DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1161 of 2889

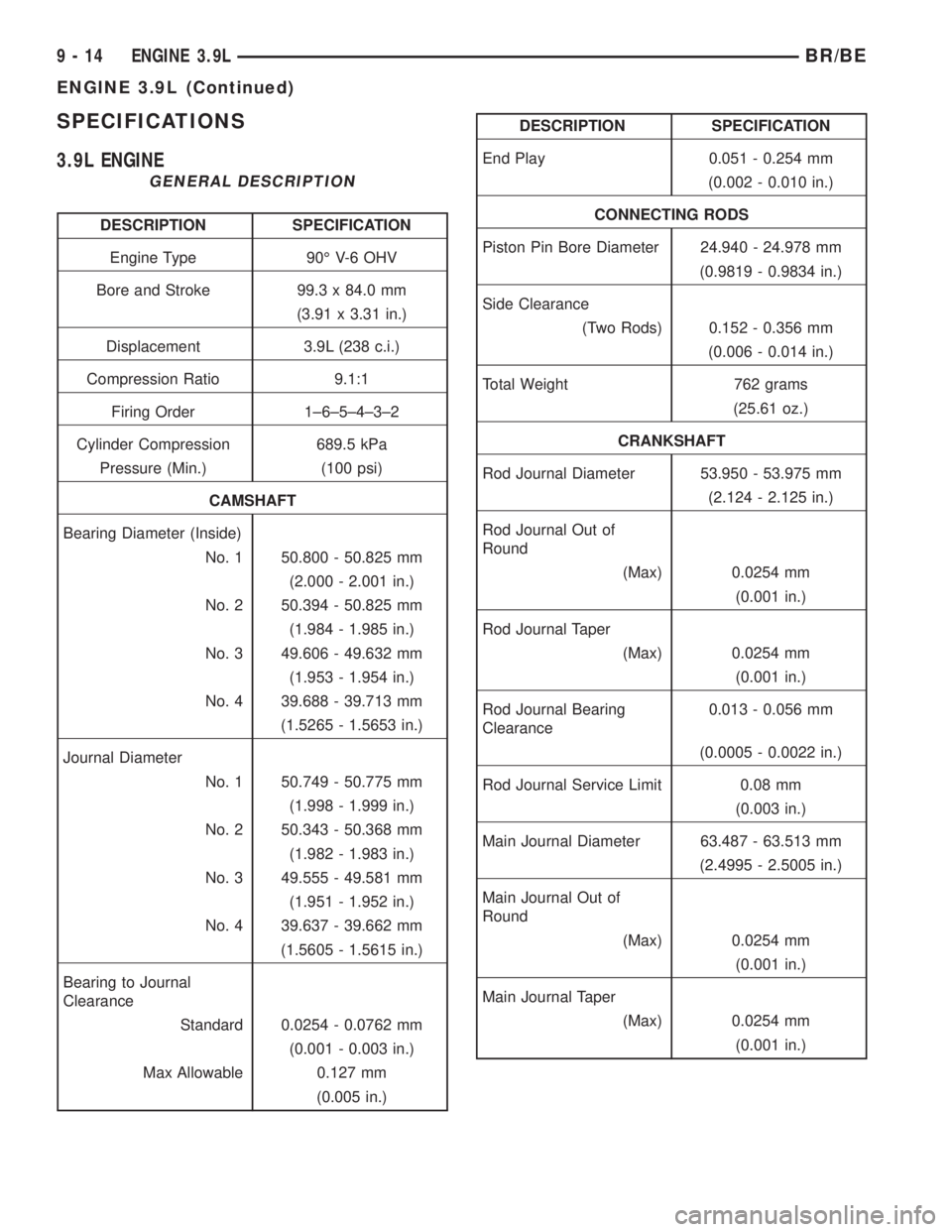

SPECIFICATIONS

3.9L ENGINE

GENERAL DESCRIPTION

DESCRIPTION SPECIFICATION

Engine Type 90É V-6 OHV

Bore and Stroke 99.3 x 84.0 mm

(3.91 x 3.31 in.)

Displacement 3.9L (238 c.i.)

Compression Ratio 9.1:1

Firing Order 1±6±5±4±3±2

Cylinder Compression 689.5 kPa

Pressure (Min.) (100 psi)

CAMSHAFT

Bearing Diameter (Inside)

No. 1 50.800 - 50.825 mm

(2.000 - 2.001 in.)

No. 2 50.394 - 50.825 mm

(1.984 - 1.985 in.)

No. 3 49.606 - 49.632 mm

(1.953 - 1.954 in.)

No. 4 39.688 - 39.713 mm

(1.5265 - 1.5653 in.)

Journal Diameter

No. 1 50.749 - 50.775 mm

(1.998 - 1.999 in.)

No. 2 50.343 - 50.368 mm

(1.982 - 1.983 in.)

No. 3 49.555 - 49.581 mm

(1.951 - 1.952 in.)

No. 4 39.637 - 39.662 mm

(1.5605 - 1.5615 in.)

Bearing to Journal

Clearance

Standard 0.0254 - 0.0762 mm

(0.001 - 0.003 in.)

Max Allowable 0.127 mm

(0.005 in.)

DESCRIPTION SPECIFICATION

End Play 0.051 - 0.254 mm

(0.002 - 0.010 in.)

CONNECTING RODS

Piston Pin Bore Diameter 24.940 - 24.978 mm

(0.9819 - 0.9834 in.)

Side Clearance

(Two Rods) 0.152 - 0.356 mm

(0.006 - 0.014 in.)

Total Weight 762 grams

(25.61 oz.)

CRANKSHAFT

Rod Journal Diameter 53.950 - 53.975 mm

(2.124 - 2.125 in.)

Rod Journal Out of

Round

(Max) 0.0254 mm

(0.001 in.)

Rod Journal Taper

(Max) 0.0254 mm

(0.001 in.)

Rod Journal Bearing

Clearance0.013 - 0.056 mm

(0.0005 - 0.0022 in.)

Rod Journal Service Limit 0.08 mm

(0.003 in.)

Main Journal Diameter 63.487 - 63.513 mm

(2.4995 - 2.5005 in.)

Main Journal Out of

Round

(Max) 0.0254 mm

(0.001 in.)

Main Journal Taper

(Max) 0.0254 mm

(0.001 in.)

