DODGE RAM 1500 1998 2.G Workshop Manual

Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2341 of 2627

HOOD

TABLE OF CONTENTS

page page

HINGE

REMOVAL.............................46

INSTALLATION.........................46

HOOD

REMOVAL.............................46

INSTALLATION.........................47

LATCH

REMOVAL.............................47

INSTALLATION.........................47LATCH RELEASE CABLE/HANDLE ASSEMBLY

REMOVAL.............................47

INSTALLATION.........................47

LATCH STRIKER / SECONDARY CATCH

REMOVAL.............................47

INSTALLATION.........................48

SUPPORT CYLINDER

REMOVAL.............................48

INSTALLATION.........................48

HINGE

REMOVAL

NOTE: It is not necessary to remove the hood to

replace one or both hinges. The hinges can be

replaced one at a time.

(1) Remove the cowl grille. (Refer to 23 - BODY/

EXTERIOR/COWL GRILLE - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

position of the hinge on the hood.

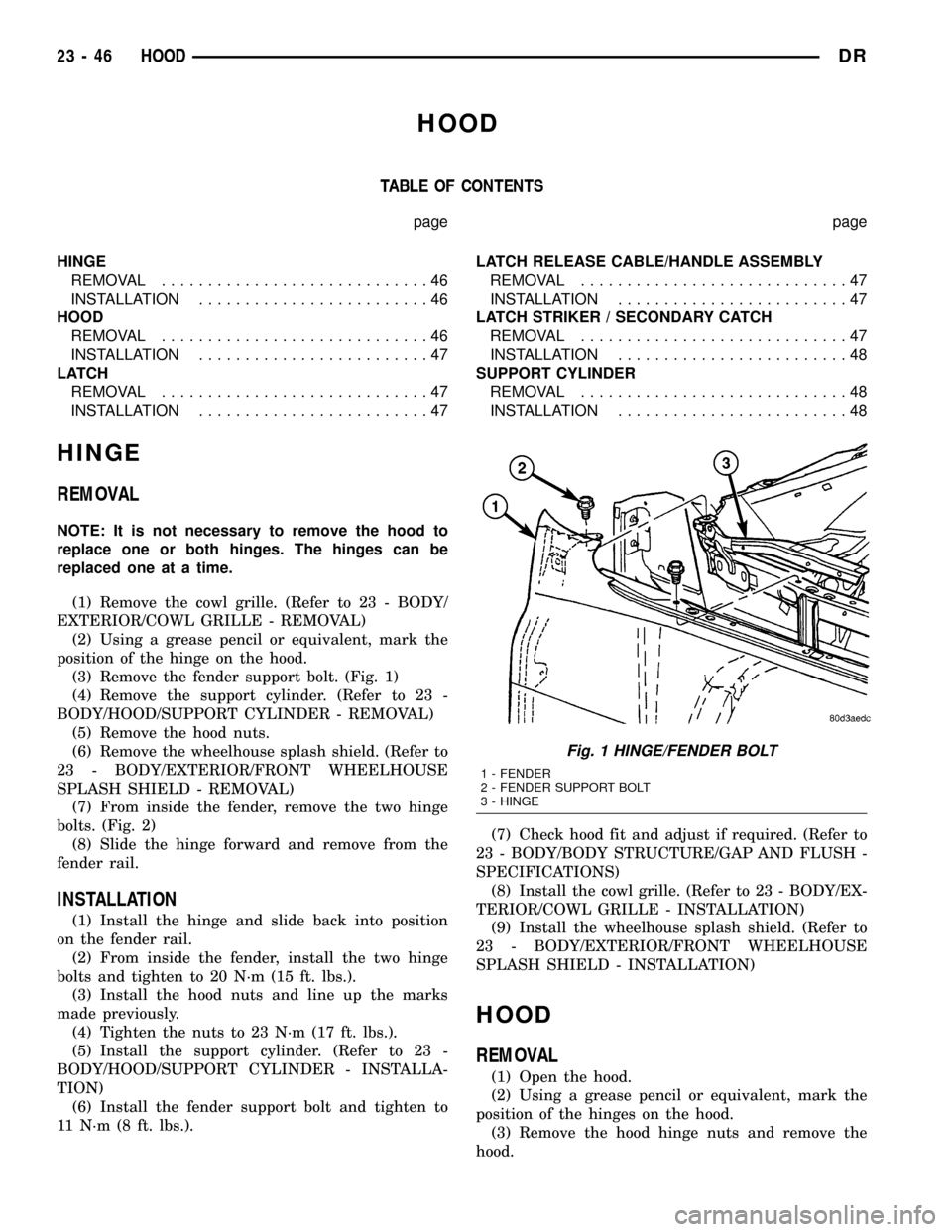

(3) Remove the fender support bolt. (Fig. 1)

(4) Remove the support cylinder. (Refer to 23 -

BODY/HOOD/SUPPORT CYLINDER - REMOVAL)

(5) Remove the hood nuts.

(6) Remove the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - REMOVAL)

