Reverse DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 617 of 2627

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WINDOW MOTOR

REMOVAL

The window motor is serviced with the window

regulator (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL).

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

junction block. If all of the LEDs are inoperative in

both the power window and lock switch units and the

power windows are inoperative, (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS - DIAGNOSIS AND

TESTING). If the power windows operate, but any or

all of the LEDs are inoperative, the power window

and lock switch units with the inoperative LED(s) is

faulty and must be replaced. For complete circuit dia-

grams, refer to the appropriate wiring information.

(1) Check the fuse in the Integrated Power Module

(IPM) and the circuit breaker located near the park

brake pedal. If OK, go to Step 2. If not OK, replace

the faulty fuse or circuit breaker.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the Inte-

grated Power Module (IPM). If OK, turn the ignition

switch to the Off position and go to Step 3. If not OK,

check circuit breaker and repair the circuit to the

ignition switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window switch unit fromthe door trim panel (passenger doors). The drivers

door switch is included with the Driver Door Module

(Refer to 8 - ELECTRICAL/POWER LOCKS/DOOR

MODULE - DIAGNOSIS AND TESTING) for service

procedures. Unplug the wire harness connector from

the switch unit.

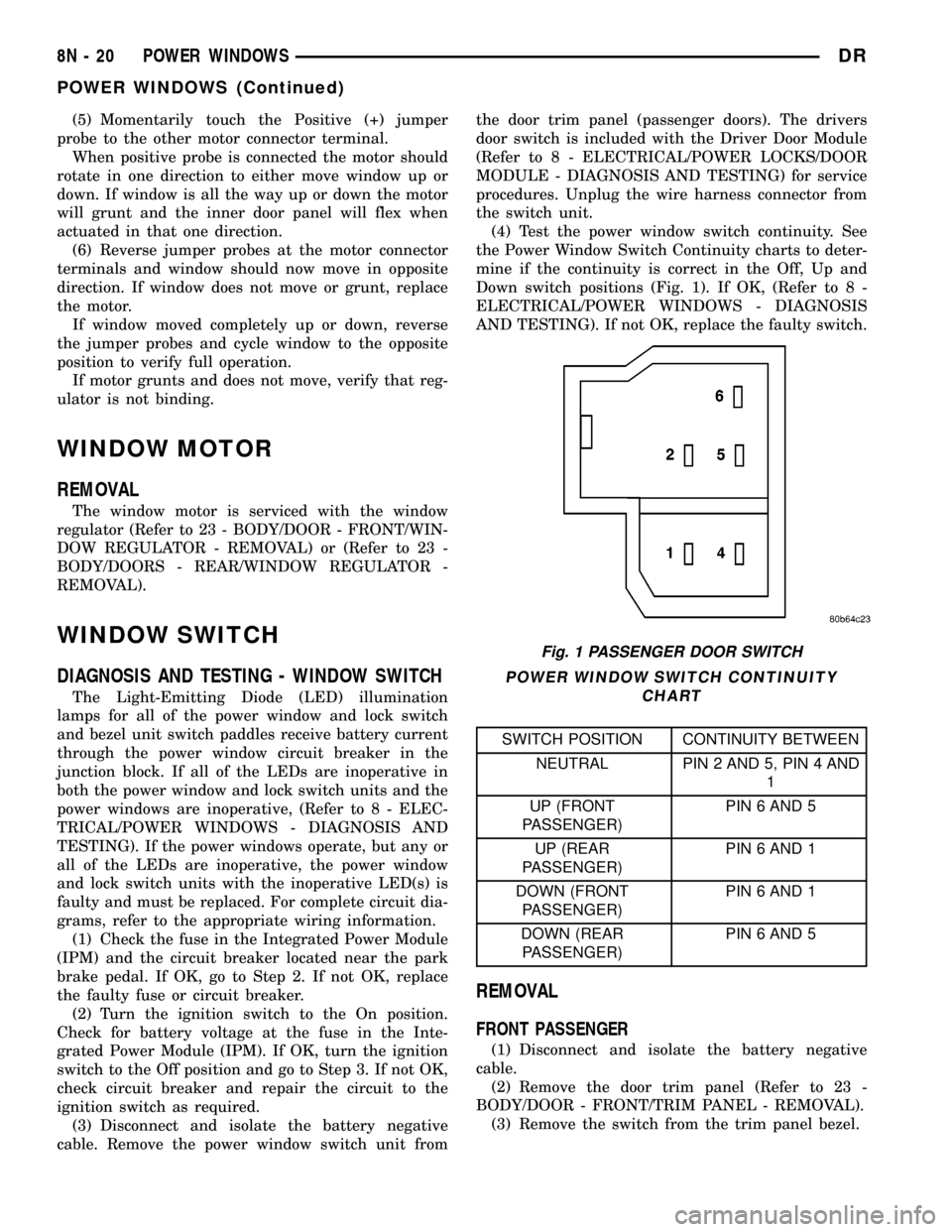

(4) Test the power window switch continuity. See

the Power Window Switch Continuity charts to deter-

mine if the continuity is correct in the Off, Up and

Down switch positions (Fig. 1). If OK, (Refer to 8 -

ELECTRICAL/POWER WINDOWS - DIAGNOSIS

AND TESTING). If not OK, replace the faulty switch.

POWER WINDOW SWITCH CONTINUITY

CHART

SWITCH POSITION CONTINUITY BETWEEN

NEUTRAL PIN 2 AND 5, PIN 4 AND

1

UP (FRONT

PASSENGER)PIN 6 AND 5

UP (REAR

PASSENGER)PIN 6 AND 1

DOWN (FRONT

PASSENGER)PIN 6 AND 1

DOWN (REAR

PASSENGER)PIN 6 AND 5

REMOVAL

FRONT PASSENGER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the switch from the trim panel bezel.

