DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1301 of 2889

REMOVAL

(1) Remove the engine from the vehicle (Refer to 9

- ENGINE - REMOVAL).

(2) Remove the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(3) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(4) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block. Be sure to keep tops of pistons covered

during this operation.

(5) Be sure each connecting rod and connecting rod

cap is identified with the cylinder number. Remove

connecting rod cap. Install connecting rod bolt guide

set on connecting rod bolts.

(6) Pistons and connecting rods must be removed

from top of cylinder block. When removing the

assemblies from the engine, rotate crankshaft so that

the connecting rod is centered in cylinder bore and at

BDC.Be careful not to nick crankshaft journals.

(7) After removal, install bearing cap on the mat-

ing rod.

CLEANING

Clean the piston and connecting rod assembly

using a suitable solvent.

INSPECTION

Check the connecting rod journal for excessive

wear, taper and scoring (Refer to 9 - ENGINE/EN-

GINE BLOCK/CONNECTING ROD BEARINGS -

STANDARD PROCEDURE).

Check the connecting rod for signs of twist or bend-

ing.

Check the piston for taper and elliptical shape

before it is fitted into the cylinder bore (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON & CONNECT-

ING ROD - STANDARD PROCEDURE).

Check the piston for scoring, or scraping marks in

the piston skirts. Check the ring lands for cracks

and/or deterioration.

INSTALLATION

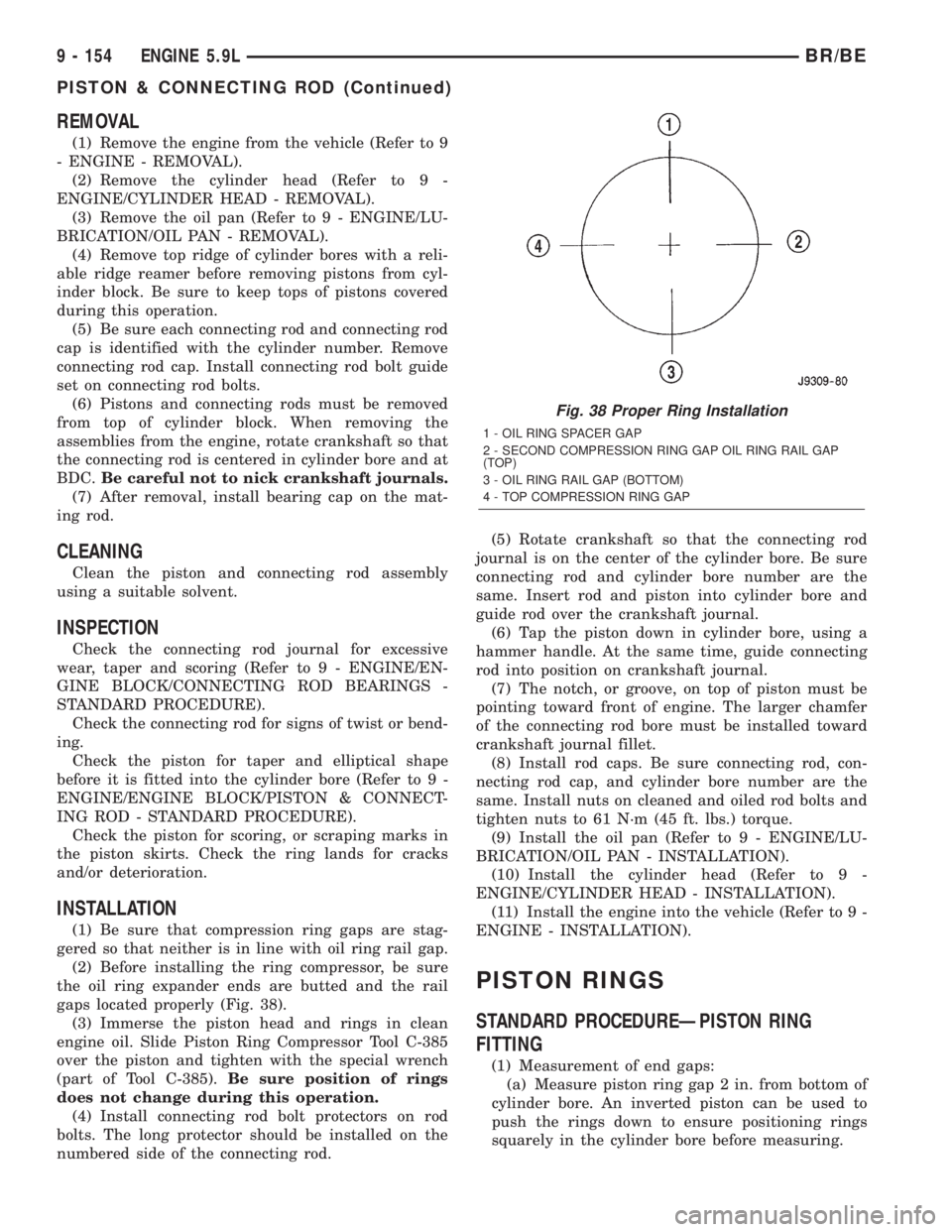

(1) Be sure that compression ring gaps are stag-

gered so that neither is in line with oil ring rail gap.

(2) Before installing the ring compressor, be sure

the oil ring expander ends are butted and the rail

gaps located properly (Fig. 38).

(3) Immerse the piston head and rings in clean

engine oil. Slide Piston Ring Compressor Tool C-385

over the piston and tighten with the special wrench

(part of Tool C-385).Be sure position of rings

does not change during this operation.

(4) Install connecting rod bolt protectors on rod

bolts. The long protector should be installed on the

numbered side of the connecting rod.(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Be sure

connecting rod and cylinder bore number are the

same. Insert rod and piston into cylinder bore and

guide rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on crankshaft journal.

(7) The notch, or groove, on top of piston must be

pointing toward front of engine. The larger chamfer

of the connecting rod bore must be installed toward

crankshaft journal fillet.

(8) Install rod caps. Be sure connecting rod, con-

necting rod cap, and cylinder bore number are the

same. Install nuts on cleaned and oiled rod bolts and

tighten nuts to 61 N´m (45 ft. lbs.) torque.

(9) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(10) Install the cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION).

(11) Install the engine into the vehicle (Refer to 9 -

ENGINE - INSTALLATION).

PISTON RINGS

STANDARD PROCEDUREÐPISTON RING

FITTING

(1) Measurement of end gaps:

(a) Measure piston ring gap 2 in. from bottom of

cylinder bore. An inverted piston can be used to

push the rings down to ensure positioning rings

squarely in the cylinder bore before measuring.

