vin DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 181 of 2627

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(8) Install the cover and any identification tag and

tighten cover bolts to 41 N´m (30 ft. lbs.).

(9) Fill differential with lubricant to bottom of the

fill plug hole. Refer to the Lubricant Specifications

for the correct quantity and type.

NOTE: Trac-lokŸ differential equipped vehicles

should be road tested by making 10 to 12 slow fig-

ure-eight turns. This maneuver will pump the lubri-

cant through the clutch discs to eliminate a

possible chatter noise complaint.

DIFFERENTIAL-TRAC-LOK

DESCRIPTION

The optional Trac-Loktdifferential case has a one-

piece design and the similar internal components as

a standard differential, plus two clutch disc pack-

s.The differential pinion mate shaft is retained with

a threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer. The removable differential

cover provides a means for inspection and service.

OPERATION

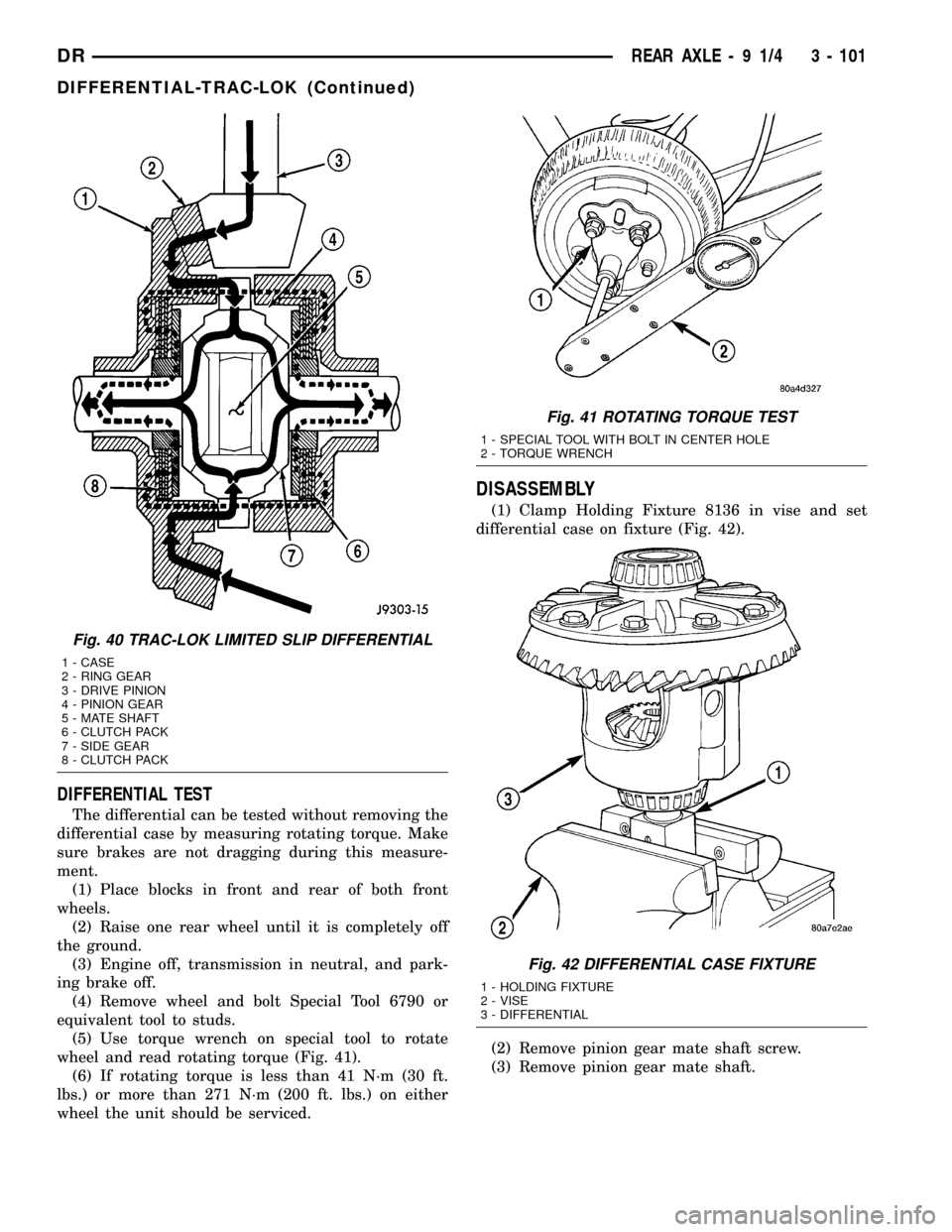

This differential clutches are engaged by two con-

current forces. The first being the preload force

exerted through Belleville spring washers within the

clutch packs. The second is the separating forces gen-

erated by the side gears as torque is applied through

the ring gear (Fig. 40).

This design provides the differential action needed

for turning corners and for driving straight ahead

during periods of unequal traction. When one wheel

looses traction, the clutch packs transfer additional

torque to the wheel having the most traction. This

differential resist wheel spin on bumpy roads and

provide more pulling power when one wheel looses

traction. Pulling power is provided continuously until

both wheels loose traction. If both wheels slip due to

unequal traction, Trac-loktoperation is normal. In

extreme cases of differences of traction, the wheel

with the least traction may spin.

