Reverse DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1766 of 2627

the alignment dowels in the case top surface and in

the housing/adapter are tight and in good condition.

Replace the gear case or housing/adapter if cracked

or broken.

ASSEMBLY

NOTE: Gaskets are not used in the transmission.

Use Mopar Silicone Sealer or equivalent on all gear

case and extension housing sealing surfaces.

COUNTERSHAFT AND REVERSE IDLER GEAR

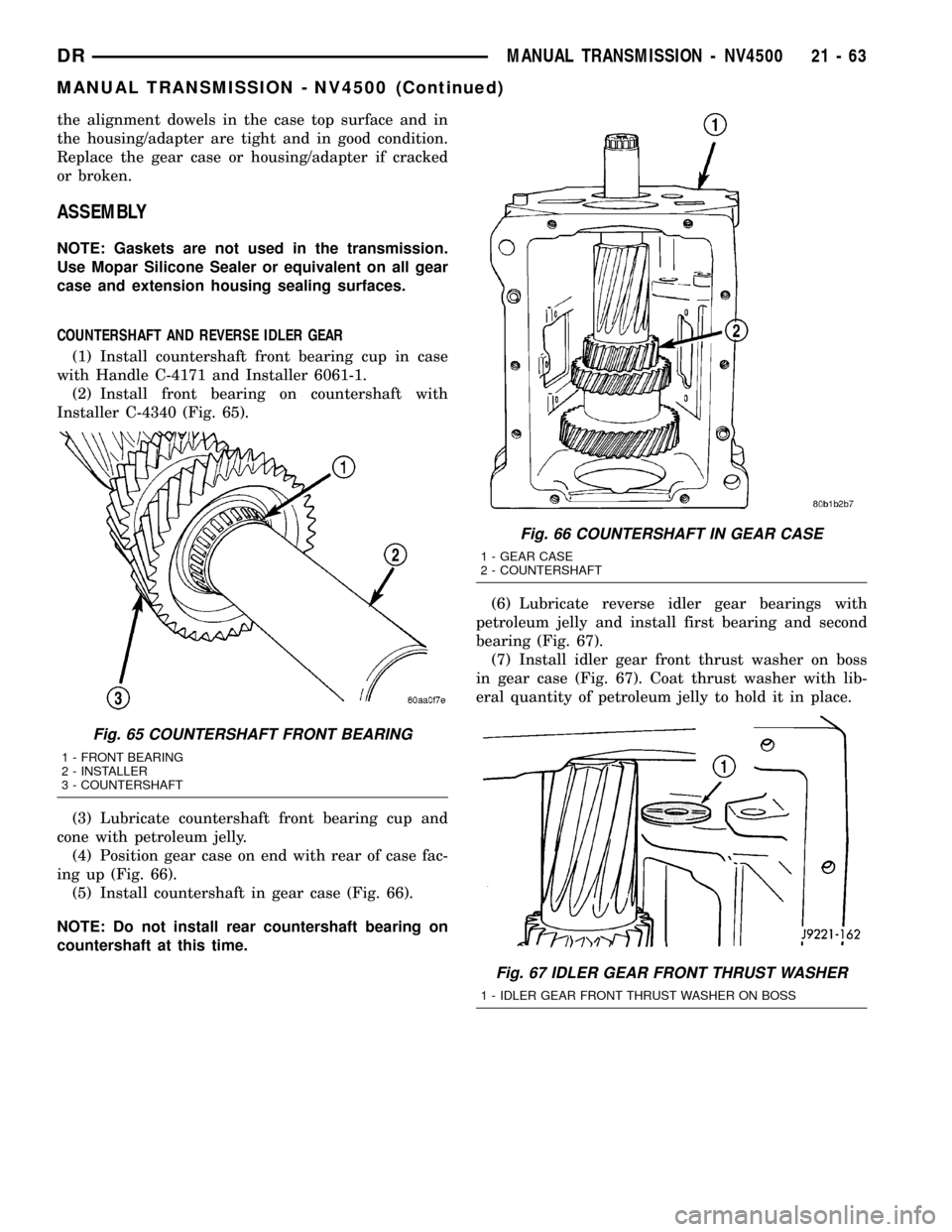

(1) Install countershaft front bearing cup in case

with Handle C-4171 and Installer 6061-1.

(2) Install front bearing on countershaft with

Installer C-4340 (Fig. 65).

(3) Lubricate countershaft front bearing cup and

cone with petroleum jelly.

(4) Position gear case on end with rear of case fac-

ing up (Fig. 66).

(5) Install countershaft in gear case (Fig. 66).

NOTE: Do not install rear countershaft bearing on

countershaft at this time.(6) Lubricate reverse idler gear bearings with

petroleum jelly and install first bearing and second

bearing (Fig. 67).

(7) Install idler gear front thrust washer on boss

in gear case (Fig. 67). Coat thrust washer with lib-

eral quantity of petroleum jelly to hold it in place.

