tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1912 of 2889

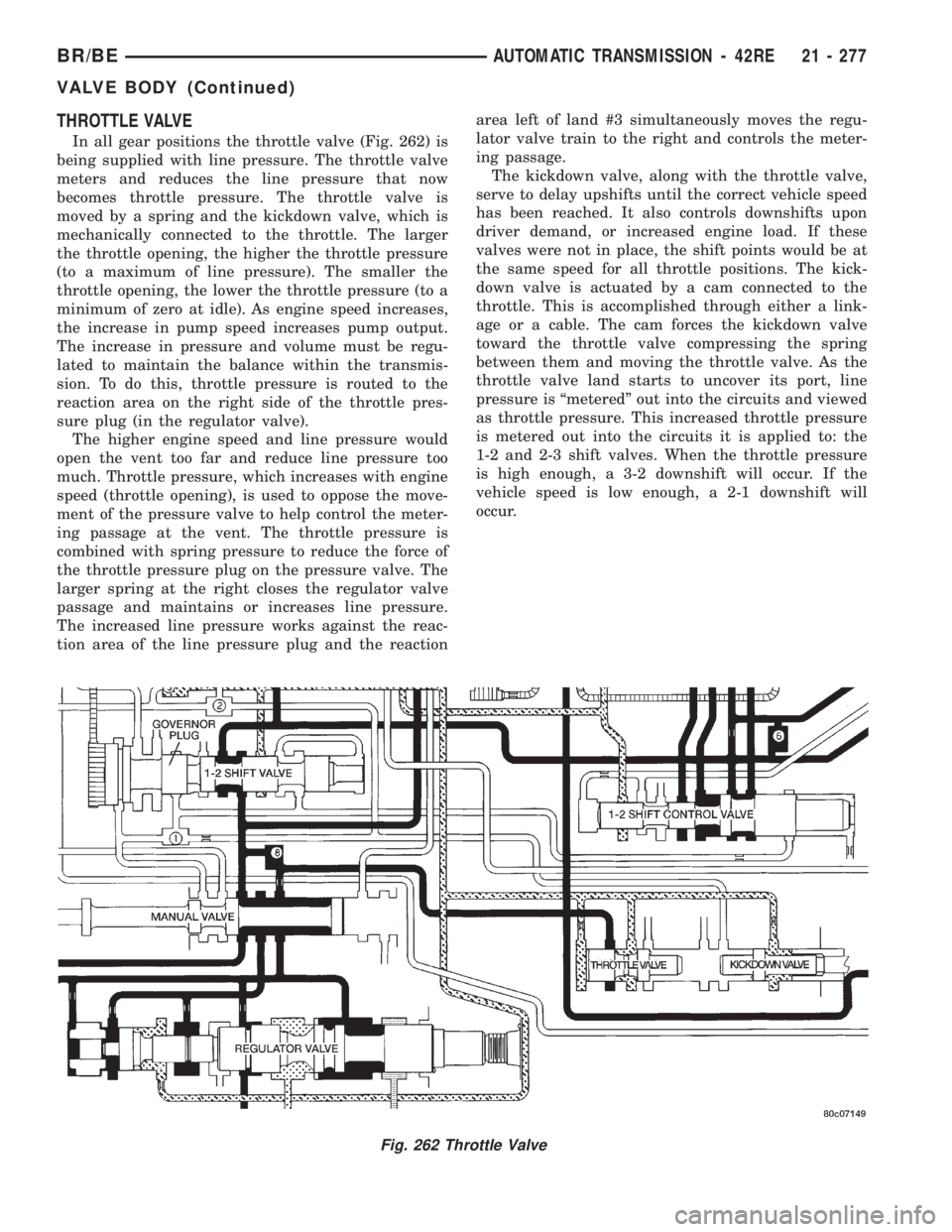

THROTTLE VALVE

In all gear positions the throttle valve (Fig. 262) is

being supplied with line pressure. The throttle valve

meters and reduces the line pressure that now

becomes throttle pressure. The throttle valve is

moved by a spring and the kickdown valve, which is

mechanically connected to the throttle. The larger

the throttle opening, the higher the throttle pressure

(to a maximum of line pressure). The smaller the

throttle opening, the lower the throttle pressure (to a

minimum of zero at idle). As engine speed increases,

the increase in pump speed increases pump output.

The increase in pressure and volume must be regu-

lated to maintain the balance within the transmis-

sion. To do this, throttle pressure is routed to the

reaction area on the right side of the throttle pres-

sure plug (in the regulator valve).

The higher engine speed and line pressure would

open the vent too far and reduce line pressure too

much. Throttle pressure, which increases with engine

speed (throttle opening), is used to oppose the move-

ment of the pressure valve to help control the meter-

ing passage at the vent. The throttle pressure is

combined with spring pressure to reduce the force of

the throttle pressure plug on the pressure valve. The

larger spring at the right closes the regulator valve

passage and maintains or increases line pressure.

The increased line pressure works against the reac-

tion area of the line pressure plug and the reactionarea left of land #3 simultaneously moves the regu-

lator valve train to the right and controls the meter-

ing passage.

The kickdown valve, along with the throttle valve,

serve to delay upshifts until the correct vehicle speed

has been reached. It also controls downshifts upon

driver demand, or increased engine load. If these

valves were not in place, the shift points would be at

the same speed for all throttle positions. The kick-

down valve is actuated by a cam connected to the

throttle. This is accomplished through either a link-

age or a cable. The cam forces the kickdown valve

toward the throttle valve compressing the spring

between them and moving the throttle valve. As the

throttle valve land starts to uncover its port, line

pressure is ªmeteredº out into the circuits and viewed

as throttle pressure. This increased throttle pressure

is metered out into the circuits it is applied to: the

1-2 and 2-3 shift valves. When the throttle pressure

is high enough, a 3-2 downshift will occur. If the

vehicle speed is low enough, a 2-1 downshift will

occur.

