belt DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1312 of 2889

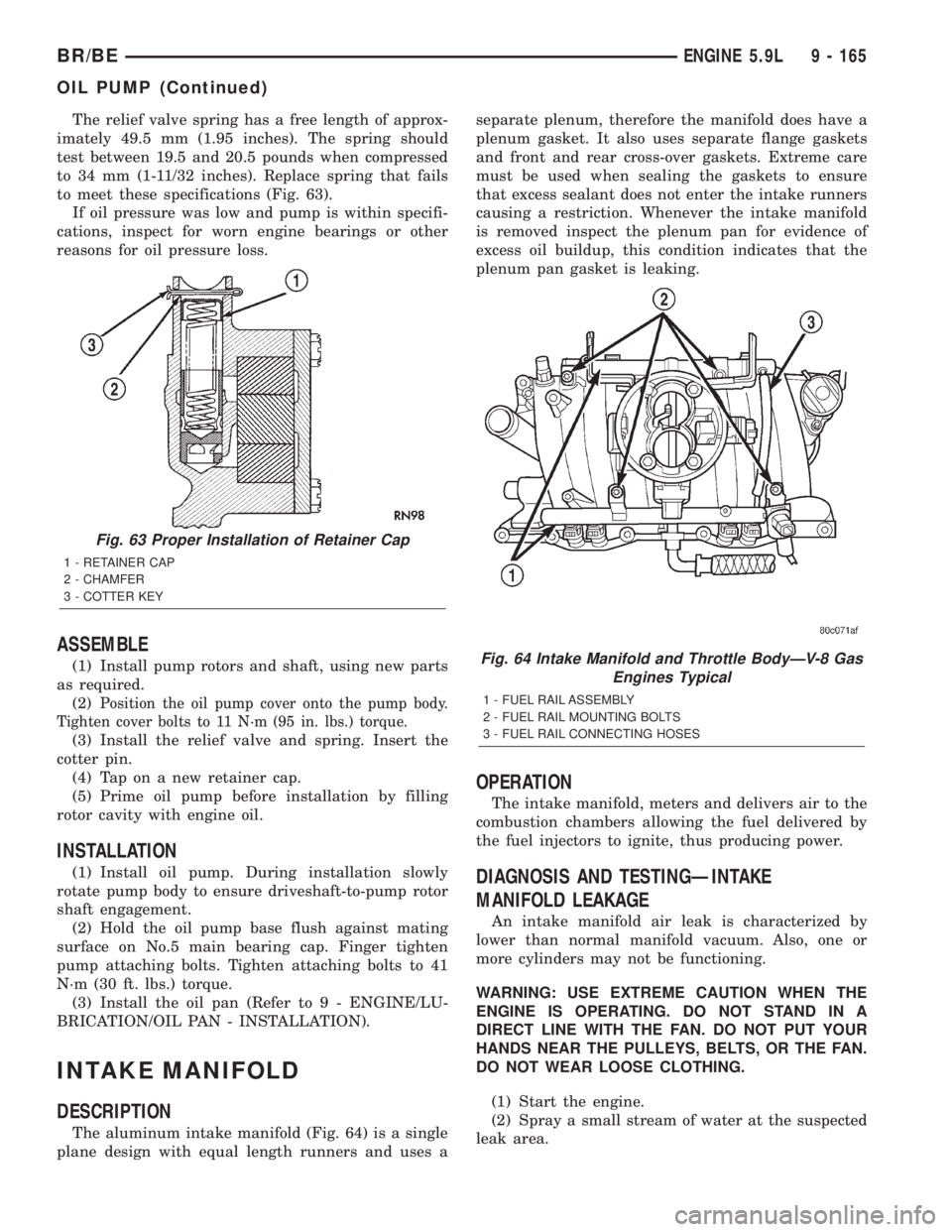

The relief valve spring has a free length of approx-

imately 49.5 mm (1.95 inches). The spring should

test between 19.5 and 20.5 pounds when compressed

to 34 mm (1-11/32 inches). Replace spring that fails

to meet these specifications (Fig. 63).

If oil pressure was low and pump is within specifi-

cations, inspect for worn engine bearings or other

reasons for oil pressure loss.

ASSEMBLE

(1) Install pump rotors and shaft, using new parts

as required.

(2)

Position the oil pump cover onto the pump body.

Tighten cover bolts to 11 N´m (95 in. lbs.) torque.

(3) Install the relief valve and spring. Insert the

cotter pin.

(4) Tap on a new retainer cap.

(5) Prime oil pump before installation by filling

rotor cavity with engine oil.

INSTALLATION

(1) Install oil pump. During installation slowly

rotate pump body to ensure driveshaft-to-pump rotor

shaft engagement.

(2) Hold the oil pump base flush against mating

surface on No.5 main bearing cap. Finger tighten

pump attaching bolts. Tighten attaching bolts to 41

N´m (30 ft. lbs.) torque.