9 - 14 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1162 of 2889

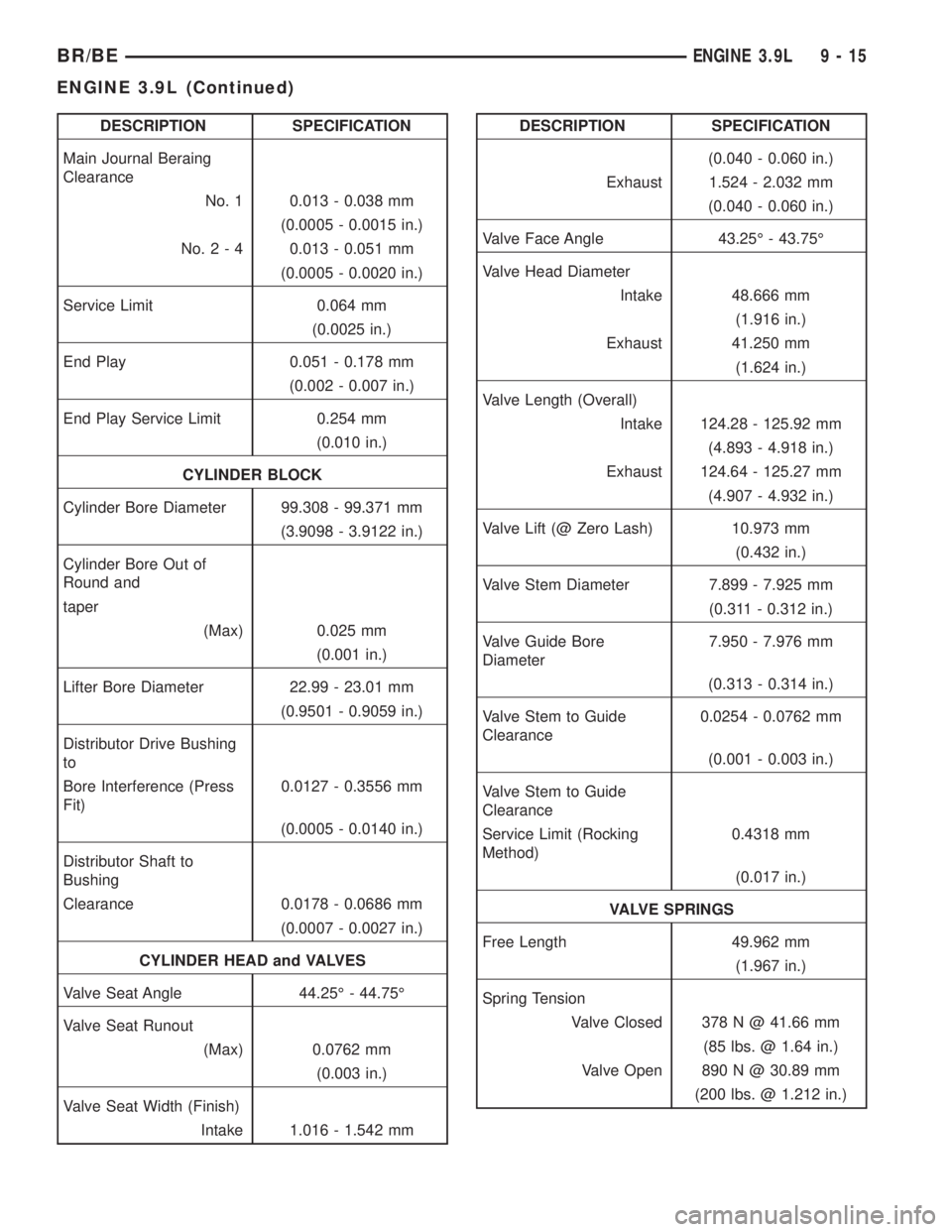

DESCRIPTION SPECIFICATION

Main Journal Beraing

Clearance

No. 1 0.013 - 0.038 mm

(0.0005 - 0.0015 in.)

No.2-40.013 - 0.051 mm

(0.0005 - 0.0020 in.)

Service Limit 0.064 mm

(0.0025 in.)

End Play 0.051 - 0.178 mm

(0.002 - 0.007 in.)

End Play Service Limit 0.254 mm

(0.010 in.)

CYLINDER BLOCK

Cylinder Bore Diameter 99.308 - 99.371 mm

(3.9098 - 3.9122 in.)

Cylinder Bore Out of

Round and

taper

(Max) 0.025 mm

(0.001 in.)

Lifter Bore Diameter 22.99 - 23.01 mm

(0.9501 - 0.9059 in.)

Distributor Drive Bushing

to

Bore Interference (Press

Fit)0.0127 - 0.3556 mm

(0.0005 - 0.0140 in.)

Distributor Shaft to

Bushing

Clearance 0.0178 - 0.0686 mm

(0.0007 - 0.0027 in.)

CYLINDER HEAD and VALVES

Valve Seat Angle 44.25É - 44.75É

Valve Seat Runout

(Max) 0.0762 mm

(0.003 in.)

Valve Seat Width (Finish)

Intake 1.016 - 1.542 mmDESCRIPTION SPECIFICATION

(0.040 - 0.060 in.)

Exhaust 1.524 - 2.032 mm

(0.040 - 0.060 in.)

Valve Face Angle 43.25É - 43.75É

Valve Head Diameter

Intake 48.666 mm

(1.916 in.)

Exhaust 41.250 mm

(1.624 in.)

Valve Length (Overall)

Intake 124.28 - 125.92 mm

(4.893 - 4.918 in.)

Exhaust 124.64 - 125.27 mm

(4.907 - 4.932 in.)

Valve Lift (@ Zero Lash) 10.973 mm

(0.432 in.)

Valve Stem Diameter 7.899 - 7.925 mm

(0.311 - 0.312 in.)

Valve Guide Bore

Diameter7.950 - 7.976 mm

(0.313 - 0.314 in.)

Valve Stem to Guide

Clearance0.0254 - 0.0762 mm

(0.001 - 0.003 in.)

Valve Stem to Guide

Clearance

Service Limit (Rocking

Method)0.4318 mm

(0.017 in.)

VALVE SPRINGS

Free Length 49.962 mm

(1.967 in.)

Spring Tension

Valve Closed 378 N @ 41.66 mm

(85 lbs. @ 1.64 in.)

Valve Open 890 N @ 30.89 mm

(200 lbs. @ 1.212 in.)