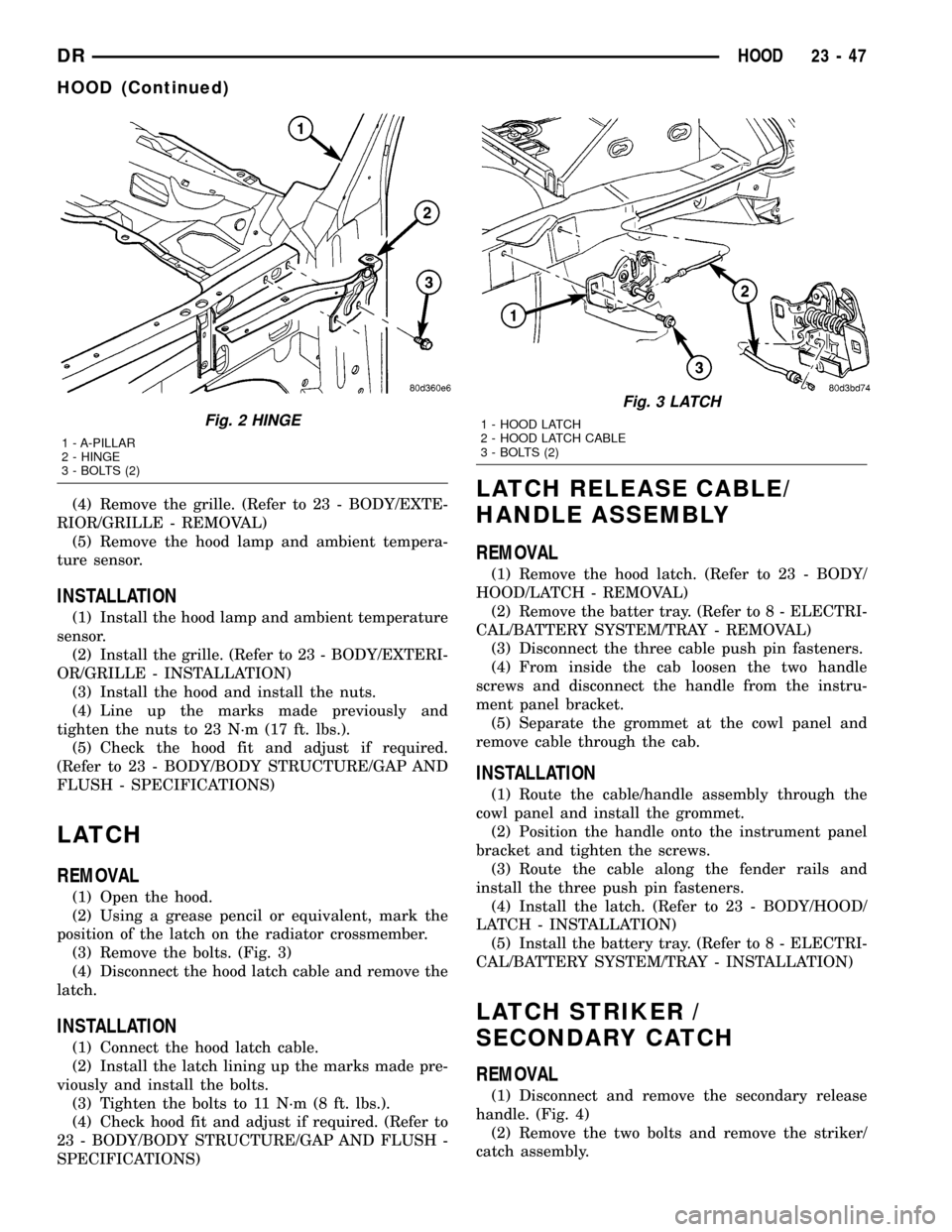

(7) From inside the fender, remove the two hinge

bolts. (Fig. 2)

(8) Slide the hinge forward and remove from the

fender rail.

INSTALLATION

(1) Install the hinge and slide back into position

on the fender rail.

(2) From inside the fender, install the two hinge

bolts and tighten to 20 N´m (15 ft. lbs.).

(3) Install the hood nuts and line up the marks

made previously.

(4) Tighten the nuts to 23 N´m (17 ft. lbs.).

(5) Install the support cylinder. (Refer to 23 -

BODY/HOOD/SUPPORT CYLINDER - INSTALLA-

TION)

(6) Install the fender support bolt and tighten to

11 N´m (8 ft. lbs.).(7) Check hood fit and adjust if required. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

(8) Install the cowl grille. (Refer to 23 - BODY/EX-

TERIOR/COWL GRILLE - INSTALLATION)

(9) Install the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - INSTALLATION)

HOOD

REMOVAL

(1) Open the hood.

(2) Using a grease pencil or equivalent, mark the

position of the hinges on the hood.

(3) Remove the hood hinge nuts and remove the

hood.

Fig. 1 HINGE/FENDER BOLT

1 - FENDER

2 - FENDER SUPPORT BOLT

3 - HINGE

23 - 46 HOODDR

Page 2342 of 2627

(4) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(5) Remove the hood lamp and ambient tempera-

ture sensor.

INSTALLATION

(1) Install the hood lamp and ambient temperature

sensor.

(2) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

(3) Install the hood and install the nuts.

(4) Line up the marks made previously and

tighten the nuts to 23 N´m (17 ft. lbs.).

(5) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

LATCH

REMOVAL

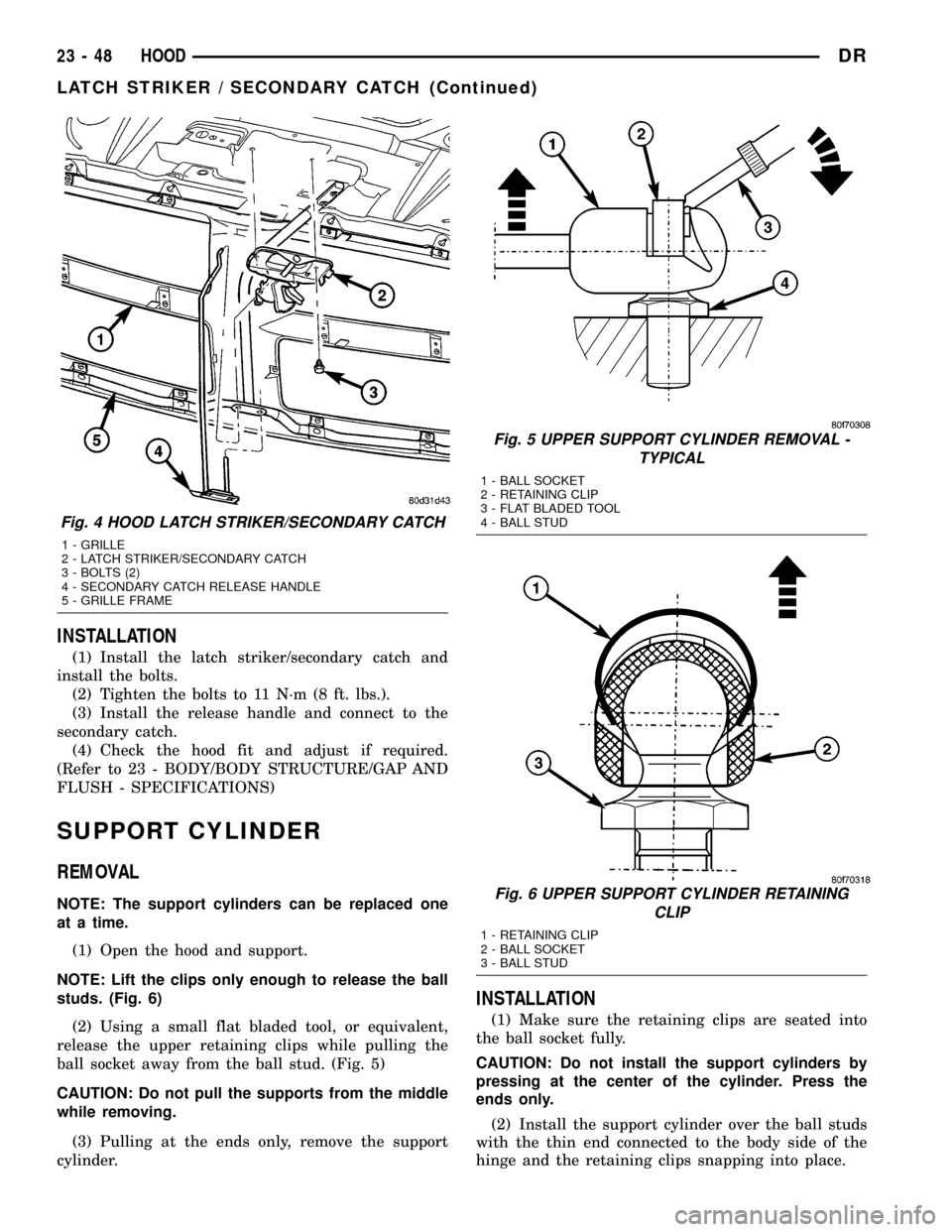

(1) Open the hood.