(3) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

INTAKE MANIFOLD

DESCRIPTION

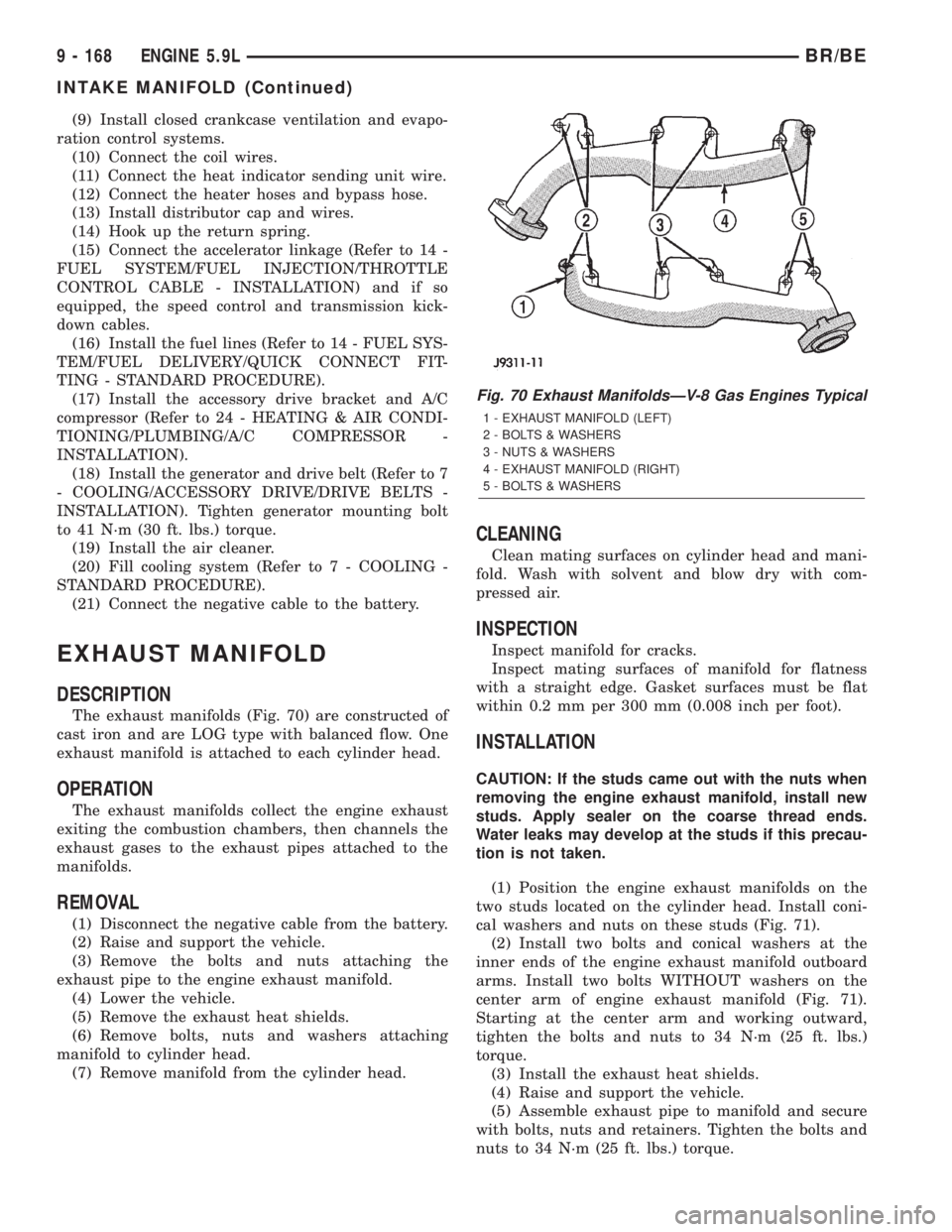

The aluminum intake manifold (Fig. 64) is a single

plane design with equal length runners and uses aseparate plenum, therefore the manifold does have a

plenum gasket. It also uses separate flange gaskets

and front and rear cross-over gaskets. Extreme care

must be used when sealing the gaskets to ensure

that excess sealant does not enter the intake runners

causing a restriction. Whenever the intake manifold

is removed inspect the plenum pan for evidence of

excess oil buildup, this condition indicates that the

plenum pan gasket is leaking.

OPERATION

The intake manifold, meters and delivers air to the

combustion chambers allowing the fuel delivered by

the fuel injectors to ignite, thus producing power.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

Fig. 63 Proper Installation of Retainer Cap

1 - RETAINER CAP

2 - CHAMFER

3 - COTTER KEY

Fig. 64 Intake Manifold and Throttle BodyÐV-8 Gas

Engines Typical

1 - FUEL RAIL ASSEMBLY

2 - FUEL RAIL MOUNTING BOLTS

3 - FUEL RAIL CONNECTING HOSES

BR/BEENGINE 5.9L 9 - 165

OIL PUMP (Continued)

Page 1315 of 2889

(9) Install closed crankcase ventilation and evapo-

ration control systems.

(10) Connect the coil wires.

(11) Connect the heat indicator sending unit wire.

(12) Connect the heater hoses and bypass hose.

(13) Install distributor cap and wires.

(14) Hook up the return spring.

(15) Connect the accelerator linkage (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/THROTTLE

CONTROL CABLE - INSTALLATION) and if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel lines (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the accessory drive bracket and A/C

compressor (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(18) Install the generator and drive belt (Refer to 7

- COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION). Tighten generator mounting bolt

to 41 N´m (30 ft. lbs.) torque.

(19) Install the air cleaner.

(20) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(21) Connect the negative cable to the battery.

