DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1171 of 2889

(5) Install the intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION) and throttle body assembly.

(6) Install exhaust manifolds (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSTALLATION).

(7) Adjust spark plugs to specifications. Install the

plugs and tighten to 41 N´m (30 ft. lbs.) torque.

(8) Install coil wires.

(9) Connect coolant temperature sending unit wire.

(10) Connect the fuel injector harness.

(11) Connect the vacuum supply hoses to the

intake manifold.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Connect the accelerator linkage and, if so

equipped, the speed control and transmission kick-

down cables.

(15) Install the fuel supply line.

(16) Install the generator and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION). Tighten generator

mounting bolt to 41 N´m (30 ft. lbs.) torque.

(17) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts.

(18) Install cylinder head covers. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(19) Install closed crankcase ventilation system.

(20) Connect the evaporation control system.

(21) Install the resonator assembly, air in-let hose

and air cleaner.

(22) Install the heat shields. Tighten the bolts to

41 N´m (30 ft. lbs.) torque.

(23) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(24) Connect the battery negative cable.

CYLINDER HEAD COVER(S)

REMOVAL

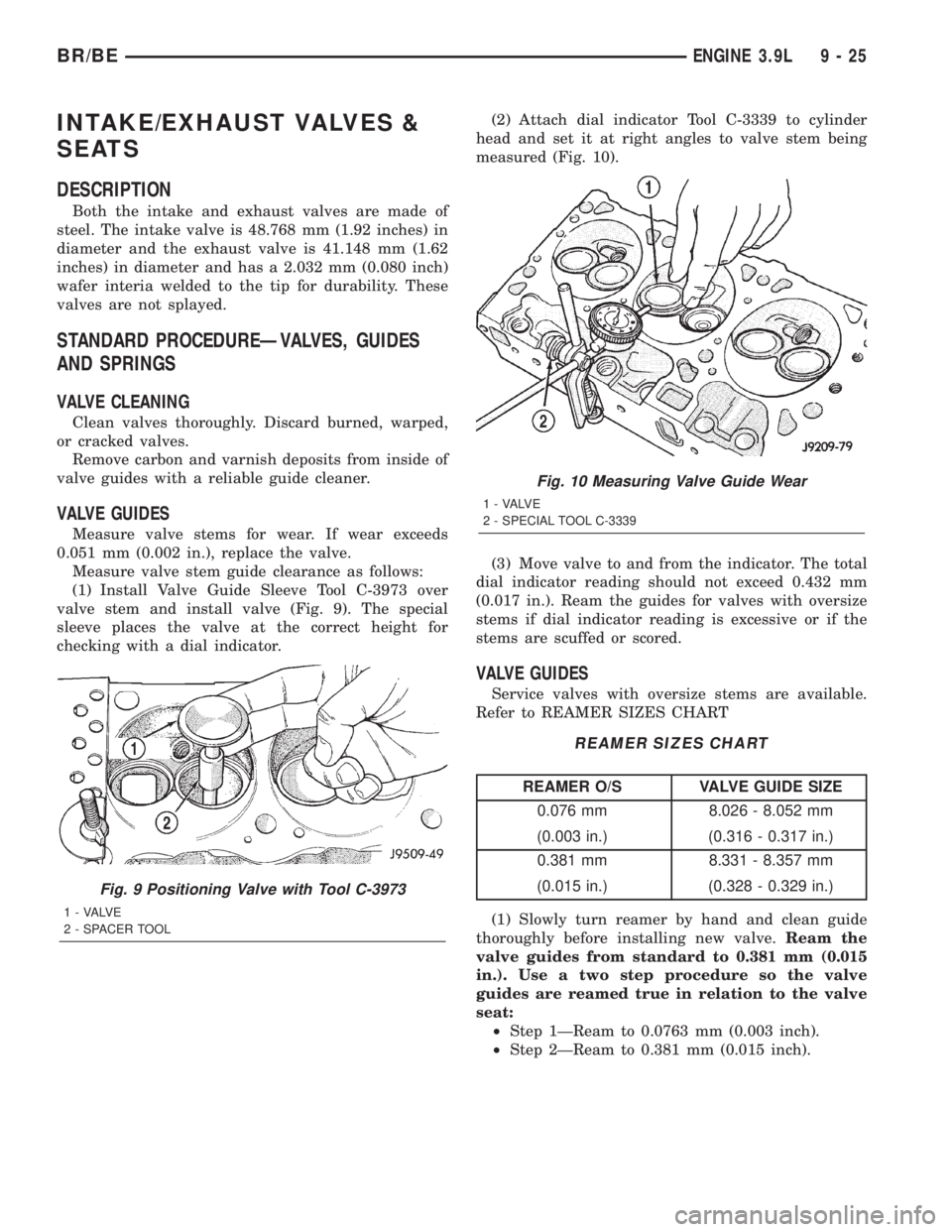

A steel-backed silicone gasket is used with the cyl-

inder head cover (Fig. 8). This gasket can be used

again.

(1) Disconnect the negative cable from the battery.

(2) Disconnect closed ventilation system and evap-

oration control system from cylinder head cover.

(3) Remove cylinder head cover bolts, cover and

gasket. The gasket may be used again.

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSPECTION

Inspect cover for distortion and straighten, if nec-

essary.

Check the gasket for use in head cover installation.

If damaged, use a new gasket.

INSTALLATION

A steel-backed silicone gasket is used with the cyl-

inder head cover (Fig. 8). This gasket can be used

again.

(1) Position the cylinder head cover gasket onto

the head rail.

(2) Position the cylinder head cover onto the gas-

ket and install the bolts. Tighten the bolts to 11 N´m

(95 in. lbs.) torque.

(3) Install closed crankcase ventilation system and

evaporation control system.

(4) Connect the negative cable to the battery.

(5) Start engine and check for leaks.

