wiper fluid DODGE RAM 2001 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 730 of 2889

the wiper blade with a new unit. Do not attempt to

repair a wiper blade that is damaged.

WASHER SYSTEM

The washer system components should be

inspected periodically, not just when washer perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Check for ice or other foreign material in the

washer reservoir. If contaminated, clean and flush

the washer system. (Refer to 8 - ELECTRICAL/WIP-

ERS/WASHERS - CLEANING).

(2) Inspect the washer plumbing for pinched, leak-

ing, deteriorated, or incorrectly routed hoses and

damaged or disconnected hose fittings. Replace dam-

aged or deteriorated hoses and hose fittings. Leaking

washer hoses can sometimes be repaired by cutting

the hose at the leak and splicing it back together

using an in-line connector fitting. Similarly, sections

of deteriorated hose can be cut out and replaced by

splicing in new sections of hose using in-line connec-

tor fittings. Whenever routing a washer hose or a

wire harness containing a washer hose, it must be

routed away from hot, sharp, or moving parts. Also,sharp bends that might pinch the washer hose must

be avoided.

WASHER FLUID LEVEL

SWITCH

DESCRIPTION

The washer fluid level switch is a single pole, sin-

gle throw reed-type switch mounted on the rear of

the washer reservoir above the washer pump/motor,

in the left front corner of the engine compartment.

Only the molded plastic switch mounting flange and

connector receptacle are visible when the switch is

installed in the reservoir. A short nipple formation

extends from the inner surface of the switch mount-

ing flange, and a barb on the nipple near the switch

mounting flange is press-fit into a rubber grommet

seal installed in the mounting hole of the reservoir. A

small plastic float pivots on the end of a bracket that

extends from the switch nipple formation. Within the

float is a small magnet, which actuates the reed

switch. The washer fluid level switch cannot be

adjusted or repaired. If faulty or damaged, the switch

must be replaced.

OPERATION

The washer fluid level switch uses a pivoting,

oblong float to monitor the level of the washer fluid

in the washer reservoir. The float contains a small

magnet. When the float pivots, the changing proxim-

ity of its magnetic field will cause the contacts of the

small, stationary reed switch to open or close. When

the fluid level in the washer reservoir is at or above

the float level, the float moves to a vertical position

and the switch contacts open. When the fluid level in

the washer reservoir falls below the pivoting float,

the float moves to a horizontal position and the

switch contacts close. The switch contacts are con-

nected in series between ground and the washer fluid

switch sense input of the instrument cluster. The

switch is connected to the vehicle electrical system

through a dedicated take out and connector of the

headlamp and dash wire harness. The switch

receives ground through another take out of the

headlamp and dash wire harness with a single eyelet

terminal connector that is secured under a nut to a

ground stud located on the front extension of the left

front wheel housing in the engine compartment. The

washer fluid level switch can be diagnosed using con-

ventional diagnostic tools and methods. (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER/WASHER

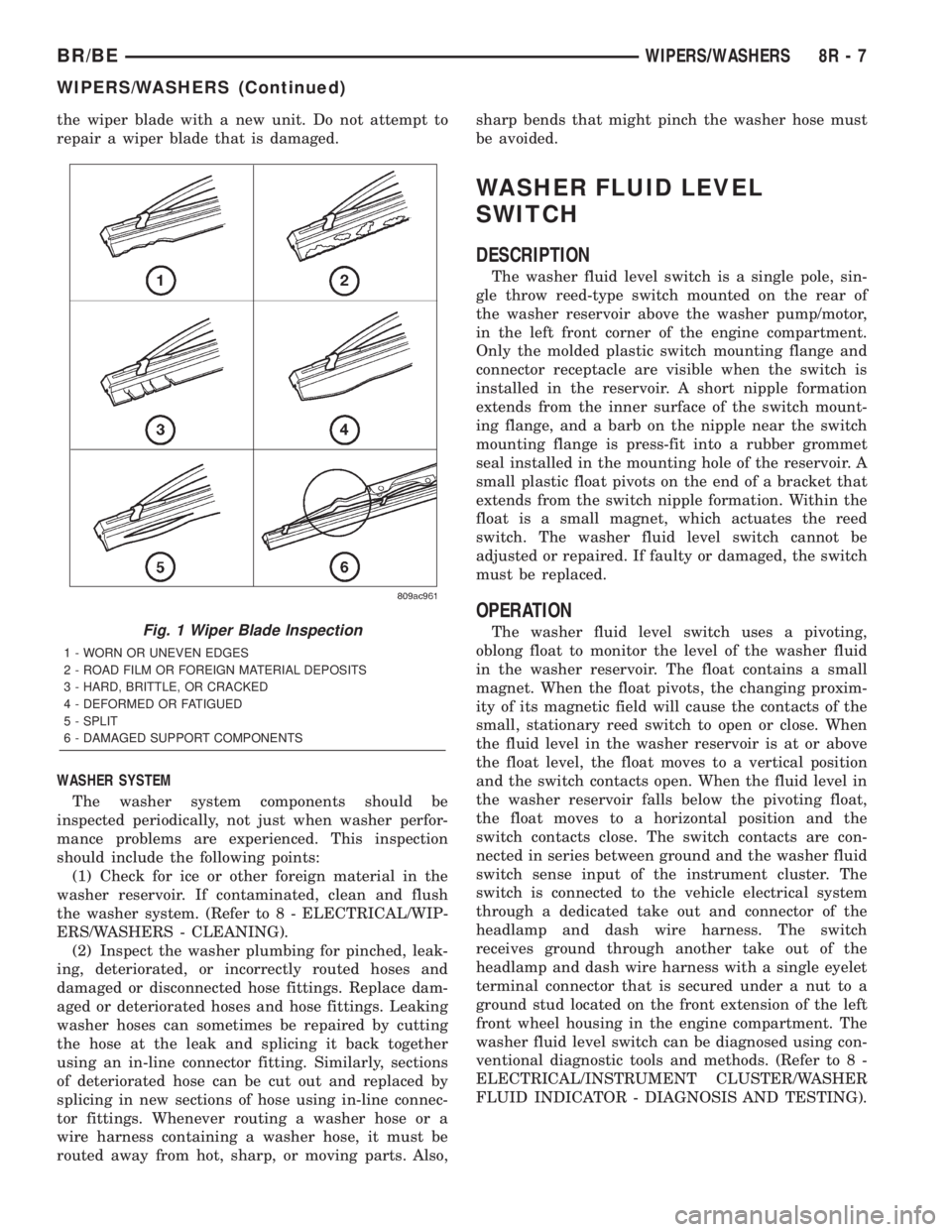

FLUID INDICATOR - DIAGNOSIS AND TESTING).Fig. 1 Wiper Blade Inspection

1 - WORN OR UNEVEN EDGES

2 - ROAD FILM OR FOREIGN MATERIAL DEPOSITS

3 - HARD, BRITTLE, OR CRACKED

4 - DEFORMED OR FATIGUED

5 - SPLIT

6 - DAMAGED SUPPORT COMPONENTS

BR/BEWIPERS/WASHERS 8R - 7

WIPERS/WASHERS (Continued)

Page 731 of 2889

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor unit and

allow the washer fluid to drain into a clean container

for reuse.