EXHAUST MANIFOLD

DESCRIPTION

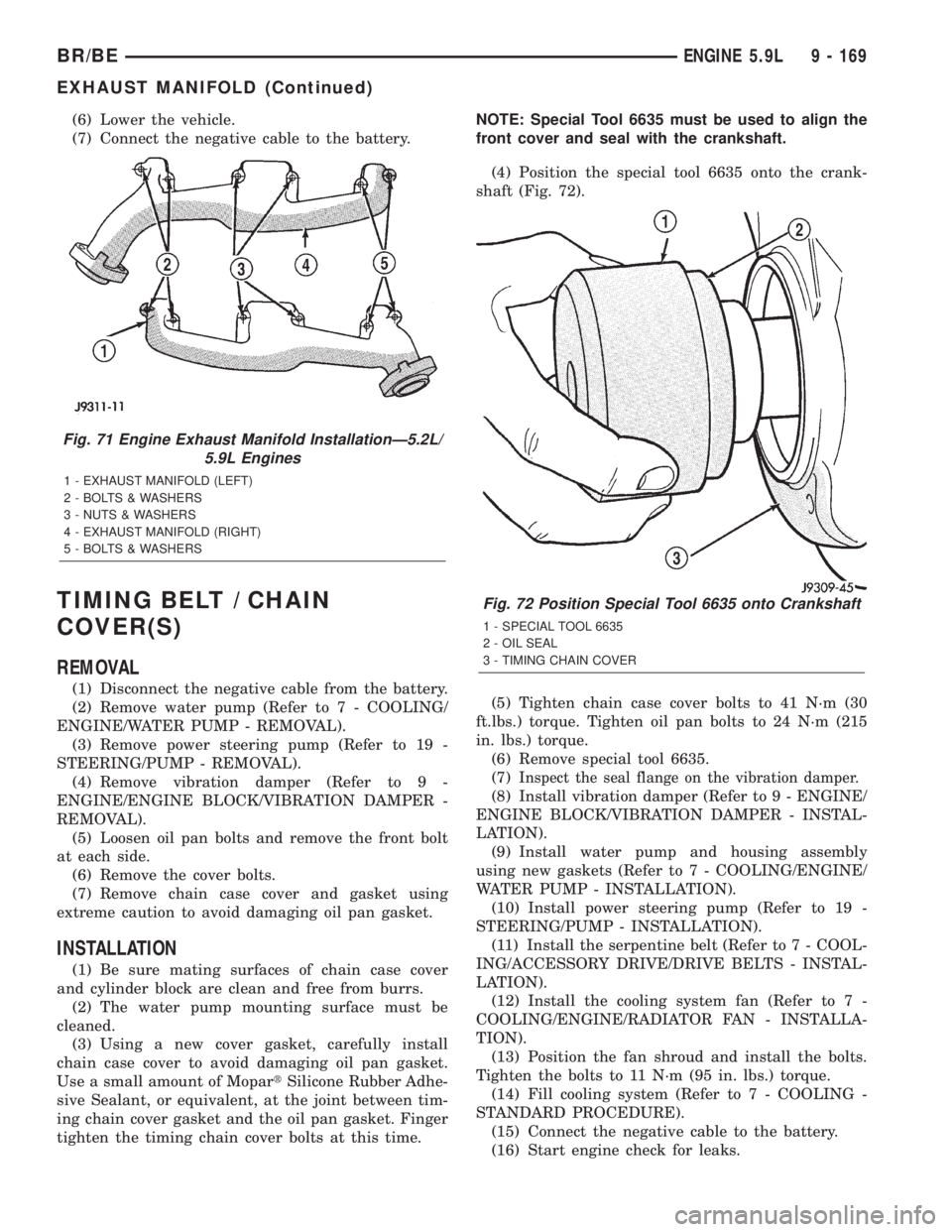

The exhaust manifolds (Fig. 70) are constructed of

cast iron and are LOG type with balanced flow. One

exhaust manifold is attached to each cylinder head.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shields.

(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold from the cylinder head.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

(1) Position the engine exhaust manifolds on the

two studs located on the cylinder head. Install coni-

cal washers and nuts on these studs (Fig. 71).

(2) Install two bolts and conical washers at the

inner ends of the engine exhaust manifold outboard

arms. Install two bolts WITHOUT washers on the

center arm of engine exhaust manifold (Fig. 71).

Starting at the center arm and working outward,

tighten the bolts and nuts to 34 N´m (25 ft. lbs.)

torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

Fig. 70 Exhaust ManifoldsÐV-8 Gas Engines Typical

1 - EXHAUST MANIFOLD (LEFT)

2 - BOLTS & WASHERS

3 - NUTS & WASHERS

4 - EXHAUST MANIFOLD (RIGHT)

5 - BOLTS & WASHERS

9 - 168 ENGINE 5.9LBR/BE

INTAKE MANIFOLD (Continued)

Page 1316 of 2889

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

(3) Remove power steering pump (Refer to 19 -

STEERING/PUMP - REMOVAL).

(4) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(5) Loosen oil pan bolts and remove the front bolt

at each side.

(6) Remove the cover bolts.

(7) Remove chain case cover and gasket using

extreme caution to avoid damaging oil pan gasket.

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

(2) The water pump mounting surface must be

cleaned.

(3) Using a new cover gasket, carefully install

chain case cover to avoid damaging oil pan gasket.

Use a small amount of MopartSilicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

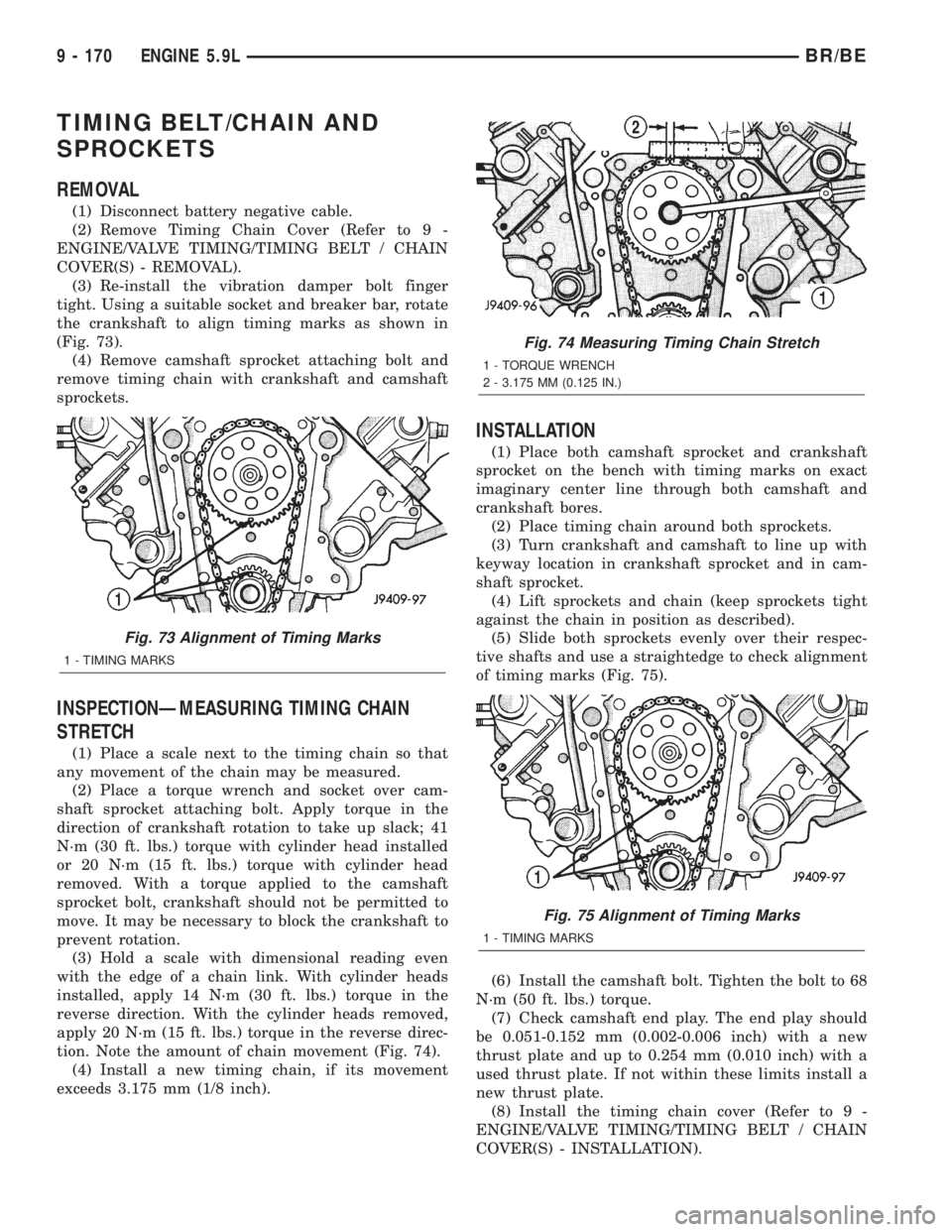

tighten the timing chain cover bolts at this time.NOTE: Special Tool 6635 must be used to align the

front cover and seal with the crankshaft.

(4) Position the special tool 6635 onto the crank-

shaft (Fig. 72).

(5) Tighten chain case cover bolts to 41 N´m (30

ft.lbs.) torque. Tighten oil pan bolts to 24 N´m (215

in. lbs.) torque.

