Fig DODGE RAM 1500 1998 2.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 115 of 2627

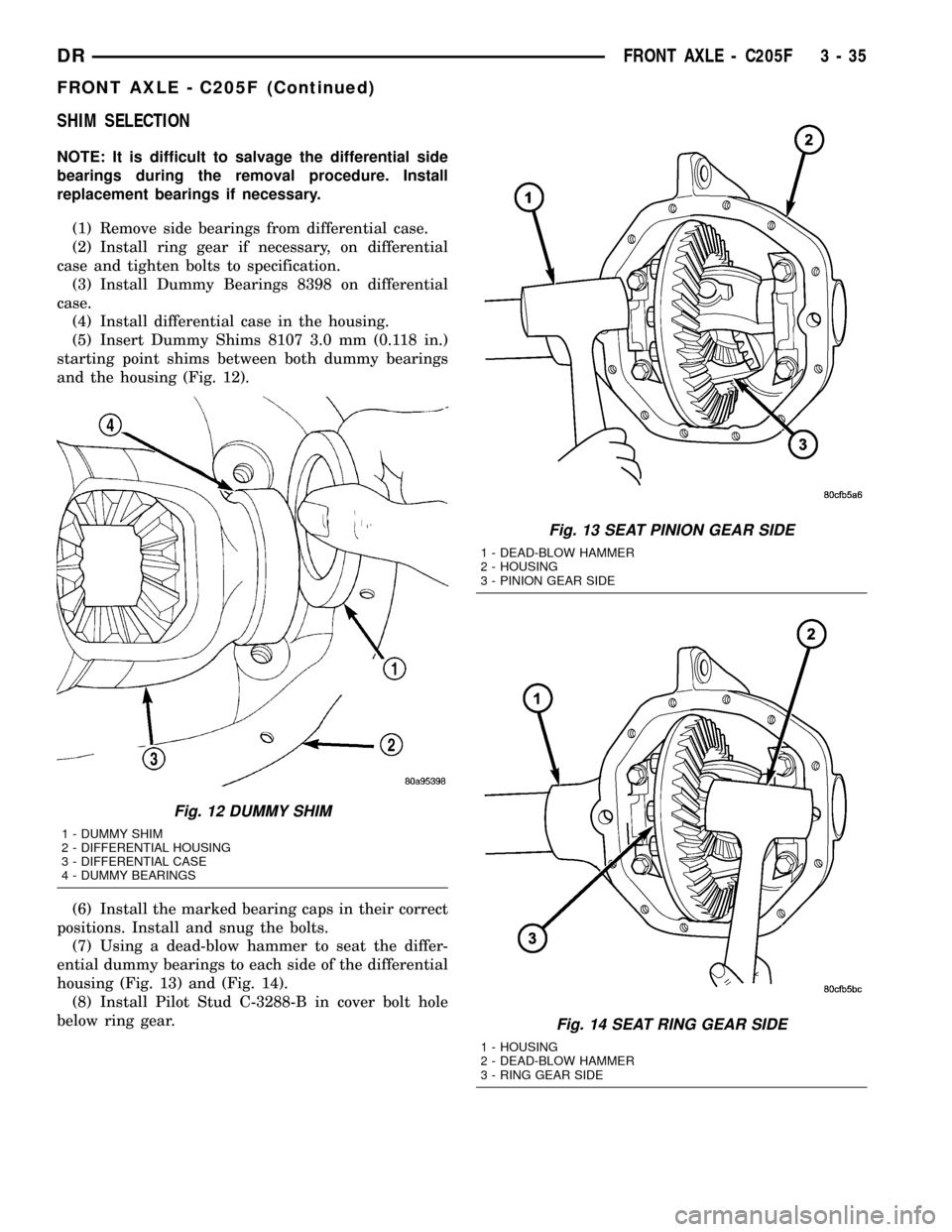

(6) Place Scooter Block/Dial Indicator in position

in the housing so dial probe and scooter block are

flush against the surface of the pinion height block.

Hold scooter block in place and zero the dial indica-

tor. Tighten dial indicator face lock screw.

(7) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

with the scooter block against the pinion height block

(Fig. 10). Slide the dial probe to the crest of the arbor

bar and record the highest reading.

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

marked on the shaft of the pinion gear using the

opposite sign on the variance number. For example, if

the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

(9) Remove the pinion depth gauge components

from the housing

DIFFERENTIAL BEARING PRELOAD AND GEAR

BACKLASH

Differential side bearing preload and gear backlash

is achieved by selective shims inserted between the

bearing cup and the housing. The proper shim thick-

ness can be determined using slip-fit Dummy Bear-

ings 8398 in place of the differential side bearings

and a Dial Indicator C-3339. Before measuring differ-

ential bearing preload and gear backlash, measure

pinion gear depth and prepare pinion for installation.Pinion gear depth is essential to establishing gear

backlash and tooth contact patterns. After measuring

shim thickness to take up differential side play,

install pinion and measure gear backlash shim thick-

ness. Overall shim thickness is the dial indicator

reading and preload specification added together. The

gear backlash measurement determines the shim

thickness used on the ring gear side of the differen-

tial case. Subtract gear backlash shim thickness from

overall shim thickness to determine shim thickness

for pinion gear side of the differential (Fig. 11).