Fig. 65 COUNTERSHAFT FRONT BEARING

1 - FRONT BEARING

2 - INSTALLER

3 - COUNTERSHAFT

Fig. 66 COUNTERSHAFT IN GEAR CASE

1 - GEAR CASE

2 - COUNTERSHAFT

Fig. 67 IDLER GEAR FRONT THRUST WASHER

1 - IDLER GEAR FRONT THRUST WASHER ON BOSS

DRMANUAL TRANSMISSION - NV4500 21 - 63

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1767 of 2627

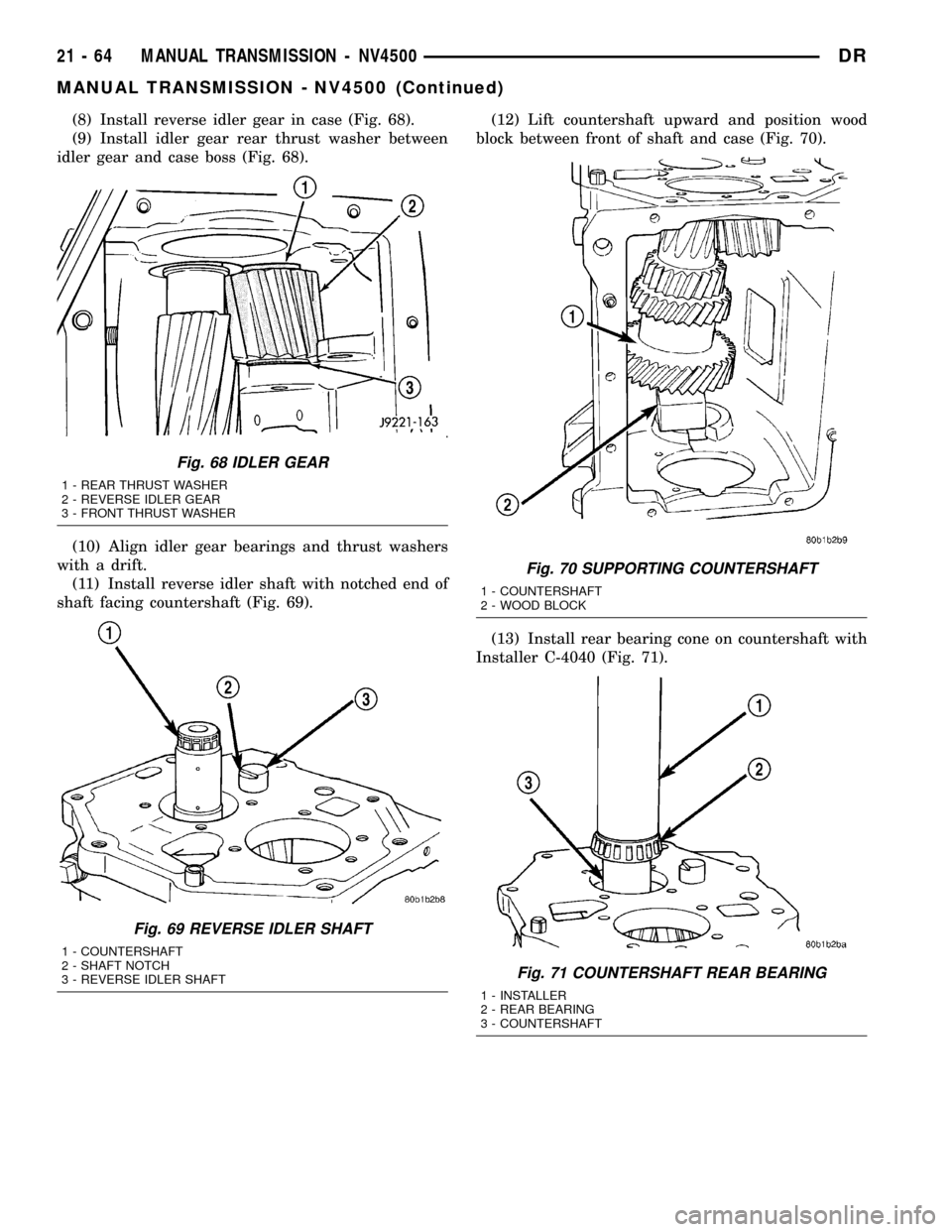

(8) Install reverse idler gear in case (Fig. 68).

(9) Install idler gear rear thrust washer between

idler gear and case boss (Fig. 68).

(10) Align idler gear bearings and thrust washers

with a drift.

(11) Install reverse idler shaft with notched end of

shaft facing countershaft (Fig. 69).(12) Lift countershaft upward and position wood

block between front of shaft and case (Fig. 70).

(13) Install rear bearing cone on countershaft with

Installer C-4040 (Fig. 71).

Fig. 68 IDLER GEAR

1 - REAR THRUST WASHER

2 - REVERSE IDLER GEAR

3 - FRONT THRUST WASHER

Fig. 69 REVERSE IDLER SHAFT

1 - COUNTERSHAFT

2 - SHAFT NOTCH

3 - REVERSE IDLER SHAFT

Fig. 70 SUPPORTING COUNTERSHAFT

1 - COUNTERSHAFT

2 - WOOD BLOCK

Fig. 71 COUNTERSHAFT REAR BEARING

1 - INSTALLER

2 - REAR BEARING

3 - COUNTERSHAFT

21 - 64 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1768 of 2627

(14) Remove wood block from under countershaft

and lower countershaft front bearing into front bear-

ing cup.

(15) Lubricate countershaft rear bearing cup and

cone with petroleum jelly.

(16) Install countershaft rear bearing cup in gear

case and over rear bearing (Fig. 72). Tap cup into

place with plastic mallet if necessary.

(17) Install countershaft rear bearing plate (Fig.

73).

NOTE: Verify plate is seated in notch in reverse

idler shaft before tightening bearing plate bolts.(18) Apply Mopar silicone adhesive/sealer or equiv-

alent to flange and lip of new cap. Installnewfront

bearing cap in gear case (Fig. 74) with Handle

C-4171 and Installer C-3972-A.

