stop start DODGE RAM 2001 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 808 of 2889

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch............... 8W-15-10, 8

A/C-Heater Control.................... 8W-15-14

A/C Heater Temperature Select........... 8W-15-12

Aftermarket Trailer Tow Connector......... 8W-15-6

Airbag Control Module.................. 8W-15-5

Ash Receiver Lamp.................... 8W-15-14

Automatic Day/Night Mirror............. 8W-15-13

Auxiliary Battery..................... 8W-15-11

Battery............................ 8W-15-11

Blend Door Actuator................... 8W-15-12

Blower Motor Relay.................... 8W-15-2

Brake Lamp Switch................... 8W-15-12

Brake Pressure Switch.................. 8W-15-3

Center High Mounted Stop Lamp No. 1..... 8W-15-17

Center High Mounted Stop Lamp No. 2..... 8W-15-17

Center Identification Lamp.............. 8W-15-18

Central Timer Module C1............... 8W-15-12

Central Timer Module C2............... 8W-15-13

Cigar Lighter........................ 8W-15-14

Clockspring.......................... 8W-15-4

Combination Flasher.................. 8W-15-13

Controller Antilock Brake................ 8W-15-5

Cummins Bus....................... 8W-15-10

Cup Holder Lamp..................... 8W-15-14

Data Link Connector.............. 8W-15-8, 10, 12

Daytime Running Lamp Module......... 8W-15-2, 3

Driver Cylinder Lock Switch............. 8W-15-16

Driver Door Ajar Switch................ 8W-15-16

Driver Door Window/Lock Switch....... 8W-15-16, 17

Driver Heated Seat Cushion............. 8W-15-15

Driver Heated Seat Switch.............. 8W-15-13

Driver Power Seat Switch............ 8W-15-15, 17

Electric Brake Provision................ 8W-15-14

Engine Control Module.................. 8W-15-9

Engine Starter Motor Relay............. 8W-15-8, 9

Fuel Heater Relay..................... 8W-15-2

Fuel Heater......................... 8W-15-10

Fuel Injection Pump.................... 8W-15-9

Fuel Pump Module..................... 8W-15-7

Fuel Pump Relay...................... 8W-15-2

Fuel Transfer Pump................... 8W-15-10

G100.......................... 8W-15-12, 5, 7

G101............................... 8W-15-5

G102............................... 8W-15-2

G105............................... 8W-15-8

G107.............................. 8W-15-10

G113 .............................. 8W-15-11

G114 .............................. 8W-15-11

G115 .............................. 8W-15-11

G116 .............................. 8W-15-11