(6) Remove special tool 6635.

(7)

Inspect the seal flange on the vibration damper.

(8) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(9) Install water pump and housing assembly

using new gaskets (Refer to 7 - COOLING/ENGINE/

WATER PUMP - INSTALLATION).

(10) Install power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(11) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(12) Install the cooling system fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(13) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(14) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(15) Connect the negative cable to the battery.

(16) Start engine check for leaks.

Fig. 71 Engine Exhaust Manifold InstallationÐ5.2L/

5.9L Engines

1 - EXHAUST MANIFOLD (LEFT)

2 - BOLTS & WASHERS

3 - NUTS & WASHERS

4 - EXHAUST MANIFOLD (RIGHT)

5 - BOLTS & WASHERS

Fig. 72 Position Special Tool 6635 onto Crankshaft

1 - SPECIAL TOOL 6635

2 - OIL SEAL

3 - TIMING CHAIN COVER

BR/BEENGINE 5.9L 9 - 169

EXHAUST MANIFOLD (Continued)

Page 1317 of 2889

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove Timing Chain Cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Re-install the vibration damper bolt finger

tight. Using a suitable socket and breaker bar, rotate

the crankshaft to align timing marks as shown in

(Fig. 73).

(4) Remove camshaft sprocket attaching bolt and

remove timing chain with crankshaft and camshaft

sprockets.

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2) Place a torque wrench and socket over cam-

shaft sprocket attaching bolt. Apply torque in the

direction of crankshaft rotation to take up slack; 41

N´m (30 ft. lbs.) torque with cylinder head installed

or 20 N´m (15 ft. lbs.) torque with cylinder head

removed. With a torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads

installed, apply 14 N´m (30 ft. lbs.) torque in the

reverse direction. With the cylinder heads removed,

apply 20 N´m (15 ft. lbs.) torque in the reverse direc-

tion. Note the amount of chain movement (Fig. 74).

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

INSTALLATION

(1) Place both camshaft sprocket and crankshaft

sprocket on the bench with timing marks on exact

imaginary center line through both camshaft and

crankshaft bores.

(2) Place timing chain around both sprockets.

(3) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(4) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(5) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 75).

(6) Install the camshaft bolt. Tighten the bolt to 68

N´m (50 ft. lbs.) torque.

(7) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(8) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

Fig. 73 Alignment of Timing Marks

1 - TIMING MARKS

Fig. 74 Measuring Timing Chain Stretch

1 - TORQUE WRENCH

2 - 3.175 MM (0.125 IN.)

Fig. 75 Alignment of Timing Marks

1 - TIMING MARKS

9 - 170 ENGINE 5.9LBR/BE

Page 1319 of 2889

LUBRICATION

DESCRIPTION..........................214

OPERATION............................214

DIAGNOSIS AND TESTING................215

ENGINE OIL LEAKS....................215

ENGINE OIL PRESSURE................215

OIL

STANDARD PROCEDURE.................217

ENGINE OIL..........................217

OIL FILTER

REMOVAL.............................218

INSTALLATION..........................218

OIL PAN

REMOVAL.............................218

CLEANING.............................218

INSPECTION...........................219

INSTALLATION..........................219

OIL PUMP

REMOVAL.............................219

CLEANING.............................220

INSPECTION...........................220

INSTALLATION..........................221INTAKE MANIFOLD

DESCRIPTION..........................222

DIAGNOSIS AND TESTING................222

INTAKE MANIFOLD LEAKAGE............222

REMOVAL.............................222

CLEANING.............................223

INSPECTION...........................223

INSTALLATION..........................223

EXHAUST MANIFOLD

DESCRIPTION..........................224

OPERATION............................224

REMOVAL.............................225

CLEANING.............................225

INSPECTION...........................225

INSTALLATION..........................225

TIMING BELT / CHAIN COVER(S)

REMOVAL.............................225

INSTALLATION..........................226

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL.............................226