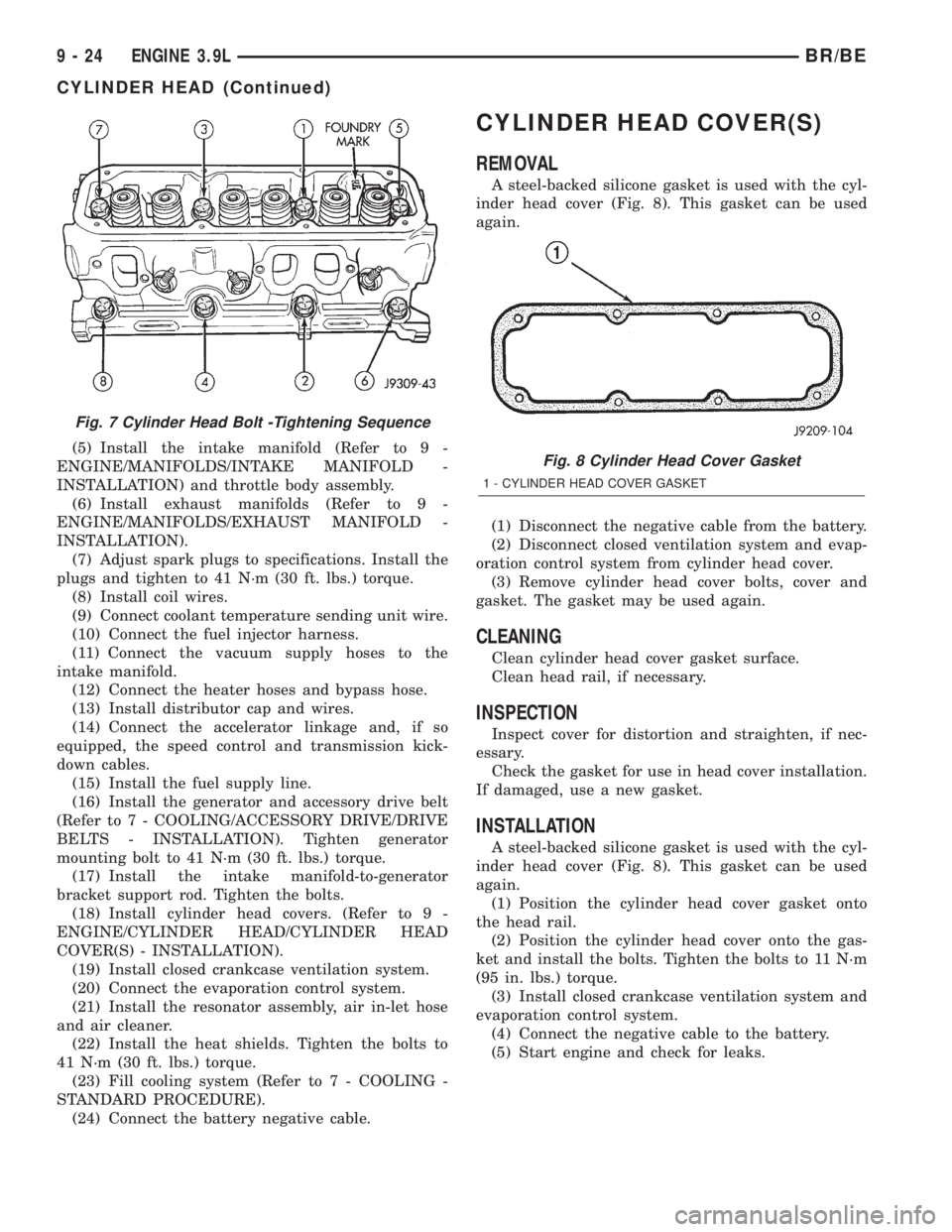

Fig. 7 Cylinder Head Bolt -Tightening Sequence

Fig. 8 Cylinder Head Cover Gasket

1 - CYLINDER HEAD COVER GASKET

9 - 24 ENGINE 3.9LBR/BE

CYLINDER HEAD (Continued)

Page 1172 of 2889

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

Both the intake and exhaust valves are made of

steel. The intake valve is 48.768 mm (1.92 inches) in

diameter and the exhaust valve is 41.148 mm (1.62

inches) in diameter and has a 2.032 mm (0.080 inch)

wafer interia welded to the tip for durability. These

valves are not splayed.

STANDARD PROCEDUREÐVALVES, GUIDES

AND SPRINGS

VALVE CLEANING

Clean valves thoroughly. Discard burned, warped,

or cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

VALVE GUIDES

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 in.), replace the valve.

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 9). The special

sleeve places the valve at the correct height for

checking with a dial indicator.(2) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angles to valve stem being

measured (Fig. 10).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 in.). Ream the guides for valves with oversize

stems if dial indicator reading is excessive or if the

stems are scuffed or scored.

VALVE GUIDES

Service valves with oversize stems are available.

Refer to REAMER SIZES CHART

REAMER SIZES CHART

REAMER O/S VALVE GUIDE SIZE

0.076 mm 8.026 - 8.052 mm

(0.003 in.) (0.316 - 0.317 in.)

0.381 mm 8.331 - 8.357 mm

(0.015 in.) (0.328 - 0.329 in.)

(1) Slowly turn reamer by hand and clean guide

thoroughly before installing new valve.Ream the

valve guides from standard to 0.381 mm (0.015

in.). Use a two step procedure so the valve

guides are reamed true in relation to the valve

seat:

²Step 1ÐReam to 0.0763 mm (0.003 inch).

²Step 2ÐReam to 0.381 mm (0.015 inch).