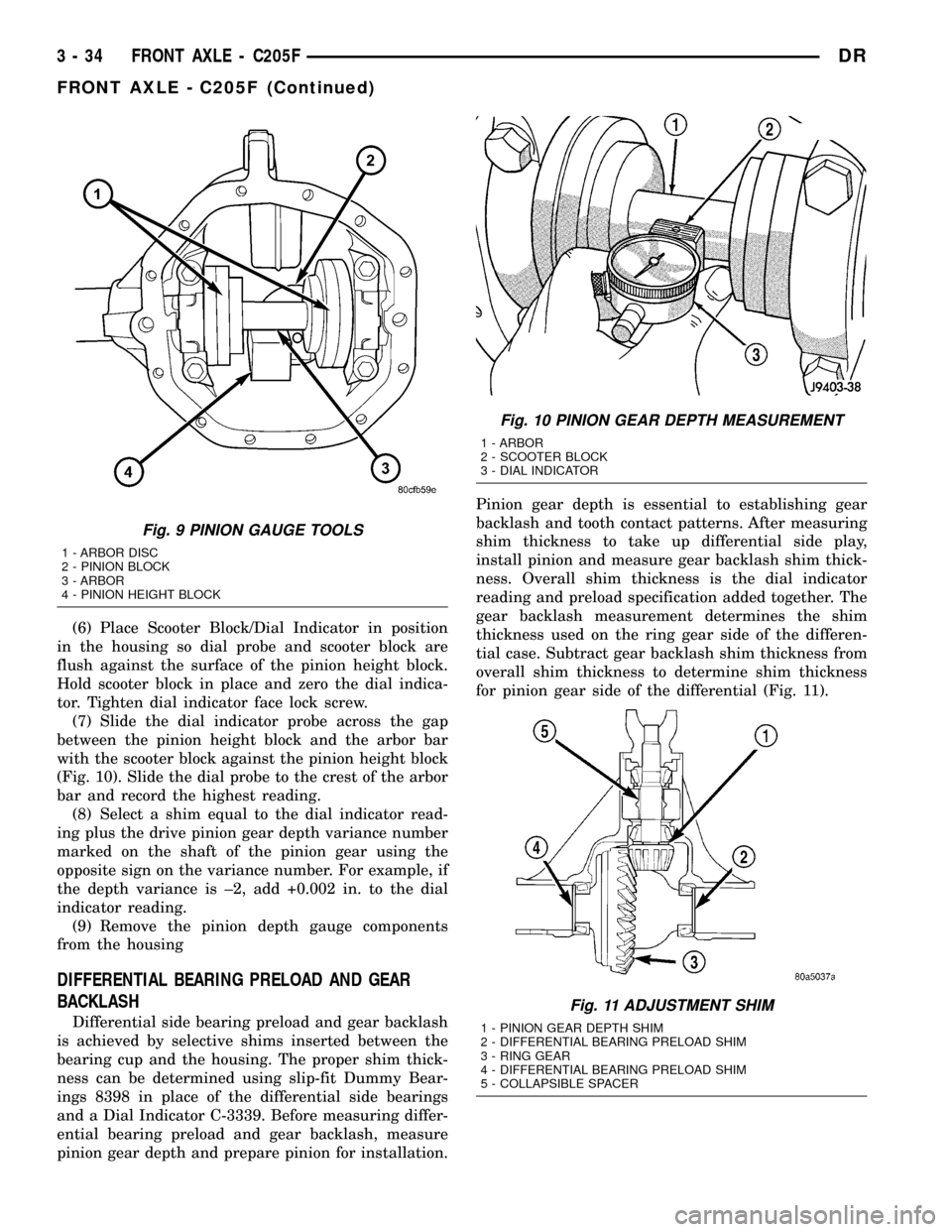

Fig. 9 PINION GAUGE TOOLS

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 10 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 11 ADJUSTMENT SHIM

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING PRELOAD SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING PRELOAD SHIM

5 - COLLAPSIBLE SPACER

3 - 34 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 116 of 2627

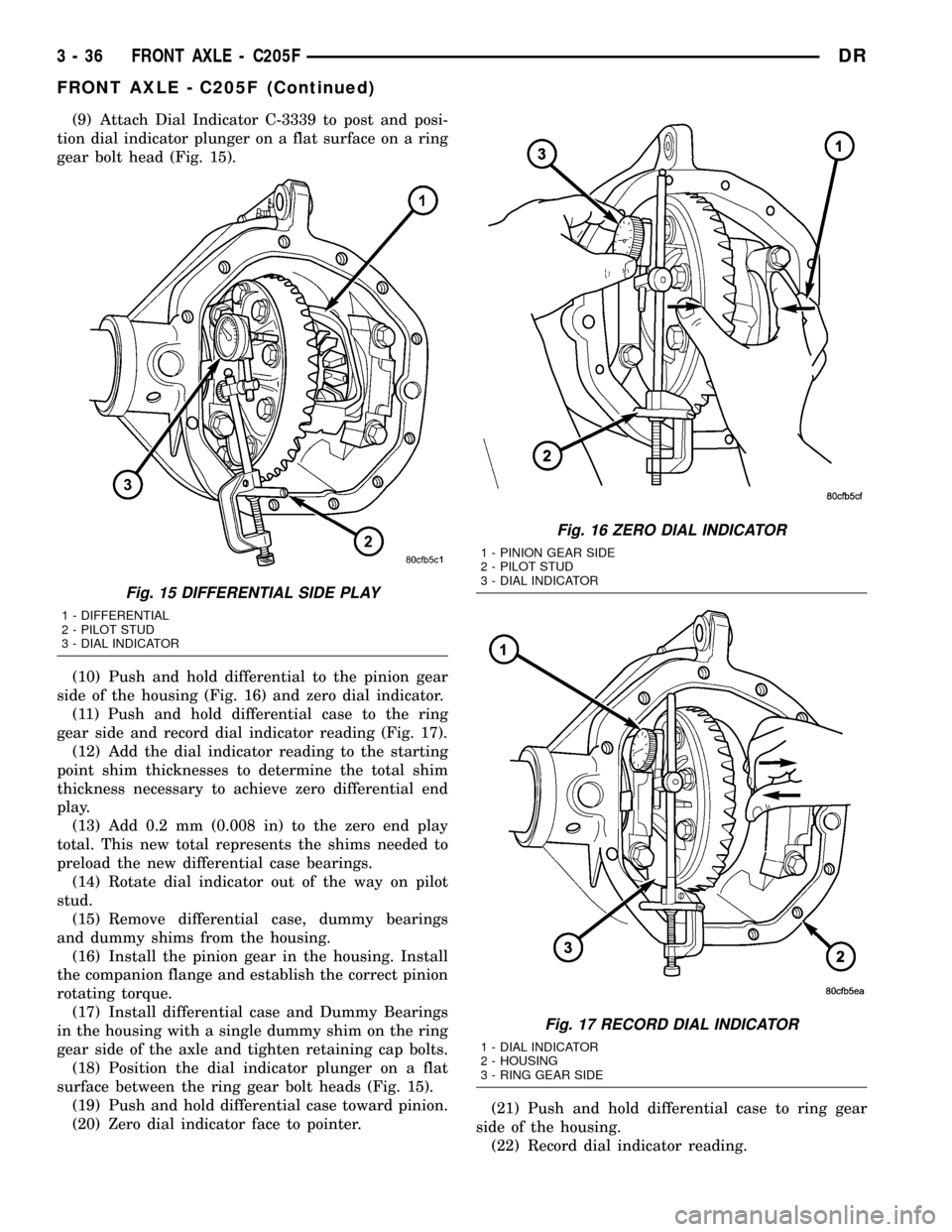

SHIM SELECTION

NOTE: It is difficult to salvage the differential side

bearings during the removal procedure. Install

replacement bearings if necessary.

(1) Remove side bearings from differential case.

(2) Install ring gear if necessary, on differential

case and tighten bolts to specification.

