Fig DODGE RAM 1500 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 128 of 2627

(12) Remove spreader from housing.

DISASSEMBLY

(1) Remove ring gear.

(2) Remove roll-pin holding mate shaft in housing.

(3) Remove pinion gear mate shaft.

(4) Rotate differential side gears (2) and remove

pinion gears (3) and thrust washers (1) (Fig. 40).

(5) Remove differential side gears and thrust

washers.

ASSEMBLY

NOTE: If the same gears and thrust washers are

being used, install them into their original locations.

(1) Lubricate differential components with hypoid

gear lubricant.

(2) Install side gears and thrust washers into the

differentail case.

(3) Rotate pinion mate gears and thrust washers

into the differentail case.

(4) Install pinion gear mate shaft.

(5) Align hole in pinion gear mate shaft with hole

in the differential case.

(6) Install roll-pin (3) in the differential case with

a punch (1) and hammer (Fig. 41). Peen edge of roll-

pin hole in differential case in two places 180É apart.

(7) Install ring gear.

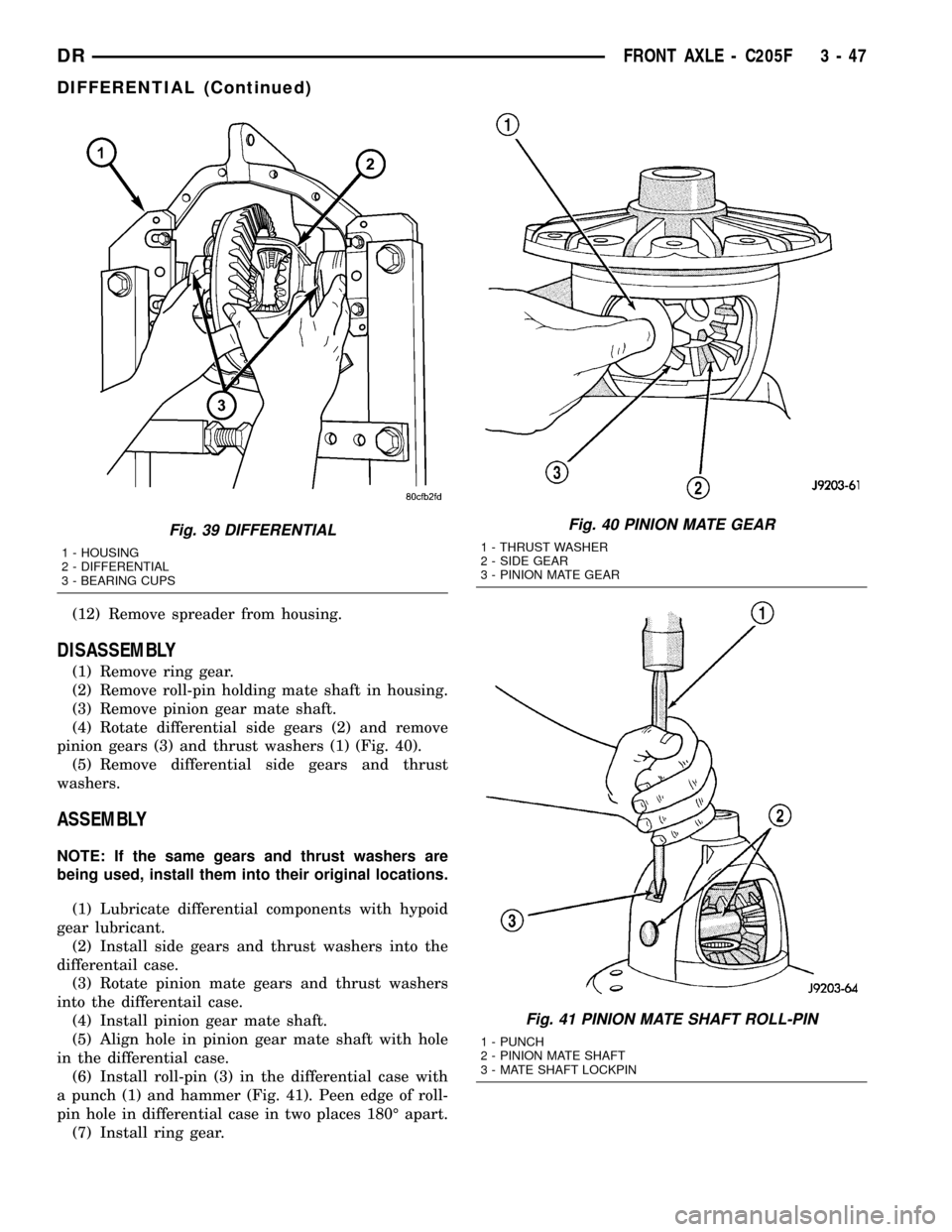

Fig. 39 DIFFERENTIAL

1 - HOUSING

2 - DIFFERENTIAL

3 - BEARING CUPS

Fig. 40 PINION MATE GEAR

1 - THRUST WASHER

2 - SIDE GEAR

3 - PINION MATE GEAR

Fig. 41 PINION MATE SHAFT ROLL-PIN

1 - PUNCH

2 - PINION MATE SHAFT

3 - MATE SHAFT LOCKPIN

DRFRONT AXLE - C205F 3 - 47

DIFFERENTIAL (Continued)

Page 129 of 2627

INSTALLATION

NOTE: If replacement differential bearings or differ-

ential case are replaced, Refer to adjustments for

Differential Bearing Preload and Gear Backlash pro-

cedures.

(1) Install Spreader W-129-B with the Adapter

Plates 8142-A and install the safety holddown

clamps. Tighten the tool turnbuckle finger-tight.

(2) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load indicator plunger against the

opposite side of the housing and zero the indicator.

(3) Spread housing and measure the distance with

the dial indicator.

CAUTION: Never spread housing over 0.50 mm

(0.020 in). Failure to heed caution may result in

damage.

(4) Remove dial indicator.

(5) Install differential case in the housing. Ensure

differential bearing cups remain in position on the

bearings and the differential preload shims are

seated in the housing. Tap differential case to ensure

bearings cups are seated in the housing.

(6) Install bearing caps to their original locations

and loosely install cap bolts.

(7) Remove housing spreader.

(8) Tighten the bearing cap bolts to 61 N´m (45 ft.

lbs.).

(9) Install axle shafts.

(10) Apply a bead of orange Mopar Axle RTV seal-

ant or equivalent to the housing cover.

