belt DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1349 of 2889

(5) Install timing chain and sprocket (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

(6) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install the crankshaft pulley/damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).

(8) Prime oil pump by squirting oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.

(9) Each tappet reused must be installed in the

same position from which it was removed.When

camshaft is replaced, all of the tappets must be

replaced.

(10) Install tappets and push rods in their original

location.

(11) Position the tappet aligning yokes and yoke

retaing spider.

(12) Install the retaining spider mounting bolts.

Tighten bolts to 22 N´m (16 ft. lbs.).

(13) Install the rocker arms (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARM / ADJUSTER

ASSY - INSTALLATION).

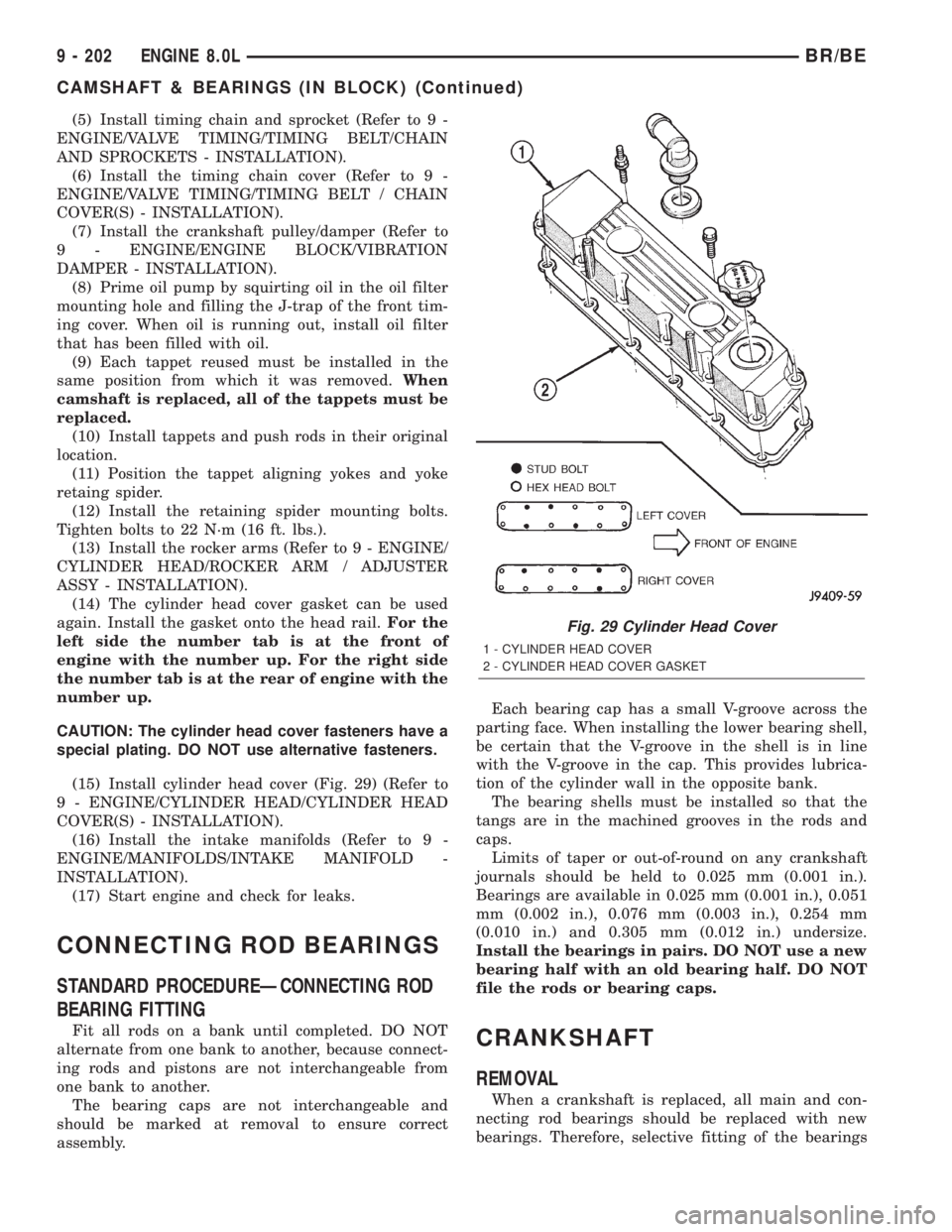

(14) The cylinder head cover gasket can be used

again. Install the gasket onto the head rail.For the

left side the number tab is at the front of

engine with the number up. For the right side

the number tab is at the rear of engine with the

number up.

CAUTION: The cylinder head cover fasteners have a

special plating. DO NOT use alternative fasteners.

(15) Install cylinder head cover (Fig. 29) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(16) Install the intake manifolds (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Start engine and check for leaks.

CONNECTING ROD BEARINGS

STANDARD PROCEDUREÐCONNECTING ROD

BEARING FITTING

Fit all rods on a bank until completed. DO NOT

alternate from one bank to another, because connect-

ing rods and pistons are not interchangeable from

one bank to another.

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly.Each bearing cap has a small V-groove across the

parting face. When installing the lower bearing shell,

be certain that the V-groove in the shell is in line

with the V-groove in the cap. This provides lubrica-

tion of the cylinder wall in the opposite bank.

The bearing shells must be installed so that the

tangs are in the machined grooves in the rods and

caps.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.025 mm (0.001 in.).

Bearings are available in 0.025 mm (0.001 in.), 0.051

mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm

(0.010 in.) and 0.305 mm (0.012 in.) undersize.

Install the bearings in pairs. DO NOT use a new

bearing half with an old bearing half. DO NOT

file the rods or bearing caps.CRANKSHAFT

REMOVAL

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

Fig. 29 Cylinder Head Cover

1 - CYLINDER HEAD COVER

2 - CYLINDER HEAD COVER GASKET

9 - 202 ENGINE 8.0LBR/BE

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1351 of 2889

REMOVAL

(1) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(2) Identify bearing caps before removal. Remove

bearing caps one at a time.