(3) Install Dummy Bearings 8398 on differential

case.

(4) Install differential case in the housing.

(5) Insert Dummy Shims 8107 3.0 mm (0.118 in.)

starting point shims between both dummy bearings

and the housing (Fig. 12).

(6) Install the marked bearing caps in their correct

positions. Install and snug the bolts.

(7) Using a dead-blow hammer to seat the differ-

ential dummy bearings to each side of the differential

housing (Fig. 13) and (Fig. 14).

(8) Install Pilot Stud C-3288-B in cover bolt hole

below ring gear.

Fig. 12 DUMMY SHIM

1 - DUMMY SHIM

2 - DIFFERENTIAL HOUSING

3 - DIFFERENTIAL CASE

4 - DUMMY BEARINGS

Fig. 13 SEAT PINION GEAR SIDE

1 - DEAD-BLOW HAMMER

2 - HOUSING

3 - PINION GEAR SIDE

Fig. 14 SEAT RING GEAR SIDE

1 - HOUSING

2 - DEAD-BLOW HAMMER

3 - RING GEAR SIDE

DRFRONT AXLE - C205F 3 - 35

FRONT AXLE - C205F (Continued)

Page 117 of 2627

(9) Attach Dial Indicator C-3339 to post and posi-

tion dial indicator plunger on a flat surface on a ring

gear bolt head (Fig. 15).

(10) Push and hold differential to the pinion gear

side of the housing (Fig. 16) and zero dial indicator.

(11) Push and hold differential case to the ring

gear side and record dial indicator reading (Fig. 17).

(12) Add the dial indicator reading to the starting

point shim thicknesses to determine the total shim

thickness necessary to achieve zero differential end

play.

(13) Add 0.2 mm (0.008 in) to the zero end play

total. This new total represents the shims needed to

preload the new differential case bearings.

(14) Rotate dial indicator out of the way on pilot

stud.

(15) Remove differential case, dummy bearings

and dummy shims from the housing.

(16) Install the pinion gear in the housing. Install

the companion flange and establish the correct pinion

rotating torque.

(17) Install differential case and Dummy Bearings

in the housing with a single dummy shim on the ring

gear side of the axle and tighten retaining cap bolts.

(18) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads (Fig. 15).

(19) Push and hold differential case toward pinion.

(20) Zero dial indicator face to pointer.(21) Push and hold differential case to ring gear

side of the housing.

(22) Record dial indicator reading.

Fig. 15 DIFFERENTIAL SIDE PLAY

1 - DIFFERENTIAL

2 - PILOT STUD

3 - DIAL INDICATOR

Fig. 16 ZERO DIAL INDICATOR

1 - PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR

Fig. 17 RECORD DIAL INDICATOR

1 - DIAL INDICATOR

2 - HOUSING

3 - RING GEAR SIDE

3 - 36 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 118 of 2627

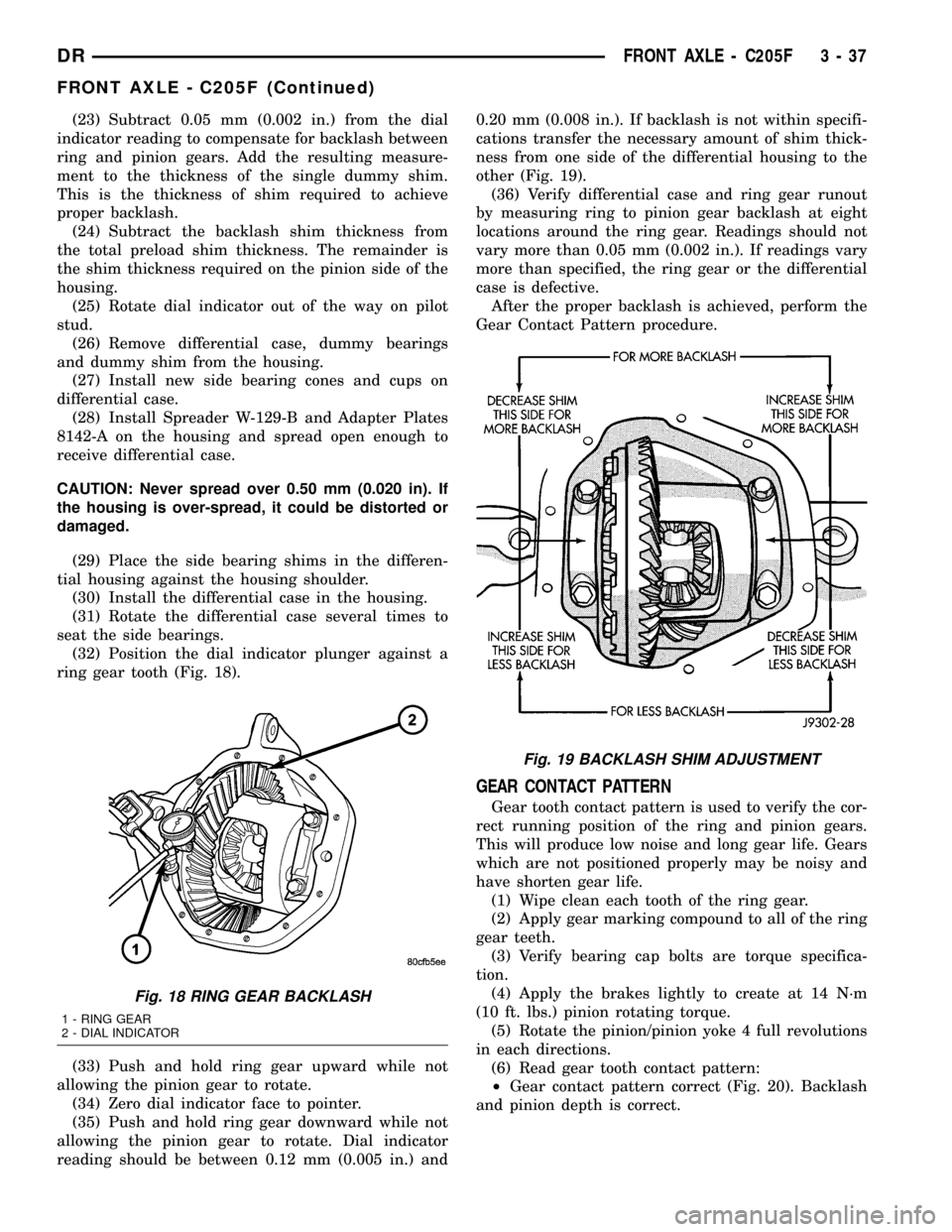

(23) Subtract 0.05 mm (0.002 in.) from the dial

indicator reading to compensate for backlash between

ring and pinion gears. Add the resulting measure-

ment to the thickness of the single dummy shim.