(3) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

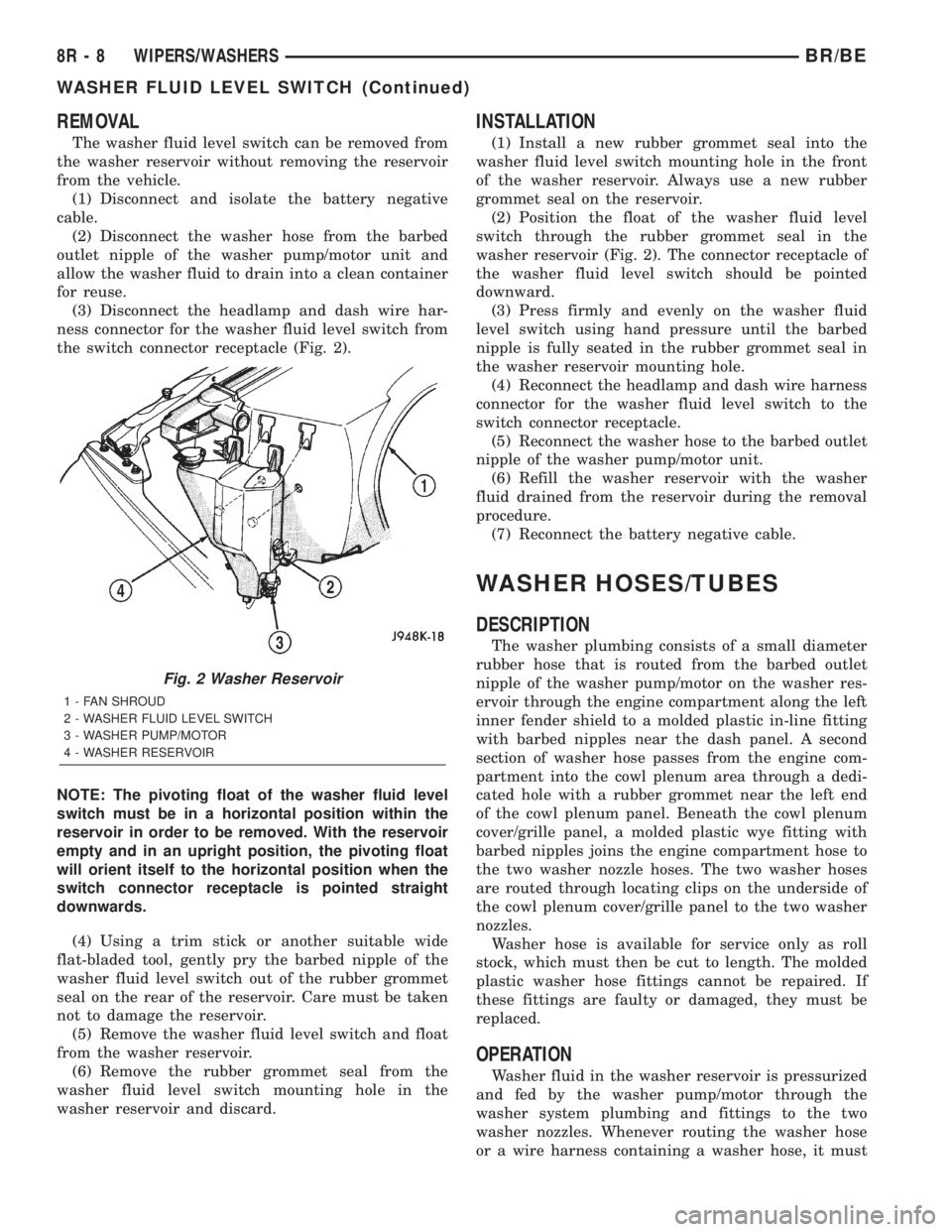

the switch connector receptacle (Fig. 2).

NOTE: The pivoting float of the washer fluid level

switch must be in a horizontal position within the

reservoir in order to be removed. With the reservoir

empty and in an upright position, the pivoting float

will orient itself to the horizontal position when the

switch connector receptacle is pointed straight

downwards.

(4) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed nipple of the

washer fluid level switch out of the rubber grommet

seal on the rear of the reservoir. Care must be taken

not to damage the reservoir.

(5) Remove the washer fluid level switch and float

from the washer reservoir.

(6) Remove the rubber grommet seal from the

washer fluid level switch mounting hole in the

washer reservoir and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer fluid level switch mounting hole in the front

of the washer reservoir. Always use a new rubber

grommet seal on the reservoir.

(2) Position the float of the washer fluid level

switch through the rubber grommet seal in the

washer reservoir (Fig. 2). The connector receptacle of

the washer fluid level switch should be pointed

downward.

(3) Press firmly and evenly on the washer fluid

level switch using hand pressure until the barbed

nipple is fully seated in the rubber grommet seal in

the washer reservoir mounting hole.

(4) Reconnect the headlamp and dash wire harness

connector for the washer fluid level switch to the

switch connector receptacle.

(5) Reconnect the washer hose to the barbed outlet

nipple of the washer pump/motor unit.

(6) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(7) Reconnect the battery negative cable.

WASHER HOSES/TUBES

DESCRIPTION

The washer plumbing consists of a small diameter

rubber hose that is routed from the barbed outlet

nipple of the washer pump/motor on the washer res-

ervoir through the engine compartment along the left

inner fender shield to a molded plastic in-line fitting

with barbed nipples near the dash panel. A second

section of washer hose passes from the engine com-

partment into the cowl plenum area through a dedi-

cated hole with a rubber grommet near the left end

of the cowl plenum panel. Beneath the cowl plenum

cover/grille panel, a molded plastic wye fitting with

barbed nipples joins the engine compartment hose to

the two washer nozzle hoses. The two washer hoses

are routed through locating clips on the underside of

the cowl plenum cover/grille panel to the two washer

nozzles.

Washer hose is available for service only as roll

stock, which must then be cut to length. The molded

plastic washer hose fittings cannot be repaired. If

these fittings are faulty or damaged, they must be

replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the

washer system plumbing and fittings to the two

washer nozzles. Whenever routing the washer hose

or a wire harness containing a washer hose, it must

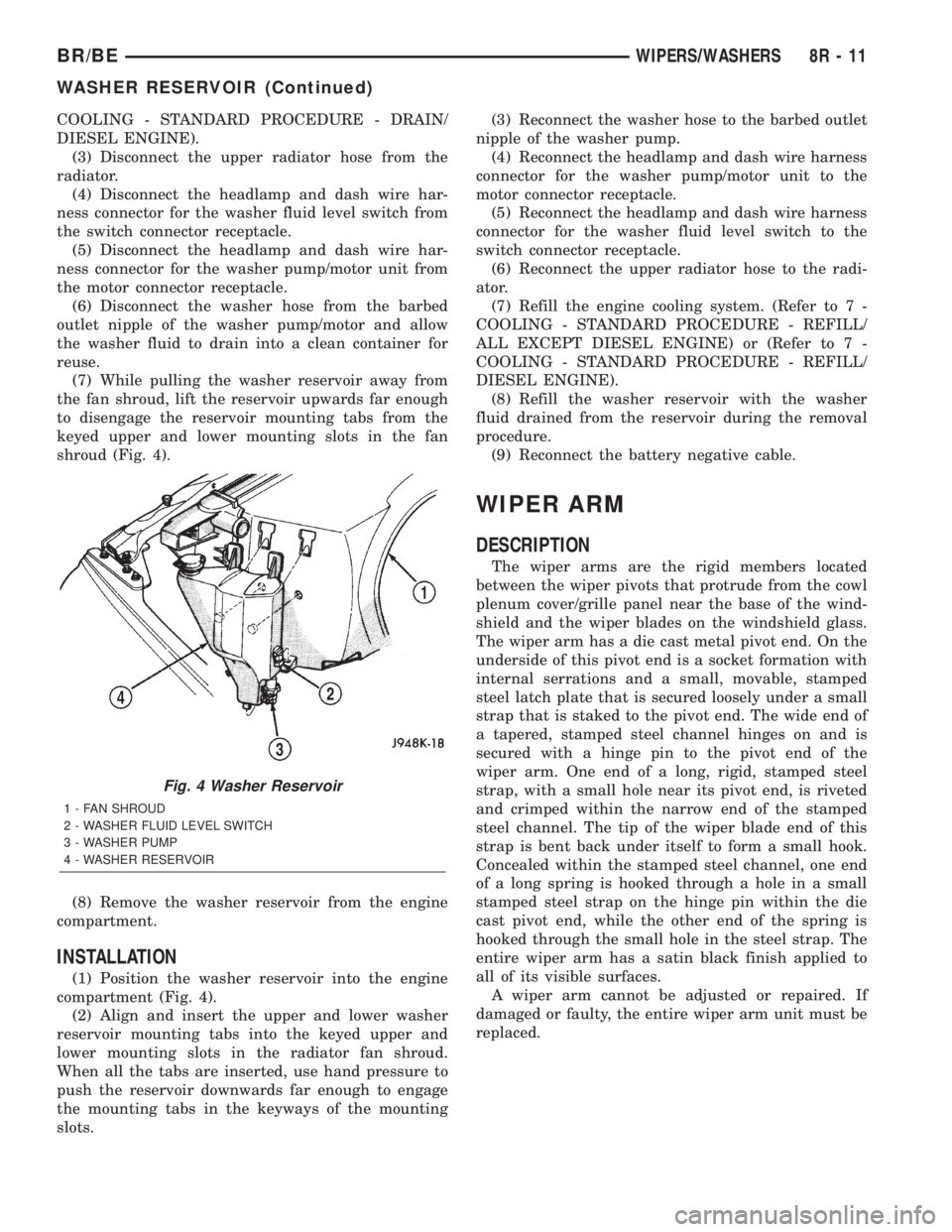

Fig. 2 Washer Reservoir

1 - FAN SHROUD

2 - WASHER FLUID LEVEL SWITCH

3 - WASHER PUMP/MOTOR

4 - WASHER RESERVOIR

8R - 8 WIPERS/WASHERSBR/BE

WASHER FLUID LEVEL SWITCH (Continued)

Page 732 of 2889

be routed away from hot, sharp, or moving parts;

and, sharp bends that might pinch the hose must be

avoided.

WASHER NOZZLE

DESCRIPTION

The two washer nozzles have integral snap fea-

tures that secure them in dedicated holes in the cowl

plenum cover/grille panel located near the base of the

windshield. The domed upper surface of the washer

nozzle is visible on the top of the plenum cover/grille

panel, and the nozzle orifice is oriented towards the

windshield glass. The washer plumbing fittings for

the washer nozzles are concealed beneath the cowl

plenum cover/grille panel. These fluidic washer noz-

zles are constructed of molded plastic. The cowl ple-

num cover/grille panel must be removed from the

vehicle to access the nozzles for service. The washer

nozzles cannot be adjusted or repaired and, if faulty

or damaged, they must be replaced.