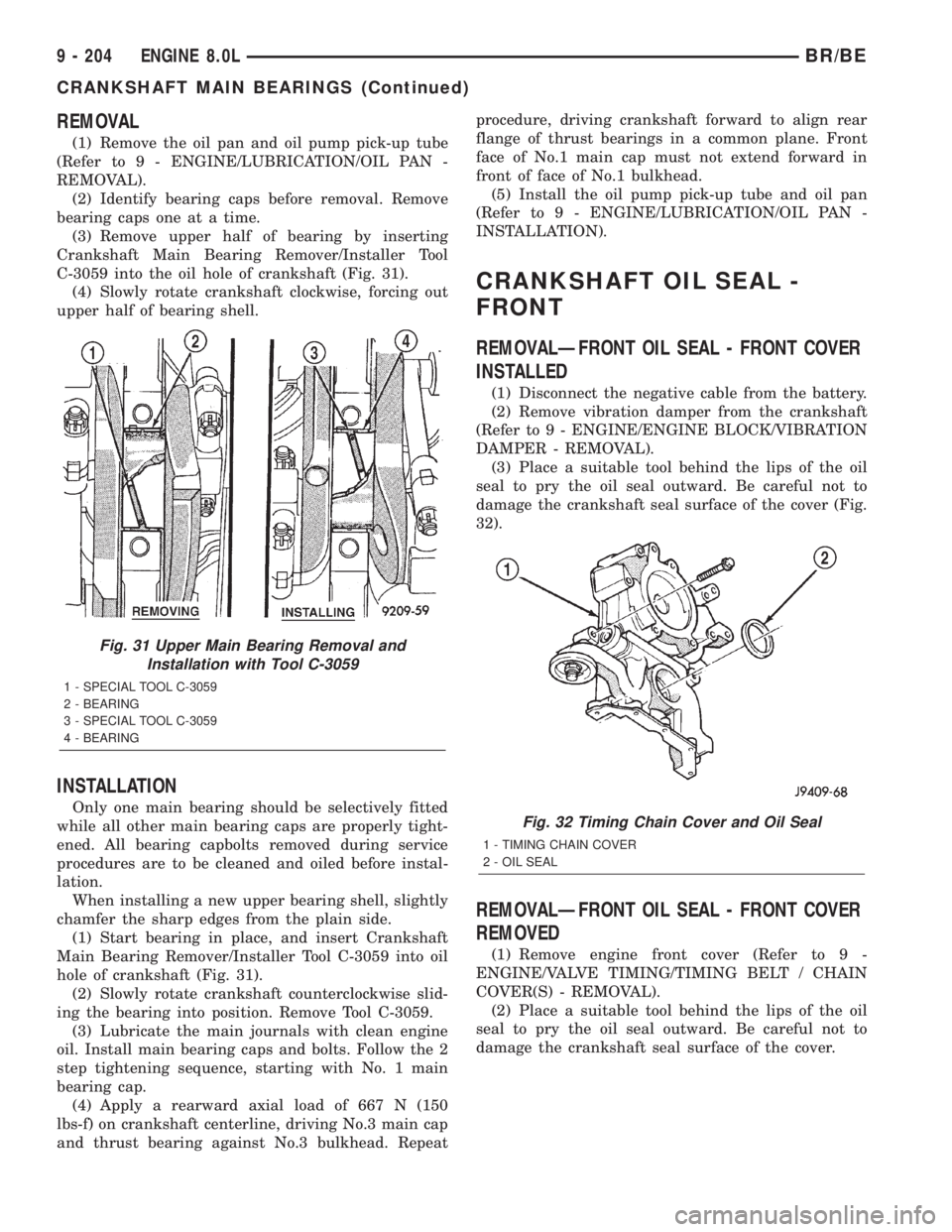

(3) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 31).

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 31).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.

(3) Lubricate the main journals with clean engine

oil. Install main bearing caps and bolts. Follow the 2

step tightening sequence, starting with No. 1 main

bearing cap.

(4) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeatprocedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(5) Install the oil pump pick-up tube and oil pan

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

CRANKSHAFT OIL SEAL -

FRONT

REMOVALÐFRONT OIL SEAL - FRONT COVER

INSTALLED

(1) Disconnect the negative cable from the battery.

(2) Remove vibration damper from the crankshaft

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(3) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of the cover (Fig.

32).

REMOVALÐFRONT OIL SEAL - FRONT COVER

REMOVED

(1) Remove engine front cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(2) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of the cover.

Fig. 31 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

Fig. 32 Timing Chain Cover and Oil Seal

1 - TIMING CHAIN COVER

2 - OIL SEAL

9 - 204 ENGINE 8.0LBR/BE

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1352 of 2889

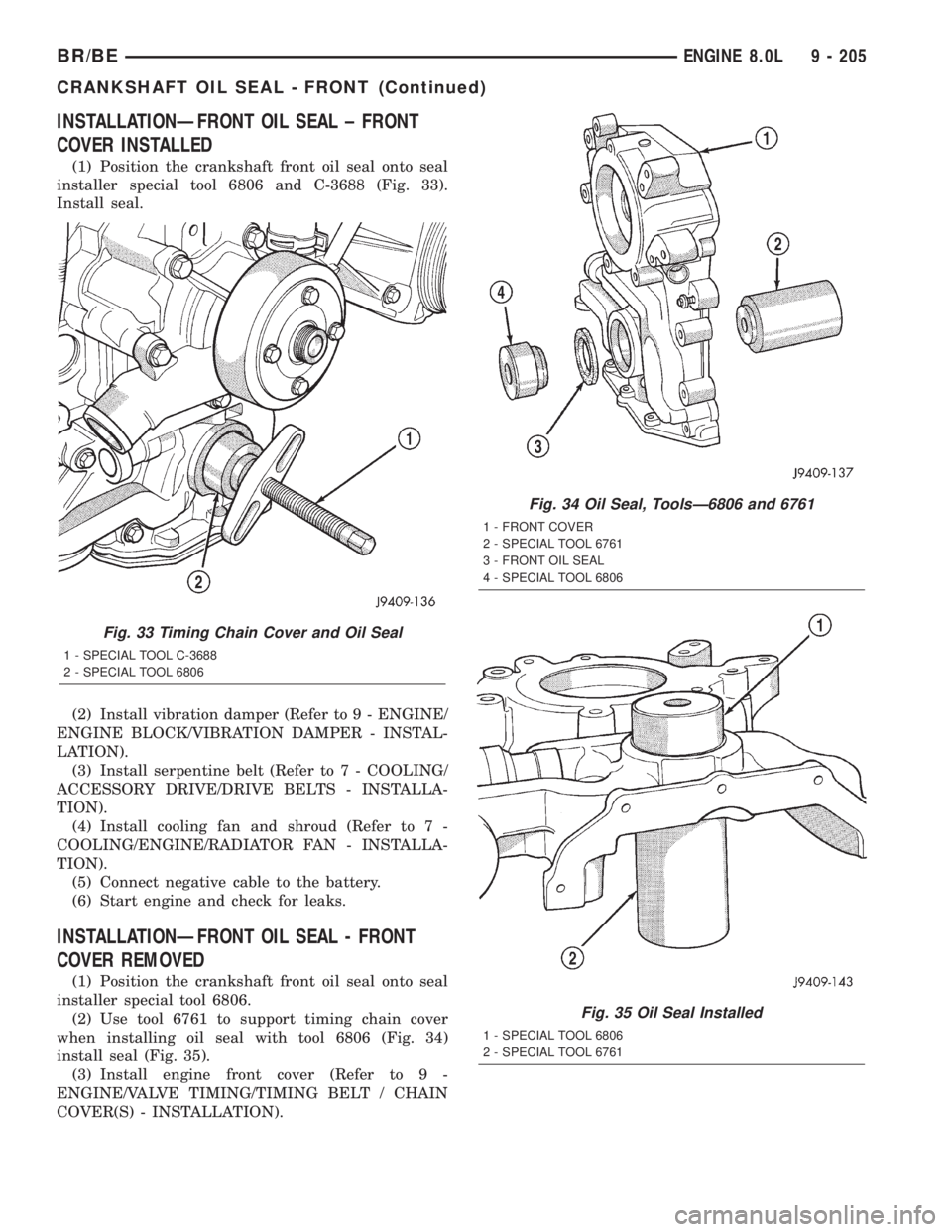

INSTALLATIONÐFRONT OIL SEAL ± FRONT

COVER INSTALLED

(1) Position the crankshaft front oil seal onto seal

installer special tool 6806 and C-3688 (Fig. 33).

