

7).

(2) Install the muffler to intermediate pipe and the

isolator supports to the underbody.

(3) Working from the front of system; align each

component to maintain position and proper clearance

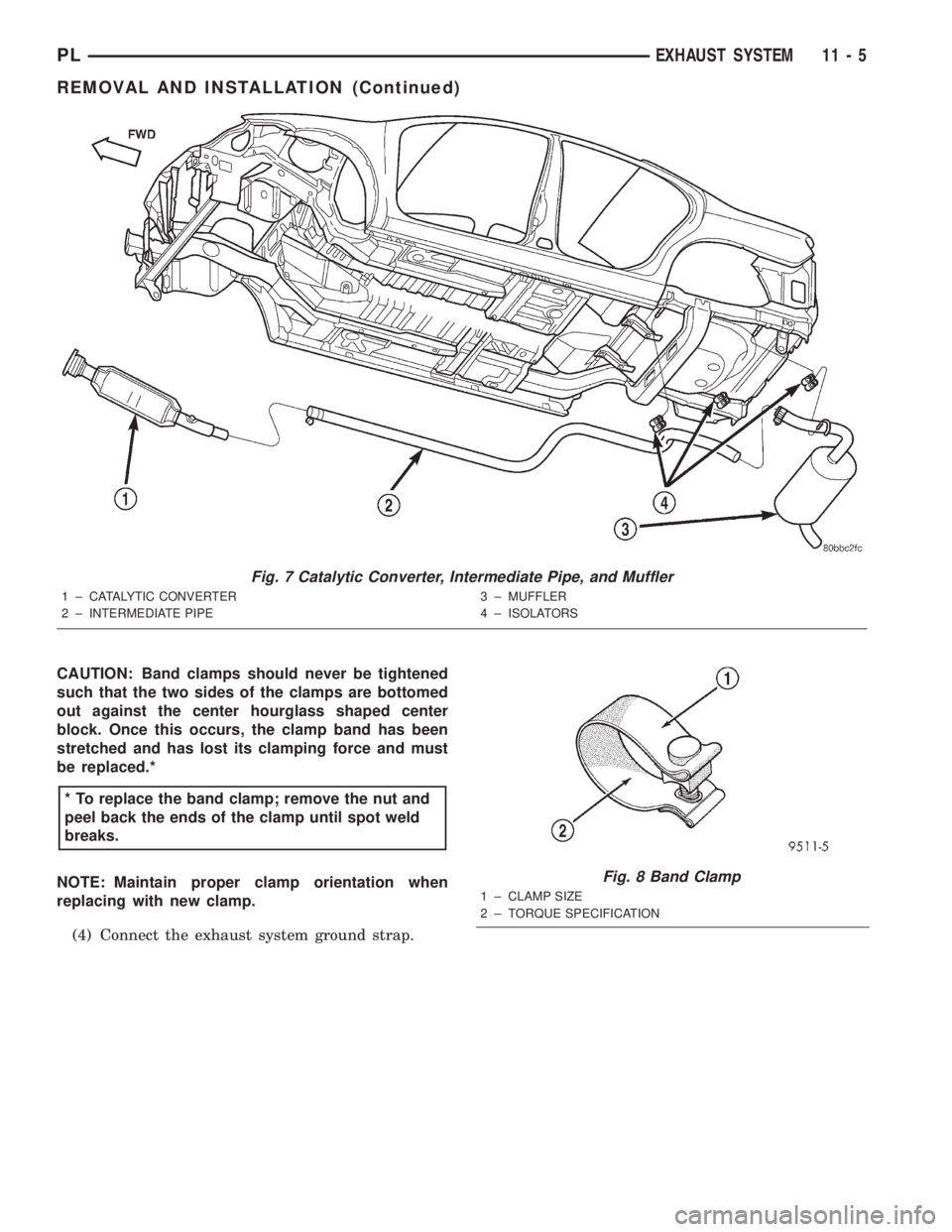

with underbody parts (Fig. 9). Tighten band clamps

to 47 N´m (35 ft. lbs.) (Fig. 8).