(2) Using a grease pencil or equivalent, mark the

position of the latch on the radiator crossmember.

(3) Remove the bolts. (Fig. 3)

(4) Disconnect the hood latch cable and remove the

latch.

INSTALLATION

(1) Connect the hood latch cable.

(2) Install the latch lining up the marks made pre-

viously and install the bolts.

(3) Tighten the bolts to 11 N´m (8 ft. lbs.).

(4) Check hood fit and adjust if required. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

LATCH RELEASE CABLE/

HANDLE ASSEMBLY

REMOVAL

(1) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)

(2) Remove the batter tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL)

(3) Disconnect the three cable push pin fasteners.

(4) From inside the cab loosen the two handle

screws and disconnect the handle from the instru-

ment panel bracket.

(5) Separate the grommet at the cowl panel and

remove cable through the cab.

INSTALLATION

(1) Route the cable/handle assembly through the

cowl panel and install the grommet.

(2) Position the handle onto the instrument panel

bracket and tighten the screws.

(3) Route the cable along the fender rails and

install the three push pin fasteners.

(4) Install the latch. (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION)

(5) Install the battery tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION)

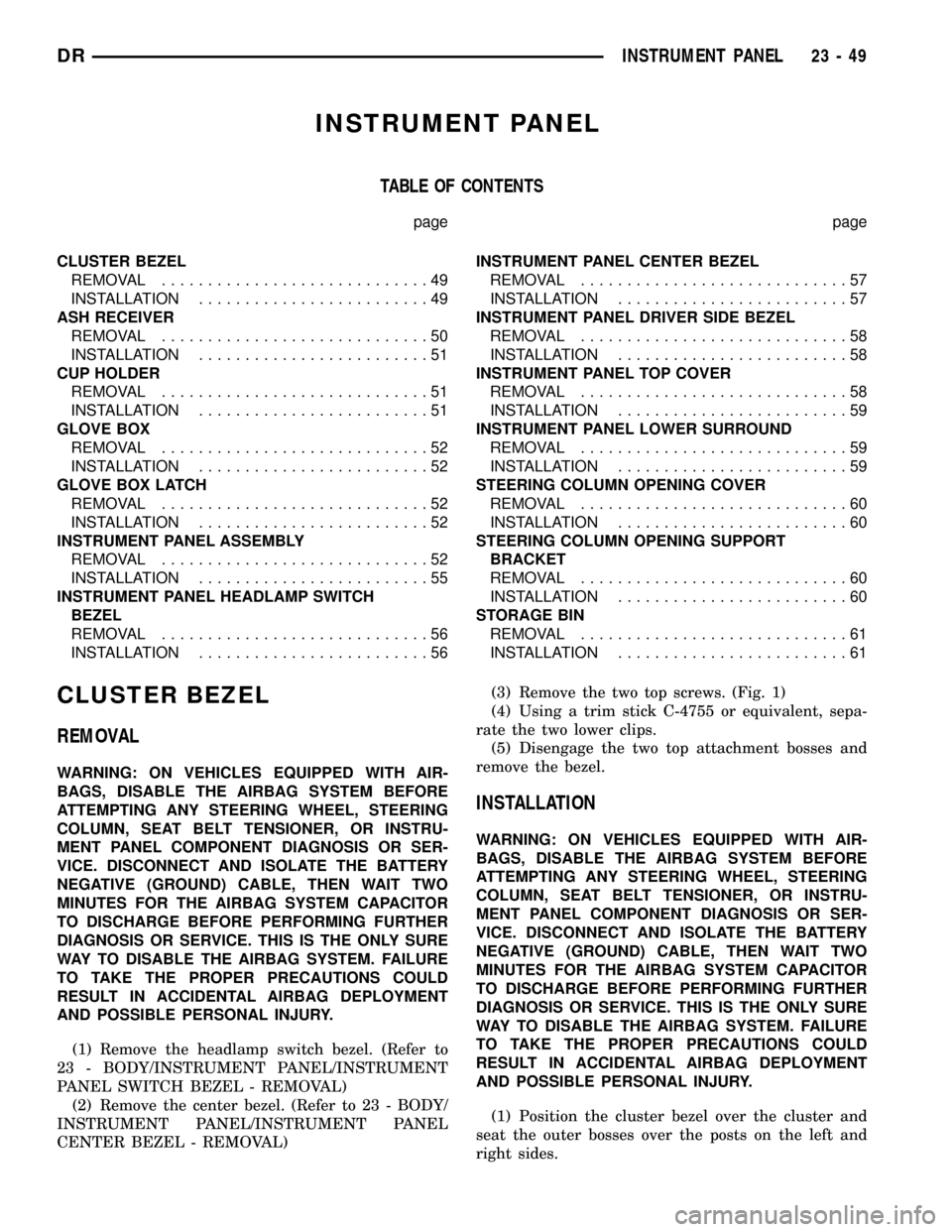

LATCH STRIKER /

SECONDARY CATCH

REMOVAL

(1) Disconnect and remove the secondary release

handle. (Fig. 4)

(2) Remove the two bolts and remove the striker/

catch assembly.

Fig. 2 HINGE

1 - A-PILLAR

2 - HINGE

3 - BOLTS (2)

Fig. 3 LATCH

1 - HOOD LATCH

2 - HOOD LATCH CABLE

3 - BOLTS (2)

DRHOOD 23 - 47

HOOD (Continued)

Page 2343 of 2627

INSTALLATION

(1) Install the latch striker/secondary catch and

install the bolts.

(2) Tighten the bolts to 11 N´m (8 ft. lbs.).

(3) Install the release handle and connect to the

secondary catch.

(4) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

SUPPORT CYLINDER

REMOVAL

NOTE: The support cylinders can be replaced one

at a time.

(1) Open the hood and support.

NOTE: Lift the clips only enough to release the ball

studs. (Fig. 6)

(2) Using a small flat bladed tool, or equivalent,

release the upper retaining clips while pulling the

ball socket away from the ball stud. (Fig. 5)

CAUTION: Do not pull the supports from the middle

while removing.

(3) Pulling at the ends only, remove the support

cylinder.