DIAGNOSIS AND TESTING

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. Add a container of Mopar Limited Slip

Additive after repair service or during a lubricant

change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

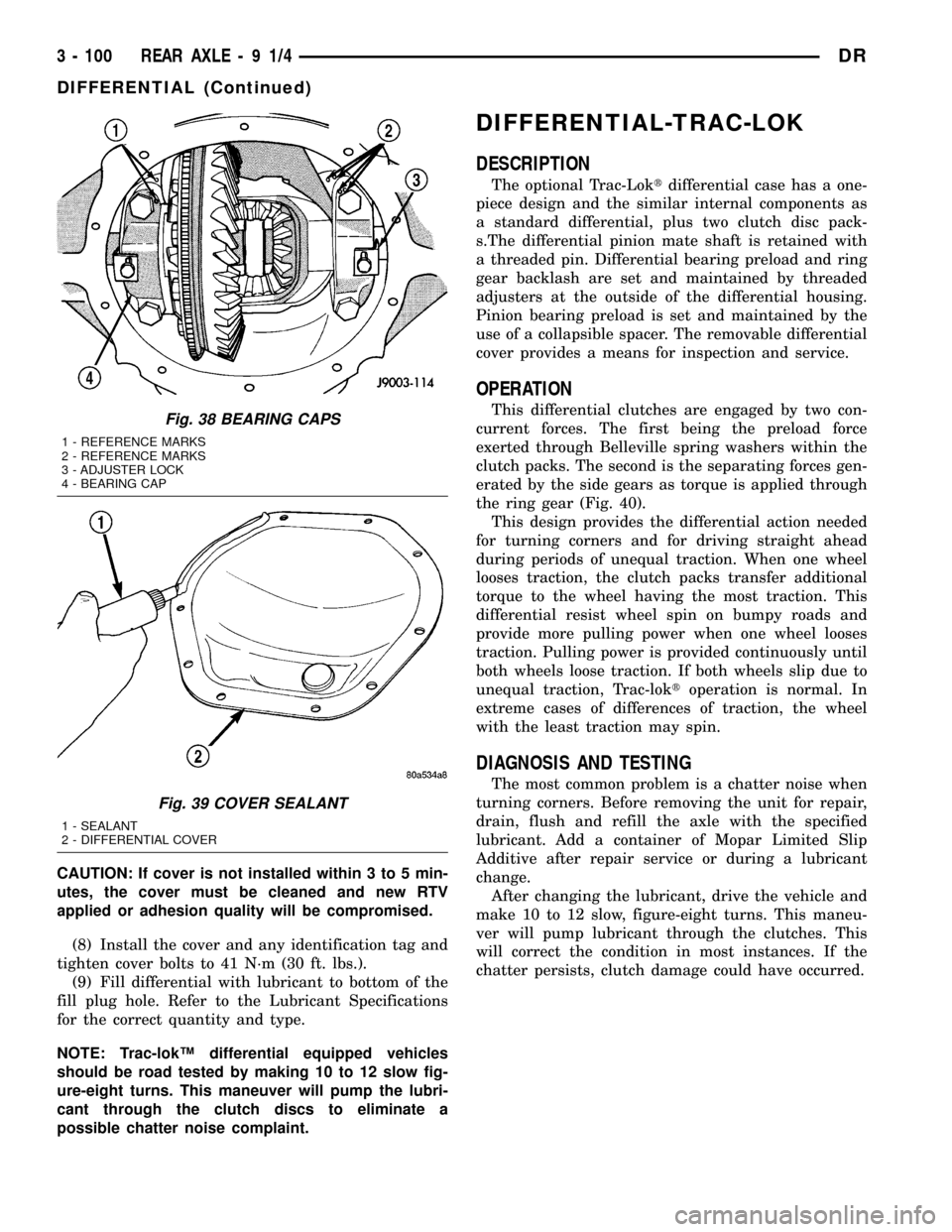

Fig. 38 BEARING CAPS

1 - REFERENCE MARKS

2 - REFERENCE MARKS

3 - ADJUSTER LOCK

4 - BEARING CAP

Fig. 39 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

3 - 100 REAR AXLE-91/4DR

DIFFERENTIAL (Continued)

