DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2111 of 2889

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

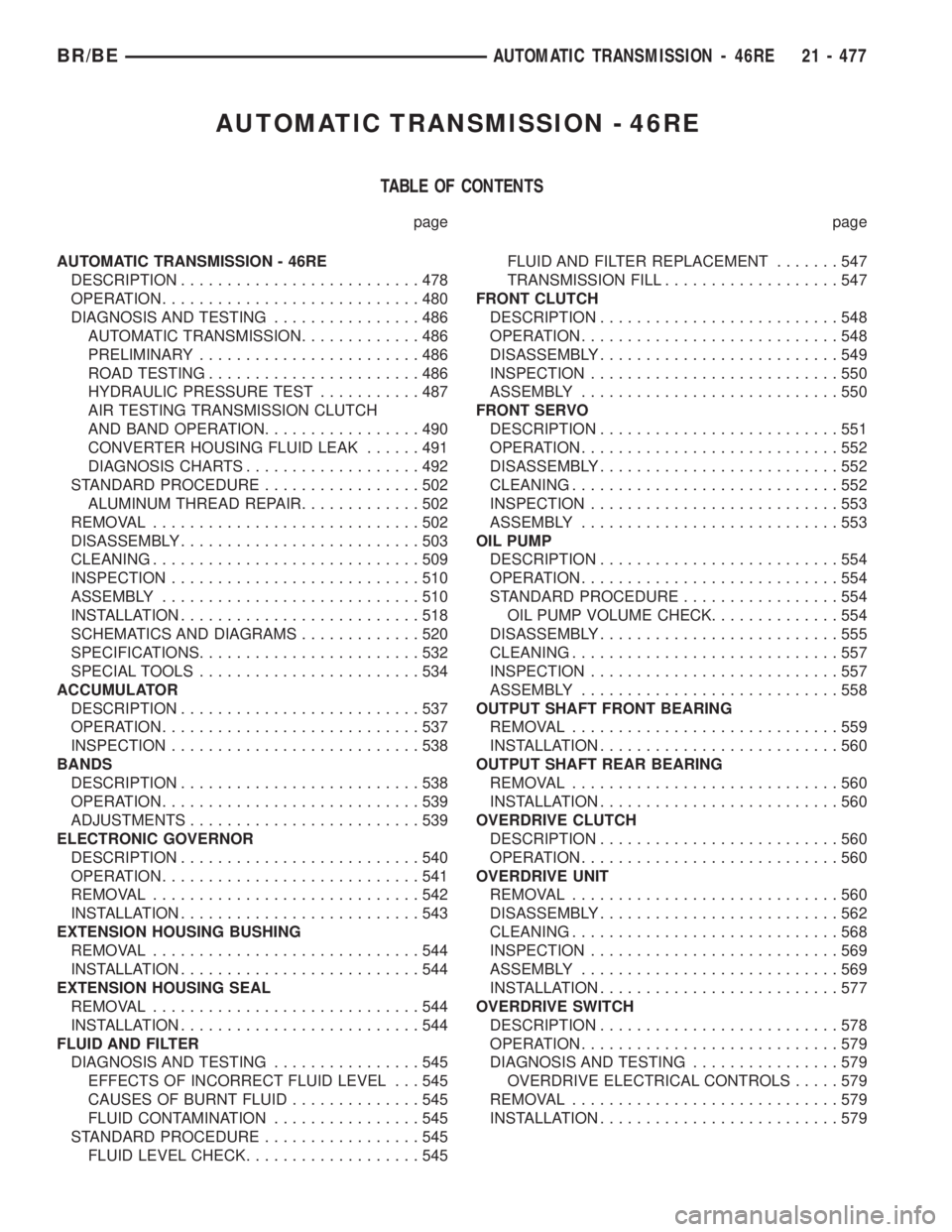

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 320).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