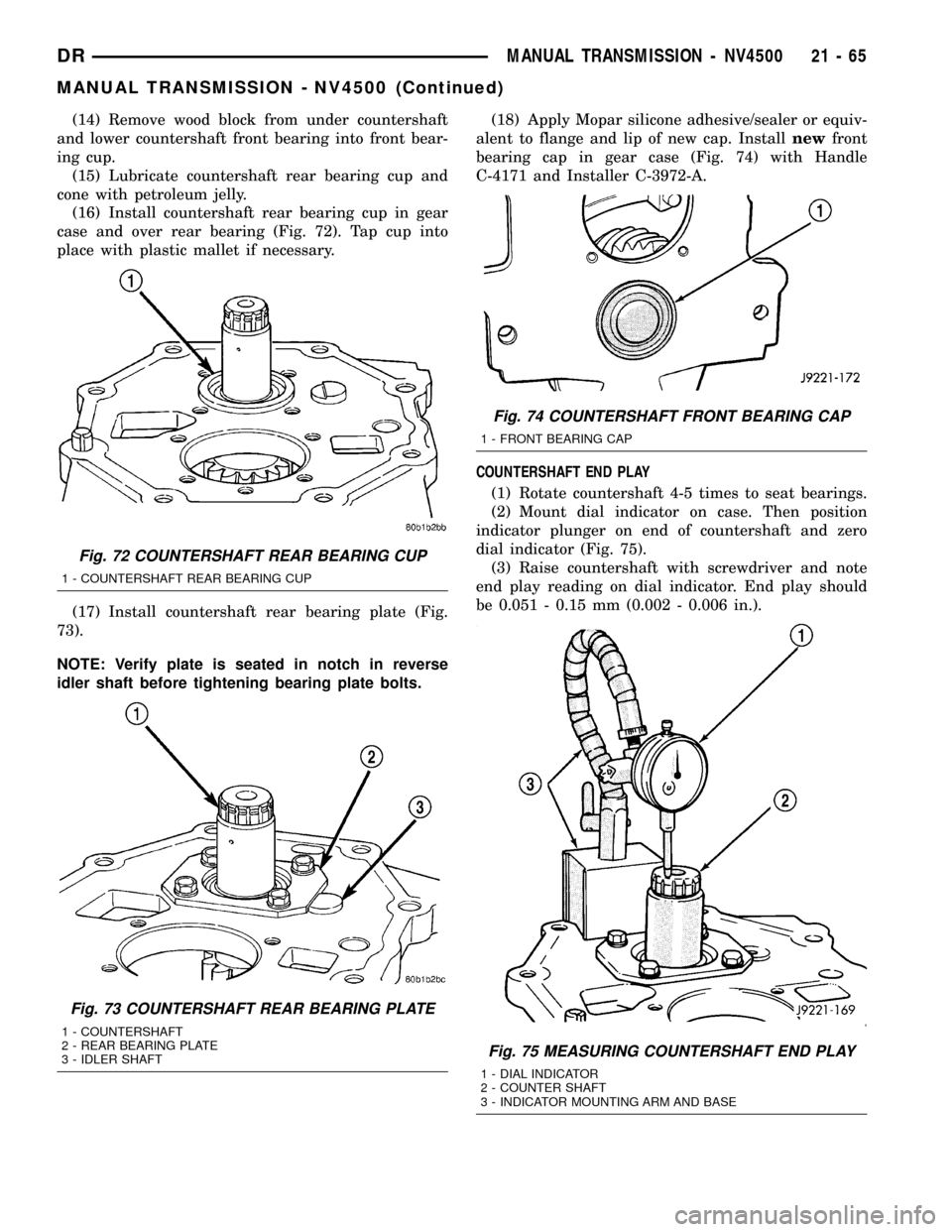

COUNTERSHAFT END PLAY

(1) Rotate countershaft 4-5 times to seat bearings.

(2) Mount dial indicator on case. Then position

indicator plunger on end of countershaft and zero

dial indicator (Fig. 75).

(3) Raise countershaft with screwdriver and note

end play reading on dial indicator. End play should

be 0.051 - 0.15 mm (0.002 - 0.006 in.).

Fig. 72 COUNTERSHAFT REAR BEARING CUP

1 - COUNTERSHAFT REAR BEARING CUP

Fig. 73 COUNTERSHAFT REAR BEARING PLATE

1 - COUNTERSHAFT

2 - REAR BEARING PLATE

3 - IDLER SHAFT

Fig. 74 COUNTERSHAFT FRONT BEARING CAP

1 - FRONT BEARING CAP

Fig. 75 MEASURING COUNTERSHAFT END PLAY

1 - DIAL INDICATOR

2 - COUNTER SHAFT

3 - INDICATOR MOUNTING ARM AND BASE

DRMANUAL TRANSMISSION - NV4500 21 - 65

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1769 of 2627

(4) Remove countershaft rear bearing plate.

(5) Install a end play shim that will provide mini-

mum countershaft end play. Position shim on rear

bearing cup (Fig. 76).

(6) Install countershaft rear bearing plate (Fig.

73).

NOTE: Verify plate is seated in reverse idler shaft

notch and end play shims are still in position

before installing bolts.

(7) Apply 1-2 drops Mopar Loc N' Seal or equiva-

lent to threads of rear bearing plate bolts. Then

install and tighten bearing plate bolts to 23 N´m (200

in. lbs.).

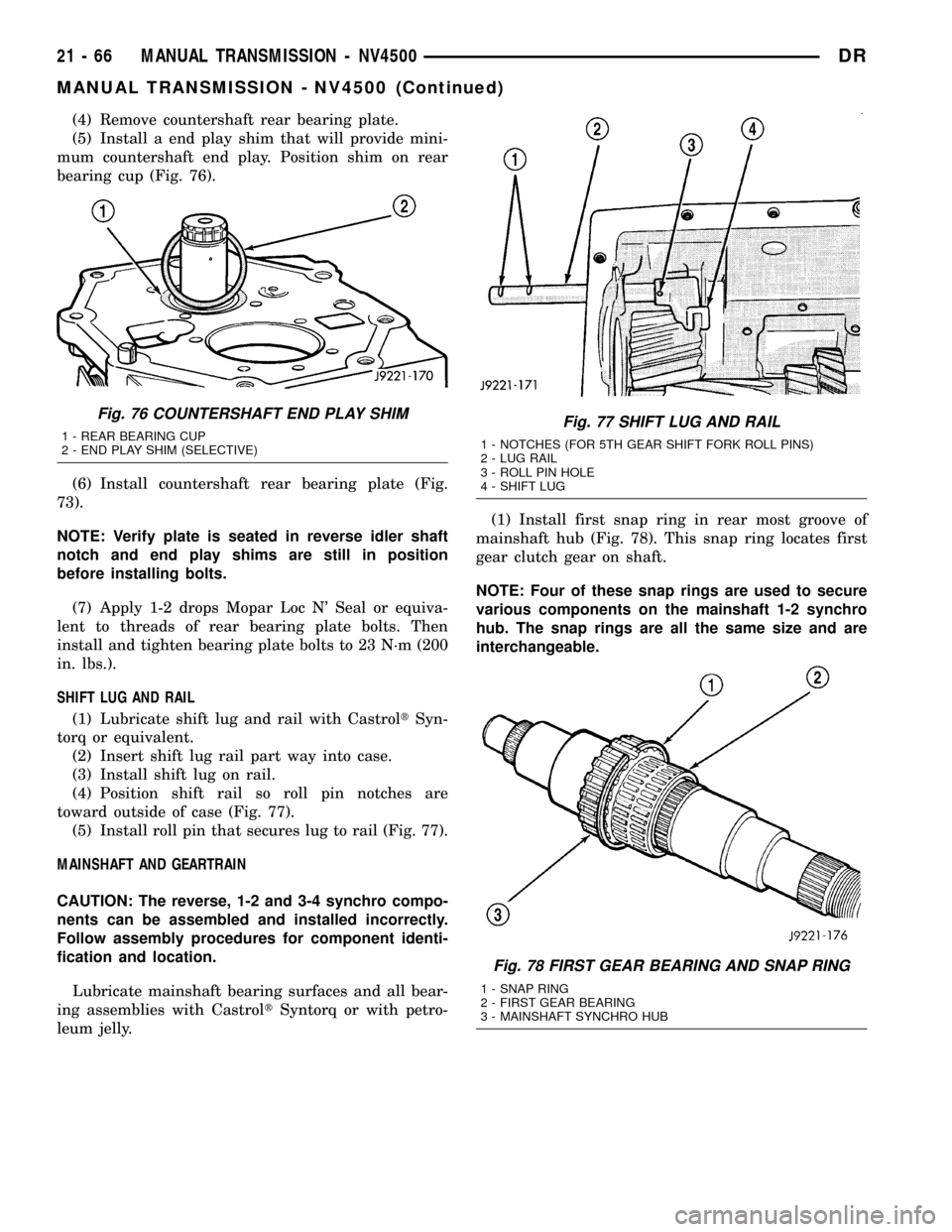

SHIFT LUG AND RAIL

(1) Lubricate shift lug and rail with CastroltSyn-

torq or equivalent.