This is the thickness of shim required to achieve

proper backlash.

(24) Subtract the backlash shim thickness from

the total preload shim thickness. The remainder is

the shim thickness required on the pinion side of the

housing.

(25) Rotate dial indicator out of the way on pilot

stud.

(26) Remove differential case, dummy bearings

and dummy shim from the housing.

(27) Install new side bearing cones and cups on

differential case.

(28) Install Spreader W-129-B and Adapter Plates

8142-A on the housing and spread open enough to

receive differential case.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(29) Place the side bearing shims in the differen-

tial housing against the housing shoulder.

(30) Install the differential case in the housing.

(31) Rotate the differential case several times to

seat the side bearings.

(32) Position the dial indicator plunger against a

ring gear tooth (Fig. 18).

(33) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(34) Zero dial indicator face to pointer.

(35) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.12 mm (0.005 in.) and0.20 mm (0.008 in.). If backlash is not within specifi-

cations transfer the necessary amount of shim thick-

ness from one side of the differential housing to the

other (Fig. 19).

(36) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings vary

more than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform the

Gear Contact Pattern procedure.

GEAR CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply the brakes lightly to create at 14 N´m

(10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

(6) Read gear tooth contact pattern:

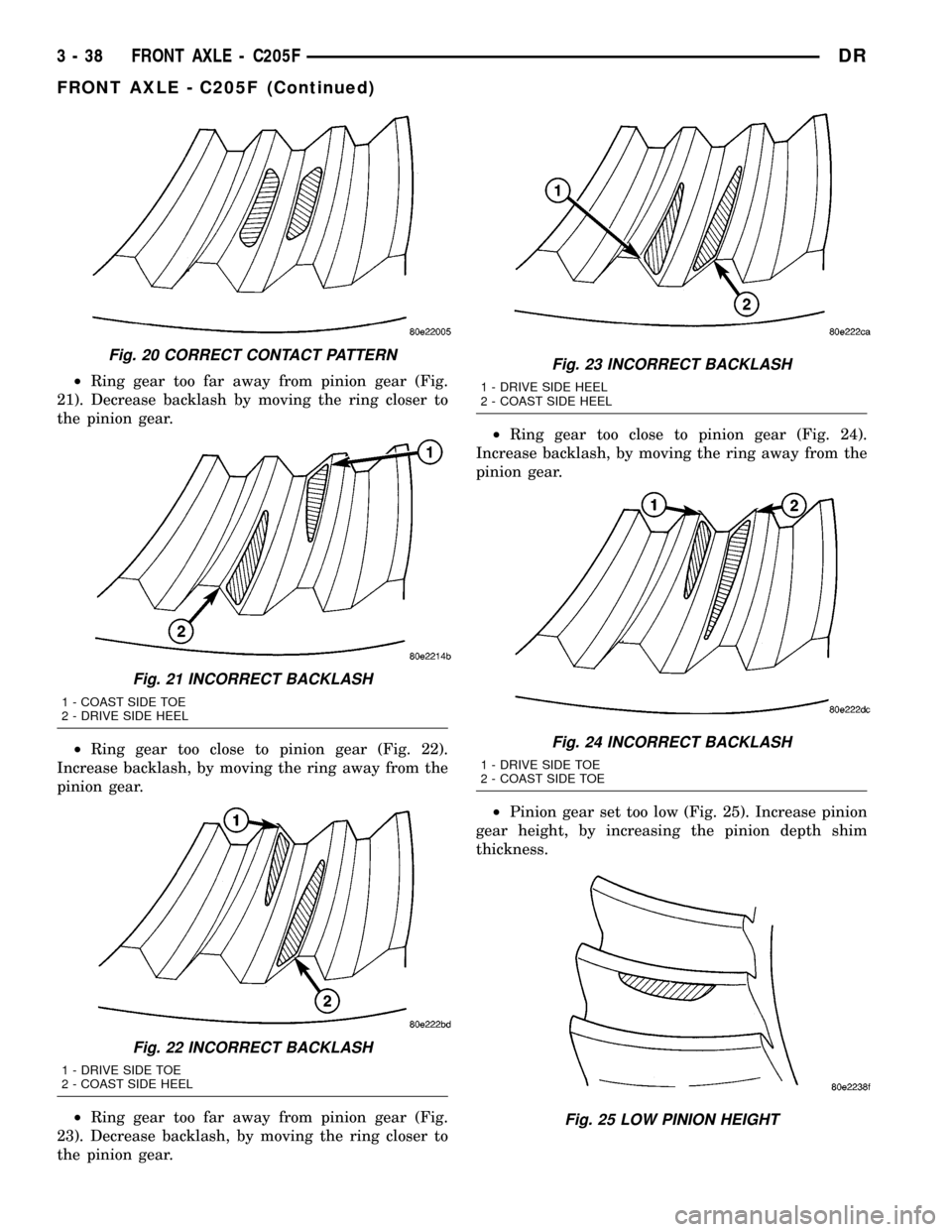

²Gear contact pattern correct (Fig. 20). Backlash

and pinion depth is correct.

Fig. 18 RING GEAR BACKLASH

1 - RING GEAR

2 - DIAL INDICATOR

Fig. 19 BACKLASH SHIM ADJUSTMENT

DRFRONT AXLE - C205F 3 - 37

FRONT AXLE - C205F (Continued)

Page 119 of 2627

²Ring gear too far away from pinion gear (Fig.

21). Decrease backlash by moving the ring closer to

the pinion gear.

²Ring gear too close to pinion gear (Fig. 22).

Increase backlash, by moving the ring away from the

pinion gear.

²Ring gear too far away from pinion gear (Fig.

23). Decrease backlash, by moving the ring closer to

the pinion gear.²Ring gear too close to pinion gear (Fig. 24).

Increase backlash, by moving the ring away from the

pinion gear.

²Pinion gear set too low (Fig. 25). Increase pinion

gear height, by increasing the pinion depth shim

thickness.