Install seal.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install serpentine belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(4) Install cooling fan and shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(5) Connect negative cable to the battery.

(6) Start engine and check for leaks.

INSTALLATIONÐFRONT OIL SEAL - FRONT

COVER REMOVED

(1) Position the crankshaft front oil seal onto seal

installer special tool 6806.

(2) Use tool 6761 to support timing chain cover

when installing oil seal with tool 6806 (Fig. 34)

install seal (Fig. 35).

(3) Install engine front cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

Fig. 34 Oil Seal, ToolsÐ6806 and 6761

1 - FRONT COVER

2 - SPECIAL TOOL 6761

3 - FRONT OIL SEAL

4 - SPECIAL TOOL 6806

Fig. 35 Oil Seal Installed

1 - SPECIAL TOOL 6806

2 - SPECIAL TOOL 6761

Fig. 33 Timing Chain Cover and Oil Seal

1 - SPECIAL TOOL C-3688

2 - SPECIAL TOOL 6806

BR/BEENGINE 8.0L 9 - 205

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1359 of 2889

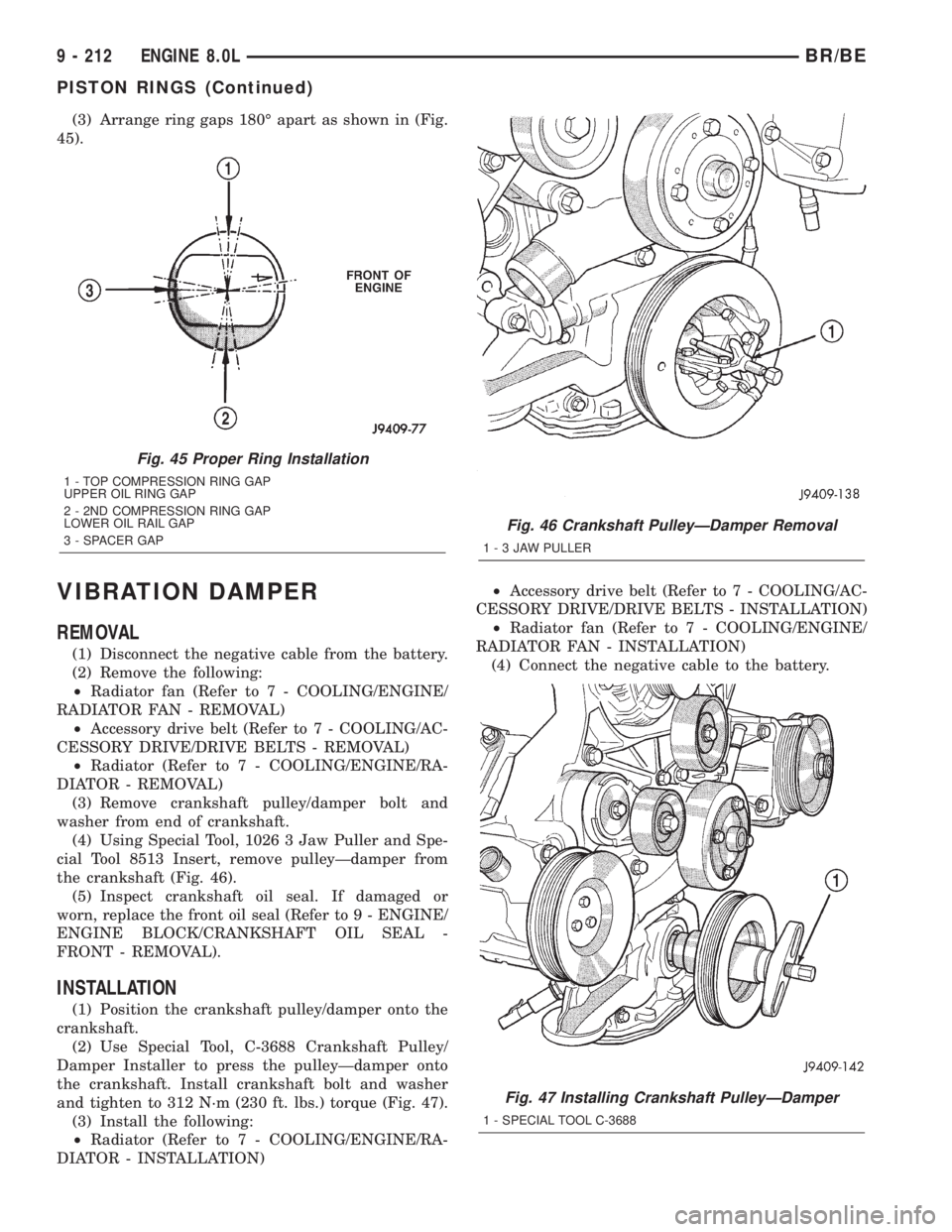

(3) Arrange ring gaps 180É apart as shown in (Fig.

45).

VIBRATION DAMPER

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the following:

²Radiator fan (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - REMOVAL)

²Accessory drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - REMOVAL)

²Radiator (Refer to 7 - COOLING/ENGINE/RA-

DIATOR - REMOVAL)

(3) Remove crankshaft pulley/damper bolt and

washer from end of crankshaft.

(4) Using Special Tool, 1026 3 Jaw Puller and Spe-

cial Tool 8513 Insert, remove pulleyÐdamper from

the crankshaft (Fig. 46).

(5) Inspect crankshaft oil seal. If damaged or

worn, replace the front oil seal (Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL -

FRONT - REMOVAL).

INSTALLATION

(1) Position the crankshaft pulley/damper onto the

crankshaft.

(2) Use Special Tool, C-3688 Crankshaft Pulley/

Damper Installer to press the pulleyÐdamper onto

the crankshaft. Install crankshaft bolt and washer

and tighten to 312 N´m (230 ft. lbs.) torque (Fig. 47).

(3) Install the following:

²Radiator (Refer to 7 - COOLING/ENGINE/RA-

DIATOR - INSTALLATION)²Accessory drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLATION)

²Radiator fan (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - INSTALLATION)

(4) Connect the negative cable to the battery.