Fig. 262 Throttle Valve

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 277

VALVE BODY (Continued)

Page 1928 of 2889

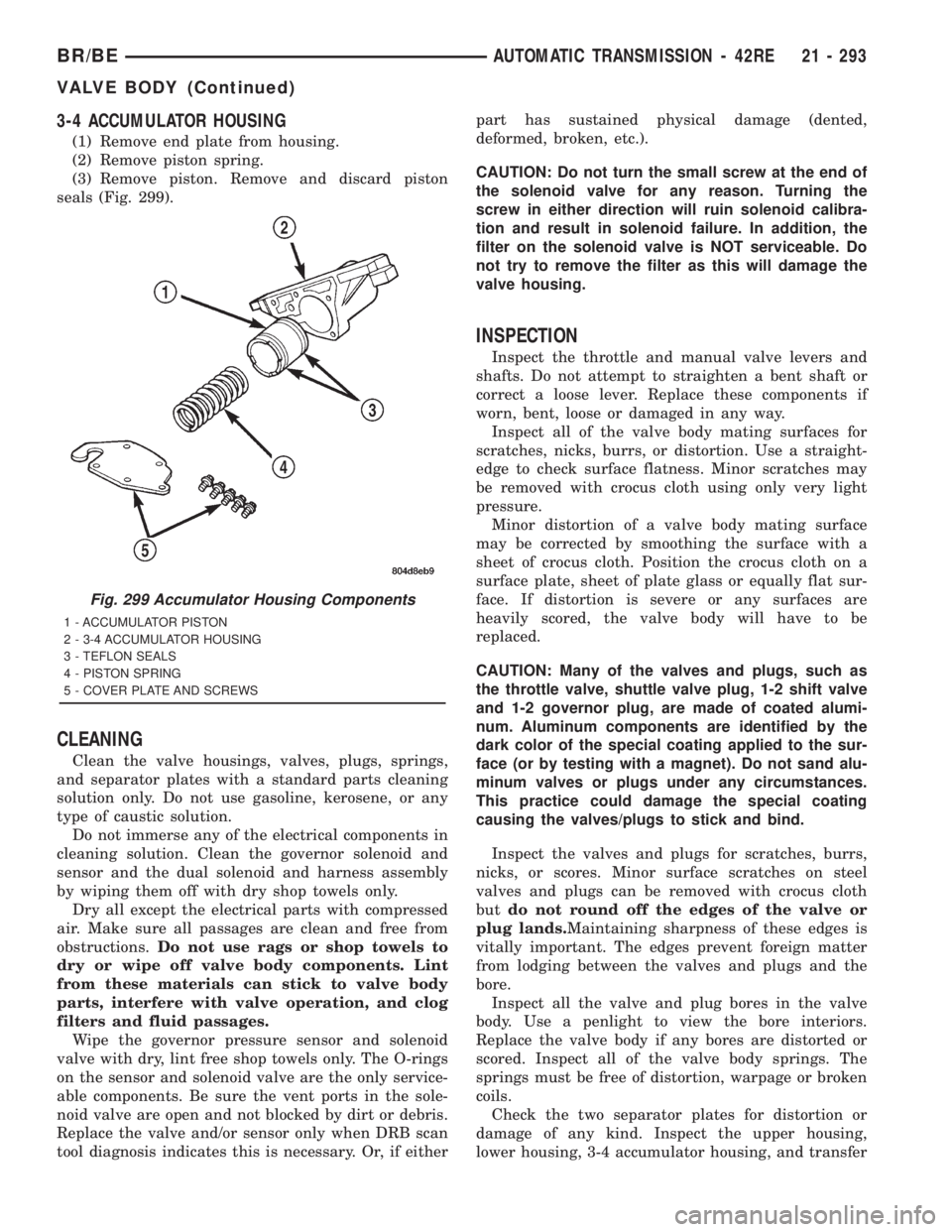

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 299).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if eitherpart has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

Fig. 299 Accumulator Housing Components

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 293

VALVE BODY (Continued)