Fig. 20 CORRECT CONTACT PATTERN

Fig. 21 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

Fig. 22 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

Fig. 23 INCORRECT BACKLASH

1 - DRIVE SIDE HEEL

2 - COAST SIDE HEEL

Fig. 24 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE TOE

Fig. 25 LOW PINION HEIGHT

3 - 38 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 120 of 2627

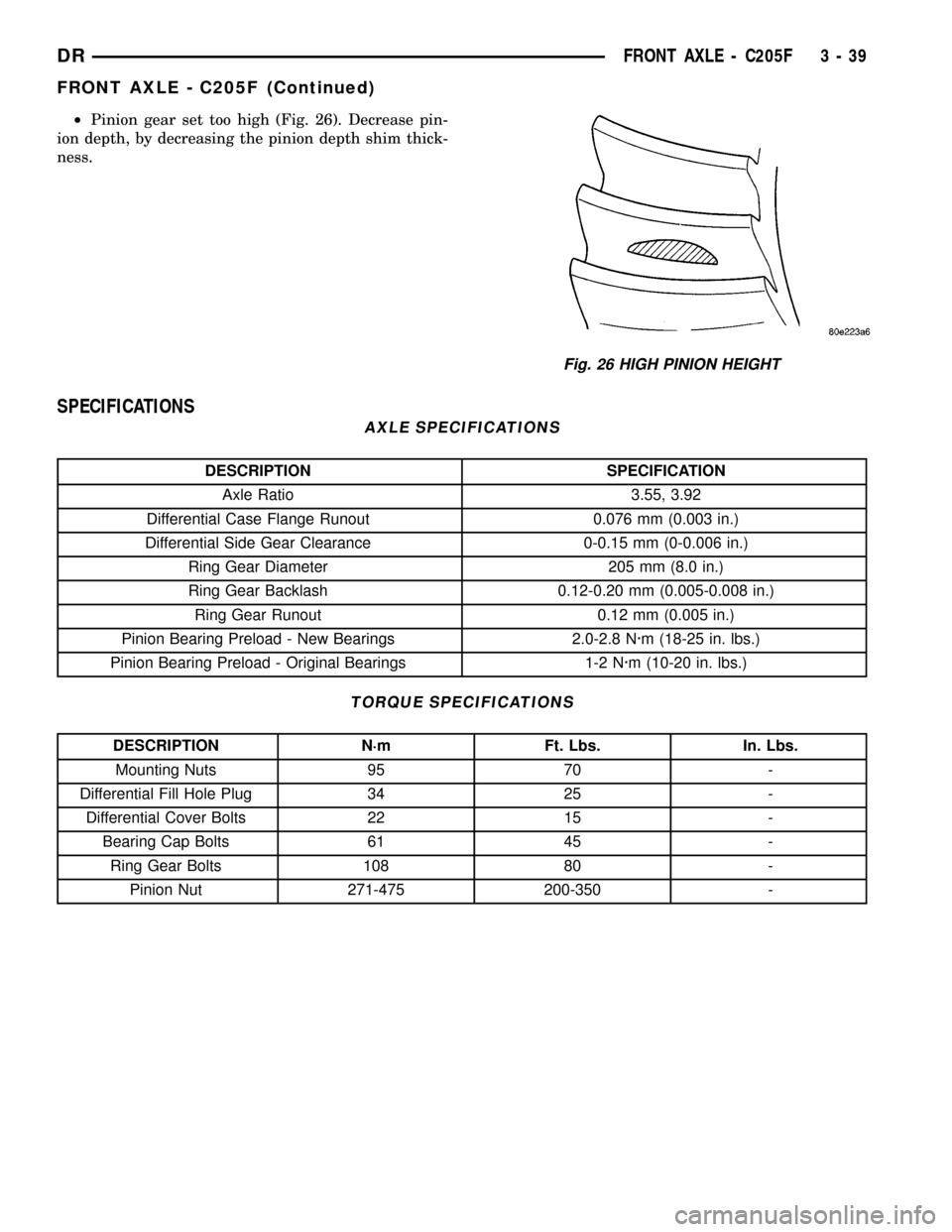

²Pinion gear set too high (Fig. 26). Decrease pin-

ion depth, by decreasing the pinion depth shim thick-

ness.

SPECIFICATIONS

AXLE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Axle Ratio 3.55, 3.92

Differential Case Flange Runout 0.076 mm (0.003 in.)

Differential Side Gear Clearance 0-0.15 mm (0-0.006 in.)

Ring Gear Diameter 205 mm (8.0 in.)

Ring Gear Backlash 0.12-0.20 mm (0.005-0.008 in.)

Ring Gear Runout 0.12 mm (0.005 in.)

Pinion Bearing Preload - New Bearings 2.0-2.8 N´m (18-25 in. lbs.)

Pinion Bearing Preload - Original Bearings 1-2 N´m (10-20 in. lbs.)

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Mounting Nuts 95 70 -

Differential Fill Hole Plug 34 25 -

Differential Cover Bolts 22 15 -

Bearing Cap Bolts 61 45 -

Ring Gear Bolts 108 80 -

Pinion Nut 271-475 200-350 -

Fig. 26 HIGH PINION HEIGHT

DRFRONT AXLE - C205F 3 - 39

FRONT AXLE - C205F (Continued)