INSTALLATION

(1) Make sure the retaining clips are seated into

the ball socket fully.

CAUTION: Do not install the support cylinders by

pressing at the center of the cylinder. Press the

ends only.

(2) Install the support cylinder over the ball studs

with the thin end connected to the body side of the

hinge and the retaining clips snapping into place.

Fig. 4 HOOD LATCH STRIKER/SECONDARY CATCH

1 - GRILLE

2 - LATCH STRIKER/SECONDARY CATCH

3 - BOLTS (2)

4 - SECONDARY CATCH RELEASE HANDLE

5 - GRILLE FRAME

Fig. 5 UPPER SUPPORT CYLINDER REMOVAL -

TYPICAL

1 - BALL SOCKET

2 - RETAINING CLIP

3 - FLAT BLADED TOOL

4 - BALL STUD

Fig. 6 UPPER SUPPORT CYLINDER RETAINING

CLIP

1 - RETAINING CLIP

2 - BALL SOCKET

3 - BALL STUD

23 - 48 HOODDR

LATCH STRIKER / SECONDARY CATCH (Continued)

Page 2344 of 2627

INSTRUMENT PANEL

TABLE OF CONTENTS

page page

CLUSTER BEZEL

REMOVAL.............................49

INSTALLATION.........................49

ASH RECEIVER

REMOVAL.............................50

INSTALLATION.........................51

CUP HOLDER

REMOVAL.............................51

INSTALLATION.........................51

GLOVE BOX

REMOVAL.............................52

INSTALLATION.........................52

GLOVE BOX LATCH

REMOVAL.............................52

INSTALLATION.........................52

INSTRUMENT PANEL ASSEMBLY

REMOVAL.............................52

INSTALLATION.........................55

INSTRUMENT PANEL HEADLAMP SWITCH

BEZEL

REMOVAL.............................56

INSTALLATION.........................56INSTRUMENT PANEL CENTER BEZEL

REMOVAL.............................57

INSTALLATION.........................57

INSTRUMENT PANEL DRIVER SIDE BEZEL

REMOVAL.............................58

INSTALLATION.........................58

INSTRUMENT PANEL TOP COVER

REMOVAL.............................58

INSTALLATION.........................59

INSTRUMENT PANEL LOWER SURROUND

REMOVAL.............................59

INSTALLATION.........................59

STEERING COLUMN OPENING COVER

REMOVAL.............................60

INSTALLATION.........................60

STEERING COLUMN OPENING SUPPORT

BRACKET

REMOVAL.............................60

INSTALLATION.........................60

STORAGE BIN

REMOVAL.............................61

INSTALLATION.........................61

CLUSTER BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

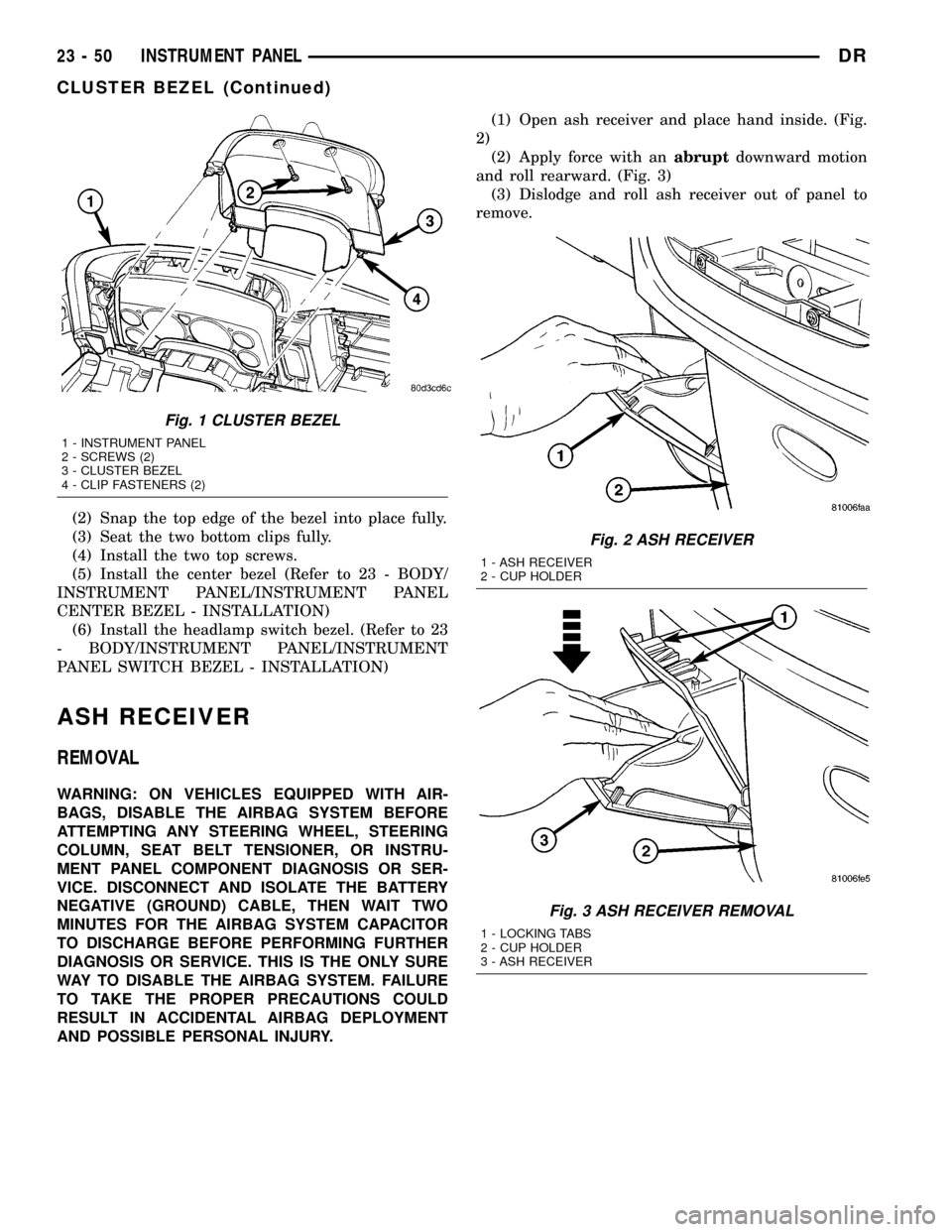

(1) Remove the headlamp switch bezel. (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SWITCH BEZEL - REMOVAL)

(2) Remove the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - REMOVAL)(3) Remove the two top screws. (Fig. 1)

(4) Using a trim stick C-4755 or equivalent, sepa-

rate the two lower clips.

(5) Disengage the two top attachment bosses and

remove the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the cluster bezel over the cluster and

seat the outer bosses over the posts on the left and

right sides.