Page 1971 of 2889

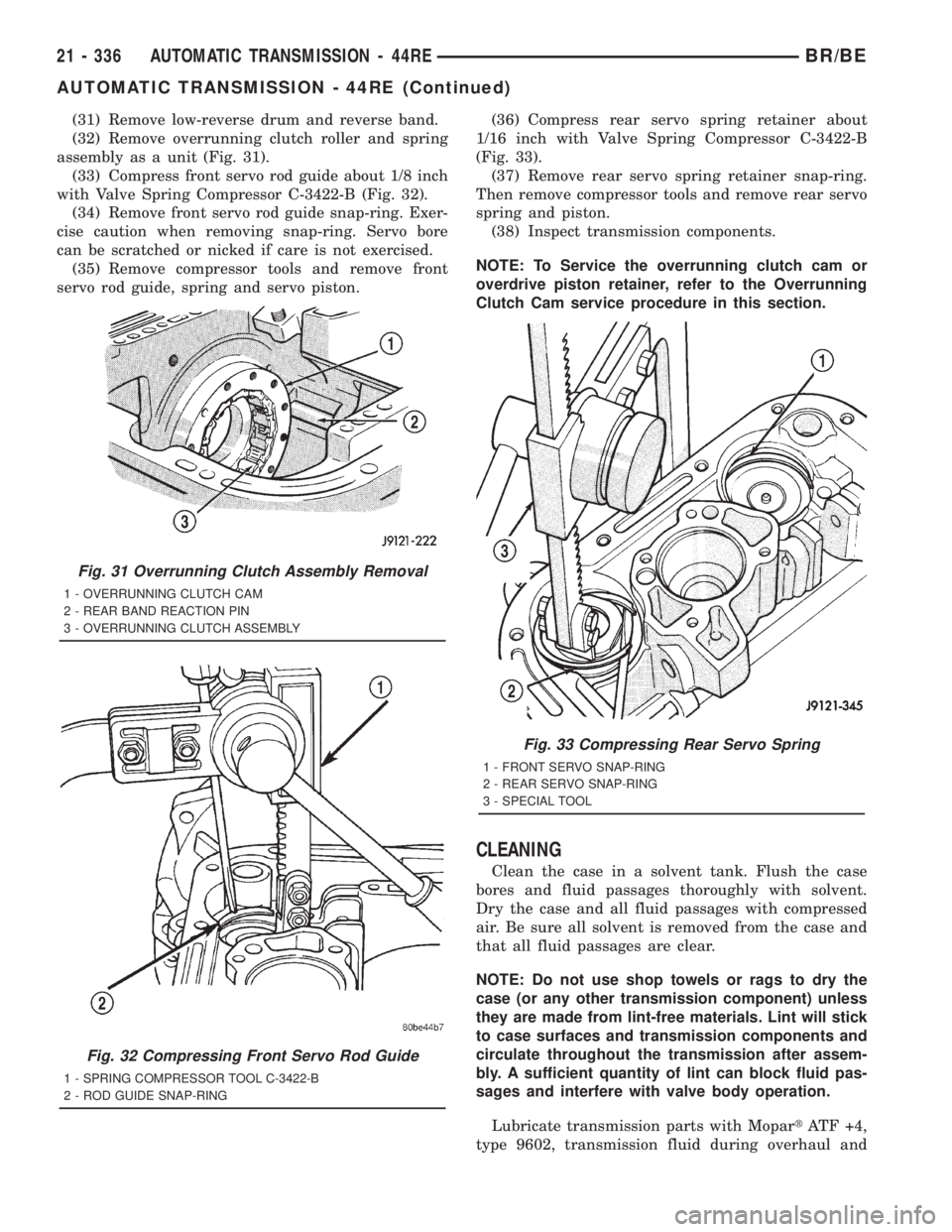

(31) Remove low-reverse drum and reverse band.

(32) Remove overrunning clutch roller and spring

assembly as a unit (Fig. 31).

(33) Compress front servo rod guide about 1/8 inch

with Valve Spring Compressor C-3422-B (Fig. 32).

(34) Remove front servo rod guide snap-ring. Exer-

cise caution when removing snap-ring. Servo bore

can be scratched or nicked if care is not exercised.

(35) Remove compressor tools and remove front

servo rod guide, spring and servo piston.(36) Compress rear servo spring retainer about

1/16 inch with Valve Spring Compressor C-3422-B

(Fig. 33).

(37) Remove rear servo spring retainer snap-ring.

Then remove compressor tools and remove rear servo

spring and piston.

(38) Inspect transmission components.

NOTE: To Service the overrunning clutch cam or

overdrive piston retainer, refer to the Overrunning

Clutch Cam service procedure in this section.

CLEANING

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

Lubricate transmission parts with MopartATF +4,

type 9602, transmission fluid during overhaul and

Fig. 31 Overrunning Clutch Assembly Removal

1 - OVERRUNNING CLUTCH CAM

2 - REAR BAND REACTION PIN

3 - OVERRUNNING CLUTCH ASSEMBLY

Fig. 32 Compressing Front Servo Rod Guide

1 - SPRING COMPRESSOR TOOL C-3422-B

2 - ROD GUIDE SNAP-RING

Fig. 33 Compressing Rear Servo Spring

1 - FRONT SERVO SNAP-RING

2 - REAR SERVO SNAP-RING

3 - SPECIAL TOOL

21 - 336 AUTOMATIC TRANSMISSION - 44REBR/BE

AUTOMATIC TRANSMISSION - 44RE (Continued)

Page 1972 of 2889

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-GlydeŸ to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Inspect the transmission bushings during overhaul.

Bushing condition is important as worn, scored bush-

ings contribute to low pressures, clutch slip and

accelerated wear of other components. However, do

not replace bushings as a matter of course. Replace

bushings only when they are actually worn, or

scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install, and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B.

Pre-sized service bushings are available for

replacement purposes. Only the sun gear bushings

are not serviced.

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

ASSEMBLY

Do not allow dirt, grease, or foreign material to

enter the case or transmission components during

assembly. Keep the transmission case and compo-

nents clean. Also make sure the tools and workbench

area used for assembly operations are equally clean.

Shop towels used for wiping off tools and hands

must be made fromlint freematerial. Lint will stick

to transmission parts and could interfere with valve

operation, or even restrict fluid passages.

Lubricate the transmission components with

Moparttransmission fluid during reassembly. Use

MopartDoor Ease, or Ru-GlydeŸ on seals and

O-rings to ease installation.

Petroleum jelly can also be used to hold thrust

washers, thrust plates and gaskets in position duringassembly. However,do notuse chassis grease, bear-

ing grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and inter-

fere with valve operation. Use petroleum jelly only.

Do not force parts into place. The transmission

components and subassemblies are easily installed by

hand when properly aligned.

If a part seems extremely difficult to install, it is

either misaligned or incorrectly assembled. Also ver-

ify that thrust washers, thrust plates and seal rings

are correctly positioned before assembly. These parts

can interfere with proper assembly if mis-positioned.

The planetary geartrain, front/rear clutch assem-

blies and oil pump are all much easier to install

when the transmission case is upright.