11 - 4 EXHAUST SYSTEMPL

Page 802 of 1285

CAUTION: Band clamps should never be tightened

such that the two sides of the clamps are bottomed

out against the center hourglass shaped center

block. Once this occurs, the clamp band has been

stretched and has lost its clamping force and must

be replaced.*

NOTE: Maintain proper clamp orientation when

replacing with new clamp.

(4) Connect the exhaust system ground strap.

Fig. 7 Catalytic Converter, Intermediate Pipe, and Muffler

1 ± CATALYTIC CONVERTER

2 ± INTERMEDIATE PIPE3 ± MUFFLER

4 ± ISOLATORS

* To replace the band clamp; remove the nut and

peel back the ends of the clamp until spot weld

breaks.

Fig. 8 Band Clamp

1 ± CLAMP SIZE

2 ± TORQUE SPECIFICATION

PLEXHAUST SYSTEM 11 - 5

REMOVAL AND INSTALLATION (Continued)

Page 804 of 1285

CATALYTIC CONVERTER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER ATTEMPT TO SERVICE ANY

PART OF THE EXHAUST SYSTEM UNTIL IT IS

COOLED. SPECIAL CARE SHOULD BE TAKEN

WHEN WORKING NEAR THE CATALYTIC CON-

VERTER. THE TEMPERATURE OF THE CONVERTER

RISES TO A HIGH LEVEL AFTER A SHORT PERIOD

OF ENGINE OPERATION TIME.

NOTE: Vehicles equipped with the ULEV emission

package are equipped with an additional catalytic

converter that is integral to the exhaust manifold.

Refer to Exhaust Manifold in Group 9, Engine for

procedure.

(1) Remove muffler and exhaust pipe. Refer to pro-

cedure in this section.

(2) Disconnect downstream oxygen sensor electri-

cal connector.