BR/BEENGINE 3.9L 9 - 15

ENGINE 3.9L (Continued)

Page 1163 of 2889

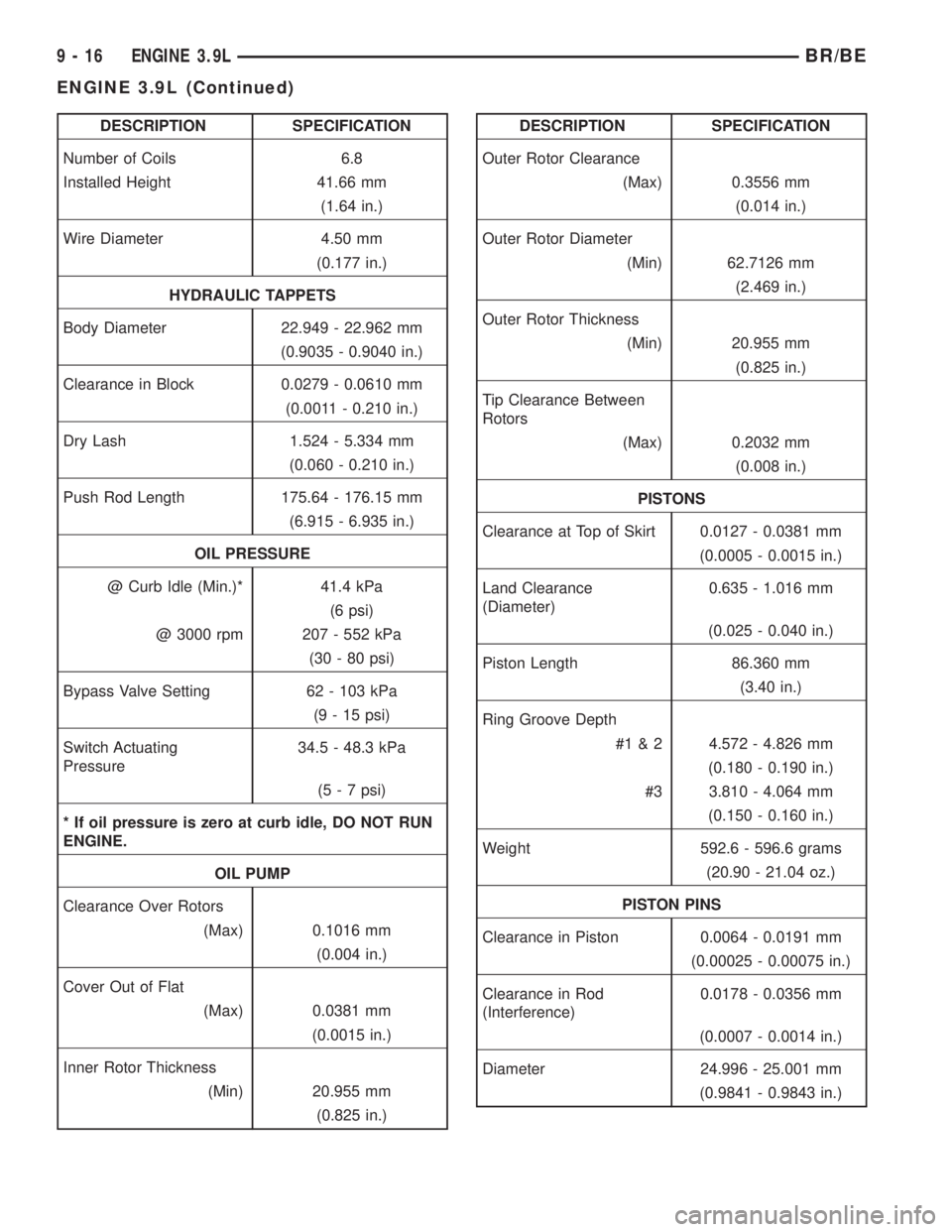

DESCRIPTION SPECIFICATION

Number of Coils 6.8

Installed Height 41.66 mm

(1.64 in.)

Wire Diameter 4.50 mm

(0.177 in.)

HYDRAULIC TAPPETS

Body Diameter 22.949 - 22.962 mm

(0.9035 - 0.9040 in.)

Clearance in Block 0.0279 - 0.0610 mm

(0.0011 - 0.210 in.)

Dry Lash 1.524 - 5.334 mm

(0.060 - 0.210 in.)

Push Rod Length 175.64 - 176.15 mm

(6.915 - 6.935 in.)

OIL PRESSURE

@ Curb Idle (Min.)* 41.4 kPa

(6 psi)

@ 3000 rpm 207 - 552 kPa

(30 - 80 psi)

Bypass Valve Setting 62 - 103 kPa

(9 - 15 psi)

Switch Actuating

Pressure34.5 - 48.3 kPa

(5 - 7 psi)

* If oil pressure is zero at curb idle, DO NOT RUN

ENGINE.

OIL PUMP

Clearance Over Rotors

(Max) 0.1016 mm

(0.004 in.)

Cover Out of Flat

(Max) 0.0381 mm

(0.0015 in.)

Inner Rotor Thickness

(Min) 20.955 mm

(0.825 in.)DESCRIPTION SPECIFICATION

Outer Rotor Clearance

(Max) 0.3556 mm

(0.014 in.)

Outer Rotor Diameter

(Min) 62.7126 mm

(2.469 in.)

Outer Rotor Thickness

(Min) 20.955 mm

(0.825 in.)

Tip Clearance Between

Rotors

(Max) 0.2032 mm

(0.008 in.)

PISTONS

Clearance at Top of Skirt 0.0127 - 0.0381 mm

(0.0005 - 0.0015 in.)

Land Clearance

(Diameter)0.635 - 1.016 mm

(0.025 - 0.040 in.)

Piston Length 86.360 mm

(3.40 in.)

Ring Groove Depth

#1 & 2 4.572 - 4.826 mm

(0.180 - 0.190 in.)

#3 3.810 - 4.064 mm

(0.150 - 0.160 in.)

Weight 592.6 - 596.6 grams

(20.90 - 21.04 oz.)

PISTON PINS

Clearance in Piston 0.0064 - 0.0191 mm

(0.00025 - 0.00075 in.)

Clearance in Rod

(Interference)0.0178 - 0.0356 mm

(0.0007 - 0.0014 in.)

Diameter 24.996 - 25.001 mm

(0.9841 - 0.9843 in.)