Fig. 1 PASSENGER DOOR SWITCH

8N - 20 POWER WINDOWSDR

POWER WINDOWS (Continued)

Page 1056 of 2627

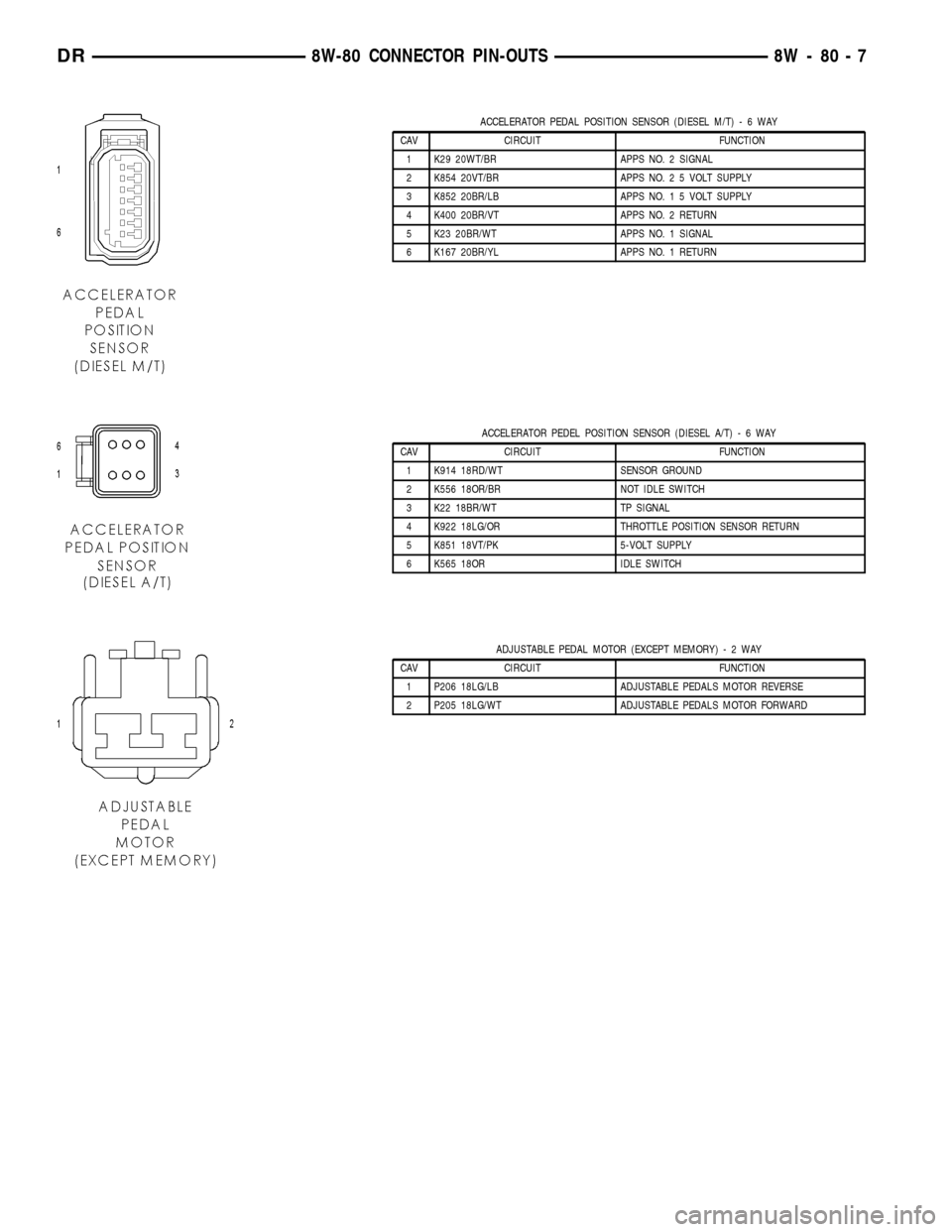

ACCELERATOR PEDAL POSITION SENSOR (DIESEL M/T)-6WAY

CAV CIRCUIT FUNCTION

1 K29 20WT/BR APPS NO. 2 SIGNAL

2 K854 20VT/BR APPS NO. 2 5 VOLT SUPPLY

3 K852 20BR/LB APPS NO. 1 5 VOLT SUPPLY

4 K400 20BR/VT APPS NO. 2 RETURN

5 K23 20BR/WT APPS NO. 1 SIGNAL

6 K167 20BR/YL APPS NO. 1 RETURN

ACCELERATOR PEDEL POSITION SENSOR (DIESEL A/T)-6WAY

CAV CIRCUIT FUNCTION

1 K914 18RD/WT SENSOR GROUND

2 K556 18OR/BR NOT IDLE SWITCH

3 K22 18BR/WT TP SIGNAL

4 K922 18LG/OR THROTTLE POSITION SENSOR RETURN

5 K851 18VT/PK 5-VOLT SUPPLY

6 K565 18OR IDLE SWITCH

ADJUSTABLE PEDAL MOTOR (EXCEPT MEMORY)-2WAY

CAV CIRCUIT FUNCTION

1 P206 18LG/LB ADJUSTABLE PEDALS MOTOR REVERSE

2 P205 18LG/WT ADJUSTABLE PEDALS MOTOR FORWARD

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 7

Page 1057 of 2627

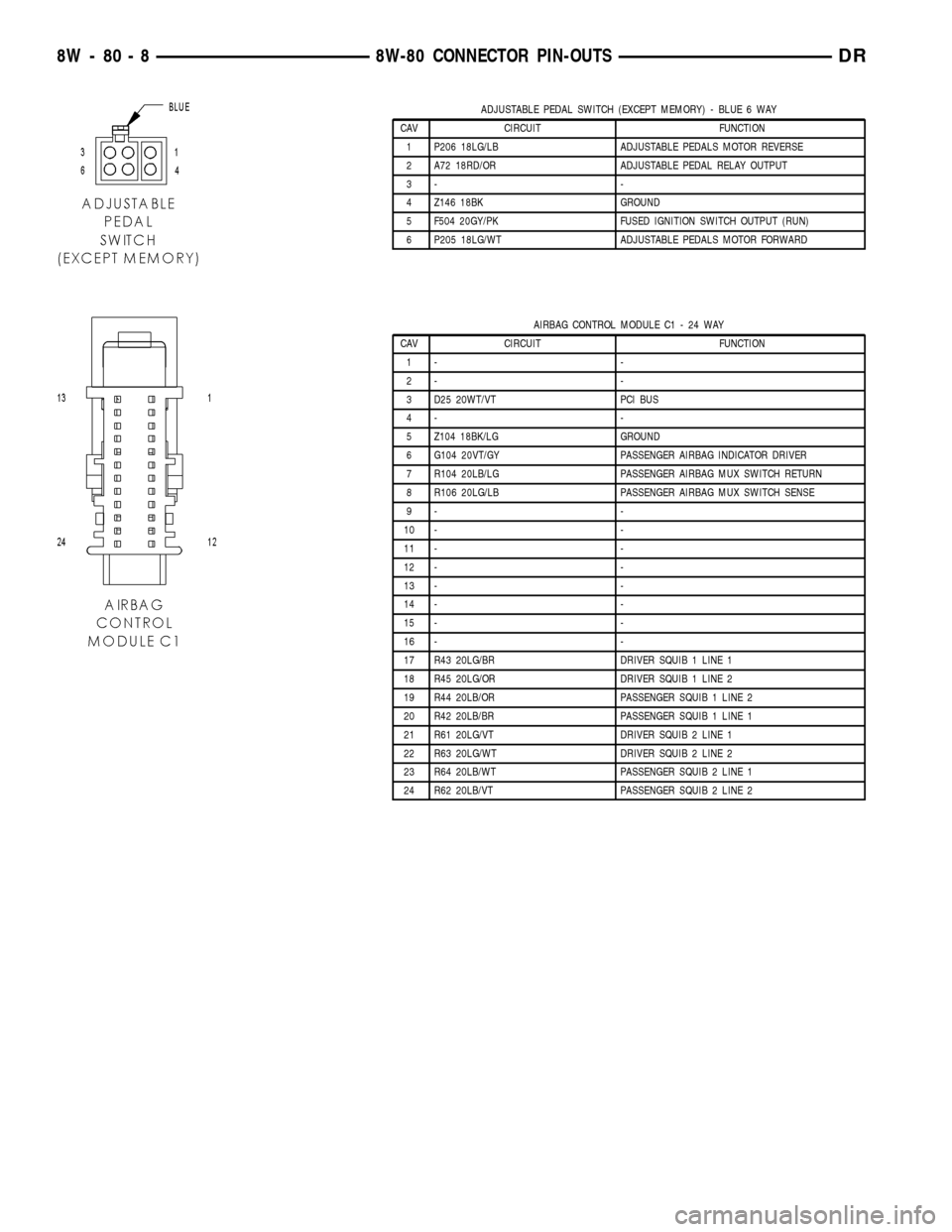

ADJUSTABLE PEDAL SWITCH (EXCEPT MEMORY) - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 P206 18LG/LB ADJUSTABLE PEDALS MOTOR REVERSE