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied. Failure to heed caution may result in dam-

age.

(11) Install cover and tighten bolts in a criss-cross

pattern to 22 N´m (15 ft. lbs.).

(12) Fill differential with lubricant.

DIFFERENTIAL CASE

BEARINGS

REMOVAL

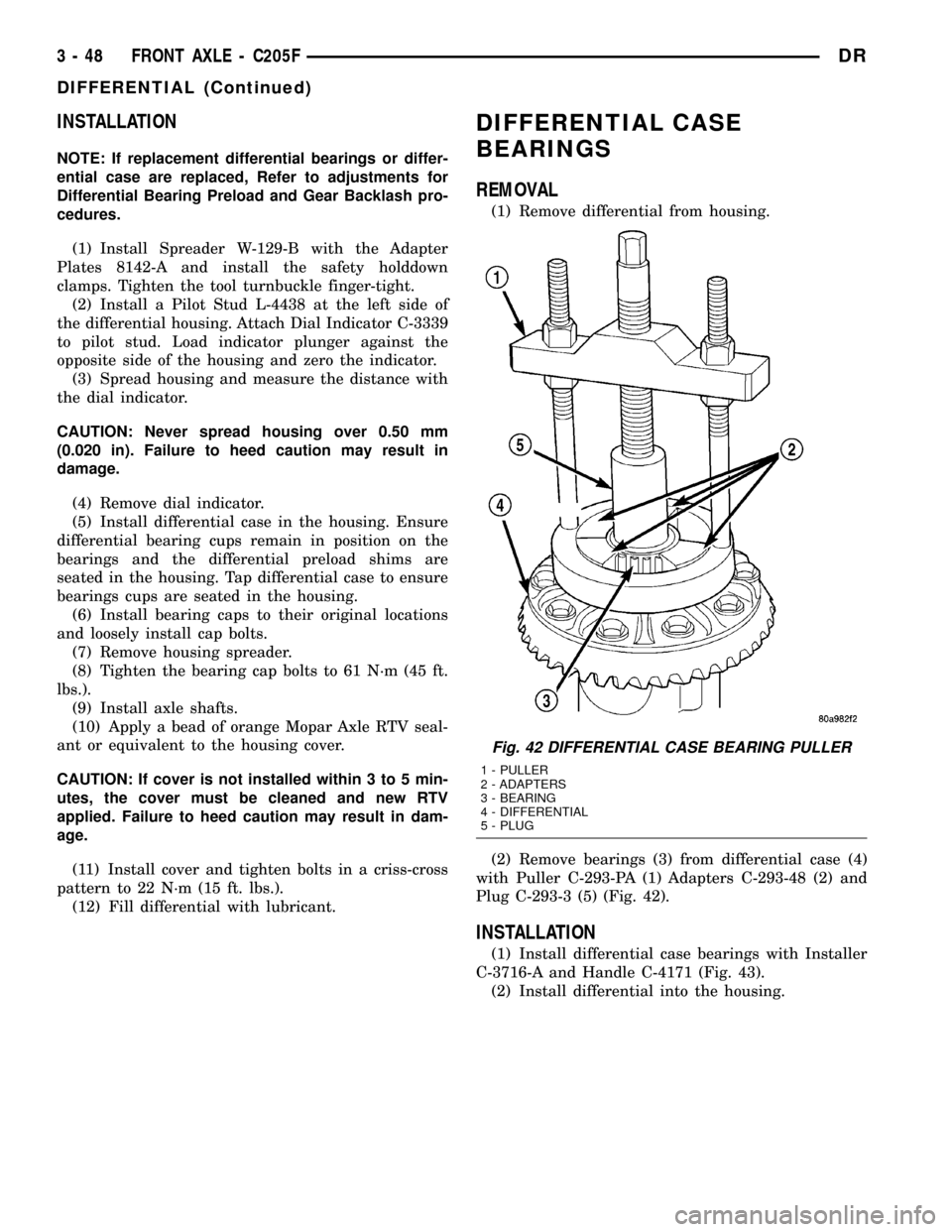

(1) Remove differential from housing.

(2) Remove bearings (3) from differential case (4)

with Puller C-293-PA (1) Adapters C-293-48 (2) and

Plug C-293-3 (5) (Fig. 42).

INSTALLATION

(1) Install differential case bearings with Installer

C-3716-A and Handle C-4171 (Fig. 43).

(2) Install differential into the housing.

Fig. 42 DIFFERENTIAL CASE BEARING PULLER

1 - PULLER

2 - ADAPTERS

3 - BEARING

4 - DIFFERENTIAL

5 - PLUG

3 - 48 FRONT AXLE - C205FDR

DIFFERENTIAL (Continued)