Page 182 of 2627

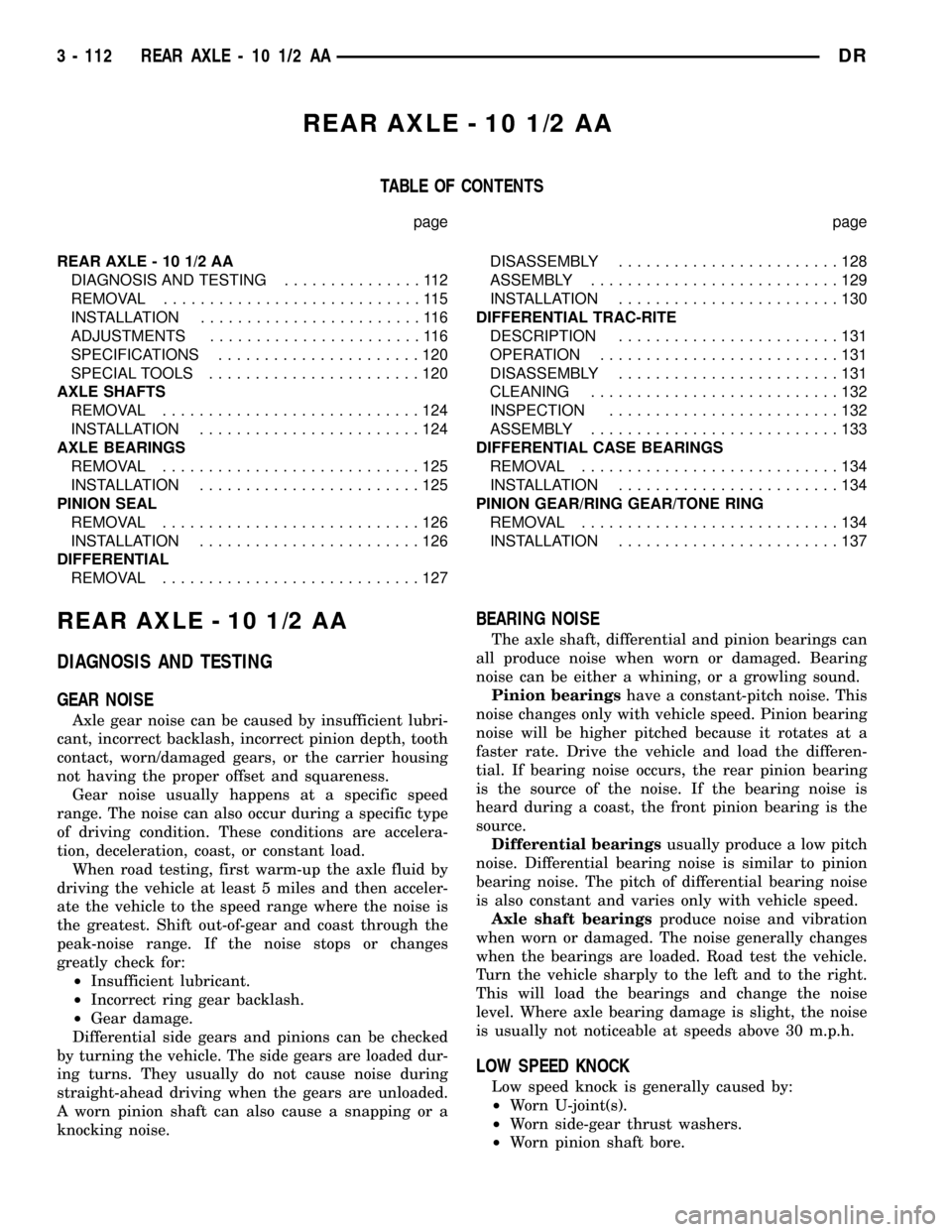

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 41).

(6) If rotating torque is less than 41 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

(1) Clamp Holding Fixture 8136 in vise and set

differential case on fixture (Fig. 42).

(2) Remove pinion gear mate shaft screw.

(3) Remove pinion gear mate shaft.

Fig. 40 TRAC-LOK LIMITED SLIP DIFFERENTIAL

1 - CASE

2 - RING GEAR

3 - DRIVE PINION

4 - PINION GEAR

5 - MATE SHAFT

6 - CLUTCH PACK

7 - SIDE GEAR

8 - CLUTCH PACK

Fig. 41 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 42 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

DRREAR AXLE - 9 1/4 3 - 101

DIFFERENTIAL-TRAC-LOK (Continued)

Page 193 of 2627

REAR AXLE - 10 1/2 AA

TABLE OF CONTENTS

page page

REAR AXLE - 10 1/2 AA

DIAGNOSIS AND TESTING...............112

REMOVAL............................115

INSTALLATION........................116

ADJUSTMENTS.......................116

SPECIFICATIONS......................120

SPECIAL TOOLS.......................120

AXLE SHAFTS

REMOVAL............................124

INSTALLATION........................124

AXLE BEARINGS

REMOVAL............................125

INSTALLATION........................125

PINION SEAL

REMOVAL............................126

INSTALLATION........................126

DIFFERENTIAL

REMOVAL............................127DISASSEMBLY........................128

ASSEMBLY...........................129

INSTALLATION........................130

DIFFERENTIAL TRAC-RITE

DESCRIPTION........................131

OPERATION..........................131

DISASSEMBLY........................131

CLEANING...........................132

INSPECTION.........................132

ASSEMBLY...........................133

DIFFERENTIAL CASE BEARINGS

REMOVAL............................134

INSTALLATION........................134

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................134

INSTALLATION........................137

REAR AXLE - 10 1/2 AA

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, tooth

contact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly check for:

²Insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. The side gears are loaded dur-

ing turns. They usually do not cause noise during

straight-ahead driving when the gears are unloaded.

A worn pinion shaft can also cause a snapping or a

knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearingshave a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Differential bearingsusually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 m.p.h.

LOW SPEED KNOCK

Low speed knock is generally caused by:

²Worn U-joint(s).

²Worn side-gear thrust washers.

²Worn pinion shaft bore.