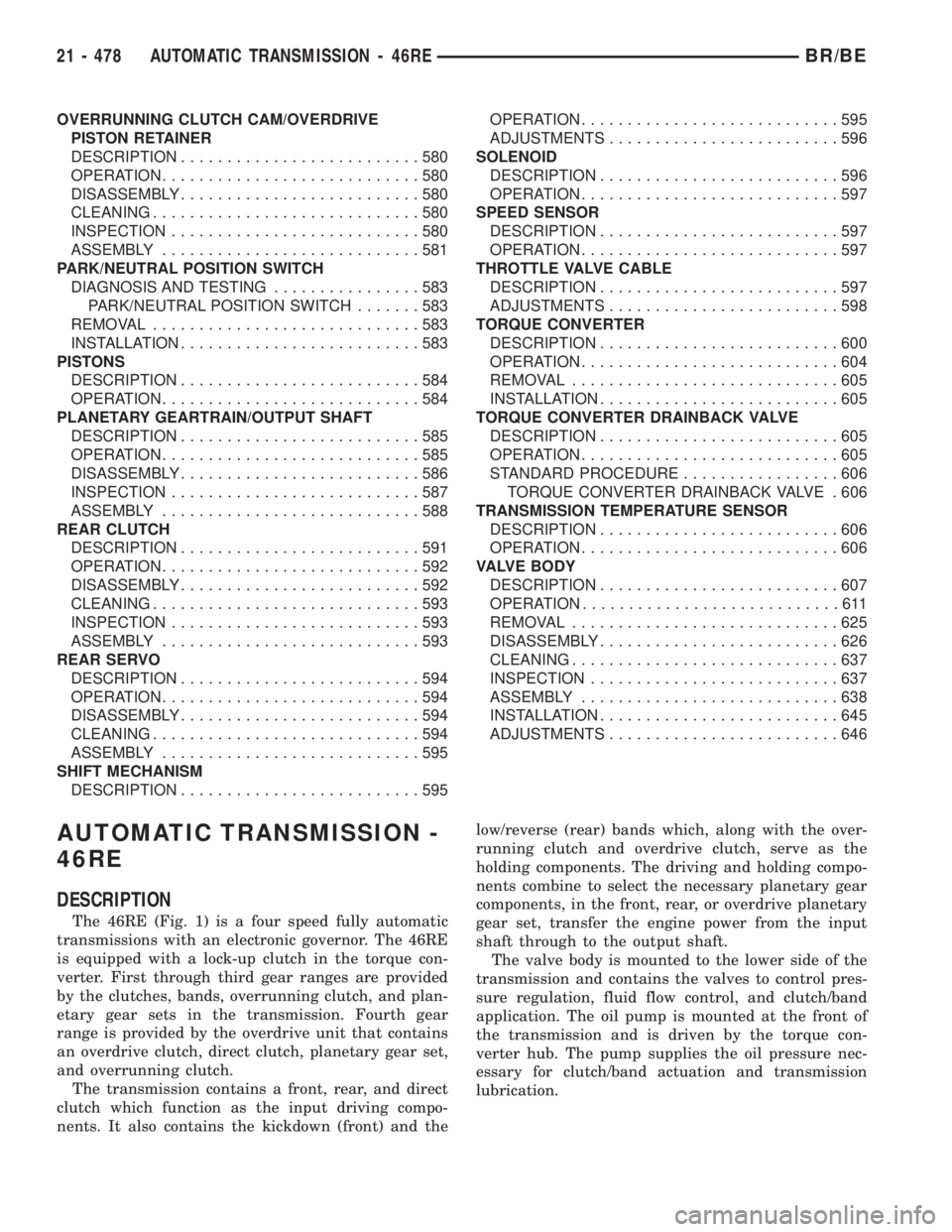

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 321).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

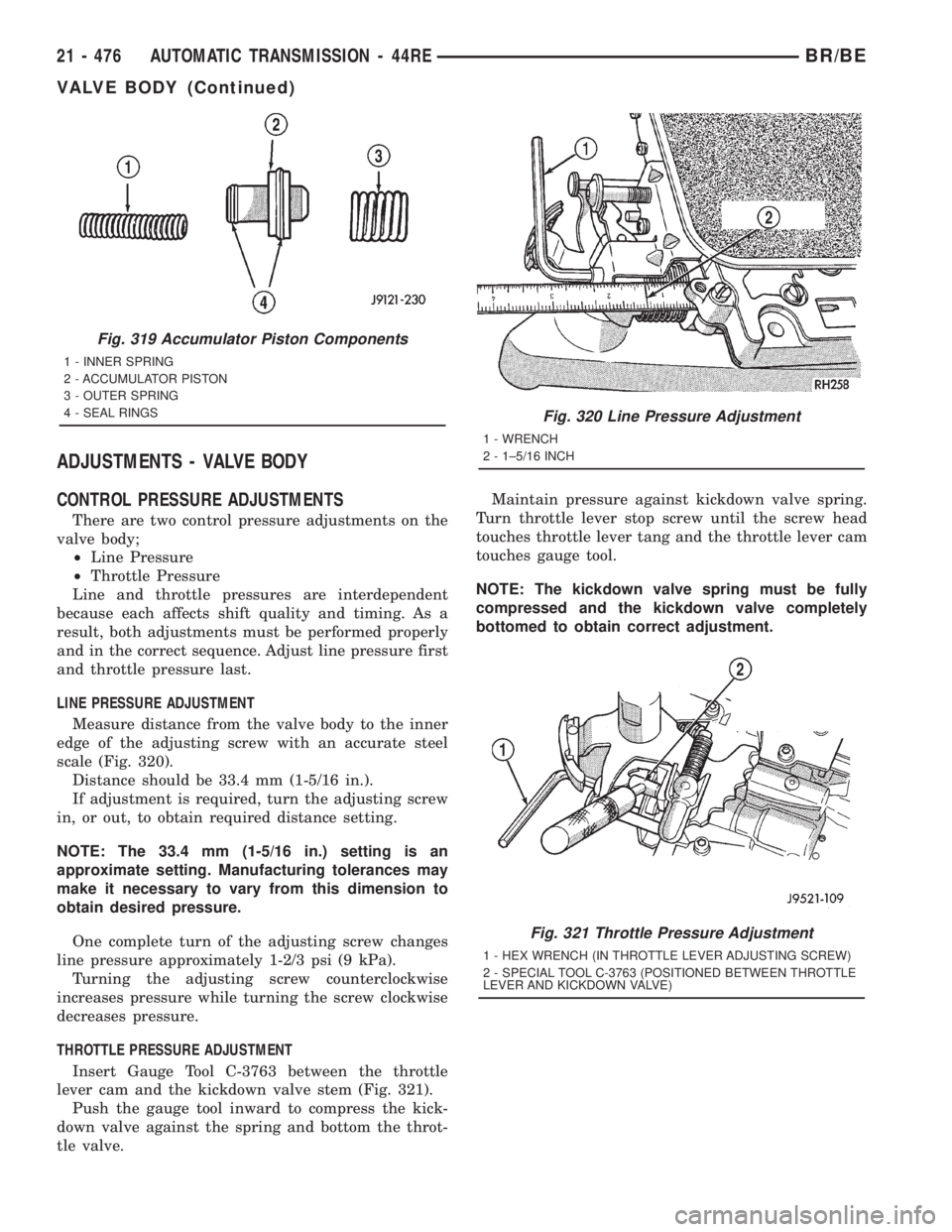

Fig. 319 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 320 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 321 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 476 AUTOMATIC TRANSMISSION - 44REBR/BE

VALVE BODY (Continued)

Page 2112 of 2889

AUTOMATIC TRANSMISSION - 46RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 46RE