Page 130 of 2627

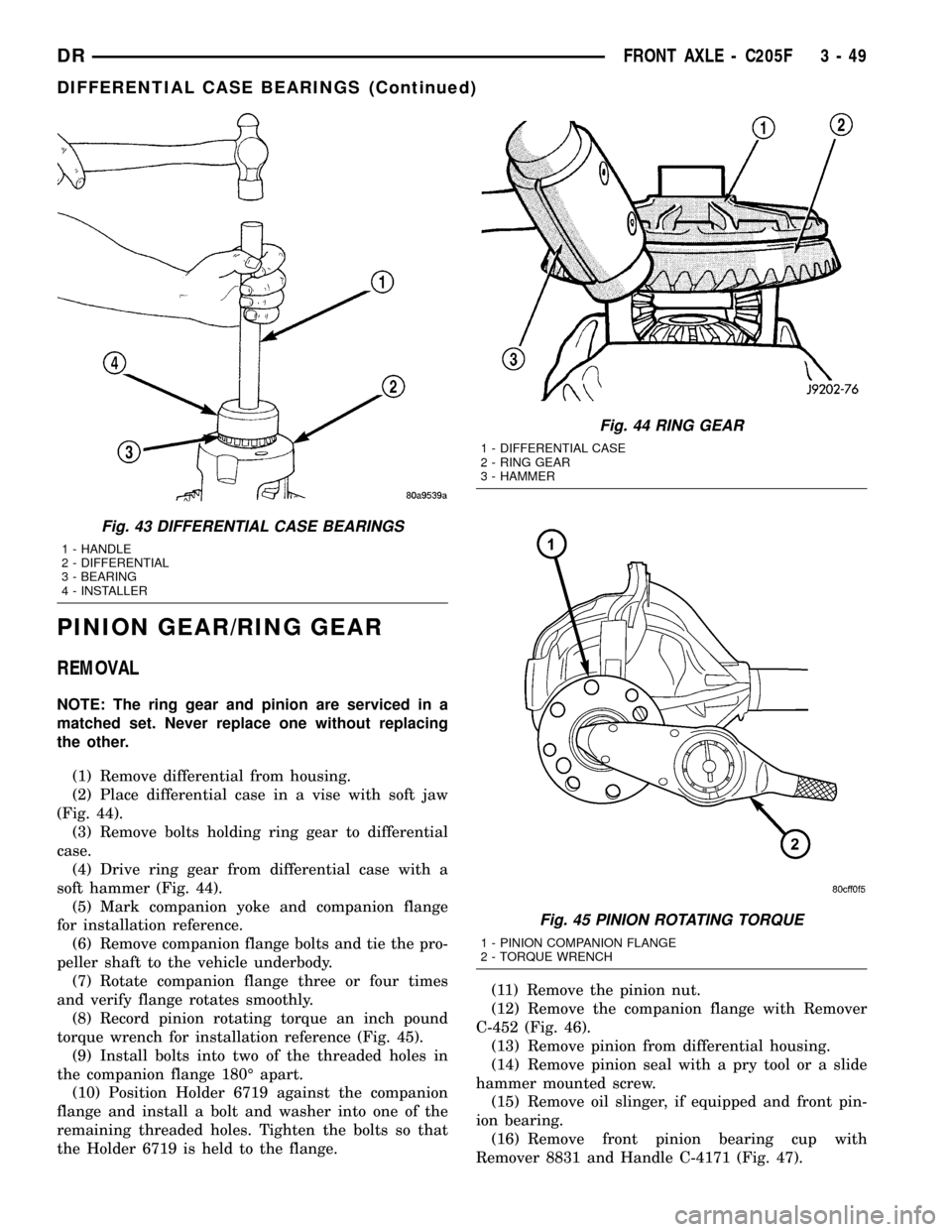

PINION GEAR/RING GEAR

REMOVAL

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one without replacing

the other.

(1) Remove differential from housing.

(2) Place differential case in a vise with soft jaw

(Fig. 44).

(3) Remove bolts holding ring gear to differential

case.

(4) Drive ring gear from differential case with a

soft hammer (Fig. 44).

(5) Mark companion yoke and companion flange

for installation reference.

(6) Remove companion flange bolts and tie the pro-

peller shaft to the vehicle underbody.

(7) Rotate companion flange three or four times

and verify flange rotates smoothly.

(8) Record pinion rotating torque an inch pound

torque wrench for installation reference (Fig. 45).

(9) Install bolts into two of the threaded holes in

the companion flange 180É apart.

(10) Position Holder 6719 against the companion

flange and install a bolt and washer into one of the

remaining threaded holes. Tighten the bolts so that

the Holder 6719 is held to the flange.(11) Remove the pinion nut.

(12) Remove the companion flange with Remover

C-452 (Fig. 46).

(13) Remove pinion from differential housing.

(14) Remove pinion seal with a pry tool or a slide

hammer mounted screw.

(15) Remove oil slinger, if equipped and front pin-

ion bearing.

(16) Remove front pinion bearing cup with

Remover 8831 and Handle C-4171 (Fig. 47).

Fig. 43 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL

3 - BEARING

4 - INSTALLER

Fig. 44 RING GEAR

1 - DIFFERENTIAL CASE

2 - RING GEAR

3 - HAMMER

Fig. 45 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

DRFRONT AXLE - C205F 3 - 49

DIFFERENTIAL CASE BEARINGS (Continued)