OPERATION

The two washer nozzles are designed to dispense

washer fluid into the wiper pattern area on the out-

side of the windshield glass. Pressurized washer fluid

is fed to each nozzle from the washer reservoir by the

washer pump/motor through rubber hoses, which are

attached to a barbed nipple on each washer nozzle

below the cowl plenum cover/grille panel. The washer

nozzles incorporate a fluidic design, which causes the

nozzle to emit the pressurized washer fluid as an

oscillating stream to more effectively cover a larger

area of the glass area to be cleaned.

REMOVAL

(1) Remove the cowl plenum cover/grille panel

from the cowl top. (Refer to 23 - BODY/EXTERIOR/

COWL GRILLE - REMOVAL).

(2) From the underside of the cowl plenum cover/

grille panel, disconnect the washer hose from the

nozzle fitting.

(3) From the underside of the cowl plenum cover/

grille panel, compress the snap features of the

washer nozzle and push the nozzle out through the

top of the panel.

INSTALLATION

(1) From the top of the cowl plenum cover/grille

panel, insert the barbed nipple of the washer nozzle

through the nozzle mounting hole.

(2) With the orifice of the washer nozzle oriented

toward the windshield, use hand pressure to push

the nozzle into the mounting hole until the snap fea-tures of the nozzle are fully engaged with the under-

side of the cowl plenum cover/grille panel.

(3) From the underside of the cowl plenum cover/

grille panel, reconnect the washer hose to the washer

nozzle fitting.

(4) Reinstall the cowl plenum cover/grille panel

onto the cowl top. (Refer to 23 - BODY/EXTERIOR/

COWL GRILLE - INSTALLATION).

WASHER PUMP/MOTOR

DESCRIPTION

The washer pump/motor unit is located on the rear

of the washer reservoir, near the bottom in the left

front corner of the engine compartment. A small per-

manently lubricated and sealed electric motor is cou-

pled to the rotor-type washer pump. A seal flange

with a large barbed inlet nipple on the pump housing

passes through a rubber grommet seal installed in

the dedicated mounting hole near the bottom of the

washer reservoir. A smaller barbed outlet nipple on

the pump housing connects the unit to the washer

hose. The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbed

pump inlet nipple and the grommet seal, which is a

light press fit. An integral electrical connector recep-

tacle is located on the motor housing. The washer

pump/motor unit cannot be repaired. If faulty or

damaged, the entire washer pump/motor unit must

be replaced.

OPERATION

The washer pump/motor unit is connected to the

vehicle electrical system through a single take out

and two-cavity connector of the headlamp and dash

wire harness. The washer pump/motor is grounded at

all times through a take out of the headlamp and

dash wire harness with a single eyelet terminal con-

nector that is secured by a nut to a ground stud

located on the forward extension of the left front

fender wheel housing in the engine compartment.

The washer pump/motor receives battery current on

a fused ignition switch output (run-acc) circuit

through the closed contacts of the momentary washer

switch within the multi-function switch only when

the washer button on the end of the switch control

stalk is depressed towards the steering column.

Washer fluid is gravity-fed from the washer reservoir

to the inlet side of the washer pump. When the pump

motor is energized, the rotor-type pump pressurizes

the washer fluid and forces it through the pump out-

let nipple, the washer plumbing, and the washer noz-

zles onto the windshield glass.

BR/BEWIPERS/WASHERS 8R - 9

WASHER HOSES/TUBES (Continued)

Page 733 of 2889

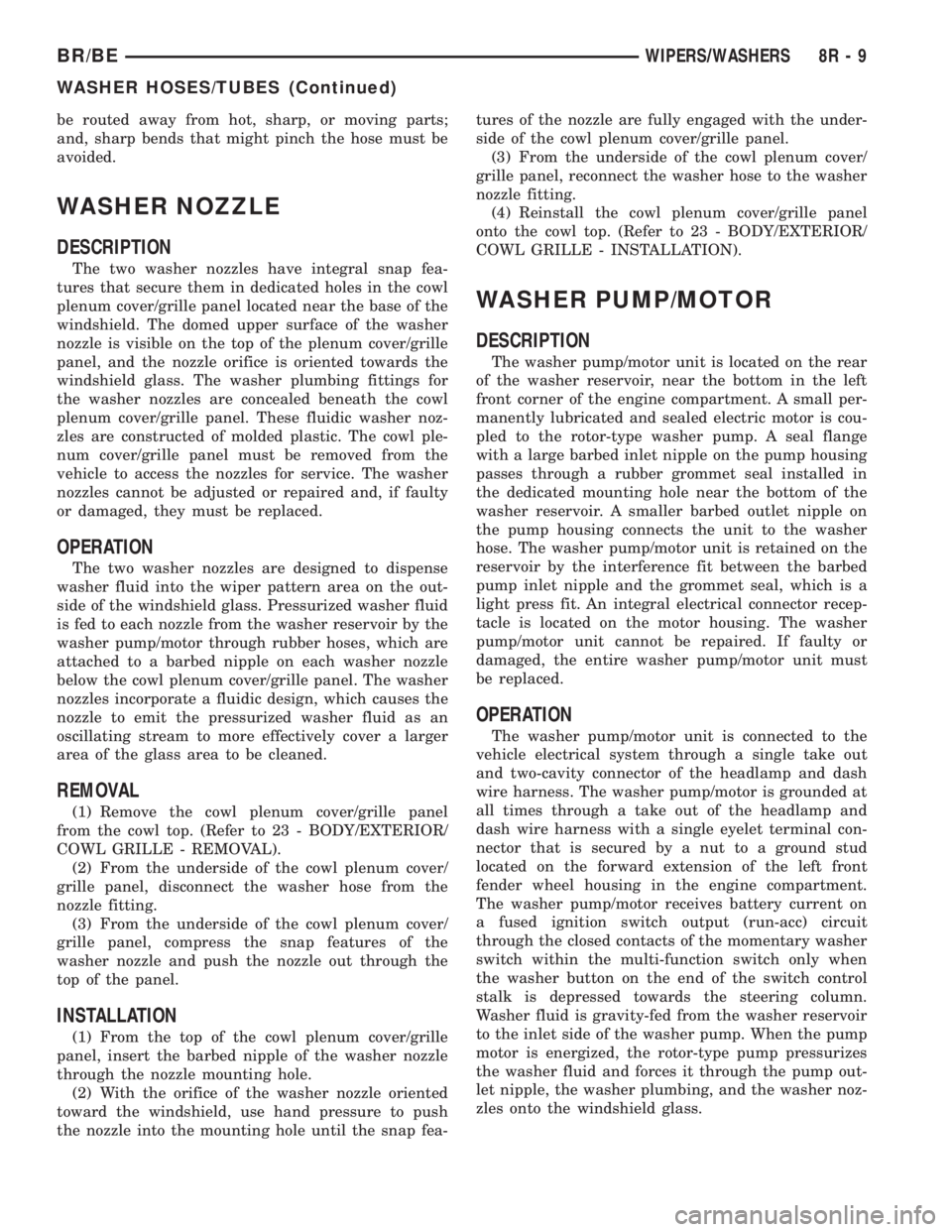

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the headlamp and dash wire har-

ness connector for the washer pump/motor from the

motor connector receptacle (Fig. 3).

(3) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor and allow

the washer fluid to drain into a clean container for

reuse.

(4) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed inlet nipple of

the washer pump out of the rubber grommet seal in

the reservoir. Care must be taken not to damage the

reservoir.

(5) Remove the rubber grommet seal from the

washer pump mounting hole in the washer reservoir

and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reser-

voir.

(2) Position the barbed inlet nipple of the washer

pump to the rubber grommet seal in the reservoir.

(3) Press firmly and evenly on the washer pump

until the barbed inlet nipple is fully seated in the

rubber grommet seal in the washer reservoir mount-

ing hole.

(4) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.(5) Reconnect the headlamp and dash wire harness

connector for the washer pump/motor unit to the

motor connector receptacle (Fig. 3).

(6) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(7) Reconnect the battery negative cable.

WASHER RESERVOIR

DESCRIPTION

The molded plastic washer fluid reservoir is

secured with integral mounting tabs to keyed slots

on the left side of the radiator fan shroud in the left

front corner of the engine compartment. A bright yel-

low plastic filler cap with a rubber seal and an Inter-

national Control and Display Symbol icon for

ªWindshield Washerº and the text ªWasher Fluid

Onlyº molded into it snaps over the open end of the

filler neck. A bail strap that is integral to the cap

secures the cap to the reservoir filler neck when it is

removed for inspecting or adjusting the fluid level in

the reservoir. There are separate, dedicated holes on

the rear side of the reservoir provided for the mount-

ing of the washer/pump motor unit and the washer

fluid level switch.