Page 124 of 2627

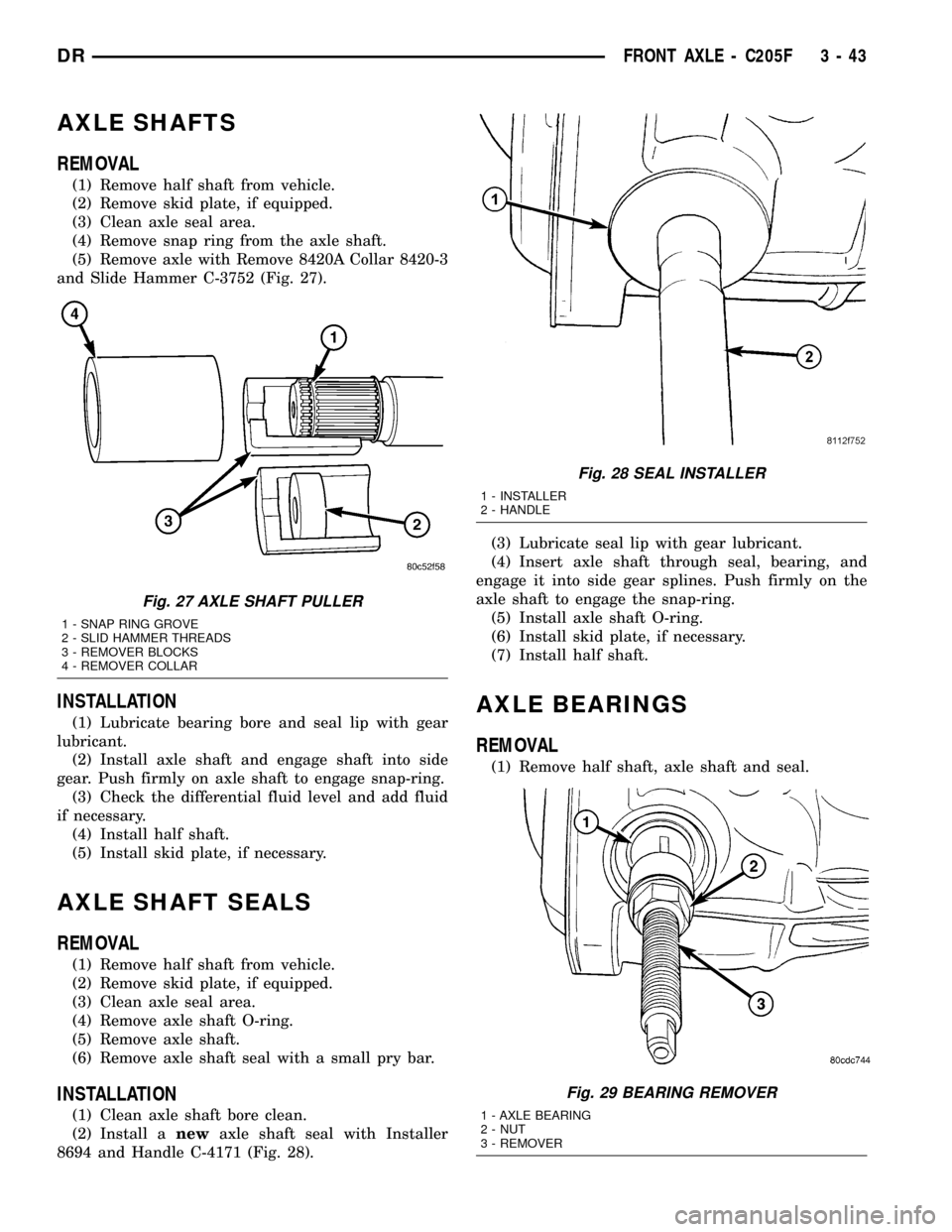

AXLE SHAFTS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove snap ring from the axle shaft.

(5) Remove axle with Remove 8420A Collar 8420-3

and Slide Hammer C-3752 (Fig. 27).

INSTALLATION

(1) Lubricate bearing bore and seal lip with gear

lubricant.

(2) Install axle shaft and engage shaft into side

gear. Push firmly on axle shaft to engage snap-ring.

(3) Check the differential fluid level and add fluid

if necessary.

(4) Install half shaft.

(5) Install skid plate, if necessary.

AXLE SHAFT SEALS

REMOVAL

(1) Remove half shaft from vehicle.

(2) Remove skid plate, if equipped.

(3) Clean axle seal area.

(4) Remove axle shaft O-ring.

(5) Remove axle shaft.

(6) Remove axle shaft seal with a small pry bar.

INSTALLATION

(1) Clean axle shaft bore clean.

(2) Install anewaxle shaft seal with Installer

8694 and Handle C-4171 (Fig. 28).(3) Lubricate seal lip with gear lubricant.

(4) Insert axle shaft through seal, bearing, and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

(5) Install axle shaft O-ring.

(6) Install skid plate, if necessary.

(7) Install half shaft.

AXLE BEARINGS

REMOVAL

(1) Remove half shaft, axle shaft and seal.

Fig. 27 AXLE SHAFT PULLER

1 - SNAP RING GROVE

2 - SLID HAMMER THREADS

3 - REMOVER BLOCKS

4 - REMOVER COLLAR

Fig. 28 SEAL INSTALLER

1 - INSTALLER

2 - HANDLE

Fig. 29 BEARING REMOVER

1 - AXLE BEARING

2 - NUT

3 - REMOVER

DRFRONT AXLE - C205F 3 - 43

Page 125 of 2627

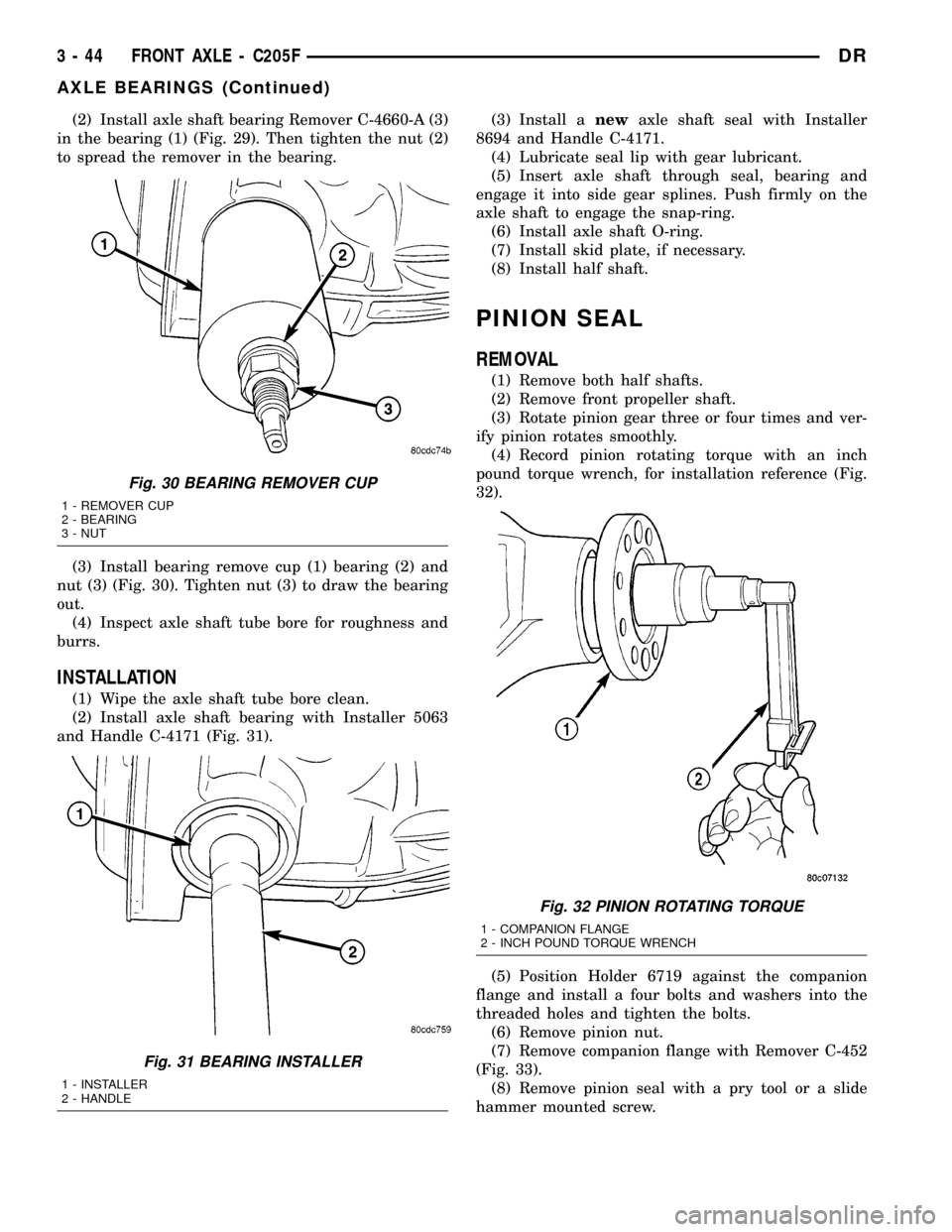

(2) Install axle shaft bearing Remover C-4660-A (3)

in the bearing (1) (Fig. 29). Then tighten the nut (2)

to spread the remover in the bearing.