DESCRIPTION..........................478

OPERATION............................480

DIAGNOSIS AND TESTING................486

AUTOMATIC TRANSMISSION.............486

PRELIMINARY........................486

ROAD TESTING.......................486

HYDRAULIC PRESSURE TEST...........487

AIR TESTING TRANSMISSION CLUTCH

AND BAND OPERATION.................490

CONVERTER HOUSING FLUID LEAK......491

DIAGNOSIS CHARTS...................492

STANDARD PROCEDURE.................502

ALUMINUM THREAD REPAIR.............502

REMOVAL.............................502

DISASSEMBLY..........................503

CLEANING.............................509

INSPECTION...........................510

ASSEMBLY............................510

INSTALLATION..........................518

SCHEMATICS AND DIAGRAMS.............520

SPECIFICATIONS........................532

SPECIAL TOOLS........................534

ACCUMULATOR

DESCRIPTION..........................537

OPERATION............................537

INSPECTION...........................538

BANDS

DESCRIPTION..........................538

OPERATION............................539

ADJUSTMENTS.........................539

ELECTRONIC GOVERNOR

DESCRIPTION..........................540

OPERATION............................541

REMOVAL.............................542

INSTALLATION..........................543

EXTENSION HOUSING BUSHING

REMOVAL.............................544

INSTALLATION..........................544

EXTENSION HOUSING SEAL

REMOVAL.............................544

INSTALLATION..........................544

FLUID AND FILTER

DIAGNOSIS AND TESTING................545

EFFECTS OF INCORRECT FLUID LEVEL . . . 545

CAUSES OF BURNT FLUID..............545

FLUID CONTAMINATION................545

STANDARD PROCEDURE.................545

FLUID LEVEL CHECK...................545FLUID AND FILTER REPLACEMENT.......547

TRANSMISSION FILL...................547

FRONT CLUTCH

DESCRIPTION..........................548

OPERATION............................548

DISASSEMBLY..........................549

INSPECTION...........................550

ASSEMBLY............................550

FRONT SERVO

DESCRIPTION..........................551

OPERATION............................552

DISASSEMBLY..........................552

CLEANING.............................552

INSPECTION...........................553

ASSEMBLY............................553

OIL PUMP

DESCRIPTION..........................554

OPERATION............................554

STANDARD PROCEDURE.................554

OIL PUMP VOLUME CHECK..............554

DISASSEMBLY..........................555

CLEANING.............................557

INSPECTION...........................557

ASSEMBLY............................558

OUTPUT SHAFT FRONT BEARING

REMOVAL.............................559

INSTALLATION..........................560

OUTPUT SHAFT REAR BEARING

REMOVAL.............................560

INSTALLATION..........................560

OVERDRIVE CLUTCH

DESCRIPTION..........................560

OPERATION............................560

OVERDRIVE UNIT

REMOVAL.............................560

DISASSEMBLY..........................562

CLEANING.............................568

INSPECTION...........................569

ASSEMBLY............................569

INSTALLATION..........................577

OVERDRIVE SWITCH

DESCRIPTION..........................578

OPERATION............................579

DIAGNOSIS AND TESTING................579

OVERDRIVE ELECTRICAL CONTROLS.....579

REMOVAL.............................579

INSTALLATION..........................579

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 477

Page 2113 of 2889

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION..........................580

OPERATION............................580

DISASSEMBLY..........................580

CLEANING.............................580

INSPECTION...........................580

ASSEMBLY............................581

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING................583

PARK/NEUTRAL POSITION SWITCH.......583

REMOVAL.............................583

INSTALLATION..........................583

PISTONS

DESCRIPTION..........................584

OPERATION............................584

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION..........................585

OPERATION............................585

DISASSEMBLY..........................586

INSPECTION...........................587

ASSEMBLY............................588

REAR CLUTCH

DESCRIPTION..........................591

OPERATION............................592

DISASSEMBLY..........................592

CLEANING.............................593

INSPECTION...........................593

ASSEMBLY............................593

REAR SERVO

DESCRIPTION..........................594

OPERATION............................594

DISASSEMBLY..........................594

CLEANING.............................594

ASSEMBLY............................595

SHIFT MECHANISM

DESCRIPTION..........................595OPERATION............................595

ADJUSTMENTS.........................596

SOLENOID

DESCRIPTION..........................596

OPERATION............................597

SPEED SENSOR

DESCRIPTION..........................597

OPERATION............................597

THROTTLE VALVE CABLE

DESCRIPTION..........................597

ADJUSTMENTS.........................598

TORQUE CONVERTER

DESCRIPTION..........................600

OPERATION............................604

REMOVAL.............................605

INSTALLATION..........................605

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION..........................605

OPERATION............................605

STANDARD PROCEDURE.................606

TORQUE CONVERTER DRAINBACK VALVE . 606

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION..........................606