3 - 112 REAR AXLE - 10 1/2 AADR

Page 198 of 2627

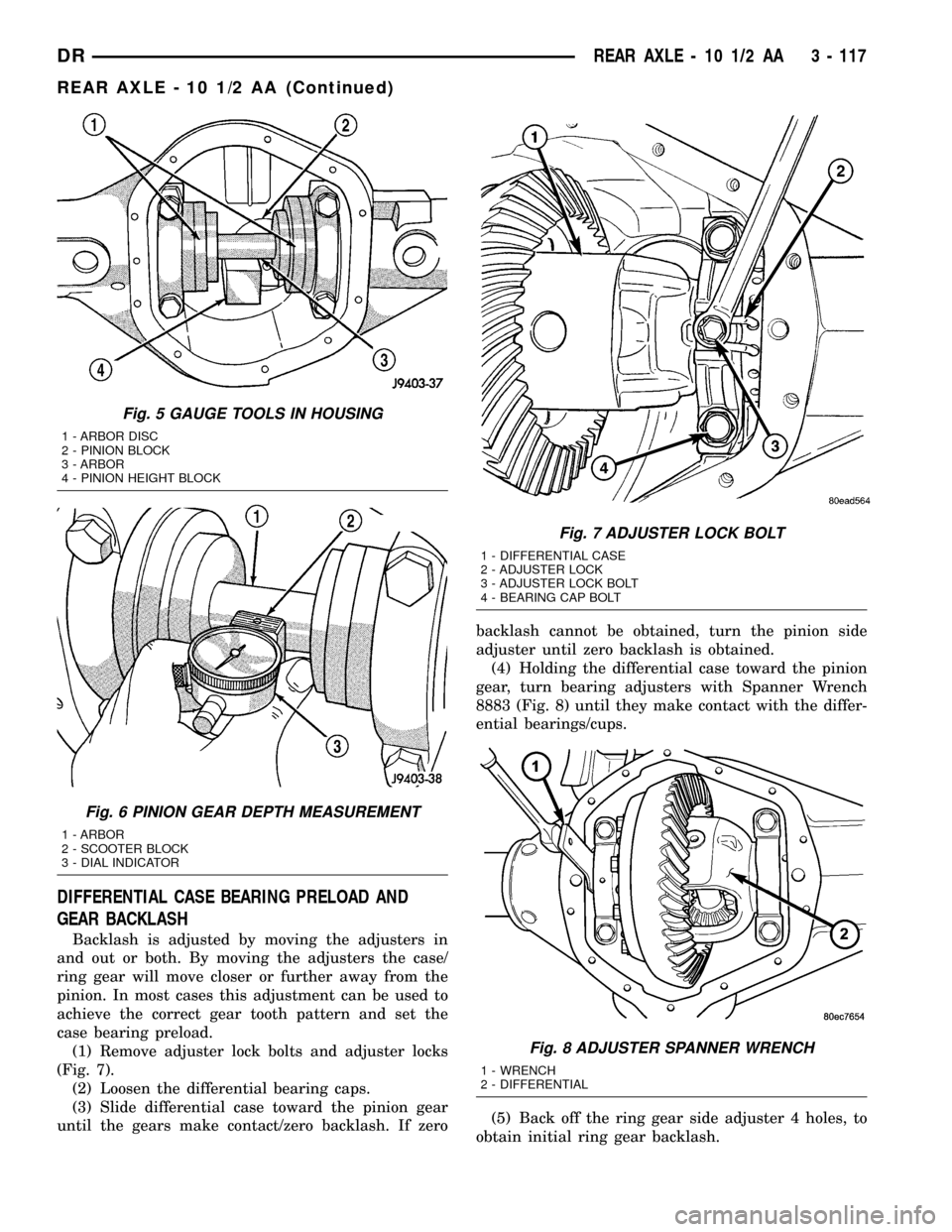

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 10 1/2 AA 3 - 117

REAR AXLE - 10 1/2 AA (Continued)

Page 199 of 2627

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.

(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(12) Tighten bearing cap bolts to 115 N´m (85 ft.

lbs.).

(13) Tighten adjuster lock bolts to 33 N´m (24 ft.

lbs.).

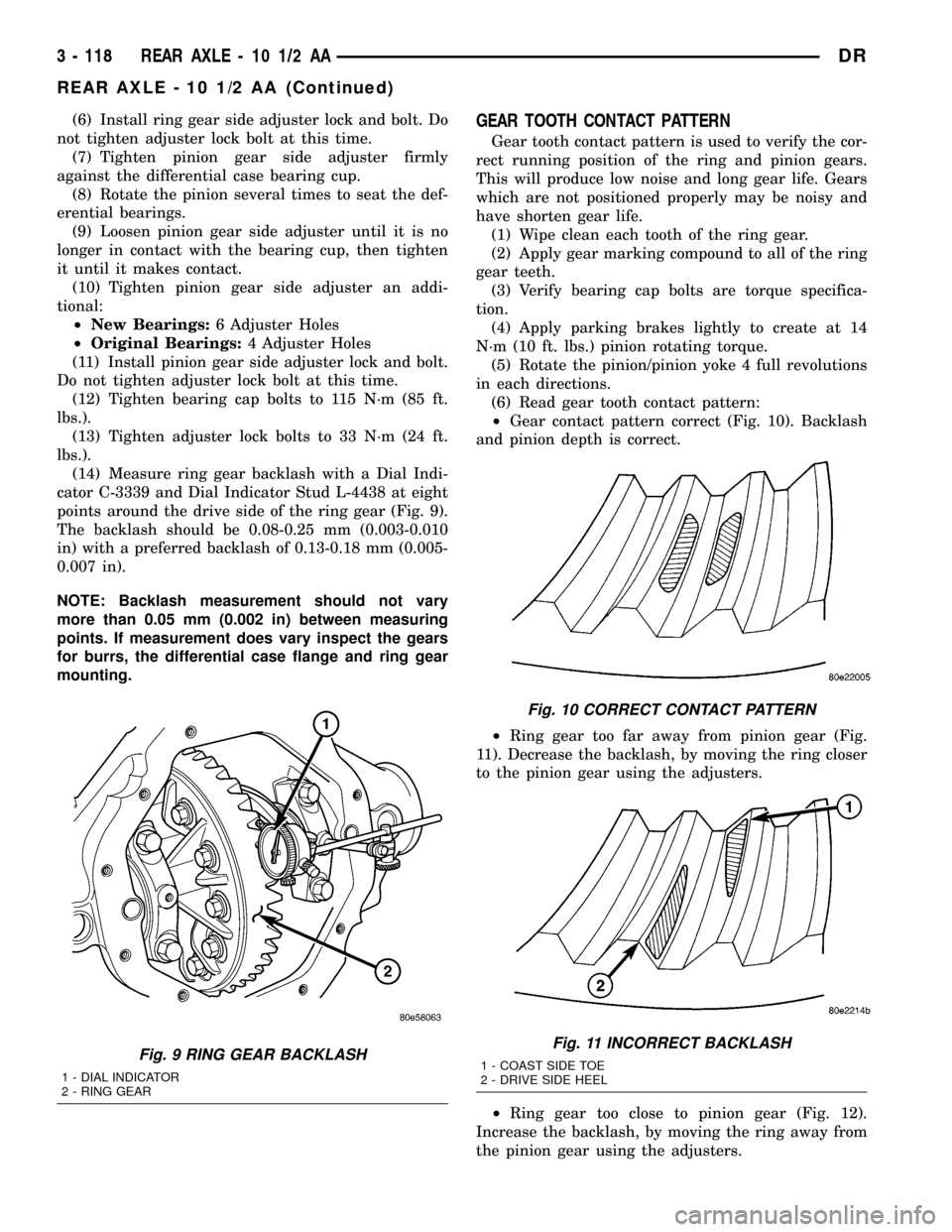

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig. 9).