(3) Install bearing remove cup (1) bearing (2) and

nut (3) (Fig. 30). Tighten nut (3) to draw the bearing

out.

(4) Inspect axle shaft tube bore for roughness and

burrs.

INSTALLATION

(1) Wipe the axle shaft tube bore clean.

(2) Install axle shaft bearing with Installer 5063

and Handle C-4171 (Fig. 31).(3) Install anewaxle shaft seal with Installer

8694 and Handle C-4171.

(4) Lubricate seal lip with gear lubricant.

(5) Insert axle shaft through seal, bearing and

engage it into side gear splines. Push firmly on the

axle shaft to engage the snap-ring.

(6) Install axle shaft O-ring.

(7) Install skid plate, if necessary.

(8) Install half shaft.

PINION SEAL

REMOVAL

(1) Remove both half shafts.

(2) Remove front propeller shaft.

(3) Rotate pinion gear three or four times and ver-

ify pinion rotates smoothly.

(4) Record pinion rotating torque with an inch

pound torque wrench, for installation reference (Fig.

32).

(5) Position Holder 6719 against the companion

flange and install a four bolts and washers into the

threaded holes and tighten the bolts.

(6) Remove pinion nut.

(7) Remove companion flange with Remover C-452

(Fig. 33).

(8) Remove pinion seal with a pry tool or a slide

hammer mounted screw.

Fig. 30 BEARING REMOVER CUP

1 - REMOVER CUP

2 - BEARING

3 - NUT

Fig. 31 BEARING INSTALLER

1 - INSTALLER

2 - HANDLE

Fig. 32 PINION ROTATING TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCH

3 - 44 FRONT AXLE - C205FDR

AXLE BEARINGS (Continued)

Page 126 of 2627

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal.

(2) Install seal with Installer 8695 and Handle

C-4171 (Fig. 34).

(3) Install companion flange onto the pinion with

Installer C-3718 and Holder 6719A.

(4) Position holder against the companion flange

and install four bolts and washers into the threaded

holes. Tighten the bolt and washer so that the holder

is held to the flange.

(5) Install anewpinion nut onto the pinion shaft

and tighten the pinion nut until there is zero bearing

end-play (Fig. 35).CAUTION: Do not exceed 271 N´m (200 ft. lbs.) the

minimum tightening torque when installing the

companion flange at this point. Failure to heed cau-

tion may result in damage.

CAUTION: Never loosen pinion nut to decrease pin-

ion bearing rotating torque and never exceed spec-

ified preload torque. Failure to heed caution may

result in damage.

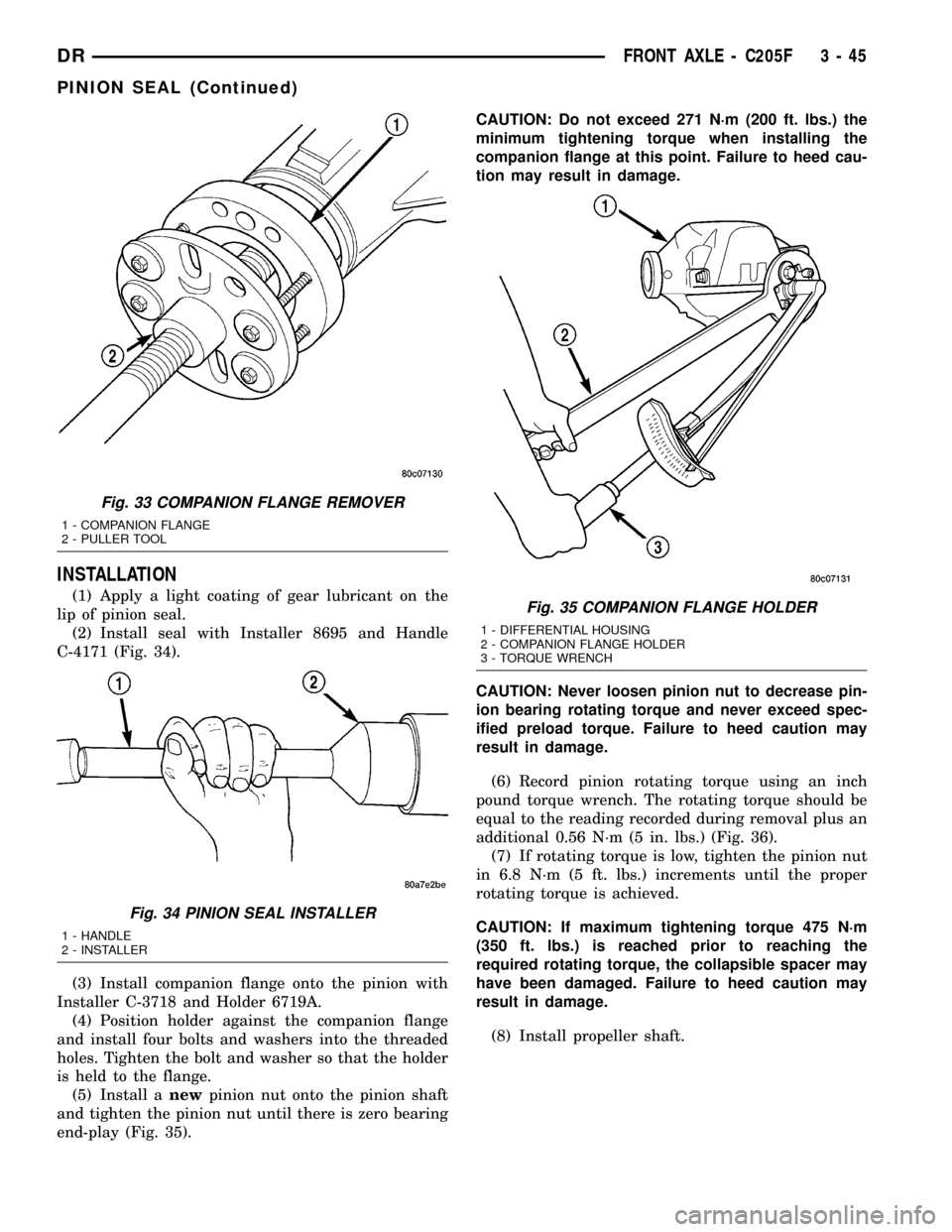

(6) Record pinion rotating torque using an inch

pound torque wrench. The rotating torque should be

equal to the reading recorded during removal plus an

additional 0.56 N´m (5 in. lbs.) (Fig. 36).