DRINSTRUMENT PANEL 23 - 49

Page 2345 of 2627

(2) Snap the top edge of the bezel into place fully.

(3) Seat the two bottom clips fully.

(4) Install the two top screws.

(5) Install the center bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

(6) Install the headlamp switch bezel. (Refer to 23

- BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SWITCH BEZEL - INSTALLATION)

ASH RECEIVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

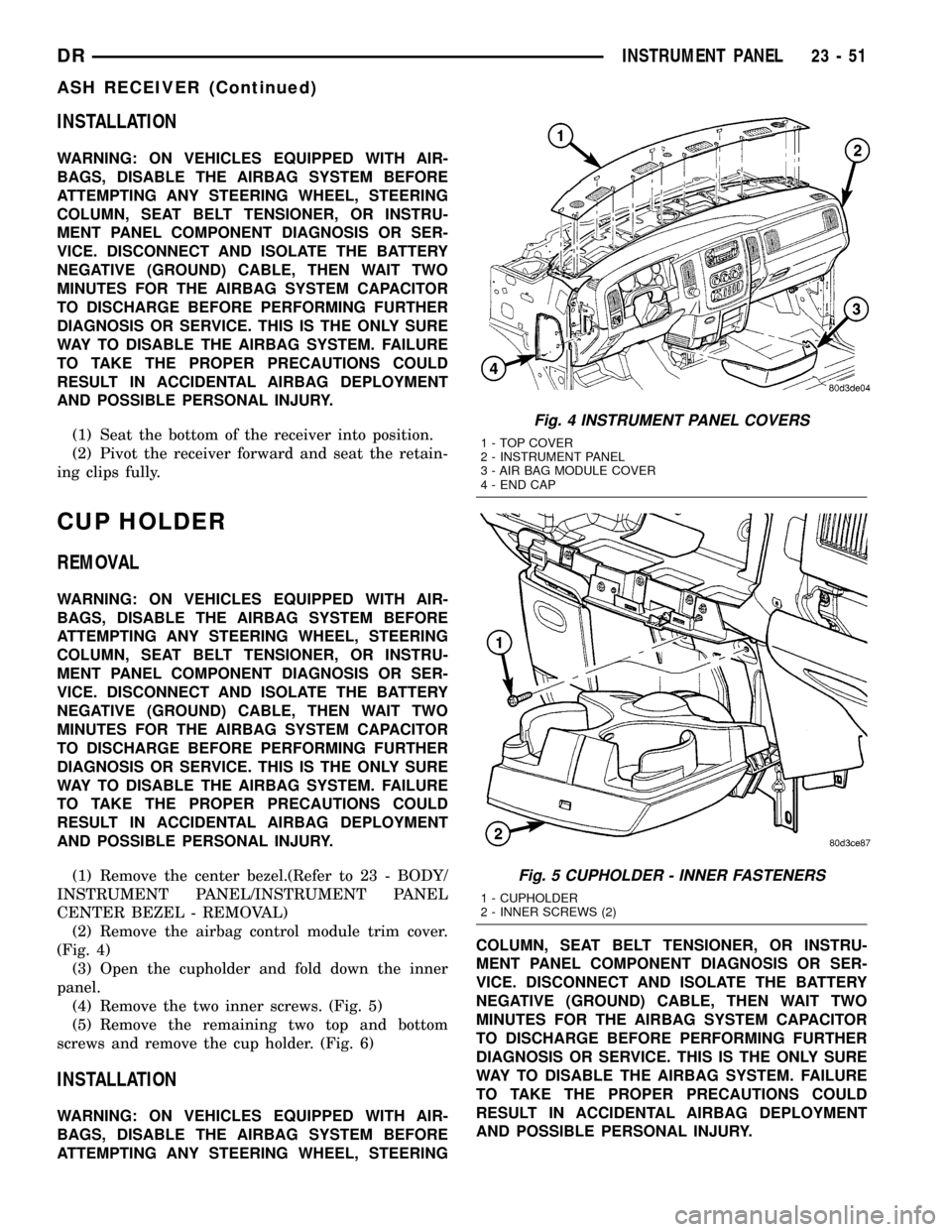

AND POSSIBLE PERSONAL INJURY.(1) Open ash receiver and place hand inside. (Fig.

2)