9 - 16 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1164 of 2889

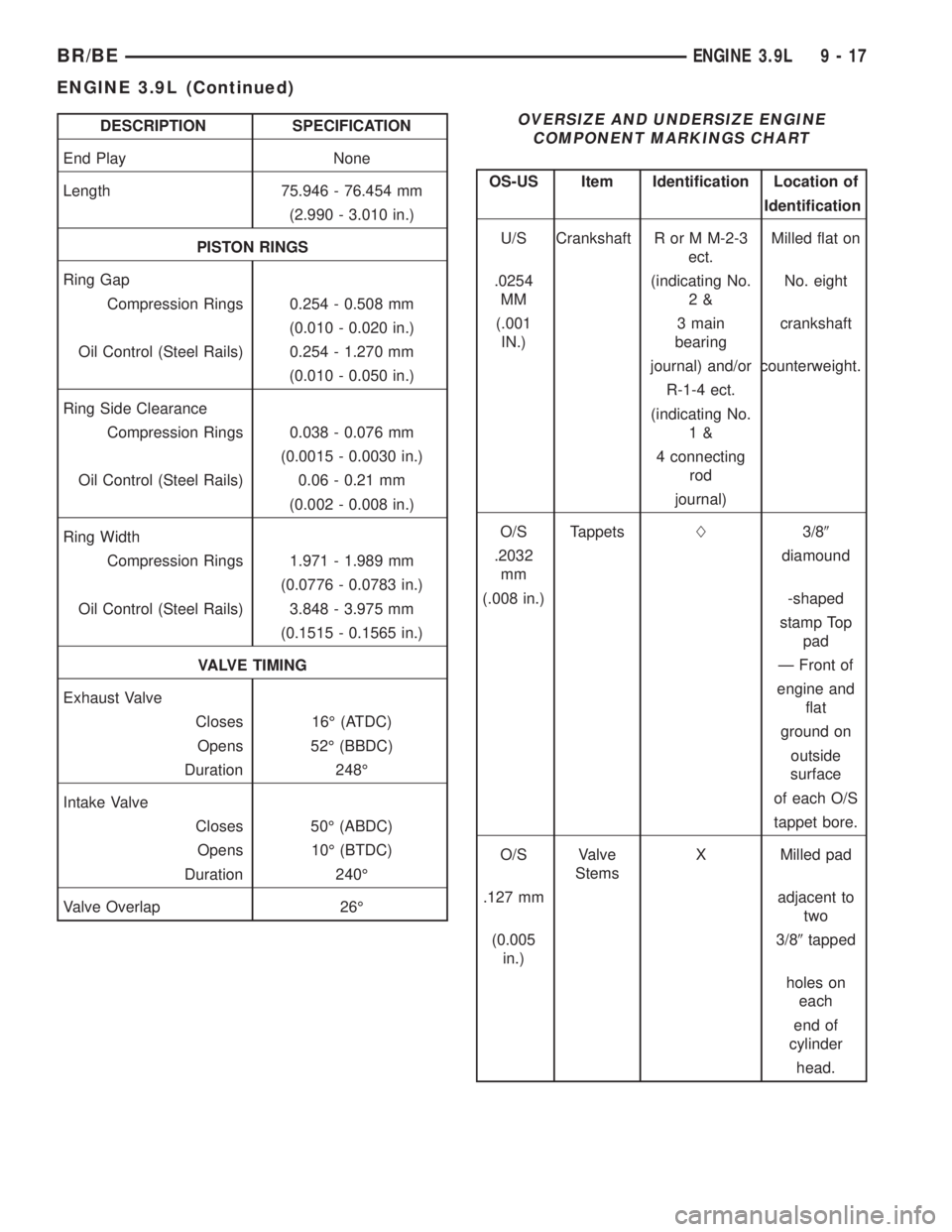

DESCRIPTION SPECIFICATION

End Play None

Length 75.946 - 76.454 mm

(2.990 - 3.010 in.)

PISTON RINGS

Ring Gap

Compression Rings 0.254 - 0.508 mm

(0.010 - 0.020 in.)

Oil Control (Steel Rails) 0.254 - 1.270 mm

(0.010 - 0.050 in.)

Ring Side Clearance

Compression Rings 0.038 - 0.076 mm

(0.0015 - 0.0030 in.)

Oil Control (Steel Rails) 0.06 - 0.21 mm

(0.002 - 0.008 in.)

Ring Width

Compression Rings 1.971 - 1.989 mm

(0.0776 - 0.0783 in.)

Oil Control (Steel Rails) 3.848 - 3.975 mm

(0.1515 - 0.1565 in.)

VALVE TIMING

Exhaust Valve

Closes 16É (ATDC)

Opens 52É (BBDC)

Duration 248É

Intake Valve

Closes 50É (ABDC)

Opens 10É (BTDC)

Duration 240É

Valve Overlap 26ÉOVERSIZE AND UNDERSIZE ENGINE

COMPONENT MARKINGS CHART

OS-US Item Identification Location of

Identification

U/S Crankshaft R or M M-2-3

ect.Milled flat on

.0254

MM(indicating No.

2&No. eight

(.001

IN.)3 main

bearingcrankshaft

journal) and/or counterweight.

R-1-4 ect.

(indicating No.

1&

4 connecting

rod

journal)

O/S TappetsL3/89

.2032

mmdiamound

(.008 in.) -shaped

stamp Top

pad

Ð Front of

engine and

flat

ground on

outside

surface

of each O/S

tappet bore.

O/S Valve

StemsX Milled pad

.127 mm adjacent to

two

(0.005

in.)3/89tapped

holes on

each

end of

cylinder

head.

BR/BEENGINE 3.9L 9 - 17

ENGINE 3.9L (Continued)