(2) Insert shift lug rail part way into case.

(3) Install shift lug on rail.

(4) Position shift rail so roll pin notches are

toward outside of case (Fig. 77).

(5) Install roll pin that secures lug to rail (Fig. 77).

MAINSHAFT AND GEARTRAIN

CAUTION: The reverse, 1-2 and 3-4 synchro compo-

nents can be assembled and installed incorrectly.

Follow assembly procedures for component identi-

fication and location.

Lubricate mainshaft bearing surfaces and all bear-

ing assemblies with CastroltSyntorq or with petro-

leum jelly.(1) Install first snap ring in rear most groove of

mainshaft hub (Fig. 78). This snap ring locates first

gear clutch gear on shaft.

NOTE: Four of these snap rings are used to secure

various components on the mainshaft 1-2 synchro

hub. The snap rings are all the same size and are

interchangeable.

Fig. 76 COUNTERSHAFT END PLAY SHIM

1 - REAR BEARING CUP

2 - END PLAY SHIM (SELECTIVE)Fig. 77 SHIFT LUG AND RAIL

1 - NOTCHES (FOR 5TH GEAR SHIFT FORK ROLL PINS)

2 - LUG RAIL

3 - ROLL PIN HOLE

4 - SHIFT LUG

Fig. 78 FIRST GEAR BEARING AND SNAP RING

1 - SNAP RING

2 - FIRST GEAR BEARING

3 - MAINSHAFT SYNCHRO HUB

21 - 66 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1775 of 2627

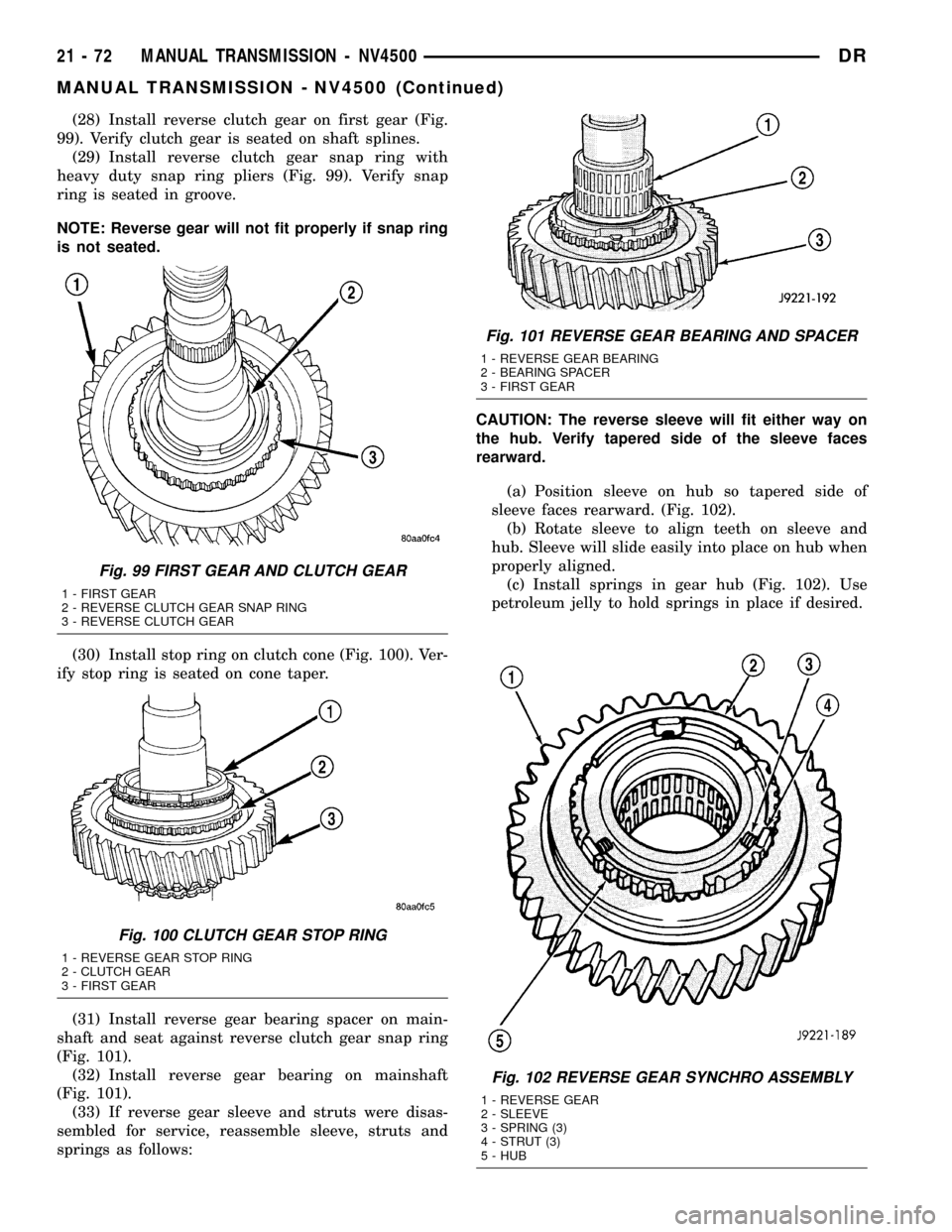

(28) Install reverse clutch gear on first gear (Fig.

99). Verify clutch gear is seated on shaft splines.

(29) Install reverse clutch gear snap ring with

heavy duty snap ring pliers (Fig. 99). Verify snap

ring is seated in groove.

NOTE: Reverse gear will not fit properly if snap ring

is not seated.

(30) Install stop ring on clutch cone (Fig. 100). Ver-

ify stop ring is seated on cone taper.