2 A72 18RD/OR ADJUSTABLE PEDAL RELAY OUTPUT

3- -

4 Z146 18BK GROUND

5 F504 20GY/PK FUSED IGNITION SWITCH OUTPUT (RUN)

6 P205 18LG/WT ADJUSTABLE PEDALS MOTOR FORWARD

AIRBAG CONTROL MODULE C1 - 24 WAY

CAV CIRCUIT FUNCTION

1- -

2- -

3 D25 20WT/VT PCI BUS

4- -

5 Z104 18BK/LG GROUND

6 G104 20VT/GY PASSENGER AIRBAG INDICATOR DRIVER

7 R104 20LB/LG PASSENGER AIRBAG MUX SWITCH RETURN

8 R106 20LG/LB PASSENGER AIRBAG MUX SWITCH SENSE

9- -

10 - -

11 - -

12 - -

13 - -

14 - -

15 - -

16 - -

17 R43 20LG/BR DRIVER SQUIB 1 LINE 1

18 R45 20LG/OR DRIVER SQUIB 1 LINE 2

19 R44 20LB/OR PASSENGER SQUIB 1 LINE 2

20 R42 20LB/BR PASSENGER SQUIB 1 LINE 1

21 R61 20LG/VT DRIVER SQUIB 2 LINE 1

22 R63 20LG/WT DRIVER SQUIB 2 LINE 2

23 R64 20LB/WT PASSENGER SQUIB 2 LINE 1

24 R62 20LB/VT PASSENGER SQUIB 2 LINE 2

8W - 80 - 8 8W-80 CONNECTOR PIN-OUTSDR

Page 1140 of 2627

POWERTRAIN CONTROL MODULE C4 (NGC) - GREEN 38 WAY

CAV CIRCUIT FUNCTION

1 T60 18YL/GY OVERDRIVE SOLENOID CONTROL

2 T259 18YL/DG 4C SOLENOID CONTROL

3- -

4 T118 18DG MS SOLENOID CONTROL

5- -

6 T219 18YL/LG 2C SOLENOID CONTROL

7- -

8 T59 18YL/LB UNDERDRIVE SOLENOID CONTROL

9- -

10 T20 18DG/WT L/R SOLENOID CONTROL

11 T140 18YL/GY PRESSURE CONTROL SOLENOID CONTROL

12 Z908 18BK GROUND

13 Z977 18BK GROUND

14 Z904 18BK (A/T) GROUND

15 T1 18DG/LB TRS T1 SENSE

16 T3 18DG/DB TRS T3 SENSE

17 T6 18DG TOW/HAUL OVERDRIVE OFF SWITCH SENSE

18 T515 20YL/DB TRANSMISSION CONTROL RELAY CONTROL

19 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

20 T48 18BR/YL 4C PRESSURE SWITCH SENSE

21 T29 18YL/WT UNDERDRIVE PRESSURE SWITCH SENSE

22 T9 18DG/TN OVERDRIVE PRESSURE SWITCH SENSE

23 - -

24 - -

25 - -

26 T4 18DG/LB TRS T2 SENSE

27 - -

28 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

29 T50 18YL/TN LOW/REVERSE PRESSURE SWITCH SENSE

30 T147 18DG/YL 2C PRESSURE SWITCH SENSE

31 T38 18YL/BR LINE PRESSURE SENSOR SIGNAL

32 T14 18DG/BR OUTPUT SPEED SENSOR SIGNAL

33 T52 18DG/OR INPUT SPEED SENSOR SIGNAL

34 T13 18DG/VT SPEED SENSOR GROUND