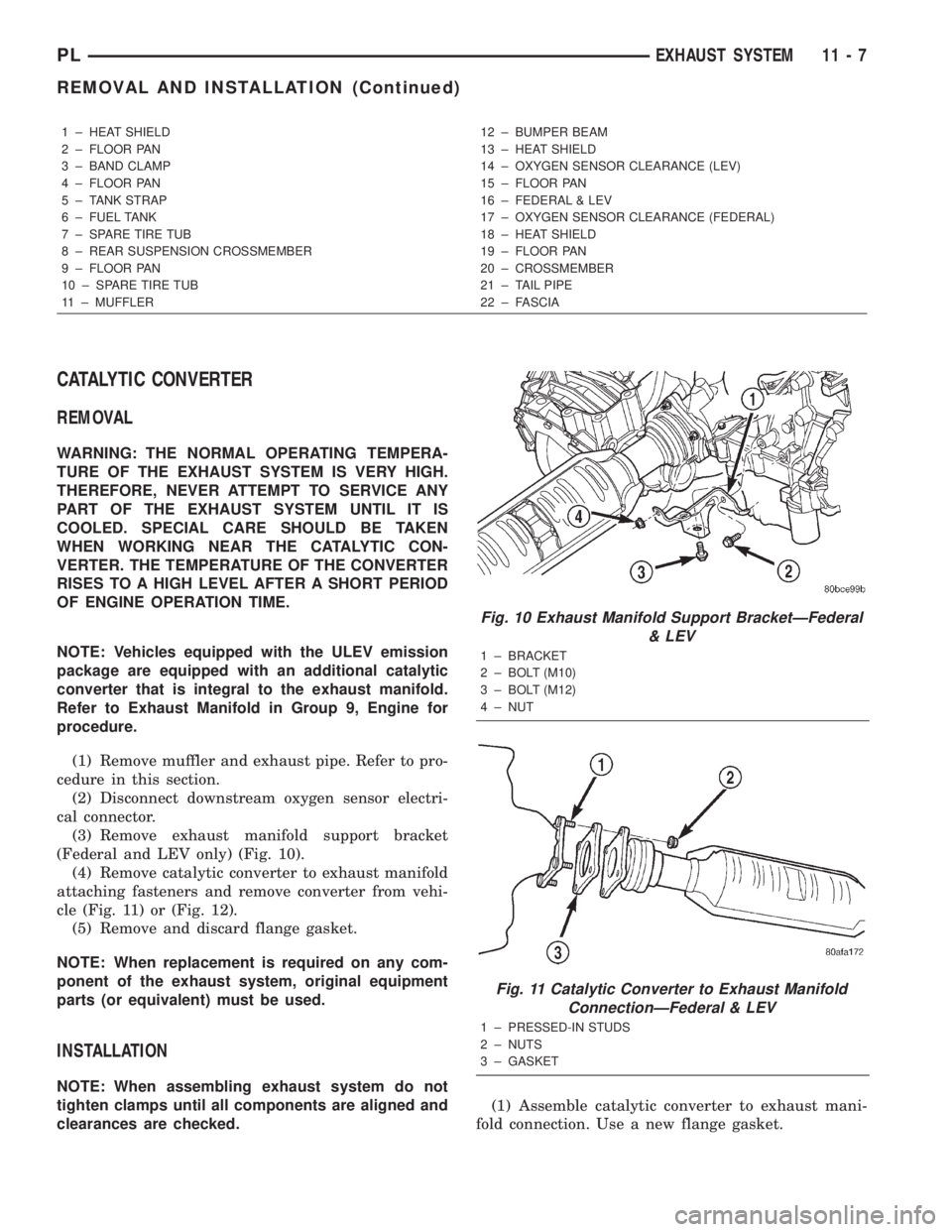

(3) Remove exhaust manifold support bracket

(Federal and LEV only) (Fig. 10).

