clock DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1610 of 2889

WORM THRUST BEARING PRELOAD

(1) Mount the gear carefully into a vise.

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

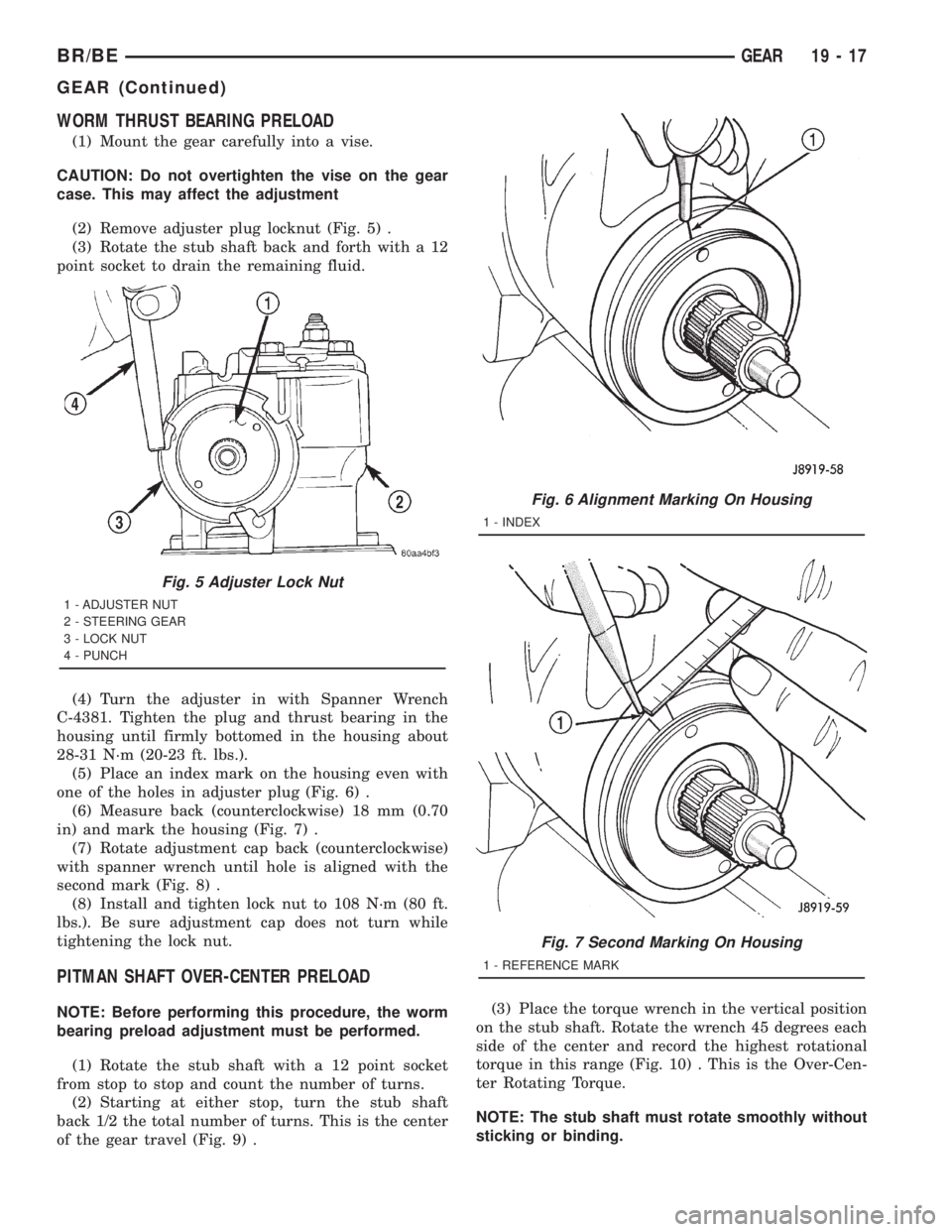

(2) Remove adjuster plug locknut (Fig. 5) .

(3) Rotate the stub shaft back and forth with a 12

point socket to drain the remaining fluid.

(4) Turn the adjuster in with Spanner Wrench

C-4381. Tighten the plug and thrust bearing in the

housing until firmly bottomed in the housing about

28-31 N´m (20-23 ft. lbs.).