G117 .............................. 8W-15-11

G118 .............................. 8W-15-11

G120.............................. 8W-15-11

G200......................... 8W-15-7, 12, 14

G201........................... 8W-15-12, 14

G300.............................. 8W-15-16

G301.............................. 8W-15-17

G302.............................. 8W-15-18

Glove Box Lamp And Switch............. 8W-15-14

Headlamp Beam Select Switch............ 8W-15-14

Headlamp Switch.................. 8W-15-13, 14

Heated Mirror Switch.................. 8W-15-13

High Note Horn....................... 8W-15-7

Ignition Switch....................... 8W-15-13

Instrument Cluster................. 8W-15-12, 14

Intake Air Heater Relay No. 1............. 8W-15-9Component Page

Intake Air Heater Relay No. 2............. 8W-15-9

Joint Connector No. 1................... 8W-15-2

Joint Connector No. 2................... 8W-15-9

Joint Connector No. 3................... 8W-15-7

Joint Connector No. 4................... 8W-15-3

Joint Connector No. 5.................. 8W-15-13

Joint Connector No. 6................... 8W-15-4

Joint Connector No. 8................ 8W-15-13, 5

Junction Block.................... 8W-15-12, 13

Left Back-Up Lamp.................... 8W-15-6

Left Front Door Speaker................. 8W-15-4

Left Front Fender Lamp................. 8W-15-6

Left License Lamp..................... 8W-15-6

Left Outboard Clearance Lamp........... 8W-15-18

Left Outboard Identification Lamp......... 8W-15-18

Left Park/Turn Signal Lamp.............. 8W-15-3

Left Power Mirror..................... 8W-15-16

Left Rear Fender Lamp................. 8W-15-6

Left Remote Radio Switch................ 8W-15-4

Left Tail/Stop/Turn Signal Lamp........... 8W-15-6

Left Visor/Vanity Lamp................. 8W-15-13

Low Note Horn....................... 8W-15-7

Overdrive Switch..................... 8W-15-12

Overhead Console..................... 8W-15-12

Oxygen Sensor 1/2 Left Bank Down......... 8W-15-8

Oxygen Sensor 1/2 Pre-Catalyst............ 8W-15-8

Oxygen Sensor 1/3 Post-Catalyst........... 8W-15-8

Oxygen Sensor 2/2 Right Bank Down........ 8W-15-8

Passenger Airbag On/Off Switch........... 8W-15-5

Passenger Cylinder Lock Switch.......... 8W-15-16

Passenger Door Ajar Switch.............. 8W-15-16

Passenger Door Window/Lock Switch....... 8W-15-16

Passenger Heated Seat Cushion........... 8W-15-15

Passenger Heated Seat Switch............ 8W-15-13

Passenger Power Seat Switch............ 8W-15-15

Power Distribution Center............... 8W-15-2