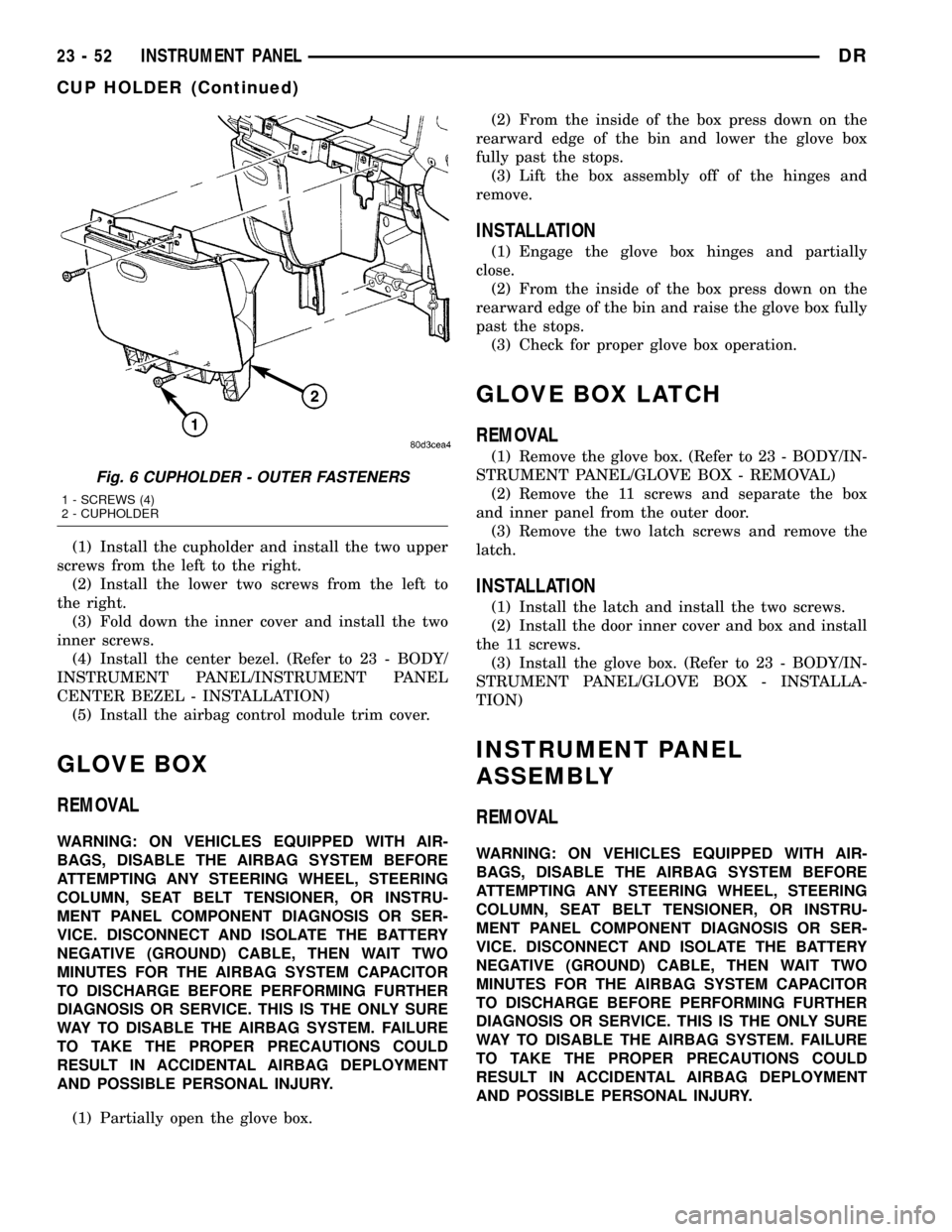

(2) Apply force with anabruptdownward motion

and roll rearward. (Fig. 3)

(3) Dislodge and roll ash receiver out of panel to

remove.

Fig. 1 CLUSTER BEZEL

1 - INSTRUMENT PANEL

2 - SCREWS (2)

3 - CLUSTER BEZEL

4 - CLIP FASTENERS (2)

Fig. 2 ASH RECEIVER

1 - ASH RECEIVER

2 - CUP HOLDER

Fig. 3 ASH RECEIVER REMOVAL

1 - LOCKING TABS

2 - CUP HOLDER

3 - ASH RECEIVER

23 - 50 INSTRUMENT PANELDR

CLUSTER BEZEL (Continued)

Page 2346 of 2627

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Seat the bottom of the receiver into position.

(2) Pivot the receiver forward and seat the retain-

ing clips fully.

CUP HOLDER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

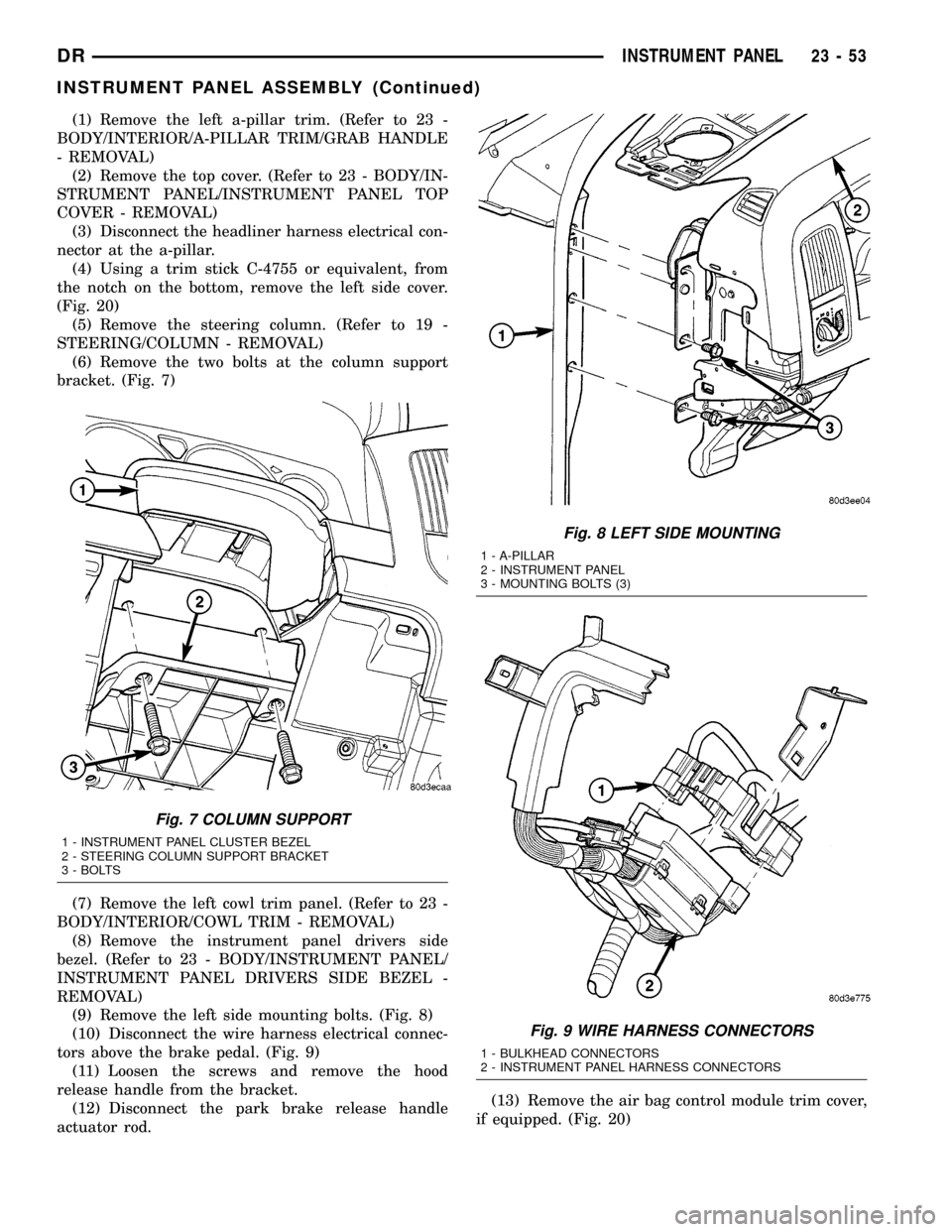

(1) Remove the center bezel.(Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - REMOVAL)

(2) Remove the airbag control module trim cover.

(Fig. 4)

(3) Open the cupholder and fold down the inner

panel.

(4) Remove the two inner screws. (Fig. 5)

(5) Remove the remaining two top and bottom

screws and remove the cup holder. (Fig. 6)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERINGCOLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Fig. 4 INSTRUMENT PANEL COVERS

1 - TOP COVER

2 - INSTRUMENT PANEL

3 - AIR BAG MODULE COVER

4 - END CAP

Fig. 5 CUPHOLDER - INNER FASTENERS

1 - CUPHOLDER

2 - INNER SCREWS (2)

DRINSTRUMENT PANEL 23 - 51

ASH RECEIVER (Continued)

Page 2347 of 2627

(1) Install the cupholder and install the two upper

screws from the left to the right.