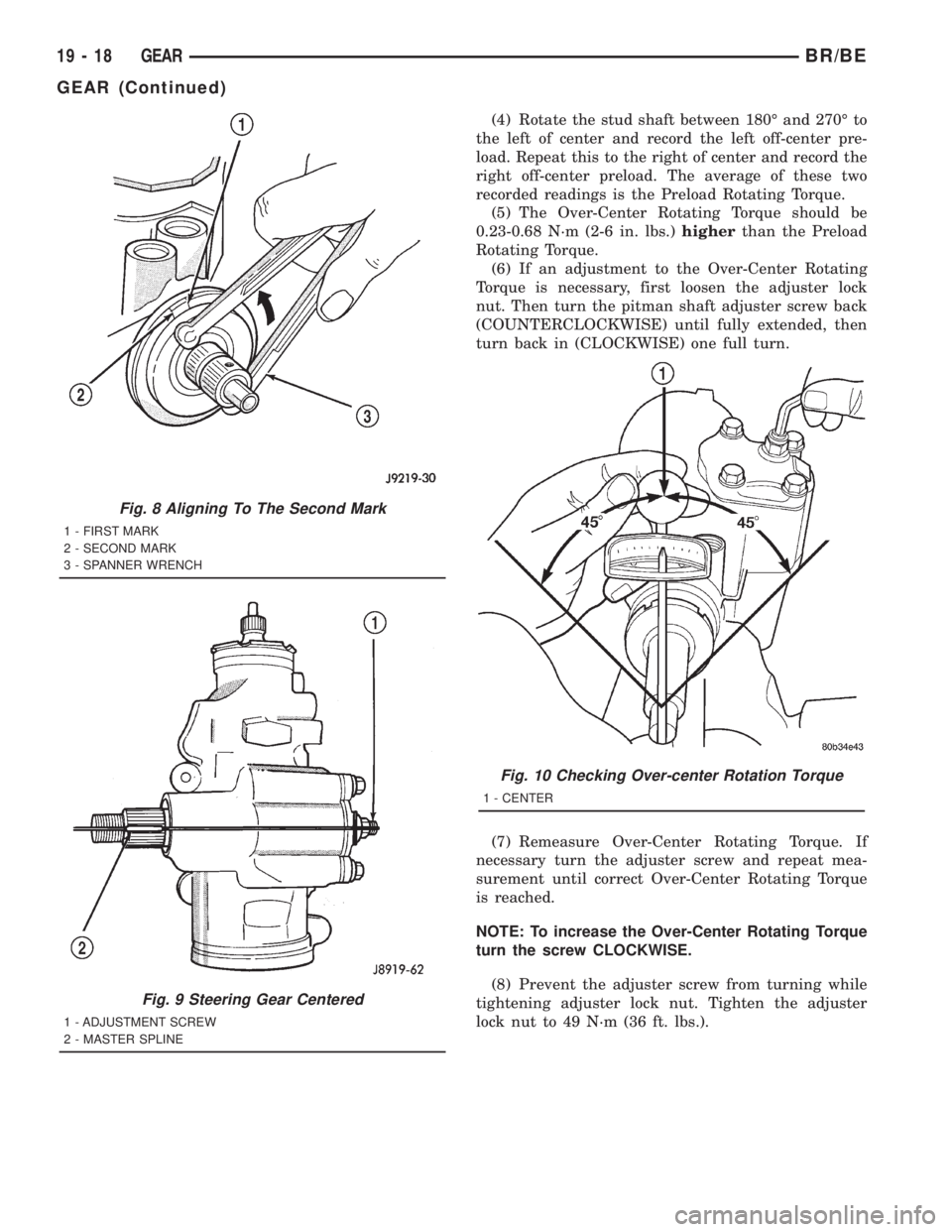

(5) Place an index mark on the housing even with

one of the holes in adjuster plug (Fig. 6) .

(6) Measure back (counterclockwise) 18 mm (0.70

in) and mark the housing (Fig. 7) .

(7) Rotate adjustment cap back (counterclockwise)

with spanner wrench until hole is aligned with the

second mark (Fig. 8) .

(8) Install and tighten lock nut to 108 N´m (80 ft.

lbs.). Be sure adjustment cap does not turn while

tightening the lock nut.

PITMAN SHAFT OVER-CENTER PRELOAD

NOTE: Before performing this procedure, the worm

bearing preload adjustment must be performed.

(1) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns.

(2) Starting at either stop, turn the stub shaft

back 1/2 the total number of turns. This is the center

of the gear travel (Fig. 9) .(3) Place the torque wrench in the vertical position

on the stub shaft. Rotate the wrench 45 degrees each

side of the center and record the highest rotational

torque in this range (Fig. 10) . This is the Over-Cen-

ter Rotating Torque.

NOTE: The stub shaft must rotate smoothly without

sticking or binding.

Fig. 5 Adjuster Lock Nut

1 - ADJUSTER NUT

2 - STEERING GEAR

3 - LOCK NUT

4 - PUNCH

Fig. 6 Alignment Marking On Housing

1 - INDEX

Fig. 7 Second Marking On Housing

1 - REFERENCE MARK

BR/BEGEAR 19 - 17

GEAR (Continued)

Page 1611 of 2889

(4) Rotate the stud shaft between 180É and 270É to

the left of center and record the left off-center pre-

load. Repeat this to the right of center and record the

right off-center preload. The average of these two

recorded readings is the Preload Rotating Torque.

(5) The Over-Center Rotating Torque should be

0.23-0.68 N´m (2-6 in. lbs.)higherthan the Preload

Rotating Torque.

(6) If an adjustment to the Over-Center Rotating

Torque is necessary, first loosen the adjuster lock

nut. Then turn the pitman shaft adjuster screw back

(COUNTERCLOCKWISE) until fully extended, then

turn back in (CLOCKWISE) one full turn.

(7) Remeasure Over-Center Rotating Torque. If

necessary turn the adjuster screw and repeat mea-

surement until correct Over-Center Rotating Torque

is reached.

NOTE: To increase the Over-Center Rotating Torque

turn the screw CLOCKWISE.

(8) Prevent the adjuster screw from turning while

tightening adjuster lock nut. Tighten the adjuster

lock nut to 49 N´m (36 ft. lbs.).

Fig. 8 Aligning To The Second Mark

1 - FIRST MARK

2 - SECOND MARK

3 - SPANNER WRENCH

Fig. 9 Steering Gear Centered

1 - ADJUSTMENT SCREW

2 - MASTER SPLINE

Fig. 10 Checking Over-center Rotation Torque

1 - CENTER

19 - 18 GEARBR/BE

GEAR (Continued)