Power Mirror Switch................... 8W-15-16

Power Outlet........................ 8W-15-14

Powertrain Control Module............ 8W-15-8 , 10

Quad High Beam Relay................. 8W-15-2

Radio Choke Relay..................... 8W-15-4

Radio.............................. 8W-15-5

Right Back-Up Lamp................... 8W-15-6

Right Front Door Speaker................ 8W-15-4

Right Front Fender Lamp................ 8W-15-6

Right License Lamp.................... 8W-15-6

Right Outboard Clearance Lamp.......... 8W-15-18

Right Outboard Identification Lamp........ 8W-15-18

Right Park/Turn Signal Lamp............. 8W-15-7

Right Power Mirror................... 8W-15-16

Right Rear Fender Lamp................ 8W-15-6

Right Remote Radio Switch............... 8W-15-4

Right Tail/Stop/Turn Signal Lamp.......... 8W-15-6

Right Visor/Vanity Lamp................ 8W-15-13

Seat Belt Switch................... 8W-15-15, 17

Seat Heat Interface Module.............. 8W-15-15

Security Relay........................ 8W-15-2

Speed Control Servo.................... 8W-15-3

Tailgate Lamp........................ 8W-15-6

Trailer Tow Connector.................. 8W-15-6

Trailer Tow Relay...................... 8W-15-2

Underhood Lamp...................... 8W-15-3

Washer Fluid Level Switch............... 8W-15-3

Windshield Washer Pump................ 8W-15-7

Wiper Motor......................... 8W-15-7

BR/BE8W-15 GROUND DISTRIBUTION 8W - 15 - 1

Page 1194 of 2889

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

OIL

STANDARD PROCEDUREÐENGINE OIL

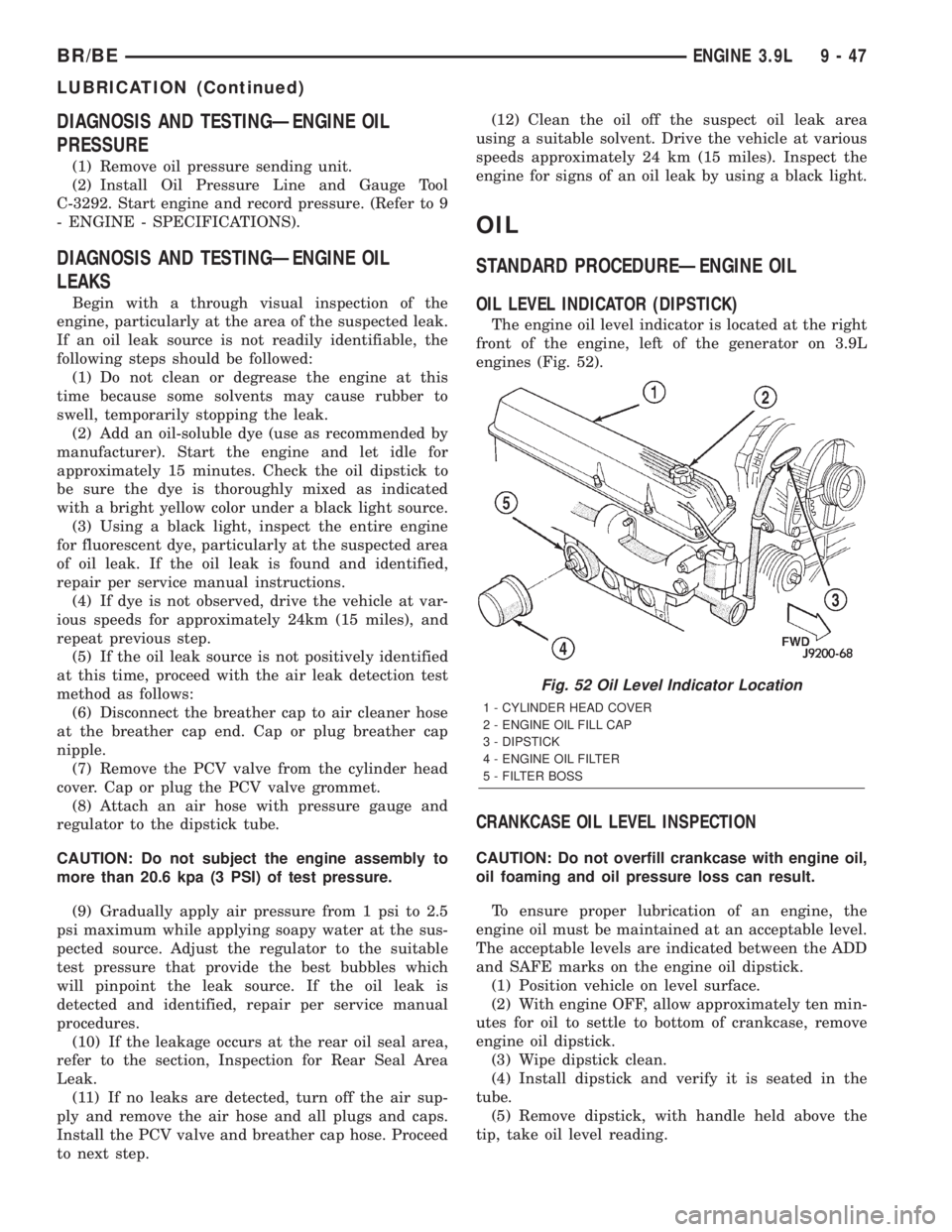

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

front of the engine, left of the generator on 3.9L

engines (Fig. 52).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

Fig. 52 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

BR/BEENGINE 3.9L 9 - 47

LUBRICATION (Continued)

Page 1195 of 2889

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE:

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

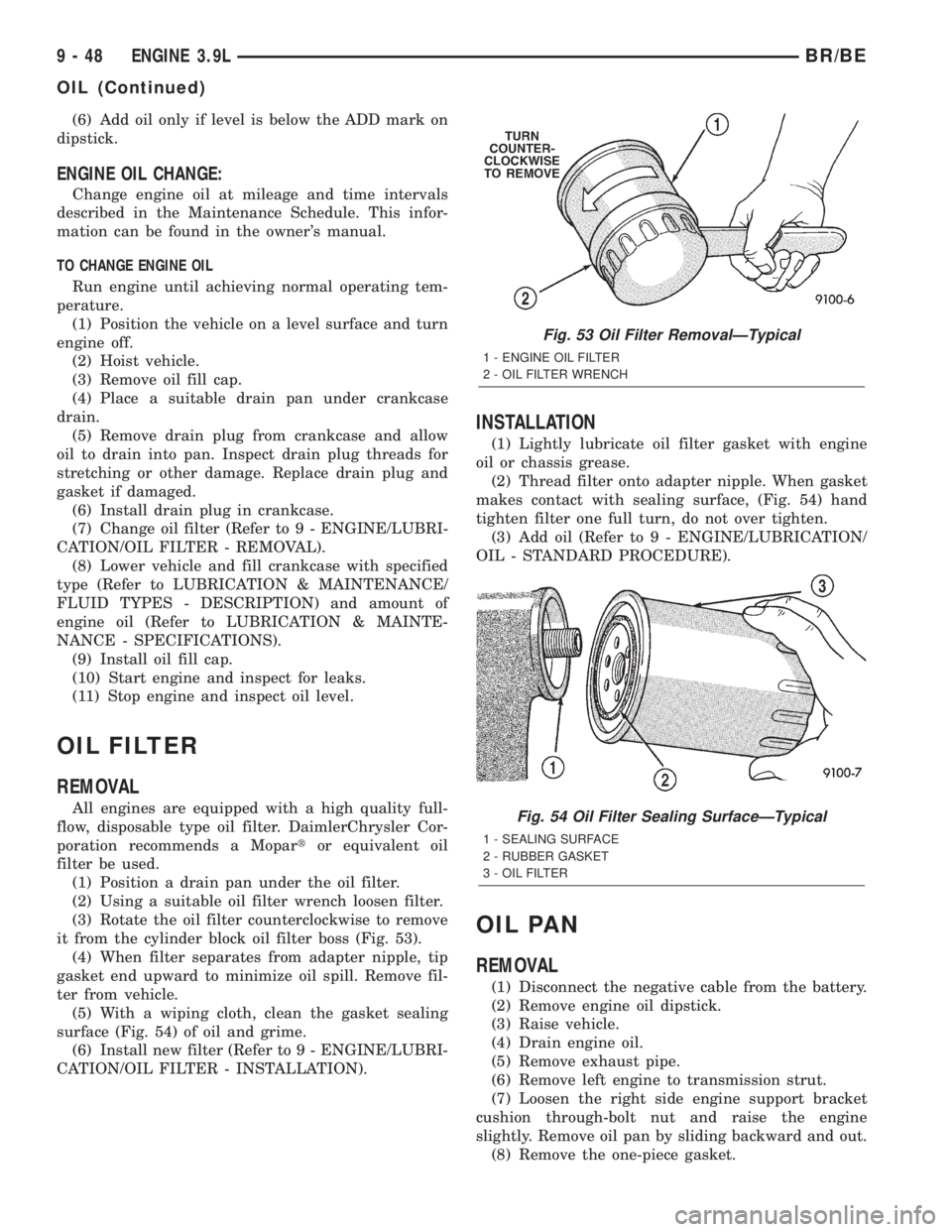

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 53).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 54) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 54) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion through-bolt nut and raise the engine

slightly. Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

Fig. 53 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 54 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

9 - 48 ENGINE 3.9LBR/BE

OIL (Continued)