Fig. 45 Proper Ring Installation

1 - TOP COMPRESSION RING GAP

UPPER OIL RING GAP

2 - 2ND COMPRESSION RING GAP

LOWER OIL RAIL GAP

3 - SPACER GAP

Fig. 46 Crankshaft PulleyÐDamper Removal

1-3JAWPULLER

Fig. 47 Installing Crankshaft PulleyÐDamper

1 - SPECIAL TOOL C-3688

9 - 212 ENGINE 8.0LBR/BE

PISTON RINGS (Continued)

Page 1366 of 2889

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

INSTALLATION

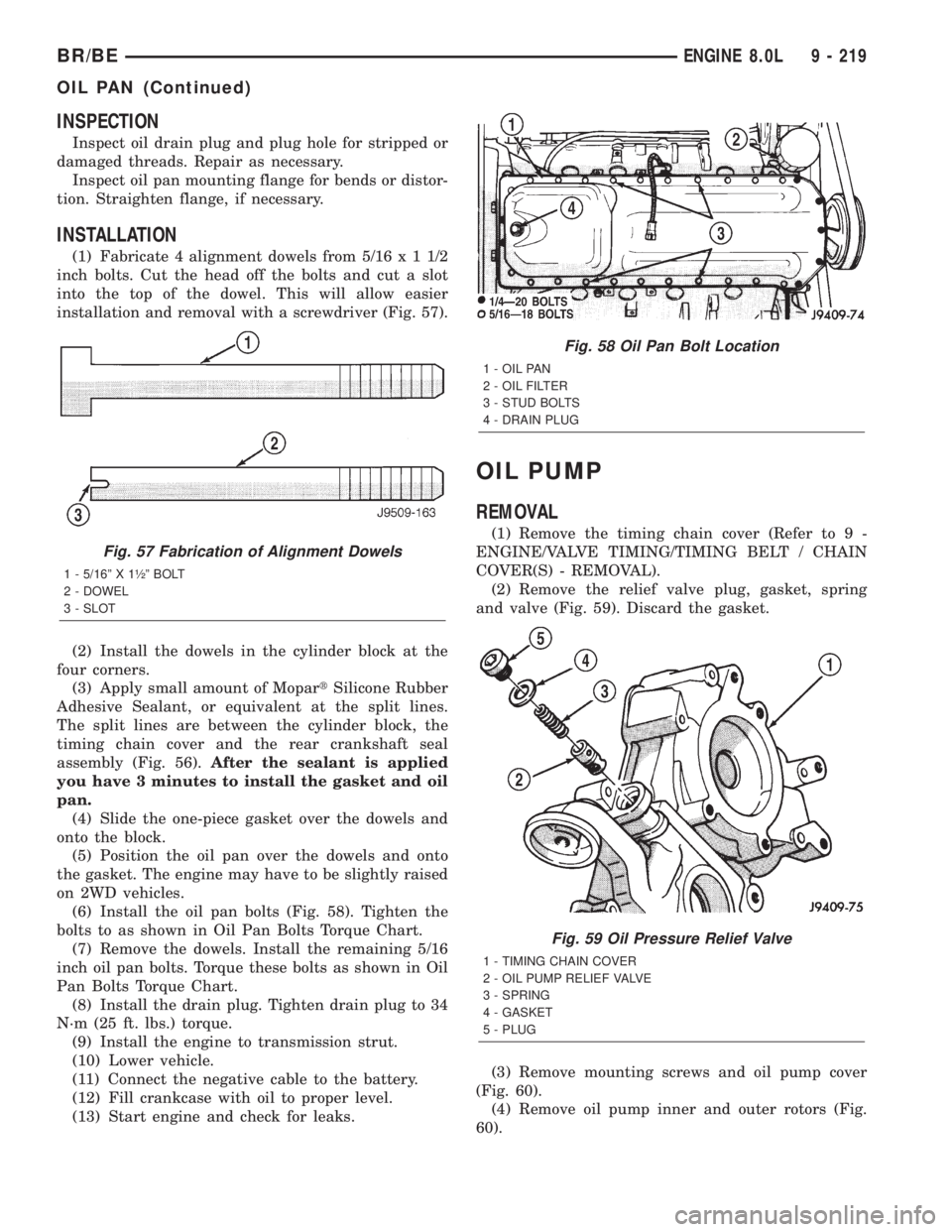

(1) Fabricate 4 alignment dowels from 5/16x11/2

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 57).

(2) Install the dowels in the cylinder block at the

four corners.

(3) Apply small amount of MopartSilicone Rubber

Adhesive Sealant, or equivalent at the split lines.

The split lines are between the cylinder block, the

timing chain cover and the rear crankshaft seal

assembly (Fig. 56).After the sealant is applied

you have 3 minutes to install the gasket and oil

pan.

(4) Slide the one-piece gasket over the dowels and

onto the block.

(5) Position the oil pan over the dowels and onto

the gasket. The engine may have to be slightly raised

on 2WD vehicles.