The washer reservoir cannot be repaired and, if

faulty or damaged, it must be replaced. The washer

reservoir, the grommet seals for the washer pump/

motor unit and the washer fluid level switch, and the

filler cap are each available for service replacement.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the washer system. The

washer reservoir filler neck provides a clearly

marked and readily accessible point from which to

add washer fluid to the reservoir. The washer/pump

motor unit is located in a sump area near the bottom

of the reservoir to be certain that washer fluid will

be available to the pump as the fluid level in the res-

ervoir becomes depleted. The washer fluid level

switch is mounted just above the sump area of the

reservoir so that there will be adequate warning to

the vehicle operator that the washer fluid level is

low, before the washer system will no longer operate.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - DRAIN/

ALL EXCEPT DIESEL ENGINE) or (Refer to 7 -

Fig. 3 Washer Reservoir

1 - FAN SHROUD

2 - WASHER FLUID LEVEL SWITCH

3 - WASHER PUMP/MOTOR

4 - WASHER RESERVOIR

8R - 10 WIPERS/WASHERSBR/BE

WASHER PUMP/MOTOR (Continued)

Page 734 of 2889

COOLING - STANDARD PROCEDURE - DRAIN/

DIESEL ENGINE).

(3) Disconnect the upper radiator hose from the

radiator.

(4) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the switch connector receptacle.

(5) Disconnect the headlamp and dash wire har-

ness connector for the washer pump/motor unit from

the motor connector receptacle.

(6) Disconnect the washer hose from the barbed

outlet nipple of the washer pump/motor and allow

the washer fluid to drain into a clean container for

reuse.

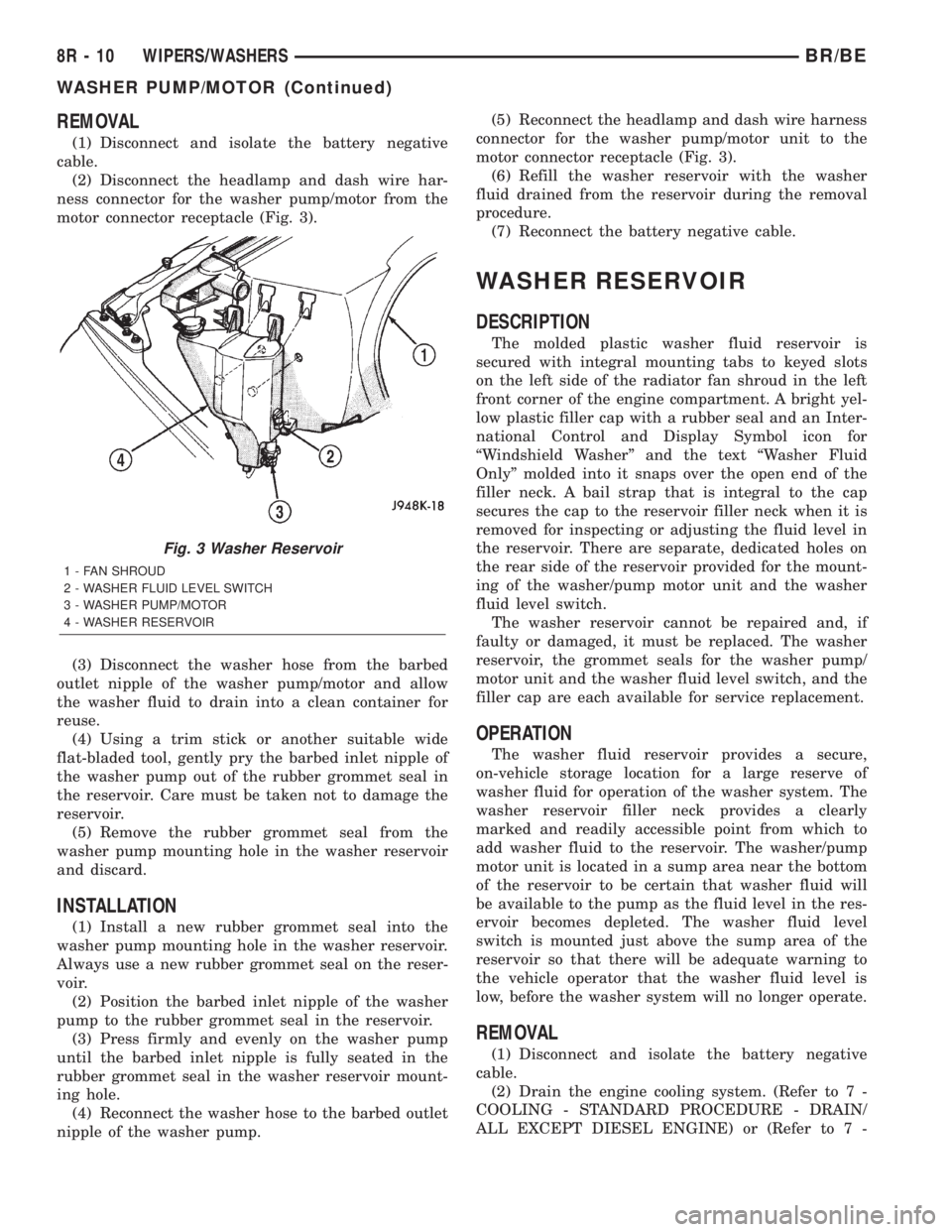

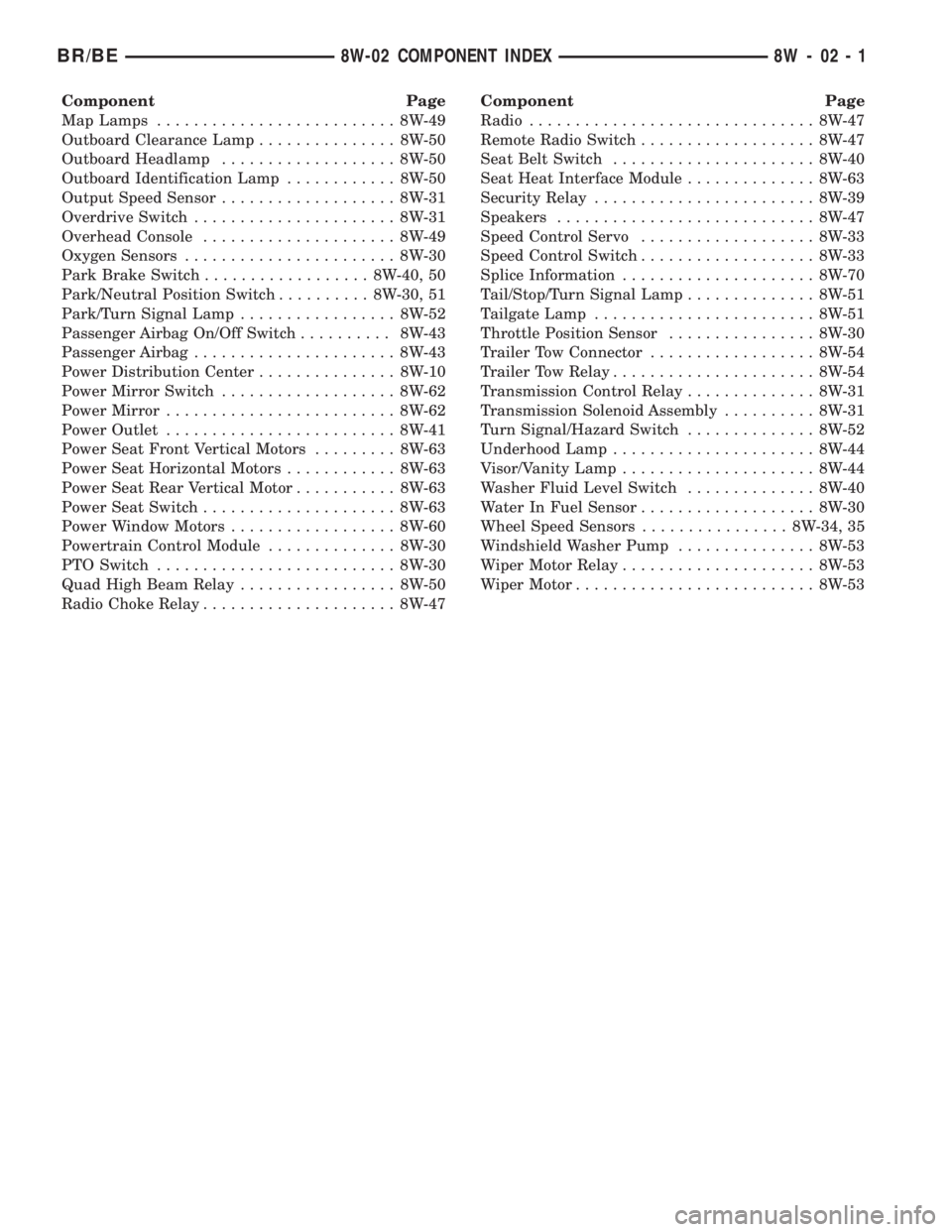

(7) While pulling the washer reservoir away from

the fan shroud, lift the reservoir upwards far enough

to disengage the reservoir mounting tabs from the

keyed upper and lower mounting slots in the fan

shroud (Fig. 4).

(8) Remove the washer reservoir from the engine

compartment.

INSTALLATION

(1) Position the washer reservoir into the engine

compartment (Fig. 4).

(2) Align and insert the upper and lower washer

reservoir mounting tabs into the keyed upper and

lower mounting slots in the radiator fan shroud.