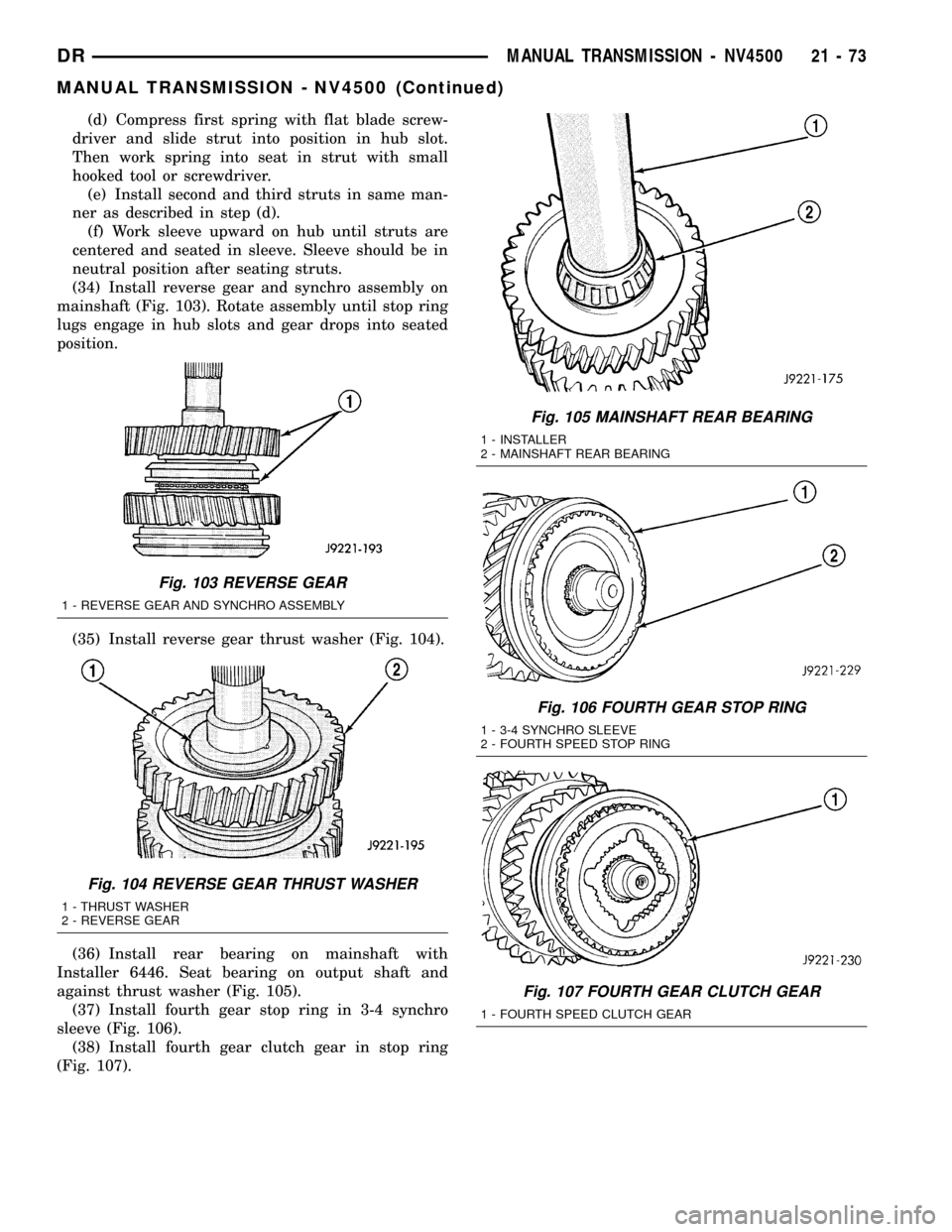

(31) Install reverse gear bearing spacer on main-

shaft and seat against reverse clutch gear snap ring

(Fig. 101).

(32) Install reverse gear bearing on mainshaft

(Fig. 101).

(33) If reverse gear sleeve and struts were disas-

sembled for service, reassemble sleeve, struts and

springs as follows:CAUTION: The reverse sleeve will fit either way on

the hub. Verify tapered side of the sleeve faces

rearward.

(a) Position sleeve on hub so tapered side of

sleeve faces rearward. (Fig. 102).

(b) Rotate sleeve to align teeth on sleeve and

hub. Sleeve will slide easily into place on hub when

properly aligned.

(c) Install springs in gear hub (Fig. 102). Use

petroleum jelly to hold springs in place if desired.

Fig. 102 REVERSE GEAR SYNCHRO ASSEMBLY

1 - REVERSE GEAR

2 - SLEEVE

3 - SPRING (3)

4 - STRUT (3)

5 - HUB

Fig. 99 FIRST GEAR AND CLUTCH GEAR

1 - FIRST GEAR

2 - REVERSE CLUTCH GEAR SNAP RING

3 - REVERSE CLUTCH GEAR

Fig. 100 CLUTCH GEAR STOP RING

1 - REVERSE GEAR STOP RING

2 - CLUTCH GEAR

3 - FIRST GEAR

Fig. 101 REVERSE GEAR BEARING AND SPACER

1 - REVERSE GEAR BEARING

2 - BEARING SPACER

3 - FIRST GEAR

21 - 72 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1776 of 2627

(d) Compress first spring with flat blade screw-

driver and slide strut into position in hub slot.

Then work spring into seat in strut with small

hooked tool or screwdriver.

(e) Install second and third struts in same man-

ner as described in step (d).

(f) Work sleeve upward on hub until struts are

centered and seated in sleeve. Sleeve should be in

neutral position after seating struts.