Page 131 of 2627

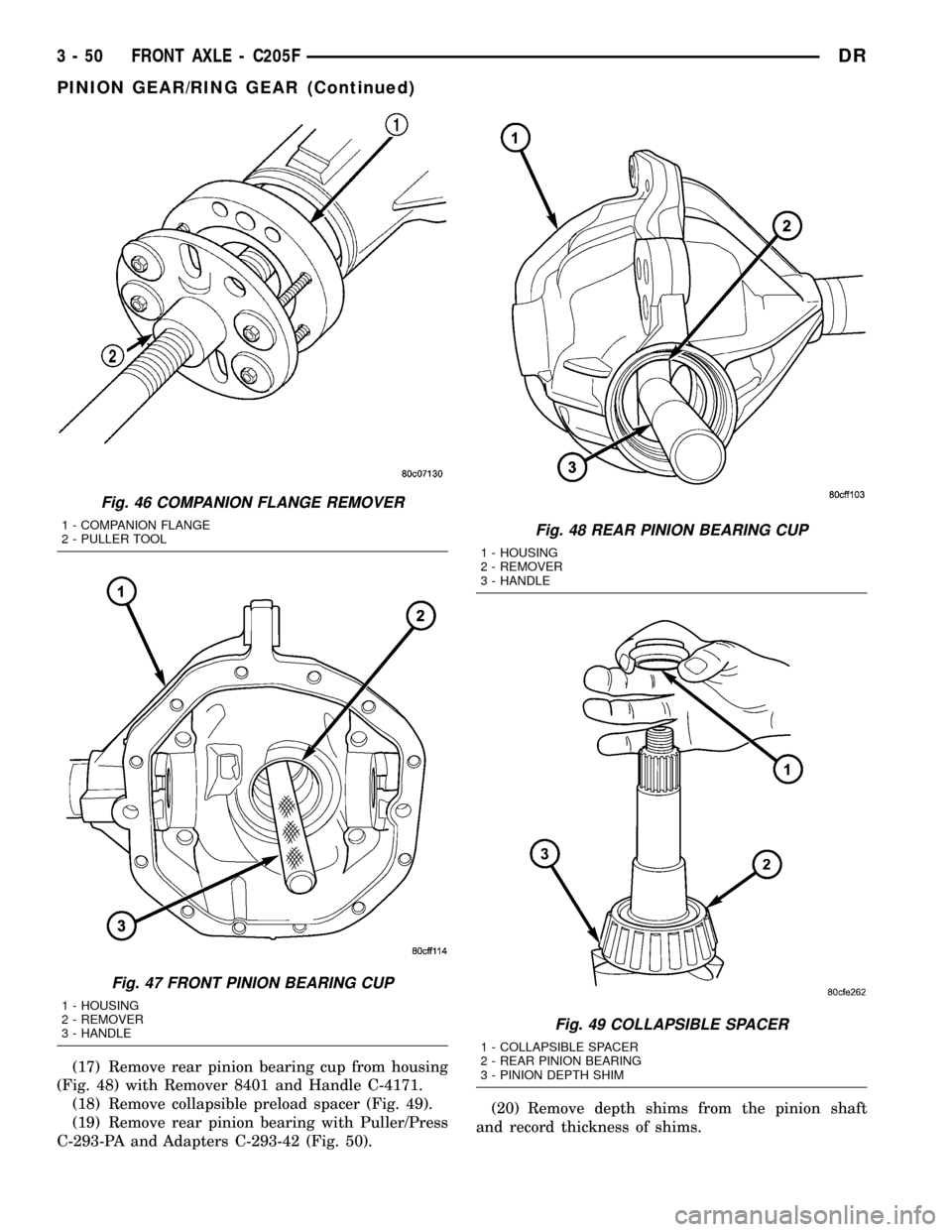

(17) Remove rear pinion bearing cup from housing

(Fig. 48) with Remover 8401 and Handle C-4171.

(18) Remove collapsible preload spacer (Fig. 49).

(19) Remove rear pinion bearing with Puller/Press

C-293-PA and Adapters C-293-42 (Fig. 50).(20) Remove depth shims from the pinion shaft

and record thickness of shims.

Fig. 46 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

Fig. 47 FRONT PINION BEARING CUP

1 - HOUSING

2 - REMOVER

3 - HANDLE

Fig. 48 REAR PINION BEARING CUP

1 - HOUSING

2 - REMOVER

3 - HANDLE

Fig. 49 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - REAR PINION BEARING

3 - PINION DEPTH SHIM

3 - 50 FRONT AXLE - C205FDR

PINION GEAR/RING GEAR (Continued)

Page 132 of 2627

INSTALLATION

NOTE: The ring gear and pinion are serviced in a

matched set. Never replace one gear without replac-

ing the other matching gear. If ring and pinion

gears or bearings are replaced, Refer to Adjust-

ments for Pinion Gear Depth Setting.

(1) Apply Mopar Door Ease or equivalent lubricant

to outside surface of the bearing cups.

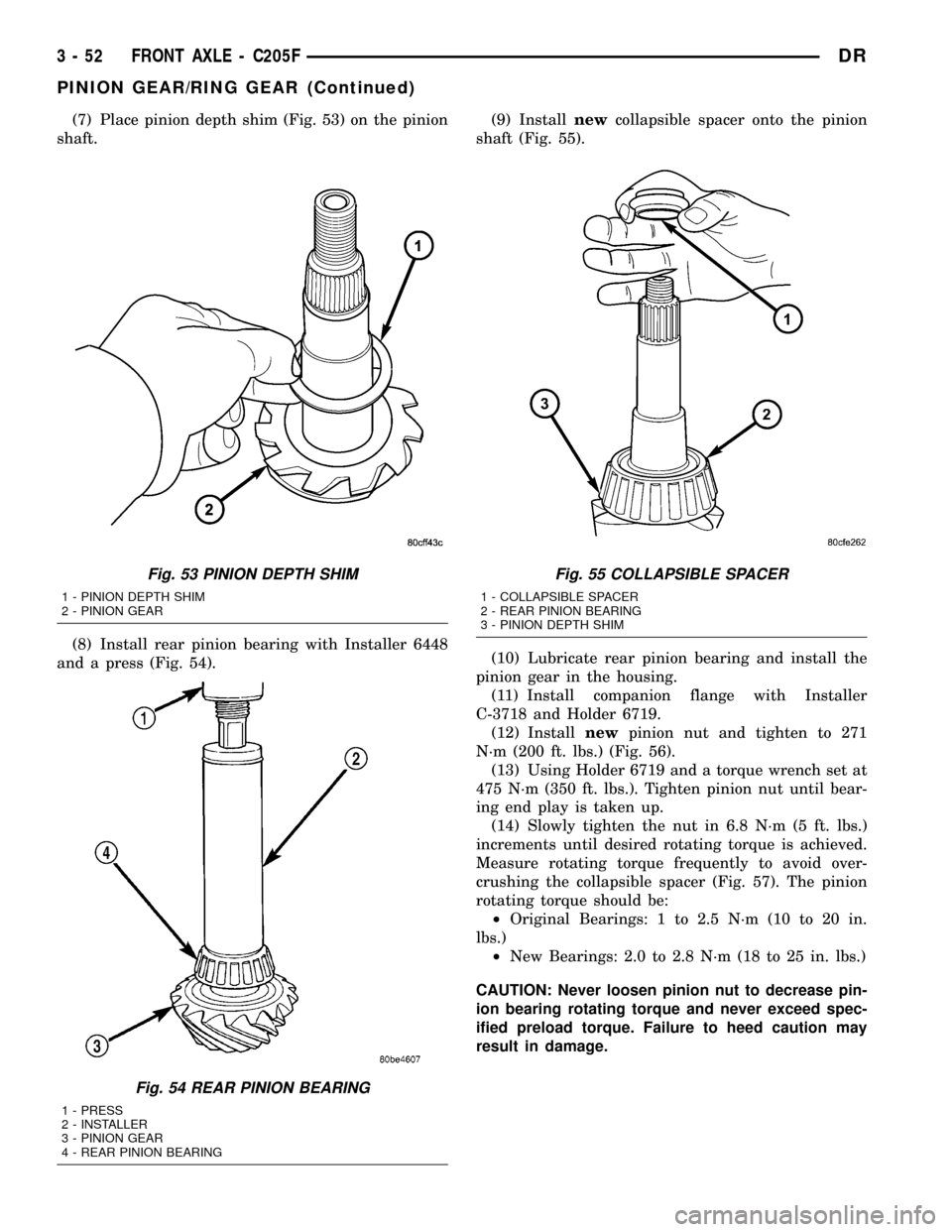

(2) Install rear pinion bearing cup with Installer

8692 and Driver Handle C-4171 (Fig. 51).

(3) Install front pinion bearing cup with Installer

8693 and Handle C-4171.

(4) Lubricate front pinion bearing and install bear-

ing in the housing.

(5) Apply a light coating of gear lubricant on the

lip of pinion seal.

(6) Install pinion seal with Installer 8695 and

Handle C-4171 (Fig. 52).

