warning DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2687 of 2889

opening upper reinforcement. Tighten the screws to

2.2 N´m (20 in. lbs.).

(3) Reinstall the trim onto the upper glove box

opening. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/GLOVE BOX OPENING UPPER TRIM -

INSTALLATION).

(4) Reconnect the battery negative cable.

GLOVE BOX OPENING UPPER

TRIM

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Open the glove box.

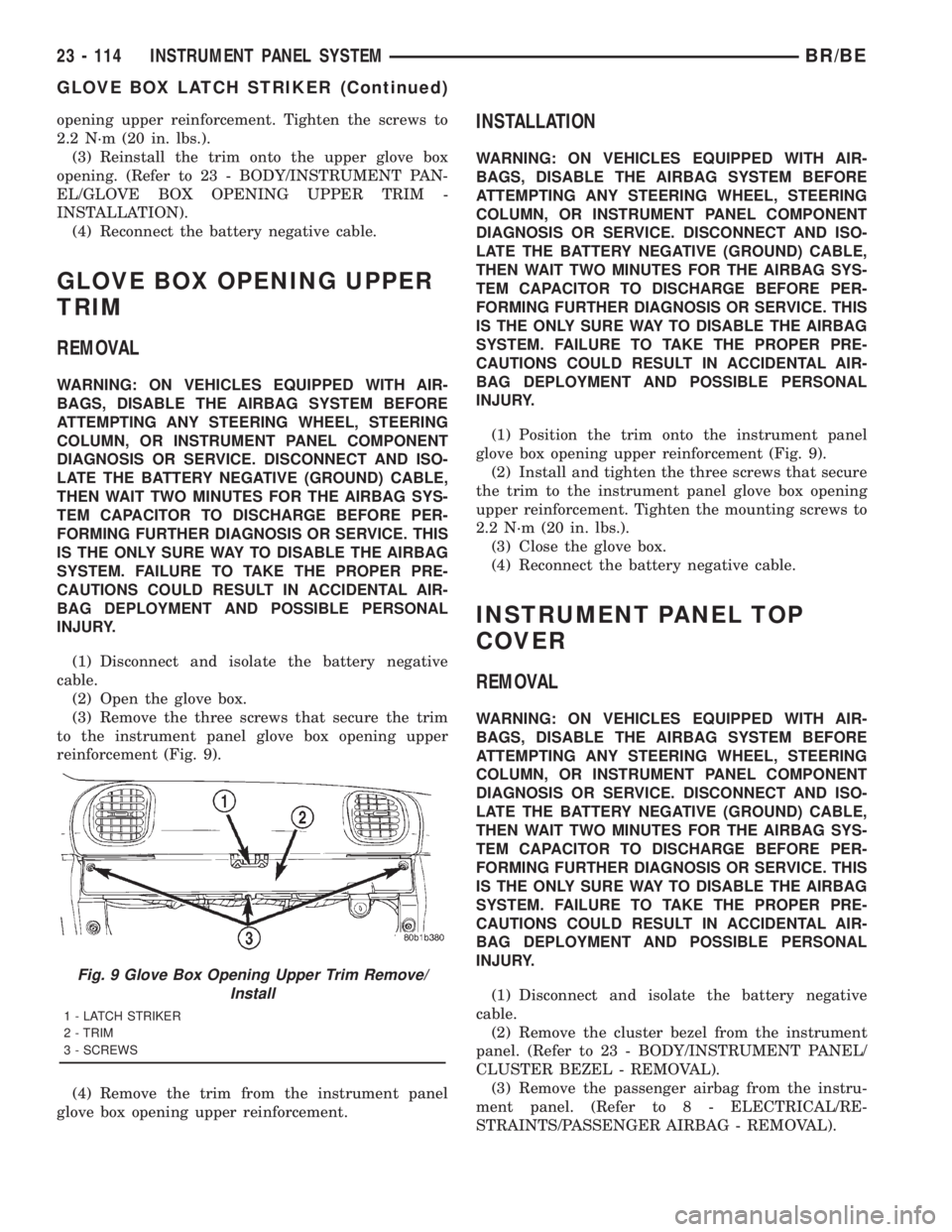

(3) Remove the three screws that secure the trim

to the instrument panel glove box opening upper

reinforcement (Fig. 9).

(4) Remove the trim from the instrument panel

glove box opening upper reinforcement.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the trim onto the instrument panel

glove box opening upper reinforcement (Fig. 9).

(2) Install and tighten the three screws that secure

the trim to the instrument panel glove box opening

upper reinforcement. Tighten the mounting screws to

2.2 N´m (20 in. lbs.).

(3) Close the glove box.

(4) Reconnect the battery negative cable.

INSTRUMENT PANEL TOP

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(3) Remove the passenger airbag from the instru-

ment panel. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/PASSENGER AIRBAG - REMOVAL).

Fig. 9 Glove Box Opening Upper Trim Remove/

Install

1 - LATCH STRIKER

2 - TRIM

3 - SCREWS

23 - 114 INSTRUMENT PANEL SYSTEMBR/BE

GLOVE BOX LATCH STRIKER (Continued)

Page 2688 of 2889

(4) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(5) Place the instrument panel on a suitable work

surface. Be certain to take the proper precautions to

protect the instrument panel from any possible cos-

metic damage.

(6) Remove the screws around the perimeter of the

top cover that secure it to the instrument panel

structural support, the defroster duct, and the demis-

ter ducts.

(7) Lift the top cover off of the instrument panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the top cover onto the instrument

panel.

(2) Install and tighten the screws around the

perimeter of the top cover that secure it to the

instrument panel structural support, the defroster

duct, and the demister ducts. Tighten the screws to

2.2 N´m (20 in. lbs.).

(3) Reinstall the instrument panel into the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

INSTALLATION).

(4) Reinstall the passenger airbag into the instru-

ment panel. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/PASSENGER AIRBAG -

INSTALLATION).