Fig. 38 Proper Ring Installation

1 - OIL RING SPACER GAP

2 - SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 - OIL RING RAIL GAP (BOTTOM)

4 - TOP COMPRESSION RING GAP

9 - 154 ENGINE 5.9LBR/BE

PISTON & CONNECTING ROD (Continued)

Page 1302 of 2889

(b) Insert feeler gauge in the gap. The top com-

pression ring gap should be between 0.254-0.508

mm (0.010-0.020 in.). The second compression ring

gap should be between 0.508-0.762 mm

(0.020-0.030 in.). The oil ring gap should be 0.254-

1.270 mm (0.010-0.050 in.).

(c) Rings with insufficient end gap may be prop-

erly filed to the correct dimension. Rings with

excess gaps should not be used.

(2) Install rings, and confirm ring side clearance:

(a)

Install oil rings being careful not to nick or

scratch the piston. Install the oil control rings accord-

ing to instructions in the package. It is not necessary

to use a tool to install the upper and lower rails.

Insert oil rail spacer first, then side rails.

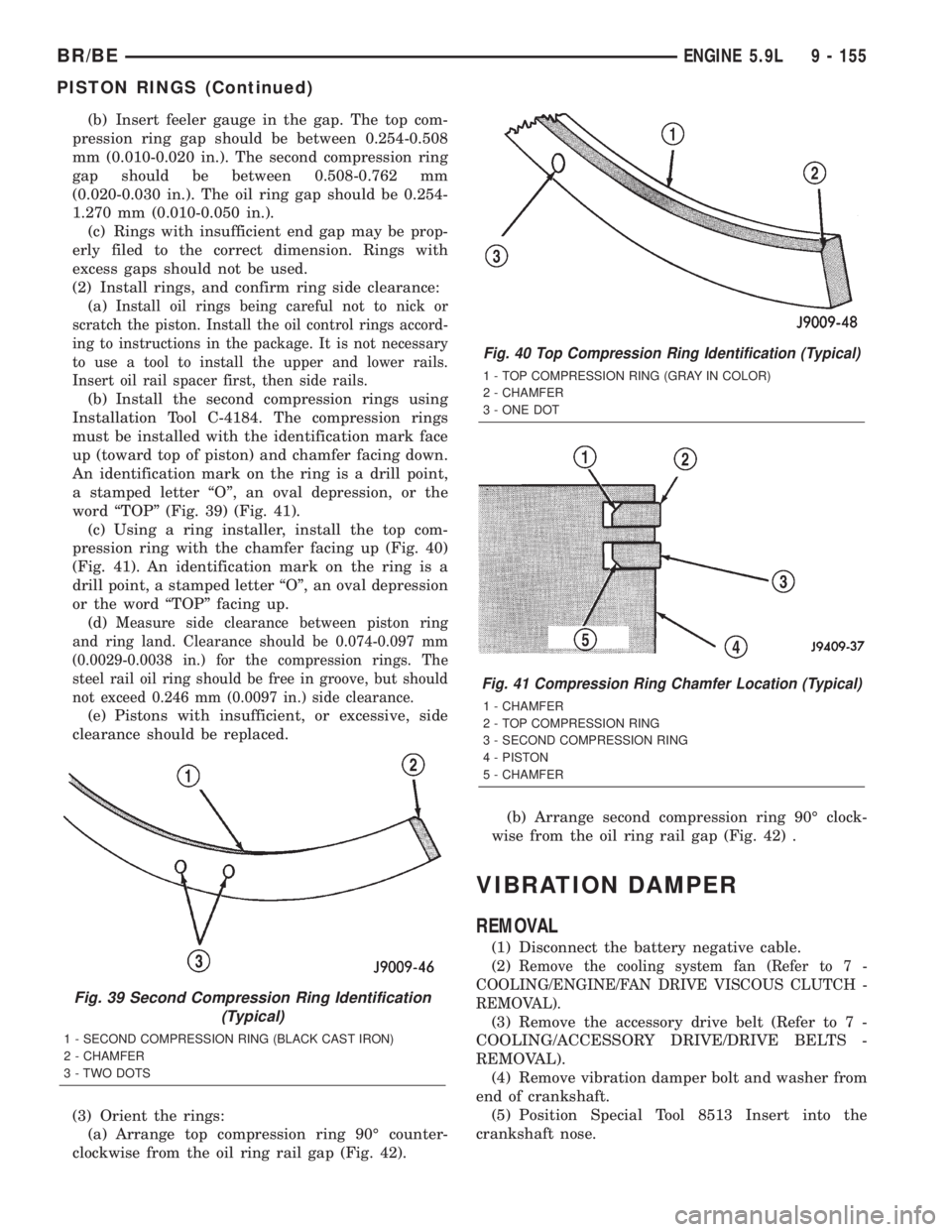

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter ªOº, an oval depression, or the

word ªTOPº (Fig. 39) (Fig. 41).

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 40)

(Fig. 41). An identification mark on the ring is a

drill point, a stamped letter ªOº, an oval depression

or the word ªTOPº facing up.

(d)

Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 in.) for the compression rings. The

steel rail oil ring should be free in groove, but should

not exceed 0.246 mm (0.0097 in.) side clearance.

(e) Pistons with insufficient, or excessive, side

clearance should be replaced.