OPERATION............................606

VALVE BODY

DESCRIPTION..........................607

OPERATION............................611

REMOVAL.............................625

DISASSEMBLY..........................626

CLEANING.............................637

INSPECTION...........................637

ASSEMBLY............................638

INSTALLATION..........................645

ADJUSTMENTS.........................646

AUTOMATIC TRANSMISSION -

46RE

DESCRIPTION

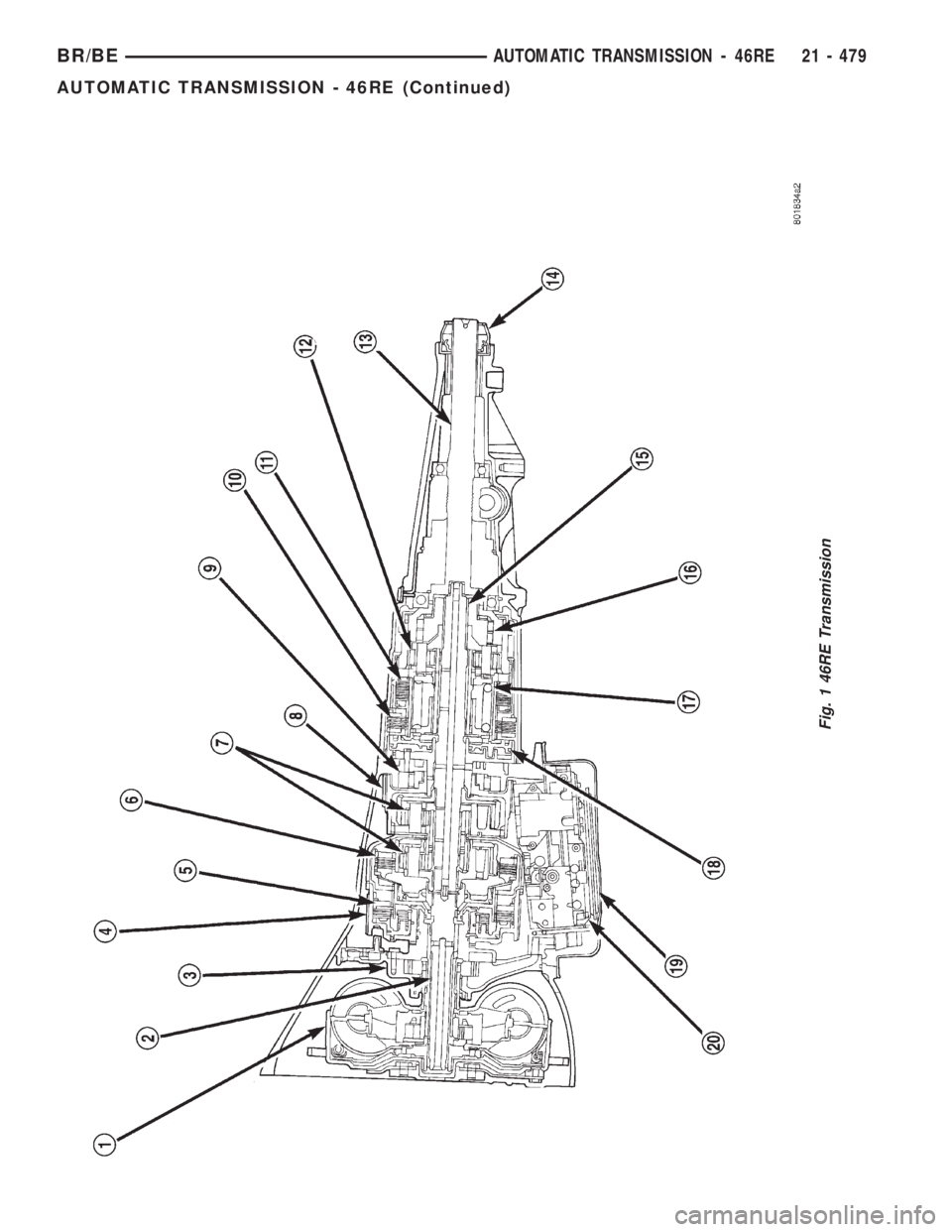

The 46RE (Fig. 1) is a four speed fully automatic

transmissions with an electronic governor. The 46RE

is equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.

The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and thelow/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

21 - 478 AUTOMATIC TRANSMISSION - 46REBR/BE

Page 2114 of 2889

Fig. 1 46RE Transmission

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 479

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2115 of 2889

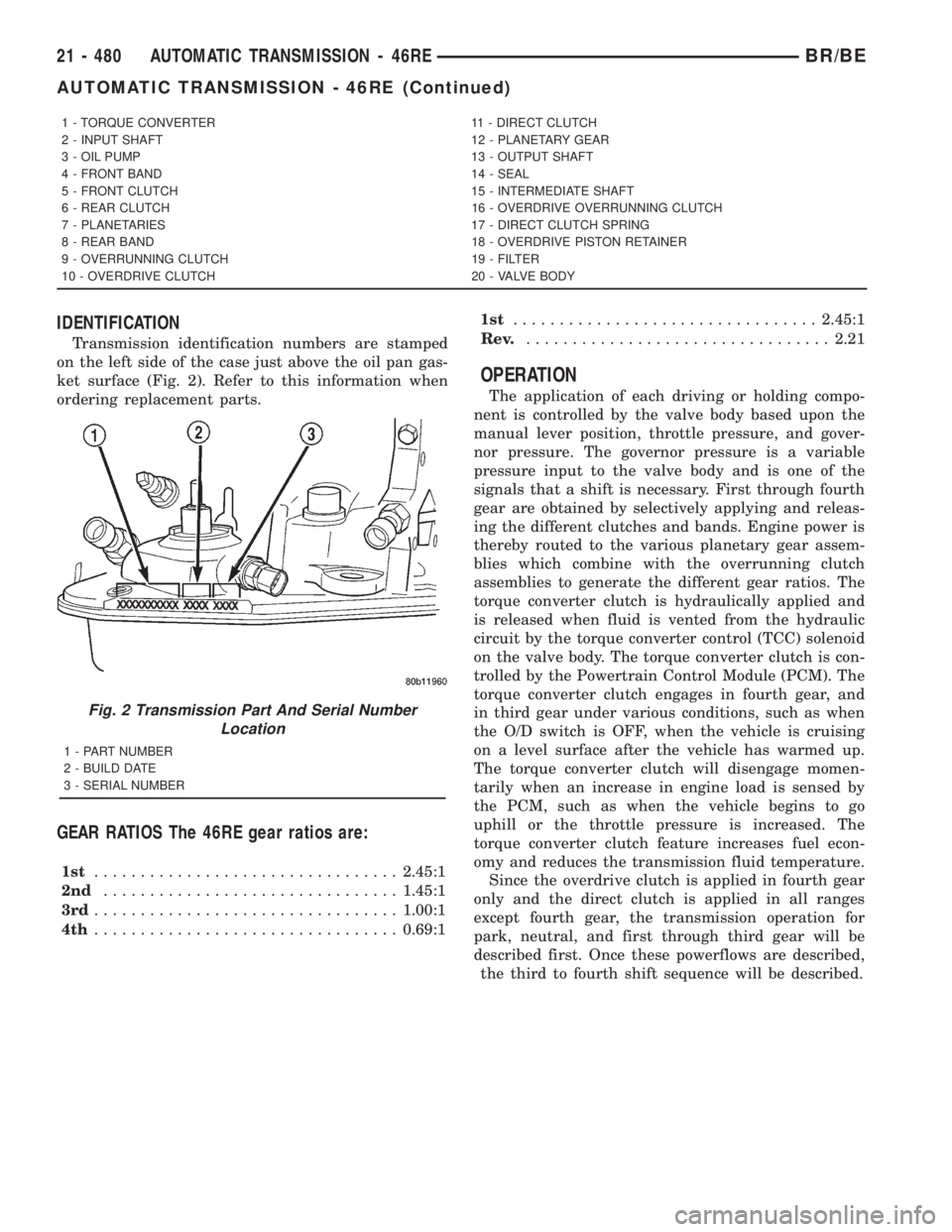

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS The 46RE gear ratios are:

1st.................................2.45:1

2nd................................1.45:1

3rd.................................1.00:1

4th.................................0.69:11st.................................2.45:1

Rev..................................2.21

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch will disengage momen-

tarily when an increase in engine load is sensed by

the PCM, such as when the vehicle begins to go

uphill or the throttle pressure is increased. The

torque converter clutch feature increases fuel econ-

omy and reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - TORQUE CONVERTER 11 - DIRECT CLUTCH

2 - INPUT SHAFT 12 - PLANETARY GEAR

3 - OIL PUMP 13 - OUTPUT SHAFT

4 - FRONT BAND 14 - SEAL

5 - FRONT CLUTCH 15 - INTERMEDIATE SHAFT

6 - REAR CLUTCH 16 - OVERDRIVE OVERRUNNING CLUTCH

7 - PLANETARIES 17 - DIRECT CLUTCH SPRING

8 - REAR BAND 18 - OVERDRIVE PISTON RETAINER

9 - OVERRUNNING CLUTCH 19 - FILTER

10 - OVERDRIVE CLUTCH 20 - VALVE BODY

Fig. 2 Transmission Part And Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