(5) Reinstall the cluster bezel onto the instrument

panel.(Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(6) Reconnect the battery negative cable.

STEERING COLUMN OPENING

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

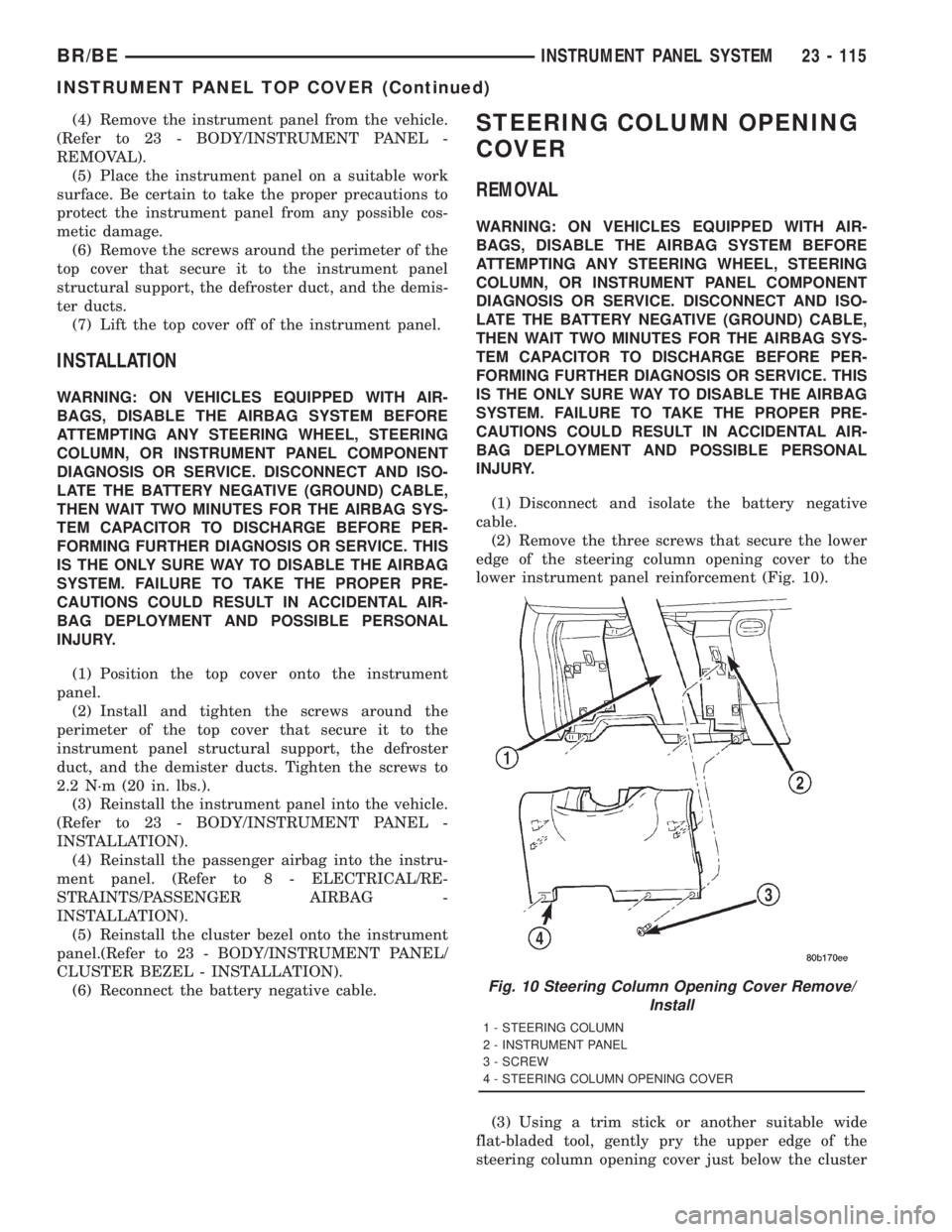

(2) Remove the three screws that secure the lower

edge of the steering column opening cover to the

lower instrument panel reinforcement (Fig. 10).

(3) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the upper edge of the

steering column opening cover just below the cluster

Fig. 10 Steering Column Opening Cover Remove/

Install

1 - STEERING COLUMN

2 - INSTRUMENT PANEL

3 - SCREW

4 - STEERING COLUMN OPENING COVER

BR/BEINSTRUMENT PANEL SYSTEM 23 - 115

INSTRUMENT PANEL TOP COVER (Continued)

Page 2689 of 2889

bezel on each side of the steering column away from

the instrument panel far enough to disengage the

snap clip retainers from their receptacles in the

instrument panel.

(4) Remove the steering column opening cover

from the instrument panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the steering column opening cover to

the instrument panel (Fig. 10).

(2) Align the snap clip retainers on the steering

column opening cover with their receptacles in the

instrument panel.

(3) Press firmly and evenly on the steering column

opening cover over the snap clip locations until each

of the snap clips is fully engaged in its receptacle.

(4) Install and tighten the three screws that secure

the lower edge of the steering column opening cover

to the lower instrument panel reinforcement. Tighten

the screws to 2.2 N´m (20 in. lbs.).

(5) Reconnect the battery negative cable.