INSPECTION...........................227

INSTALLATION..........................227

ENGINE 8.0L

DESCRIPTION

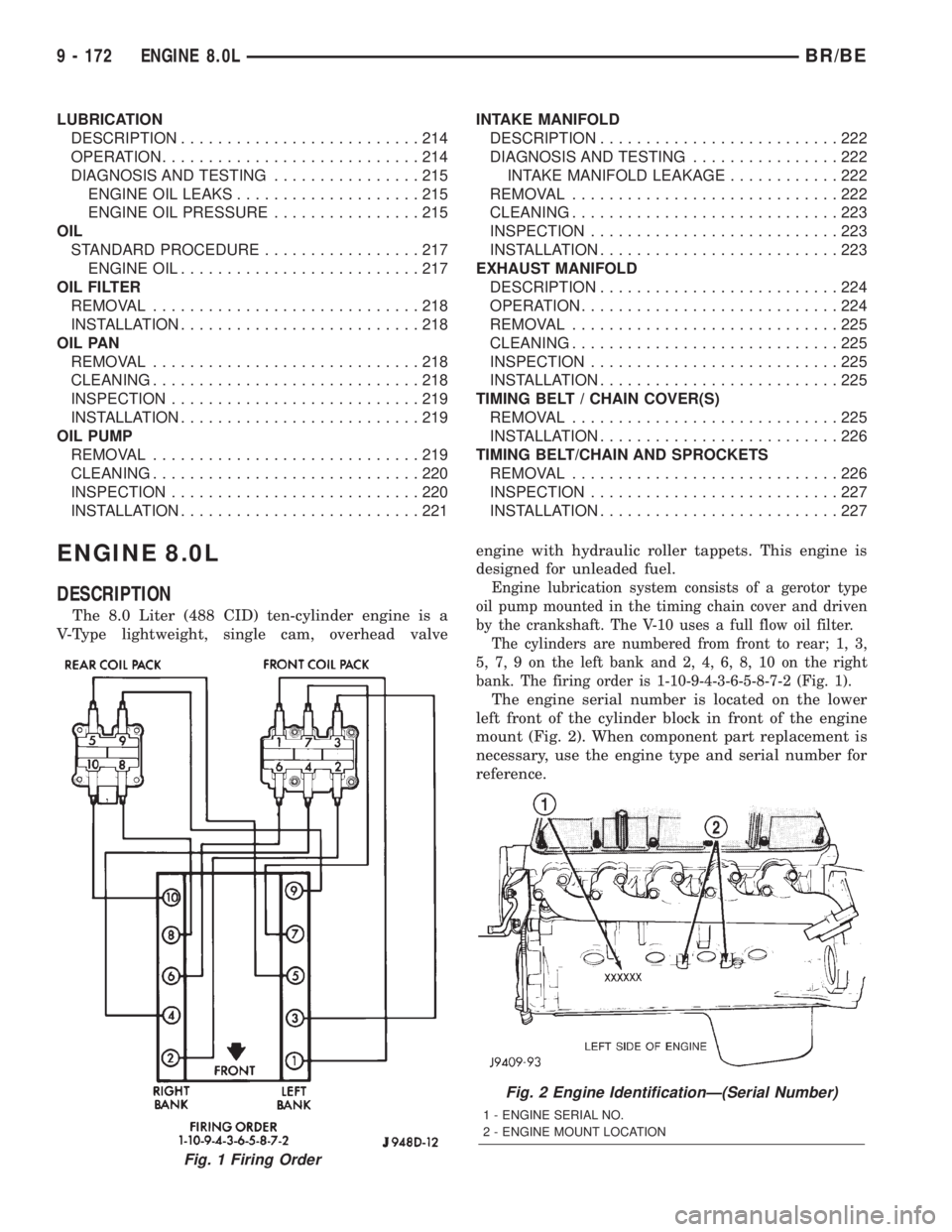

The 8.0 Liter (488 CID) ten-cylinder engine is a

V-Type lightweight, single cam, overhead valveengine with hydraulic roller tappets. This engine is

designed for unleaded fuel.

Engine lubrication system consists of a gerotor type

oil pump mounted in the timing chain cover and driven

by the crankshaft. The V-10 uses a full flow oil filter.

The cylinders are numbered from front to rear; 1, 3,

5, 7, 9 on the left bank and 2, 4, 6, 8, 10 on the right

bank. The firing order is 1-10-9-4-3-6-5-8-7-2 (Fig. 1).

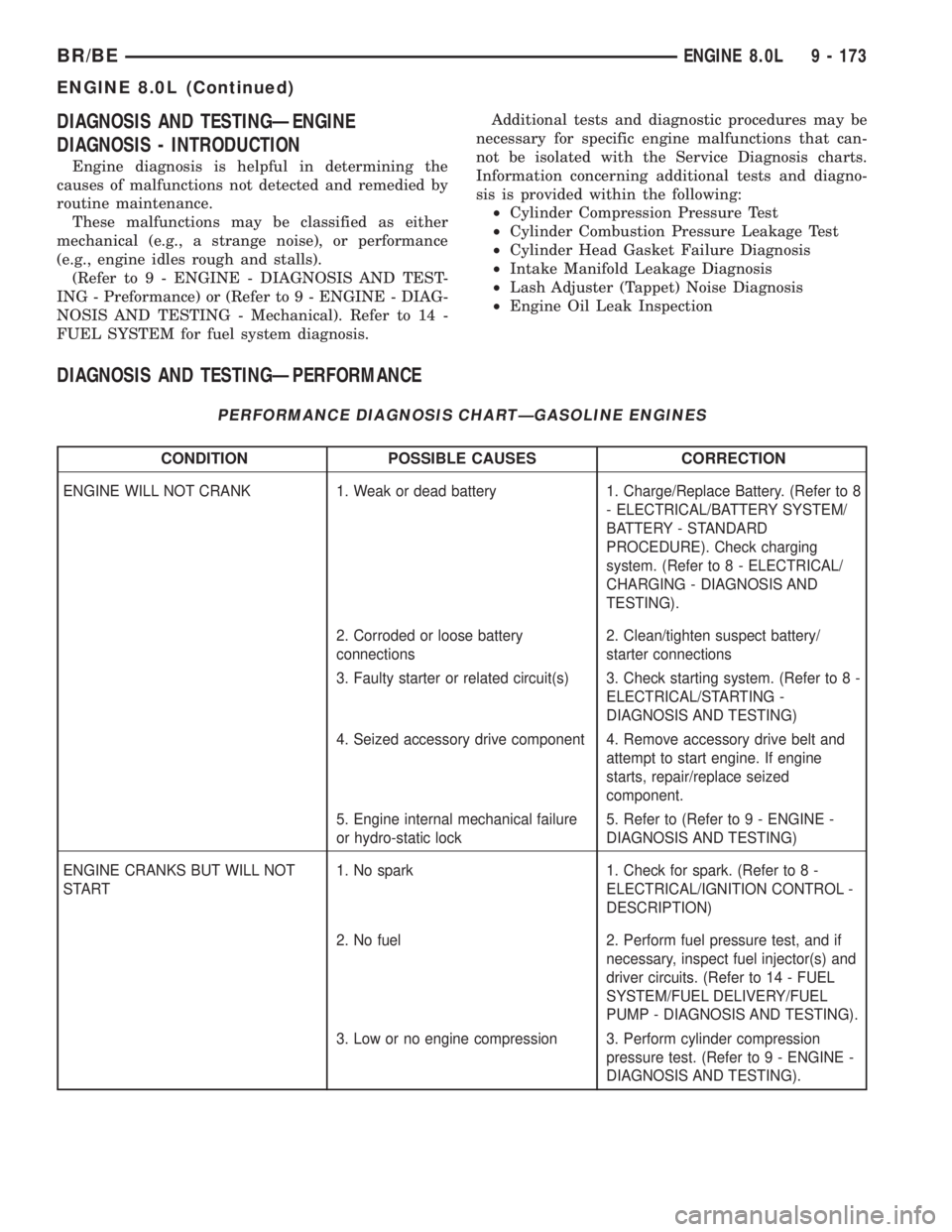

The engine serial number is located on the lower

left front of the cylinder block in front of the engine

mount (Fig. 2). When component part replacement is

necessary, use the engine type and serial number for

reference.

Fig. 1 Firing Order

Fig. 2 Engine IdentificationÐ(Serial Number)

1 - ENGINE SERIAL NO.