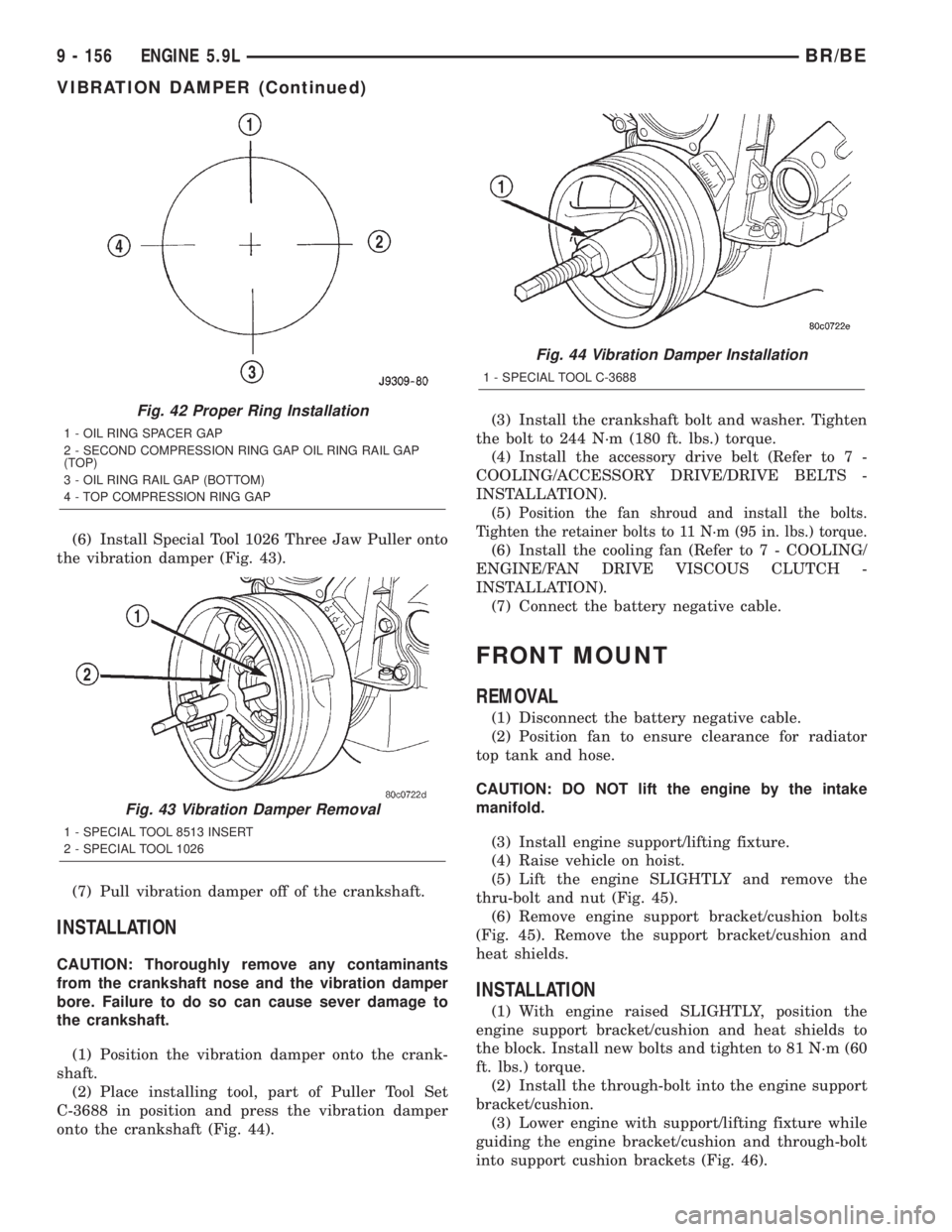

(3) Orient the rings:

(a) Arrange top compression ring 90É counter-

clockwise from the oil ring rail gap (Fig. 42).(b) Arrange second compression ring 90É clock-

wise from the oil ring rail gap (Fig. 42) .

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2)

Remove the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS CLUTCH -

REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove vibration damper bolt and washer from

end of crankshaft.

(5) Position Special Tool 8513 Insert into the

crankshaft nose.

Fig. 39 Second Compression Ring Identification

(Typical)

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 40 Top Compression Ring Identification (Typical)

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 41 Compression Ring Chamfer Location (Typical)

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

BR/BEENGINE 5.9L 9 - 155

PISTON RINGS (Continued)

Page 1303 of 2889

(6) Install Special Tool 1026 Three Jaw Puller onto

the vibration damper (Fig. 43).

(7) Pull vibration damper off of the crankshaft.

INSTALLATION

CAUTION: Thoroughly remove any contaminants

from the crankshaft nose and the vibration damper

bore. Failure to do so can cause sever damage to

the crankshaft.

(1) Position the vibration damper onto the crank-

shaft.

(2) Place installing tool, part of Puller Tool Set

C-3688 in position and press the vibration damper

onto the crankshaft (Fig. 44).(3) Install the crankshaft bolt and washer. Tighten

the bolt to 244 N´m (180 ft. lbs.) torque.

(4) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(5)

Position the fan shroud and install the bolts.

Tighten the retainer bolts to 11 N´m (95 in. lbs.) torque.

(6) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/FAN DRIVE VISCOUS CLUTCH -

INSTALLATION).

(7) Connect the battery negative cable.

FRONT MOUNT

REMOVAL

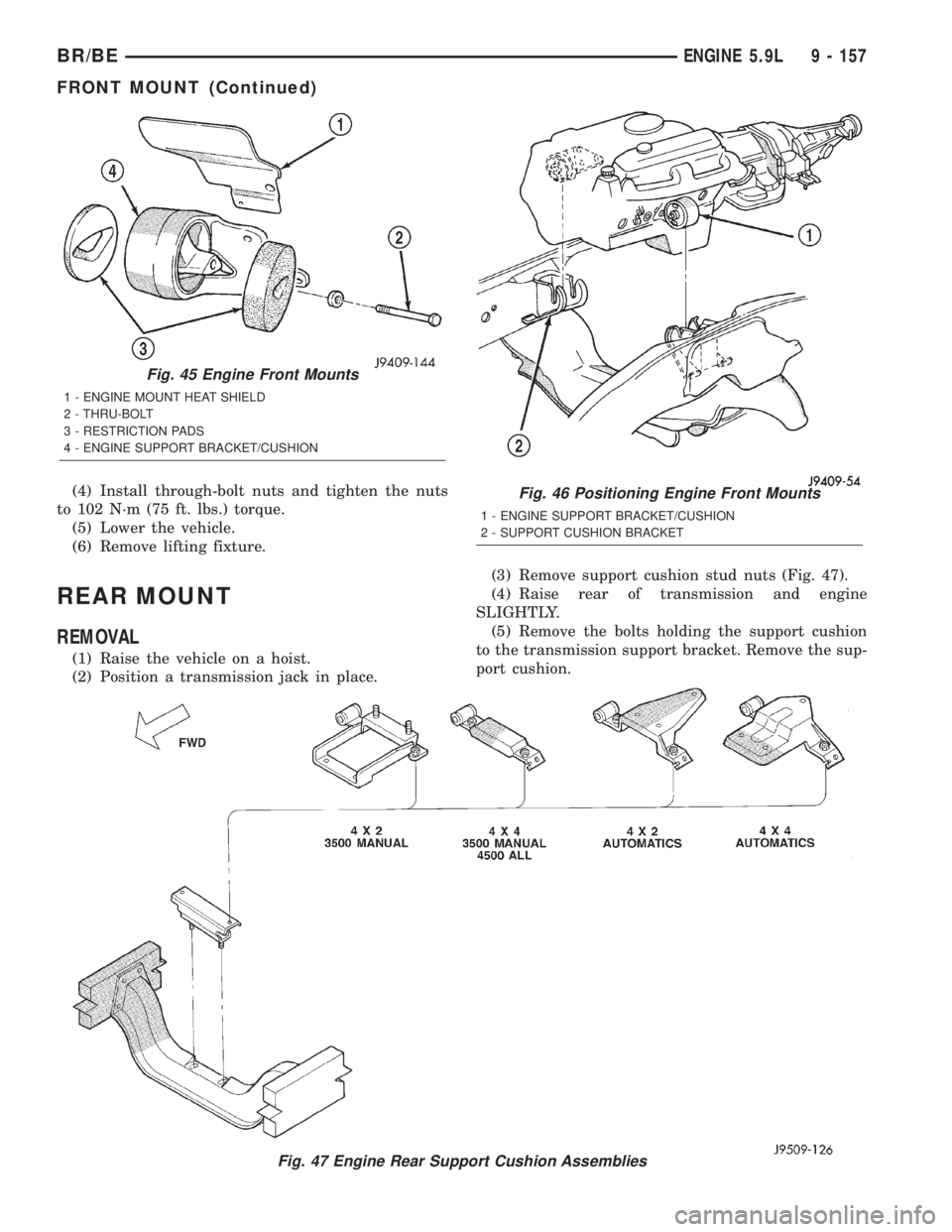

(1) Disconnect the battery negative cable.