Page 1251 of 2889

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

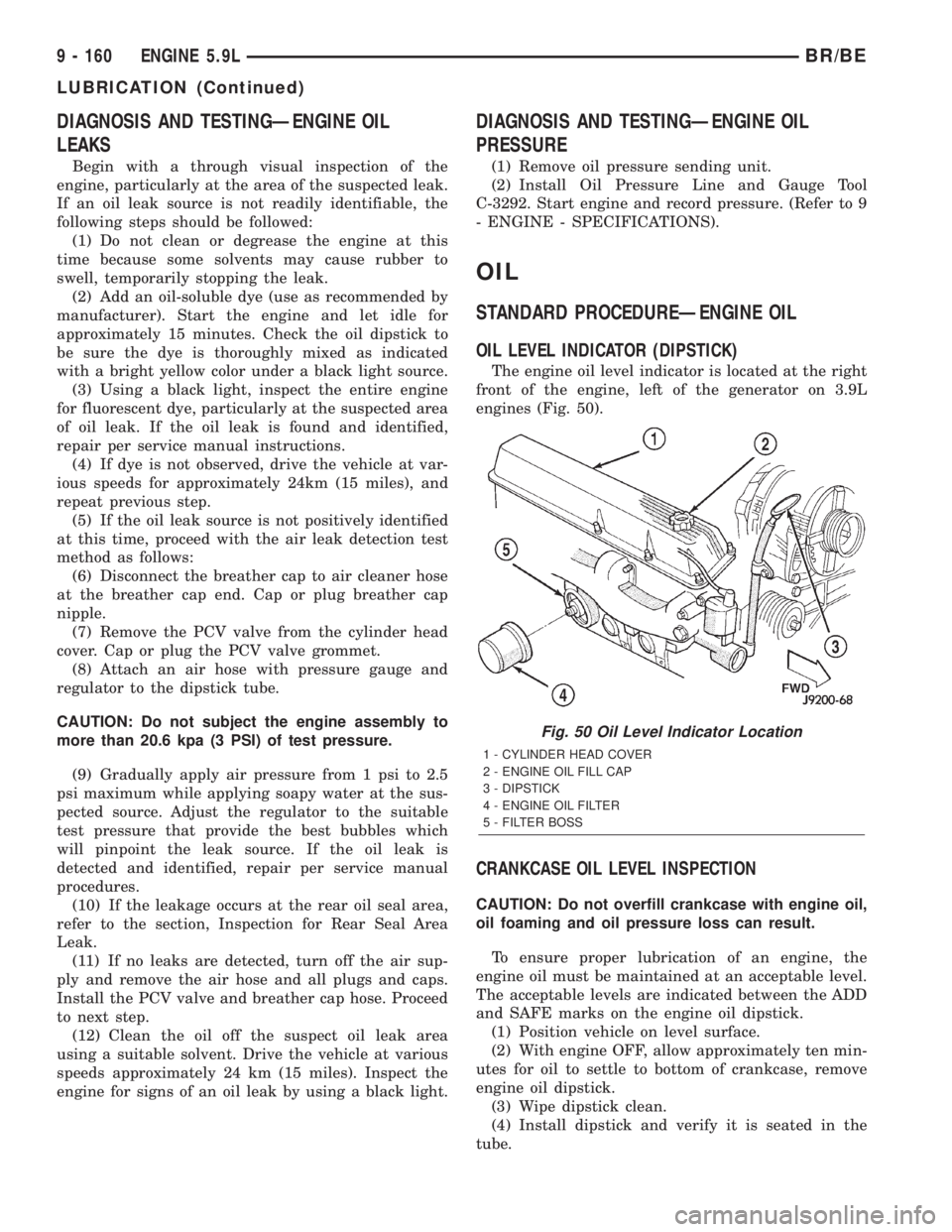

OIL

STANDARD PROCEDUREÐENGINE OIL

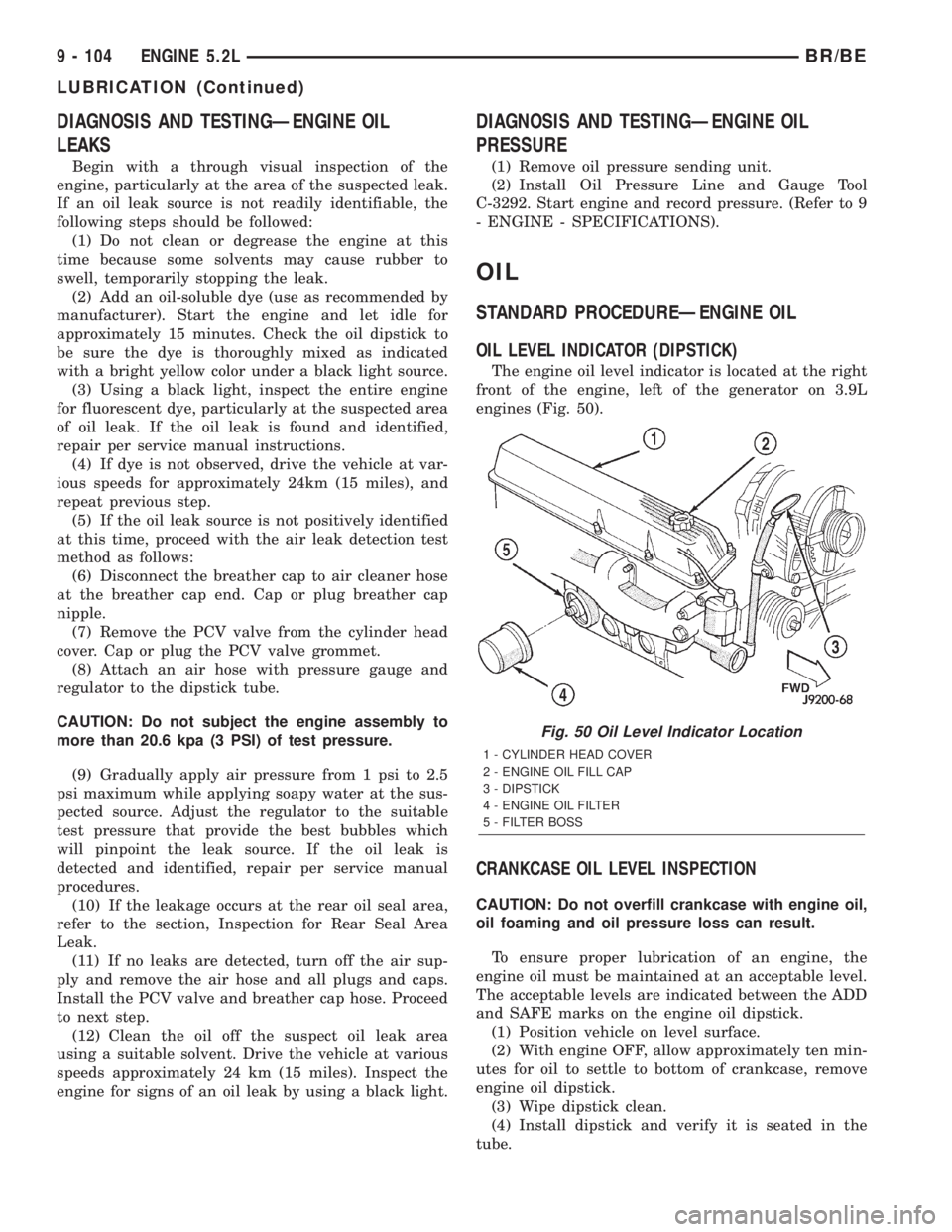

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

front of the engine, left of the generator on 3.9L

engines (Fig. 50).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

Fig. 50 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

9 - 104 ENGINE 5.2LBR/BE

LUBRICATION (Continued)