2 - ENGINE MOUNT LOCATION

9 - 172 ENGINE 8.0LBR/BE

Page 1320 of 2889

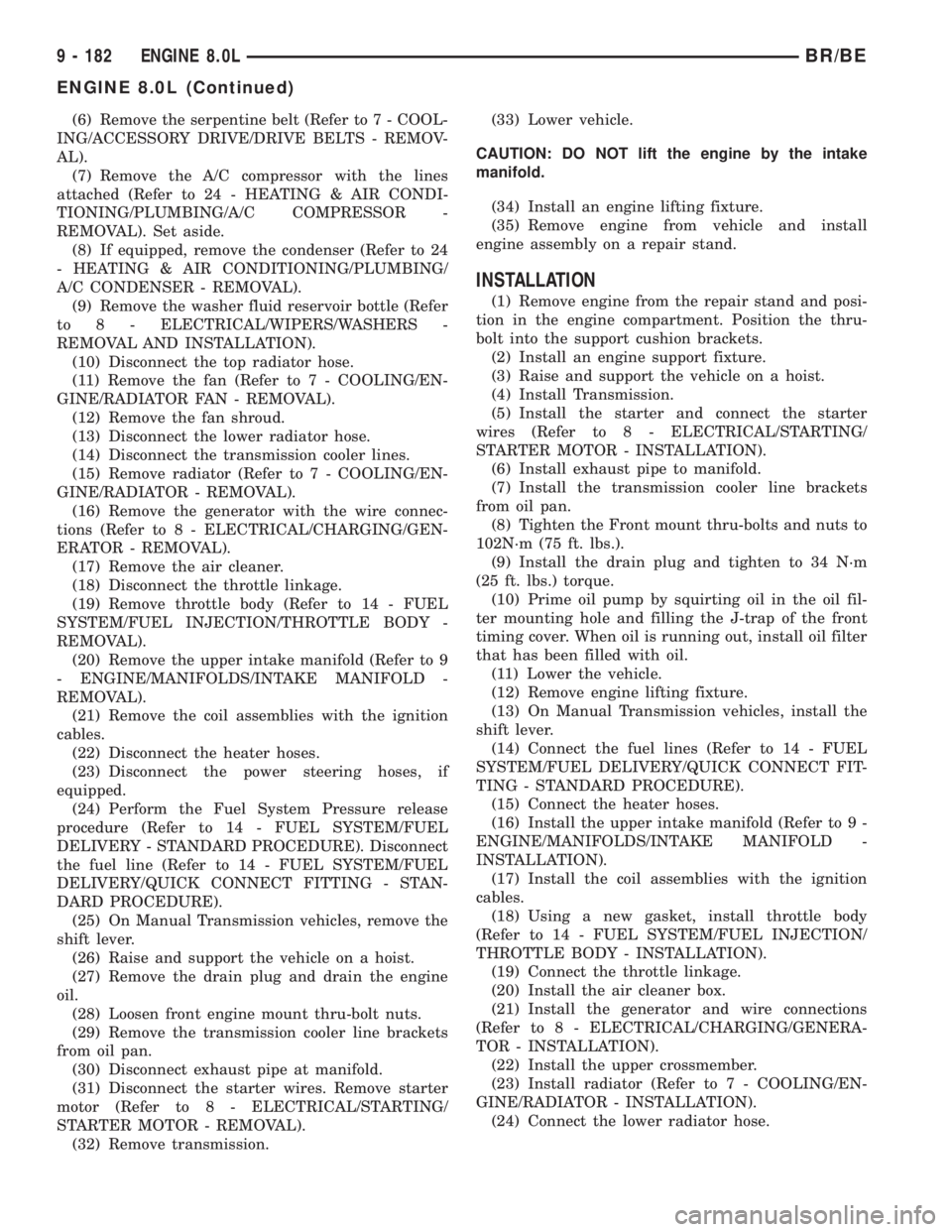

DIAGNOSIS AND TESTINGÐENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

DIAGNOSIS AND TESTINGÐPERFORMANCE

PERFORMANCE DIAGNOSIS CHARTÐGASOLINE ENGINES

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT CRANK 1. Weak or dead battery 1. Charge/Replace Battery. (Refer to 8

- ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD

PROCEDURE). Check charging

system. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND

TESTING).

2. Corroded or loose battery

connections2. Clean/tighten suspect battery/

starter connections

3. Faulty starter or related circuit(s) 3. Check starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Seized accessory drive component 4. Remove accessory drive belt and

attempt to start engine. If engine

starts, repair/replace seized

component.

5. Engine internal mechanical failure

or hydro-static lock5. Refer to (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

ENGINE CRANKS BUT WILL NOT

START1. No spark 1. Check for spark. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL -

DESCRIPTION)

2. No fuel 2. Perform fuel pressure test, and if

necessary, inspect fuel injector(s) and

driver circuits. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/FUEL

PUMP - DIAGNOSIS AND TESTING).

3. Low or no engine compression 3. Perform cylinder compression

pressure test. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

BR/BEENGINE 8.0L 9 - 173

ENGINE 8.0L (Continued)

Page 1329 of 2889

(6) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(7) Remove the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL). Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(9) Remove the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS -

REMOVAL AND INSTALLATION).

(10) Disconnect the top radiator hose.

(11) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

(12) Remove the fan shroud.

(13) Disconnect the lower radiator hose.

(14) Disconnect the transmission cooler lines.

(15) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(16) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(17) Remove the air cleaner.

(18) Disconnect the throttle linkage.

(19) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(20) Remove the upper intake manifold (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(21) Remove the coil assemblies with the ignition

cables.

(22) Disconnect the heater hoses.

(23) Disconnect the power steering hoses, if

equipped.

(24) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). Disconnect

the fuel line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(25) On Manual Transmission vehicles, remove the

shift lever.

(26) Raise and support the vehicle on a hoist.

(27) Remove the drain plug and drain the engine

oil.

(28) Loosen front engine mount thru-bolt nuts.

(29) Remove the transmission cooler line brackets

from oil pan.

(30) Disconnect exhaust pipe at manifold.

(31) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(32) Remove transmission.(33) Lower vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(34) Install an engine lifting fixture.

(35) Remove engine from vehicle and install

engine assembly on a repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install Transmission.

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7) Install the transmission cooler line brackets

from oil pan.

(8) Tighten the Front mount thru-bolts and nuts to

102N´m (75 ft. lbs.).

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Prime oil pump by squirting oil in the oil fil-

ter mounting hole and filling the J-trap of the front

timing cover. When oil is running out, install oil filter

that has been filled with oil.

(11) Lower the vehicle.

(12) Remove engine lifting fixture.

(13) On Manual Transmission vehicles, install the

shift lever.

(14) Connect the fuel lines (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(15) Connect the heater hoses.

(16) Install the upper intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Install the coil assemblies with the ignition

cables.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(22) Install the upper crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the lower radiator hose.

9 - 182 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)

Page 1330 of 2889

(25) Install the transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

(26) Connect the transmission cooler lines.

(27) Connect the power steering hoses, if equipped.

(28) Install the fan shroud.

(29) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(30) Connect the top radiator hose.

(31) Install the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS - INSTAL-

LATION).

(32) If equipped, install the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - INSTALLATION).

(33) Install the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION).

(34) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(35) Evacuate (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE) and charge the air conditioning system, if

equipped (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE).

(36) Add coolant to the cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery.

(38) Warm engine and adjust as required.

(39) Road test vehicle.

BR/BEENGINE 8.0L 9 - 183

ENGINE 8.0L (Continued)

Page 1340 of 2889

ARM / ADJUSTER ASSY - REMOVAL). Identify to

ensure installation in original locations.