STORAGE BIN

REMOVAL

Vehicles equipped with an automatic transmission

have a lighted fold-down cup holder installed on the

instrument panel just inboard of the glove box. Vehi-

cles equipped with a manual transmission have a

lighted storage bin installed on the instrument panel

in place of the fold-down cup holder.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

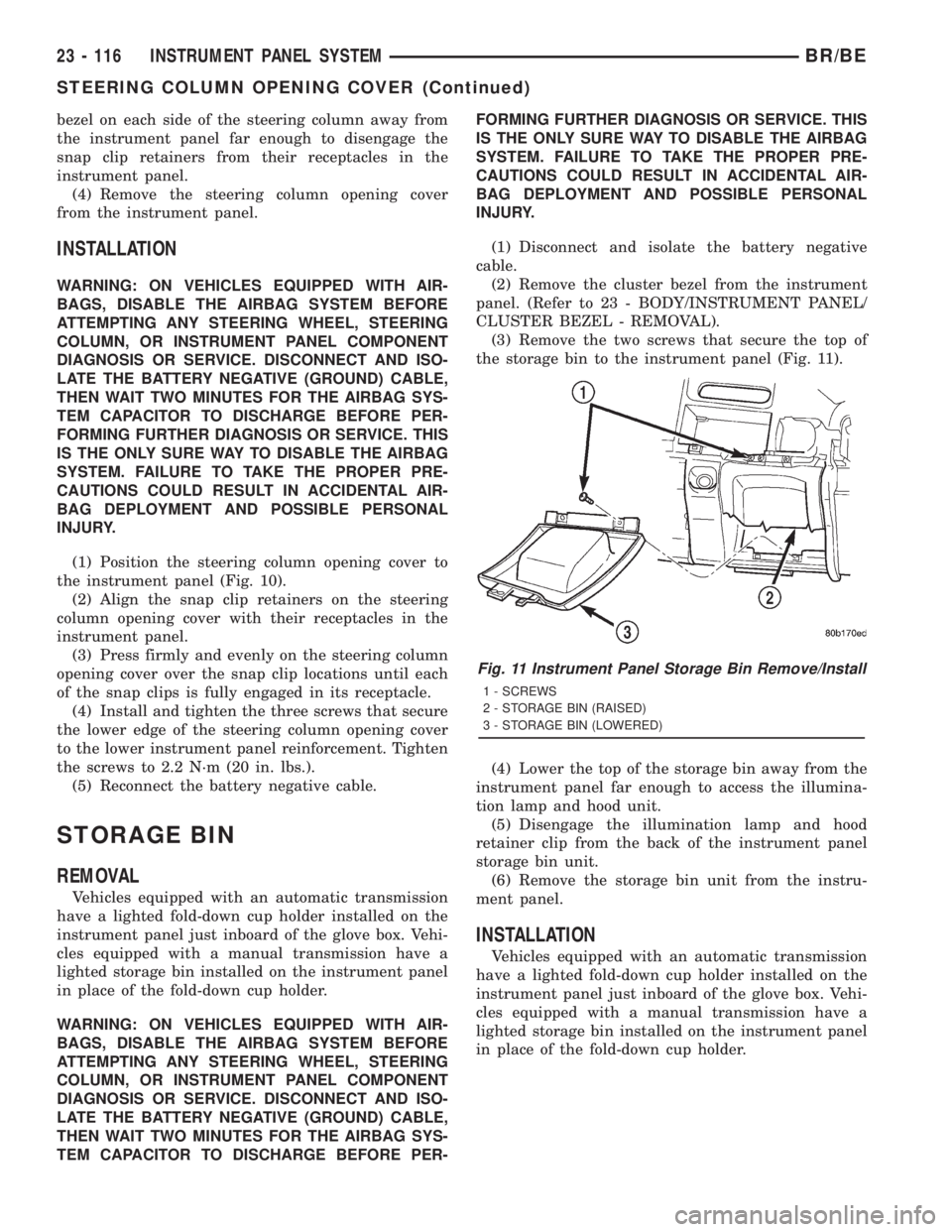

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(3) Remove the two screws that secure the top of

the storage bin to the instrument panel (Fig. 11).

(4) Lower the top of the storage bin away from the

instrument panel far enough to access the illumina-

tion lamp and hood unit.

(5) Disengage the illumination lamp and hood

retainer clip from the back of the instrument panel

storage bin unit.

(6) Remove the storage bin unit from the instru-

ment panel.

INSTALLATION

Vehicles equipped with an automatic transmission

have a lighted fold-down cup holder installed on the

instrument panel just inboard of the glove box. Vehi-

cles equipped with a manual transmission have a

lighted storage bin installed on the instrument panel

in place of the fold-down cup holder.

Fig. 11 Instrument Panel Storage Bin Remove/Install

1 - SCREWS

2 - STORAGE BIN (RAISED)

3 - STORAGE BIN (LOWERED)

23 - 116 INSTRUMENT PANEL SYSTEMBR/BE

STEERING COLUMN OPENING COVER (Continued)

Page 2690 of 2889

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Position the storage bin unit onto the instru-

ment panel (Fig. 11).

(2) Engage the illumination lamp and hood

retainer clip to the back of the instrument panel stor-

age bin unit.

(3) Raise and position the top of the storage bin to

the instrument panel.

(4) Install and tighten the two screws that secure

the top of the storage bin unit to the instrument

panel. Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Reinstall the cluster bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - INSTALLATION).

(6) Reconnect the battery negative cable.

BR/BEINSTRUMENT PANEL SYSTEM 23 - 117

STORAGE BIN (Continued)

Page 2703 of 2889

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

OPERATION

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with Moparž Tar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

WET SANDING/BUFFING &

POLISHING

DESCRIPTION

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light finesse sanding, hand buffing, and polish-

ing.If the finish has been finesse sanded in the

past, it cannot be repeated. Finesse sanding

operation should be performed by a trained

automotive paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

23 - 130 PAINTBR/BE

PAINT TOUCH-UP (Continued)