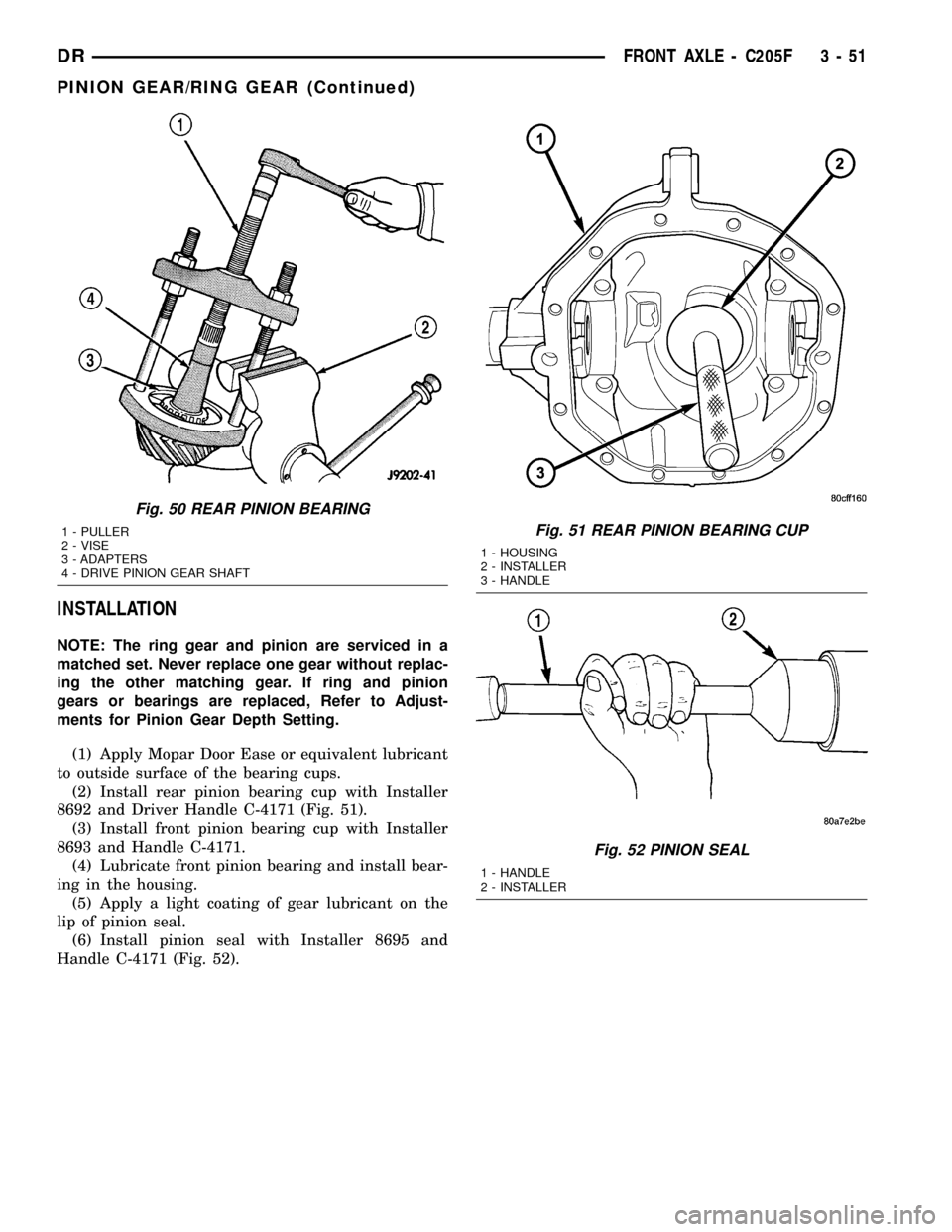

Fig. 50 REAR PINION BEARING

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - DRIVE PINION GEAR SHAFTFig. 51 REAR PINION BEARING CUP

1 - HOUSING

2 - INSTALLER

3 - HANDLE

Fig. 52 PINION SEAL

1 - HANDLE

2 - INSTALLER

DRFRONT AXLE - C205F 3 - 51

PINION GEAR/RING GEAR (Continued)