(7) If rotating torque is low, tighten the pinion nut

in 6.8 N´m (5 ft. lbs.) increments until the proper

rotating torque is achieved.

CAUTION: If maximum tightening torque 475 N´m

(350 ft. lbs.) is reached prior to reaching the

required rotating torque, the collapsible spacer may

have been damaged. Failure to heed caution may

result in damage.

(8) Install propeller shaft.

Fig. 33 COMPANION FLANGE REMOVER

1 - COMPANION FLANGE

2 - PULLER TOOL

Fig. 34 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 35 COMPANION FLANGE HOLDER

1 - DIFFERENTIAL HOUSING

2 - COMPANION FLANGE HOLDER

3 - TORQUE WRENCH

DRFRONT AXLE - C205F 3 - 45

PINION SEAL (Continued)

Page 127 of 2627

DIFFERENTIAL

REMOVAL

(1) Remove differential housing cover and drain

fluid.

(2) Remove axle shafts.

(3) Loosen bearing cap bolts.

NOTE: Differential bearing cap reference numbers

are stamped on caps and machined flat on the

housing. If reference numbers cannot be found,

make new marks for later reference.

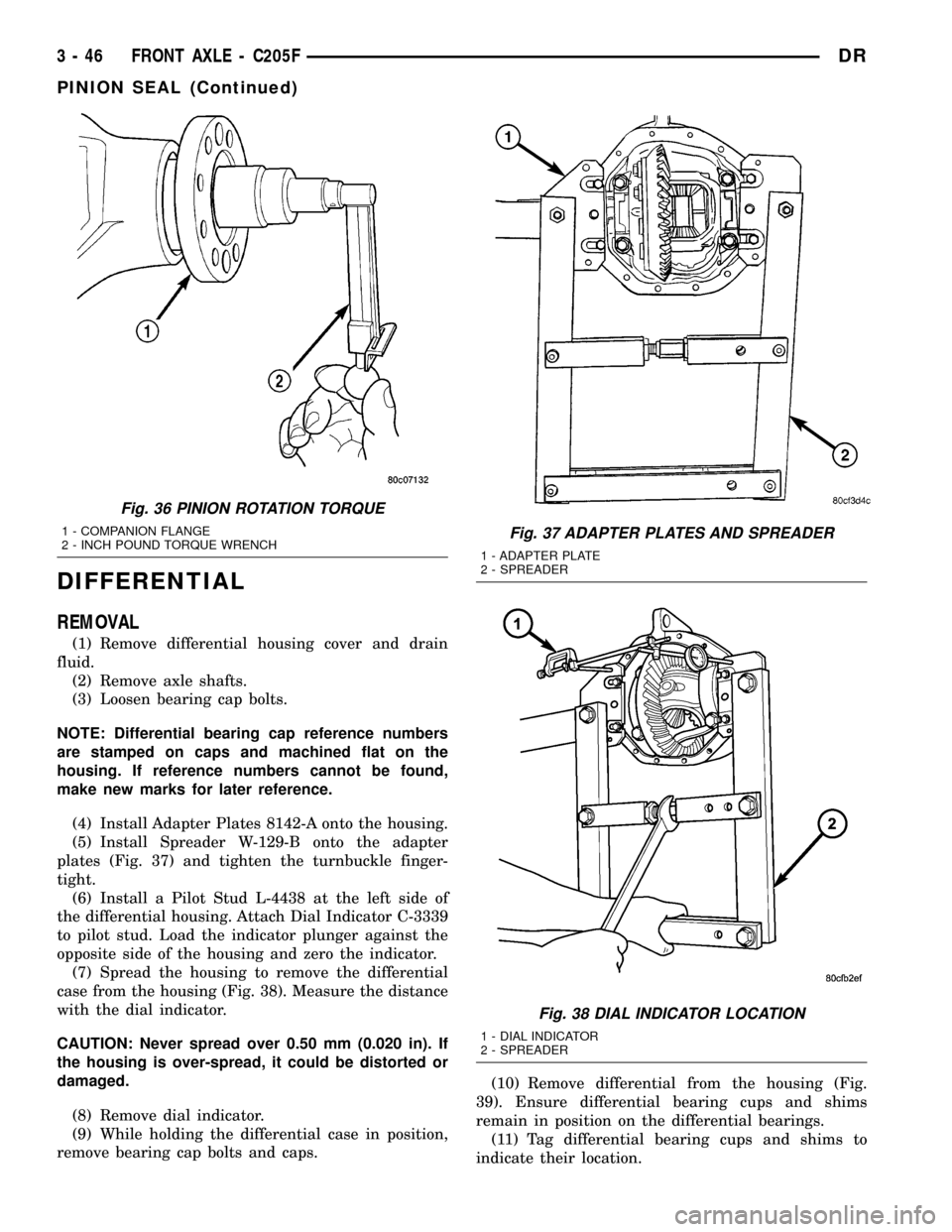

(4) Install Adapter Plates 8142-A onto the housing.

(5) Install Spreader W-129-B onto the adapter

plates (Fig. 37) and tighten the turnbuckle finger-

tight.

(6) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(7) Spread the housing to remove the differential

case from the housing (Fig. 38). Measure the distance

with the dial indicator.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(8) Remove dial indicator.

(9) While holding the differential case in position,

remove bearing cap bolts and caps.(10) Remove differential from the housing (Fig.

39). Ensure differential bearing cups and shims

remain in position on the differential bearings.

(11) Tag differential bearing cups and shims to

indicate their location.

Fig. 36 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCHFig. 37 ADAPTER PLATES AND SPREADER

1 - ADAPTER PLATE

2 - SPREADER

Fig. 38 DIAL INDICATOR LOCATION

1 - DIAL INDICATOR

2 - SPREADER

3 - 46 FRONT AXLE - C205FDR

PINION SEAL (Continued)