Page 2709 of 2889

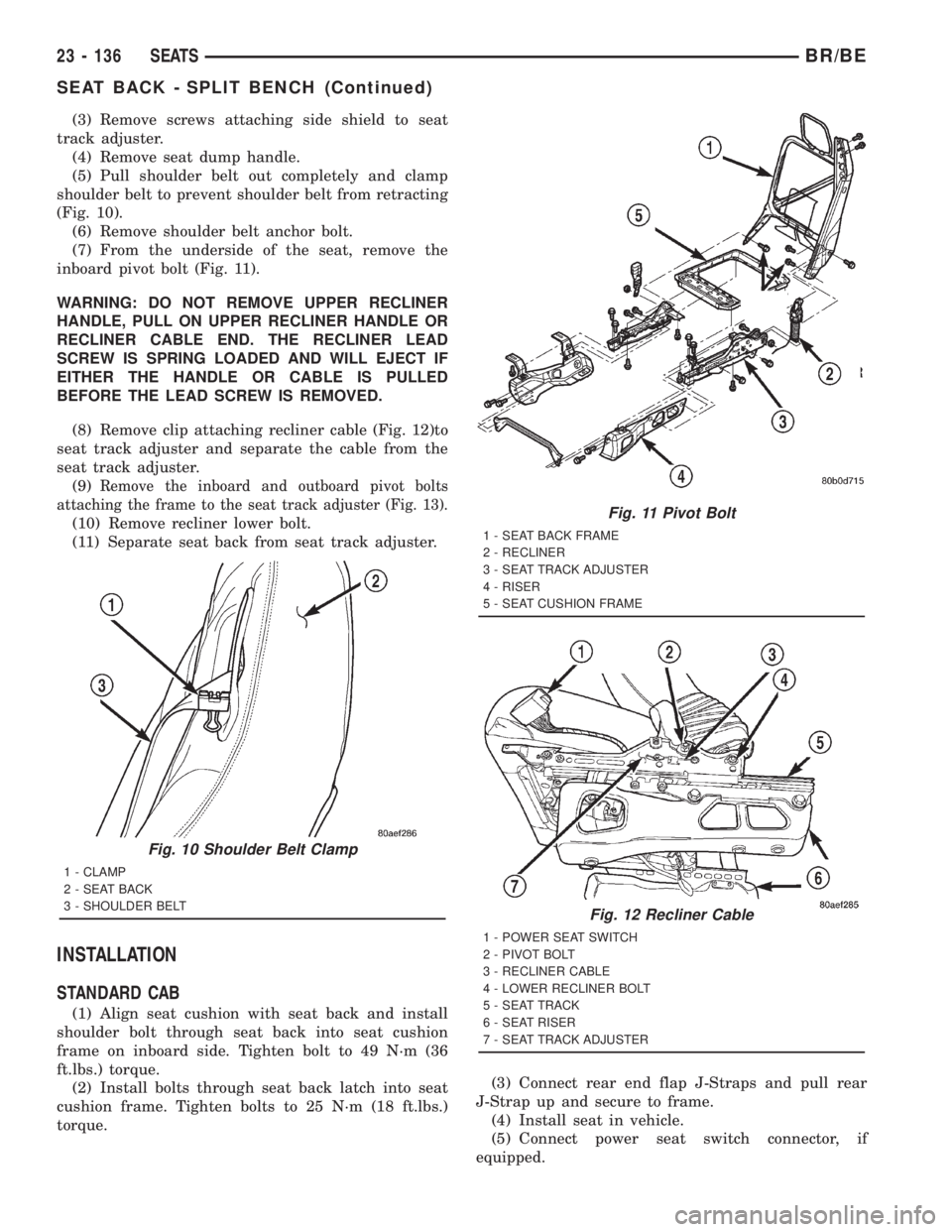

(3) Remove screws attaching side shield to seat

track adjuster.

(4) Remove seat dump handle.

(5) Pull shoulder belt out completely and clamp

shoulder belt to prevent shoulder belt from retracting

(Fig. 10).

(6) Remove shoulder belt anchor bolt.

(7) From the underside of the seat, remove the

inboard pivot bolt (Fig. 11).

WARNING: DO NOT REMOVE UPPER RECLINER

HANDLE, PULL ON UPPER RECLINER HANDLE OR

RECLINER CABLE END. THE RECLINER LEAD

SCREW IS SPRING LOADED AND WILL EJECT IF

EITHER THE HANDLE OR CABLE IS PULLED

BEFORE THE LEAD SCREW IS REMOVED.

(8) Remove clip attaching recliner cable (Fig. 12)to

seat track adjuster and separate the cable from the

seat track adjuster.

(9)

Remove the inboard and outboard pivot bolts

attaching the frame to the seat track adjuster (Fig. 13).

(10) Remove recliner lower bolt.

(11) Separate seat back from seat track adjuster.

INSTALLATION

STANDARD CAB

(1) Align seat cushion with seat back and install

shoulder bolt through seat back into seat cushion

frame on inboard side. Tighten bolt to 49 N´m (36

ft.lbs.) torque.

(2) Install bolts through seat back latch into seat

cushion frame. Tighten bolts to 25 N´m (18 ft.lbs.)

torque.(3) Connect rear end flap J-Straps and pull rear

J-Strap up and secure to frame.

(4) Install seat in vehicle.

(5) Connect power seat switch connector, if

equipped.

Fig. 10 Shoulder Belt Clamp

1 - CLAMP

2 - SEAT BACK

3 - SHOULDER BELT

Fig. 11 Pivot Bolt

1 - SEAT BACK FRAME

2 - RECLINER

3 - SEAT TRACK ADJUSTER

4 - RISER

5 - SEAT CUSHION FRAME

Fig. 12 Recliner Cable

1 - POWER SEAT SWITCH

2 - PIVOT BOLT

3 - RECLINER CABLE

4 - LOWER RECLINER BOLT

5 - SEAT TRACK

6 - SEAT RISER

7 - SEAT TRACK ADJUSTER

23 - 136 SEATSBR/BE

SEAT BACK - SPLIT BENCH (Continued)

Page 2711 of 2889

(7) With seat back in a normal vertical position,

roll cover upwards and remove.

INSTALLATION

(1) With seat back in a normal vertical position,

roll cover downwards over seat back.

(2) Install hog rings, if equipped.

(3) Engage J-Straps at base of seat back.

(4) Align lumbar handle with lumbar cam and tap

on with rubber mallet until seated.

(5) Install latch release bezel.

(6) Install latch release knob.