Page 1620 of 2889

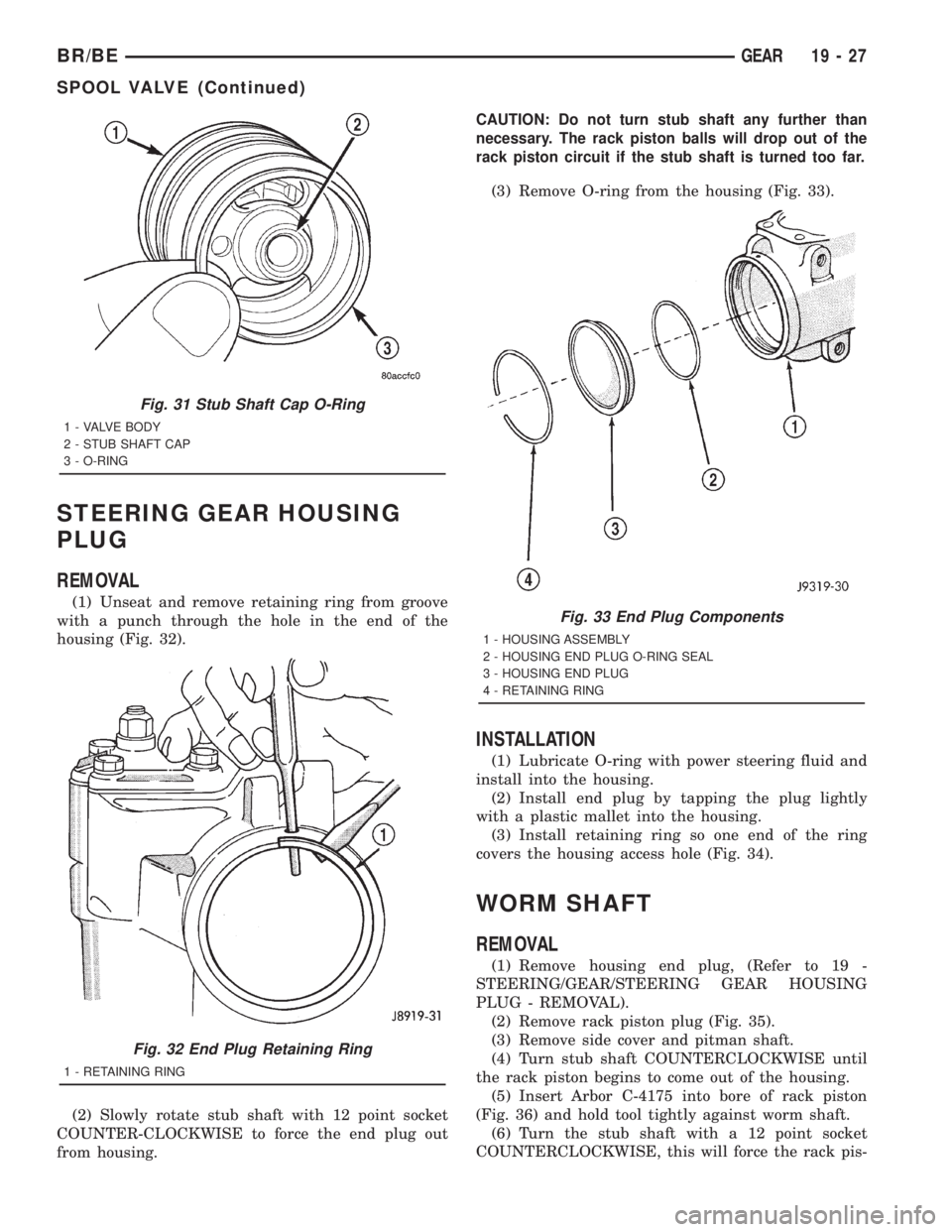

STEERING GEAR HOUSING

PLUG

REMOVAL

(1) Unseat and remove retaining ring from groove

with a punch through the hole in the end of the

housing (Fig. 32).

(2) Slowly rotate stub shaft with 12 point socket

COUNTER-CLOCKWISE to force the end plug out

from housing.

CAUTION: Do not turn stub shaft any further than

necessary. The rack piston balls will drop out of the

rack piston circuit if the stub shaft is turned too far.

(3) Remove O-ring from the housing (Fig. 33).

INSTALLATION

(1) Lubricate O-ring with power steering fluid and

install into the housing.

(2) Install end plug by tapping the plug lightly

with a plastic mallet into the housing.

(3) Install retaining ring so one end of the ring

covers the housing access hole (Fig. 34).

WORM SHAFT

REMOVAL

(1) Remove housing end plug, (Refer to 19 -

STEERING/GEAR/STEERING GEAR HOUSING

PLUG - REMOVAL).

(2) Remove rack piston plug (Fig. 35).

(3) Remove side cover and pitman shaft.

(4) Turn stub shaft COUNTERCLOCKWISE until

the rack piston begins to come out of the housing.

(5) Insert Arbor C-4175 into bore of rack piston

(Fig. 36) and hold tool tightly against worm shaft.

(6) Turn the stub shaft with a 12 point socket

COUNTERCLOCKWISE, this will force the rack pis-

Fig. 31 Stub Shaft Cap O-Ring

1 - VALVE BODY

2 - STUB SHAFT CAP

3 - O-RING

Fig. 32 End Plug Retaining Ring

1 - RETAINING RING

Fig. 33 End Plug Components

1 - HOUSING ASSEMBLY

2 - HOUSING END PLUG O-RING SEAL

3 - HOUSING END PLUG

4 - RETAINING RING

BR/BEGEAR 19 - 27

SPOOL VALVE (Continued)