Page 1165 of 2889

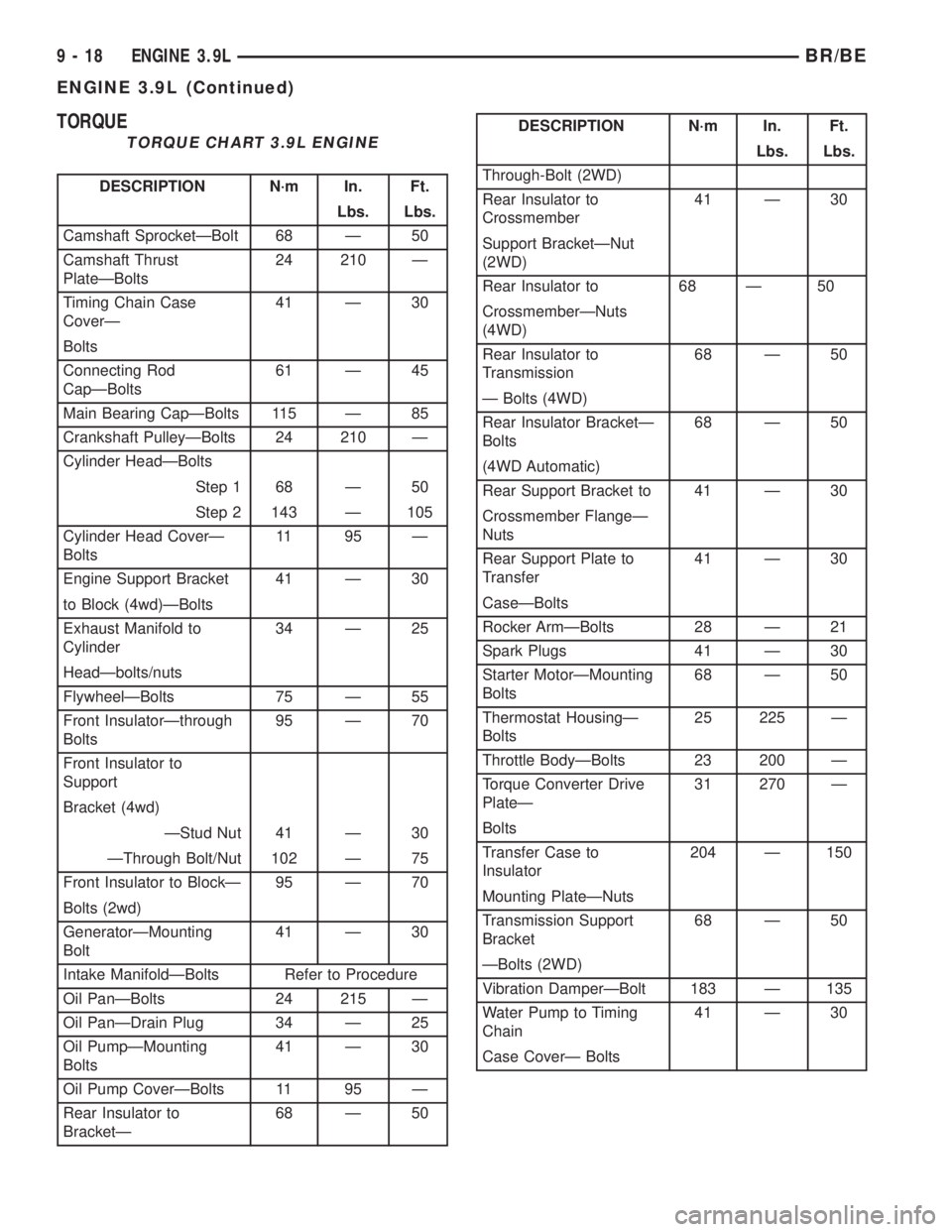

TORQUE

TORQUE CHART 3.9L ENGINE

DESCRIPTION N´m In. Ft.

Lbs. Lbs.

Camshaft SprocketÐBolt 68 Ð 50

Camshaft Thrust

PlateÐBolts24 210 Ð

Timing Chain Case

CoverÐ41 Ð 30

Bolts

Connecting Rod

CapÐBolts61 Ð 45

Main Bearing CapÐBolts 115 Ð 85

Crankshaft PulleyÐBolts 24 210 Ð

Cylinder HeadÐBolts

Step 1 68 Ð 50

Step 2 143 Ð 105

Cylinder Head CoverÐ

Bolts11 95 Ð

Engine Support Bracket 41 Ð 30

to Block (4wd)ÐBolts

Exhaust Manifold to

Cylinder34 Ð 25

HeadÐbolts/nuts

FlywheelÐBolts 75 Ð 55

Front InsulatorÐthrough

Bolts95 Ð 70

Front Insulator to

Support

Bracket (4wd)

ÐStud Nut 41 Ð 30

ÐThrough Bolt/Nut 102 Ð 75

Front Insulator to BlockÐ 95 Ð 70

Bolts (2wd)

GeneratorÐMounting

Bolt41 Ð 30

Intake ManifoldÐBolts Refer to Procedure

Oil PanÐBolts 24 215 Ð

Oil PanÐDrain Plug 34 Ð 25

Oil PumpÐMounting

Bolts41 Ð 30

Oil Pump CoverÐBolts 11 95 Ð

Rear Insulator to

BracketÐ68 Ð 50

DESCRIPTION N´m In. Ft.

Lbs. Lbs.

Through-Bolt (2WD)

Rear Insulator to

Crossmember41 Ð 30

Support BracketÐNut

(2WD)

Rear Insulator to 68 Ð 50

CrossmemberÐNuts

(4WD)

Rear Insulator to

Transmission68 Ð 50

Ð Bolts (4WD)

Rear Insulator BracketÐ

Bolts68 Ð 50

(4WD Automatic)

Rear Support Bracket to 41 Ð 30

Crossmember FlangeÐ

Nuts

Rear Support Plate to

Transfer41 Ð 30

CaseÐBolts

Rocker ArmÐBolts 28 Ð 21

Spark Plugs 41 Ð 30

Starter MotorÐMounting

Bolts68 Ð 50

Thermostat HousingÐ

Bolts25 225 Ð

Throttle BodyÐBolts 23 200 Ð

Torque Converter Drive

PlateÐ31 270 Ð

Bolts

Transfer Case to

Insulator204 Ð 150

Mounting PlateÐNuts

Transmission Support

Bracket68 Ð 50

ÐBolts (2WD)