Fig. 9 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

Fig. 10 Measuring Valve Guide Wear

1 - VALVE

2 - SPECIAL TOOL C-3339

BR/BEENGINE 3.9L 9 - 25

Page 1173 of 2889

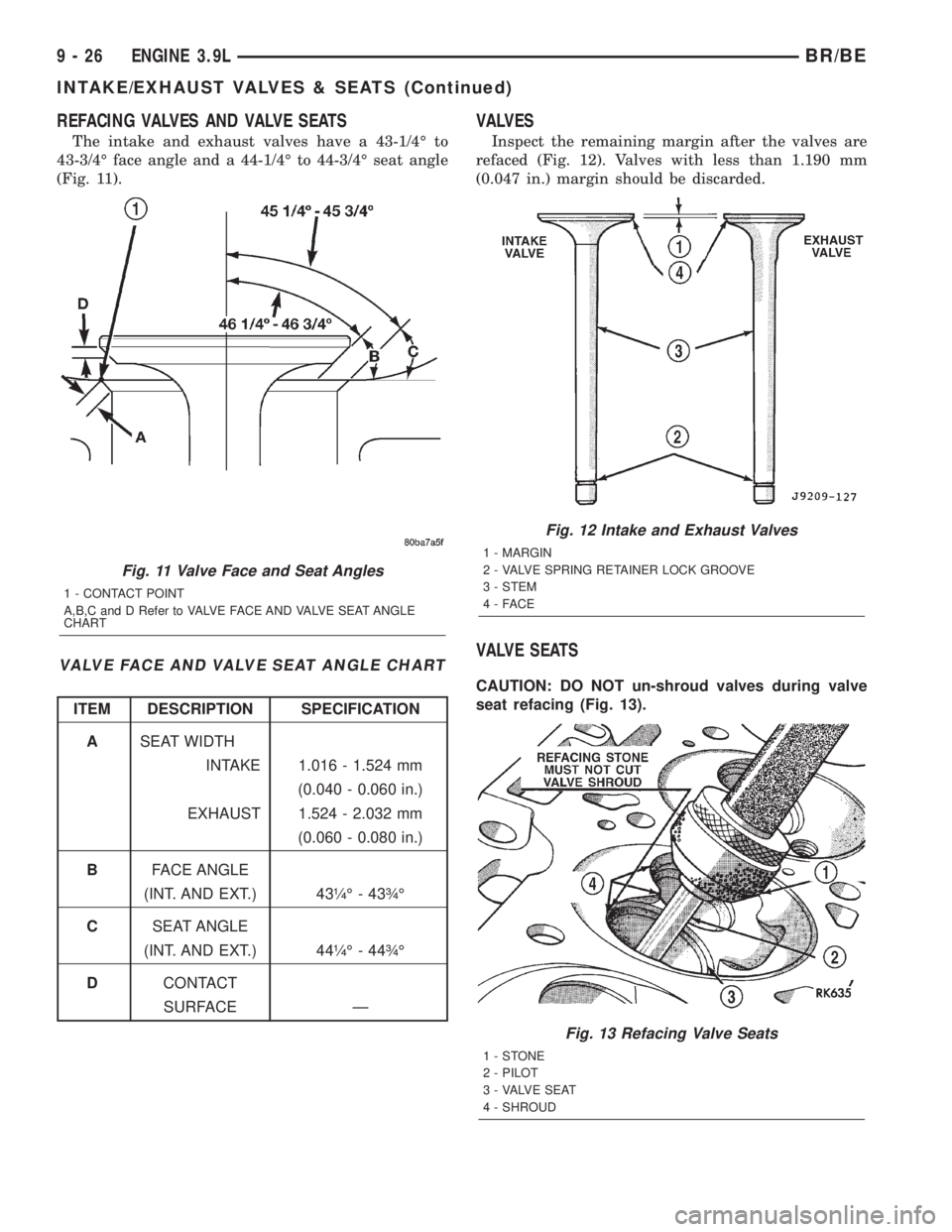

REFACING VALVES AND VALVE SEATS

The intake and exhaust valves have a 43-1/4É to

43-3/4É face angle and a 44-1/4É to 44-3/4É seat angle

(Fig. 11).

VALVE FACE AND VALVE SEAT ANGLE CHART

ITEM DESCRIPTION SPECIFICATION

ASEAT WIDTH

INTAKE 1.016 - 1.524 mm

(0.040 - 0.060 in.)

EXHAUST 1.524 - 2.032 mm

(0.060 - 0.080 in.)

BFACE ANGLE

(INT. AND EXT.) 43òÉ - 43ôÉ

CSEAT ANGLE

(INT. AND EXT.) 44òÉ - 44ôÉ

DCONTACT

SURFACE Ð

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 12). Valves with less than 1.190 mm

(0.047 in.) margin should be discarded.

VALVE SEATS

CAUTION: DO NOT un-shroud valves during valve

seat refacing (Fig. 13).

Fig. 11 Valve Face and Seat Angles

1 - CONTACT POINT

A,B,C and D Refer to VALVE FACE AND VALVE SEAT ANGLE

CHART

Fig. 12 Intake and Exhaust Valves

1 - MARGIN

2 - VALVE SPRING RETAINER LOCK GROOVE

3 - STEM

4-FACE

Fig. 13 Refacing Valve Seats

1-STONE

2 - PILOT

3 - VALVE SEAT

4 - SHROUD

9 - 26 ENGINE 3.9LBR/BE

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1174 of 2889

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 in.) total indicator reading.

(3) Inspect the valve seat with Prussian blue, to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

intake seats should be 1.016-1.524 mm (0.040-0.060

in.). The width of the exhaust seats should be 1.524-

2.032 mm (0.060-0.080 in.).

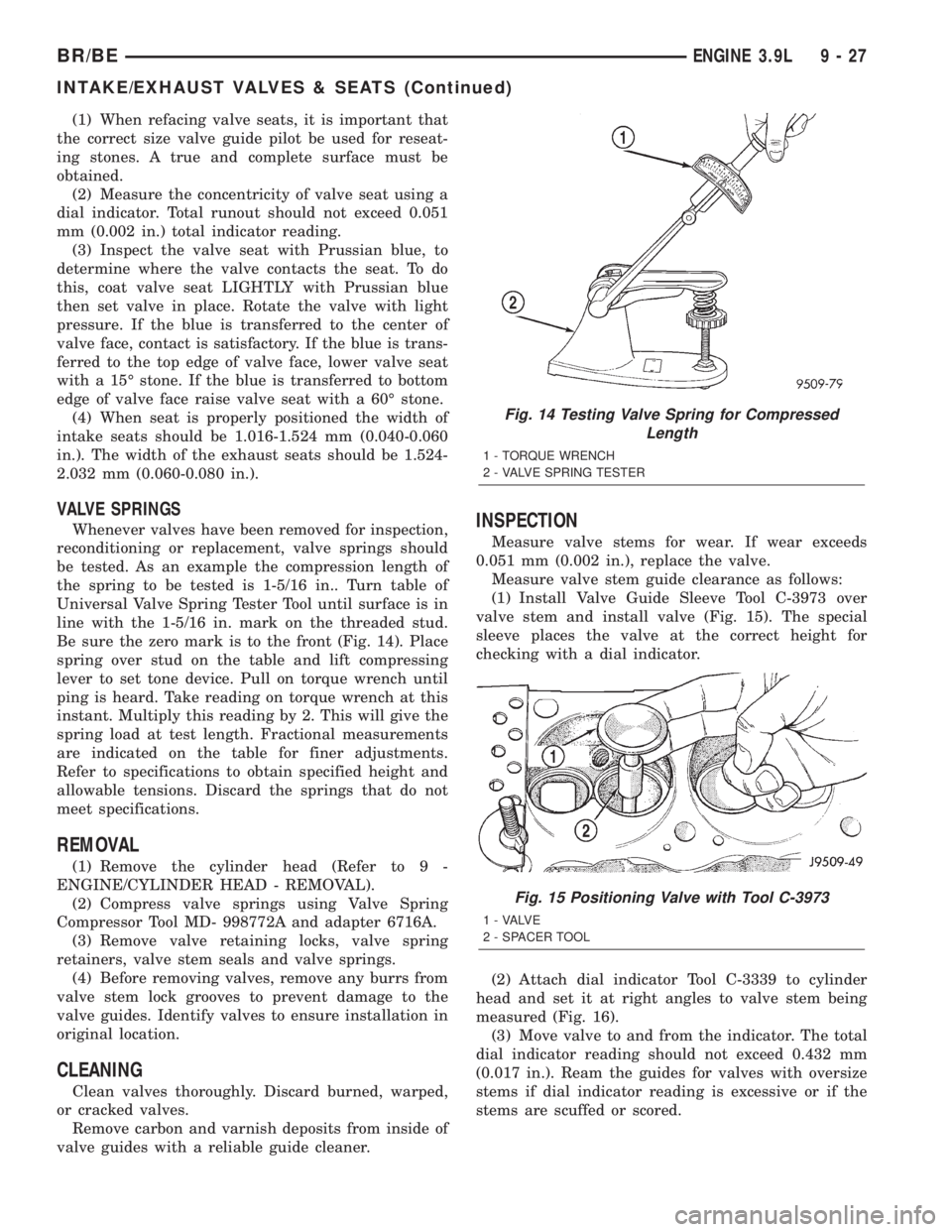

VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested. As an example the compression length of

the spring to be tested is 1-5/16 in.. Turn table of

Universal Valve Spring Tester Tool until surface is in

line with the 1-5/16 in. mark on the threaded stud.

Be sure the zero mark is to the front (Fig. 14). Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by 2. This will give the

spring load at test length. Fractional measurements

are indicated on the table for finer adjustments.

Refer to specifications to obtain specified height and

allowable tensions. Discard the springs that do not

meet specifications.

REMOVAL

(1) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(2) Compress valve springs using Valve Spring

Compressor Tool MD- 998772A and adapter 6716A.