35 T54 18DG/OR TRANSMISSION TEMPERATURE SENSOR SIGNAL

36 - -

37 T42 18DG/YL TRS T42 SENSE

38 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 91

Page 1151 of 2627

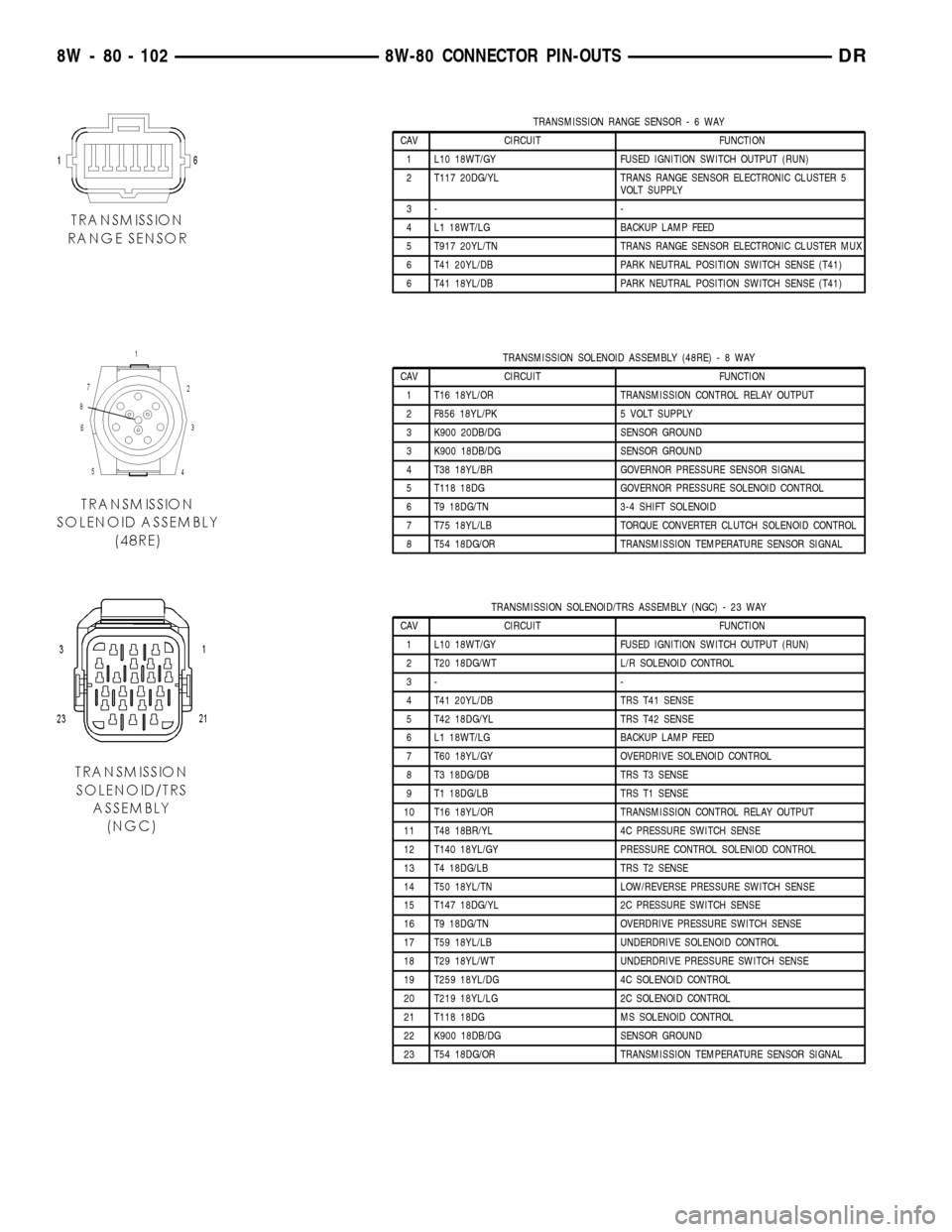

TRANSMISSION RANGE SENSOR-6WAY

CAV CIRCUIT FUNCTION

1 L10 18WT/GY FUSED IGNITION SWITCH OUTPUT (RUN)

2 T117 20DG/YL TRANS RANGE SENSOR ELECTRONIC CLUSTER 5

VOLT SUPPLY

3- -

4 L1 18WT/LG BACKUP LAMP FEED

5 T917 20YL/TN TRANS RANGE SENSOR ELECTRONIC CLUSTER MUX

6 T41 20YL/DB PARK NEUTRAL POSITION SWITCH SENSE (T41)

6 T41 18YL/DB PARK NEUTRAL POSITION SWITCH SENSE (T41)

TRANSMISSION SOLENOID ASSEMBLY (48RE)-8WAY

CAV CIRCUIT FUNCTION

1 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

2 F856 18YL/PK 5 VOLT SUPPLY

3 K900 20DB/DG SENSOR GROUND

3 K900 18DB/DG SENSOR GROUND

4 T38 18YL/BR GOVERNOR PRESSURE SENSOR SIGNAL

5 T118 18DG GOVERNOR PRESSURE SOLENOID CONTROL

6 T9 18DG/TN 3-4 SHIFT SOLENOID

7 T75 18YL/LB TORQUE CONVERTER CLUTCH SOLENOID CONTROL

8 T54 18DG/OR TRANSMISSION TEMPERATURE SENSOR SIGNAL

TRANSMISSION SOLENOID/TRS ASSEMBLY (NGC) - 23 WAY

CAV CIRCUIT FUNCTION

1 L10 18WT/GY FUSED IGNITION SWITCH OUTPUT (RUN)

2 T20 18DG/WT L/R SOLENOID CONTROL

3- -

4 T41 20YL/DB TRS T41 SENSE

5 T42 18DG/YL TRS T42 SENSE

6 L1 18WT/LG BACKUP LAMP FEED

7 T60 18YL/GY OVERDRIVE SOLENOID CONTROL

8 T3 18DG/DB TRS T3 SENSE

9 T1 18DG/LB TRS T1 SENSE

10 T16 18YL/OR TRANSMISSION CONTROL RELAY OUTPUT

11 T48 18BR/YL 4C PRESSURE SWITCH SENSE

12 T140 18YL/GY PRESSURE CONTROL SOLENIOD CONTROL

13 T4 18DG/LB TRS T2 SENSE

14 T50 18YL/TN LOW/REVERSE PRESSURE SWITCH SENSE

15 T147 18DG/YL 2C PRESSURE SWITCH SENSE

16 T9 18DG/TN OVERDRIVE PRESSURE SWITCH SENSE

17 T59 18YL/LB UNDERDRIVE SOLENOID CONTROL

18 T29 18YL/WT UNDERDRIVE PRESSURE SWITCH SENSE

19 T259 18YL/DG 4C SOLENOID CONTROL

20 T219 18YL/LG 2C SOLENOID CONTROL

21 T118 18DG MS SOLENOID CONTROL

22 K900 18DB/DG SENSOR GROUND

23 T54 18DG/OR TRANSMISSION TEMPERATURE SENSOR SIGNAL

8W - 80 - 102 8W-80 CONNECTOR PIN-OUTSDR

Page 1296 of 2627

(1) Start the engine.