Page 1252 of 2889

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

OIL FILTER

REMOVAL

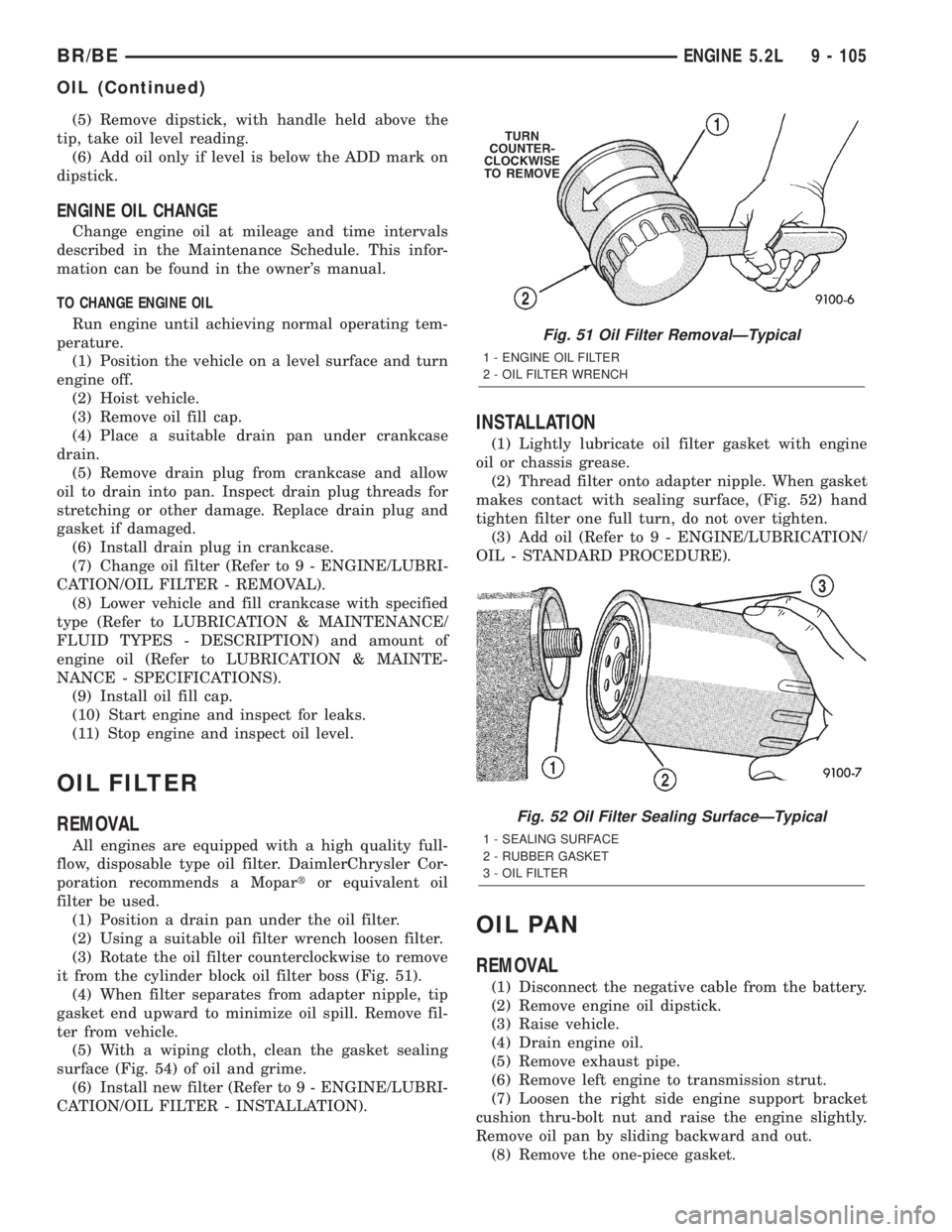

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 54) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion thru-bolt nut and raise the engine slightly.

Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

BR/BEENGINE 5.2L 9 - 105

OIL (Continued)

Page 1307 of 2889

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

OIL

STANDARD PROCEDUREÐENGINE OIL

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located at the right

front of the engine, left of the generator on 3.9L

engines (Fig. 50).