(2) Install the lower two screws from the left to

the right.

(3) Fold down the inner cover and install the two

inner screws.

(4) Install the center bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

CENTER BEZEL - INSTALLATION)

(5) Install the airbag control module trim cover.

GLOVE BOX

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Partially open the glove box.(2) From the inside of the box press down on the

rearward edge of the bin and lower the glove box

fully past the stops.

(3) Lift the box assembly off of the hinges and

remove.

INSTALLATION

(1) Engage the glove box hinges and partially

close.

(2) From the inside of the box press down on the

rearward edge of the bin and raise the glove box fully

past the stops.

(3) Check for proper glove box operation.

GLOVE BOX LATCH

REMOVAL

(1) Remove the glove box. (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL)

(2) Remove the 11 screws and separate the box

and inner panel from the outer door.

(3) Remove the two latch screws and remove the

latch.

INSTALLATION

(1) Install the latch and install the two screws.

(2) Install the door inner cover and box and install

the 11 screws.

(3) Install the glove box. (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION)

INSTRUMENT PANEL

ASSEMBLY

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Fig. 6 CUPHOLDER - OUTER FASTENERS

1 - SCREWS (4)

2 - CUPHOLDER

23 - 52 INSTRUMENT PANELDR

CUP HOLDER (Continued)

Page 2348 of 2627

(1) Remove the left a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM/GRAB HANDLE

- REMOVAL)

(2) Remove the top cover. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL TOP

COVER - REMOVAL)

(3) Disconnect the headliner harness electrical con-

nector at the a-pillar.

(4) Using a trim stick C-4755 or equivalent, from

the notch on the bottom, remove the left side cover.

(Fig. 20)

(5) Remove the steering column. (Refer to 19 -

STEERING/COLUMN - REMOVAL)

(6) Remove the two bolts at the column support

bracket. (Fig. 7)

(7) Remove the left cowl trim panel. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - REMOVAL)

(8) Remove the instrument panel drivers side

bezel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL DRIVERS SIDE BEZEL -

REMOVAL)

(9) Remove the left side mounting bolts. (Fig. 8)

(10) Disconnect the wire harness electrical connec-

tors above the brake pedal. (Fig. 9)

(11) Loosen the screws and remove the hood

release handle from the bracket.

(12) Disconnect the park brake release handle

actuator rod.(13) Remove the air bag control module trim cover,

if equipped. (Fig. 20)

Fig. 7 COLUMN SUPPORT

1 - INSTRUMENT PANEL CLUSTER BEZEL

2 - STEERING COLUMN SUPPORT BRACKET

3 - BOLTS

Fig. 8 LEFT SIDE MOUNTING

1 - A-PILLAR

2 - INSTRUMENT PANEL

3 - MOUNTING BOLTS (3)

Fig. 9 WIRE HARNESS CONNECTORS

1 - BULKHEAD CONNECTORS

2 - INSTRUMENT PANEL HARNESS CONNECTORS

DRINSTRUMENT PANEL 23 - 53

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2349 of 2627

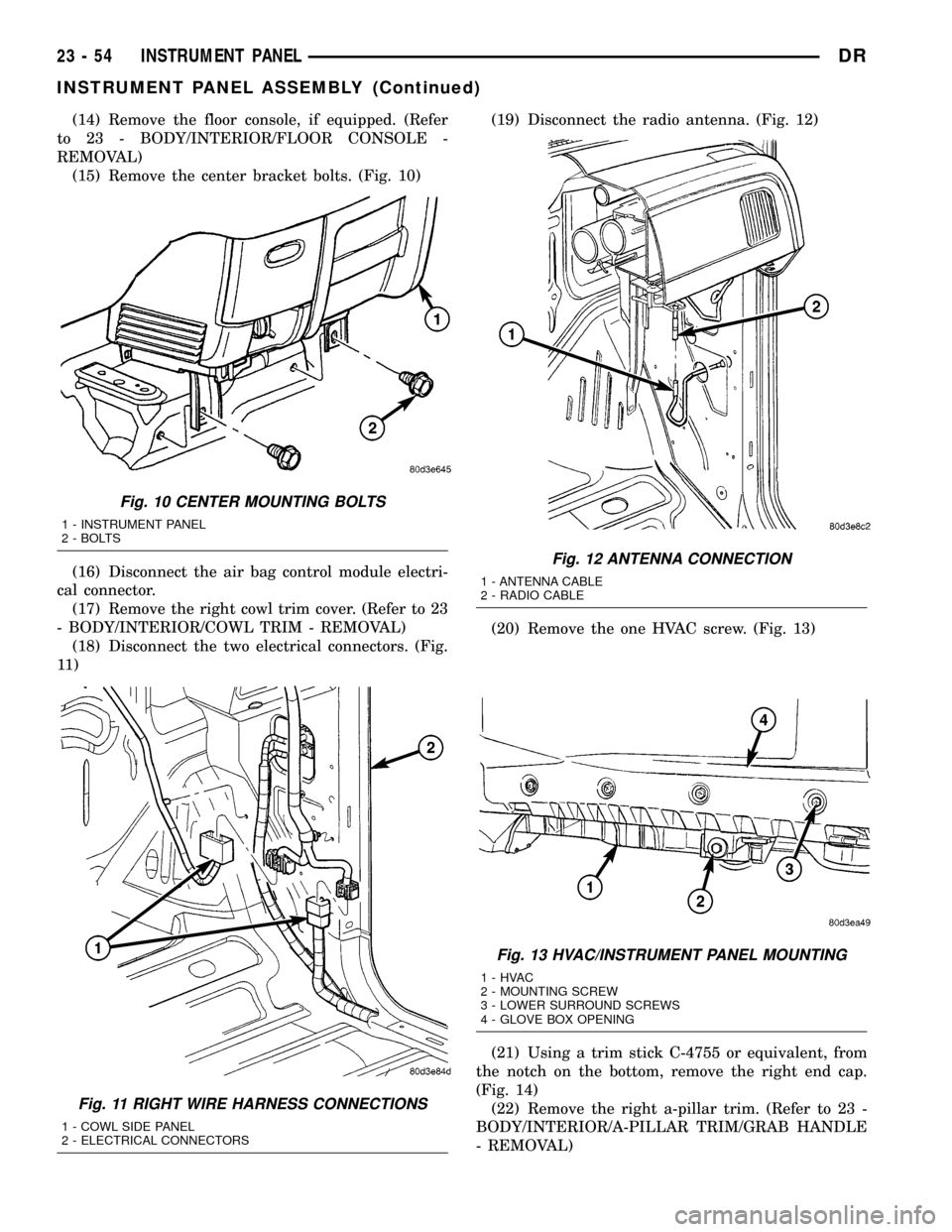

(14) Remove the floor console, if equipped. (Refer

to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(15) Remove the center bracket bolts. (Fig. 10)

(16) Disconnect the air bag control module electri-

cal connector.