(2) Spray a small stream of water (spray bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(15) Remove the heater hoses from the engine

front cover and the heater core.

(16) Unclip and remove heater hoses and tubes

from intake manifold.

(17) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - REMOVAL).

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence.

(19) Remove intake manifold.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

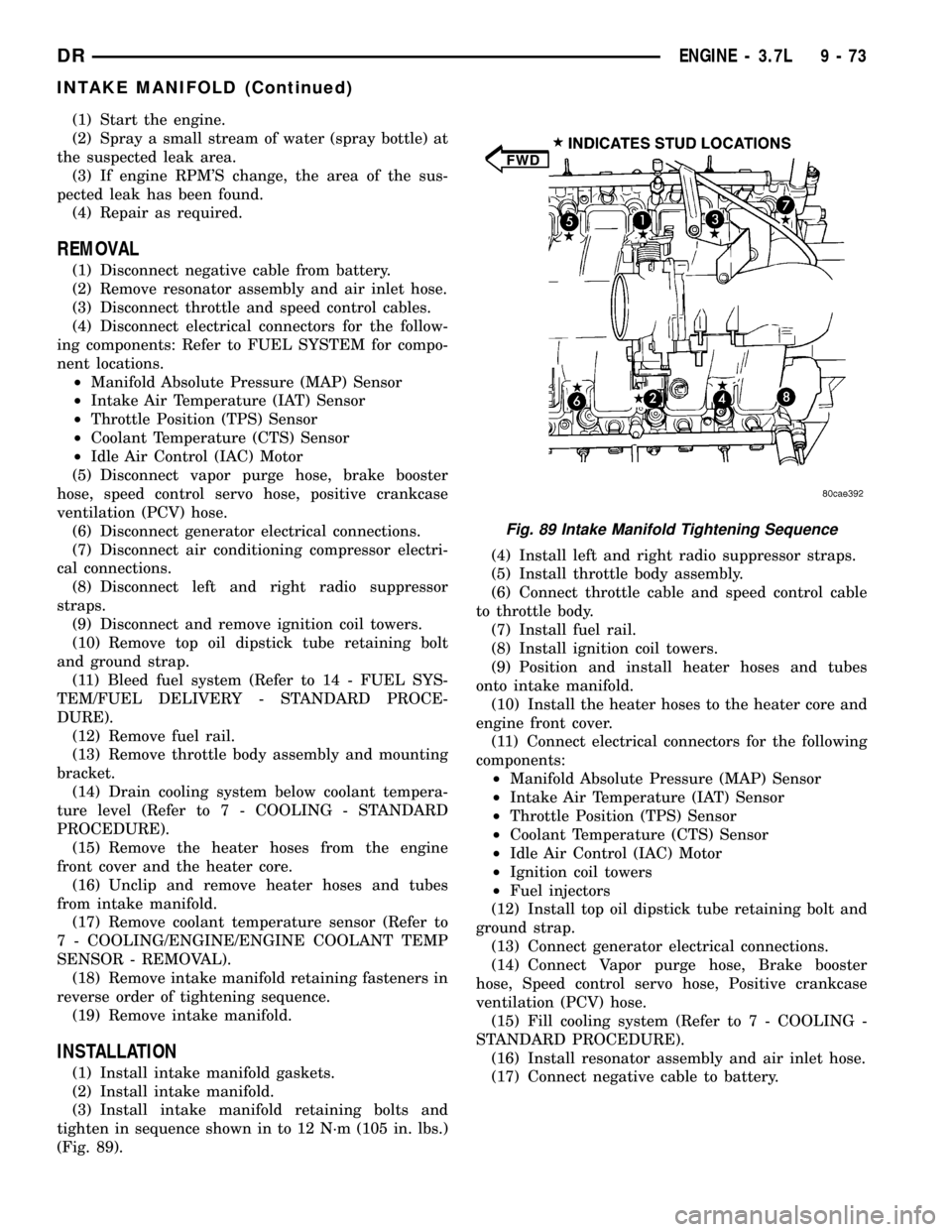

(3) Install intake manifold retaining bolts and

tighten in sequence shown in to 12 N´m (105 in. lbs.)

(Fig. 89).(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Connect throttle cable and speed control cable

to throttle body.

(7) Install fuel rail.

(8) Install ignition coil towers.

(9) Position and install heater hoses and tubes

onto intake manifold.

(10) Install the heater hoses to the heater core and

engine front cover.

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Connect generator electrical connections.

(14) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(15) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(16) Install resonator assembly and air inlet hose.

(17) Connect negative cable to battery.

Fig. 89 Intake Manifold Tightening Sequence

DRENGINE - 3.7L 9 - 73

INTAKE MANIFOLD (Continued)