The backlash should be 0.08-0.25 mm (0.003-0.010

in) with a preferred backlash of 0.13-0.18 mm (0.005-

0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

mounting.GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

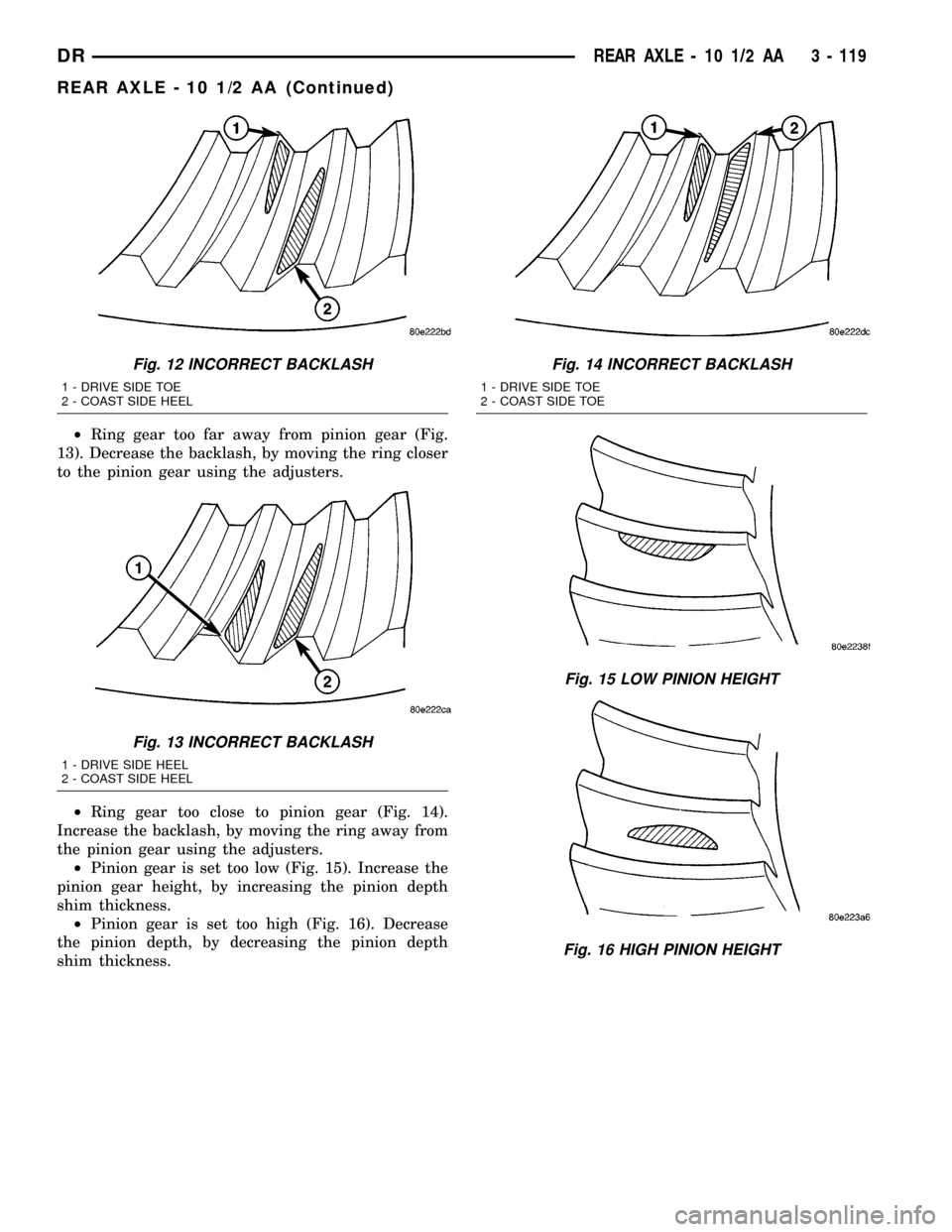

(6) Read gear tooth contact pattern:

²Gear contact pattern correct (Fig. 10). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

11). Decrease the backlash, by moving the ring closer

to the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 12).

Increase the backlash, by moving the ring away from

the pinion gear using the adjusters.

Fig. 9 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 10 CORRECT CONTACT PATTERN

Fig. 11 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

3 - 118 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 200 of 2627

²Ring gear too far away from pinion gear (Fig.

13). Decrease the backlash, by moving the ring closer

to the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 14).

Increase the backlash, by moving the ring away from

the pinion gear using the adjusters.

²Pinion gear is set too low (Fig. 15). Increase the

pinion gear height, by increasing the pinion depth

shim thickness.

²Pinion gear is set too high (Fig. 16). Decrease

the pinion depth, by decreasing the pinion depth

shim thickness.

Fig. 12 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

Fig. 13 INCORRECT BACKLASH

1 - DRIVE SIDE HEEL

2 - COAST SIDE HEEL

Fig. 14 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE TOE

Fig. 15 LOW PINION HEIGHT

Fig. 16 HIGH PINION HEIGHT

DRREAR AXLE - 10 1/2 AA 3 - 119

REAR AXLE - 10 1/2 AA (Continued)

Page 221 of 2627

REAR AXLE - 11 1/2 AA

TABLE OF CONTENTS

page page

REAR AXLE - 11 1/2 AA

DIAGNOSIS AND TESTING...............140

REMOVAL............................143

INSTALLATION........................144

ADJUSTMENTS.......................144

SPECIFICATIONS......................148

SPECIAL TOOLS.......................148

AXLE SHAFTS

REMOVAL............................152

INSTALLATION........................152

AXLE BEARINGS

REMOVAL............................152

INSTALLATION........................153

PINION SEAL

REMOVAL............................153

INSTALLATION........................154

DIFFERENTIAL

REMOVAL............................155DISASSEMBLY........................155

ASSEMBLY...........................156

INSTALLATION........................157

DIFFERENTIAL TRAC-RITE

DESCRIPTION........................158

OPERATION..........................158

DISASSEMBLY........................158

CLEANING...........................160

INSPECTION.........................160

ASSEMBLY...........................161

DIFFERENTIAL CASE BEARINGS

REMOVAL............................161

INSTALLATION........................161

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................162

INSTALLATION........................164

REAR AXLE - 11 1/2 AA

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, incorrect pinion depth, tooth

contact, worn/damaged gears, or the carrier housing

not having the proper offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast, or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly check for:

²Insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. The side gears are loaded dur-

ing turns. They usually do not cause noise during

straight-ahead driving when the gears are unloaded.

A worn pinion shaft can also cause a snapping or a

knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearingshave a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Differential bearingsusually produce a low pitch

noise. Differential bearing noise is similar to pinion

bearing noise. The pitch of differential bearing noise

is also constant and varies only with vehicle speed.

Axle shaft bearingsproduce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by:

²Worn U-joint(s).

²Worn side gear thrust washers.