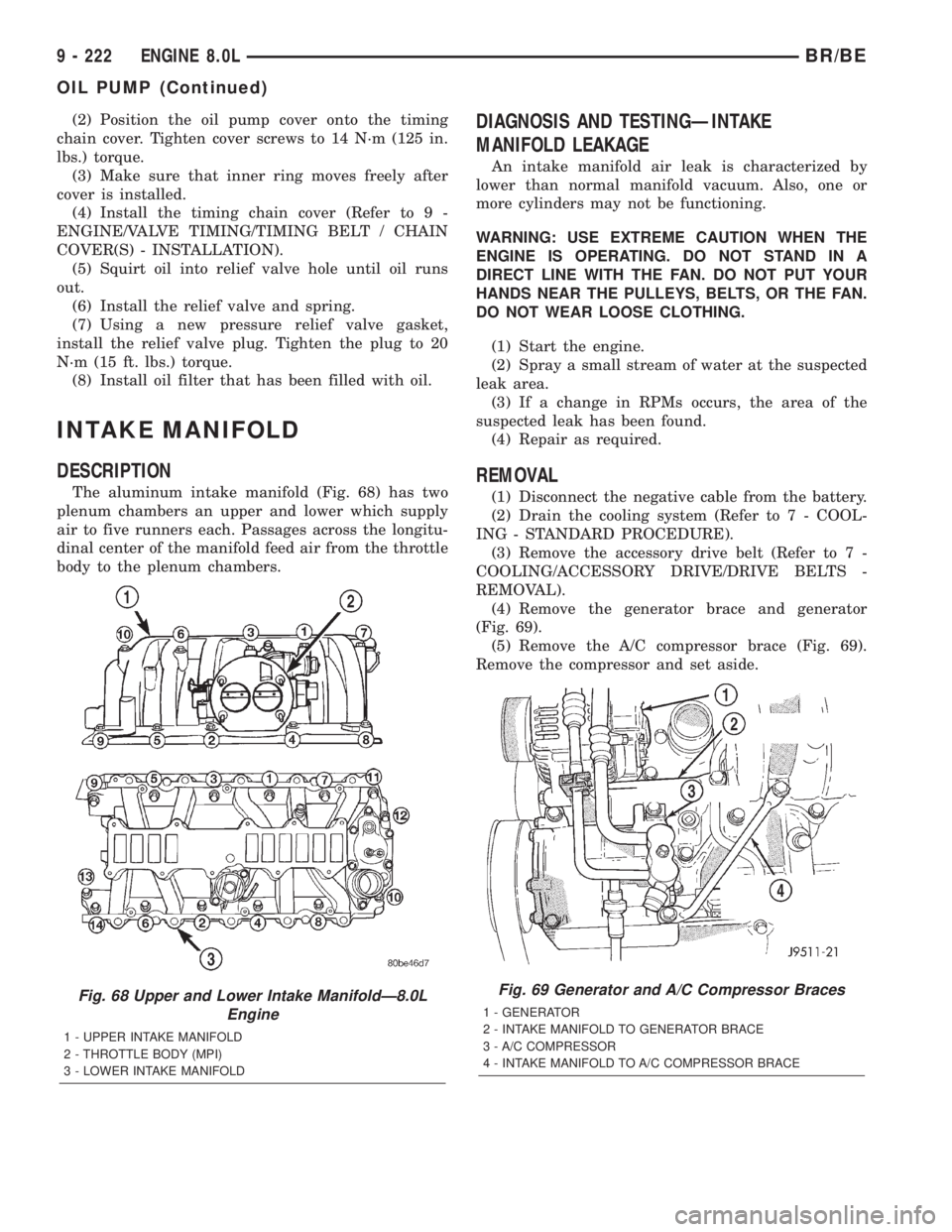

(6) Install the oil pan bolts (Fig. 58). Tighten the

bolts to as shown in Oil Pan Bolts Torque Chart.

(7) Remove the dowels. Install the remaining 5/16

inch oil pan bolts. Torque these bolts as shown in Oil

Pan Bolts Torque Chart.

(8) Install the drain plug. Tighten drain plug to 34

N´m (25 ft. lbs.) torque.

(9) Install the engine to transmission strut.

(10) Lower vehicle.

(11) Connect the negative cable to the battery.

(12) Fill crankcase with oil to proper level.

(13) Start engine and check for leaks.

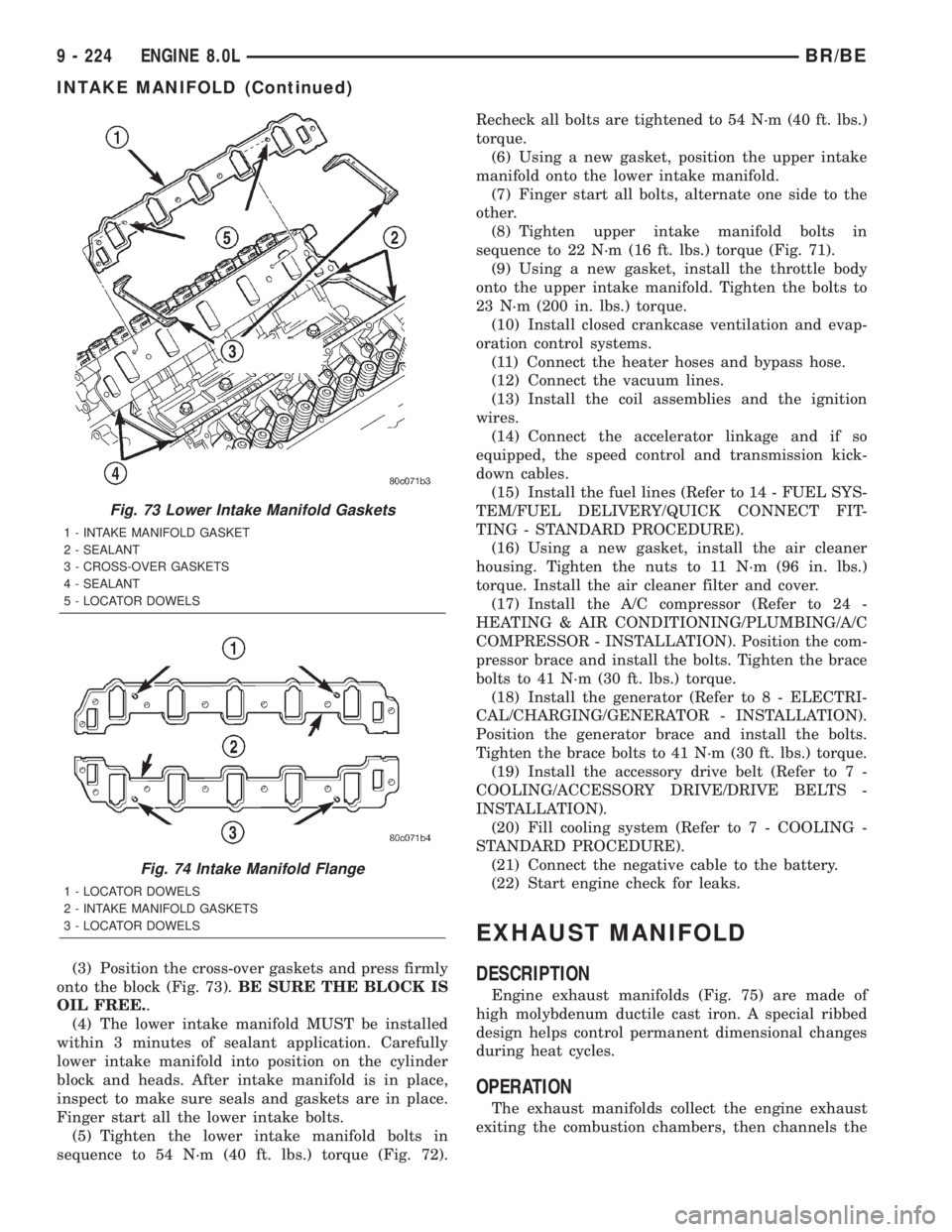

OIL PUMP

REMOVAL

(1) Remove the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(2) Remove the relief valve plug, gasket, spring

and valve (Fig. 59). Discard the gasket.

(3) Remove mounting screws and oil pump cover

(Fig. 60).

(4) Remove oil pump inner and outer rotors (Fig.

60).

Fig. 57 Fabrication of Alignment Dowels

1 - 5/16º X 1óº BOLT

2 - DOWEL

3 - SLOT

Fig. 58 Oil Pan Bolt Location

1 - OIL PAN

2 - OIL FILTER

3 - STUD BOLTS

4 - DRAIN PLUG

Fig. 59 Oil Pressure Relief Valve

1 - TIMING CHAIN COVER

2 - OIL PUMP RELIEF VALVE

3 - SPRING

4 - GASKET

5 - PLUG

BR/BEENGINE 8.0L 9 - 219

OIL PAN (Continued)

Page 1369 of 2889

(2) Position the oil pump cover onto the timing

chain cover. Tighten cover screws to 14 N´m (125 in.

lbs.) torque.

(3) Make sure that inner ring moves freely after

cover is installed.

(4) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(5) Squirt oil into relief valve hole until oil runs

out.

(6) Install the relief valve and spring.

(7) Using a new pressure relief valve gasket,

install the relief valve plug. Tighten the plug to 20

N´m (15 ft. lbs.) torque.

(8) Install oil filter that has been filled with oil.