21 - 480 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2116 of 2889

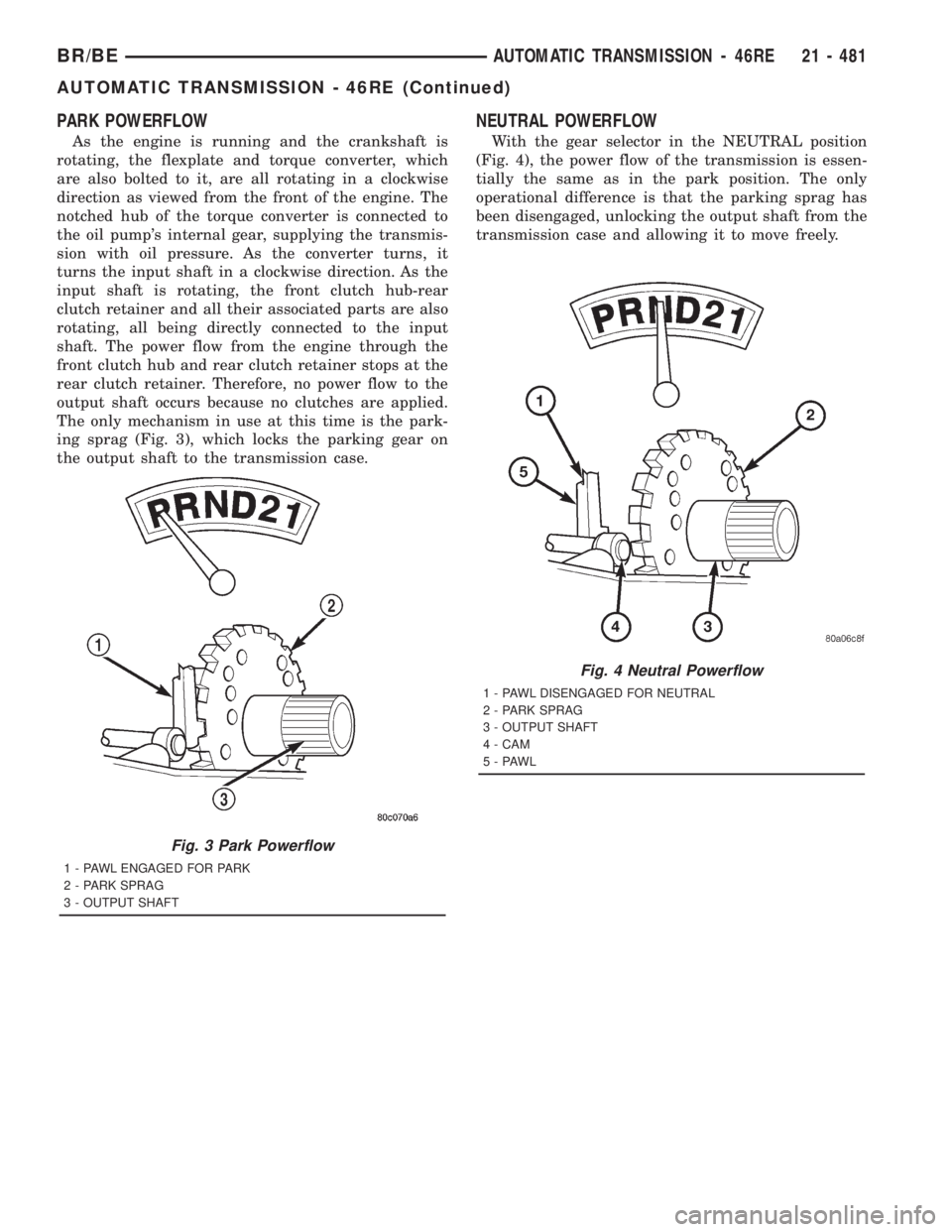

PARK POWERFLOW

As the engine is running and the crankshaft is

rotating, the flexplate and torque converter, which

are also bolted to it, are all rotating in a clockwise

direction as viewed from the front of the engine. The

notched hub of the torque converter is connected to

the oil pump's internal gear, supplying the transmis-

sion with oil pressure. As the converter turns, it

turns the input shaft in a clockwise direction. As the

input shaft is rotating, the front clutch hub-rear

clutch retainer and all their associated parts are also

rotating, all being directly connected to the input

shaft. The power flow from the engine through the

front clutch hub and rear clutch retainer stops at the

rear clutch retainer. Therefore, no power flow to the

output shaft occurs because no clutches are applied.

The only mechanism in use at this time is the park-

ing sprag (Fig. 3), which locks the parking gear on

the output shaft to the transmission case.

NEUTRAL POWERFLOW

With the gear selector in the NEUTRAL position

(Fig. 4), the power flow of the transmission is essen-

tially the same as in the park position. The only

operational difference is that the parking sprag has

been disengaged, unlocking the output shaft from the

transmission case and allowing it to move freely.