Page 133 of 2627

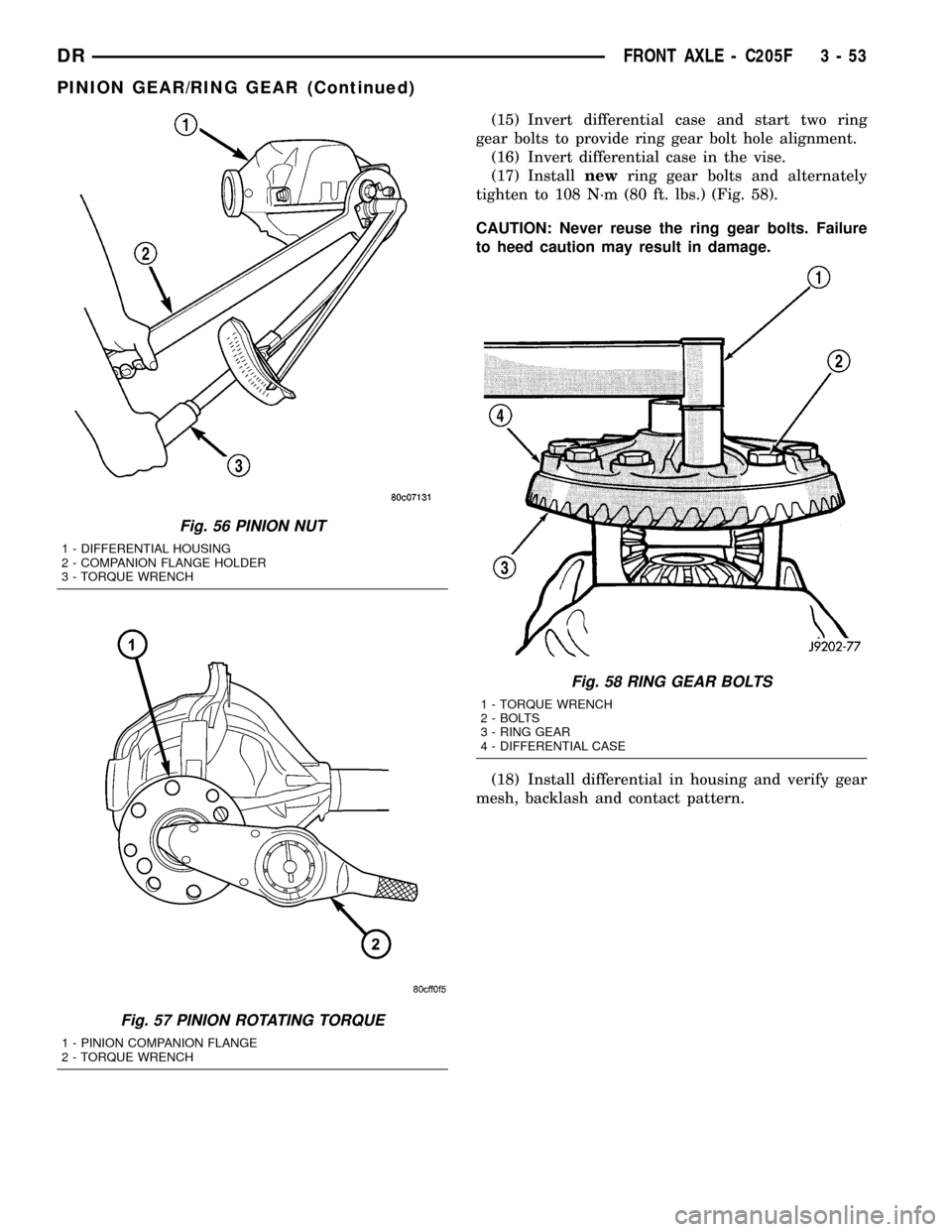

(7) Place pinion depth shim (Fig. 53) on the pinion

shaft.

(8) Install rear pinion bearing with Installer 6448

and a press (Fig. 54).(9) Installnewcollapsible spacer onto the pinion

shaft (Fig. 55).

(10) Lubricate rear pinion bearing and install the

pinion gear in the housing.

(11) Install companion flange with Installer

C-3718 and Holder 6719.

(12) Installnewpinion nut and tighten to 271

N´m (200 ft. lbs.) (Fig. 56).

(13) Using Holder 6719 and a torque wrench set at

475 N´m (350 ft. lbs.). Tighten pinion nut until bear-

ing end play is taken up.

(14) Slowly tighten the nut in 6.8 N´m (5 ft. lbs.)

increments until desired rotating torque is achieved.

Measure rotating torque frequently to avoid over-

crushing the collapsible spacer (Fig. 57). The pinion

rotating torque should be:

²Original Bearings: 1 to 2.5 N´m (10 to 20 in.

lbs.)

²New Bearings: 2.0 to 2.8 N´m (18 to 25 in. lbs.)

CAUTION: Never loosen pinion nut to decrease pin-

ion bearing rotating torque and never exceed spec-

ified preload torque. Failure to heed caution may

result in damage.

Fig. 53 PINION DEPTH SHIM

1 - PINION DEPTH SHIM

2 - PINION GEAR

Fig. 54 REAR PINION BEARING

1 - PRESS

2 - INSTALLER

3 - PINION GEAR

4 - REAR PINION BEARING

Fig. 55 COLLAPSIBLE SPACER

1 - COLLAPSIBLE SPACER

2 - REAR PINION BEARING

3 - PINION DEPTH SHIM

3 - 52 FRONT AXLE - C205FDR

PINION GEAR/RING GEAR (Continued)

Page 134 of 2627

(15) Invert differential case and start two ring

gear bolts to provide ring gear bolt hole alignment.

(16) Invert differential case in the vise.

(17) Installnewring gear bolts and alternately

tighten to 108 N´m (80 ft. lbs.) (Fig. 58).

CAUTION: Never reuse the ring gear bolts. Failure

to heed caution may result in damage.

(18) Install differential in housing and verify gear

mesh, backlash and contact pattern.

Fig. 56 PINION NUT

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

Fig. 57 PINION ROTATING TORQUE

1 - PINION COMPANION FLANGE

2 - TORQUE WRENCH

Fig. 58 RING GEAR BOLTS

1 - TORQUE WRENCH

2 - BOLTS

3 - RING GEAR

4 - DIFFERENTIAL CASE

DRFRONT AXLE - C205F 3 - 53

PINION GEAR/RING GEAR (Continued)