(3) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(4) Before removing valves, remove any burrs from

valve stem lock grooves to prevent damage to the

valve guides. Identify valves to ensure installation in

original location.

CLEANING

Clean valves thoroughly. Discard burned, warped,

or cracked valves.

Remove carbon and varnish deposits from inside of

valve guides with a reliable guide cleaner.

INSPECTION

Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 in.), replace the valve.

Measure valve stem guide clearance as follows:

(1) Install Valve Guide Sleeve Tool C-3973 over

valve stem and install valve (Fig. 15). The special

sleeve places the valve at the correct height for

checking with a dial indicator.

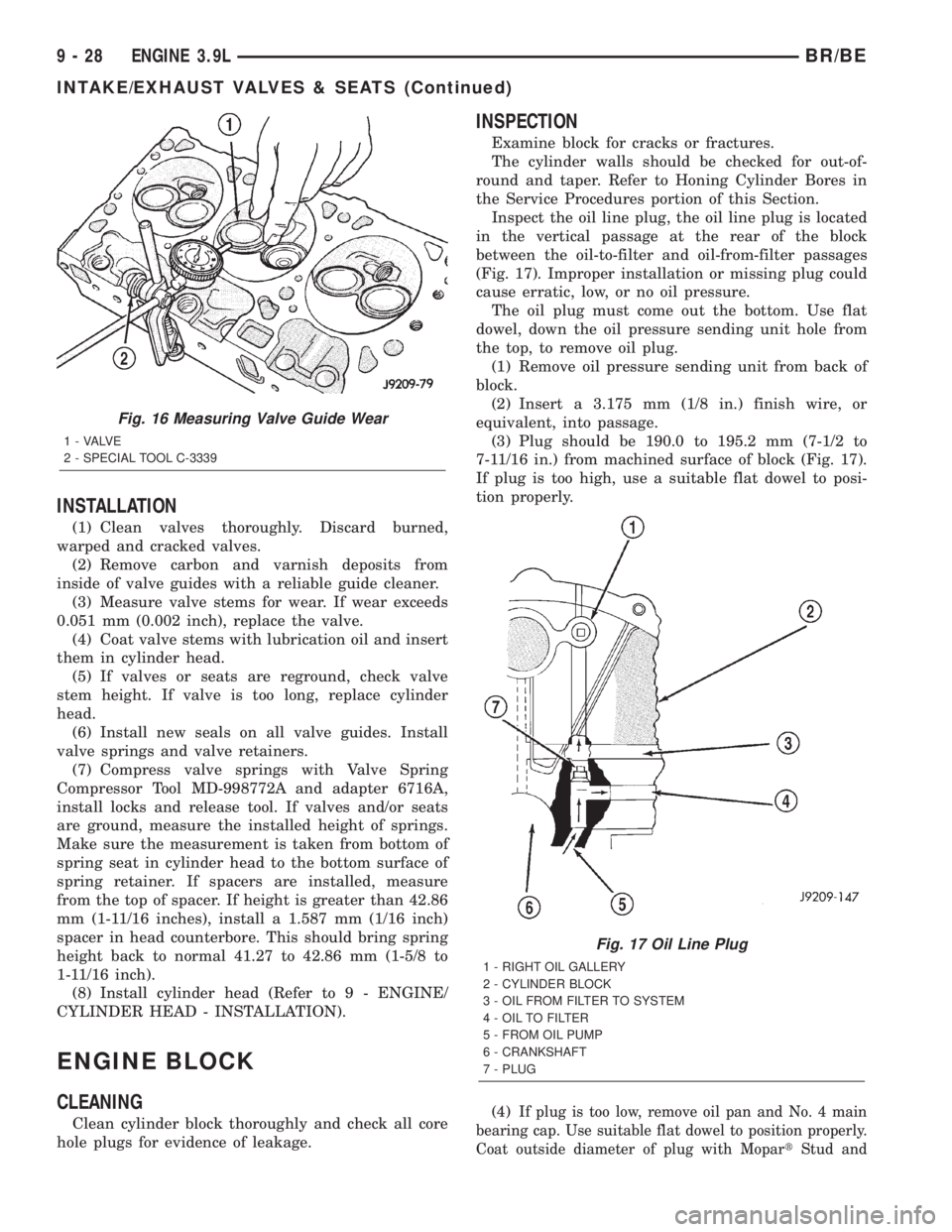

(2) Attach dial indicator Tool C-3339 to cylinder

head and set it at right angles to valve stem being

measured (Fig. 16).

(3) Move valve to and from the indicator. The total

dial indicator reading should not exceed 0.432 mm

(0.017 in.). Ream the guides for valves with oversize

stems if dial indicator reading is excessive or if the

stems are scuffed or scored.

Fig. 14 Testing Valve Spring for Compressed

Length

1 - TORQUE WRENCH

2 - VALVE SPRING TESTER

Fig. 15 Positioning Valve with Tool C-3973

1 - VALVE

2 - SPACER TOOL

BR/BEENGINE 3.9L 9 - 27

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1175 of 2889

INSTALLATION

(1) Clean valves thoroughly. Discard burned,

warped and cracked valves.

(2) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(3) Measure valve stems for wear. If wear exceeds

0.051 mm (0.002 inch), replace the valve.

(4) Coat valve stems with lubrication oil and insert

them in cylinder head.

(5) If valves or seats are reground, check valve

stem height. If valve is too long, replace cylinder

head.

(6) Install new seals on all valve guides. Install

valve springs and valve retainers.

(7) Compress valve springs with Valve Spring

Compressor Tool MD-998772A and adapter 6716A,

install locks and release tool. If valves and/or seats

are ground, measure the installed height of springs.

Make sure the measurement is taken from bottom of

spring seat in cylinder head to the bottom surface of

spring retainer. If spacers are installed, measure

from the top of spacer. If height is greater than 42.86

mm (1-11/16 inches), install a 1.587 mm (1/16 inch)

spacer in head counterbore. This should bring spring

height back to normal 41.27 to 42.86 mm (1-5/8 to

1-11/16 inch).

(8) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

ENGINE BLOCK

CLEANING

Clean cylinder block thoroughly and check all core

hole plugs for evidence of leakage.

INSPECTION

Examine block for cracks or fractures.

The cylinder walls should be checked for out-of-

round and taper. Refer to Honing Cylinder Bores in

the Service Procedures portion of this Section.