Page 1622 of 2889

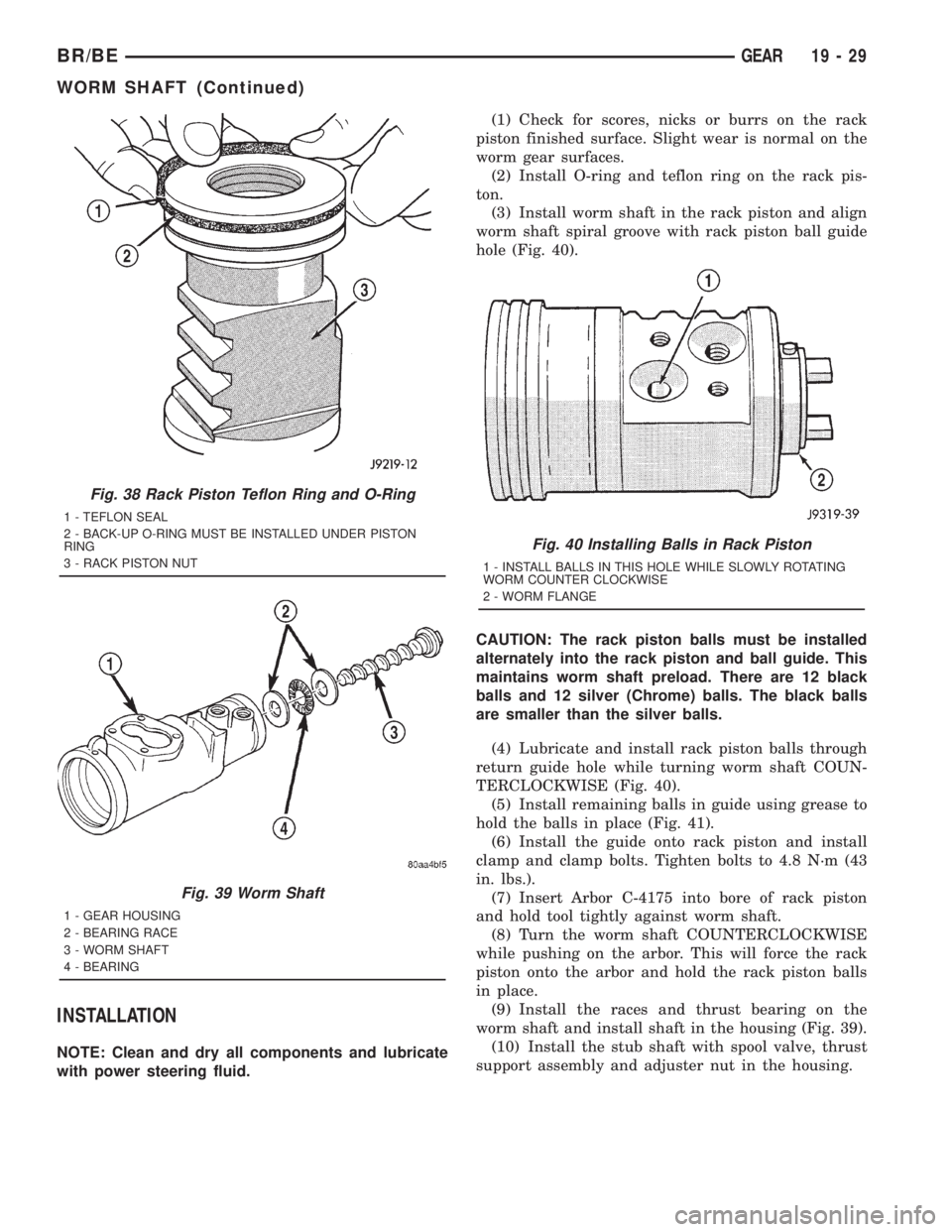

INSTALLATION

NOTE: Clean and dry all components and lubricate

with power steering fluid.(1) Check for scores, nicks or burrs on the rack

piston finished surface. Slight wear is normal on the

worm gear surfaces.

(2) Install O-ring and teflon ring on the rack pis-

ton.

(3) Install worm shaft in the rack piston and align

worm shaft spiral groove with rack piston ball guide

hole (Fig. 40).

CAUTION: The rack piston balls must be installed

alternately into the rack piston and ball guide. This

maintains worm shaft preload. There are 12 black

balls and 12 silver (Chrome) balls. The black balls

are smaller than the silver balls.

(4) Lubricate and install rack piston balls through

return guide hole while turning worm shaft COUN-

TERCLOCKWISE (Fig. 40).

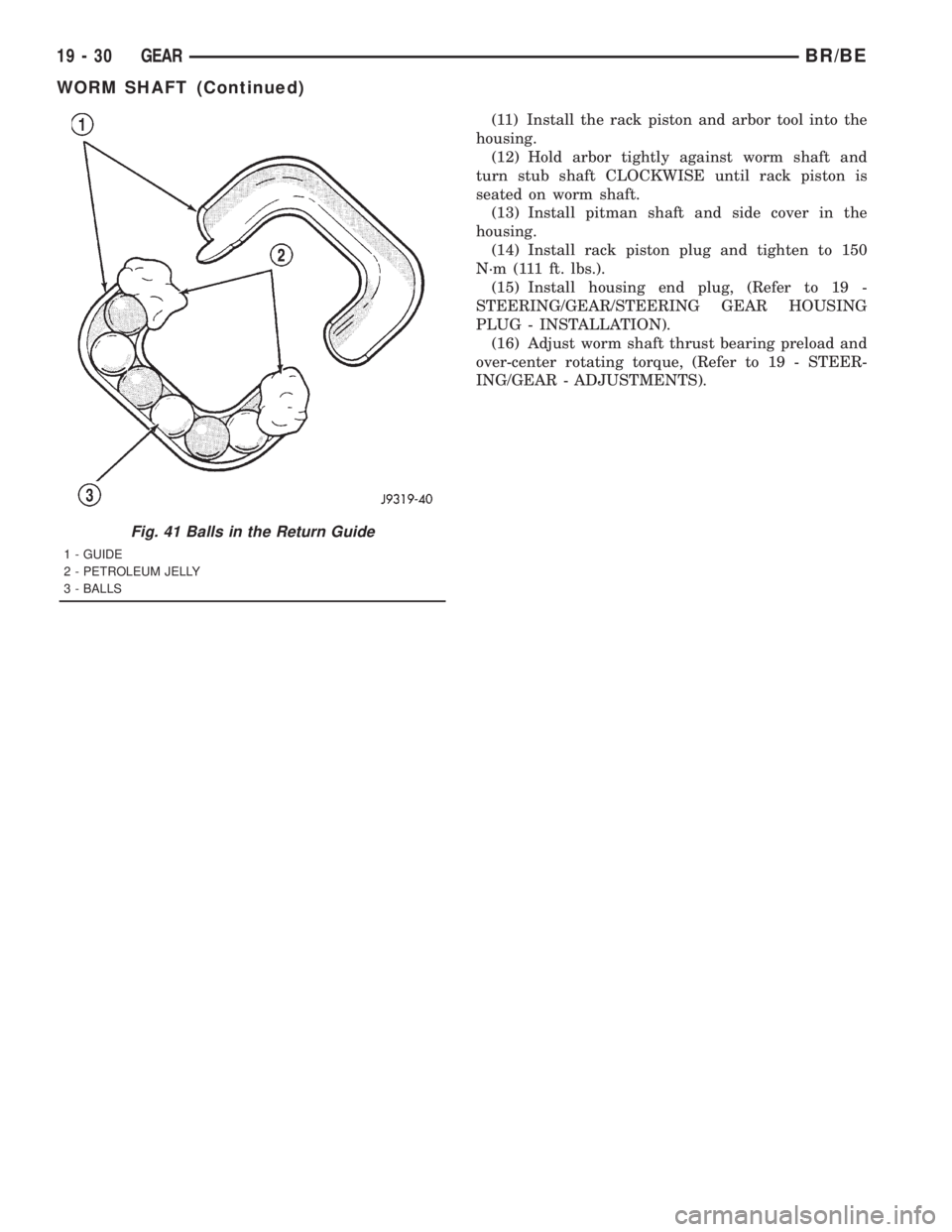

(5) Install remaining balls in guide using grease to

hold the balls in place (Fig. 41).