²Worn pinion shaft bore.

3 - 140 REAR AXLE - 11 1/2 AADR

Page 226 of 2627

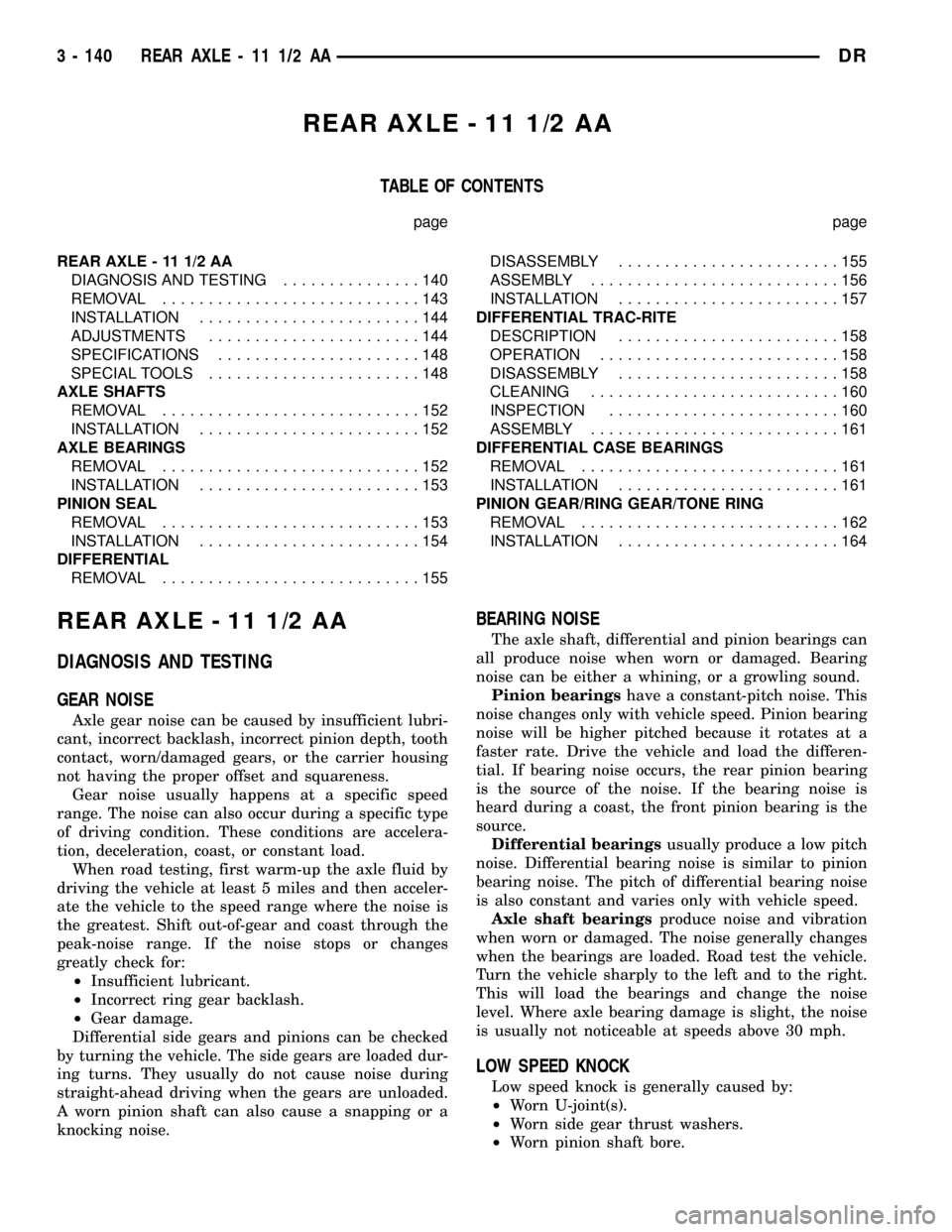

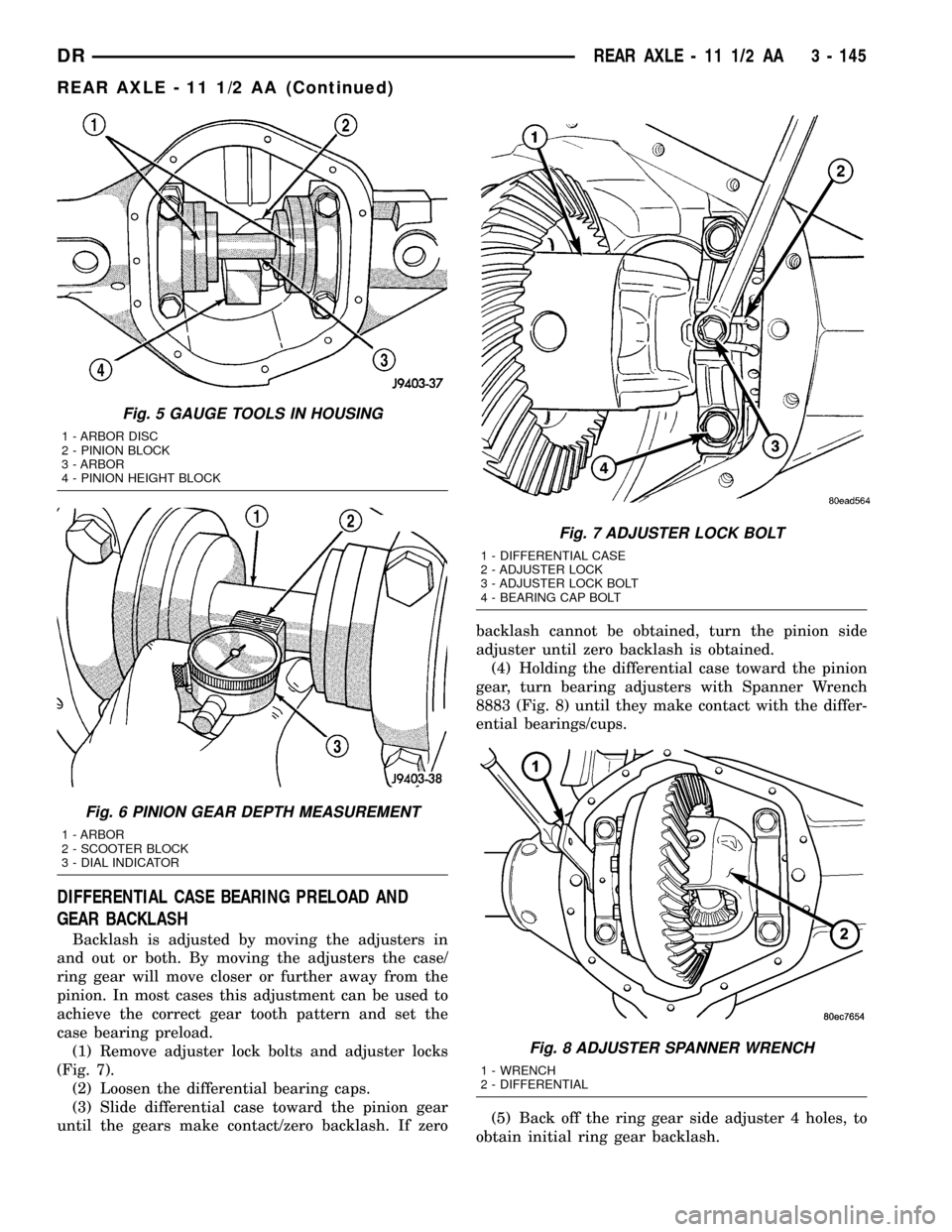

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 11 1/2 AA 3 - 145

REAR AXLE - 11 1/2 AA (Continued)

Page 227 of 2627

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the def-

erential bearings.

(9) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup, then tighten

it until it makes contact.