When all the tabs are inserted, use hand pressure to

push the reservoir downwards far enough to engage

the mounting tabs in the keyways of the mounting

slots.(3) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.

(4) Reconnect the headlamp and dash wire harness

connector for the washer pump/motor unit to the

motor connector receptacle.

(5) Reconnect the headlamp and dash wire harness

connector for the washer fluid level switch to the

switch connector receptacle.

(6) Reconnect the upper radiator hose to the radi-

ator.

(7) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - REFILL/

ALL EXCEPT DIESEL ENGINE) or (Refer to 7 -

COOLING - STANDARD PROCEDURE - REFILL/

DIESEL ENGINE).

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

WIPER ARM

DESCRIPTION

The wiper arms are the rigid members located

between the wiper pivots that protrude from the cowl

plenum cover/grille panel near the base of the wind-

shield and the wiper blades on the windshield glass.

The wiper arm has a die cast metal pivot end. On the

underside of this pivot end is a socket formation with

internal serrations and a small, movable, stamped

steel latch plate that is secured loosely under a small

strap that is staked to the pivot end. The wide end of

a tapered, stamped steel channel hinges on and is

secured with a hinge pin to the pivot end of the

wiper arm. One end of a long, rigid, stamped steel

strap, with a small hole near its pivot end, is riveted

and crimped within the narrow end of the stamped

steel channel. The tip of the wiper blade end of this

strap is bent back under itself to form a small hook.

Concealed within the stamped steel channel, one end

of a long spring is hooked through a hole in a small

stamped steel strap on the hinge pin within the die

cast pivot end, while the other end of the spring is

hooked through the small hole in the steel strap. The

entire wiper arm has a satin black finish applied to

all of its visible surfaces.

A wiper arm cannot be adjusted or repaired. If

damaged or faulty, the entire wiper arm unit must be

replaced.

Fig. 4 Washer Reservoir

1 - FAN SHROUD

2 - WASHER FLUID LEVEL SWITCH

3 - WASHER PUMP

4 - WASHER RESERVOIR

BR/BEWIPERS/WASHERS 8R - 11

WASHER RESERVOIR (Continued)

Page 757 of 2889

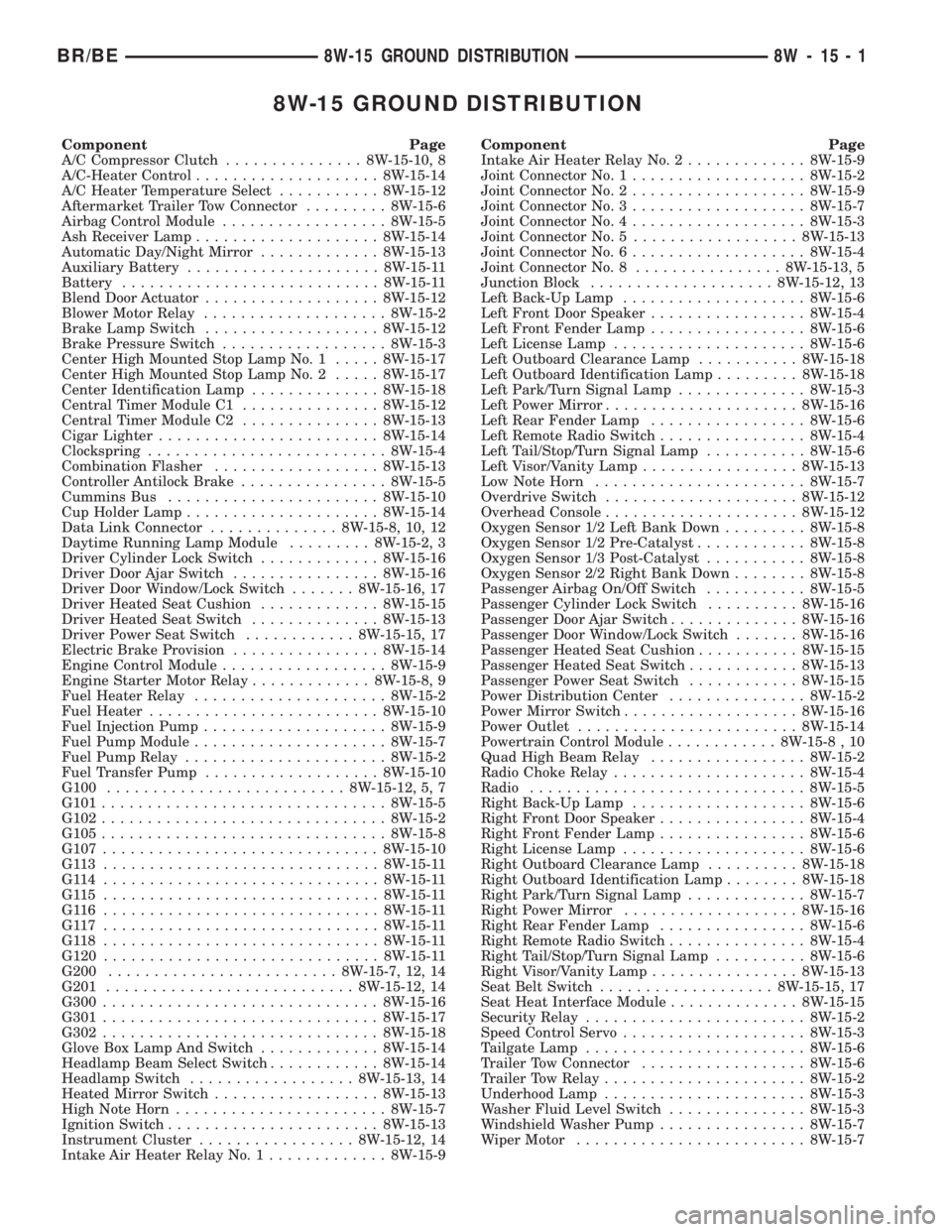

Component Page

Map Lamps.......................... 8W-49

Outboard Clearance Lamp............... 8W-50

Outboard Headlamp................... 8W-50

Outboard Identification Lamp............ 8W-50

Output Speed Sensor................... 8W-31

Overdrive Switch...................... 8W-31

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Park Brake Switch.................. 8W-40, 50

Park/Neutral Position Switch.......... 8W-30, 51

Park/Turn Signal Lamp................. 8W-52

Passenger Airbag On/Off Switch.......... 8W-43

Passenger Airbag...................... 8W-43

Power Distribution Center............... 8W-10

Power Mirror Switch................... 8W-62

Power Mirror......................... 8W-62

Power Outlet......................... 8W-41

Power Seat Front Vertical Motors......... 8W-63

Power Seat Horizontal Motors............ 8W-63

Power Seat Rear Vertical Motor........... 8W-63

Power Seat Switch..................... 8W-63

Power Window Motors.................. 8W-60

Powertrain Control Module.............. 8W-30

PTO Switch.......................... 8W-30

Quad High Beam Relay................. 8W-50

Radio Choke Relay..................... 8W-47Component Page

Radio............................... 8W-47

Remote Radio Switch................... 8W-47

Seat Belt Switch...................... 8W-40

Seat Heat Interface Module.............. 8W-63

Security Relay........................ 8W-39

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switch................... 8W-33

Splice Information..................... 8W-70

Tail/Stop/Turn Signal Lamp.............. 8W-51

Tailgate Lamp........................ 8W-51

Throttle Position Sensor................ 8W-30

Trailer Tow Connector.................. 8W-54

Trailer Tow Relay...................... 8W-54

Transmission Control Relay.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Turn Signal/Hazard Switch.............. 8W-52