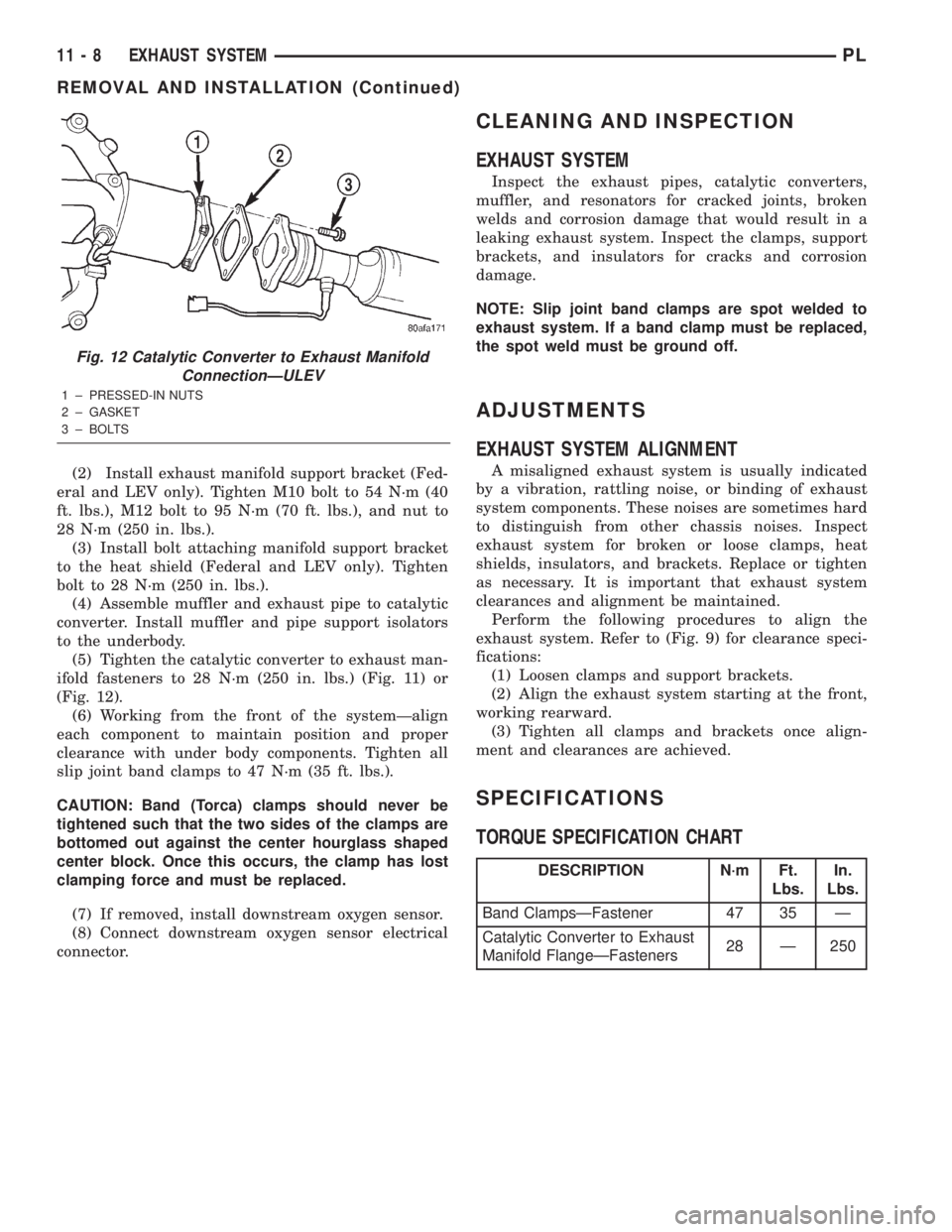

(4) Remove catalytic converter to exhaust manifold

attaching fasteners and remove converter from vehi-

cle (Fig. 11) or (Fig. 12).

(5) Remove and discard flange gasket.

NOTE: When replacement is required on any com-

ponent of the exhaust system, original equipment

parts (or equivalent) must be used.

INSTALLATION

NOTE: When assembling exhaust system do not

tighten clamps until all components are aligned and

clearances are checked.(1) Assemble catalytic converter to exhaust mani-

fold connection. Use a new flange gasket.

1 ± HEAT SHIELD

2 ± FLOOR PAN

3 ± BAND CLAMP

4 ± FLOOR PAN

5 ± TANK STRAP

6 ± FUEL TANK

7 ± SPARE TIRE TUB

8 ± REAR SUSPENSION CROSSMEMBER

9 ± FLOOR PAN

10 ± SPARE TIRE TUB

11 ± MUFFLER12 ± BUMPER BEAM

13 ± HEAT SHIELD

14 ± OXYGEN SENSOR CLEARANCE (LEV)

15 ± FLOOR PAN

16 ± FEDERAL & LEV

17 ± OXYGEN SENSOR CLEARANCE (FEDERAL)

18 ± HEAT SHIELD

19 ± FLOOR PAN

20 ± CROSSMEMBER

21 ± TAIL PIPE

22 ± FASCIA

Fig. 10 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

Fig. 11 Catalytic Converter to Exhaust Manifold

ConnectionÐFederal & LEV

1 ± PRESSED-IN STUDS

2 ± NUTS

3 ± GASKET

PLEXHAUST SYSTEM 11 - 7

REMOVAL AND INSTALLATION (Continued)

Page 805 of 1285

(2) Install exhaust manifold support bracket (Fed-

eral and LEV only). Tighten M10 bolt to 54 N´m (40

ft. lbs.), M12 bolt to 95 N´m (70 ft. lbs.), and nut to

28 N´m (250 in. lbs.).

(3) Install bolt attaching manifold support bracket

to the heat shield (Federal and LEV only). Tighten

bolt to 28 N´m (250 in. lbs.).

(4) Assemble muffler and exhaust pipe to catalytic

converter. Install muffler and pipe support isolators

to the underbody.