(2) Position fan to ensure clearance for radiator

top tank and hose.

CAUTION: DO NOT lift the engine by the intake

manifold.

(3) Install engine support/lifting fixture.

(4) Raise vehicle on hoist.

(5) Lift the engine SLIGHTLY and remove the

thru-bolt and nut (Fig. 45).

(6) Remove engine support bracket/cushion bolts

(Fig. 45). Remove the support bracket/cushion and

heat shields.

INSTALLATION

(1) With engine raised SLIGHTLY, position the

engine support bracket/cushion and heat shields to

the block. Install new bolts and tighten to 81 N´m (60

ft. lbs.) torque.

(2) Install the through-bolt into the engine support

bracket/cushion.

(3) Lower engine with support/lifting fixture while

guiding the engine bracket/cushion and through-bolt

into support cushion brackets (Fig. 46).

Fig. 42 Proper Ring Installation

1 - OIL RING SPACER GAP

2 - SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 - OIL RING RAIL GAP (BOTTOM)

4 - TOP COMPRESSION RING GAP

Fig. 43 Vibration Damper Removal

1 - SPECIAL TOOL 8513 INSERT

2 - SPECIAL TOOL 1026

Fig. 44 Vibration Damper Installation

1 - SPECIAL TOOL C-3688

9 - 156 ENGINE 5.9LBR/BE

VIBRATION DAMPER (Continued)

Page 1304 of 2889

(4) Install through-bolt nuts and tighten the nuts

to 102 N´m (75 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Remove lifting fixture.

REAR MOUNT

REMOVAL

(1) Raise the vehicle on a hoist.

(2) Position a transmission jack in place.(3) Remove support cushion stud nuts (Fig. 47).

(4) Raise rear of transmission and engine

SLIGHTLY.

(5) Remove the bolts holding the support cushion

to the transmission support bracket. Remove the sup-

port cushion.

Fig. 46 Positioning Engine Front Mounts

1 - ENGINE SUPPORT BRACKET/CUSHION

2 - SUPPORT CUSHION BRACKET

Fig. 47 Engine Rear Support Cushion Assemblies

Fig. 45 Engine Front Mounts

1 - ENGINE MOUNT HEAT SHIELD

2 - THRU-BOLT

3 - RESTRICTION PADS

4 - ENGINE SUPPORT BRACKET/CUSHION

BR/BEENGINE 5.9L 9 - 157

FRONT MOUNT (Continued)

Page 1305 of 2889

(6) If necessary, remove the bolts holding the

transmission support bracket to the transmission.

INSTALLATION

(1) If removed, position the transmission support

bracket to the transmission. Install new attaching

bolts and tighten to 88 N´m (65 ft. lbs.) torque.

(2) Position support cushion to transmission sup-

port bracket. Install stud nuts and tighten to 41 N´m

(30 ft. lbs.) torque.

(3) Using the transmission jack, lower the trans-

mission and support cushion onto the crossmember

(Fig. 49).

(4) Install the support cushion bolts and tighten to

41 N´m (30 ft. lbs.) torque.

(5) Remove the transmission jack.

(6) Lower the vehicle.