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

Fig. 50 Oil Level Indicator Location

1 - CYLINDER HEAD COVER

2 - ENGINE OIL FILL CAP

3 - DIPSTICK

4 - ENGINE OIL FILTER

5 - FILTER BOSS

9 - 160 ENGINE 5.9LBR/BE

LUBRICATION (Continued)

Page 1308 of 2889

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in the owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist vehicle.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

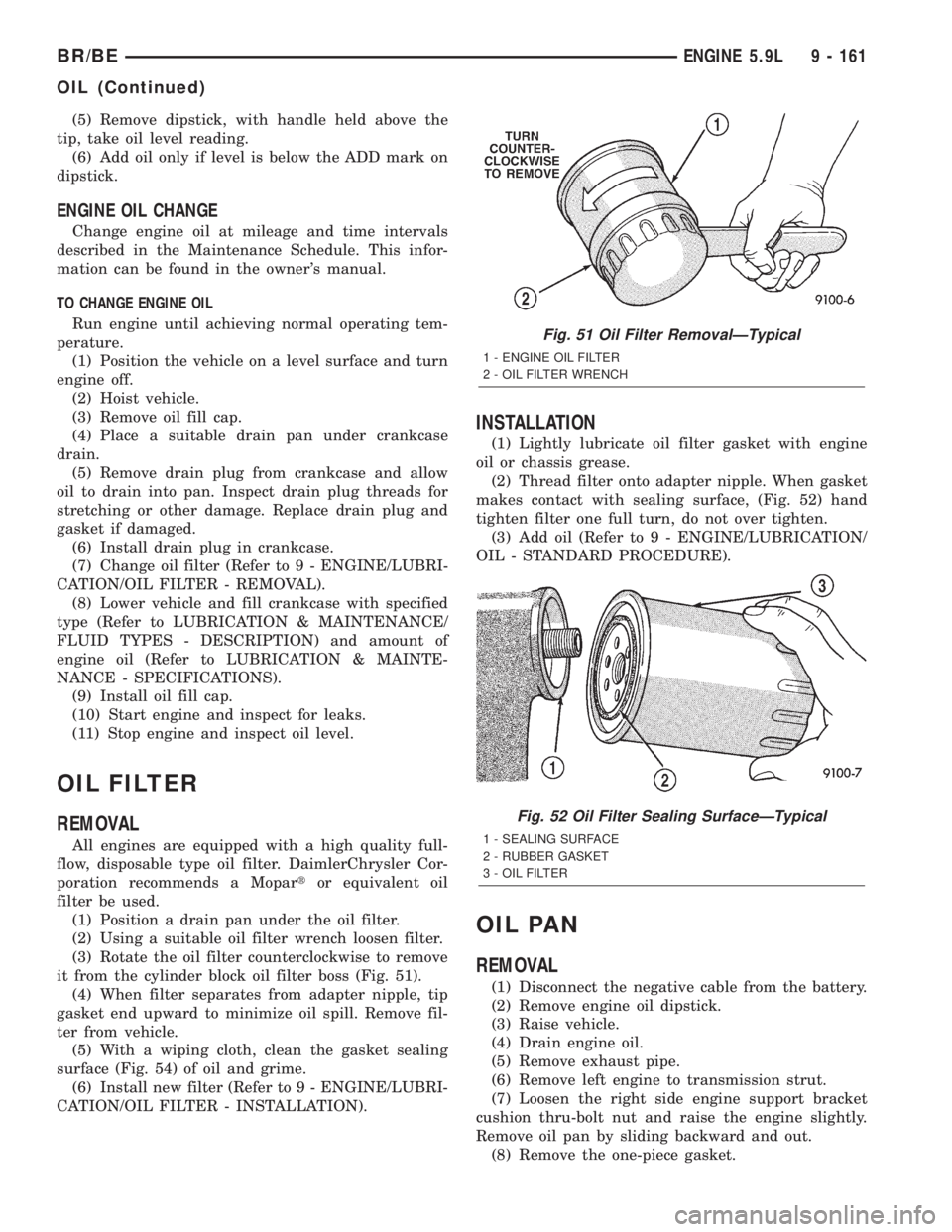

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 54) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion thru-bolt nut and raise the engine slightly.

Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

BR/BEENGINE 5.9L 9 - 161

OIL (Continued)

Page 1362 of 2889

rotates. This oil throwoff lubricates the camshaft

lobes, cylinder walls, and piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. The camshaft bearings

receive oil from the main bearing galleries. The front

camshaft bearing journal passes oil through the cam-

shaft sprocket to the timing chain. Oil drains back to

the oil pan under the No. 1 main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets, which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components.

The oil then passes down through the push rod guide

holes and the oil drain-back passages in the cylinder

head, past the valve tappet area, and then returns to

the oil pan (Fig. 52).

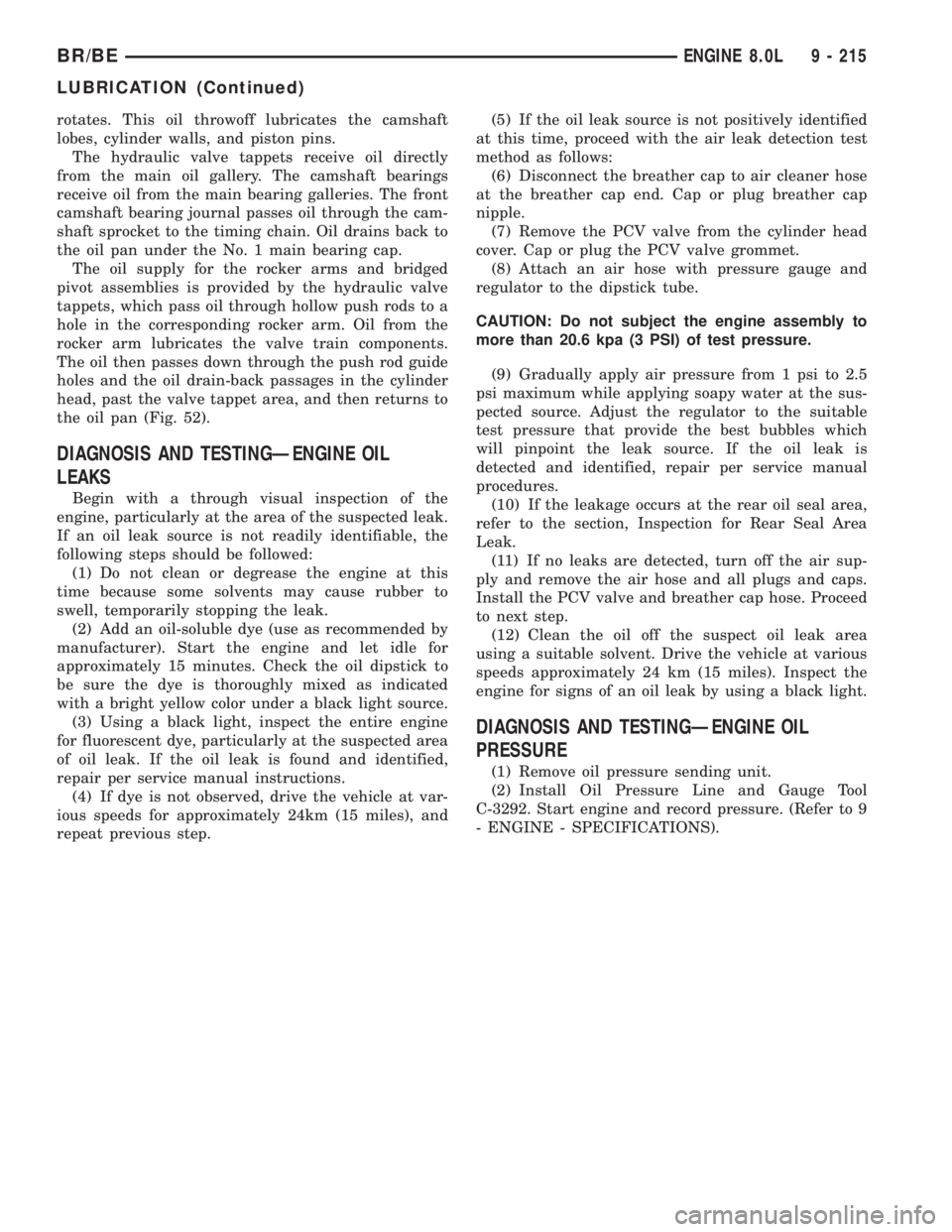

DIAGNOSIS AND TESTINGÐENGINE OIL

LEAKS

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. (Refer to 9

- ENGINE - SPECIFICATIONS).