Vibration DamperÐBolt 183 Ð 135

Water Pump to Timing

Chain41 Ð 30

Case CoverÐ Bolts

9 - 18 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1166 of 2889

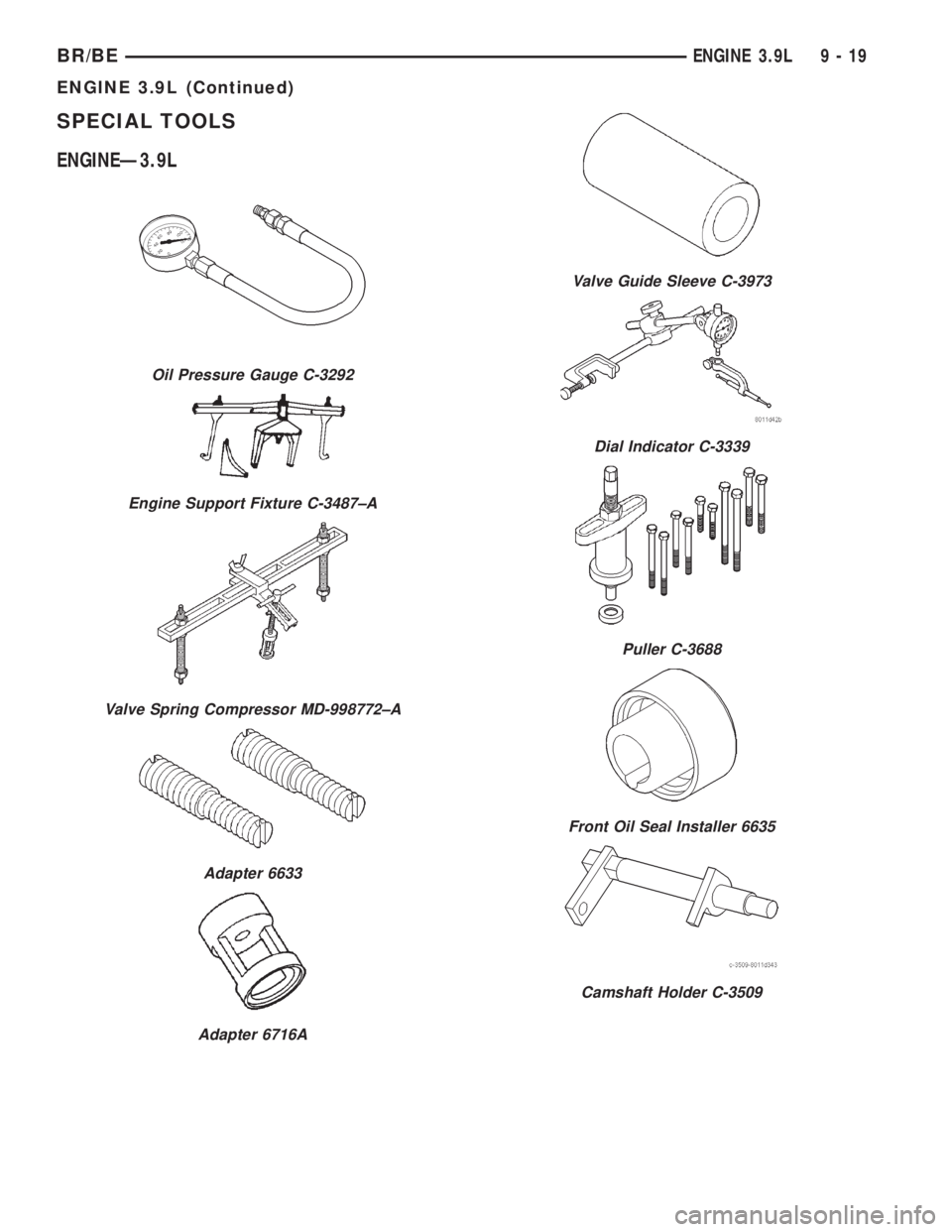

SPECIAL TOOLS

ENGINEÐ3.9L

Oil Pressure Gauge C-3292

Engine Support Fixture C-3487±A

Valve Spring Compressor MD-998772±A

Adapter 6633

Adapter 6716A

Valve Guide Sleeve C-3973

Dial Indicator C-3339

Puller C-3688

Front Oil Seal Installer 6635

Camshaft Holder C-3509

BR/BEENGINE 3.9L 9 - 19

ENGINE 3.9L (Continued)

Page 1167 of 2889

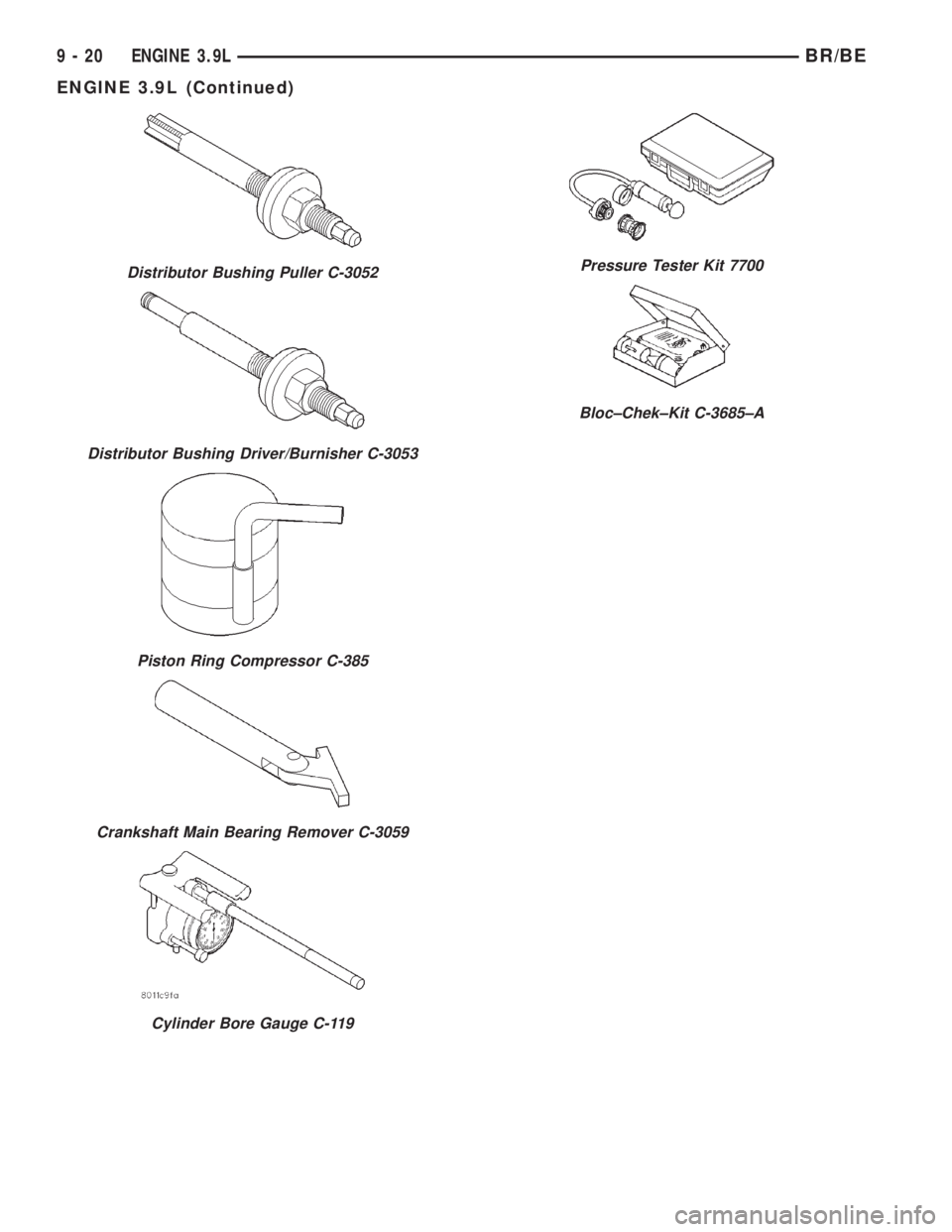

Distributor Bushing Puller C-3052

Distributor Bushing Driver/Burnisher C-3053

Piston Ring Compressor C-385

Crankshaft Main Bearing Remover C-3059

Cylinder Bore Gauge C-119

Pressure Tester Kit 7700

Bloc±Chek±Kit C-3685±A

9 - 20 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1168 of 2889

AIR CLEANER ELEMENT

REMOVAL - 3.9L/5.2L/5.9L

For air cleaner element required maintenance

schedules (listed in time or mileage intervals), refer

to 0, Lubrication and Maintenance.

CAUTION: Do not attempt to remove air cleaner ele-

ment (filter) from housing by removing top cover

only. To prevent damage to air cleaner housing, the

entire air cleaner housing assembly must be

removed from engine for air cleaner element

replacement.