(5) Tighten the catalytic converter to exhaust man-

ifold fasteners to 28 N´m (250 in. lbs.) (Fig. 11) or

(Fig. 12).

(6) Working from the front of the systemÐalign

each component to maintain position and proper

clearance with under body components. Tighten all

slip joint band clamps to 47 N´m (35 ft. lbs.).

CAUTION: Band (Torca) clamps should never be

tightened such that the two sides of the clamps are

bottomed out against the center hourglass shaped

center block. Once this occurs, the clamp has lost

clamping force and must be replaced.

(7) If removed, install downstream oxygen sensor.

(8) Connect downstream oxygen sensor electrical

connector.

CLEANING AND INSPECTION

EXHAUST SYSTEM

Inspect the exhaust pipes, catalytic converters,

muffler, and resonators for cracked joints, broken

welds and corrosion damage that would result in a

leaking exhaust system. Inspect the clamps, support

brackets, and insulators for cracks and corrosion

damage.

NOTE: Slip joint band clamps are spot welded to

exhaust system. If a band clamp must be replaced,

the spot weld must be ground off.

ADJUSTMENTS

EXHAUST SYSTEM ALIGNMENT

A misaligned exhaust system is usually indicated

by a vibration, rattling noise, or binding of exhaust

system components. These noises are sometimes hard

to distinguish from other chassis noises. Inspect

exhaust system for broken or loose clamps, heat

shields, insulators, and brackets. Replace or tighten

as necessary. It is important that exhaust system

clearances and alignment be maintained.

Perform the following procedures to align the

exhaust system. Refer to (Fig. 9) for clearance speci-

fications:

(1) Loosen clamps and support brackets.

(2) Align the exhaust system starting at the front,

working rearward.

(3) Tighten all clamps and brackets once align-

ment and clearances are achieved.

SPECIFICATIONS

TORQUE SPECIFICATION CHART

Fig. 12 Catalytic Converter to Exhaust Manifold

ConnectionÐULEV

1 ± PRESSED-IN NUTS

2 ± GASKET

3 ± BOLTS

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Band ClampsÐFastener 47 35 Ð

Catalytic Converter to Exhaust

Manifold FlangeÐFasteners28 Ð 250

11 - 8 EXHAUST SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 823 of 1285

REFORMULATED GASOLINE

Many areas of the country require the use of

cleaner burning gasoline referred to as ªreformulat-

edº gasoline. Reformulated gasoline contain oxygen-

ates, and are specifically blended to reduce vehicle

emissions and improve air quality.

DaimlerChrysler Corporation strongly supports the

use of reformulated gasoline. Properly blended refor-

mulated gasoline will provide excellent performance

and durability for the engine and fuel system compo-

nents.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

oxygenates such as 10% ethanol, MTBE, and ETBE.

Oxygenates are required in some areas of the country

during the winter months to reduce carbon monoxide

emissions. Fuels blended with these oxygenates may

be used in your vehicle.

CAUTION: DO NOT use gasoline containing METH-

ANOL. Gasoline containing methanol may damage

critical fuel system components.

MMT

MMT is a manganese-containing metallic additive

that is blended into some gasoline to increase octane.

Gasoline blended with MMT provide no performance

advantage beyond gasoline of the same octane num-

ber without MMT. Gasoline blended with MMT

reduce spark plug life and reduce emission system

performance in some vehicles. DaimlerChrysler rec-

ommends that gasoline without MMT be used in your

vehicle. The MMT content of gasoline may not be

indicated on the gasoline pump; therefore, you should

ask your gasoline retailer whether or not his/her gas-

oline contains MMT.

It is even more important to look for gasoline with-

out MMT in Canada because MMT can be used at

levels higher than allowed in the United States.

MMT is prohibited in Federal and California refor-

mulated gasoline.

SULFUR IN GASOLINE

If you live in the northeast United States, your

vehicle may have been designed to meet California

low emission standards with clean-burning, low-sul-

fur, California gasoline. Gasoline sold outside of Cal-

ifornia is permitted to have higher sulfur levels

which may affect the performance of the vehicle's cat-

alytic converter. This may cause the Check Engine or

Service Engine Soon light to illuminate.