(10) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(11) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(12) Tighten bearing cap bolts to 115 N´m (85 ft.

lbs.).

(13) Tighten adjuster lock bolts to 33 N´m (24 ft.

lbs.).

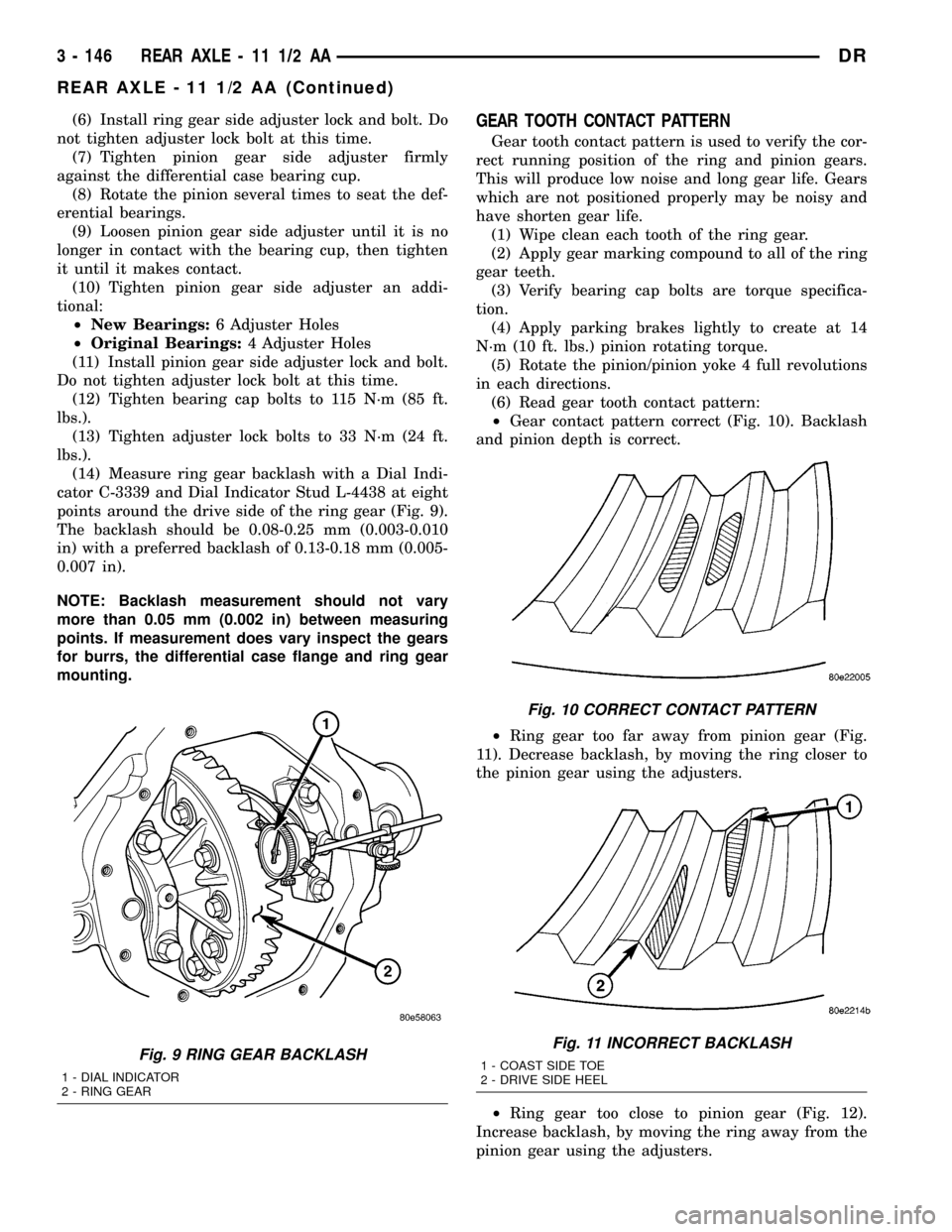

(14) Measure ring gear backlash with a Dial Indi-

cator C-3339 and Dial Indicator Stud L-4438 at eight

points around the drive side of the ring gear (Fig. 9).

The backlash should be 0.08-0.25 mm (0.003-0.010

in) with a preferred backlash of 0.13-0.18 mm (0.005-

0.007 in).