(7) Install seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - INSTALLATION)

SEAT BACK RECLINER

REMOVAL

(1) Remove seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - REMOVAL)

(2) Disengage J-straps at base of seat back and

roll seat back cover upward to access rubber bellows

push-in fasteners.

NOTE: Notice the routing of the recliner cable for

installation.

(3) Remove the push-in fasteners attaching upper

rubber bellows to the seat back frame.

(4) Remove rubber bellows.

(5) Remove seat dump handle, 2±door ªBEº vehi-

cles only.

WARNING: Do not pull on upper recliner handle or

recliner cable end. The recliner lead screw is spring

loaded and will eject if either the handle or cable is

pulled before the lead screw is removed.

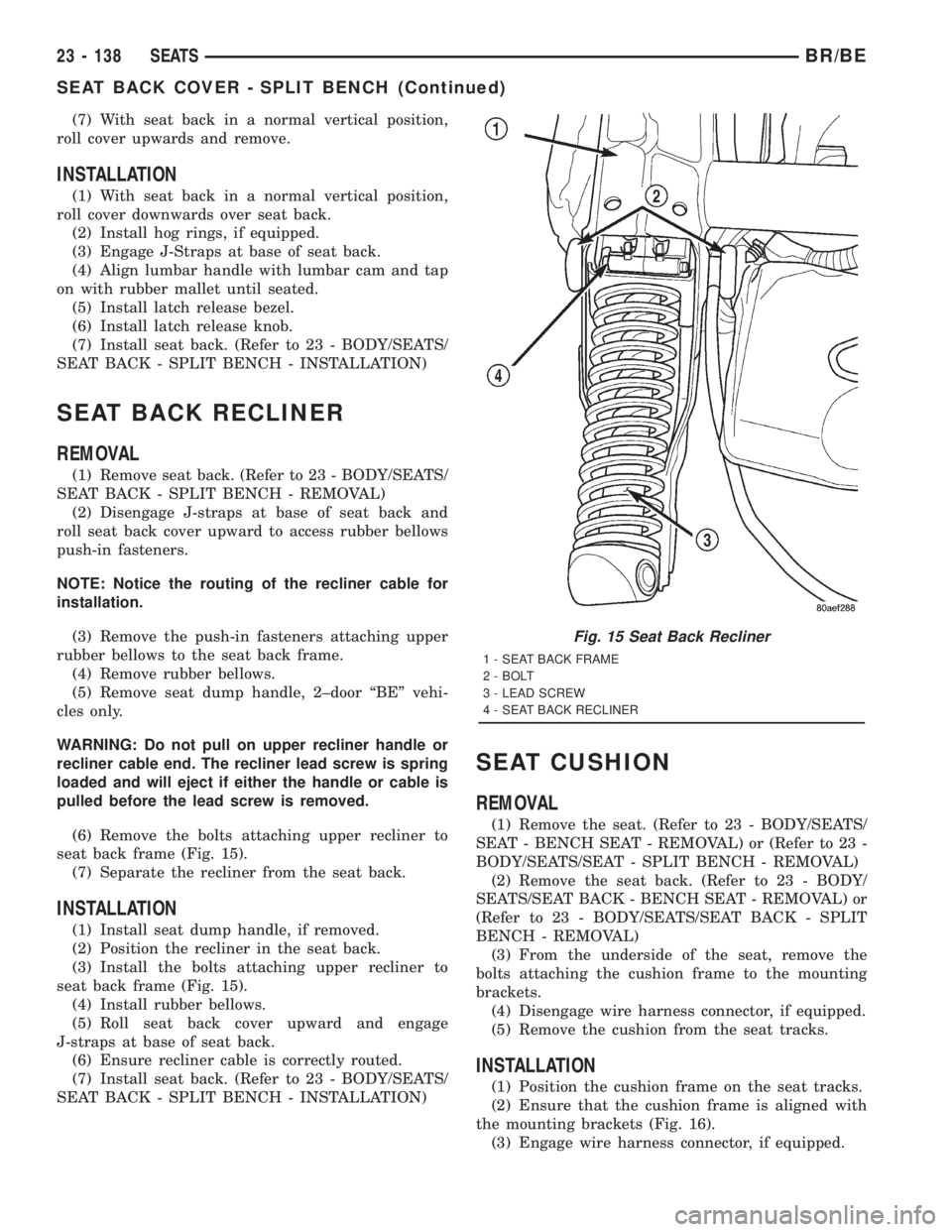

(6) Remove the bolts attaching upper recliner to

seat back frame (Fig. 15).

(7) Separate the recliner from the seat back.

INSTALLATION

(1) Install seat dump handle, if removed.

(2) Position the recliner in the seat back.

(3) Install the bolts attaching upper recliner to

seat back frame (Fig. 15).

(4) Install rubber bellows.

(5) Roll seat back cover upward and engage

J-straps at base of seat back.

(6) Ensure recliner cable is correctly routed.

(7) Install seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - INSTALLATION)

SEAT CUSHION

REMOVAL

(1) Remove the seat. (Refer to 23 - BODY/SEATS/

SEAT - BENCH SEAT - REMOVAL) or (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - REMOVAL)

(2) Remove the seat back. (Refer to 23 - BODY/

SEATS/SEAT BACK - BENCH SEAT - REMOVAL) or

(Refer to 23 - BODY/SEATS/SEAT BACK - SPLIT

BENCH - REMOVAL)

(3) From the underside of the seat, remove the

bolts attaching the cushion frame to the mounting

brackets.

(4) Disengage wire harness connector, if equipped.

(5) Remove the cushion from the seat tracks.

INSTALLATION

(1) Position the cushion frame on the seat tracks.

(2) Ensure that the cushion frame is aligned with

the mounting brackets (Fig. 16).

(3) Engage wire harness connector, if equipped.