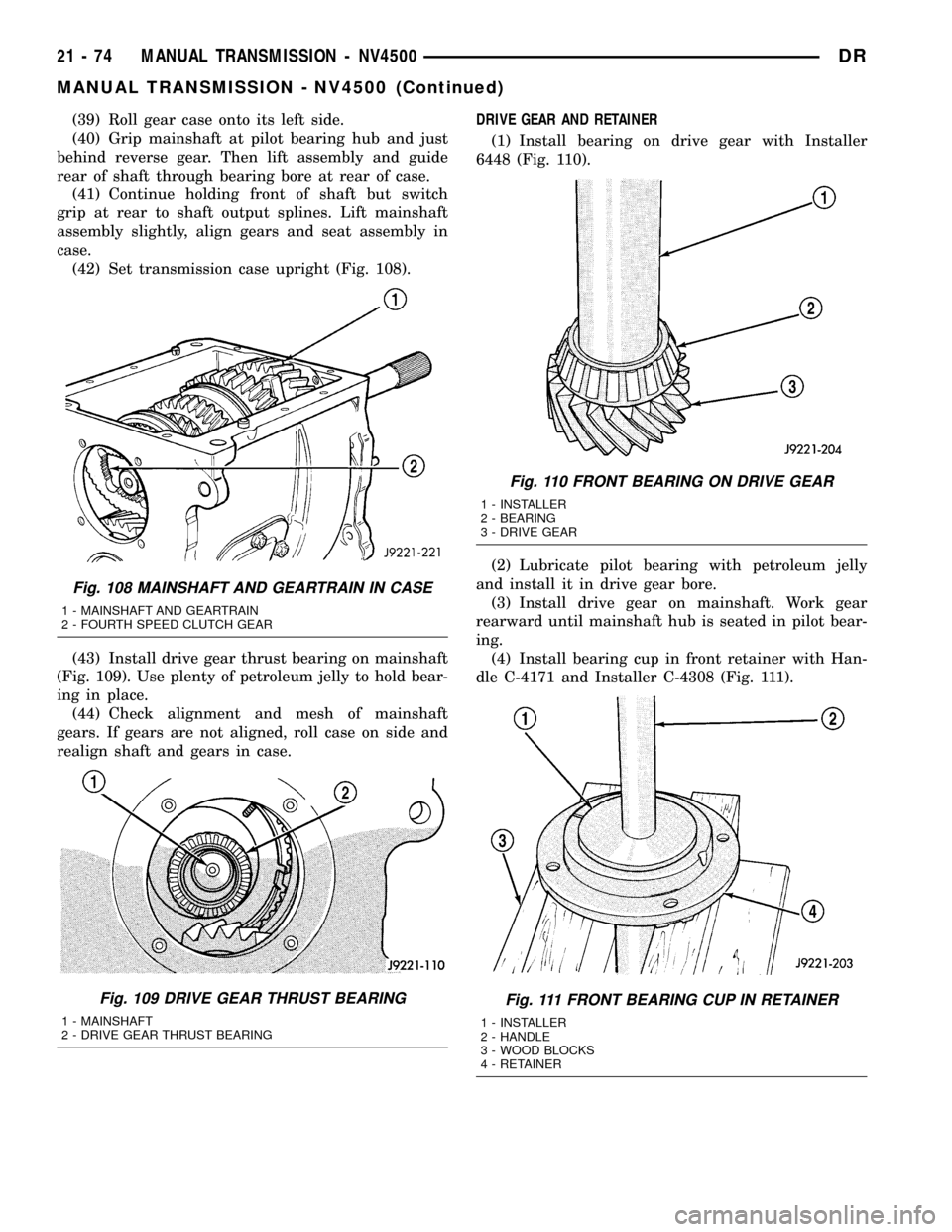

(34) Install reverse gear and synchro assembly on

mainshaft (Fig. 103). Rotate assembly until stop ring

lugs engage in hub slots and gear drops into seated

position.

(35) Install reverse gear thrust washer (Fig. 104).

(36) Install rear bearing on mainshaft with

Installer 6446. Seat bearing on output shaft and

against thrust washer (Fig. 105).

(37) Install fourth gear stop ring in 3-4 synchro

sleeve (Fig. 106).

(38) Install fourth gear clutch gear in stop ring

(Fig. 107).

Fig. 103 REVERSE GEAR

1 - REVERSE GEAR AND SYNCHRO ASSEMBLY

Fig. 104 REVERSE GEAR THRUST WASHER

1 - THRUST WASHER

2 - REVERSE GEAR

Fig. 105 MAINSHAFT REAR BEARING

1 - INSTALLER

2 - MAINSHAFT REAR BEARING

Fig. 106 FOURTH GEAR STOP RING

1 - 3-4 SYNCHRO SLEEVE

2 - FOURTH SPEED STOP RING

Fig. 107 FOURTH GEAR CLUTCH GEAR

1 - FOURTH SPEED CLUTCH GEAR

DRMANUAL TRANSMISSION - NV4500 21 - 73

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1777 of 2627

(39) Roll gear case onto its left side.

(40) Grip mainshaft at pilot bearing hub and just

behind reverse gear. Then lift assembly and guide

rear of shaft through bearing bore at rear of case.

(41) Continue holding front of shaft but switch

grip at rear to shaft output splines. Lift mainshaft

assembly slightly, align gears and seat assembly in

case.

(42) Set transmission case upright (Fig. 108).

(43) Install drive gear thrust bearing on mainshaft

(Fig. 109). Use plenty of petroleum jelly to hold bear-

ing in place.

(44) Check alignment and mesh of mainshaft

gears. If gears are not aligned, roll case on side and

realign shaft and gears in case.DRIVE GEAR AND RETAINER

(1) Install bearing on drive gear with Installer

6448 (Fig. 110).

(2) Lubricate pilot bearing with petroleum jelly

and install it in drive gear bore.

(3) Install drive gear on mainshaft. Work gear

rearward until mainshaft hub is seated in pilot bear-

ing.

(4) Install bearing cup in front retainer with Han-

dle C-4171 and Installer C-4308 (Fig. 111).

Fig. 108 MAINSHAFT AND GEARTRAIN IN CASE

1 - MAINSHAFT AND GEARTRAIN

2 - FOURTH SPEED CLUTCH GEAR

Fig. 109 DRIVE GEAR THRUST BEARING

1 - MAINSHAFT

2 - DRIVE GEAR THRUST BEARING

Fig. 110 FRONT BEARING ON DRIVE GEAR

1 - INSTALLER

2 - BEARING

3 - DRIVE GEAR

Fig. 111 FRONT BEARING CUP IN RETAINER

1 - INSTALLER

2 - HANDLE

3 - WOOD BLOCKS

4 - RETAINER

21 - 74 MANUAL TRANSMISSION - NV4500DR

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1782 of 2627

(10) Tighten fifth gear nut with Nut Wrench 6743

and high capacity torque wrench. Tighten nut to 366-

380 N´m (270-280 ft. lbs.). Have helper hold trans-

mission steady if necessary.

(11) Torque the fifth gear clamp nut clamping bolt

to 13.5 N´m (10 ft. lbs.).

(12) Unlock the mainshaft gears by shifting all

synchro sleeves out of the engaged position.