NOTE: Backlash measurement should not vary

more than 0.05 mm (0.002 in) between measuring

points. If measurement does vary inspect the gears

for burrs, the differential case flange and ring gear

mounting.GEAR TOOTH CONTACT PATTERN

Gear tooth contact pattern is used to verify the cor-

rect running position of the ring and pinion gears.

This will produce low noise and long gear life. Gears

which are not positioned properly may be noisy and

have shorten gear life.

(1) Wipe clean each tooth of the ring gear.

(2) Apply gear marking compound to all of the ring

gear teeth.

(3) Verify bearing cap bolts are torque specifica-

tion.

(4) Apply parking brakes lightly to create at 14

N´m (10 ft. lbs.) pinion rotating torque.

(5) Rotate the pinion/pinion yoke 4 full revolutions

in each directions.

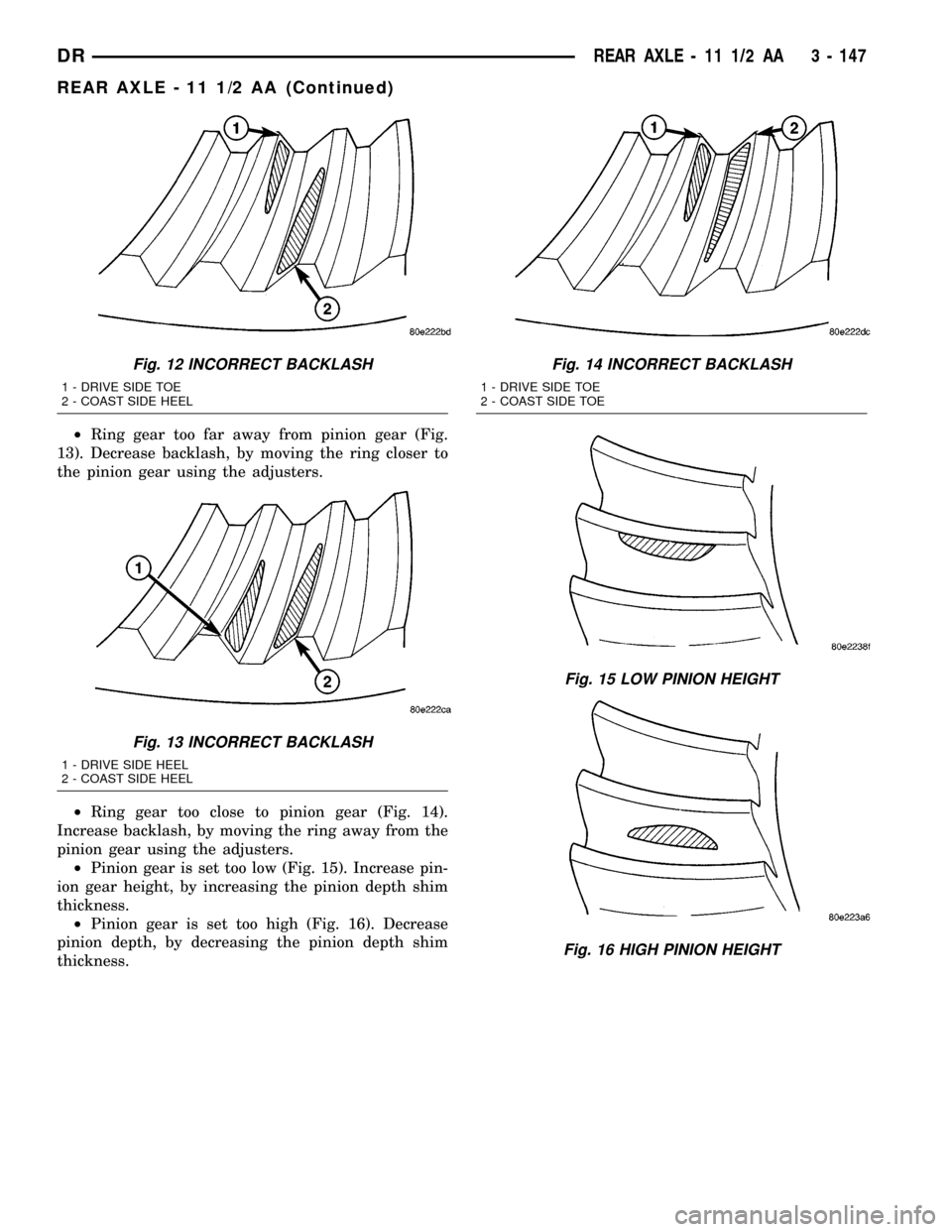

(6) Read gear tooth contact pattern:

²Gear contact pattern correct (Fig. 10). Backlash

and pinion depth is correct.

²Ring gear too far away from pinion gear (Fig.

11). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 12).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

Fig. 9 RING GEAR BACKLASH

1 - DIAL INDICATOR

2 - RING GEAR

Fig. 10 CORRECT CONTACT PATTERN

Fig. 11 INCORRECT BACKLASH

1 - COAST SIDE TOE

2 - DRIVE SIDE HEEL

3 - 146 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)

Page 228 of 2627

²Ring gear too far away from pinion gear (Fig.

13). Decrease backlash, by moving the ring closer to

the pinion gear using the adjusters.

²Ring gear too close to pinion gear (Fig. 14).

Increase backlash, by moving the ring away from the

pinion gear using the adjusters.

²Pinion gear is set too low (Fig. 15). Increase pin-

ion gear height, by increasing the pinion depth shim

thickness.

²Pinion gear is set too high (Fig. 16). Decrease

pinion depth, by decreasing the pinion depth shim

thickness.

Fig. 12 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE HEEL

Fig. 13 INCORRECT BACKLASH

1 - DRIVE SIDE HEEL

2 - COAST SIDE HEEL

Fig. 14 INCORRECT BACKLASH

1 - DRIVE SIDE TOE

2 - COAST SIDE TOE

Fig. 15 LOW PINION HEIGHT

Fig. 16 HIGH PINION HEIGHT

DRREAR AXLE - 11 1/2 AA 3 - 147

REAR AXLE - 11 1/2 AA (Continued)