Page 1383 of 2627

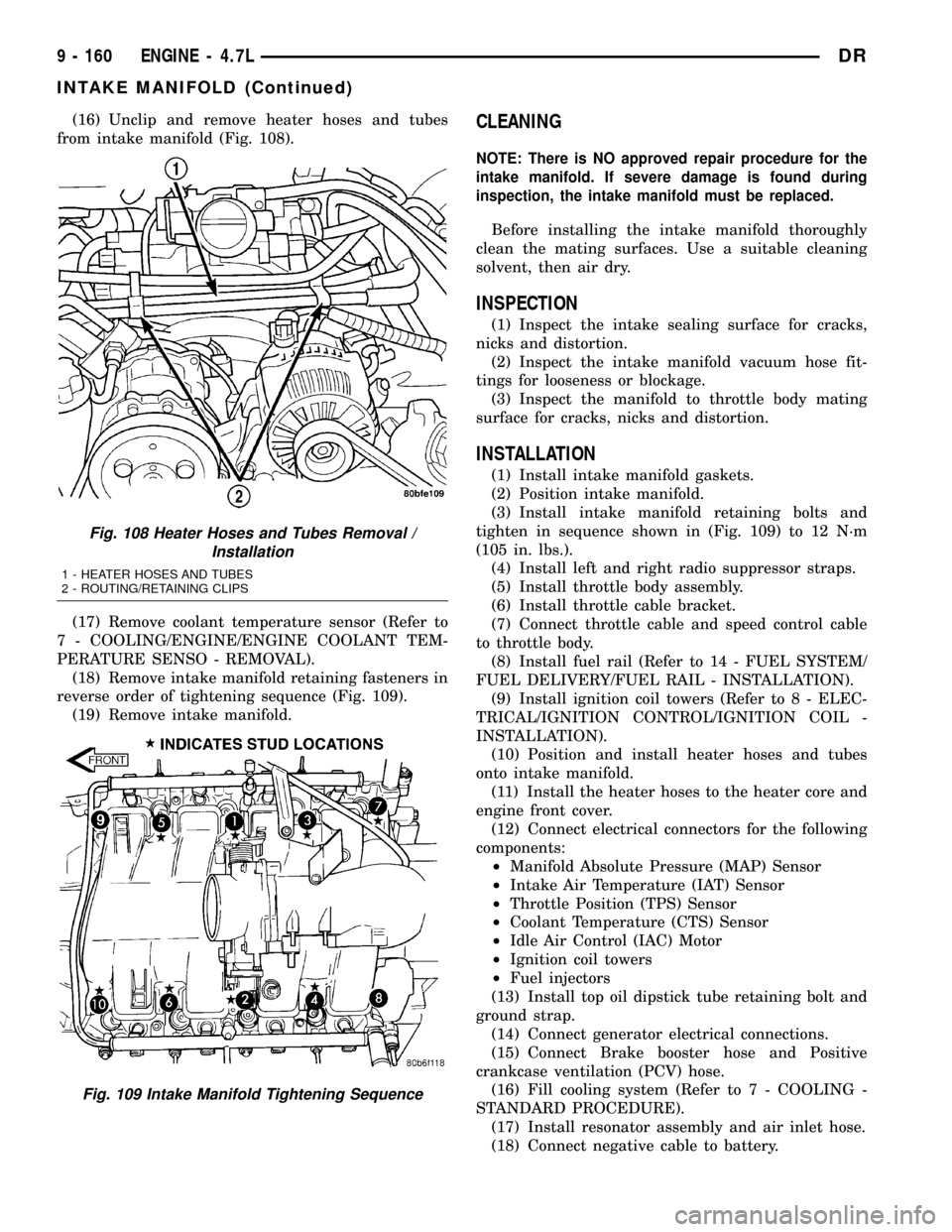

(16) Unclip and remove heater hoses and tubes

from intake manifold (Fig. 108).

(17) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEM-

PERATURE SENSO - REMOVAL).

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence (Fig. 109).

(19) Remove intake manifold.CLEANING

NOTE: There is NO approved repair procedure for the

intake manifold. If severe damage is found during

inspection, the intake manifold must be replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.

(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Position intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 109) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install ignition coil towers (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

(10) Position and install heater hoses and tubes

onto intake manifold.

(11) Install the heater hoses to the heater core and

engine front cover.

(12) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(13) Install top oil dipstick tube retaining bolt and

ground strap.

(14) Connect generator electrical connections.

(15) Connect Brake booster hose and Positive

crankcase ventilation (PCV) hose.

(16) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Install resonator assembly and air inlet hose.

(18) Connect negative cable to battery.

Fig. 108 Heater Hoses and Tubes Removal /

Installation

1 - HEATER HOSES AND TUBES

2 - ROUTING/RETAINING CLIPS

Fig. 109 Intake Manifold Tightening Sequence

9 - 160 ENGINE - 4.7LDR

INTAKE MANIFOLD (Continued)