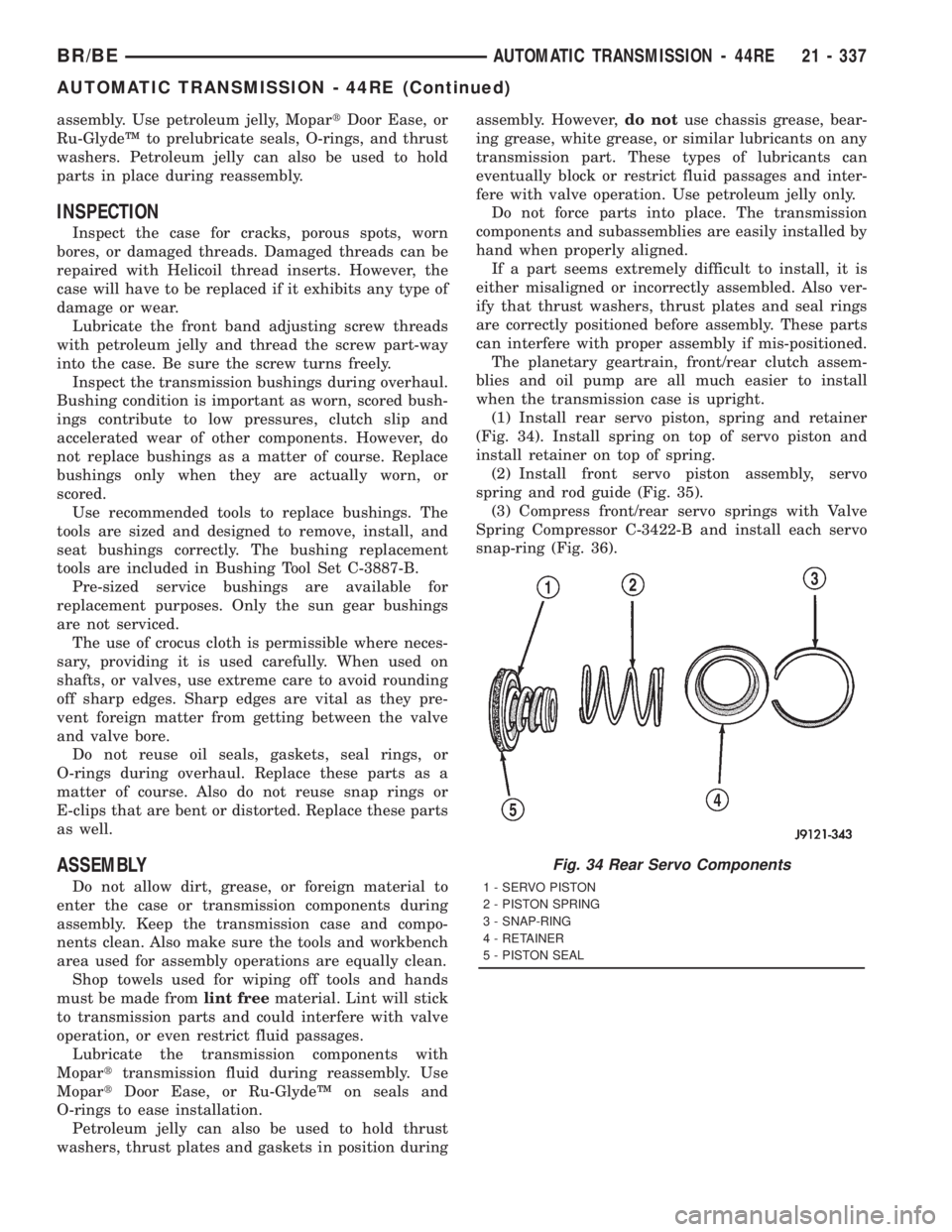

(1) Install rear servo piston, spring and retainer

(Fig. 34). Install spring on top of servo piston and

install retainer on top of spring.

(2) Install front servo piston assembly, servo

spring and rod guide (Fig. 35).

(3) Compress front/rear servo springs with Valve

Spring Compressor C-3422-B and install each servo

snap-ring (Fig. 36).

Fig. 34 Rear Servo Components

1 - SERVO PISTON

2 - PISTON SPRING

3 - SNAP-RING

4 - RETAINER

5 - PISTON SEAL

BR/BEAUTOMATIC TRANSMISSION - 44RE 21 - 337

AUTOMATIC TRANSMISSION - 44RE (Continued)

Page 1975 of 2889

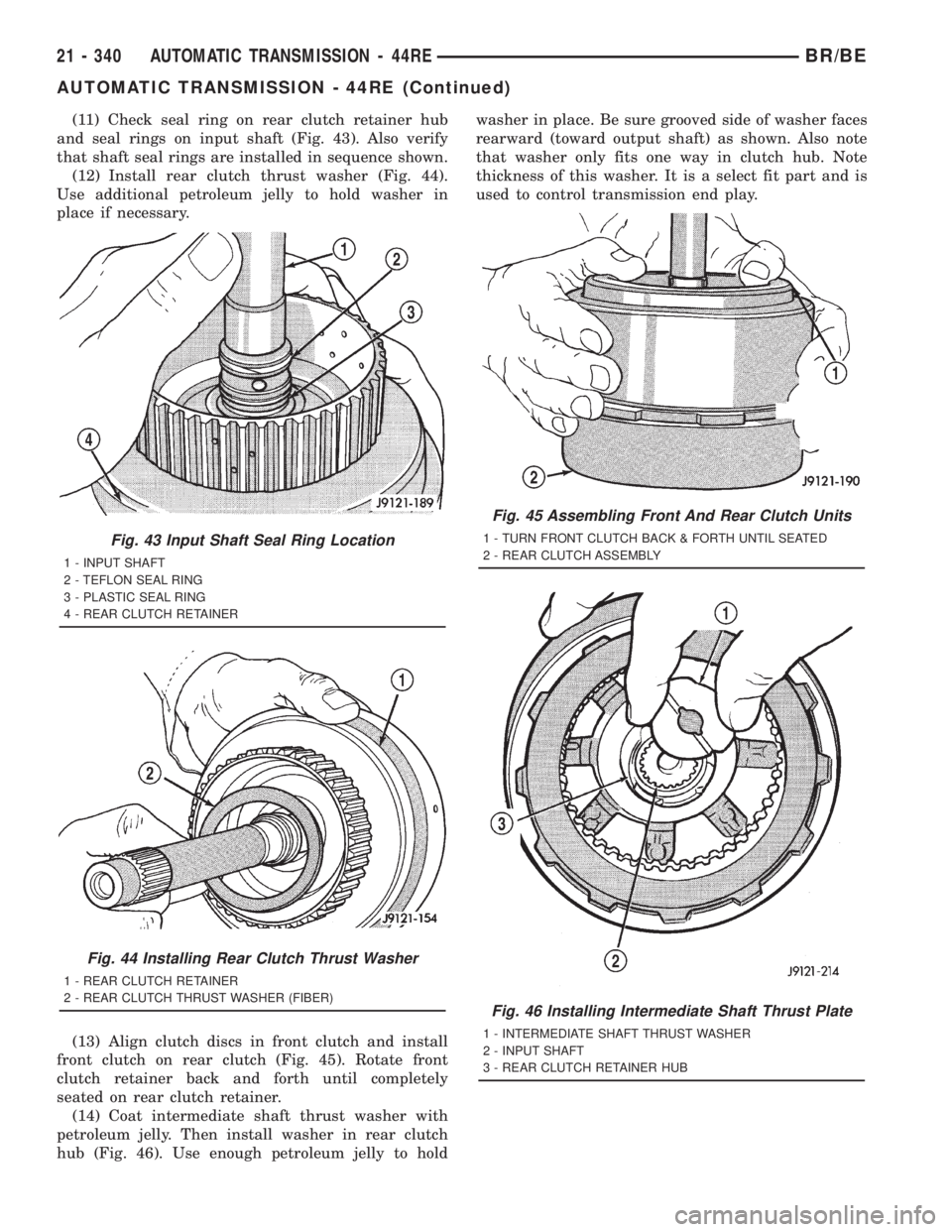

(11) Check seal ring on rear clutch retainer hub

and seal rings on input shaft (Fig. 43). Also verify

that shaft seal rings are installed in sequence shown.