Page 138 of 2627

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

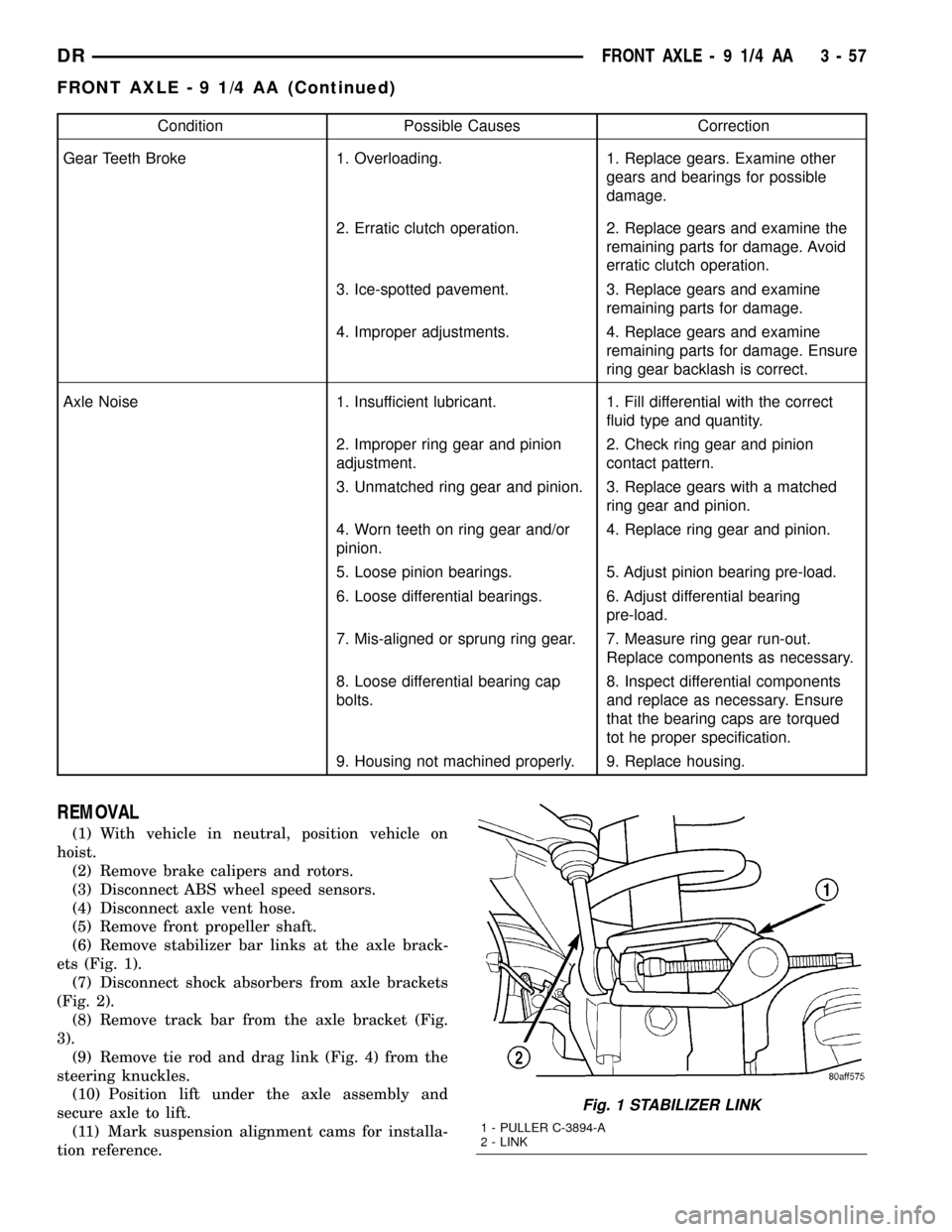

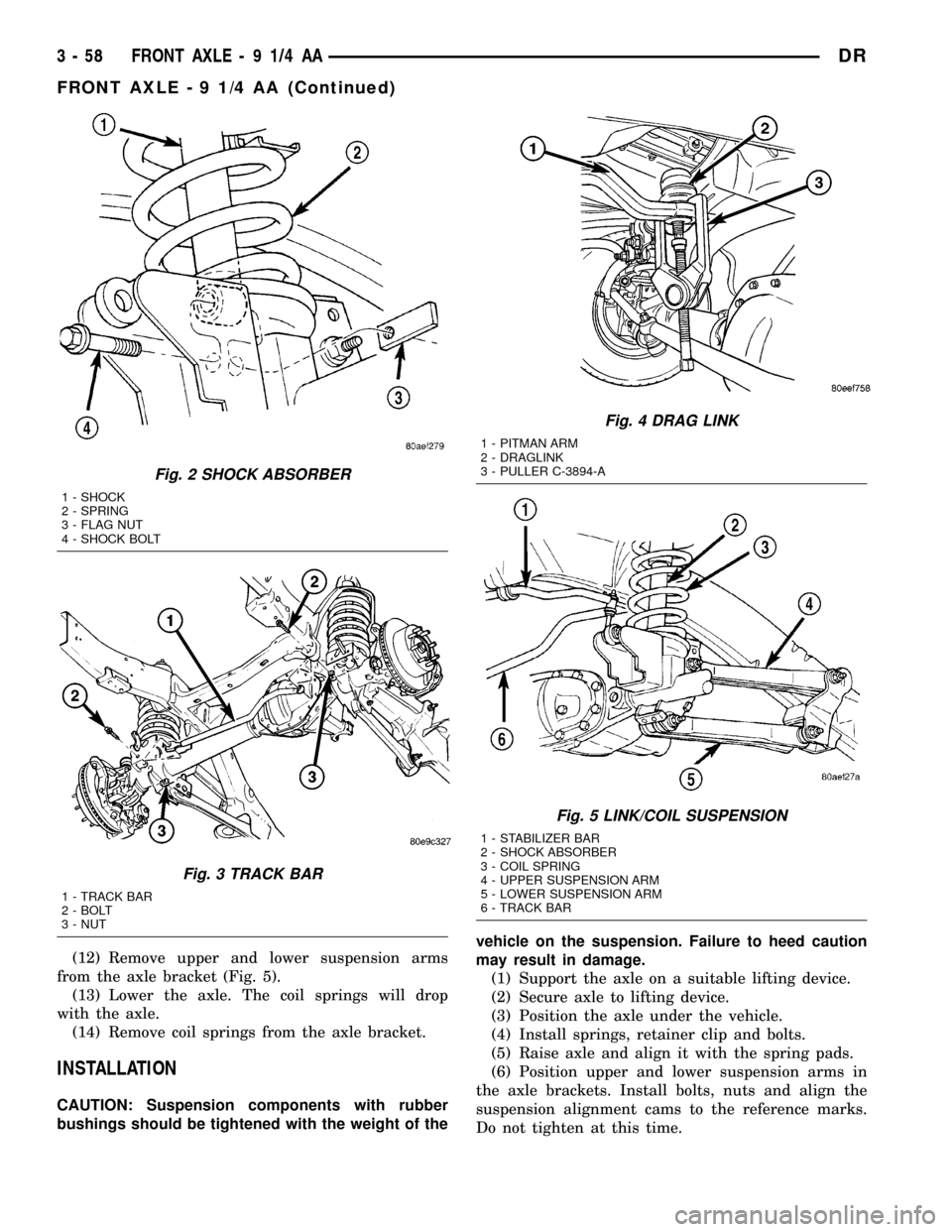

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove brake calipers and rotors.

(3) Disconnect ABS wheel speed sensors.

(4) Disconnect axle vent hose.

(5) Remove front propeller shaft.

(6) Remove stabilizer bar links at the axle brack-

ets (Fig. 1).

(7) Disconnect shock absorbers from axle brackets

(Fig. 2).

(8) Remove track bar from the axle bracket (Fig.

3).

(9) Remove tie rod and drag link (Fig. 4) from the

steering knuckles.

(10) Position lift under the axle assembly and

secure axle to lift.

(11) Mark suspension alignment cams for installa-

tion reference.

Fig. 1 STABILIZER LINK

1 - PULLER C-3894-A

2 - LINK

DRFRONT AXLE - 9 1/4 AA 3 - 57

FRONT AXLE - 9 1/4 AA (Continued)

Page 139 of 2627

(12) Remove upper and lower suspension arms

from the axle bracket (Fig. 5).

(13) Lower the axle. The coil springs will drop

with the axle.

(14) Remove coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the weight of thevehicle on the suspension. Failure to heed caution

may result in damage.

(1) Support the axle on a suitable lifting device.

(2) Secure axle to lifting device.

(3) Position the axle under the vehicle.

(4) Install springs, retainer clip and bolts.

(5) Raise axle and align it with the spring pads.