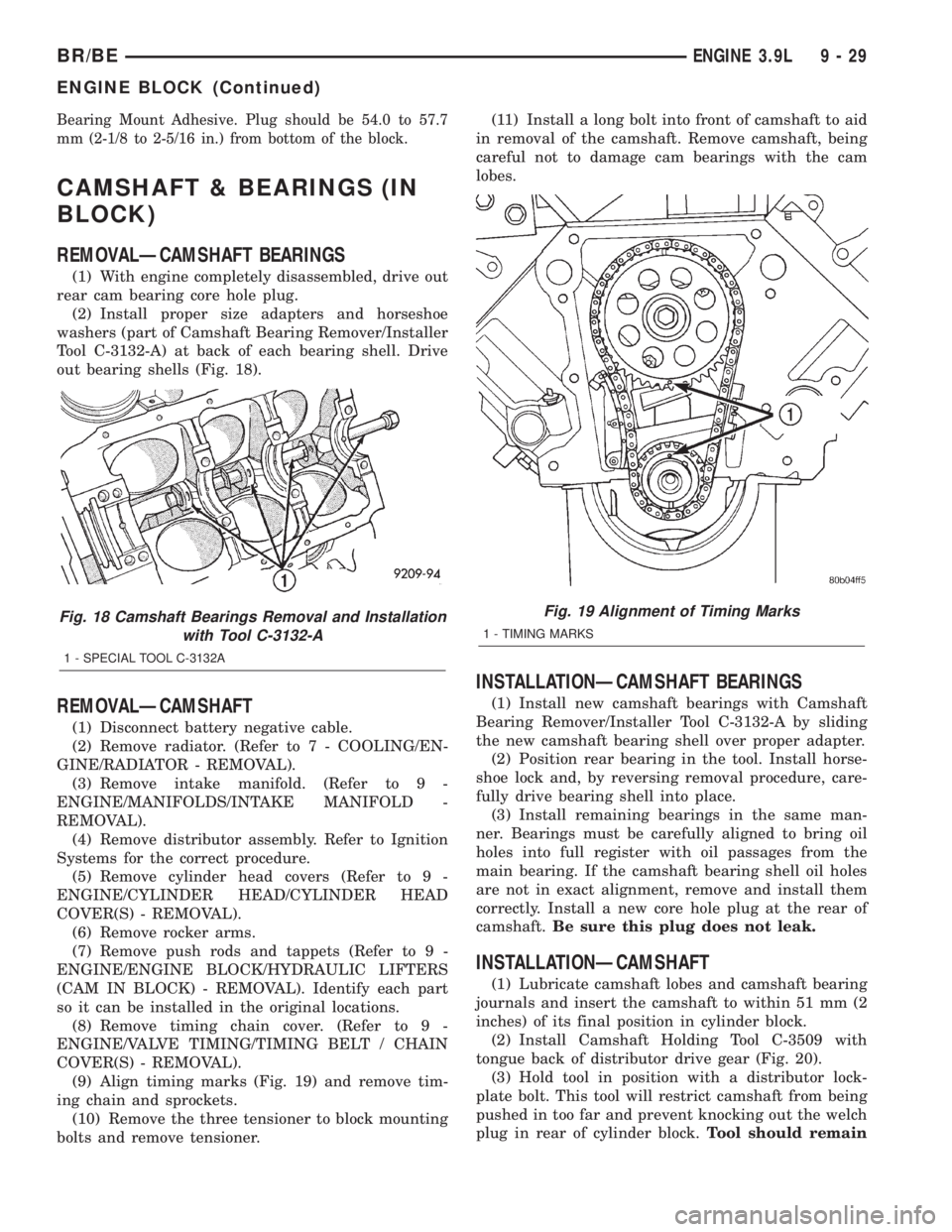

Inspect the oil line plug, the oil line plug is located

in the vertical passage at the rear of the block

between the oil-to-filter and oil-from-filter passages

(Fig. 17). Improper installation or missing plug could

cause erratic, low, or no oil pressure.

The oil plug must come out the bottom. Use flat

dowel, down the oil pressure sending unit hole from

the top, to remove oil plug.

(1) Remove oil pressure sending unit from back of

block.

(2) Insert a 3.175 mm (1/8 in.) finish wire, or

equivalent, into passage.

(3) Plug should be 190.0 to 195.2 mm (7-1/2 to

7-11/16 in.) from machined surface of block (Fig. 17).

If plug is too high, use a suitable flat dowel to posi-

tion properly.

(4)

If plug is too low, remove oil pan and No. 4 main

bearing cap. Use suitable flat dowel to position properly.

Coat outside diameter of plug with MopartStud and

Fig. 16 Measuring Valve Guide Wear

1 - VALVE

2 - SPECIAL TOOL C-3339

Fig. 17 Oil Line Plug

1 - RIGHT OIL GALLERY

2 - CYLINDER BLOCK

3 - OIL FROM FILTER TO SYSTEM

4 - OIL TO FILTER

5 - FROM OIL PUMP

6 - CRANKSHAFT

7 - PLUG

9 - 28 ENGINE 3.9LBR/BE

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1176 of 2889

Bearing Mount Adhesive. Plug should be 54.0 to 57.7

mm (2-1/8 to 2-5/16 in.) from bottom of the block.

CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVALÐCAMSHAFT BEARINGS

(1) With engine completely disassembled, drive out

rear cam bearing core hole plug.

(2) Install proper size adapters and horseshoe

washers (part of Camshaft Bearing Remover/Installer

Tool C-3132-A) at back of each bearing shell. Drive

out bearing shells (Fig. 18).

REMOVALÐCAMSHAFT

(1) Disconnect battery negative cable.

(2) Remove radiator. (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(3) Remove intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(4) Remove distributor assembly. Refer to Ignition

Systems for the correct procedure.

(5) Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(6) Remove rocker arms.

(7) Remove push rods and tappets (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - REMOVAL). Identify each part

so it can be installed in the original locations.