LUBRICATION

DESCRIPTION

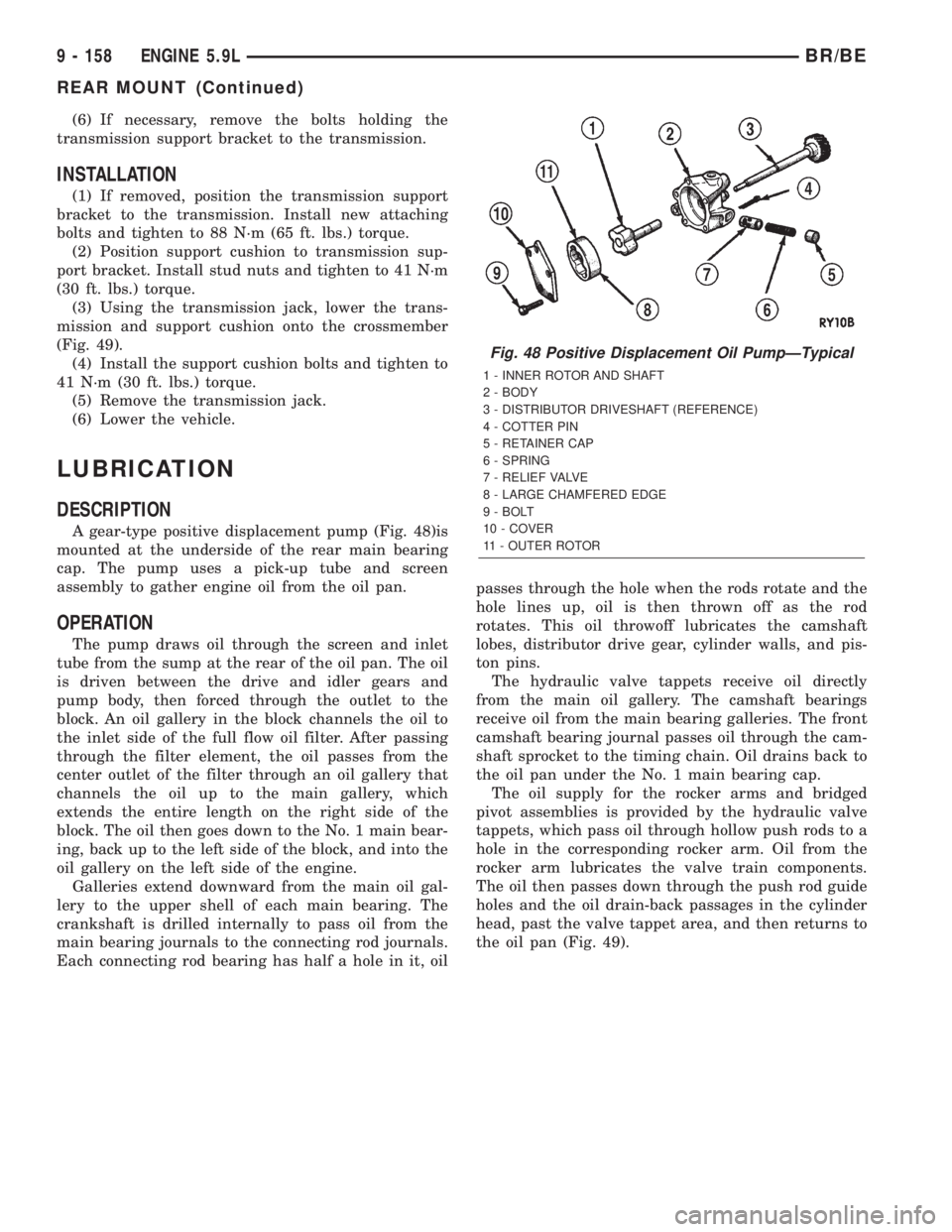

A gear-type positive displacement pump (Fig. 48)is

mounted at the underside of the rear main bearing

cap. The pump uses a pick-up tube and screen

assembly to gather engine oil from the oil pan.

OPERATION

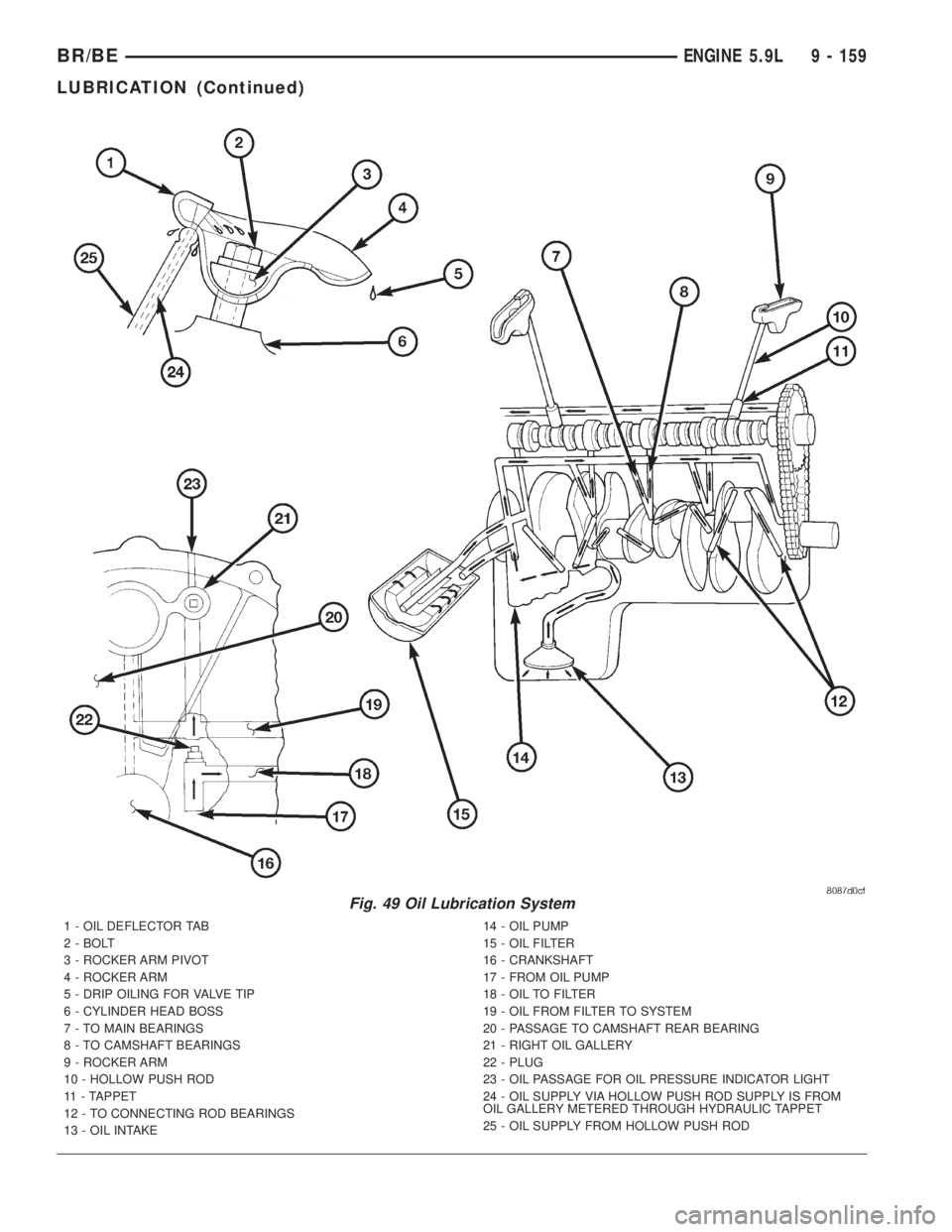

The pump draws oil through the screen and inlet

tube from the sump at the rear of the oil pan. The oil

is driven between the drive and idler gears and

pump body, then forced through the outlet to the

block. An oil gallery in the block channels the oil to

the inlet side of the full flow oil filter. After passing

through the filter element, the oil passes from the

center outlet of the filter through an oil gallery that

channels the oil up to the main gallery, which

extends the entire length on the right side of the

block. The oil then goes down to the No. 1 main bear-

ing, back up to the left side of the block, and into the

oil gallery on the left side of the engine.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals to the connecting rod journals.

Each connecting rod bearing has half a hole in it, oilpasses through the hole when the rods rotate and the

hole lines up, oil is then thrown off as the rod

rotates. This oil throwoff lubricates the camshaft

lobes, distributor drive gear, cylinder walls, and pis-

ton pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. The camshaft bearings

receive oil from the main bearing galleries. The front

camshaft bearing journal passes oil through the cam-

shaft sprocket to the timing chain. Oil drains back to

the oil pan under the No. 1 main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets, which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components.

The oil then passes down through the push rod guide

holes and the oil drain-back passages in the cylinder

head, past the valve tappet area, and then returns to

the oil pan (Fig. 49).