(6) Install the guide onto rack piston and install

clamp and clamp bolts. Tighten bolts to 4.8 N´m (43

in. lbs.).

(7) Insert Arbor C-4175 into bore of rack piston

and hold tool tightly against worm shaft.

(8) Turn the worm shaft COUNTERCLOCKWISE

while pushing on the arbor. This will force the rack

piston onto the arbor and hold the rack piston balls

in place.

(9) Install the races and thrust bearing on the

worm shaft and install shaft in the housing (Fig. 39).

(10) Install the stub shaft with spool valve, thrust

support assembly and adjuster nut in the housing.

Fig. 38 Rack Piston Teflon Ring and O-Ring

1 - TEFLON SEAL

2 - BACK-UP O-RING MUST BE INSTALLED UNDER PISTON

RING

3 - RACK PISTON NUT

Fig. 39 Worm Shaft

1 - GEAR HOUSING

2 - BEARING RACE

3 - WORM SHAFT

4 - BEARING

Fig. 40 Installing Balls in Rack Piston

1 - INSTALL BALLS IN THIS HOLE WHILE SLOWLY ROTATING

WORM COUNTER CLOCKWISE

2 - WORM FLANGE

BR/BEGEAR 19 - 29

WORM SHAFT (Continued)

Page 1623 of 2889

(11) Install the rack piston and arbor tool into the

housing.

(12) Hold arbor tightly against worm shaft and

turn stub shaft CLOCKWISE until rack piston is

seated on worm shaft.

(13) Install pitman shaft and side cover in the

housing.

(14) Install rack piston plug and tighten to 150

N´m (111 ft. lbs.).

(15) Install housing end plug, (Refer to 19 -

STEERING/GEAR/STEERING GEAR HOUSING

PLUG - INSTALLATION).

(16) Adjust worm shaft thrust bearing preload and

over-center rotating torque, (Refer to 19 - STEER-

ING/GEAR - ADJUSTMENTS).

Fig. 41 Balls in the Return Guide

1 - GUIDE

2 - PETROLEUM JELLY

3 - BALLS

19 - 30 GEARBR/BE

WORM SHAFT (Continued)

Page 1689 of 2889

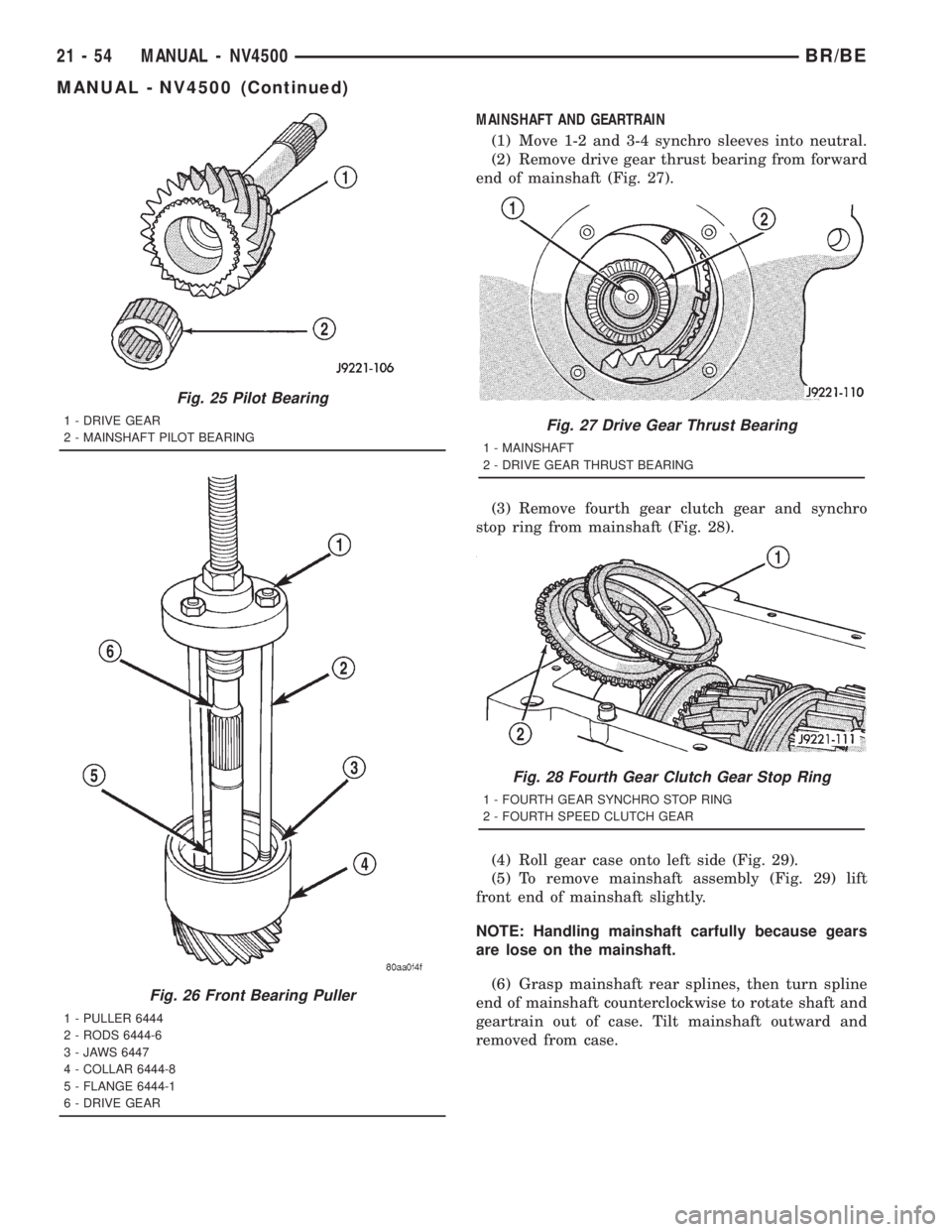

MAINSHAFT AND GEARTRAIN

(1) Move 1-2 and 3-4 synchro sleeves into neutral.