(8) Remove timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

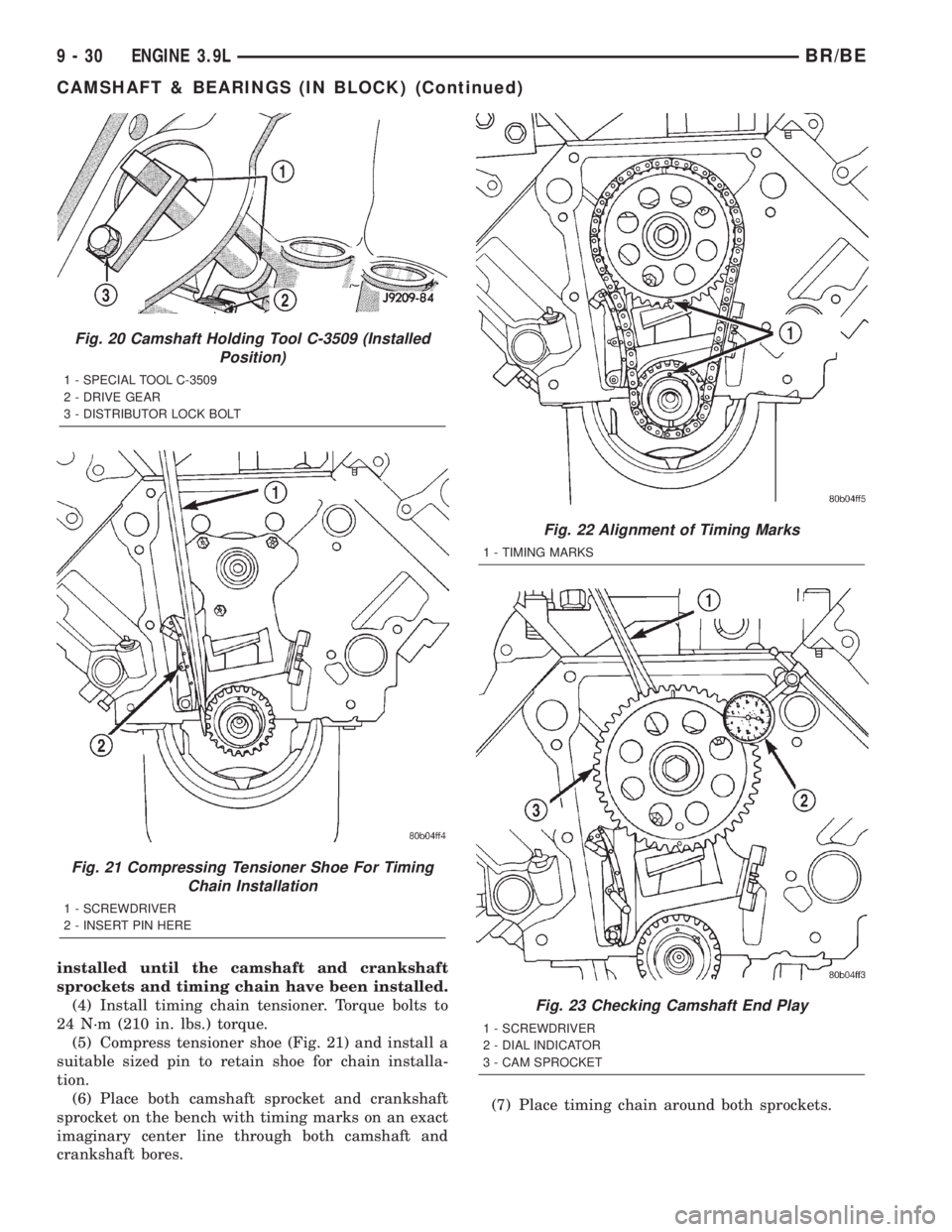

(9) Align timing marks (Fig. 19) and remove tim-

ing chain and sprockets.

(10) Remove the three tensioner to block mounting

bolts and remove tensioner.(11) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSTALLATIONÐCAMSHAFT BEARINGS

(1) Install new camshaft bearings with Camshaft

Bearing Remover/Installer Tool C-3132-A by sliding

the new camshaft bearing shell over proper adapter.

(2) Position rear bearing in the tool. Install horse-

shoe lock and, by reversing removal procedure, care-

fully drive bearing shell into place.

(3) Install remaining bearings in the same man-

ner. Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holes

are not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

INSTALLATIONÐCAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft to within 51 mm (2

inches) of its final position in cylinder block.

(2) Install Camshaft Holding Tool C-3509 with

tongue back of distributor drive gear (Fig. 20).

(3) Hold tool in position with a distributor lock-

plate bolt. This tool will restrict camshaft from being

pushed in too far and prevent knocking out the welch

plug in rear of cylinder block.Tool should remain

Fig. 18 Camshaft Bearings Removal and Installation

with Tool C-3132-A

1 - SPECIAL TOOL C-3132A

Fig. 19 Alignment of Timing Marks

1 - TIMING MARKS

BR/BEENGINE 3.9L 9 - 29

ENGINE BLOCK (Continued)

Page 1177 of 2889

installed until the camshaft and crankshaft

sprockets and timing chain have been installed.

(4) Install timing chain tensioner. Torque bolts to

24 N´m (210 in. lbs.) torque.

(5) Compress tensioner shoe (Fig. 21) and install a

suitable sized pin to retain shoe for chain installa-

tion.

(6) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on an exact

imaginary center line through both camshaft and

crankshaft bores.(7) Place timing chain around both sprockets.

Fig. 20 Camshaft Holding Tool C-3509 (Installed

Position)

1 - SPECIAL TOOL C-3509

2 - DRIVE GEAR

3 - DISTRIBUTOR LOCK BOLT

Fig. 21 Compressing Tensioner Shoe For Timing

Chain Installation

1 - SCREWDRIVER

2 - INSERT PIN HERE

Fig. 22 Alignment of Timing Marks

1 - TIMING MARKS

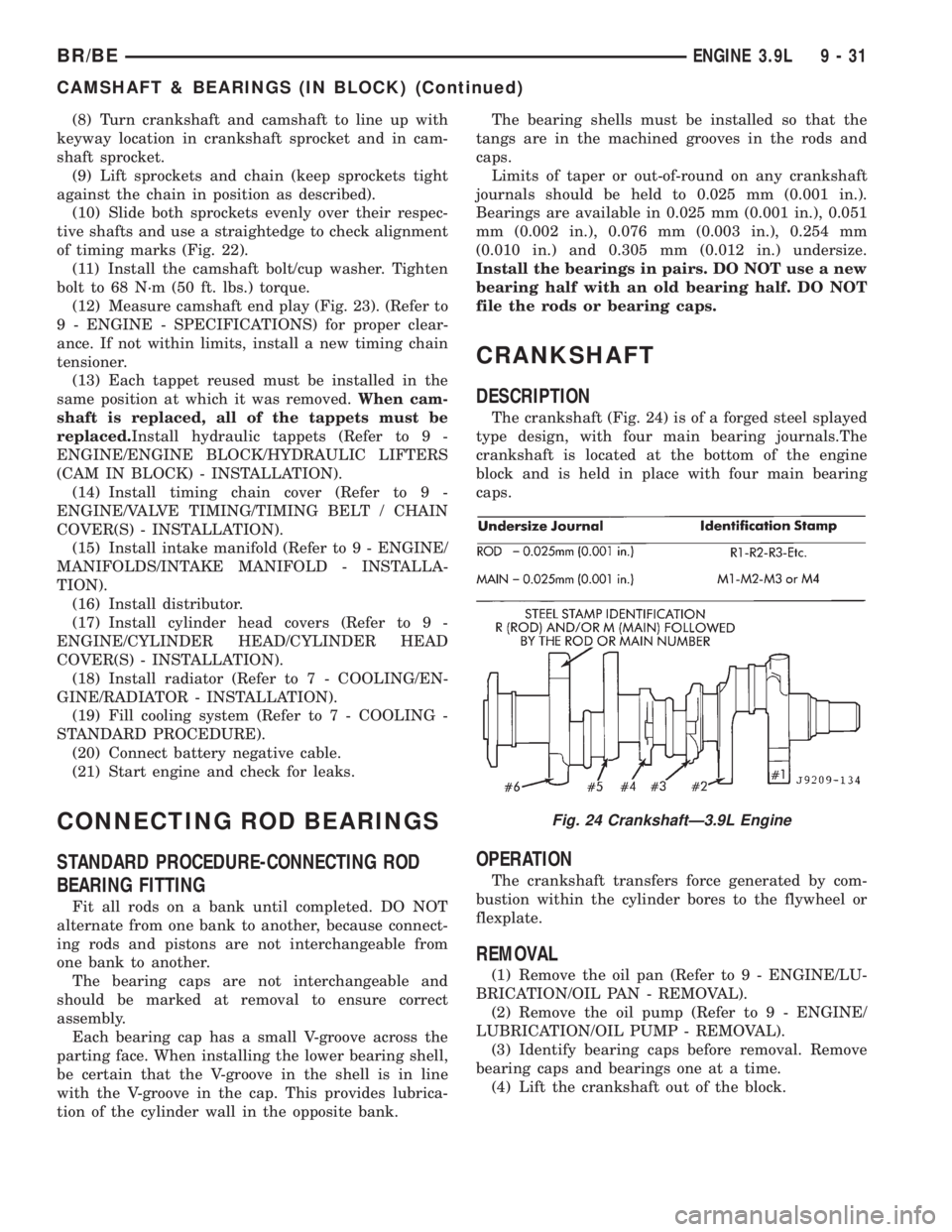

Fig. 23 Checking Camshaft End Play

1 - SCREWDRIVER

2 - DIAL INDICATOR

3 - CAM SPROCKET

9 - 30 ENGINE 3.9LBR/BE

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1178 of 2889

(8) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(9) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(10) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 22).