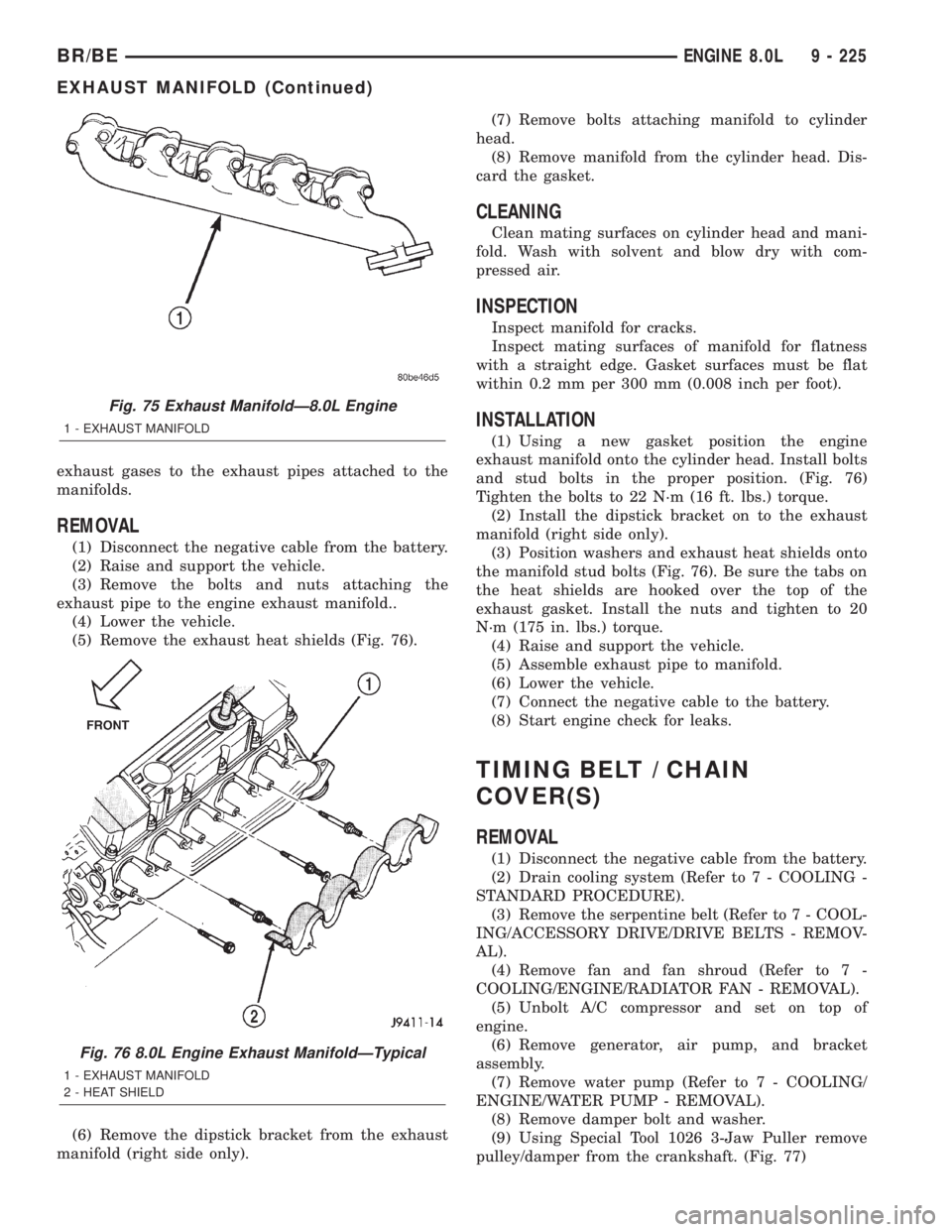

INTAKE MANIFOLD

DESCRIPTION

The aluminum intake manifold (Fig. 68) has two

plenum chambers an upper and lower which supply

air to five runners each. Passages across the longitu-

dinal center of the manifold feed air from the throttle

body to the plenum chambers.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS, OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPMs occurs, the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the generator brace and generator

(Fig. 69).

(5) Remove the A/C compressor brace (Fig. 69).

Remove the compressor and set aside.

Fig. 68 Upper and Lower Intake ManifoldÐ8.0L

Engine

1 - UPPER INTAKE MANIFOLD

2 - THROTTLE BODY (MPI)

3 - LOWER INTAKE MANIFOLD

Fig. 69 Generator and A/C Compressor Braces

1 - GENERATOR

2 - INTAKE MANIFOLD TO GENERATOR BRACE

3 - A/C COMPRESSOR

4 - INTAKE MANIFOLD TO A/C COMPRESSOR BRACE

9 - 222 ENGINE 8.0LBR/BE

OIL PUMP (Continued)

Page 1371 of 2889

(3) Position the cross-over gaskets and press firmly

onto the block (Fig. 73).BE SURE THE BLOCK IS

OIL FREE..

(4) The lower intake manifold MUST be installed

within 3 minutes of sealant application. Carefully

lower intake manifold into position on the cylinder

block and heads. After intake manifold is in place,

inspect to make sure seals and gaskets are in place.

Finger start all the lower intake bolts.

(5) Tighten the lower intake manifold bolts in

sequence to 54 N´m (40 ft. lbs.) torque (Fig. 72).Recheck all bolts are tightened to 54 N´m (40 ft. lbs.)

torque.

(6) Using a new gasket, position the upper intake

manifold onto the lower intake manifold.

(7) Finger start all bolts, alternate one side to the

other.

(8) Tighten upper intake manifold bolts in

sequence to 22 N´m (16 ft. lbs.) torque (Fig. 71).

(9) Using a new gasket, install the throttle body

onto the upper intake manifold. Tighten the bolts to

23 N´m (200 in. lbs.) torque.

(10) Install closed crankcase ventilation and evap-

oration control systems.

(11) Connect the heater hoses and bypass hose.

(12) Connect the vacuum lines.

(13) Install the coil assemblies and the ignition

wires.

(14) Connect the accelerator linkage and if so

equipped, the speed control and transmission kick-

down cables.

(15) Install the fuel lines (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(16) Using a new gasket, install the air cleaner

housing. Tighten the nuts to 11 N´m (96 in. lbs.)

torque. Install the air cleaner filter and cover.

(17) Install the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION). Position the com-

pressor brace and install the bolts. Tighten the brace

bolts to 41 N´m (30 ft. lbs.) torque.

(18) Install the generator (Refer to 8 - ELECTRI-

CAL/CHARGING/GENERATOR - INSTALLATION).

Position the generator brace and install the bolts.

Tighten the brace bolts to 41 N´m (30 ft. lbs.) torque.

(19) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(20) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(21) Connect the negative cable to the battery.

(22) Start engine check for leaks.

EXHAUST MANIFOLD

DESCRIPTION

Engine exhaust manifolds (Fig. 75) are made of

high molybdenum ductile cast iron. A special ribbed

design helps control permanent dimensional changes

during heat cycles.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

Fig. 73 Lower Intake Manifold Gaskets

1 - INTAKE MANIFOLD GASKET

2 - SEALANT

3 - CROSS-OVER GASKETS

4 - SEALANT

5 - LOCATOR DOWELS

Fig. 74 Intake Manifold Flange

1 - LOCATOR DOWELS

2 - INTAKE MANIFOLD GASKETS

3 - LOCATOR DOWELS

9 - 224 ENGINE 8.0LBR/BE

INTAKE MANIFOLD (Continued)

Page 1372 of 2889

exhaust gases to the exhaust pipes attached to the

manifolds.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold..