Fig. 48 Positive Displacement Oil PumpÐTypical

1 - INNER ROTOR AND SHAFT

2 - BODY

3 - DISTRIBUTOR DRIVESHAFT (REFERENCE)

4 - COTTER PIN

5 - RETAINER CAP

6 - SPRING

7 - RELIEF VALVE

8 - LARGE CHAMFERED EDGE

9 - BOLT

10 - COVER

11 - OUTER ROTOR

9 - 158 ENGINE 5.9LBR/BE

REAR MOUNT (Continued)

Page 1306 of 2889

Fig. 49 Oil Lubrication System

1 - OIL DEFLECTOR TAB

2 - BOLT

3 - ROCKER ARM PIVOT

4 - ROCKER ARM

5 - DRIP OILING FOR VALVE TIP

6 - CYLINDER HEAD BOSS

7 - TO MAIN BEARINGS

8 - TO CAMSHAFT BEARINGS

9 - ROCKER ARM

10 - HOLLOW PUSH ROD

11 - TAPPET

12 - TO CONNECTING ROD BEARINGS

13 - OIL INTAKE14 - OIL PUMP

15 - OIL FILTER

16 - CRANKSHAFT

17 - FROM OIL PUMP

18 - OIL TO FILTER

19 - OIL FROM FILTER TO SYSTEM

20 - PASSAGE TO CAMSHAFT REAR BEARING

21 - RIGHT OIL GALLERY

22 - PLUG

23 - OIL PASSAGE FOR OIL PRESSURE INDICATOR LIGHT

24 - OIL SUPPLY VIA HOLLOW PUSH ROD SUPPLY IS FROM

OIL GALLERY METERED THROUGH HYDRAULIC TAPPET

25 - OIL SUPPLY FROM HOLLOW PUSH ROD

BR/BEENGINE 5.9L 9 - 159

LUBRICATION (Continued)

Page 1307 of 2889

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

OIL

STANDARD PROCEDUREÐENGINE OIL

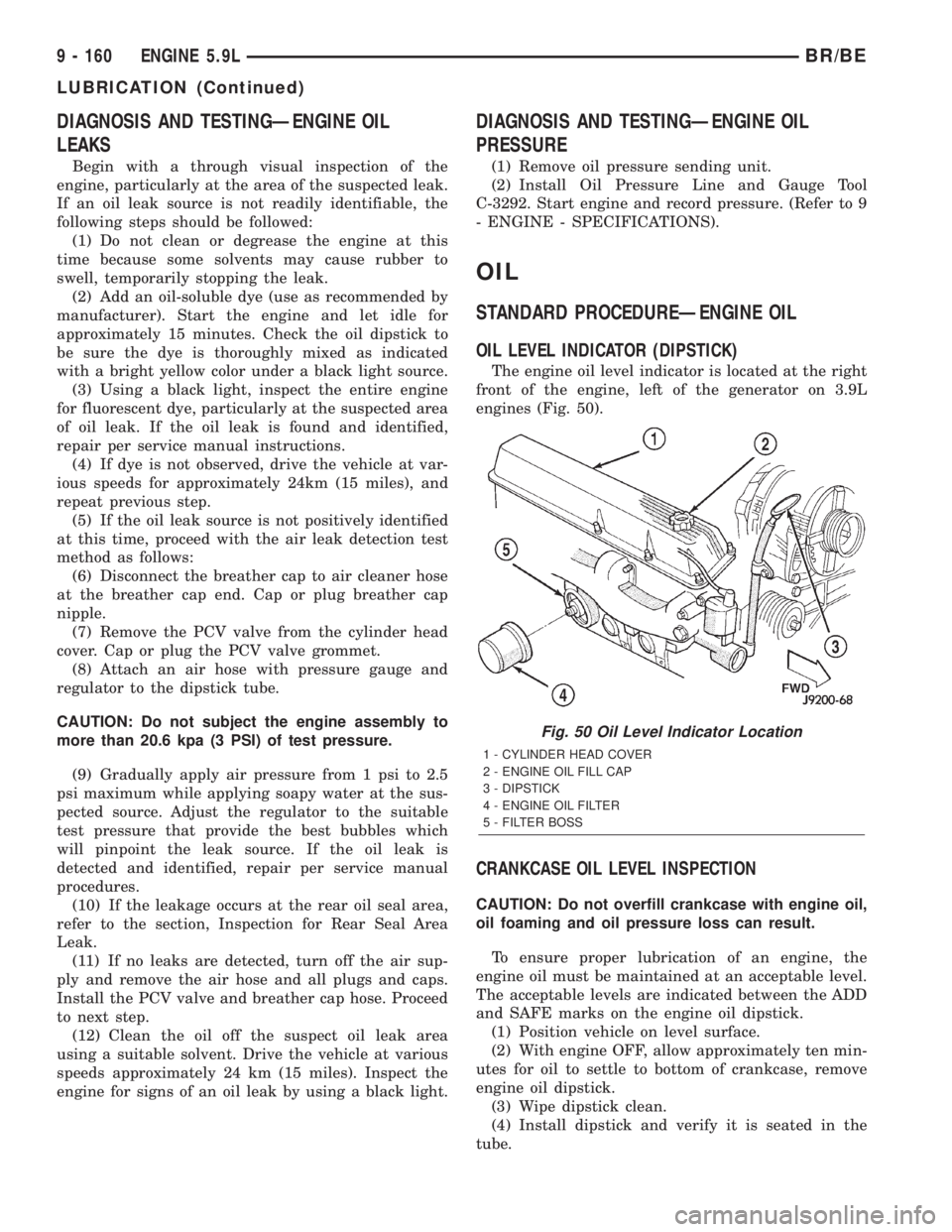

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

front of the engine, left of the generator on 3.9L

engines (Fig. 50).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

Fig. 50 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

9 - 160 ENGINE 5.9LBR/BE

LUBRICATION (Continued)