(2) Remove drive gear thrust bearing from forward

end of mainshaft (Fig. 27).

(3) Remove fourth gear clutch gear and synchro

stop ring from mainshaft (Fig. 28).

(4) Roll gear case onto left side (Fig. 29).

(5) To remove mainshaft assembly (Fig. 29) lift

front end of mainshaft slightly.

NOTE: Handling mainshaft carfully because gears

are lose on the mainshaft.

(6) Grasp mainshaft rear splines, then turn spline

end of mainshaft counterclockwise to rotate shaft and

geartrain out of case. Tilt mainshaft outward and

removed from case.

Fig. 25 Pilot Bearing

1 - DRIVE GEAR

2 - MAINSHAFT PILOT BEARING

Fig. 26 Front Bearing Puller

1 - PULLER 6444

2 - RODS 6444-6

3 - JAWS 6447

4 - COLLAR 6444-8

5 - FLANGE 6444-1

6 - DRIVE GEAR

Fig. 27 Drive Gear Thrust Bearing

1 - MAINSHAFT

2 - DRIVE GEAR THRUST BEARING

Fig. 28 Fourth Gear Clutch Gear Stop Ring

1 - FOURTH GEAR SYNCHRO STOP RING

2 - FOURTH SPEED CLUTCH GEAR

21 - 54 MANUAL - NV4500BR/BE

MANUAL - NV4500 (Continued)

Page 1712 of 2889

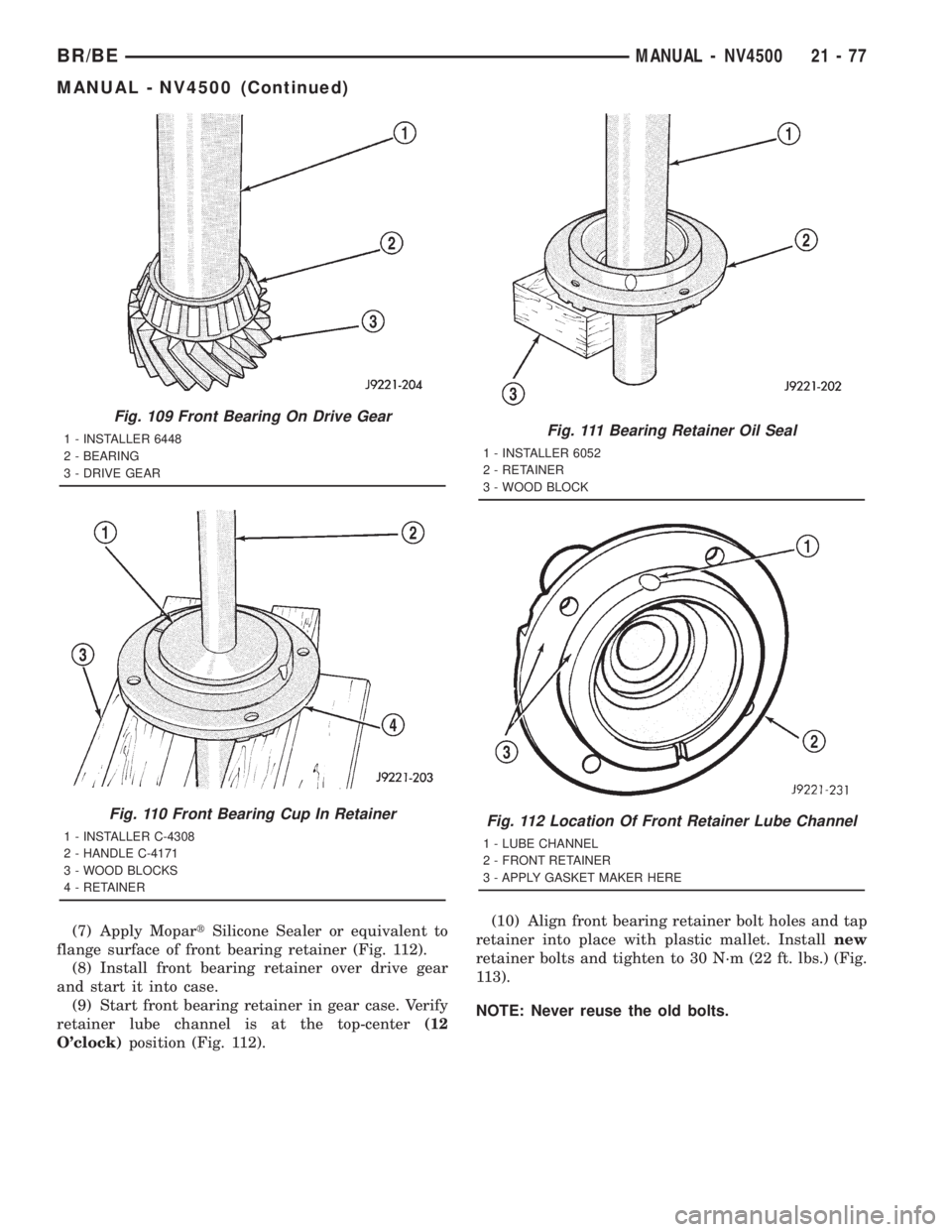

(7) Apply MopartSilicone Sealer or equivalent to

flange surface of front bearing retainer (Fig. 112).

(8) Install front bearing retainer over drive gear

and start it into case.

(9) Start front bearing retainer in gear case. Verify

retainer lube channel is at the top-center(12

O'clock)position (Fig. 112).(10) Align front bearing retainer bolt holes and tap

retainer into place with plastic mallet. Installnew

retainer bolts and tighten to 30 N´m (22 ft. lbs.) (Fig.

113).

NOTE: Never reuse the old bolts.