Underhood Lamp...................... 8W-44

Visor/Vanity Lamp..................... 8W-44

Washer Fluid Level Switch.............. 8W-40

Water In Fuel Sensor................... 8W-30

Wheel Speed Sensors................ 8W-34, 35

Windshield Washer Pump............... 8W-53

Wiper Motor Relay..................... 8W-53

Wiper Motor.......................... 8W-53

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1

Page 808 of 2889

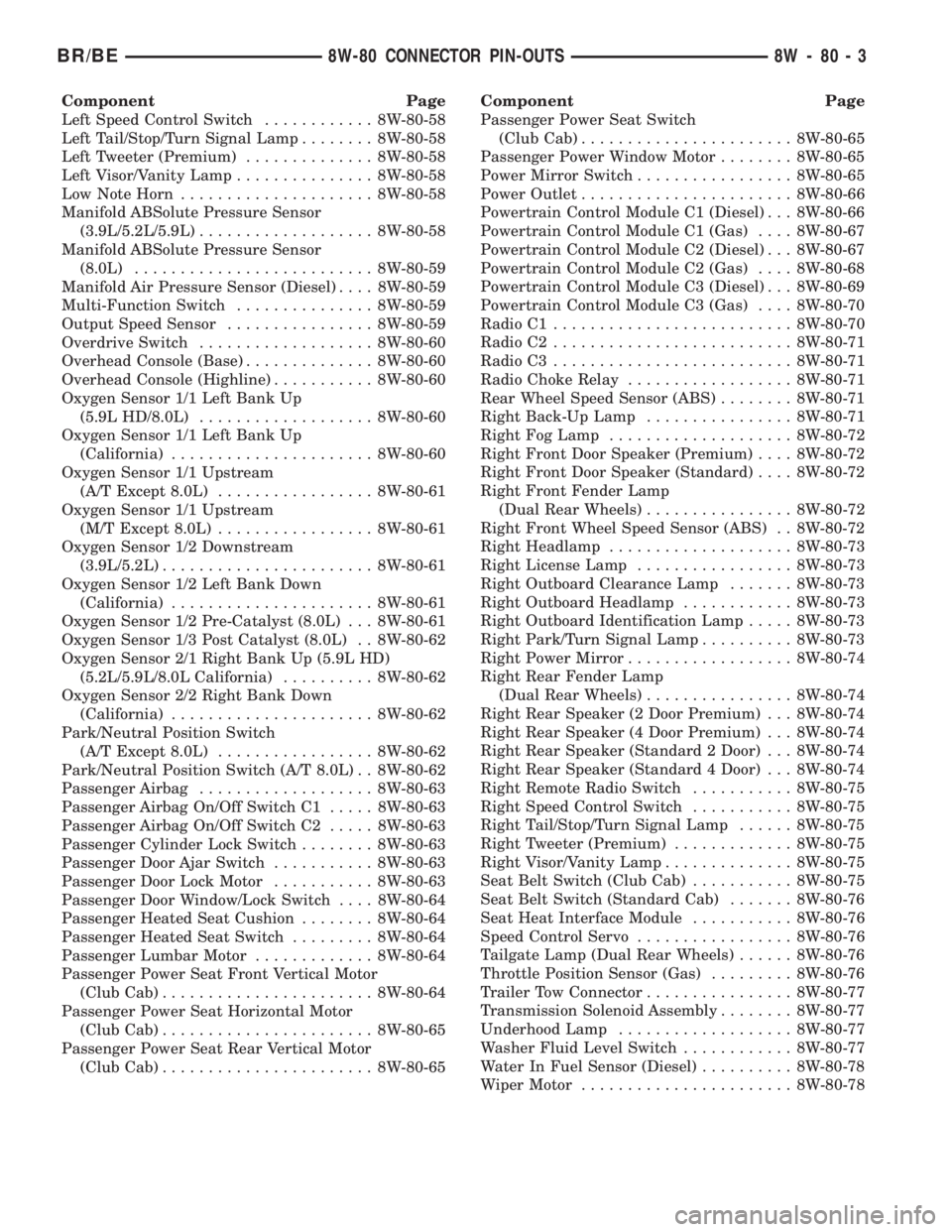

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch............... 8W-15-10, 8