Illumination of either light while operating on high

sulfur gasoline does not necessarily mean your emis-

sion control system is malfunctioning. DaimlerChrysler

recommends that you try a different brand of unleadedgasoline having lower sulfur to determine if the prob-

lem is fuel related prior to returning your vehicle to an

authorized dealer for service.

CAUTION: If the Check Engine or Service Engine

Soon light is flashing, immediate service is

required; see on-board diagnostics system section.

MATERIALS ADDED TO FUEL

All gasoline sold in the United States and Canada

are required to contain effective detergent additives.

Use of additional detergents or other additives is not

needed under normal conditions.

FUEL SYSTEM CAUTIONS

CAUTION: Follow these guidelines to maintain your

vehicle's performance:

²The use of leaded gas is prohibited by Federal

law. Using leaded gasoline can impair engine perfor-

mance, damage the emission control system, and

could result in loss of warranty coverage.

²An out-of-tune engine, or certain fuel or ignition

malfunctions, can cause the catalytic converter to

overheat. If you notice a pungent burning odor or

some light smoke, your engine may be out of tune or

malfunctioning and may require immediate service.

Contact your dealer for service assistance.

²When pulling a heavy load or driving a fully

loaded vehicle when the humidity is low and the tem-

perature is high, use a premium unleaded fuel to

help prevent spark knock. If spark knock persists,

lighten the load, or engine piston damage may result.

²The use of fuel additives which are now being

sold as octane enhancers is not recommended. Most

of these products contain high concentrations of

methanol. Fuel system damage or vehicle perfor-

mance problems resulting from the use of such fuels

or additives is not the responsibility of

DaimlerChrysler Corporation and may not be covered

under the new vehicle warranty.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

GASOLINE/OXYGENATE BLENDS

OPERATION

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

14 - 2 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 854 of 1285

grammed (fixed) values and inputs from other sen-

sors.

DOWNSTREAM OXYGEN SENSOR 1/2

The Downstream O2 Sensor has two functions.

One function is measuring catalyst efficiency. This is

an OBD II requirement. The oxygen content of theexhaust gasses has significantly less fluctuation than

at the inlet if the converter is working properly. The

PCM compares upstream and Downstream O2 Sen-

sor switch rates under specific operating conditions

to determine if the catalyst is functioning properly.

The other function is a downstream fuel control

which was introduced in 1996. The upstream O2 goal

varies within the window of operation of the O2 Sen-

sor. In the past the goal was a preprogrammed fixed

value based upon where it believed the catalyst oper-

ated most efficiently.

While the Upstream O2 Sensor input is used to

maintain the 14.7:1 air/fuel ratio, variations in

engines, exhaust systems and catalytic converters

may cause this ratio to not be the most ideal for a

particular catalyst and engine. To help maintain the

catalyst operating at maximum efficiency, the PCM

will fine tune the air/fuel ratio entering the catalyst

based upon the oxygen content leaving the catalyst.

This is accomplished by modifying the Upstream O2

Sensor voltage goal.

If the exhaust leaving the catalyst has too much

oxygen (lean ) the PCM increases the upstream O2

goal which increases fuel in the mixture causing less

oxygen to be left over. Conversely, if the oxygen con-

tent leaving the catalyst has is too little oxygen (rich)

the PCM decreases the upstream O2 goal down

which removes fuel from the mixture causing more

oxygen to be left over. This function only occurs dur-

ing downstream closed loop mode operation.