(6) Position upper and lower suspension arms in

the axle brackets. Install bolts, nuts and align the

suspension alignment cams to the reference marks.

Do not tighten at this time.

Fig. 2 SHOCK ABSORBER

1 - SHOCK

2 - SPRING

3 - FLAG NUT

4 - SHOCK BOLT

Fig. 3 TRACK BAR

1 - TRACK BAR

2 - BOLT

3 - NUT

Fig. 4 DRAG LINK

1 - PITMAN ARM

2 - DRAGLINK

3 - PULLER C-3894-A

Fig. 5 LINK/COIL SUSPENSION

1 - STABILIZER BAR

2 - SHOCK ABSORBER

3 - COIL SPRING

4 - UPPER SUSPENSION ARM

5 - LOWER SUSPENSION ARM

6 - TRACK BAR

3 - 58 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 140 of 2627

(7) Connect track bar to the axle bracket and

install the bolt. Do not tighten at this time.

(8) Install shock absorber and tighten bolts to 121

N´m (89 ft. lbs.).

(9) Install stabilizer bar link to the axle bracket.

Tighten the nut to 68 N´m (50 ft. lbs.).

(10) Install drag link and tie rod to the steering

knuckles and tighten the nuts to 108 N´m (80 ft.

lbs.).

(11) Install ABS wheel speed sensors.

(12) Install rotors and brake calipers.

(13) Connect the axle vent hose.

(14) Install front propeller shaft.

(15) With vehicle on the ground, tighten upper

suspension arm nuts at axle to 149 N´m (110 ft. lbs.).

Tighten upper suspension arm nuts at frame to 149

N´m (110 ft. lbs.).

(16) With vehicle on the ground, tighten lower sus-

pension arm nuts at axle to 190 N´m (140 ft. lbs.).

Tighten the lower suspension arm nuts at frame to

190 N´m (140 ft. lbs.).

(17) Tighten track bar bolt at the axle bracket to

176 N´m (130 ft. lbs.).

(18) Check front wheel alignment.

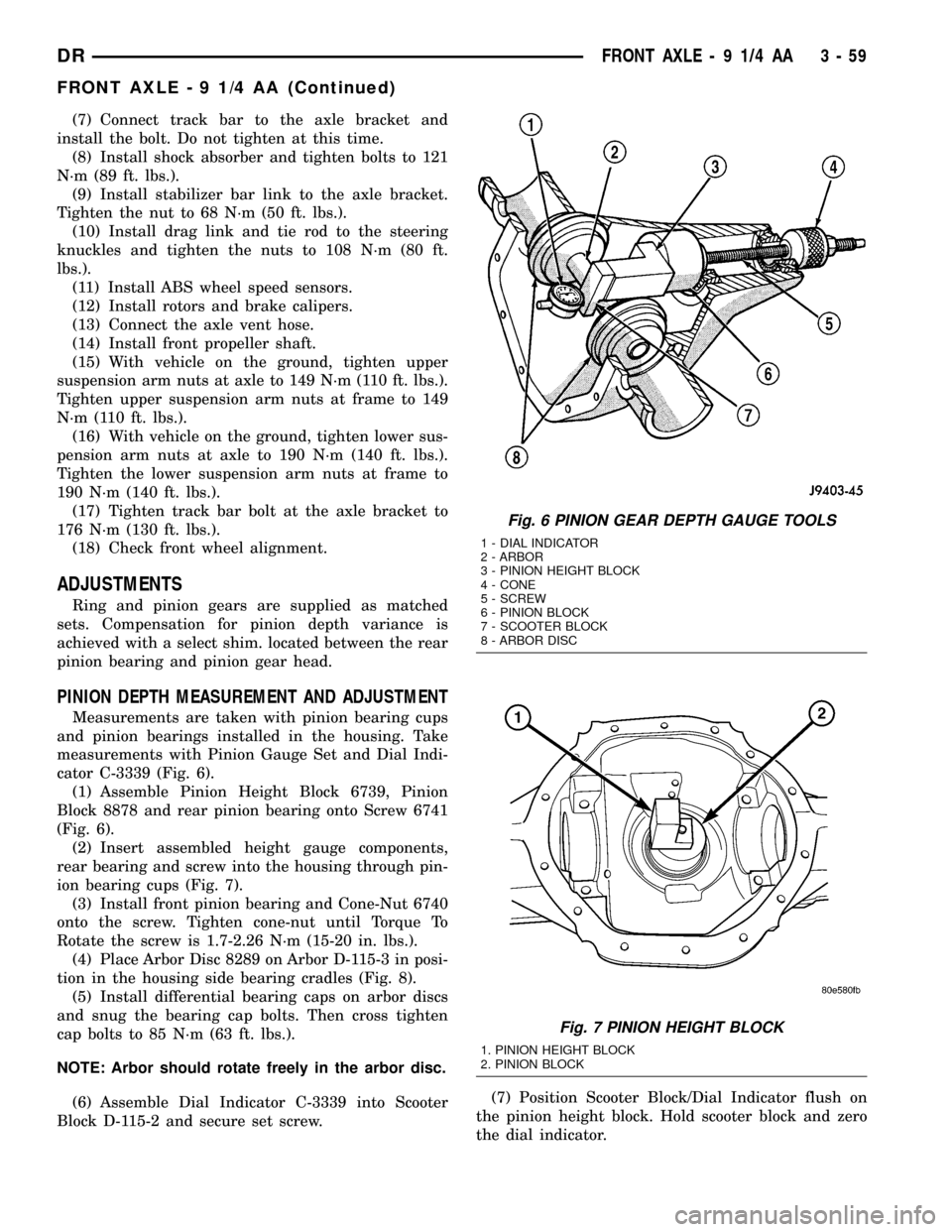

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets. Compensation for pinion depth variance is

achieved with a select shim. located between the rear

pinion bearing and pinion gear head.

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 6).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8878 and rear pinion bearing onto Screw 6741

(Fig. 6).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 7).

(3) Install front pinion bearing and Cone-Nut 6740

onto the screw. Tighten cone-nut until Torque To

Rotate the screw is 1.7-2.26 N´m (15-20 in. lbs.).

(4) Place Arbor Disc 8289 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 8).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 85 N´m (63 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor disc.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

Fig. 6 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 7 PINION HEIGHT BLOCK

1. PINION HEIGHT BLOCK

2. PINION BLOCK

DRFRONT AXLE - 9 1/4 AA 3 - 59

FRONT AXLE - 9 1/4 AA (Continued)