A/C-Heater Control.................... 8W-15-14

A/C Heater Temperature Select........... 8W-15-12

Aftermarket Trailer Tow Connector......... 8W-15-6

Airbag Control Module.................. 8W-15-5

Ash Receiver Lamp.................... 8W-15-14

Automatic Day/Night Mirror............. 8W-15-13

Auxiliary Battery..................... 8W-15-11

Battery............................ 8W-15-11

Blend Door Actuator................... 8W-15-12

Blower Motor Relay.................... 8W-15-2

Brake Lamp Switch................... 8W-15-12

Brake Pressure Switch.................. 8W-15-3

Center High Mounted Stop Lamp No. 1..... 8W-15-17

Center High Mounted Stop Lamp No. 2..... 8W-15-17

Center Identification Lamp.............. 8W-15-18

Central Timer Module C1............... 8W-15-12

Central Timer Module C2............... 8W-15-13

Cigar Lighter........................ 8W-15-14

Clockspring.......................... 8W-15-4

Combination Flasher.................. 8W-15-13

Controller Antilock Brake................ 8W-15-5

Cummins Bus....................... 8W-15-10

Cup Holder Lamp..................... 8W-15-14

Data Link Connector.............. 8W-15-8, 10, 12

Daytime Running Lamp Module......... 8W-15-2, 3

Driver Cylinder Lock Switch............. 8W-15-16

Driver Door Ajar Switch................ 8W-15-16

Driver Door Window/Lock Switch....... 8W-15-16, 17

Driver Heated Seat Cushion............. 8W-15-15

Driver Heated Seat Switch.............. 8W-15-13

Driver Power Seat Switch............ 8W-15-15, 17

Electric Brake Provision................ 8W-15-14

Engine Control Module.................. 8W-15-9

Engine Starter Motor Relay............. 8W-15-8, 9

Fuel Heater Relay..................... 8W-15-2

Fuel Heater......................... 8W-15-10

Fuel Injection Pump.................... 8W-15-9

Fuel Pump Module..................... 8W-15-7

Fuel Pump Relay...................... 8W-15-2

Fuel Transfer Pump................... 8W-15-10

G100.......................... 8W-15-12, 5, 7

G101............................... 8W-15-5

G102............................... 8W-15-2

G105............................... 8W-15-8

G107.............................. 8W-15-10

G113 .............................. 8W-15-11

G114 .............................. 8W-15-11

G115 .............................. 8W-15-11

G116 .............................. 8W-15-11

G117 .............................. 8W-15-11

G118 .............................. 8W-15-11

G120.............................. 8W-15-11

G200......................... 8W-15-7, 12, 14

G201........................... 8W-15-12, 14

G300.............................. 8W-15-16

G301.............................. 8W-15-17

G302.............................. 8W-15-18

Glove Box Lamp And Switch............. 8W-15-14

Headlamp Beam Select Switch............ 8W-15-14

Headlamp Switch.................. 8W-15-13, 14

Heated Mirror Switch.................. 8W-15-13

High Note Horn....................... 8W-15-7

Ignition Switch....................... 8W-15-13

Instrument Cluster................. 8W-15-12, 14

Intake Air Heater Relay No. 1............. 8W-15-9Component Page

Intake Air Heater Relay No. 2............. 8W-15-9

Joint Connector No. 1................... 8W-15-2

Joint Connector No. 2................... 8W-15-9

Joint Connector No. 3................... 8W-15-7

Joint Connector No. 4................... 8W-15-3

Joint Connector No. 5.................. 8W-15-13

Joint Connector No. 6................... 8W-15-4

Joint Connector No. 8................ 8W-15-13, 5

Junction Block.................... 8W-15-12, 13

Left Back-Up Lamp.................... 8W-15-6

Left Front Door Speaker................. 8W-15-4

Left Front Fender Lamp................. 8W-15-6

Left License Lamp..................... 8W-15-6

Left Outboard Clearance Lamp........... 8W-15-18

Left Outboard Identification Lamp......... 8W-15-18

Left Park/Turn Signal Lamp.............. 8W-15-3

Left Power Mirror..................... 8W-15-16

Left Rear Fender Lamp................. 8W-15-6

Left Remote Radio Switch................ 8W-15-4

Left Tail/Stop/Turn Signal Lamp........... 8W-15-6

Left Visor/Vanity Lamp................. 8W-15-13

Low Note Horn....................... 8W-15-7

Overdrive Switch..................... 8W-15-12

Overhead Console..................... 8W-15-12

Oxygen Sensor 1/2 Left Bank Down......... 8W-15-8

Oxygen Sensor 1/2 Pre-Catalyst............ 8W-15-8

Oxygen Sensor 1/3 Post-Catalyst........... 8W-15-8

Oxygen Sensor 2/2 Right Bank Down........ 8W-15-8

Passenger Airbag On/Off Switch........... 8W-15-5

Passenger Cylinder Lock Switch.......... 8W-15-16

Passenger Door Ajar Switch.............. 8W-15-16

Passenger Door Window/Lock Switch....... 8W-15-16

Passenger Heated Seat Cushion........... 8W-15-15

Passenger Heated Seat Switch............ 8W-15-13

Passenger Power Seat Switch............ 8W-15-15

Power Distribution Center............... 8W-15-2

Power Mirror Switch................... 8W-15-16

Power Outlet........................ 8W-15-14

Powertrain Control Module............ 8W-15-8 , 10

Quad High Beam Relay................. 8W-15-2

Radio Choke Relay..................... 8W-15-4

Radio.............................. 8W-15-5

Right Back-Up Lamp................... 8W-15-6

Right Front Door Speaker................ 8W-15-4

Right Front Fender Lamp................ 8W-15-6

Right License Lamp.................... 8W-15-6

Right Outboard Clearance Lamp.......... 8W-15-18

Right Outboard Identification Lamp........ 8W-15-18

Right Park/Turn Signal Lamp............. 8W-15-7

Right Power Mirror................... 8W-15-16

Right Rear Fender Lamp................ 8W-15-6

Right Remote Radio Switch............... 8W-15-4

Right Tail/Stop/Turn Signal Lamp.......... 8W-15-6

Right Visor/Vanity Lamp................ 8W-15-13

Seat Belt Switch................... 8W-15-15, 17

Seat Heat Interface Module.............. 8W-15-15

Security Relay........................ 8W-15-2

Speed Control Servo.................... 8W-15-3

Tailgate Lamp........................ 8W-15-6

Trailer Tow Connector.................. 8W-15-6

Trailer Tow Relay...................... 8W-15-2

Underhood Lamp...................... 8W-15-3

Washer Fluid Level Switch............... 8W-15-3

Windshield Washer Pump................ 8W-15-7

Wiper Motor......................... 8W-15-7

BR/BE8W-15 GROUND DISTRIBUTION 8W - 15 - 1

Page 1016 of 2889

Component Page

Left Speed Control Switch............ 8W-80-58

Left Tail/Stop/Turn Signal Lamp........ 8W-80-58

Left Tweeter (Premium).............. 8W-80-58

Left Visor/Vanity Lamp............... 8W-80-58

Low Note Horn..................... 8W-80-58

Manifold ABSolute Pressure Sensor

(3.9L/5.2L/5.9L)................... 8W-80-58

Manifold ABSolute Pressure Sensor

(8.0L).......................... 8W-80-59

Manifold Air Pressure Sensor (Diesel).... 8W-80-59

Multi-Function Switch............... 8W-80-59

Output Speed Sensor................ 8W-80-59

Overdrive Switch................... 8W-80-60

Overhead Console (Base).............. 8W-80-60

Overhead Console (Highline)........... 8W-80-60

Oxygen Sensor 1/1 Left Bank Up

(5.9L HD/8.0L)................... 8W-80-60

Oxygen Sensor 1/1 Left Bank Up

(California)...................... 8W-80-60

Oxygen Sensor 1/1 Upstream

(A/T Except 8.0L)................. 8W-80-61

Oxygen Sensor 1/1 Upstream

(M/T Except 8.0L)................. 8W-80-61

Oxygen Sensor 1/2 Downstream

(3.9L/5.2L)....................... 8W-80-61

Oxygen Sensor 1/2 Left Bank Down

(California)...................... 8W-80-61

Oxygen Sensor 1/2 Pre-Catalyst (8.0L) . . . 8W-80-61

Oxygen Sensor 1/3 Post Catalyst (8.0L) . . 8W-80-62

Oxygen Sensor 2/1 Right Bank Up (5.9L HD)

(5.2L/5.9L/8.0L California).......... 8W-80-62

Oxygen Sensor 2/2 Right Bank Down

(California)...................... 8W-80-62

Park/Neutral Position Switch

(A/T Except 8.0L)................. 8W-80-62

Park/Neutral Position Switch (A/T 8.0L) . . 8W-80-62

Passenger Airbag................... 8W-80-63

Passenger Airbag On/Off Switch C1..... 8W-80-63

Passenger Airbag On/Off Switch C2..... 8W-80-63

Passenger Cylinder Lock Switch........ 8W-80-63

Passenger Door Ajar Switch........... 8W-80-63

Passenger Door Lock Motor........... 8W-80-63

Passenger Door Window/Lock Switch.... 8W-80-64

Passenger Heated Seat Cushion........ 8W-80-64

Passenger Heated Seat Switch......... 8W-80-64

Passenger Lumbar Motor............. 8W-80-64

Passenger Power Seat Front Vertical Motor

(Club Cab)....................... 8W-80-64

Passenger Power Seat Horizontal Motor

(Club Cab)....................... 8W-80-65

Passenger Power Seat Rear Vertical Motor

(Club Cab)....................... 8W-80-65Component Page

Passenger Power Seat Switch

(Club Cab)....................... 8W-80-65

Passenger Power Window Motor........ 8W-80-65

Power Mirror Switch................. 8W-80-65

Power Outlet....................... 8W-80-66

Powertrain Control Module C1 (Diesel) . . . 8W-80-66

Powertrain Control Module C1 (Gas).... 8W-80-67

Powertrain Control Module C2 (Diesel) . . . 8W-80-67

Powertrain Control Module C2 (Gas).... 8W-80-68

Powertrain Control Module C3 (Diesel) . . . 8W-80-69

Powertrain Control Module C3 (Gas).... 8W-80-70

Radio C1.......................... 8W-80-70

Radio C2.......................... 8W-80-71

Radio C3.......................... 8W-80-71

Radio Choke Relay.................. 8W-80-71

Rear Wheel Speed Sensor (ABS)........ 8W-80-71

Right Back-Up Lamp................ 8W-80-71

Right Fog Lamp.................... 8W-80-72

Right Front Door Speaker (Premium).... 8W-80-72

Right Front Door Speaker (Standard).... 8W-80-72

Right Front Fender Lamp

(Dual Rear Wheels)................ 8W-80-72

Right Front Wheel Speed Sensor (ABS) . . 8W-80-72

Right Headlamp.................... 8W-80-73

Right License Lamp................. 8W-80-73

Right Outboard Clearance Lamp....... 8W-80-73

Right Outboard Headlamp............ 8W-80-73

Right Outboard Identification Lamp..... 8W-80-73

Right Park/Turn Signal Lamp.......... 8W-80-73

Right Power Mirror.................. 8W-80-74

Right Rear Fender Lamp

(Dual Rear Wheels)................ 8W-80-74

Right Rear Speaker (2 Door Premium) . . . 8W-80-74

Right Rear Speaker (4 Door Premium) . . . 8W-80-74

Right Rear Speaker (Standard 2 Door) . . . 8W-80-74

Right Rear Speaker (Standard 4 Door) . . . 8W-80-74

Right Remote Radio Switch........... 8W-80-75

Right Speed Control Switch........... 8W-80-75

Right Tail/Stop/Turn Signal Lamp...... 8W-80-75

Right Tweeter (Premium)............. 8W-80-75

Right Visor/Vanity Lamp.............. 8W-80-75

Seat Belt Switch (Club Cab)........... 8W-80-75

Seat Belt Switch (Standard Cab)....... 8W-80-76

Seat Heat Interface Module........... 8W-80-76

Speed Control Servo................. 8W-80-76

Tailgate Lamp (Dual Rear Wheels)...... 8W-80-76

Throttle Position Sensor (Gas)......... 8W-80-76

Trailer Tow Connector................ 8W-80-77

Transmission Solenoid Assembly........ 8W-80-77

Underhood Lamp................... 8W-80-77

Washer Fluid Level Switch............ 8W-80-77

Water In Fuel Sensor (Diesel).......... 8W-80-78

Wiper Motor....................... 8W-80-78

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 3

Page 1098 of 2889

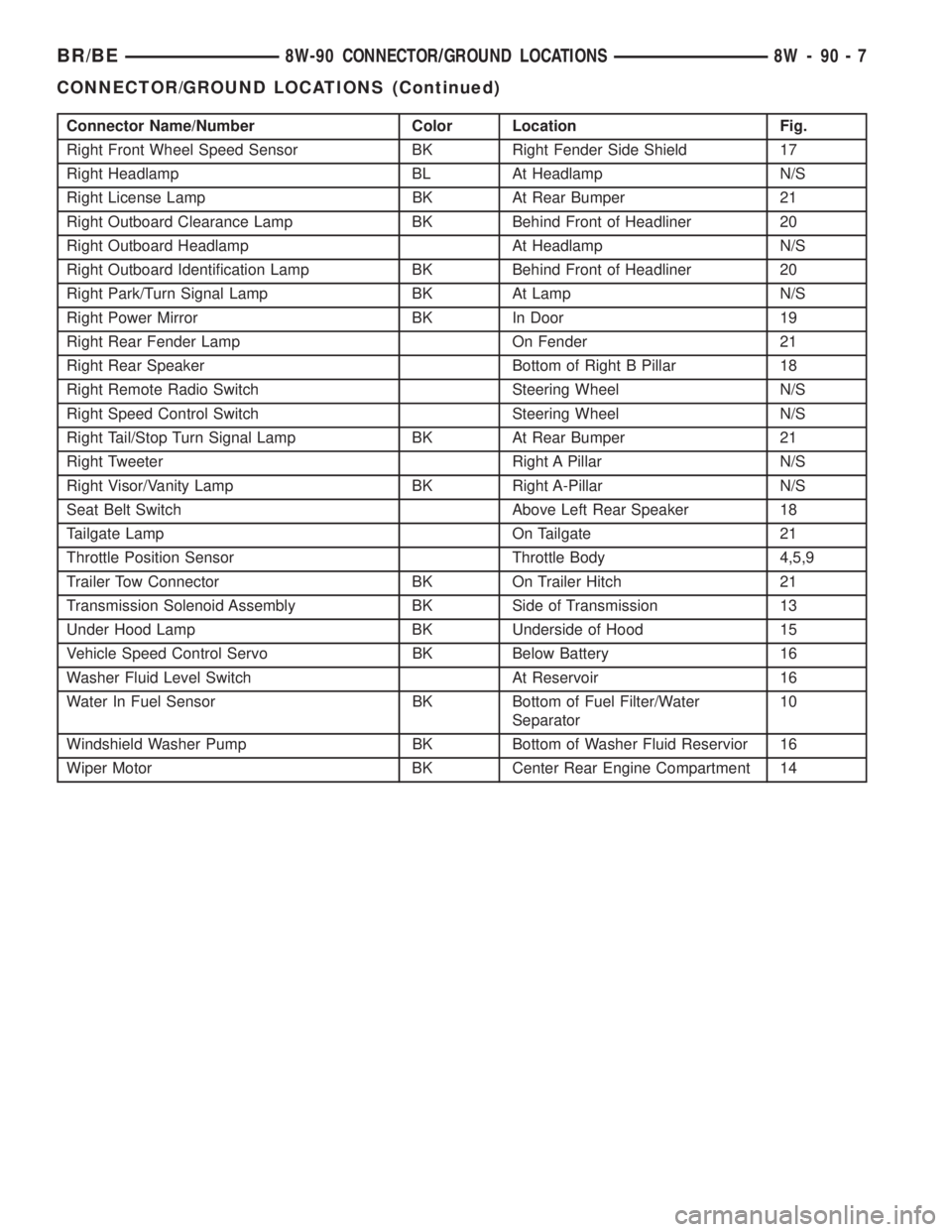

Connector Name/Number Color Location Fig.