(21) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

(22) Remove spark plugs.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads. Be sure material does not fall into the lifters

and surrounding valley.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

Clean the exhaust manifold to cylinder head mat-

ing areas.

INSPECTION

Inspect all surfaces with a straightedge if there is

any reason to suspect leakage. The out-of-flatness

specifications are 0.0007 mm/mm (0.0004 inch/inch),

0.127 mm/152 mm (0.005 inch/6 inches) any direction

or 0.254 mm (0.010 inch) overall across head. If

exceeded, either replace head or lightly machine the

head surface.

The cylinder head surface finish should be

1.78-4.57 microns (15-80 microinches).

Inspect push rods. Replace worn or bent rods.

Inspect rocker arms. Replace if worn or scored.

INSTALLATION

(1) Position the new cylinder head gaskets onto

the cylinder block.

(2) Position the cylinder heads onto head gaskets

and cylinder block.

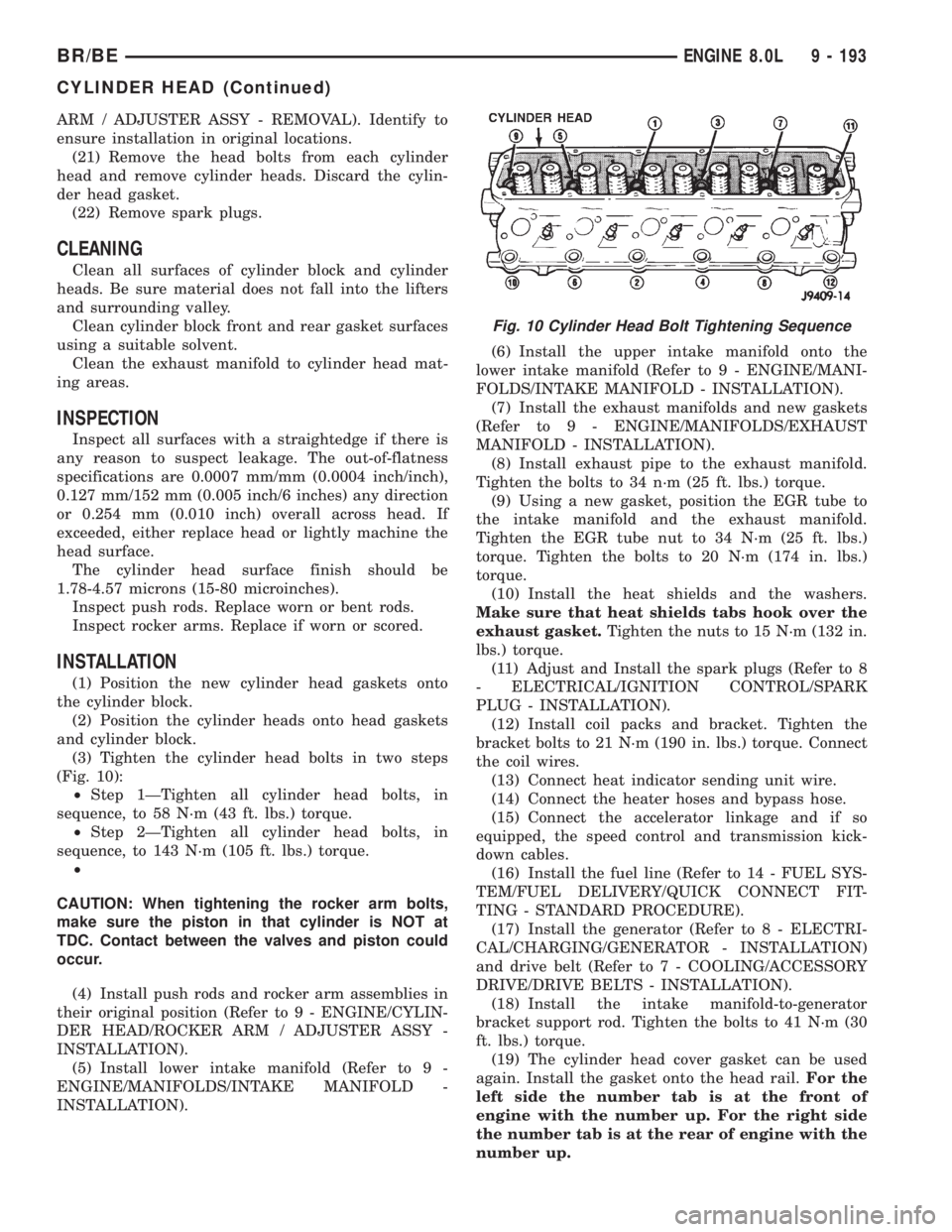

(3) Tighten the cylinder head bolts in two steps

(Fig. 10):

²Step 1ÐTighten all cylinder head bolts, in

sequence, to 58 N´m (43 ft. lbs.) torque.

²Step 2ÐTighten all cylinder head bolts, in

sequence, to 143 N´m (105 ft. lbs.) torque.

²

CAUTION: When tightening the rocker arm bolts,

make sure the piston in that cylinder is NOT at

TDC. Contact between the valves and piston could

occur.

(4) Install push rods and rocker arm assemblies in

their original position (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(5) Install lower intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).(6) Install the upper intake manifold onto the

lower intake manifold (Refer to 9 - ENGINE/MANI-

FOLDS/INTAKE MANIFOLD - INSTALLATION).

(7) Install the exhaust manifolds and new gaskets

(Refer to 9 - ENGINE/MANIFOLDS/EXHAUST

MANIFOLD - INSTALLATION).

(8) Install exhaust pipe to the exhaust manifold.

Tighten the bolts to 34 n´m (25 ft. lbs.) torque.

(9) Using a new gasket, position the EGR tube to

the intake manifold and the exhaust manifold.

Tighten the EGR tube nut to 34 N´m (25 ft. lbs.)

torque. Tighten the bolts to 20 N´m (174 in. lbs.)

torque.

(10) Install the heat shields and the washers.

Make sure that heat shields tabs hook over the

exhaust gasket.Tighten the nuts to 15 N´m (132 in.

lbs.) torque.

(11) Adjust and Install the spark plugs (Refer to 8

- ELECTRICAL/IGNITION CONTROL/SPARK

PLUG - INSTALLATION).

(12) Install coil packs and bracket. Tighten the

bracket bolts to 21 N´m (190 in. lbs.) torque. Connect

the coil wires.

(13) Connect heat indicator sending unit wire.

(14) Connect the heater hoses and bypass hose.

(15) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(16) Install the fuel line (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(17) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION)

and drive belt (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - INSTALLATION).