Fig. 109 Front Bearing On Drive Gear

1 - INSTALLER 6448

2 - BEARING

3 - DRIVE GEAR

Fig. 110 Front Bearing Cup In Retainer

1 - INSTALLER C-4308

2 - HANDLE C-4171

3 - WOOD BLOCKS

4 - RETAINER

Fig. 111 Bearing Retainer Oil Seal

1 - INSTALLER 6052

2 - RETAINER

3 - WOOD BLOCK

Fig. 112 Location Of Front Retainer Lube Channel

1 - LUBE CHANNEL

2 - FRONT RETAINER

3 - APPLY GASKET MAKER HERE

BR/BEMANUAL - NV4500 21 - 77

MANUAL - NV4500 (Continued)

Page 1759 of 2889

EXTENSION/ADAPTER HOUSING

(1) Install extension housing bushing with

Installer 8156 and Handle C-4171, if necessary. The

oil feed hole must be at the 12 o'clock position when

installed.

(2) On 4X2 vehicles, install extension housing seal

with Installer 8154 and Handle C-4171, with the

weep hole at the bottom.

NOTE: Drain hole located in the dust boot portion

of the seal must face downward ( toward the

ground) when installed.

(3) On 4X4 vehicles, install adapter housing seal

with Installer C-3860-A and Handle C-4171.

(4) Install the crossover cam bushing into the

extension/adapter housing with Installer 8239 and

Handle C-4171.

(5) Clean the rear of the transmission case of all

sealer.

(6) Install reverse countershaft gear bearing race

onto the reverse countershaft gear bearing.

(7) Measure the distance from the back of the

bearing race to Gauge Bar 6311 (Fig. 94).(8) Measure thickness of the gauge bar and record

the total of the two measurements.

(9) Clean all the sealer from the extension/adapter

housing.

(10) Place Gauge Bar 6311 across the housing face.

Measure the distance from the top of the bar to the

bottom of the reverse countershaft bearing race bore

(Fig. 95).

(11) Subtract thickness of the gauge bar from the

measurement and record the result.

(12) The difference between the two measurements

is the end-play for the reverse countershaft gear

assembly.

(13) Install shims to achieve 0.15-0.25 mm (0.006-

0.010 in.) end-play for the reverse countershaft gear

assembly into the reverse countershaft bearing race

bore.

(14) Use Installer to install the reverse counter-

shaft bearing race into the extension/adapter hous-

ing.

(15) Install back-up lamp switch and a new gasket

into the extension/adapter housing. Tighten switch to

28 N´m (20 ft.lbs.).

(16) Install crossover cam into the extension/

adapter housing.

(17) Install bolt to hold the crossover cam to the

extension/adapter housing (Fig. 96).