(4) Lower the vehicle.

(5) Remove the exhaust heat shields (Fig. 76).

(6) Remove the dipstick bracket from the exhaust

manifold (right side only).(7) Remove bolts attaching manifold to cylinder

head.

(8) Remove manifold from the cylinder head. Dis-

card the gasket.

CLEANING

Clean mating surfaces on cylinder head and mani-

fold. Wash with solvent and blow dry with com-

pressed air.

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straight edge. Gasket surfaces must be flat

within 0.2 mm per 300 mm (0.008 inch per foot).

INSTALLATION

(1) Using a new gasket position the engine

exhaust manifold onto the cylinder head. Install bolts

and stud bolts in the proper position. (Fig. 76)

Tighten the bolts to 22 N´m (16 ft. lbs.) torque.

(2) Install the dipstick bracket on to the exhaust

manifold (right side only).

(3) Position washers and exhaust heat shields onto

the manifold stud bolts (Fig. 76). Be sure the tabs on

the heat shields are hooked over the top of the

exhaust gasket. Install the nuts and tighten to 20

N´m (175 in. lbs.) torque.

(4) Raise and support the vehicle.

(5) Assemble exhaust pipe to manifold.

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

(8) Start engine check for leaks.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(4) Remove fan and fan shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(5) Unbolt A/C compressor and set on top of

engine.

(6) Remove generator, air pump, and bracket

assembly.

(7) Remove water pump (Refer to 7 - COOLING/

ENGINE/WATER PUMP - REMOVAL).

(8) Remove damper bolt and washer.

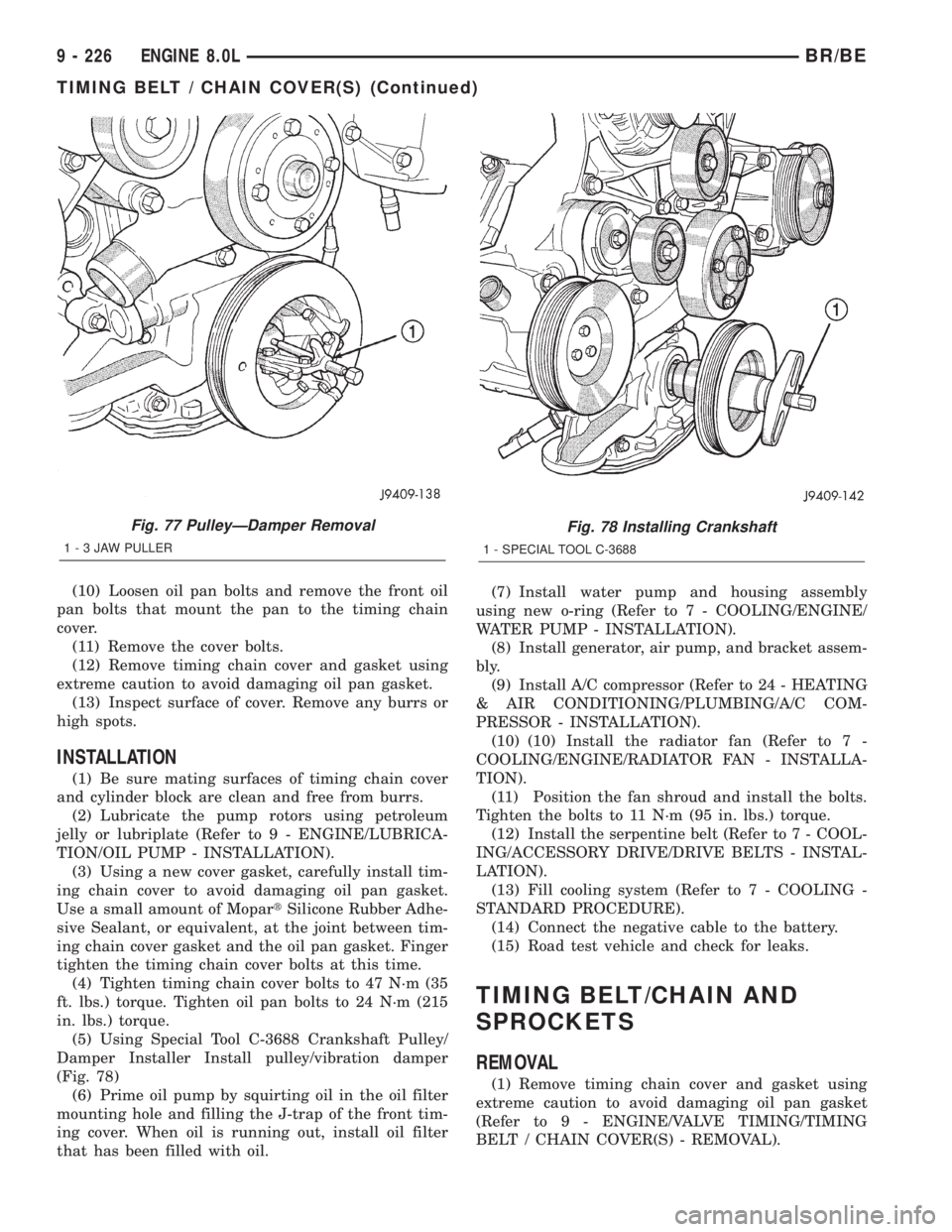

(9) Using Special Tool 1026 3-Jaw Puller remove

pulley/damper from the crankshaft. (Fig. 77)

Fig. 75 Exhaust ManifoldÐ8.0L Engine

1 - EXHAUST MANIFOLD

Fig. 76 8.0L Engine Exhaust ManifoldÐTypical

1 - EXHAUST MANIFOLD

2 - HEAT SHIELD

BR/BEENGINE 8.0L 9 - 225

EXHAUST MANIFOLD (Continued)

Page 1373 of 2889

(10) Loosen oil pan bolts and remove the front oil

pan bolts that mount the pan to the timing chain

cover.

(11) Remove the cover bolts.

(12) Remove timing chain cover and gasket using

extreme caution to avoid damaging oil pan gasket.

(13) Inspect surface of cover. Remove any burrs or

high spots.

INSTALLATION

(1) Be sure mating surfaces of timing chain cover

and cylinder block are clean and free from burrs.

(2) Lubricate the pump rotors using petroleum

jelly or lubriplate (Refer to 9 - ENGINE/LUBRICA-

TION/OIL PUMP - INSTALLATION).

(3) Using a new cover gasket, carefully install tim-

ing chain cover to avoid damaging oil pan gasket.

Use a small amount of MopartSilicone Rubber Adhe-

sive Sealant, or equivalent, at the joint between tim-

ing chain cover gasket and the oil pan gasket. Finger

tighten the timing chain cover bolts at this time.