Fig. 15 Seat Back Recliner

1 - SEAT BACK FRAME

2 - BOLT

3 - LEAD SCREW

4 - SEAT BACK RECLINER

23 - 138 SEATSBR/BE

SEAT BACK COVER - SPLIT BENCH (Continued)

Page 2716 of 2889

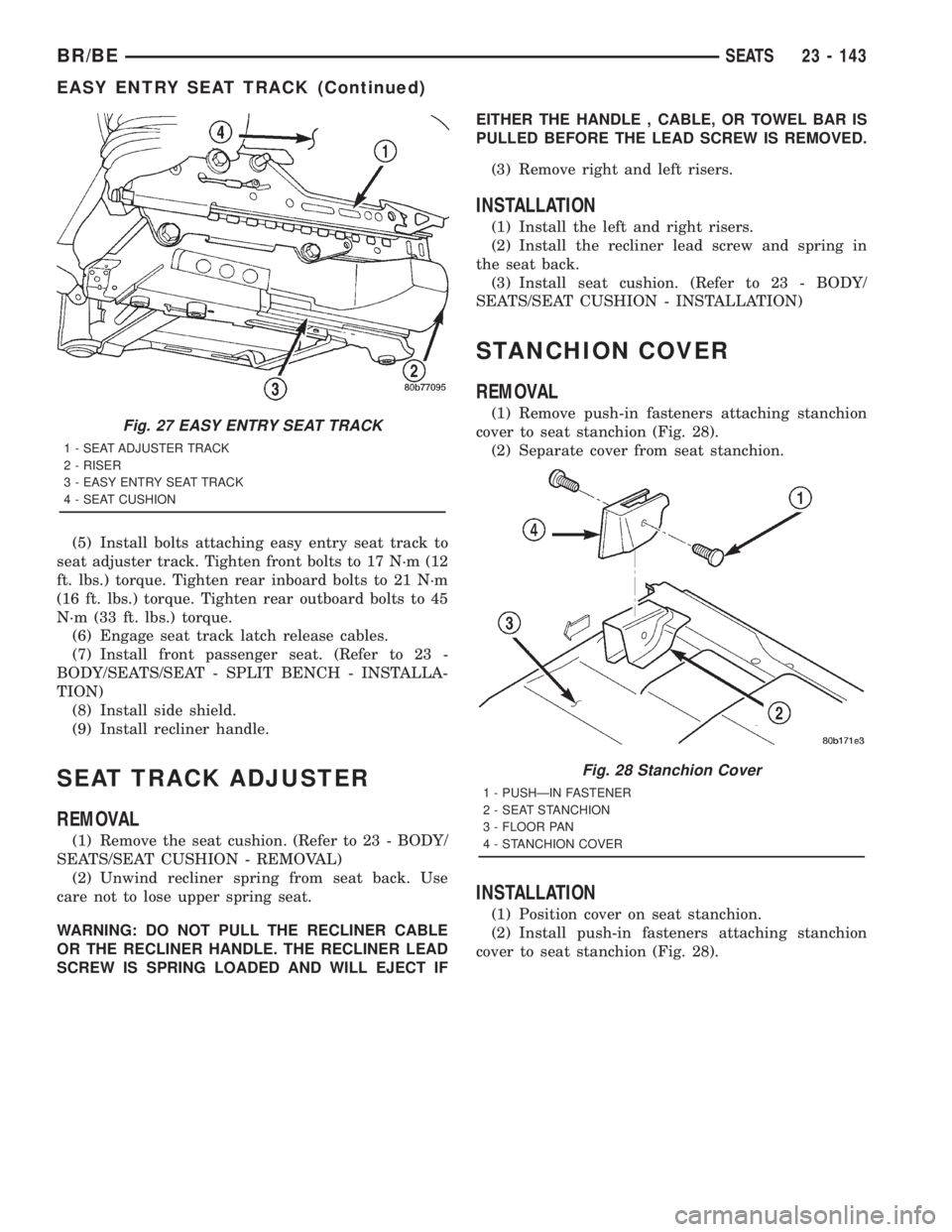

(5) Install bolts attaching easy entry seat track to

seat adjuster track. Tighten front bolts to 17 N´m (12

ft. lbs.) torque. Tighten rear inboard bolts to 21 N´m

(16 ft. lbs.) torque. Tighten rear outboard bolts to 45

N´m (33 ft. lbs.) torque.

(6) Engage seat track latch release cables.

(7) Install front passenger seat. (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - INSTALLA-

TION)

(8) Install side shield.

(9) Install recliner handle.

SEAT TRACK ADJUSTER

REMOVAL

(1) Remove the seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - REMOVAL)

(2) Unwind recliner spring from seat back. Use

care not to lose upper spring seat.

WARNING: DO NOT PULL THE RECLINER CABLE

OR THE RECLINER HANDLE. THE RECLINER LEAD

SCREW IS SPRING LOADED AND WILL EJECT IFEITHER THE HANDLE , CABLE, OR TOWEL BAR IS

PULLED BEFORE THE LEAD SCREW IS REMOVED.

(3) Remove right and left risers.

INSTALLATION

(1) Install the left and right risers.

(2) Install the recliner lead screw and spring in

the seat back.

(3) Install seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - INSTALLATION)

STANCHION COVER

REMOVAL

(1) Remove push-in fasteners attaching stanchion

cover to seat stanchion (Fig. 28).

(2) Separate cover from seat stanchion.

INSTALLATION

(1) Position cover on seat stanchion.

(2) Install push-in fasteners attaching stanchion

cover to seat stanchion (Fig. 28).