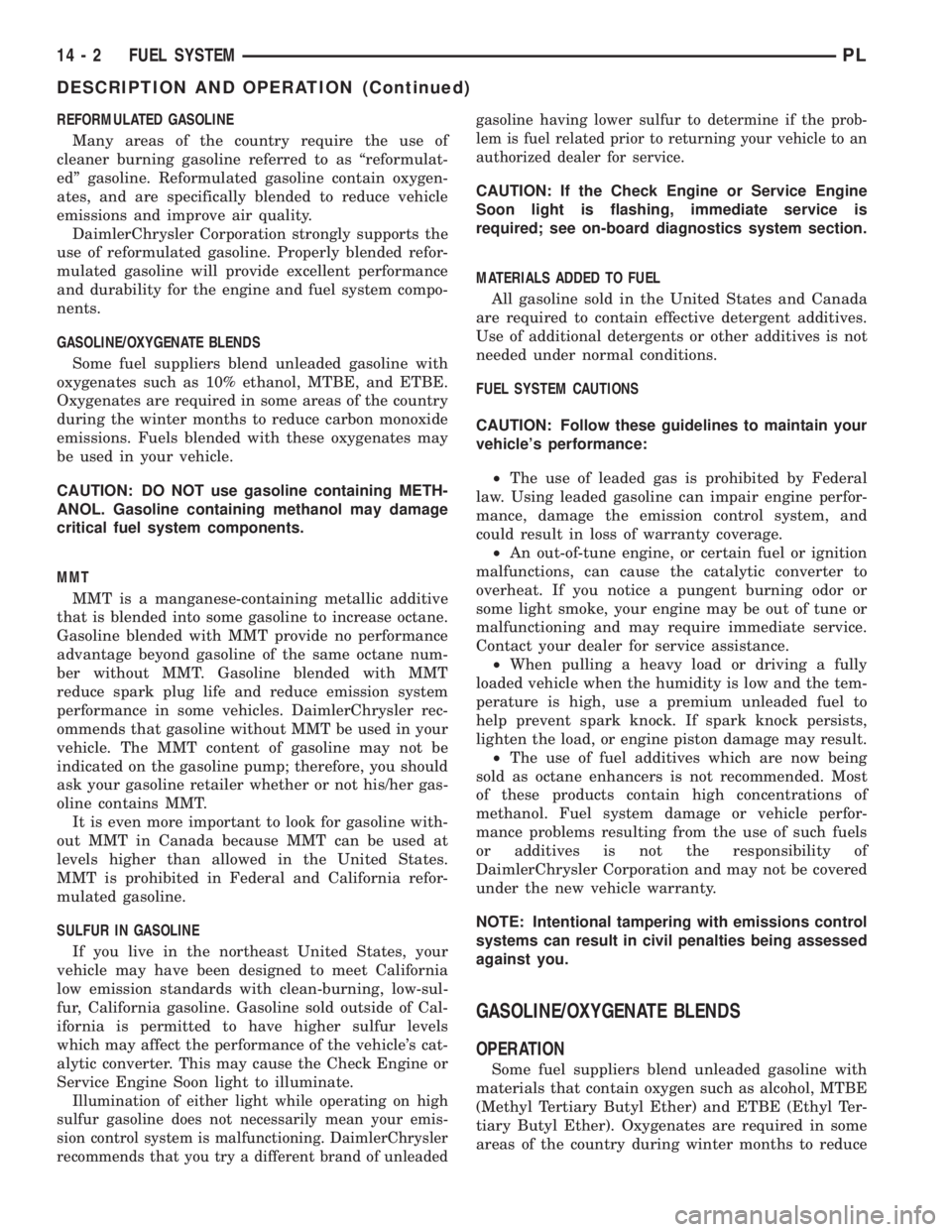

Fig. 13 Heated Oxygen Sensor Systems

1 ± CATALYTIC CONVERTER (LEV EMISSION)

2 ± CLOSE-COUPLED CATALYTIC CONVERTER

(ULEV EMISSION)

3 ± UNDER-FLOOR CATALYTIC CONVERTER

(ULEV EMISSION)

4 ± OXYGEN SENSORS5 ± OXYGEN SENSOR

6 ± CATALYTIC CONVERTER

(FEDERAL EMISSION)