(4) Tighten timing chain cover bolts to 47 N´m (35

ft. lbs.) torque. Tighten oil pan bolts to 24 N´m (215

in. lbs.) torque.

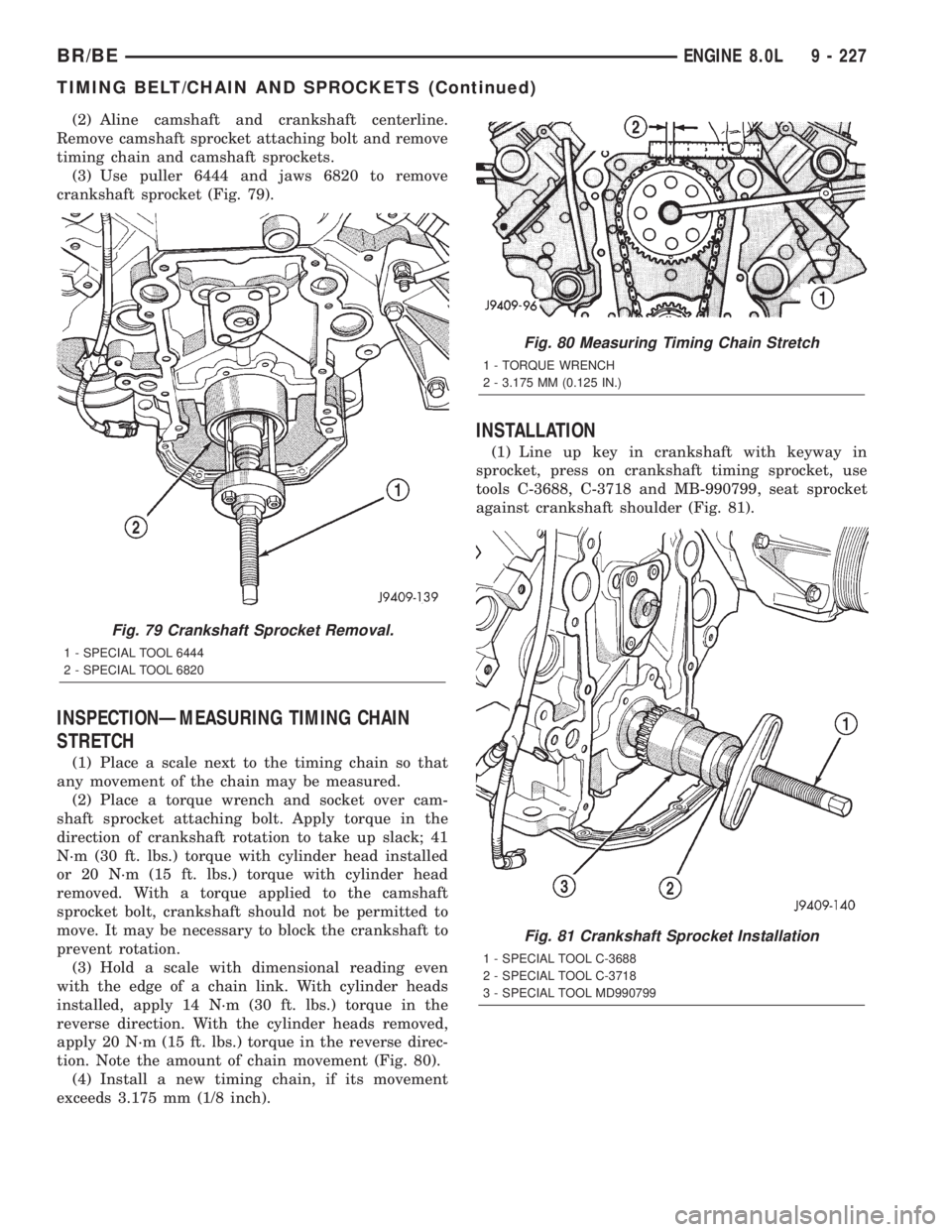

(5) Using Special Tool C-3688 Crankshaft Pulley/

Damper Installer Install pulley/vibration damper

(Fig. 78)

(6) Prime oil pump by squirting oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.(7) Install water pump and housing assembly

using new o-ring (Refer to 7 - COOLING/ENGINE/

WATER PUMP - INSTALLATION).

(8) Install generator, air pump, and bracket assem-

bly.

(9) Install A/C compressor (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(10) (10) Install the radiator fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(11) Position the fan shroud and install the bolts.

Tighten the bolts to 11 N´m (95 in. lbs.) torque.

(12) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(13) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Connect the negative cable to the battery.

(15) Road test vehicle and check for leaks.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

(1) Remove timing chain cover and gasket using

extreme caution to avoid damaging oil pan gasket

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

Fig. 77 PulleyÐDamper Removal

1-3JAWPULLER

Fig. 78 Installing Crankshaft

1 - SPECIAL TOOL C-3688

9 - 226 ENGINE 8.0LBR/BE

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1374 of 2889

(2) Aline camshaft and crankshaft centerline.

Remove camshaft sprocket attaching bolt and remove

timing chain and camshaft sprockets.

(3) Use puller 6444 and jaws 6820 to remove

crankshaft sprocket (Fig. 79).

INSPECTIONÐMEASURING TIMING CHAIN

STRETCH

(1) Place a scale next to the timing chain so that

any movement of the chain may be measured.

(2) Place a torque wrench and socket over cam-

shaft sprocket attaching bolt. Apply torque in the

direction of crankshaft rotation to take up slack; 41

N´m (30 ft. lbs.) torque with cylinder head installed

or 20 N´m (15 ft. lbs.) torque with cylinder head

removed. With a torque applied to the camshaft

sprocket bolt, crankshaft should not be permitted to

move. It may be necessary to block the crankshaft to

prevent rotation.

(3) Hold a scale with dimensional reading even

with the edge of a chain link. With cylinder heads

installed, apply 14 N´m (30 ft. lbs.) torque in the

reverse direction. With the cylinder heads removed,

apply 20 N´m (15 ft. lbs.) torque in the reverse direc-

tion. Note the amount of chain movement (Fig. 80).

(4) Install a new timing chain, if its movement

exceeds 3.175 mm (1/8 inch).

INSTALLATION

(1) Line up key in crankshaft with keyway in

sprocket, press on crankshaft timing sprocket, use

tools C-3688, C-3718 and MB-990799, seat sprocket

against crankshaft shoulder (Fig. 81).

Fig. 79 Crankshaft Sprocket Removal.

1 - SPECIAL TOOL 6444

2 - SPECIAL TOOL 6820

Fig. 80 Measuring Timing Chain Stretch

1 - TORQUE WRENCH

2 - 3.175 MM (0.125 IN.)

Fig. 81 Crankshaft Sprocket Installation

1 - SPECIAL TOOL C-3688

2 - SPECIAL TOOL C-3718

3 - SPECIAL TOOL MD990799

BR/BEENGINE 8.0L 9 - 227

TIMING BELT/CHAIN AND SPROCKETS (Continued)