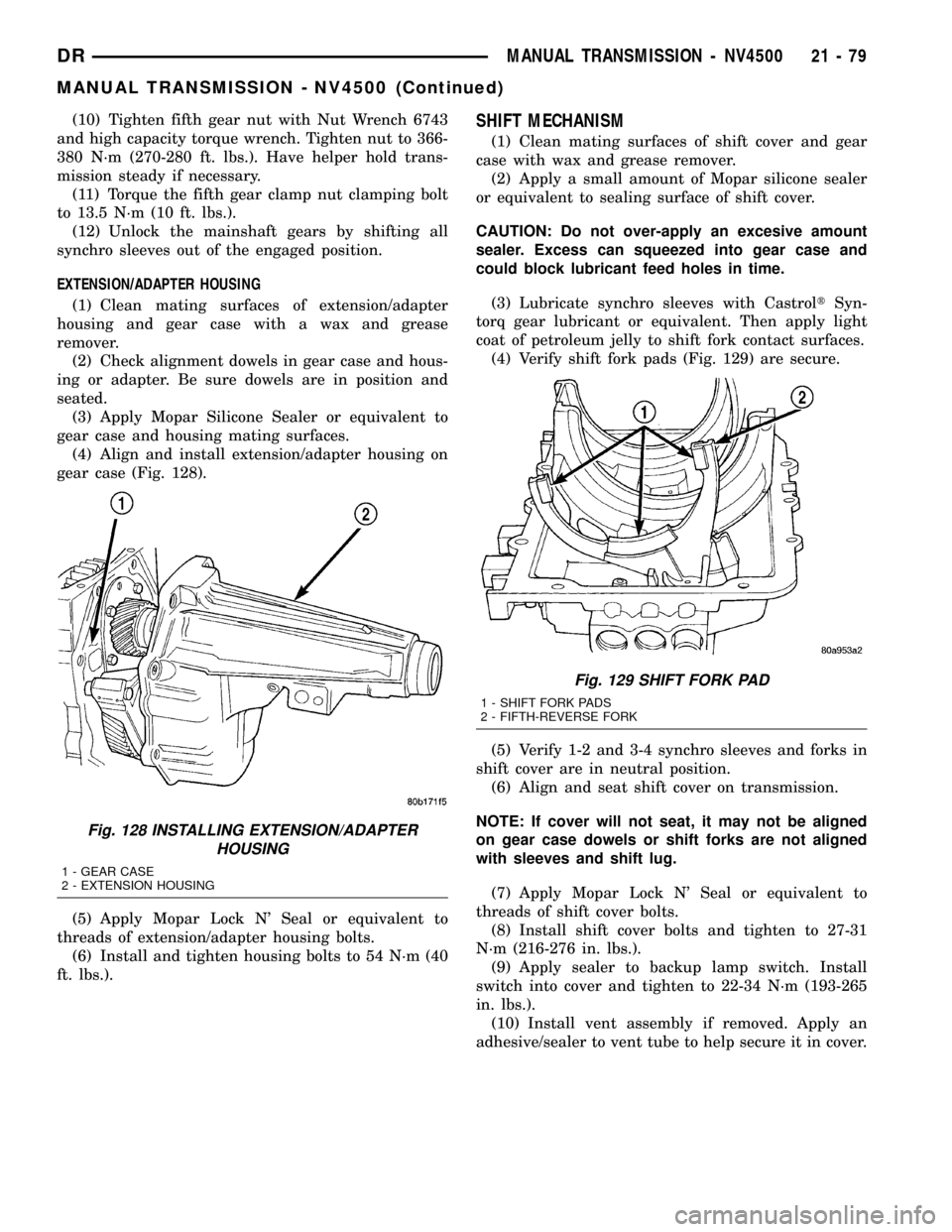

EXTENSION/ADAPTER HOUSING

(1) Clean mating surfaces of extension/adapter

housing and gear case with a wax and grease

remover.

(2) Check alignment dowels in gear case and hous-

ing or adapter. Be sure dowels are in position and

seated.

(3) Apply Mopar Silicone Sealer or equivalent to

gear case and housing mating surfaces.

(4) Align and install extension/adapter housing on

gear case (Fig. 128).

(5) Apply Mopar Lock N' Seal or equivalent to

threads of extension/adapter housing bolts.

(6) Install and tighten housing bolts to 54 N´m (40

ft. lbs.).SHIFT MECHANISM

(1) Clean mating surfaces of shift cover and gear

case with wax and grease remover.

(2) Apply a small amount of Mopar silicone sealer

or equivalent to sealing surface of shift cover.

CAUTION: Do not over-apply an excesive amount

sealer. Excess can squeezed into gear case and

could block lubricant feed holes in time.

(3) Lubricate synchro sleeves with CastroltSyn-

torq gear lubricant or equivalent. Then apply light

coat of petroleum jelly to shift fork contact surfaces.

(4) Verify shift fork pads (Fig. 129) are secure.

(5) Verify 1-2 and 3-4 synchro sleeves and forks in

shift cover are in neutral position.

(6) Align and seat shift cover on transmission.

NOTE: If cover will not seat, it may not be aligned

on gear case dowels or shift forks are not aligned

with sleeves and shift lug.

(7) Apply Mopar Lock N' Seal or equivalent to

threads of shift cover bolts.

(8) Install shift cover bolts and tighten to 27-31

N´m (216-276 in. lbs.).

(9) Apply sealer to backup lamp switch. Install

switch into cover and tighten to 22-34 N´m (193-265

in. lbs.).

(10) Install vent assembly if removed. Apply an

adhesive/sealer to vent tube to help secure it in cover.

Fig. 128 INSTALLING EXTENSION/ADAPTER

HOUSING

1 - GEAR CASE

2 - EXTENSION HOUSING

Fig. 129 SHIFT FORK PAD

1 - SHIFT FORK PADS

2 - FIFTH-REVERSE FORK

DRMANUAL TRANSMISSION - NV4500 21 - 79

MANUAL TRANSMISSION - NV4500 (Continued)