(17) Remove the right cowl trim cover. (Refer to 23

- BODY/INTERIOR/COWL TRIM - REMOVAL)

(18) Disconnect the two electrical connectors. (Fig.

11 )(19) Disconnect the radio antenna. (Fig. 12)

(20) Remove the one HVAC screw. (Fig. 13)

(21) Using a trim stick C-4755 or equivalent, from

the notch on the bottom, remove the right end cap.

(Fig. 14)

(22) Remove the right a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM/GRAB HANDLE

- REMOVAL)

Fig. 10 CENTER MOUNTING BOLTS

1 - INSTRUMENT PANEL

2 - BOLTS

Fig. 11 RIGHT WIRE HARNESS CONNECTIONS

1 - COWL SIDE PANEL

2 - ELECTRICAL CONNECTORS

Fig. 12 ANTENNA CONNECTION

1 - ANTENNA CABLE

2 - RADIO CABLE

Fig. 13 HVAC/INSTRUMENT PANEL MOUNTING

1-HVAC

2 - MOUNTING SCREW

3 - LOWER SURROUND SCREWS

4 - GLOVE BOX OPENING

23 - 54 INSTRUMENT PANELDR

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2350 of 2627

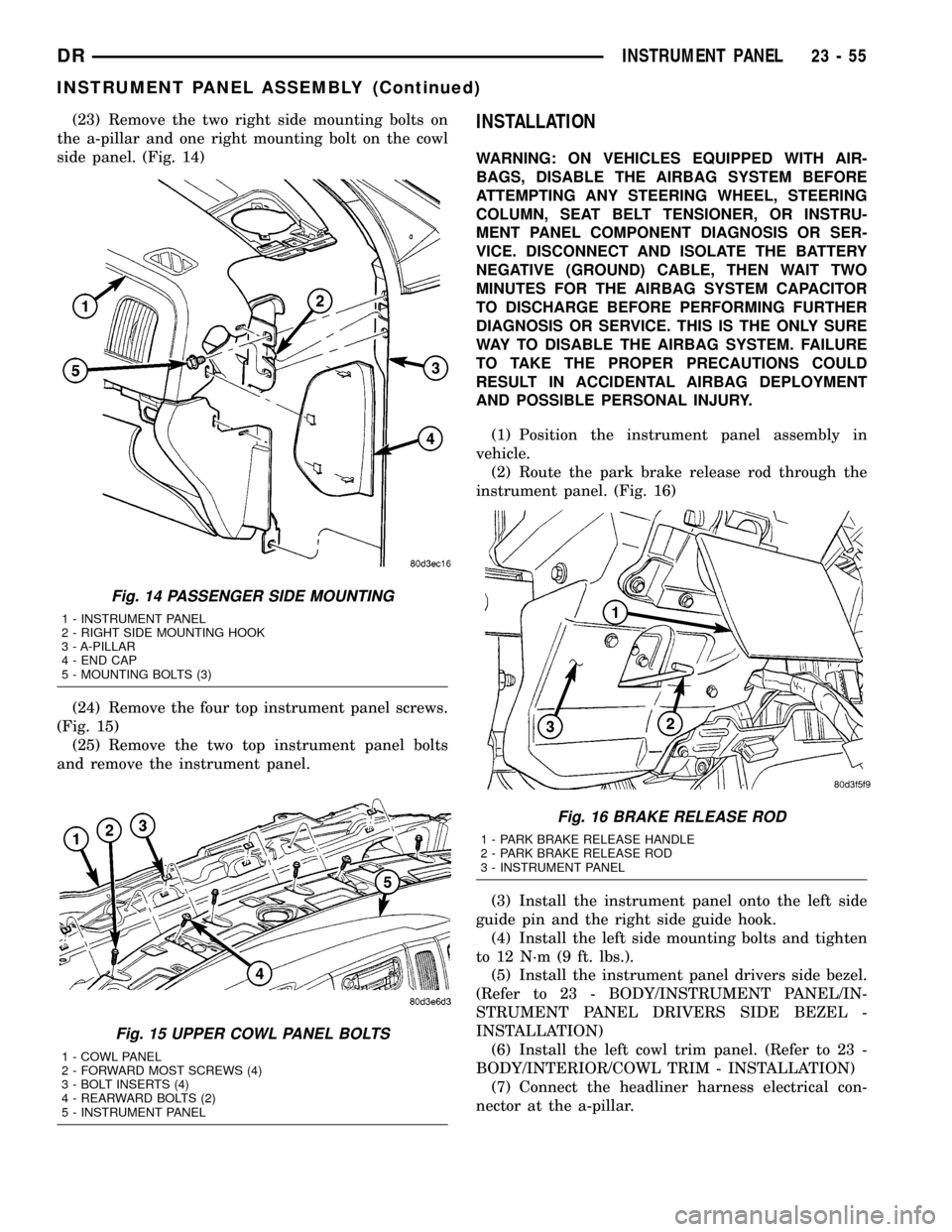

(23) Remove the two right side mounting bolts on

the a-pillar and one right mounting bolt on the cowl

side panel. (Fig. 14)

(24) Remove the four top instrument panel screws.

(Fig. 15)

(25) Remove the two top instrument panel bolts

and remove the instrument panel.INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the instrument panel assembly in

vehicle.

(2) Route the park brake release rod through the

instrument panel. (Fig. 16)

(3) Install the instrument panel onto the left side

guide pin and the right side guide hook.

(4) Install the left side mounting bolts and tighten

to 12 N´m (9 ft. lbs.).

(5) Install the instrument panel drivers side bezel.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL DRIVERS SIDE BEZEL -

INSTALLATION)

(6) Install the left cowl trim panel. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(7) Connect the headliner harness electrical con-

nector at the a-pillar.

Fig. 14 PASSENGER SIDE MOUNTING

1 - INSTRUMENT PANEL

2 - RIGHT SIDE MOUNTING HOOK

3 - A-PILLAR

4 - END CAP

5 - MOUNTING BOLTS (3)

Fig. 15 UPPER COWL PANEL BOLTS

1 - COWL PANEL

2 - FORWARD MOST SCREWS (4)

3 - BOLT INSERTS (4)

4 - REARWARD BOLTS (2)

5 - INSTRUMENT PANEL

Fig. 16 BRAKE RELEASE ROD

1 - PARK BRAKE RELEASE HANDLE

2 - PARK BRAKE RELEASE ROD

3 - INSTRUMENT PANEL

DRINSTRUMENT PANEL 23 - 55

INSTRUMENT PANEL ASSEMBLY (Continued)