(12) Install rear clutch thrust washer (Fig. 44).

Use additional petroleum jelly to hold washer in

place if necessary.

(13) Align clutch discs in front clutch and install

front clutch on rear clutch (Fig. 45). Rotate front

clutch retainer back and forth until completely

seated on rear clutch retainer.

(14) Coat intermediate shaft thrust washer with

petroleum jelly. Then install washer in rear clutch

hub (Fig. 46). Use enough petroleum jelly to holdwasher in place. Be sure grooved side of washer faces

rearward (toward output shaft) as shown. Also note

that washer only fits one way in clutch hub. Note

thickness of this washer. It is a select fit part and is

used to control transmission end play.

Fig. 43 Input Shaft Seal Ring Location

1 - INPUT SHAFT

2 - TEFLON SEAL RING

3 - PLASTIC SEAL RING

4 - REAR CLUTCH RETAINER

Fig. 44 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER (FIBER)

Fig. 45 Assembling Front And Rear Clutch Units

1 - TURN FRONT CLUTCH BACK & FORTH UNTIL SEATED

2 - REAR CLUTCH ASSEMBLY

Fig. 46 Installing Intermediate Shaft Thrust Plate

1 - INTERMEDIATE SHAFT THRUST WASHER

2 - INPUT SHAFT

3 - REAR CLUTCH RETAINER HUB

21 - 340 AUTOMATIC TRANSMISSION - 44REBR/BE

AUTOMATIC TRANSMISSION - 44RE (Continued)

Page 2005 of 2889

FLUID AND FILTER

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has two primary causes.

(1)

A result of restricted fluid flow through the main

and/or auxiliary cooler. This condition is usually the

result of a faulty or improperly installed drainback

valve, a damaged main cooler, or severe restrictions in

the coolers and lines caused by debris or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²

overheat that generates sludge (fluid breakdown)

²failure to reverse flush cooler and lines after repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease andother foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary coolers

as well. The torque converter should also be replaced

whenever a failure generates sludge and debris. This is

necessary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transmission vent where it may be mis-

taken for a leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transmission recondition is

needed. Be sure to examine the fluid on the dipstick

closely. If there is any doubt about its condition,

drain out a sample for a double check.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at

curb idle speed, the transmission in NEUTRAL and the

transmission fluid at normal operating temperature.

The engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.

The transmission fluid level can be checked two ways.

21 - 370 AUTOMATIC TRANSMISSION - 44REBR/BE

Page 2019 of 2889

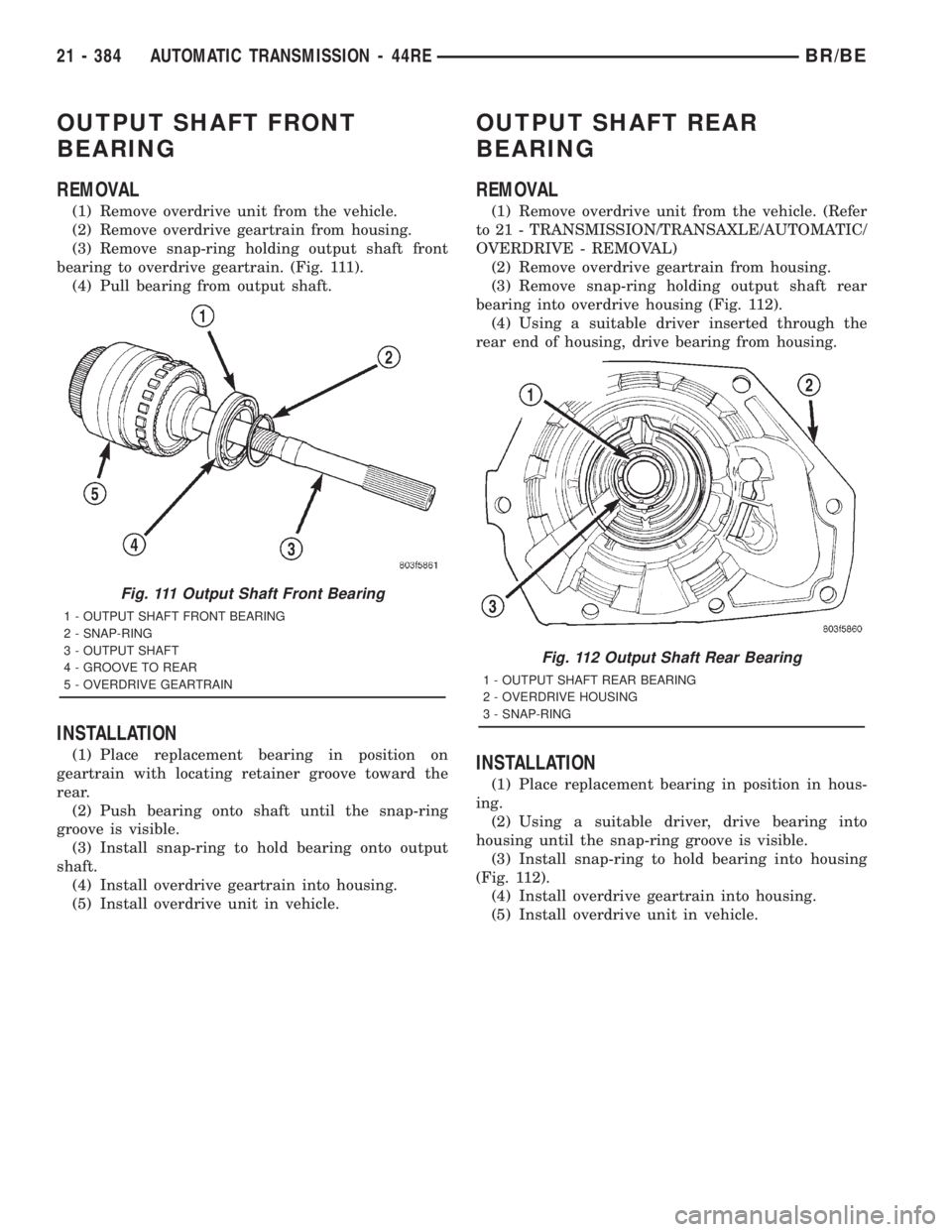

OUTPUT SHAFT FRONT

BEARING

REMOVAL

(1) Remove overdrive unit from the vehicle.