(11) Install the camshaft bolt/cup washer. Tighten

bolt to 68 N´m (50 ft. lbs.) torque.

(12) Measure camshaft end play (Fig. 23). (Refer to

9 - ENGINE - SPECIFICATIONS) for proper clear-

ance. If not within limits, install a new timing chain

tensioner.

(13) Each tappet reused must be installed in the

same position at which it was removed.When cam-

shaft is replaced, all of the tappets must be

replaced.Install hydraulic tappets (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - INSTALLATION).

(14) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(15) Install intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(16) Install distributor.

(17) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(19) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(20) Connect battery negative cable.

(21) Start engine and check for leaks.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE-CONNECTING ROD

BEARING FITTING

Fit all rods on a bank until completed. DO NOT

alternate from one bank to another, because connect-

ing rods and pistons are not interchangeable from

one bank to another.

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly.

Each bearing cap has a small V-groove across the

parting face. When installing the lower bearing shell,

be certain that the V-groove in the shell is in line

with the V-groove in the cap. This provides lubrica-

tion of the cylinder wall in the opposite bank.The bearing shells must be installed so that the

tangs are in the machined grooves in the rods and

caps.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.025 mm (0.001 in.).

Bearings are available in 0.025 mm (0.001 in.), 0.051

mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm

(0.010 in.) and 0.305 mm (0.012 in.) undersize.

Install the bearings in pairs. DO NOT use a new

bearing half with an old bearing half. DO NOT

file the rods or bearing caps.

CRANKSHAFT

DESCRIPTION

The crankshaft (Fig. 24) is of a forged steel splayed

type design, with four main bearing journals.The

crankshaft is located at the bottom of the engine

block and is held in place with four main bearing

caps.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Identify bearing caps before removal. Remove

bearing caps and bearings one at a time.

(4) Lift the crankshaft out of the block.

Fig. 24 CrankshaftÐ3.9L Engine

BR/BEENGINE 3.9L 9 - 31

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1179 of 2889

(5) Remove and discard the crankshaft rear oil

seals.

(6) Remove and discard the front crankshaft oil

seal.

INSTALLATION

(1) Lightly oil the new upper seal lips with engine

oil.

(2) Install the new upper rear bearing oil seal with

the white paint facing towards the rear of the engine.

(3) Position the crankshaft into the cylinder block.

(4) Lightly oil the new lower seal lips with engine

oil.

(5) Install the new lower rear bearing oil seal into

the bearing cap with the white paint facing towards

the rear of the engine.

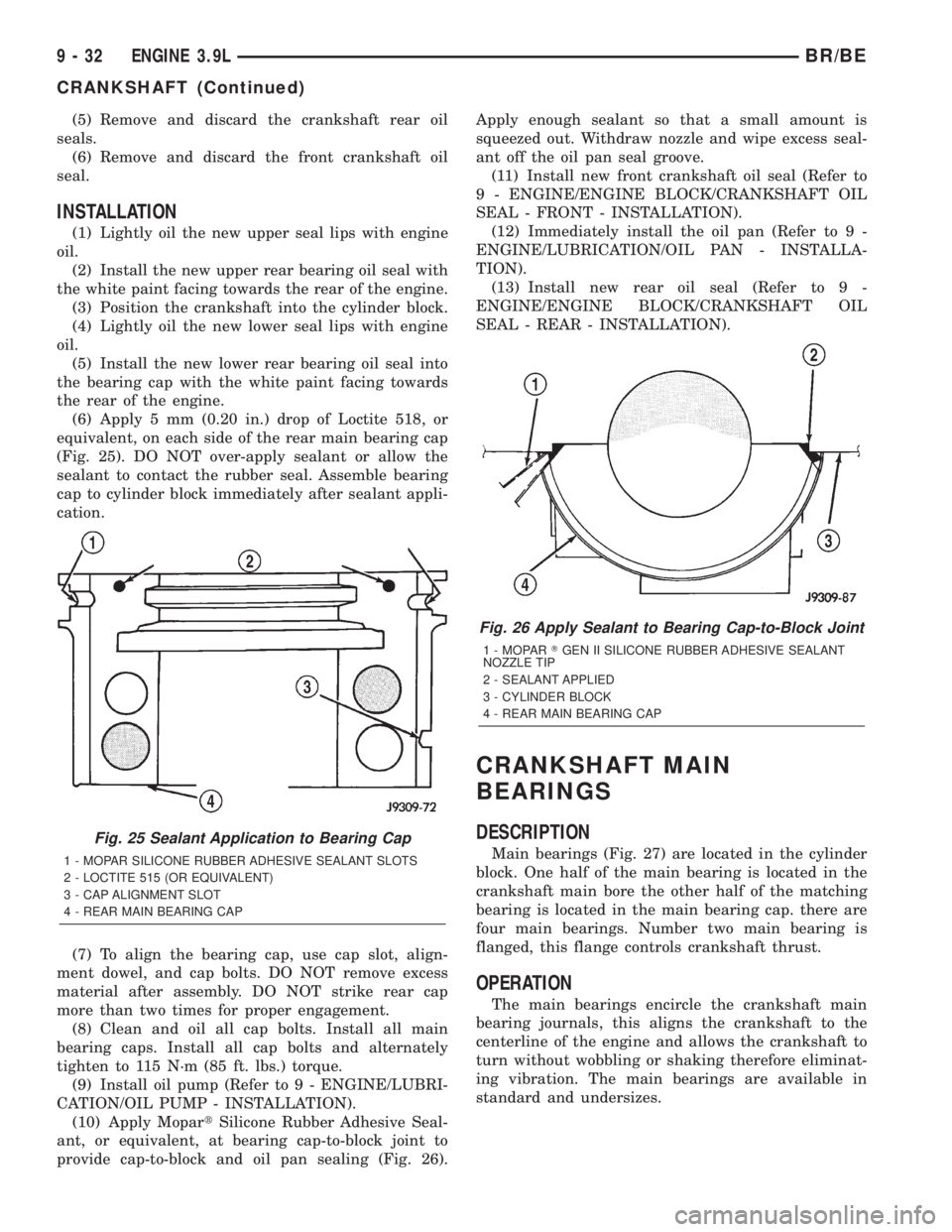

(6) Apply 5 mm (0.20 in.) drop of Loctite 518, or

equivalent, on each side of the rear main bearing cap

(Fig. 25). DO NOT over-apply sealant or allow the

sealant to contact the rubber seal. Assemble bearing

cap to cylinder block immediately after sealant appli-

cation.