Fig. 3 Park Powerflow

1 - PAWL ENGAGED FOR PARK

2 - PARK SPRAG

3 - OUTPUT SHAFT

Fig. 4 Neutral Powerflow

1 - PAWL DISENGAGED FOR NEUTRAL

2 - PARK SPRAG

3 - OUTPUT SHAFT

4 - CAM

5-PAWL

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 481

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2117 of 2889

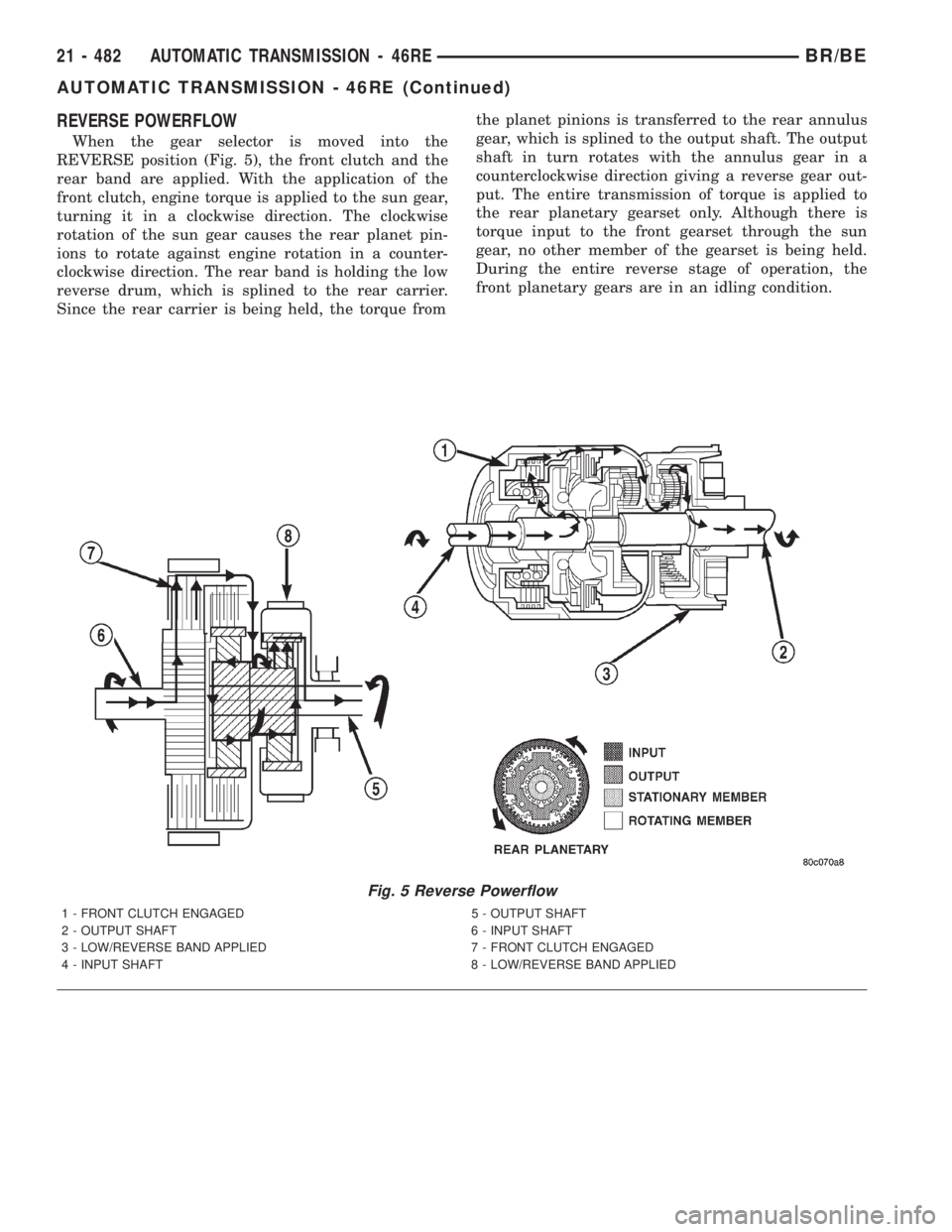

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pin-

ions to rotate against engine rotation in a counter-

clockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque fromthe planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear out-

put. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

Fig. 5 Reverse Powerflow

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

21 - 482 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2118 of 2889

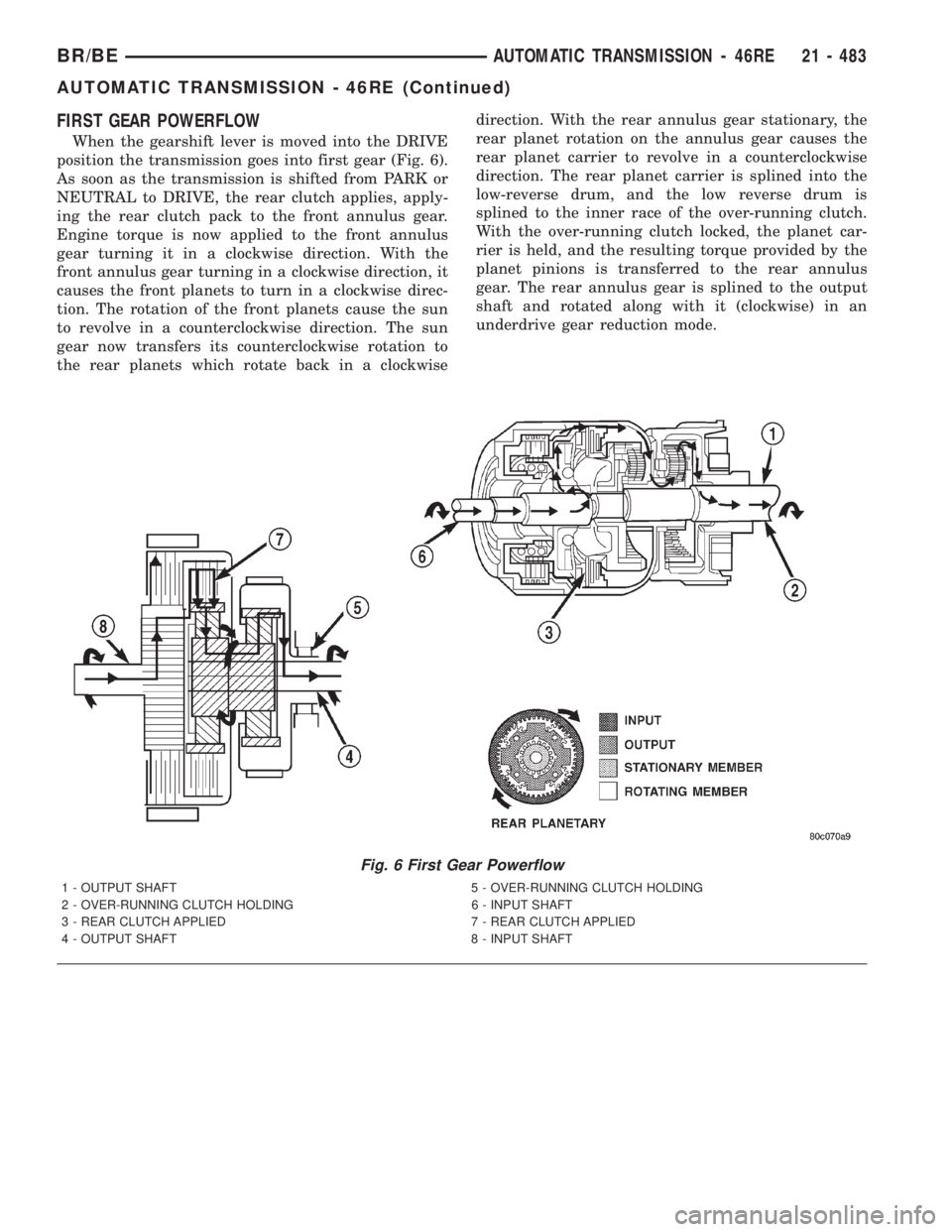

FIRST GEAR POWERFLOW

When the gearshift lever is moved into the DRIVE

position the transmission goes into first gear (Fig. 6).