Page 1597 of 2627

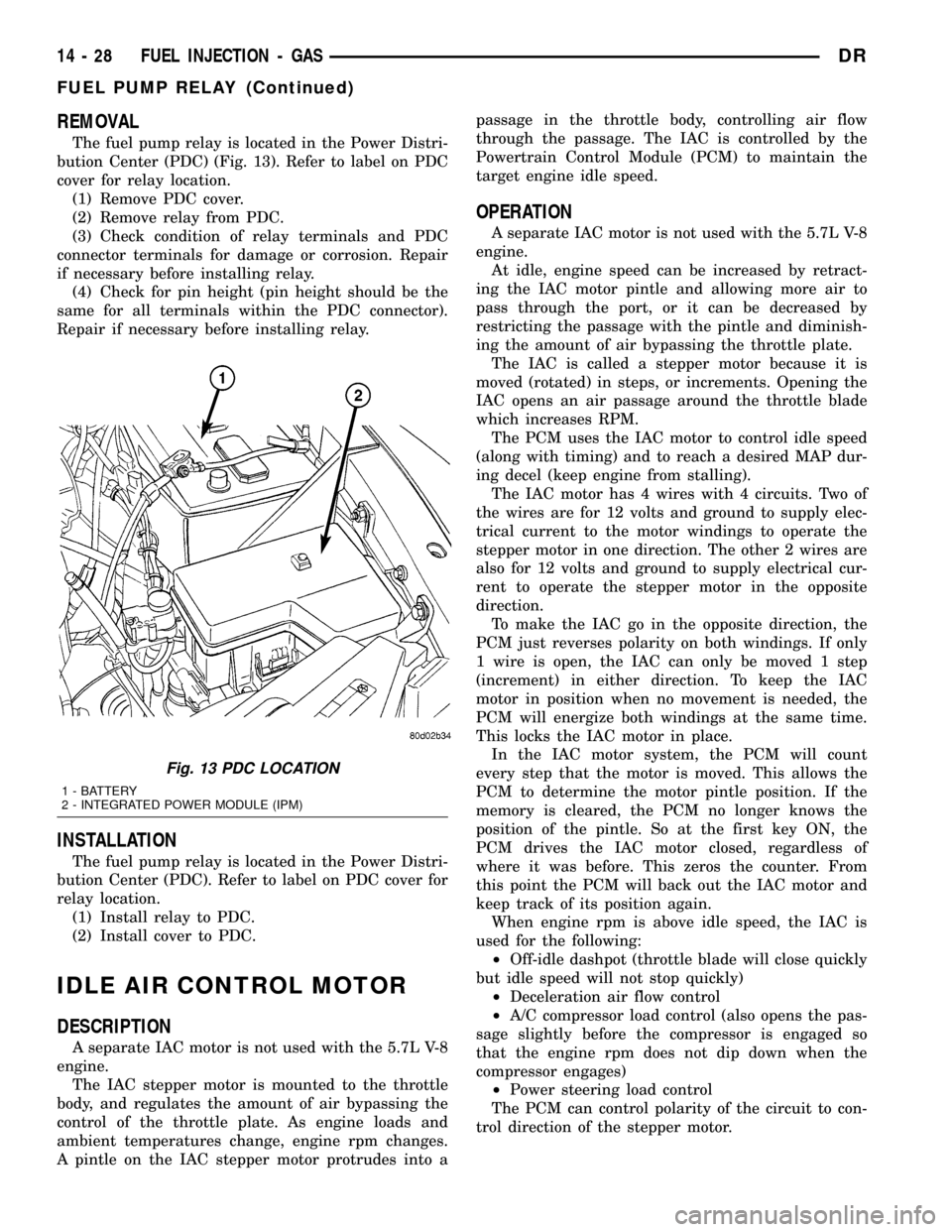

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 13). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC). Refer to label on PDC cover for

relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

A separate IAC motor is not used with the 5.7L V-8

engine.

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into apassage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

A separate IAC motor is not used with the 5.7L V-8

engine.

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

Fig. 13 PDC LOCATION

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

14 - 28 FUEL INJECTION - GASDR

FUEL PUMP RELAY (Continued)

Page 1710 of 2627

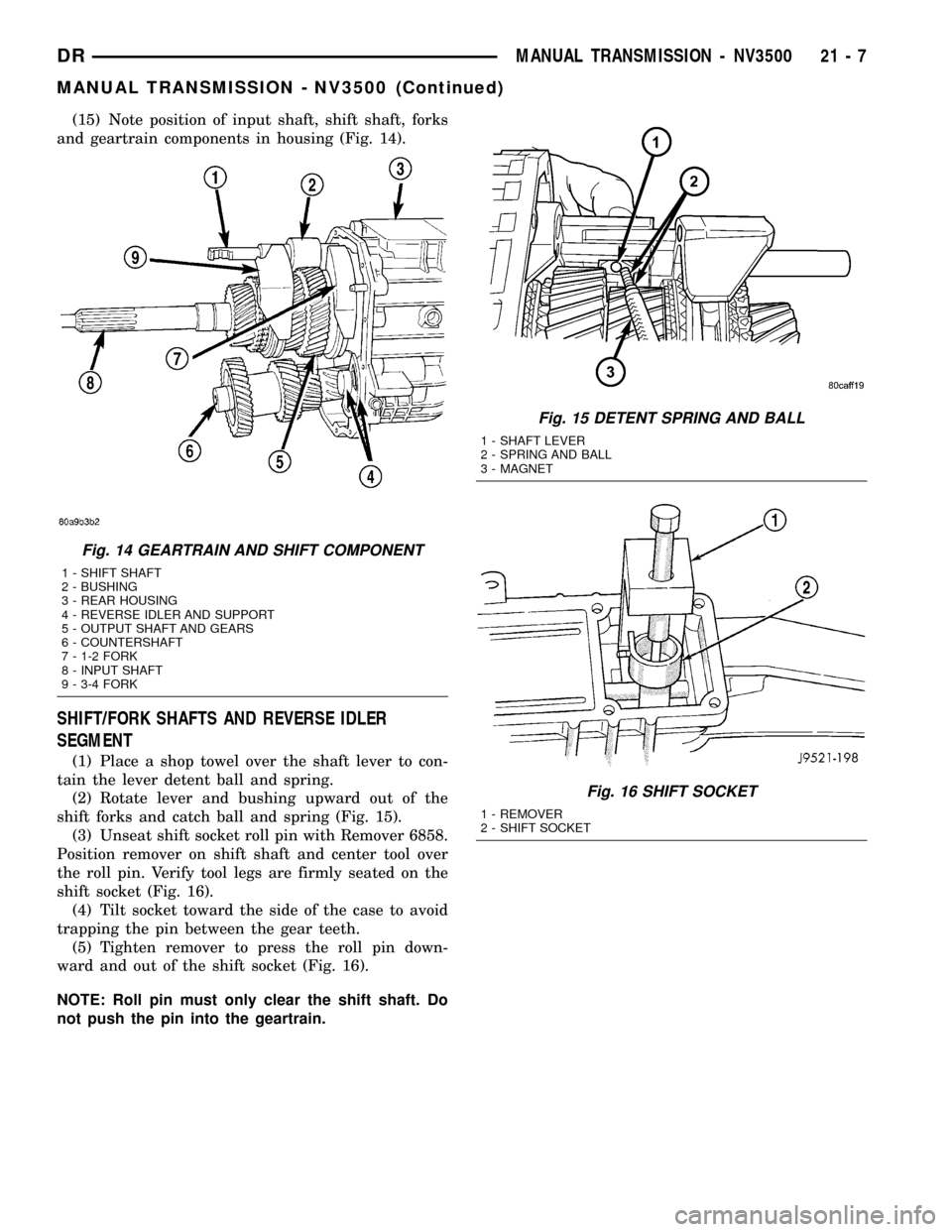

(15) Note position of input shaft, shift shaft, forks

and geartrain components in housing (Fig. 14).

SHIFT/FORK SHAFTS AND REVERSE IDLER

SEGMENT

(1) Place a shop towel over the shaft lever to con-

tain the lever detent ball and spring.

(2) Rotate lever and bushing upward out of the

shift forks and catch ball and spring (Fig. 15).

(3) Unseat shift socket roll pin with Remover 6858.

Position remover on shift shaft and center tool over

the roll pin. Verify tool legs are firmly seated on the

shift socket (Fig. 16).