Fig. 94 Measure Height of Reverse Countershaft

1 - MEASURE DISTANCE FROM RACE TO GAUGE BAR 6311

Fig. 95 Reverse Countershaft Gear Bearing Race

Bore

1 - GAUGE BAR 6311 TO BEARING RACE BORE

MEASUREMENT

21 - 124 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1773 of 2889

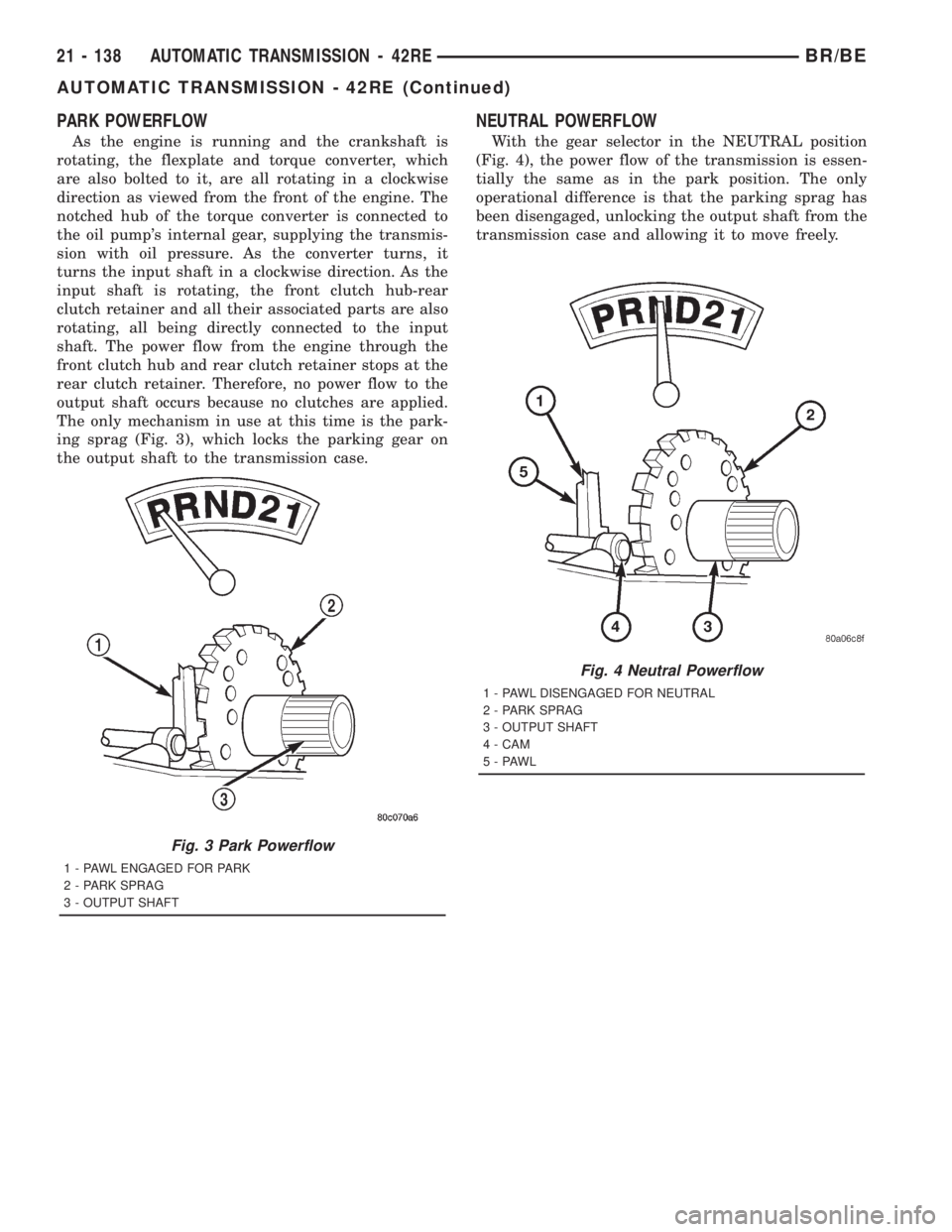

PARK POWERFLOW

As the engine is running and the crankshaft is

rotating, the flexplate and torque converter, which

are also bolted to it, are all rotating in a clockwise

direction as viewed from the front of the engine. The

notched hub of the torque converter is connected to

the oil pump's internal gear, supplying the transmis-

sion with oil pressure. As the converter turns, it

turns the input shaft in a clockwise direction. As the

input shaft is rotating, the front clutch hub-rear

clutch retainer and all their associated parts are also

rotating, all being directly connected to the input

shaft. The power flow from the engine through the

front clutch hub and rear clutch retainer stops at the

rear clutch retainer. Therefore, no power flow to the

output shaft occurs because no clutches are applied.

The only mechanism in use at this time is the park-

ing sprag (Fig. 3), which locks the parking gear on

the output shaft to the transmission case.

NEUTRAL POWERFLOW

With the gear selector in the NEUTRAL position

(Fig. 4), the power flow of the transmission is essen-

tially the same as in the park position. The only

operational difference is that the parking sprag has

been disengaged, unlocking the output shaft from the

transmission case and allowing it to move freely.

Fig. 3 Park Powerflow

1 - PAWL ENGAGED FOR PARK

2 - PARK SPRAG

3 - OUTPUT SHAFT

Fig. 4 Neutral Powerflow

1 - PAWL DISENGAGED FOR NEUTRAL

2 - PARK SPRAG

3 - OUTPUT SHAFT

4 - CAM

5-PAWL

21 - 138 AUTOMATIC TRANSMISSION - 42REBR/BE

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1774 of 2889

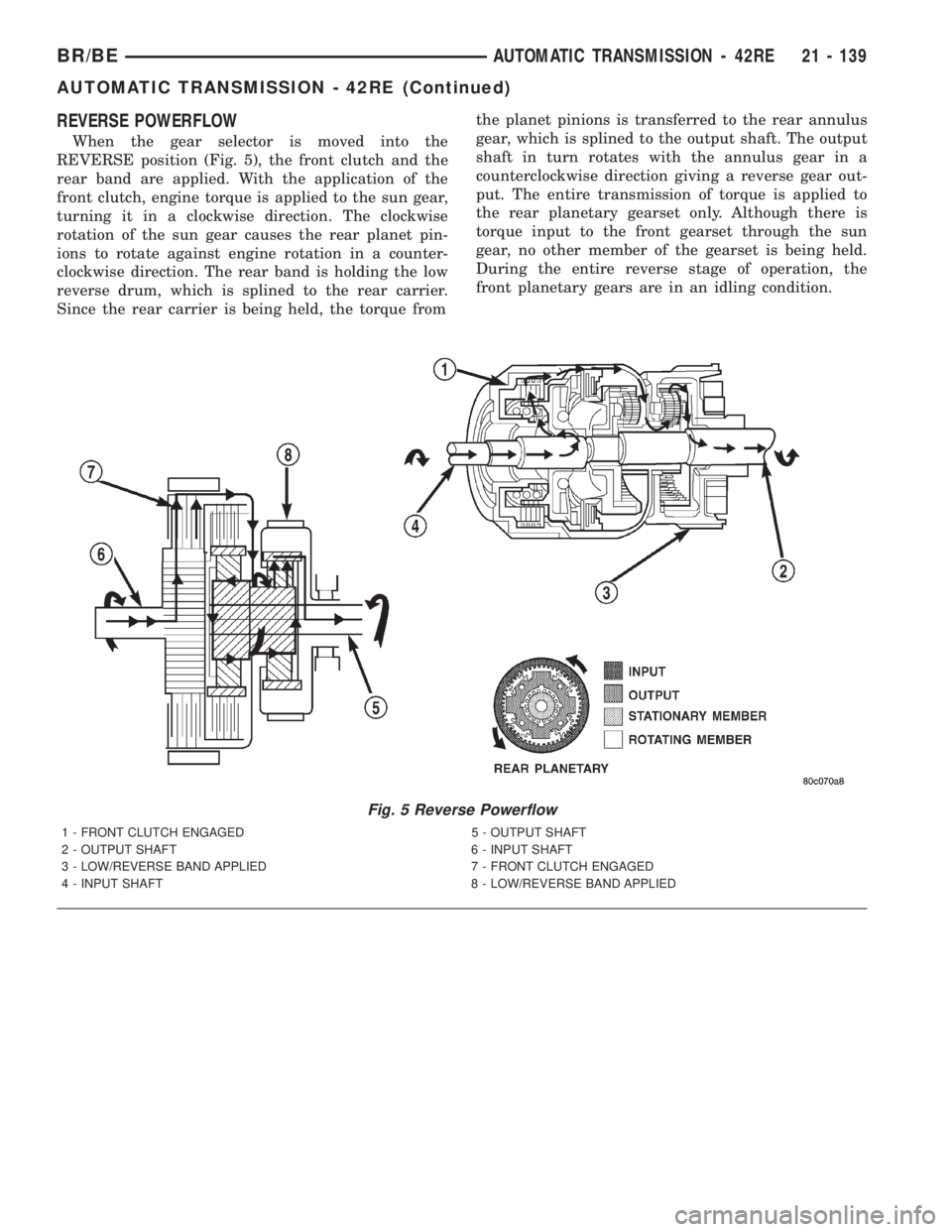

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque fromthe planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 5 Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 139

AUTOMATIC TRANSMISSION - 42RE (Continued)