(7) To align the bearing cap, use cap slot, align-

ment dowel, and cap bolts. DO NOT remove excess

material after assembly. DO NOT strike rear cap

more than two times for proper engagement.

(8) Clean and oil all cap bolts. Install all main

bearing caps. Install all cap bolts and alternately

tighten to 115 N´m (85 ft. lbs.) torque.

(9) Install oil pump (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PUMP - INSTALLATION).

(10) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap-to-block joint to

provide cap-to-block and oil pan sealing (Fig. 26).Apply enough sealant so that a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(11) Install new front crankshaft oil seal (Refer to

9 - ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION).

(12) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(13) Install new rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - INSTALLATION).

CRANKSHAFT MAIN

BEARINGS

DESCRIPTION

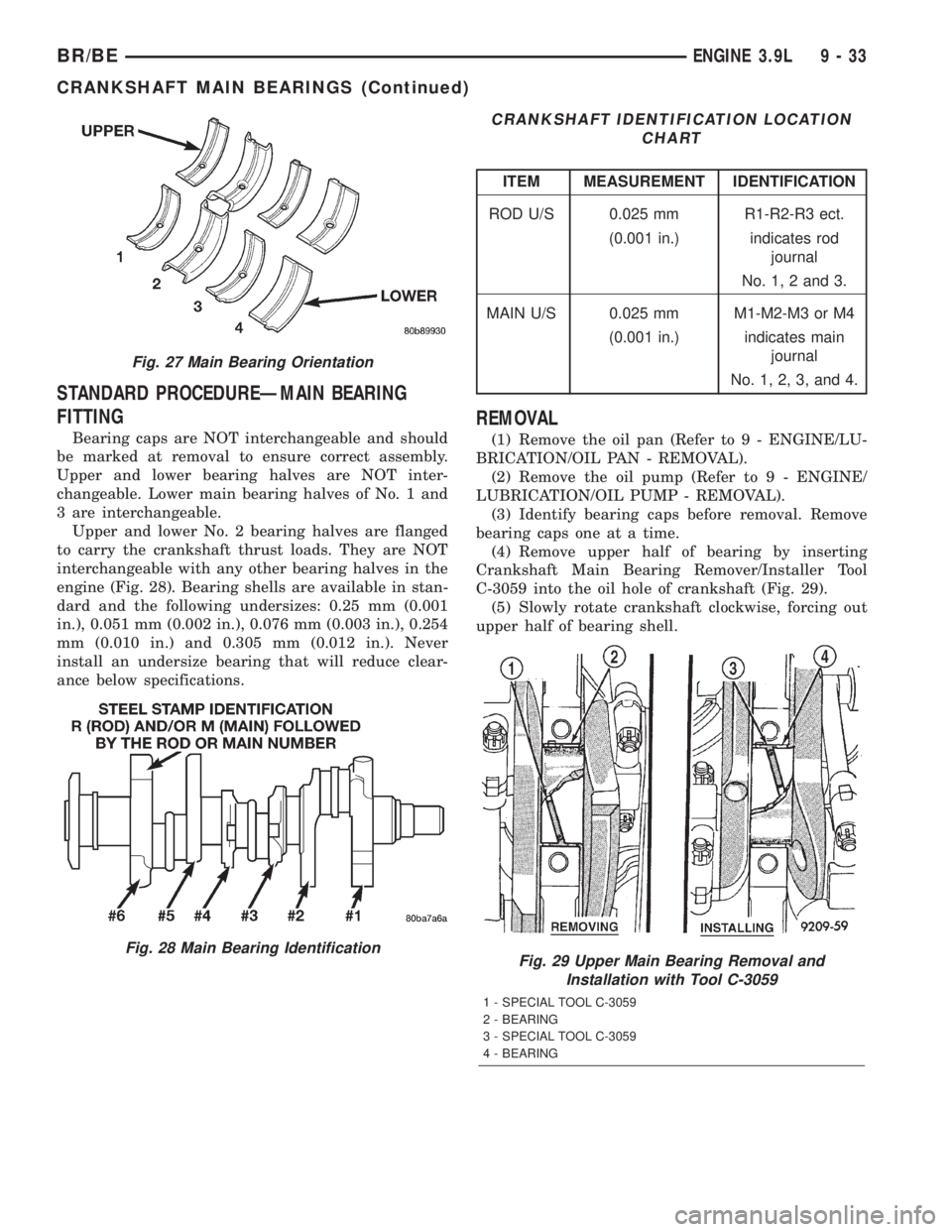

Main bearings (Fig. 27) are located in the cylinder

block. One half of the main bearing is located in the

crankshaft main bore the other half of the matching

bearing is located in the main bearing cap. there are

four main bearings. Number two main bearing is

flanged, this flange controls crankshaft thrust.

OPERATION

The main bearings encircle the crankshaft main

bearing journals, this aligns the crankshaft to the

centerline of the engine and allows the crankshaft to

turn without wobbling or shaking therefore eliminat-

ing vibration. The main bearings are available in

standard and undersizes.

Fig. 25 Sealant Application to Bearing Cap

1 - MOPAR SILICONE RUBBER ADHESIVE SEALANT SLOTS

2 - LOCTITE 515 (OR EQUIVALENT)

3 - CAP ALIGNMENT SLOT

4 - REAR MAIN BEARING CAP

Fig. 26 Apply Sealant to Bearing Cap-to-Block Joint

1 - MOPARTGEN II SILICONE RUBBER ADHESIVE SEALANT

NOZZLE TIP

2 - SEALANT APPLIED

3 - CYLINDER BLOCK

4 - REAR MAIN BEARING CAP

9 - 32 ENGINE 3.9LBR/BE

CRANKSHAFT (Continued)

Page 1180 of 2889

STANDARD PROCEDUREÐMAIN BEARING

FITTING

Bearing caps are NOT interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of No. 1 and

3 are interchangeable.

Upper and lower No. 2 bearing halves are flanged

to carry the crankshaft thrust loads. They are NOT

interchangeable with any other bearing halves in the

engine (Fig. 28). Bearing shells are available in stan-

dard and the following undersizes: 0.25 mm (0.001

in.), 0.051 mm (0.002 in.), 0.076 mm (0.003 in.), 0.254

mm (0.010 in.) and 0.305 mm (0.012 in.). Never

install an undersize bearing that will reduce clear-

ance below specifications.

CRANKSHAFT IDENTIFICATION LOCATION

CHART

ITEM MEASUREMENT IDENTIFICATION

ROD U/S 0.025 mm R1-R2-R3 ect.

(0.001 in.) indicates rod

journal

No. 1, 2 and 3.

MAIN U/S 0.025 mm M1-M2-M3 or M4

(0.001 in.) indicates main

journal

No. 1, 2, 3, and 4.

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Identify bearing caps before removal. Remove

bearing caps one at a time.

(4) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 29).

(5) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

Fig. 27 Main Bearing Orientation

Fig. 28 Main Bearing IdentificationFig. 29 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

BR/BEENGINE 3.9L 9 - 33

CRANKSHAFT MAIN BEARINGS (Continued)