7 ± OXYGEN SENSOR

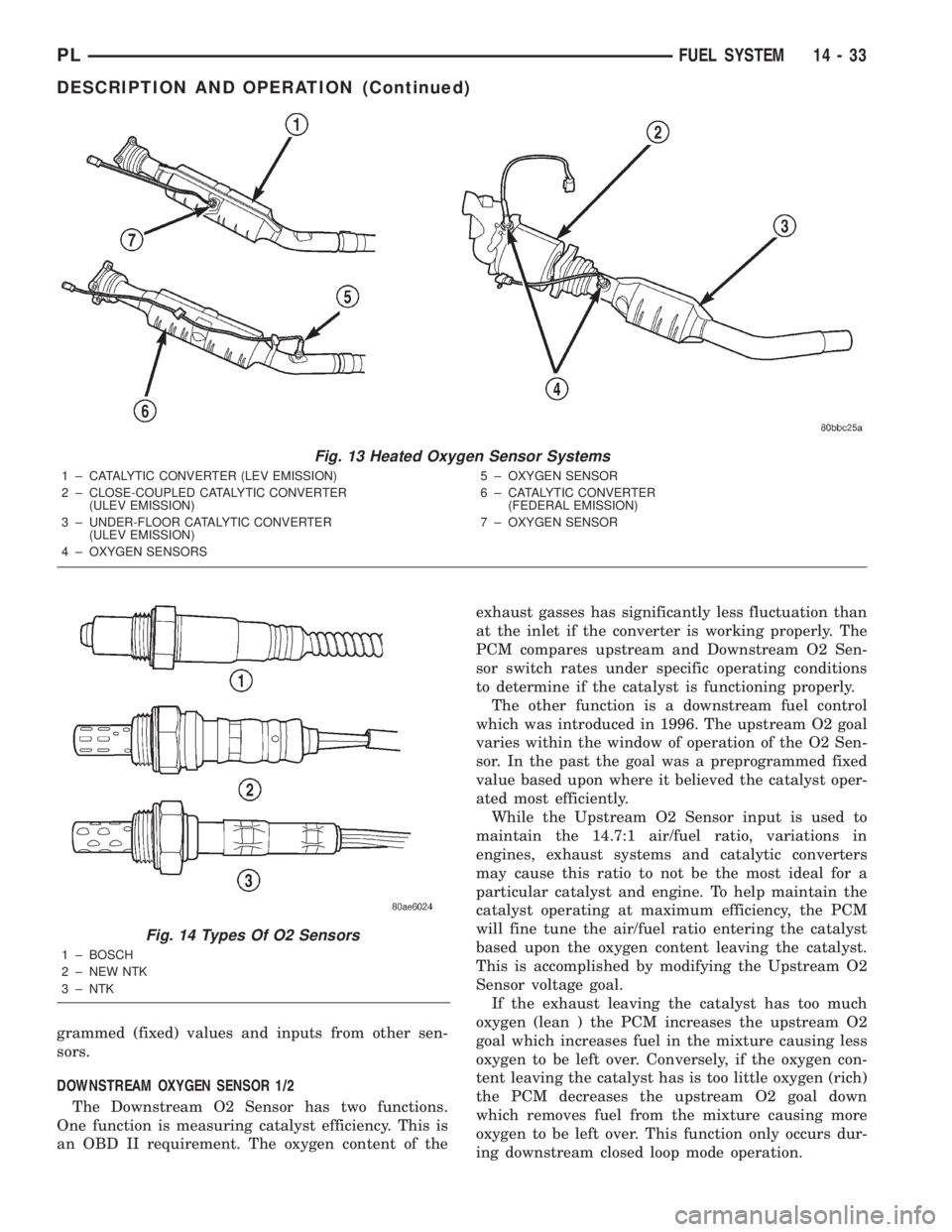

Fig. 14 Types Of O2 Sensors

1 ± BOSCH

2 ± NEW NTK

3 ± NTK

PLFUEL SYSTEM 14 - 33

DESCRIPTION AND OPERATION (Continued)