(2) Remove overdrive geartrain from housing.

(3) Remove snap-ring holding output shaft front

bearing to overdrive geartrain. (Fig. 111).

(4) Pull bearing from output shaft.

INSTALLATION

(1) Place replacement bearing in position on

geartrain with locating retainer groove toward the

rear.

(2) Push bearing onto shaft until the snap-ring

groove is visible.

(3) Install snap-ring to hold bearing onto output

shaft.

(4) Install overdrive geartrain into housing.

(5) Install overdrive unit in vehicle.

OUTPUT SHAFT REAR

BEARING

REMOVAL

(1) Remove overdrive unit from the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC/

OVERDRIVE - REMOVAL)

(2) Remove overdrive geartrain from housing.

(3) Remove snap-ring holding output shaft rear

bearing into overdrive housing (Fig. 112).

(4) Using a suitable driver inserted through the

rear end of housing, drive bearing from housing.

INSTALLATION

(1) Place replacement bearing in position in hous-

ing.

(2) Using a suitable driver, drive bearing into

housing until the snap-ring groove is visible.

(3) Install snap-ring to hold bearing into housing

(Fig. 112).

(4) Install overdrive geartrain into housing.

(5) Install overdrive unit in vehicle.

Fig. 111 Output Shaft Front Bearing

1 - OUTPUT SHAFT FRONT BEARING

2 - SNAP-RING

3 - OUTPUT SHAFT

4 - GROOVE TO REAR

5 - OVERDRIVE GEARTRAIN

Fig. 112 Output Shaft Rear Bearing

1 - OUTPUT SHAFT REAR BEARING

2 - OVERDRIVE HOUSING

3 - SNAP-RING

21 - 384 AUTOMATIC TRANSMISSION - 44REBR/BE

Page 2029 of 2889

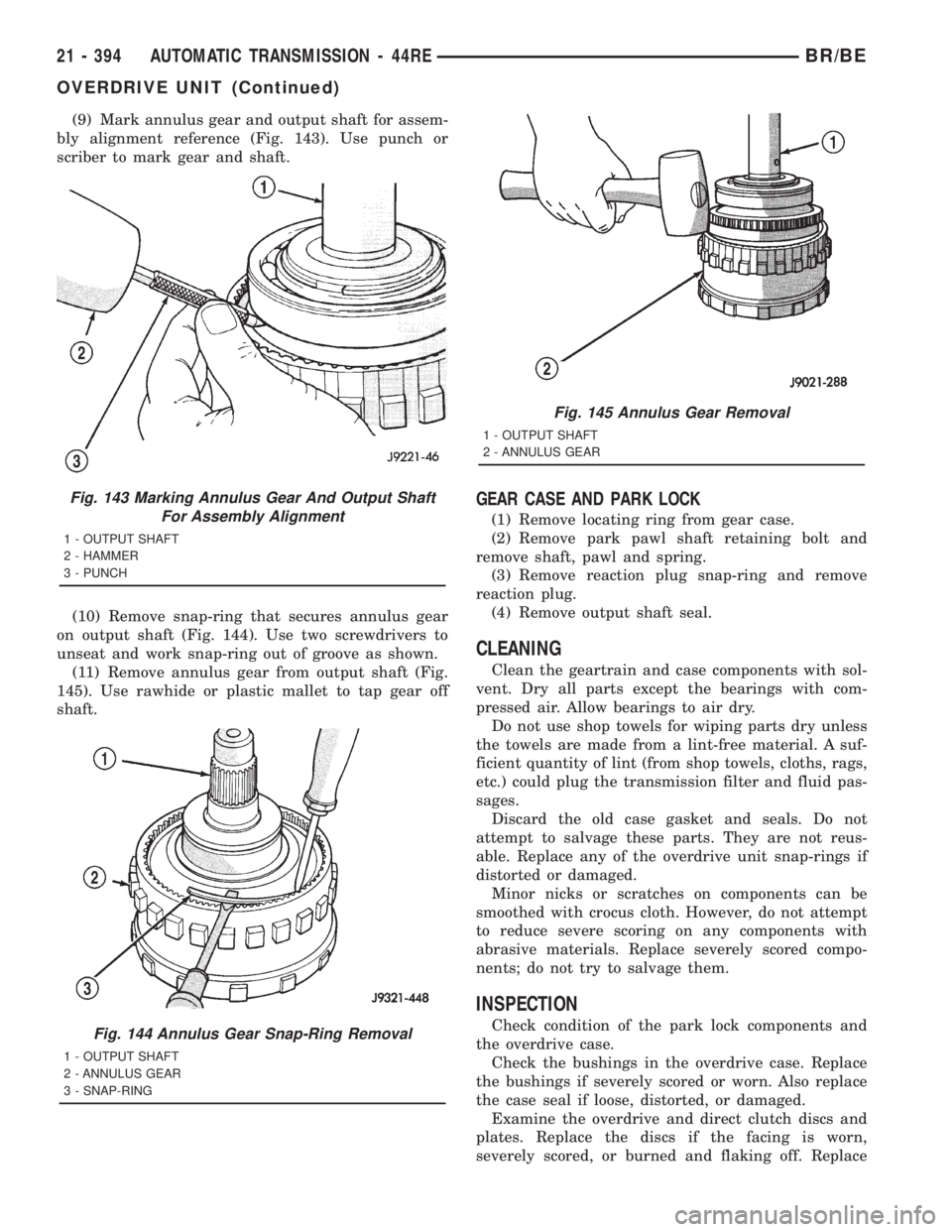

(9) Mark annulus gear and output shaft for assem-

bly alignment reference (Fig. 143). Use punch or

scriber to mark gear and shaft.

(10) Remove snap-ring that secures annulus gear

on output shaft (Fig. 144). Use two screwdrivers to

unseat and work snap-ring out of groove as shown.