As soon as the transmission is shifted from PARK or

NEUTRAL to DRIVE, the rear clutch applies, apply-

ing the rear clutch pack to the front annulus gear.

Engine torque is now applied to the front annulus

gear turning it in a clockwise direction. With the

front annulus gear turning in a clockwise direction, it

causes the front planets to turn in a clockwise direc-

tion. The rotation of the front planets cause the sun

to revolve in a counterclockwise direction. The sun

gear now transfers its counterclockwise rotation to

the rear planets which rotate back in a clockwisedirection. With the rear annulus gear stationary, the

rear planet rotation on the annulus gear causes the

rear planet carrier to revolve in a counterclockwise

direction. The rear planet carrier is splined into the

low-reverse drum, and the low reverse drum is

splined to the inner race of the over-running clutch.

With the over-running clutch locked, the planet car-

rier is held, and the resulting torque provided by the

planet pinions is transferred to the rear annulus

gear. The rear annulus gear is splined to the output

shaft and rotated along with it (clockwise) in an

underdrive gear reduction mode.

Fig. 6 First Gear Powerflow

1 - OUTPUT SHAFT 5 - OVER-RUNNING CLUTCH HOLDING

2 - OVER-RUNNING CLUTCH HOLDING 6 - INPUT SHAFT

3 - REAR CLUTCH APPLIED 7 - REAR CLUTCH APPLIED

4 - OUTPUT SHAFT 8 - INPUT SHAFT

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 483

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2119 of 2889

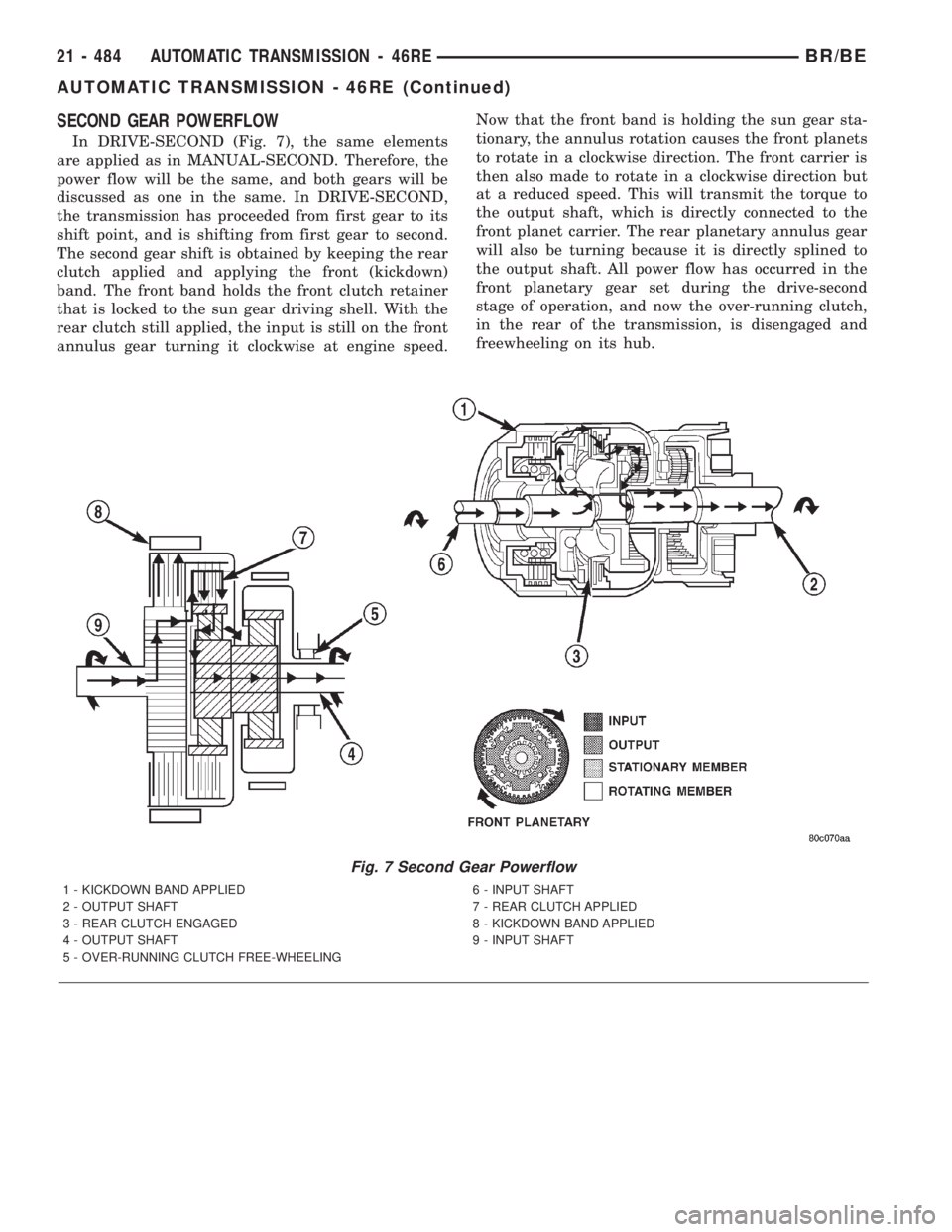

SECOND GEAR POWERFLOW

In DRIVE-SECOND (Fig. 7), the same elements

are applied as in MANUAL-SECOND. Therefore, the

power flow will be the same, and both gears will be

discussed as one in the same. In DRIVE-SECOND,

the transmission has proceeded from first gear to its

shift point, and is shifting from first gear to second.