Page 1308 of 2889

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

OIL FILTER

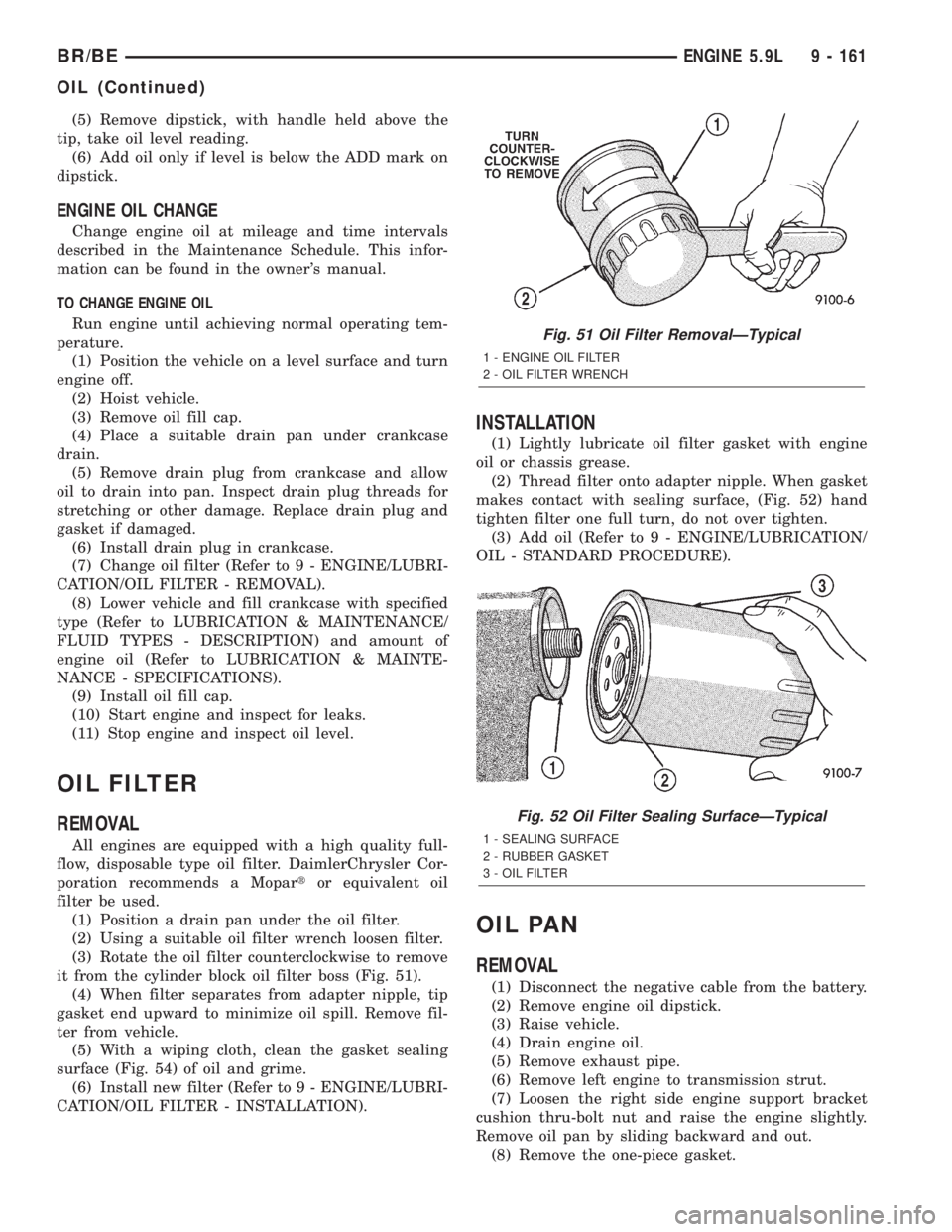

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 54) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion thru-bolt nut and raise the engine slightly.

Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

BR/BEENGINE 5.9L 9 - 161

OIL (Continued)

Page 1309 of 2889

CLEANING

Clean the block and pan gasket surfaces.

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

INSTALLATION

(1) Clean the block and pan gasket surfaces.

(2) Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

(3) If present, trim excess sealant from inside the

engine.

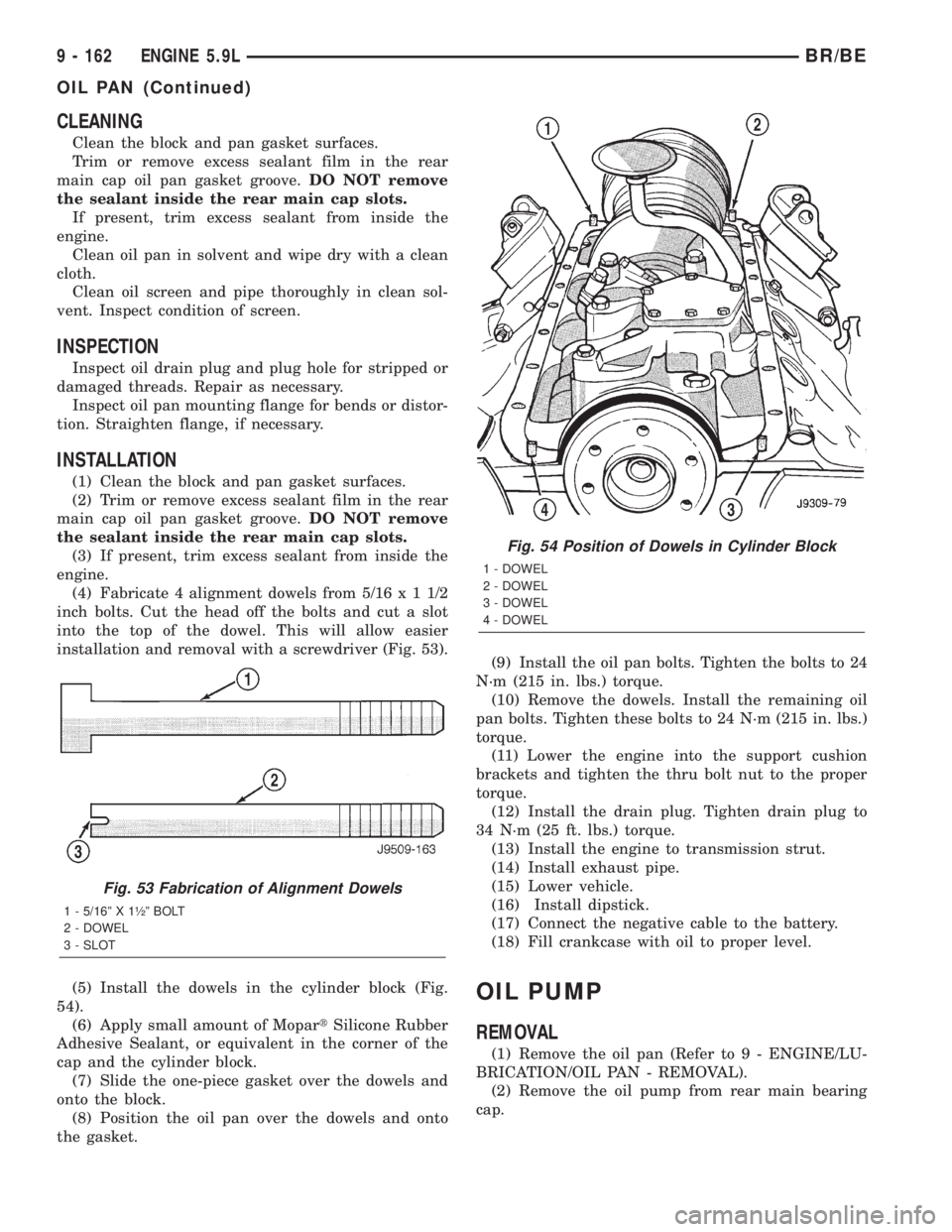

(4) Fabricate 4 alignment dowels from 5/16x11/2

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 53).

(5) Install the dowels in the cylinder block (Fig.

54).

(6) Apply small amount of MopartSilicone Rubber

Adhesive Sealant, or equivalent in the corner of the

cap and the cylinder block.