Page 1789 of 2627

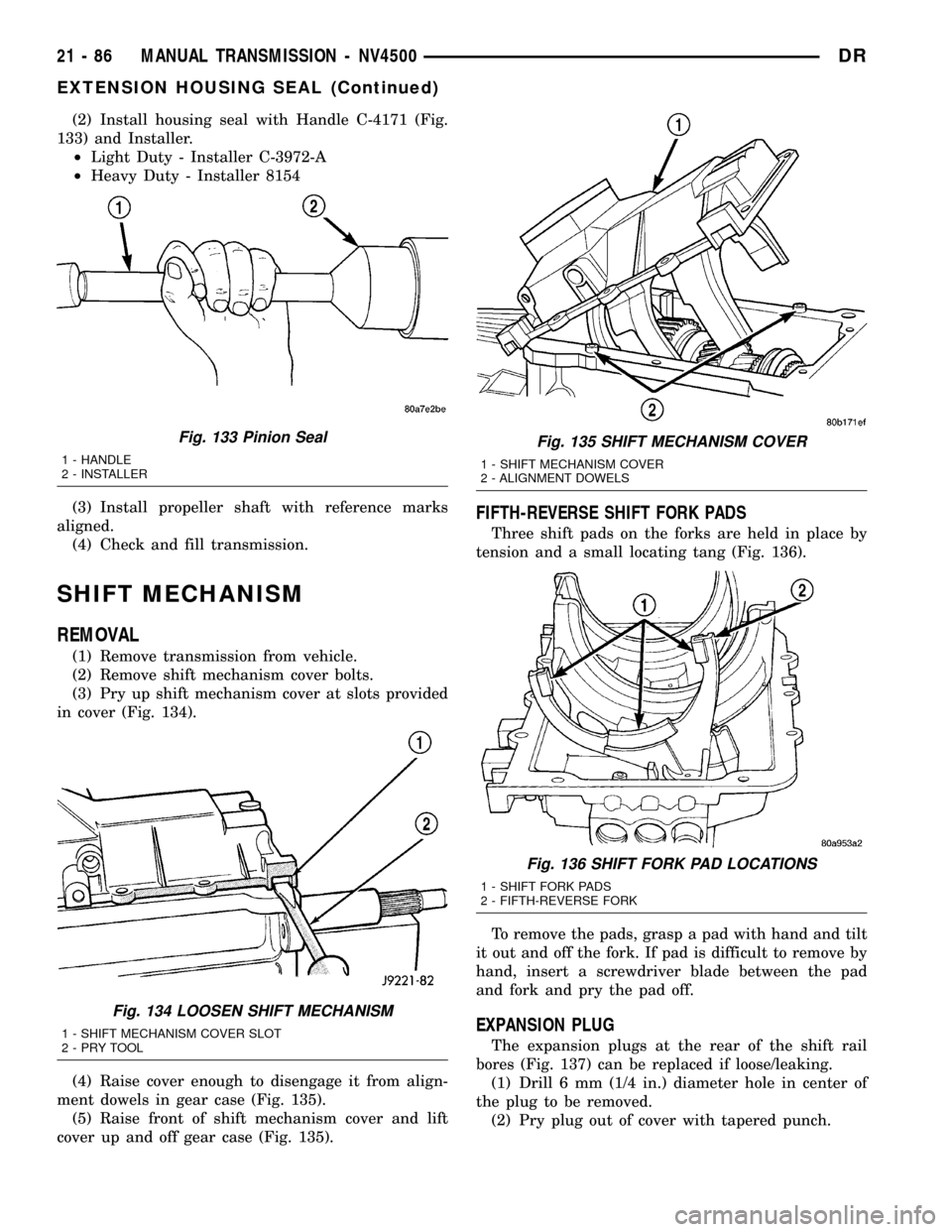

(2) Install housing seal with Handle C-4171 (Fig.

133) and Installer.

²Light Duty - Installer C-3972-A

²Heavy Duty - Installer 8154

(3) Install propeller shaft with reference marks

aligned.

(4) Check and fill transmission.

SHIFT MECHANISM

REMOVAL

(1) Remove transmission from vehicle.

(2) Remove shift mechanism cover bolts.

(3) Pry up shift mechanism cover at slots provided

in cover (Fig. 134).

(4) Raise cover enough to disengage it from align-

ment dowels in gear case (Fig. 135).

(5) Raise front of shift mechanism cover and lift

cover up and off gear case (Fig. 135).

FIFTH-REVERSE SHIFT FORK PADS

Three shift pads on the forks are held in place by

tension and a small locating tang (Fig. 136).

To remove the pads, grasp a pad with hand and tilt

it out and off the fork. If pad is difficult to remove by

hand, insert a screwdriver blade between the pad

and fork and pry the pad off.

EXPANSION PLUG

The expansion plugs at the rear of the shift rail

bores (Fig. 137) can be replaced if loose/leaking.

(1) Drill 6 mm (1/4 in.) diameter hole in center of

the plug to be removed.

(2) Pry plug out of cover with tapered punch.

Fig. 133 Pinion Seal

1 - HANDLE

2 - INSTALLER

Fig. 134 LOOSEN SHIFT MECHANISM

1 - SHIFT MECHANISM COVER SLOT

2-PRYTOOL

Fig. 135 SHIFT MECHANISM COVER

1 - SHIFT MECHANISM COVER

2 - ALIGNMENT DOWELS

Fig. 136 SHIFT FORK PAD LOCATIONS

1 - SHIFT FORK PADS

2 - FIFTH-REVERSE FORK

21 - 86 MANUAL TRANSMISSION - NV4500DR

EXTENSION HOUSING SEAL (Continued)

Page 1790 of 2627

(3) Clean all chips from shift cover and plug bores.

Then clean plug bores with solvent and dry with

clean shop towel.

INSTALLATION

EXPANSION PLUG

(1) Apply small bead of Mopar silicone sealer or

equivalent to outer edge of each new plug.

(2) Position each plug in bore and tap into place

with hammer and punch or socket.

FIFTH-REVERSE SHIFT FORK PADS

(1) Align pad locating tab.

(2) Snap pads into place and verify locating tabs

are locked-in.

SHIFT COVER

(1) Clean mating surfaces of shift mechanism

cover and gear case with wax and grease remover.

(2)

Apply a small amount of Mopar silicone sealer or

equivalent to sealing surface of shift mechanism cover.

CAUTION: Do not use an excessive amount sealer.

Excess can squeezed into gear case and could

block lubricant feed holes in time.

(3) Lubricate synchro sleeves with CastroltSyn-

torq gear lubricant or equivalent. Then apply light

coat of petroleum jelly to shift fork contact surfaces.

(4) Verify shift fork pads (Fig. 138) are secure.

(5) Verify 1-2 and 3-4 synchro sleeves and forks in

shift cover are in neutral position.

(6) Align and seat shift mechanism cover on trans-

mission.

NOTE: If cover will not seat, it may not be aligned

on gear case dowels or shift forks are not aligned

with sleeves and shift lug.

(7) Apply Mopar Lock N' Seal or equivalent to

threads of shift cover bolts.

(8) Install shift cover mechanism bolts and tighten

to 27-31 N´m (216-276 in. lbs.).(9)

Apply sealer to backup lamp switch. Install switch

into cover and tighten to 22-34 N´m (193-265 in. lbs.).

(10) Install vent assembly if removed. Apply an

adhesive/sealer to vent tube to help secure it in cover.

(11) Install transmission.

SHIFT COVER

REMOVAL

(1) Shift transmission into Neutral.

(2) Unscrew and remove the shift lever extension

from the shift

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(4) Remove the bolts holding the shift tower to the

isolator plate and transmission shift cover.

(5) Remove the shift tower and isolator plate from

the transmission shift cover.

INSTALLATION

(1) Clean the mating surfaces of shift tower, isola-

tor plate and shift cover with suitable wax and

grease remover.

(2) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the shift cover. Do not over

apply sealant.

(3) Install the isolator plate onto the shift cover,

metal side down.

(4) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

the isolator plate.

(5) Verify shift tower, isolator plate and shift tower

bushings are properly aligned.

(6) Install bolts to hold the shift tower to the iso-

lator plate and the shift cover. Tighten the shift

tower bolts to 10.2-11.25 N´m (7.5-8.3 ft. lbs.).

(7) I

nstall shift lever extension, shift boot and bezel.

Fig. 137 EXPANSION PLUG LOCATION

1 - EXPANSION PLUGS

Fig. 138 SHIFT FORK PAD

1 - SHIFT FORK PADS

2 - FIFTH-REVERSE FORK

DRMANUAL TRANSMISSION - NV4500 21 - 87

SHIFT MECHANISM (Continued)