(18) Install the intake manifold-to-generator

bracket support rod. Tighten the bolts to 41 N´m (30

ft. lbs.) torque.

(19) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

Fig. 10 Cylinder Head Bolt Tightening Sequence

BR/BEENGINE 8.0L 9 - 193

CYLINDER HEAD (Continued)

Page 1348 of 2889

(2) Using recommended tool 8544 Camshaft Bush-

ing Remover Installer, Drive out bearing shells.

REMOVALÐCAMSHAFT

(1) Remove rocker arms and push rods (Refer to 9

- ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL). Identify each part

so it can be installed in its original location.

NOTE: The 4 corner tappets can not be removed

without removing the cylinder heads and gaskets.

However, they can be lifted and retained for cam-

shaft removal.

(2) Remove the Bolts retaining the yoke retaining

spider. Remove the yoke retaining spider, tappet

aligning yokes and tappets.

(3) Remove upper and lower intake manifolds

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL).

(4) Remove timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL) and timing chain and

sprockets (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL).

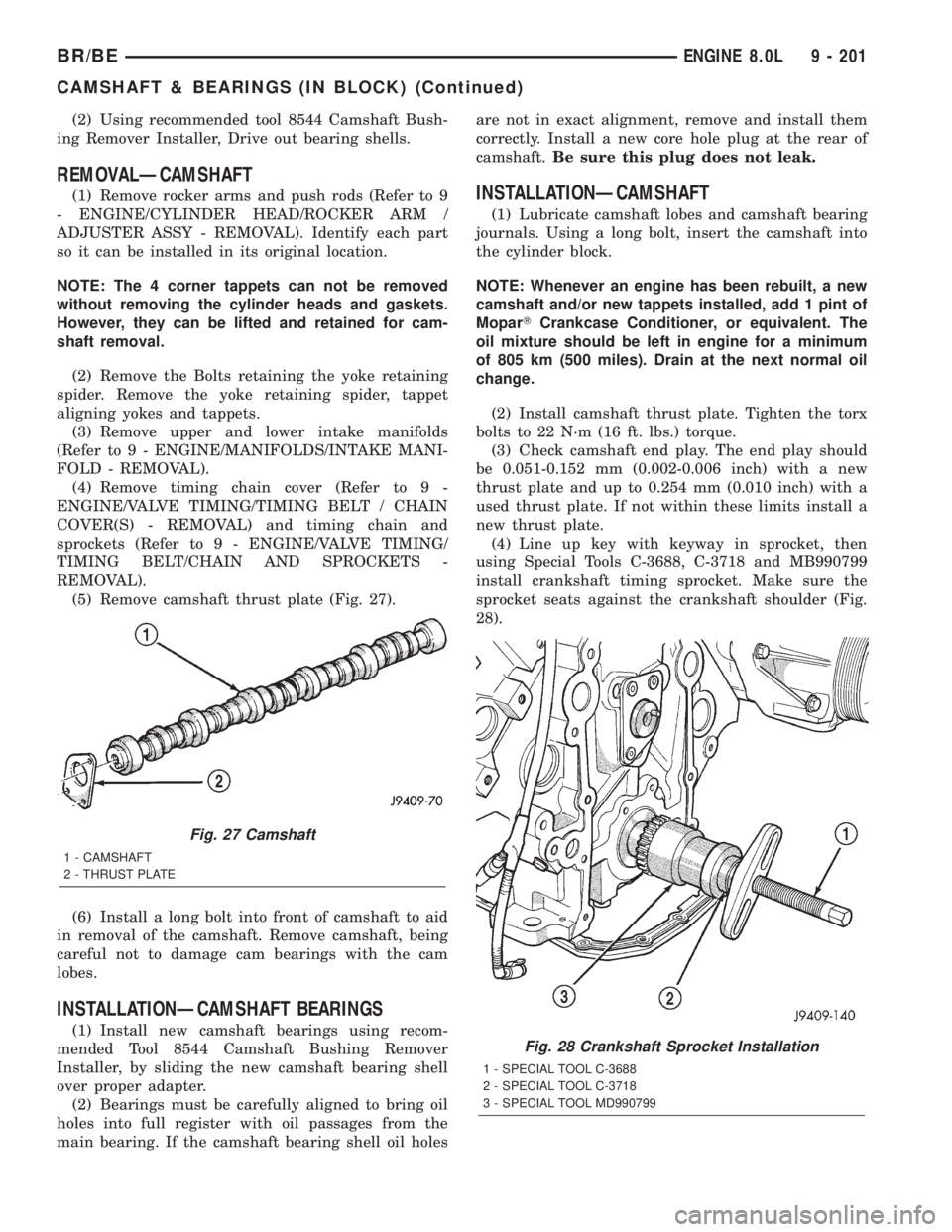

(5) Remove camshaft thrust plate (Fig. 27).

(6) Install a long bolt into front of camshaft to aid

in removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSTALLATIONÐCAMSHAFT BEARINGS

(1) Install new camshaft bearings using recom-

mended Tool 8544 Camshaft Bushing Remover

Installer, by sliding the new camshaft bearing shell

over proper adapter.

(2) Bearings must be carefully aligned to bring oil

holes into full register with oil passages from the

main bearing. If the camshaft bearing shell oil holesare not in exact alignment, remove and install them

correctly. Install a new core hole plug at the rear of

camshaft.Be sure this plug does not leak.

INSTALLATIONÐCAMSHAFT

(1) Lubricate camshaft lobes and camshaft bearing

journals. Using a long bolt, insert the camshaft into

the cylinder block.

NOTE: Whenever an engine has been rebuilt, a new

camshaft and/or new tappets installed, add 1 pint of

MoparTCrankcase Conditioner, or equivalent. The

oil mixture should be left in engine for a minimum

of 805 km (500 miles). Drain at the next normal oil

change.

(2) Install camshaft thrust plate. Tighten the torx

bolts to 22 N´m (16 ft. lbs.) torque.

(3) Check camshaft end play. The end play should

be 0.051-0.152 mm (0.002-0.006 inch) with a new

thrust plate and up to 0.254 mm (0.010 inch) with a

used thrust plate. If not within these limits install a

new thrust plate.

(4) Line up key with keyway in sprocket, then

using Special Tools C-3688, C-3718 and MB990799

install crankshaft timing sprocket. Make sure the

sprocket seats against the crankshaft shoulder (Fig.

28).

Fig. 27 Camshaft

1 - CAMSHAFT

2 - THRUST PLATE

Fig. 28 Crankshaft Sprocket Installation

1 - SPECIAL TOOL C-3688

2 - SPECIAL TOOL C-3718

3 - SPECIAL TOOL MD990799

BR/BEENGINE 8.0L 9 - 201

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)