(7) Slide the one-piece gasket over the dowels and

onto the block.

(8) Position the oil pan over the dowels and onto

the gasket.(9) Install the oil pan bolts. Tighten the bolts to 24

N´m (215 in. lbs.) torque.

(10) Remove the dowels. Install the remaining oil

pan bolts. Tighten these bolts to 24 N´m (215 in. lbs.)

torque.

(11) Lower the engine into the support cushion

brackets and tighten the thru bolt nut to the proper

torque.

(12) Install the drain plug. Tighten drain plug to

34 N´m (25 ft. lbs.) torque.

(13) Install the engine to transmission strut.

(14) Install exhaust pipe.

(15) Lower vehicle.

(16) Install dipstick.

(17) Connect the negative cable to the battery.

(18) Fill crankcase with oil to proper level.

OIL PUMP

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump from rear main bearing

cap.

Fig. 53 Fabrication of Alignment Dowels

1 - 5/16º X 1óº BOLT

2 - DOWEL

3 - SLOT

Fig. 54 Position of Dowels in Cylinder Block

1 - DOWEL

2 - DOWEL

3 - DOWEL

4 - DOWEL

9 - 162 ENGINE 5.9LBR/BE

OIL PAN (Continued)

Page 1310 of 2889

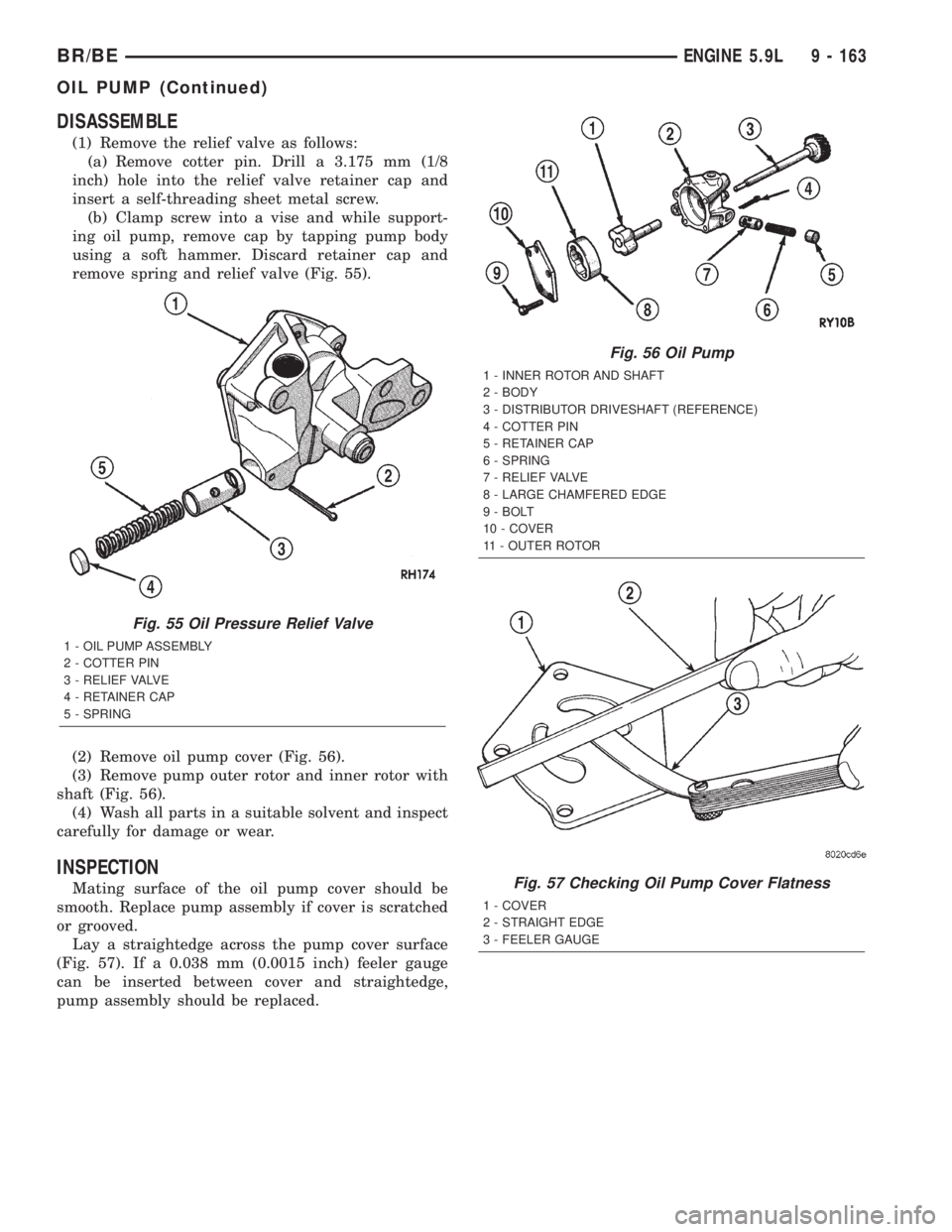

DISASSEMBLE

(1) Remove the relief valve as follows:

(a) Remove cotter pin. Drill a 3.175 mm (1/8

inch) hole into the relief valve retainer cap and

insert a self-threading sheet metal screw.

(b) Clamp screw into a vise and while support-

ing oil pump, remove cap by tapping pump body

using a soft hammer. Discard retainer cap and

remove spring and relief valve (Fig. 55).

(2) Remove oil pump cover (Fig. 56).

(3) Remove pump outer rotor and inner rotor with

shaft (Fig. 56).

(4) Wash all parts in a suitable solvent and inspect

carefully for damage or wear.

INSPECTION

Mating surface of the oil pump cover should be

smooth. Replace pump assembly if cover is scratched

or grooved.

Lay a straightedge across the pump cover surface

(Fig. 57). If a 0.038 mm (0.0015 inch) feeler gauge

can be inserted between cover and straightedge,

pump assembly should be replaced.

Fig. 55 Oil Pressure Relief Valve

1 - OIL PUMP ASSEMBLY

2 - COTTER PIN

3 - RELIEF VALVE

4 - RETAINER CAP

5 - SPRING

Fig. 56 Oil Pump

1 - INNER ROTOR AND SHAFT

2 - BODY

3 - DISTRIBUTOR DRIVESHAFT (REFERENCE)

4 - COTTER PIN

5 - RETAINER CAP

6 - SPRING

7 - RELIEF VALVE

8 - LARGE CHAMFERED EDGE

9 - BOLT

10 - COVER

11 - OUTER ROTOR

Fig. 57 Checking Oil Pump Cover Flatness

1 - COVER

2 - STRAIGHT EDGE

3 - FEELER GAUGE

BR/BEENGINE 5.9L 9 - 163

OIL PUMP (Continued)