The second gear shift is obtained by keeping the rear

clutch applied and applying the front (kickdown)

band. The front band holds the front clutch retainer

that is locked to the sun gear driving shell. With the

rear clutch still applied, the input is still on the front

annulus gear turning it clockwise at engine speed.Now that the front band is holding the sun gear sta-

tionary, the annulus rotation causes the front planets

to rotate in a clockwise direction. The front carrier is

then also made to rotate in a clockwise direction but

at a reduced speed. This will transmit the torque to

the output shaft, which is directly connected to the

front planet carrier. The rear planetary annulus gear

will also be turning because it is directly splined to

the output shaft. All power flow has occurred in the

front planetary gear set during the drive-second

stage of operation, and now the over-running clutch,

in the rear of the transmission, is disengaged and

freewheeling on its hub.

Fig. 7 Second Gear Powerflow

1 - KICKDOWN BAND APPLIED 6 - INPUT SHAFT

2 - OUTPUT SHAFT 7 - REAR CLUTCH APPLIED

3 - REAR CLUTCH ENGAGED 8 - KICKDOWN BAND APPLIED

4 - OUTPUT SHAFT 9 - INPUT SHAFT

5 - OVER-RUNNING CLUTCH FREE-WHEELING

21 - 484 AUTOMATIC TRANSMISSION - 46REBR/BE

AUTOMATIC TRANSMISSION - 46RE (Continued)

Page 2120 of 2889

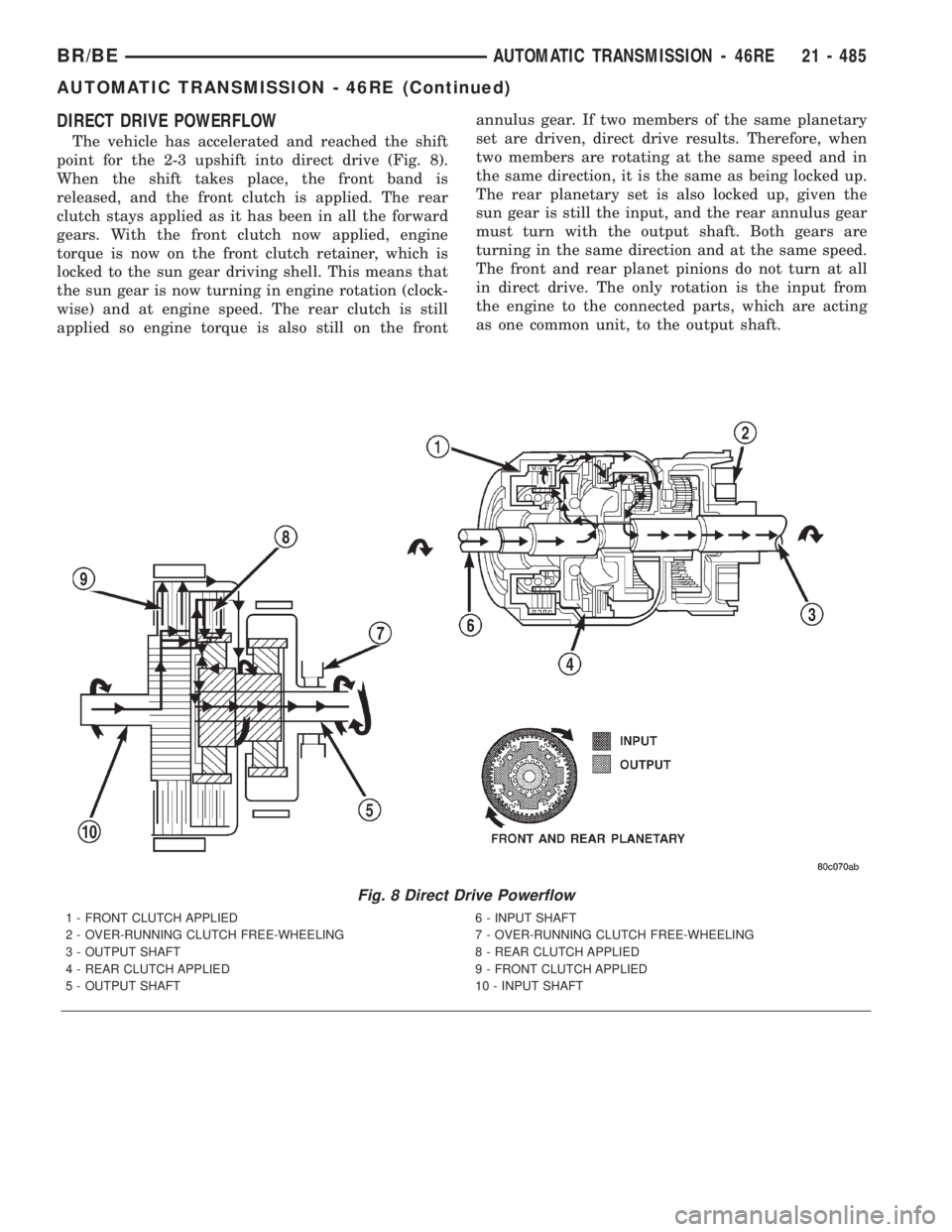

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift

point for the 2-3 upshift into direct drive (Fig. 8).

When the shift takes place, the front band is

released, and the front clutch is applied. The rear

clutch stays applied as it has been in all the forward

gears. With the front clutch now applied, engine

torque is now on the front clutch retainer, which is

locked to the sun gear driving shell. This means that

the sun gear is now turning in engine rotation (clock-

wise) and at engine speed. The rear clutch is still

applied so engine torque is also still on the frontannulus gear. If two members of the same planetary

set are driven, direct drive results. Therefore, when

two members are rotating at the same speed and in

the same direction, it is the same as being locked up.

The rear planetary set is also locked up, given the

sun gear is still the input, and the rear annulus gear

must turn with the output shaft. Both gears are

turning in the same direction and at the same speed.

The front and rear planet pinions do not turn at all

in direct drive. The only rotation is the input from

the engine to the connected parts, which are acting

as one common unit, to the output shaft.

Fig. 8 Direct Drive Powerflow

1 - FRONT CLUTCH APPLIED 6 - INPUT SHAFT

2 - OVER-RUNNING CLUTCH FREE-WHEELING 7 - OVER-RUNNING CLUTCH FREE-WHEELING

3 - OUTPUT SHAFT 8 - REAR CLUTCH APPLIED

4 - REAR CLUTCH APPLIED 9 - FRONT CLUTCH APPLIED

5 - OUTPUT SHAFT 10 - INPUT SHAFT

BR/BEAUTOMATIC TRANSMISSION - 46RE 21 - 485

AUTOMATIC TRANSMISSION - 46RE (Continued)