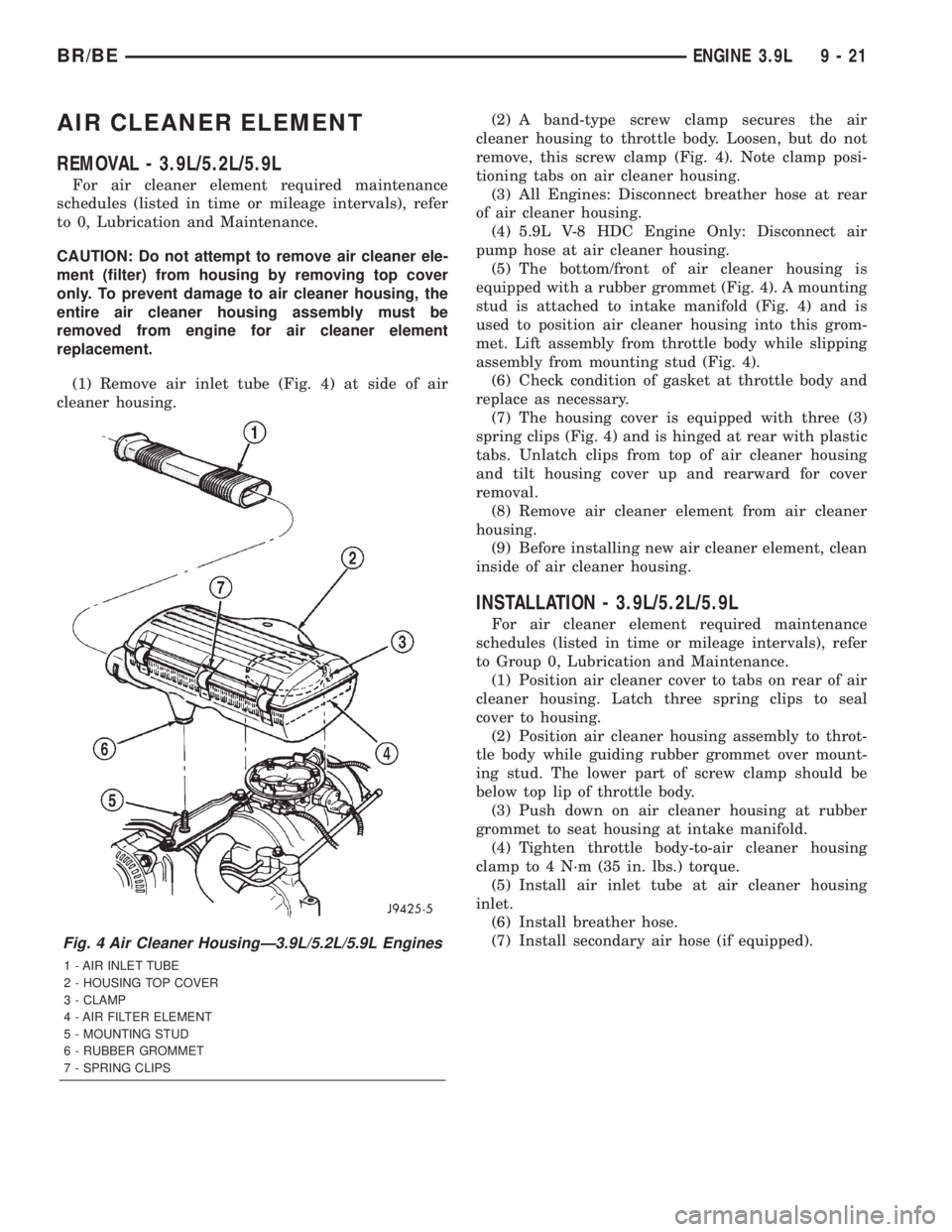

(1) Remove air inlet tube (Fig. 4) at side of air

cleaner housing.(2) A band-type screw clamp secures the air

cleaner housing to throttle body. Loosen, but do not

remove, this screw clamp (Fig. 4). Note clamp posi-

tioning tabs on air cleaner housing.

(3) All Engines: Disconnect breather hose at rear

of air cleaner housing.

(4) 5.9L V-8 HDC Engine Only: Disconnect air

pump hose at air cleaner housing.

(5) The bottom/front of air cleaner housing is

equipped with a rubber grommet (Fig. 4). A mounting

stud is attached to intake manifold (Fig. 4) and is

used to position air cleaner housing into this grom-

met. Lift assembly from throttle body while slipping

assembly from mounting stud (Fig. 4).

(6) Check condition of gasket at throttle body and

replace as necessary.

(7) The housing cover is equipped with three (3)

spring clips (Fig. 4) and is hinged at rear with plastic

tabs. Unlatch clips from top of air cleaner housing

and tilt housing cover up and rearward for cover

removal.

(8) Remove air cleaner element from air cleaner

housing.

(9) Before installing new air cleaner element, clean

inside of air cleaner housing.

INSTALLATION - 3.9L/5.2L/5.9L

For air cleaner element required maintenance

schedules (listed in time or mileage intervals), refer

to Group 0, Lubrication and Maintenance.

(1) Position air cleaner cover to tabs on rear of air

cleaner housing. Latch three spring clips to seal

cover to housing.

(2) Position air cleaner housing assembly to throt-

tle body while guiding rubber grommet over mount-

ing stud. The lower part of screw clamp should be

below top lip of throttle body.

(3) Push down on air cleaner housing at rubber

grommet to seat housing at intake manifold.

(4) Tighten throttle body-to-air cleaner housing

clamp to 4 N´m (35 in. lbs.) torque.

(5) Install air inlet tube at air cleaner housing

inlet.

(6) Install breather hose.

(7) Install secondary air hose (if equipped).