(4) Tilt socket toward the side of the case to avoid

trapping the pin between the gear teeth.

(5) Tighten remover to press the roll pin down-

ward and out of the shift socket (Fig. 16).

NOTE: Roll pin must only clear the shift shaft. Do

not push the pin into the geartrain.

Fig. 14 GEARTRAIN AND SHIFT COMPONENT

1 - SHIFT SHAFT

2 - BUSHING

3 - REAR HOUSING

4 - REVERSE IDLER AND SUPPORT

5 - OUTPUT SHAFT AND GEARS

6 - COUNTERSHAFT

7 - 1-2 FORK

8 - INPUT SHAFT

9 - 3-4 FORK

Fig. 15 DETENT SPRING AND BALL

1 - SHAFT LEVER

2 - SPRING AND BALL

3 - MAGNET

Fig. 16 SHIFT SOCKET

1 - REMOVER

2 - SHIFT SOCKET

DRMANUAL TRANSMISSION - NV3500 21 - 7

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1711 of 2627

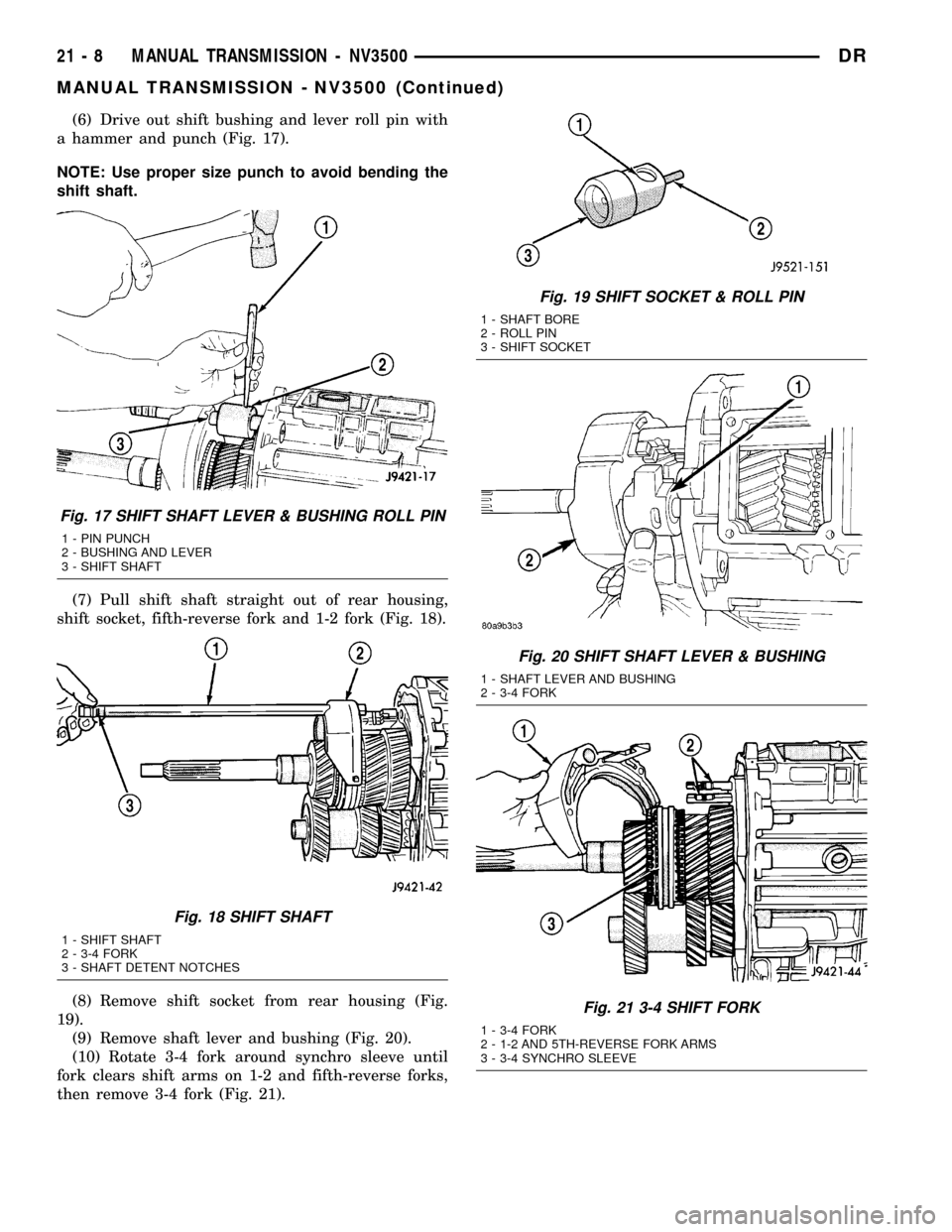

(6) Drive out shift bushing and lever roll pin with

a hammer and punch (Fig. 17).

NOTE: Use proper size punch to avoid bending the

shift shaft.

(7) Pull shift shaft straight out of rear housing,

shift socket, fifth-reverse fork and 1-2 fork (Fig. 18).

(8) Remove shift socket from rear housing (Fig.

19).

(9) Remove shaft lever and bushing (Fig. 20).

(10) Rotate 3-4 fork around synchro sleeve until

fork clears shift arms on 1-2 and fifth-reverse forks,

then remove 3-4 fork (Fig. 21).

Fig. 17 SHIFT SHAFT LEVER & BUSHING ROLL PIN

1 - PIN PUNCH

2 - BUSHING AND LEVER

3 - SHIFT SHAFT

Fig. 18 SHIFT SHAFT

1 - SHIFT SHAFT

2 - 3-4 FORK

3 - SHAFT DETENT NOTCHES

Fig. 19 SHIFT SOCKET & ROLL PIN

1 - SHAFT BORE

2 - ROLL PIN

3 - SHIFT SOCKET

Fig. 20 SHIFT SHAFT LEVER & BUSHING

1 - SHAFT LEVER AND BUSHING

2 - 3-4 FORK

Fig. 21 3-4 SHIFT FORK

1 - 3-4 FORK

2 - 1-2 AND 5TH-REVERSE FORK ARMS

3 - 3-4 SYNCHRO SLEEVE

21 - 8 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)