Right Front Wheel Speed Sensor BK Right Fender Side Shield 17

Right Headlamp BL At Headlamp N/S

Right License Lamp BK At Rear Bumper 21

Right Outboard Clearance Lamp BK Behind Front of Headliner 20

Right Outboard Headlamp At Headlamp N/S

Right Outboard Identification Lamp BK Behind Front of Headliner 20

Right Park/Turn Signal Lamp BK At Lamp N/S

Right Power Mirror BK In Door 19

Right Rear Fender Lamp On Fender 21

Right Rear Speaker Bottom of Right B Pillar 18

Right Remote Radio Switch Steering Wheel N/S

Right Speed Control Switch Steering Wheel N/S

Right Tail/Stop Turn Signal Lamp BK At Rear Bumper 21

Right Tweeter Right A Pillar N/S

Right Visor/Vanity Lamp BK Right A-Pillar N/S

Seat Belt Switch Above Left Rear Speaker 18

Tailgate Lamp On Tailgate 21

Throttle Position Sensor Throttle Body 4,5,9

Trailer Tow Connector BK On Trailer Hitch 21

Transmission Solenoid Assembly BK Side of Transmission 13

Under Hood Lamp BK Underside of Hood 15

Vehicle Speed Control Servo BK Below Battery 16

Washer Fluid Level Switch At Reservoir 16

Water In Fuel Sensor BK Bottom of Fuel Filter/Water

Separator10

Windshield Washer Pump BK Bottom of Washer Fluid Reservior 16

Wiper Motor BK Center Rear Engine Compartment 14

BR/BE8W-90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 7

CONNECTOR/GROUND LOCATIONS (Continued)

Page 1329 of 2889

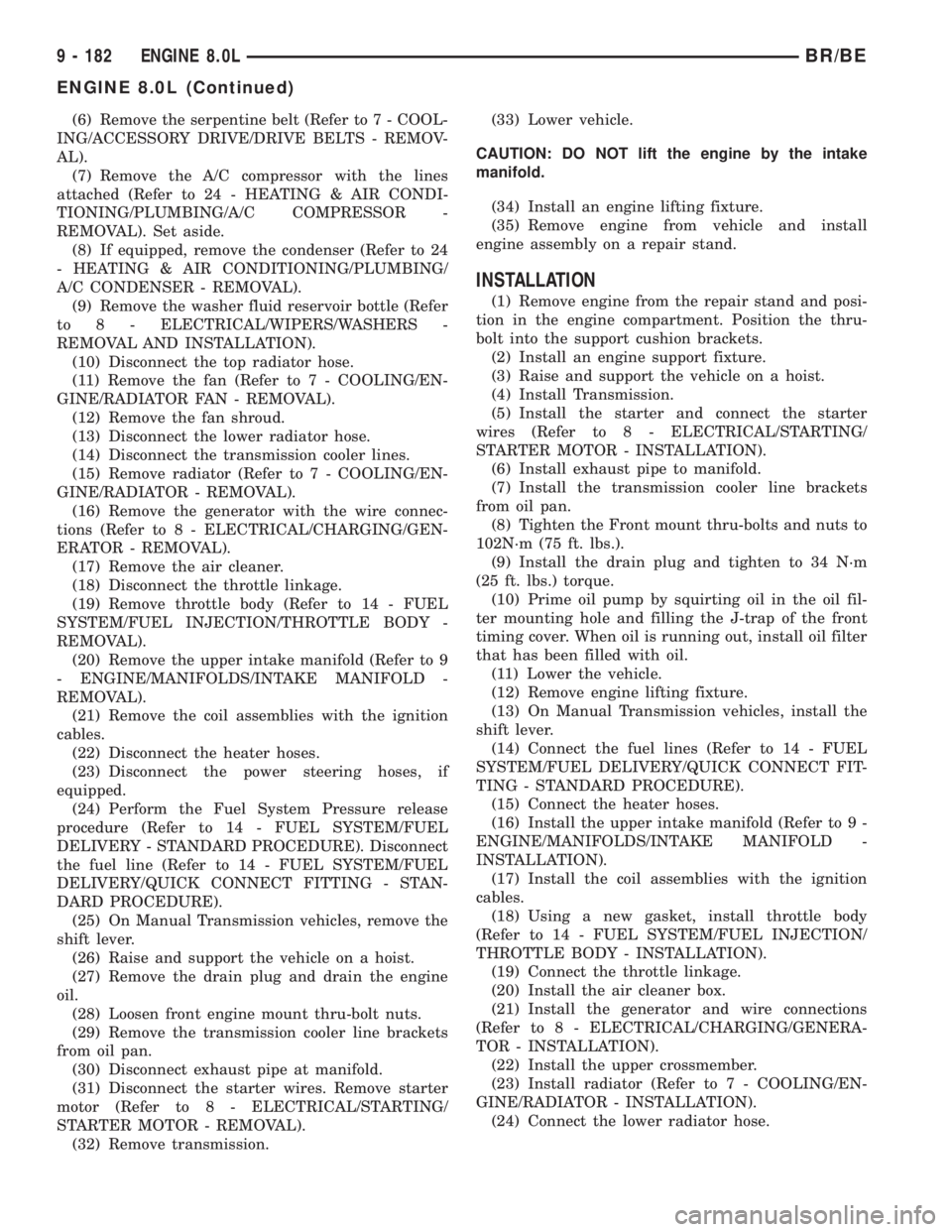

(6) Remove the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - REMOV-

AL).

(7) Remove the A/C compressor with the lines

attached (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL). Set aside.

(8) If equipped, remove the condenser (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

A/C CONDENSER - REMOVAL).

(9) Remove the washer fluid reservoir bottle (Refer

to 8 - ELECTRICAL/WIPERS/WASHERS -

REMOVAL AND INSTALLATION).

(10) Disconnect the top radiator hose.

(11) Remove the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - REMOVAL).

(12) Remove the fan shroud.

(13) Disconnect the lower radiator hose.

(14) Disconnect the transmission cooler lines.

(15) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(16) Remove the generator with the wire connec-

tions (Refer to 8 - ELECTRICAL/CHARGING/GEN-

ERATOR - REMOVAL).

(17) Remove the air cleaner.

(18) Disconnect the throttle linkage.

(19) Remove throttle body (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/THROTTLE BODY -

REMOVAL).

(20) Remove the upper intake manifold (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(21) Remove the coil assemblies with the ignition

cables.

(22) Disconnect the heater hoses.

(23) Disconnect the power steering hoses, if

equipped.

(24) Perform the Fuel System Pressure release

procedure (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). Disconnect

the fuel line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(25) On Manual Transmission vehicles, remove the

shift lever.

(26) Raise and support the vehicle on a hoist.

(27) Remove the drain plug and drain the engine

oil.

(28) Loosen front engine mount thru-bolt nuts.

(29) Remove the transmission cooler line brackets

from oil pan.

(30) Disconnect exhaust pipe at manifold.

(31) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(32) Remove transmission.(33) Lower vehicle.

CAUTION: DO NOT lift the engine by the intake

manifold.

(34) Install an engine lifting fixture.

(35) Remove engine from vehicle and install

engine assembly on a repair stand.

INSTALLATION

(1) Remove engine from the repair stand and posi-

tion in the engine compartment. Position the thru-

bolt into the support cushion brackets.

(2) Install an engine support fixture.

(3) Raise and support the vehicle on a hoist.

(4) Install Transmission.

(5) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(6) Install exhaust pipe to manifold.

(7) Install the transmission cooler line brackets

from oil pan.

(8) Tighten the Front mount thru-bolts and nuts to

102N´m (75 ft. lbs.).

(9) Install the drain plug and tighten to 34 N´m

(25 ft. lbs.) torque.

(10) Prime oil pump by squirting oil in the oil fil-

ter mounting hole and filling the J-trap of the front

timing cover. When oil is running out, install oil filter

that has been filled with oil.

(11) Lower the vehicle.

(12) Remove engine lifting fixture.

(13) On Manual Transmission vehicles, install the

shift lever.

(14) Connect the fuel lines (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE).

(15) Connect the heater hoses.

(16) Install the upper intake manifold (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(17) Install the coil assemblies with the ignition

cables.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Connect the throttle linkage.

(20) Install the air cleaner box.

(21) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(22) Install the upper crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the lower radiator hose.

9 - 182 ENGINE 8.0LBR/BE

ENGINE 8.0L (Continued)