Fig. 4 Air Cleaner HousingÐ3.9L/5.2L/5.9L Engines

1 - AIR INLET TUBE

2 - HOUSING TOP COVER

3 - CLAMP

4 - AIR FILTER ELEMENT

5 - MOUNTING STUD

6 - RUBBER GROMMET

7 - SPRING CLIPS

BR/BEENGINE 3.9L 9 - 21

Page 1169 of 2889

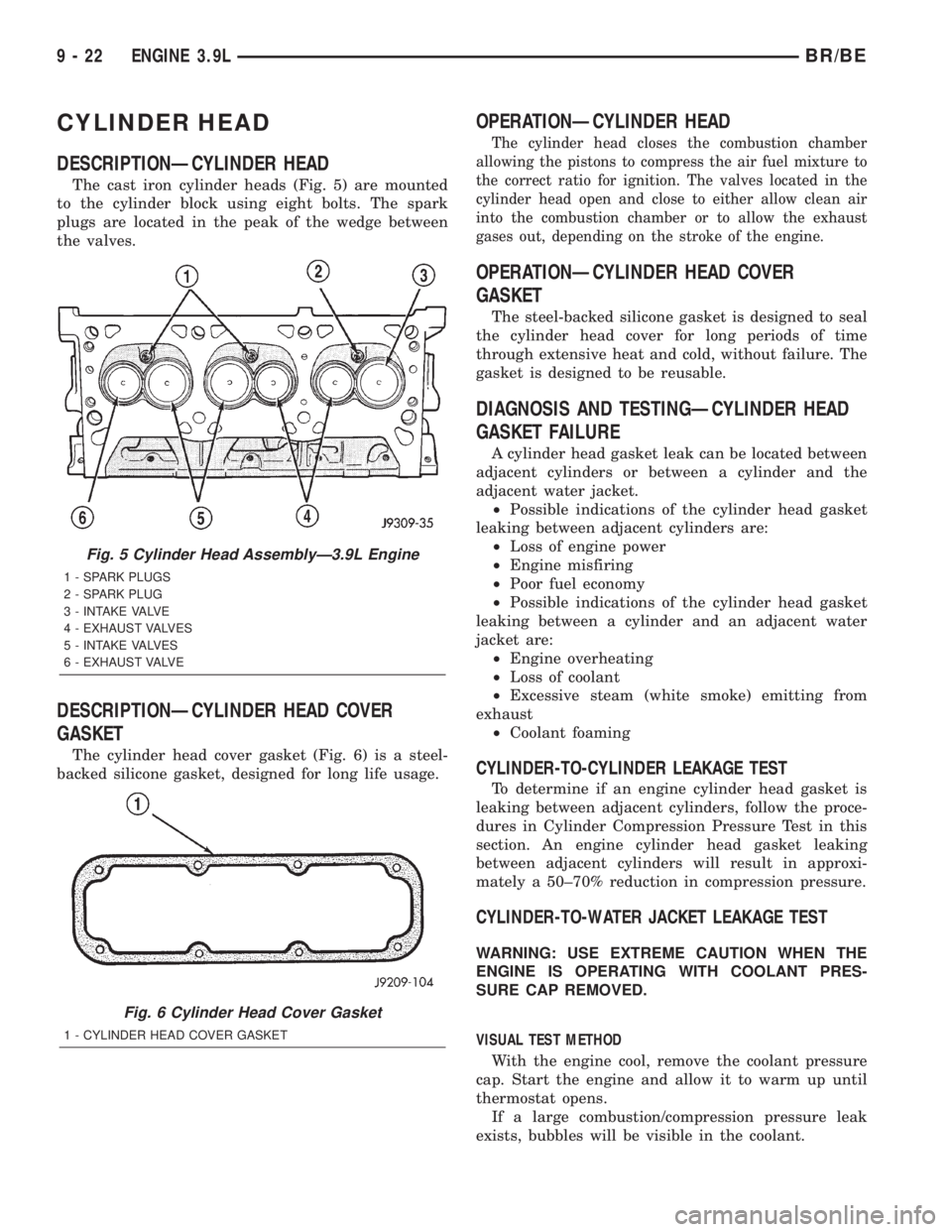

CYLINDER HEAD

DESCRIPTIONÐCYLINDER HEAD

The cast iron cylinder heads (Fig. 5) are mounted

to the cylinder block using eight bolts. The spark

plugs are located in the peak of the wedge between

the valves.

DESCRIPTIONÐCYLINDER HEAD COVER

GASKET

The cylinder head cover gasket (Fig. 6) is a steel-

backed silicone gasket, designed for long life usage.

OPERATIONÐCYLINDER HEAD

The cylinder head closes the combustion chamber

allowing the pistons to compress the air fuel mixture to

the correct ratio for ignition. The valves located in the

cylinder head open and close to either allow clean air

into the combustion chamber or to allow the exhaust

gases out, depending on the stroke of the engine.

OPERATIONÐCYLINDER HEAD COVER

GASKET

The steel-backed silicone gasket is designed to seal

the cylinder head cover for long periods of time

through extensive heat and cold, without failure. The

gasket is designed to be reusable.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET FAILURE

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

Fig. 5 Cylinder Head AssemblyÐ3.9L Engine

1 - SPARK PLUGS

2 - SPARK PLUG

3 - INTAKE VALVE

4 - EXHAUST VALVES

5 - INTAKE VALVES

6 - EXHAUST VALVE

Fig. 6 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

9 - 22 ENGINE 3.9LBR/BE

Page 1170 of 2889

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

The alloy cast iron cylinder heads (Fig. 7) are held

in place by eight bolts. The spark plugs are located

at the peak of the wedge between the valves.

(1) Disconnect the battery negative cable from the

battery.

(2) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the intake manifold-to-generator

bracket support rod. Remove the generator.

(4) Remove closed crankcase ventilation system.

(5) Disconnect the evaporation control system.

(6) Remove the air cleaner, air in-let hose and res-

onator.

(7) Perform fuel system pressure release procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(8) Disconnect the fuel supply line from the fuel

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(9) Disconnect accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(10) Remove distributor cap and wires.

(11) Disconnect the coil wires.

(12) Disconnect coolant temperature sending unit

wire.

(13) Disconnect heater hoses and bypass hose.

(14) Disconnect the vacuum supply hoses from the

intake manifold.

(15) Disconnect the fuel injector harness and

secure out of the way.

(16) Remove cylinder head covers and gaskets

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).(17) Remove intake manifold and throttle body as

an assembly. Discard the flange side gaskets and the

front and rear cross-over gaskets.

(18) Remove exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

REMOVAL).

(19) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(20) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(21) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. If out-of-flatness

exceeds 0.00075mm (0.0001in.) times the span length

in any direction, either replace head or lightly

machine the head surface.

FOR EXAMPLE:ÐA 305 mm (12 in.) span is

0.102 mm (0.004 in.) out-of-flat. The allowable out-of-

flat is 305 x 0.00075 (12 x 0.00075) equals 0.23 mm

(0.009 in.). This amount of out-of-flat is acceptable.

The cylinder head surface finish should be

1.78-3.00 microns (70-125 microinches).

Inspect push rods. Replace worn or bent rods.

INSTALLATION

The alloy cast iron cylinder heads (Fig. 7) are held

in place by eight bolts. The spark plugs are located

at the peak of the wedge between the valves.

(1) Position the new cylinder head gaskets onto

the cylinder block.

(2) Position the cylinder heads onto head gaskets

and cylinder block.

(3) Starting at top center, tighten all cylinder head

bolts, in sequence, to 68 N´m (50 ft. lbs.) torque (Fig.

7). Repeat procedure, tighten all cylinder head bolts

to 143 N´m (105 ft. lbs.) torque. Repeat procedure to

confirm that all bolts are at 143 N´m (105 ft. lbs.)

torque.

CAUTION: When tightening the rocker arm bolts, be

sure the piston in that cylinder is NOT at TDC. Con-

tact between the valves and piston could occur.

(4) Install push rods and rocker arm assemblies in

their original positions. Tighten the bolts to 28 N´m

(21 ft. lbs.) torque.

BR/BEENGINE 3.9L 9 - 23

CYLINDER HEAD (Continued)