Fig. 27 EASY ENTRY SEAT TRACK

1 - SEAT ADJUSTER TRACK

2 - RISER

3 - EASY ENTRY SEAT TRACK

4 - SEAT CUSHION

Fig. 28 Stanchion Cover

1 - PUSHÐIN FASTENER

2 - SEAT STANCHION

3 - FLOOR PAN

4 - STANCHION COVER

BR/BESEATS 23 - 143

EASY ENTRY SEAT TRACK (Continued)

Page 2721 of 2889

WINDSHIELD

DESCRIPTION

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCH WELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

DAIMLERCHRYSLER DOES NOT RECOMMEND

GLASS ADHESIVE BY BRAND. TECHNICIANS

SHOULD REVIEW PRODUCT LABELS AND TECHNI-

CAL DATA SHEETS, AND USE ONLY ADHESIVES

THAT THEIR MANUFACTURES WARRANT WILL

RESTORE A VEHICLE TO THE REQUIREMENTS OF

FMVSS 212. TECHNICIANS SHOULD ALSO INSURE

THAT PRIMERS AND CLEANERS ARE COMPATIBLE

WITH THE PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

OPERATION

The windshield is attached to the window frame

with urethane adhesive. The urethane adhesive is

applied cold and seals the surface area between the

window opening and the glass. The primer adheres

the urethane adhesive to the windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficultto cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL

(1) Remove inside rear view mirror. (Refer to 23 -

BODY/INTERIOR/REAR VIEW MIRROR - REMOV-

AL).

(2) Remove cowl grill. (Refer to 23 - BODY/EXTE-

RIOR/COWL GRILLE - REMOVAL).

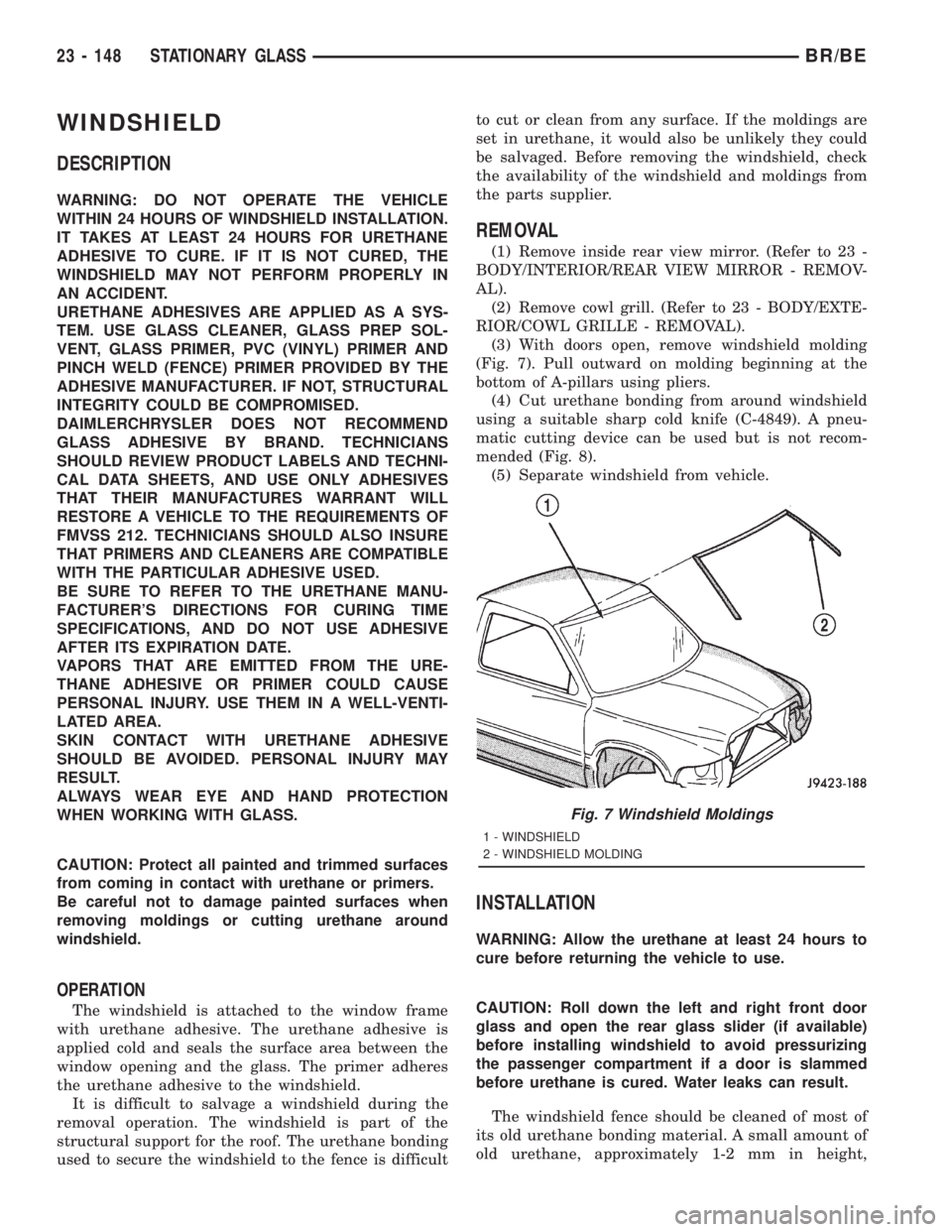

(3) With doors open, remove windshield molding

(Fig. 7). Pull outward on molding beginning at the

bottom of A-pillars using pliers.

(4) Cut urethane bonding from around windshield

using a suitable sharp cold knife (C-4849). A pneu-

matic cutting device can be used but is not recom-

mended (Fig. 8).

(5) Separate windshield from vehicle.

INSTALLATION

WARNING: Allow the urethane at least 24 hours to

cure before returning the vehicle to use.

CAUTION: Roll down the left and right front door

glass and open the rear glass slider (if available)

before installing windshield to avoid pressurizing

the passenger compartment if a door is slammed

before urethane is cured. Water leaks can result.

The windshield fence should be cleaned of most of

its old urethane bonding material. A small amount of

old urethane, approximately 1-2 mm in height,

Fig. 7 Windshield Moldings

1 - WINDSHIELD

2 - WINDSHIELD MOLDING

23 - 148 STATIONARY GLASSBR/BE

Page 2731 of 2889

heated air. This air conditioning system uses a fixed ori-

fice tube in the middle of the liquid line to meter refrig-

erant flow to the evaporator coil. To maintain minimum

evaporator temperature and prevent evaporator freez-

ing, the a/c low pressure switch on the accumulator

cycles the compressor clutch.