(11) Remove annulus gear from output shaft (Fig.

145). Use rawhide or plastic mallet to tap gear off

shaft.

GEAR CASE AND PARK LOCK

(1) Remove locating ring from gear case.

(2) Remove park pawl shaft retaining bolt and

remove shaft, pawl and spring.

(3) Remove reaction plug snap-ring and remove

reaction plug.

(4) Remove output shaft seal.

CLEANING

Clean the geartrain and case components with sol-

vent. Dry all parts except the bearings with com-

pressed air. Allow bearings to air dry.

Do not use shop towels for wiping parts dry unless

the towels are made from a lint-free material. A suf-

ficient quantity of lint (from shop towels, cloths, rags,

etc.) could plug the transmission filter and fluid pas-

sages.

Discard the old case gasket and seals. Do not

attempt to salvage these parts. They are not reus-

able. Replace any of the overdrive unit snap-rings if

distorted or damaged.

Minor nicks or scratches on components can be

smoothed with crocus cloth. However, do not attempt

to reduce severe scoring on any components with

abrasive materials. Replace severely scored compo-

nents; do not try to salvage them.

INSPECTION

Check condition of the park lock components and

the overdrive case.

Check the bushings in the overdrive case. Replace

the bushings if severely scored or worn. Also replace

the case seal if loose, distorted, or damaged.

Examine the overdrive and direct clutch discs and

plates. Replace the discs if the facing is worn,

severely scored, or burned and flaking off. Replace

Fig. 143 Marking Annulus Gear And Output Shaft

For Assembly Alignment

1 - OUTPUT SHAFT

2 - HAMMER

3 - PUNCH

Fig. 144 Annulus Gear Snap-Ring Removal

1 - OUTPUT SHAFT

2 - ANNULUS GEAR

3 - SNAP-RING

Fig. 145 Annulus Gear Removal

1 - OUTPUT SHAFT

2 - ANNULUS GEAR

21 - 394 AUTOMATIC TRANSMISSION - 44REBR/BE

OVERDRIVE UNIT (Continued)

Page 2031 of 2889

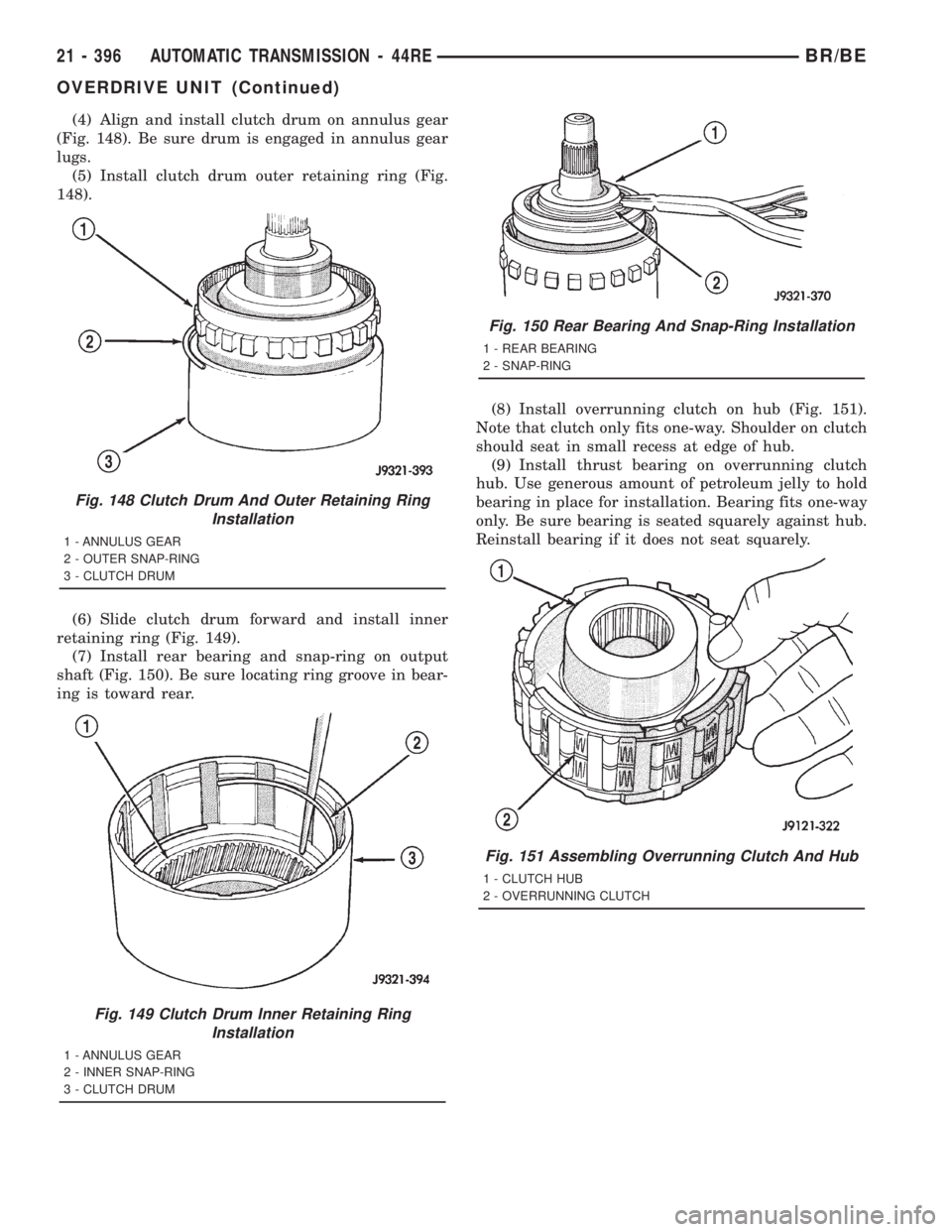

(4) Align and install clutch drum on annulus gear

(Fig. 148). Be sure drum is engaged in annulus gear

lugs.

(5) Install clutch drum outer retaining ring (Fig.

148).

(6) Slide clutch drum forward and install inner

retaining ring (Fig. 149).

(7) Install rear bearing and snap-ring on output

shaft (Fig. 150). Be sure locating ring groove in bear-

ing is toward rear.(8) Install overrunning clutch on hub (Fig. 151).