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line between the condenser and the evaporator,

near the front of the engine compartment. The low

pressure service port is located on the suction line,

near the accumulator outlet.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low humidity air. The evaporator, located in the

HVAC housing on the dash panel below the instru-

ment panel, is cooled to temperatures near the freez-

ing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator tubes and the moisture

in the air condenses on the evaporator fins. During

periods of high heat and humidity, an air condition-

ing system will be more effective in the recirculation

mode (Max-A/C). With the system in the recirculation

mode, only air from the passenger compartment

passes through the evaporator. As the passenger com-

partment air dehumidifies, the air conditioning sys-

tem performance levels improve.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature of

the moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from theirair conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

Before proceeding, (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). The air temperature in

the test room and in the vehicle must be a minimum

of 21É C (70É F) for this test.

(1)

Connect a tachometer and a manifold gauge set.

(2) Set the a/c heater mode control switch knob to

the recirculation mode (Max-A/C) position, the tem-

perature control knob to the full cool position, and

the blower motor switch to the highest speed posi-

tion.

(3) Start the engine and hold the idle speed at

1,000 rpm with the compressor clutch engaged. If the

compressor clutch does not engage, (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

COMPRESSOR CLUTCH COIL - DIAGNOSIS AND

TESTING).

(4) The engine should be at operating temperature.

The doors and windows must be closed and the hood

must be mostly closed.

(5)

Insert a thermometer in the driver side center

A/C (panel) outlet. Operate the engine for five minutes.

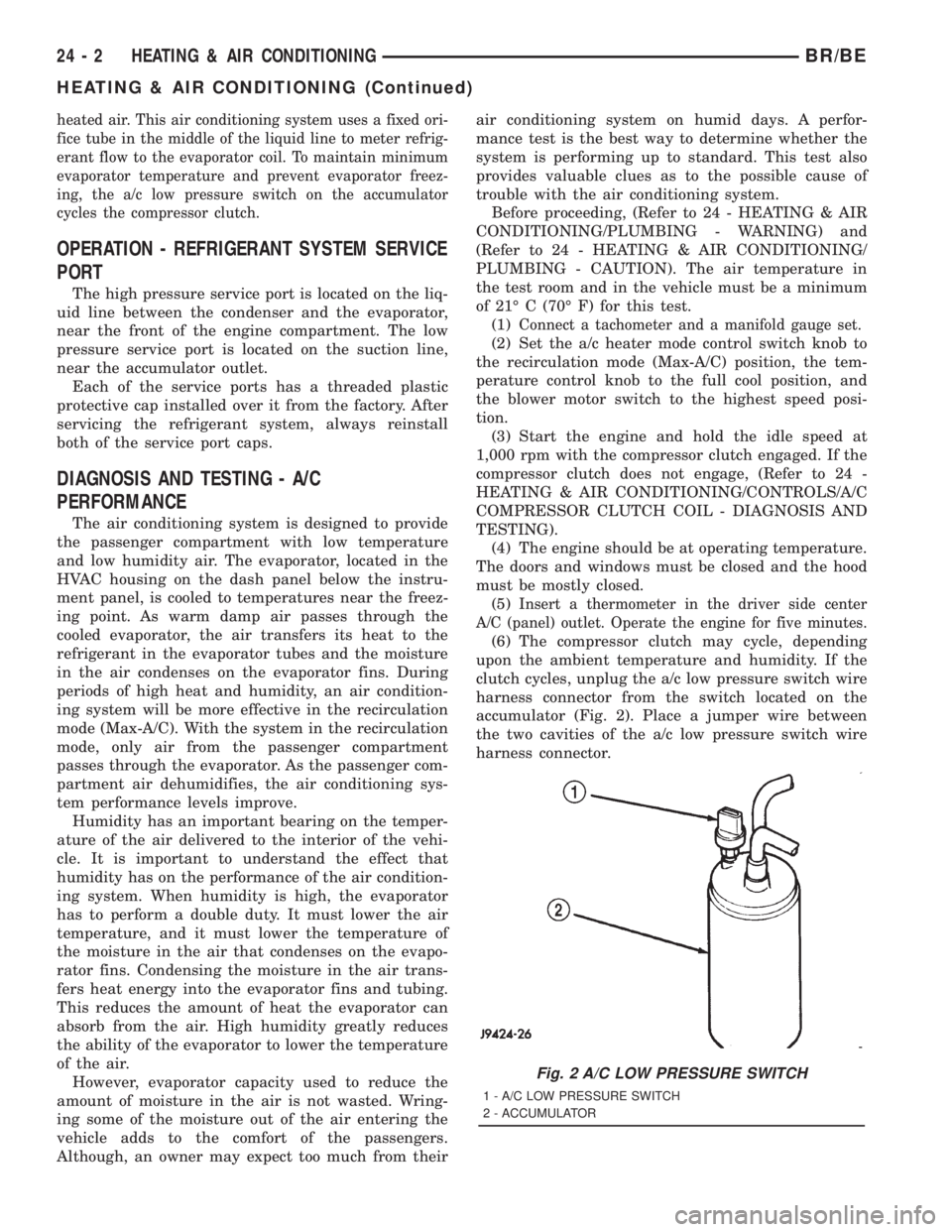

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity. If the

clutch cycles, unplug the a/c low pressure switch wire

harness connector from the switch located on the

accumulator (Fig. 2). Place a jumper wire between

the two cavities of the a/c low pressure switch wire

harness connector.

Fig. 2 A/C LOW PRESSURE SWITCH

1 - A/C LOW PRESSURE SWITCH

2 - ACCUMULATOR

24 - 2 HEATING & AIR CONDITIONINGBR/BE

HEATING & AIR CONDITIONING (Continued)