Note that clutch only fits one-way. Shoulder on clutch

should seat in small recess at edge of hub.

(9) Install thrust bearing on overrunning clutch

hub. Use generous amount of petroleum jelly to hold

bearing in place for installation. Bearing fits one-way

only. Be sure bearing is seated squarely against hub.

Reinstall bearing if it does not seat squarely.

Fig. 148 Clutch Drum And Outer Retaining Ring

Installation

1 - ANNULUS GEAR

2 - OUTER SNAP-RING

3 - CLUTCH DRUM

Fig. 149 Clutch Drum Inner Retaining Ring

Installation

1 - ANNULUS GEAR

2 - INNER SNAP-RING

3 - CLUTCH DRUM

Fig. 150 Rear Bearing And Snap-Ring Installation

1 - REAR BEARING

2 - SNAP-RING

Fig. 151 Assembling Overrunning Clutch And Hub

1 - CLUTCH HUB

2 - OVERRUNNING CLUTCH

21 - 396 AUTOMATIC TRANSMISSION - 44REBR/BE

OVERDRIVE UNIT (Continued)

Page 2040 of 2889

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.

(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-

essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER

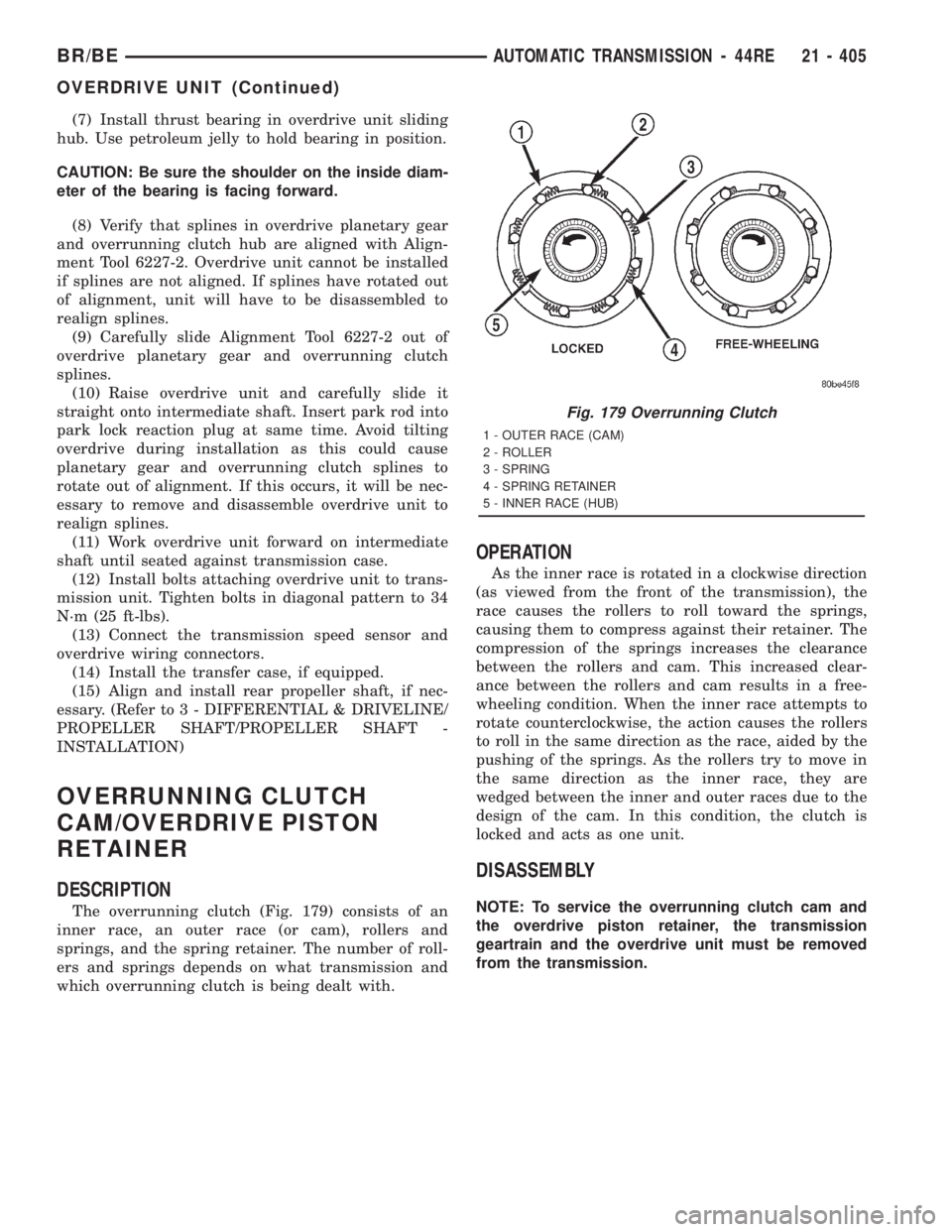

DESCRIPTION

The overrunning clutch (Fig. 179) consists of an

inner race, an outer race (or cam), rollers and

springs, and the spring retainer. The number of roll-

ers and springs depends on what transmission and

which overrunning clutch is being dealt with.

OPERATION

As the inner race is rotated in a clockwise direction

(as viewed from the front of the transmission), the

race causes the rollers to roll toward the springs,

causing them to compress against their retainer. The

compression of the springs increases the clearance

between the rollers and cam. This increased clear-

ance between the rollers and cam results in a free-

wheeling condition. When the inner race attempts to

rotate counterclockwise, the action causes the rollers

to roll in the same direction as the race, aided by the

pushing of the springs. As the rollers try to move in

the same direction as the inner race, they are

wedged between the inner and outer races due to the

design of the cam. In this condition, the clutch is

locked and acts as one unit.

DISASSEMBLY

NOTE: To service the overrunning clutch cam and

the overdrive piston retainer, the transmission

geartrain and the overdrive unit must be removed

from the transmission.

Fig. 179 Overrunning Clutch

1 - OUTER RACE (CAM)

2 - ROLLER

3 - SPRING

4 - SPRING RETAINER

5 - INNER RACE (HUB)

BR/BEAUTOMATIC TRANSMISSION - 44RE 21 - 405

OVERDRIVE UNIT (Continued)