BR/BEENGINE 8.0L 9 - 215

LUBRICATION (Continued)

Page 1365 of 2889

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

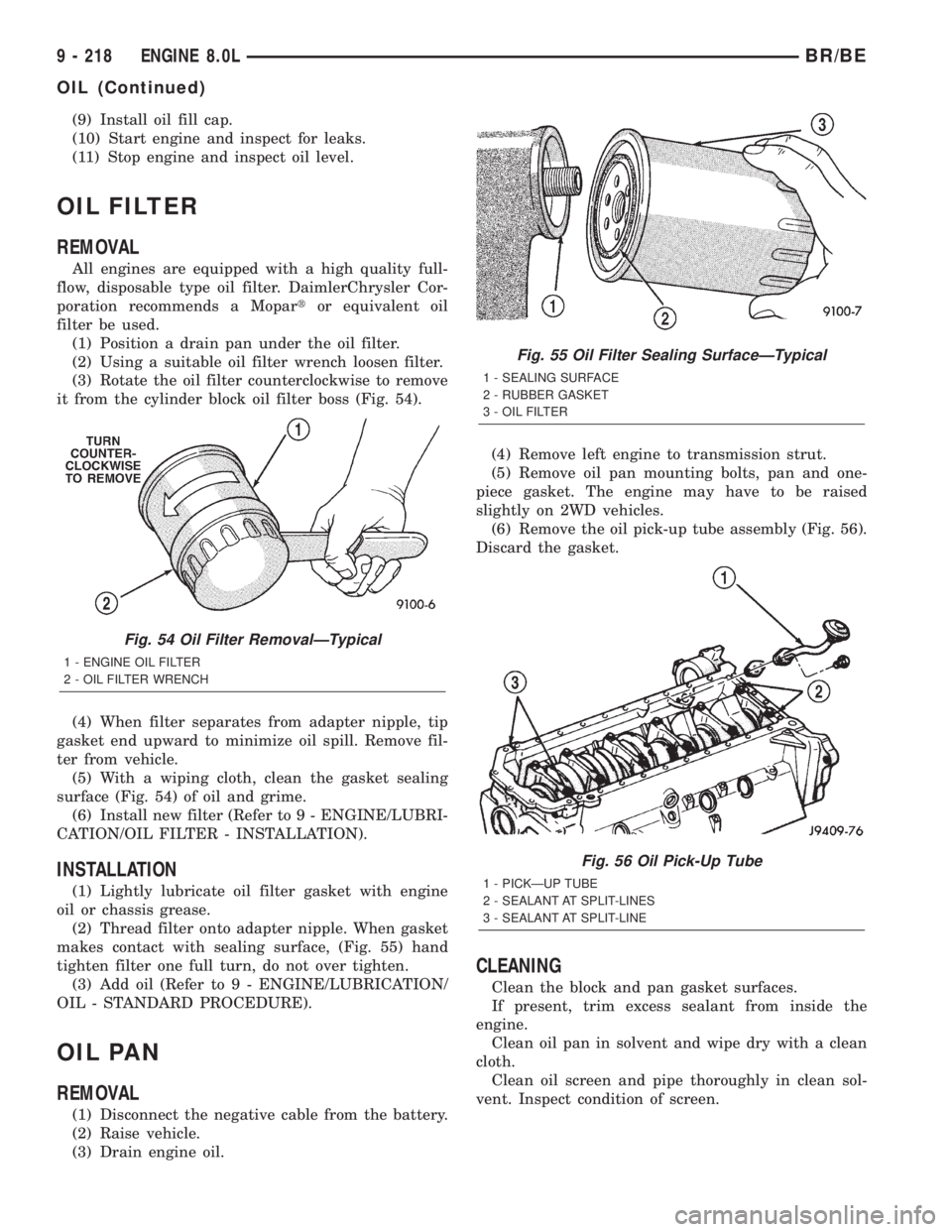

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 54).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 54) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 55) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle.

(3) Drain engine oil.(4) Remove left engine to transmission strut.

(5) Remove oil pan mounting bolts, pan and one-

piece gasket. The engine may have to be raised

slightly on 2WD vehicles.

(6) Remove the oil pick-up tube assembly (Fig. 56).

Discard the gasket.

CLEANING

Clean the block and pan gasket surfaces.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

Fig. 54 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 55 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 56 Oil Pick-Up Tube

1 - PICKÐUP TUBE

2 - SEALANT AT SPLIT-LINES

3 - SEALANT AT SPLIT-LINE

9 - 218 ENGINE 8.0LBR/BE

OIL (Continued)

Page 1443 of 2889

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 60

N´m (44 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait several minutes to allow the

oil to drain back to the pan and check the level

again.

USED ENGINE OIL DISPOSAL Care should be

exercised when disposing of used engine oil after

it has been drained from a vehicle's engine.

OIL COOLER & LINES

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter using a 90-95 mm filter wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional ó turn.

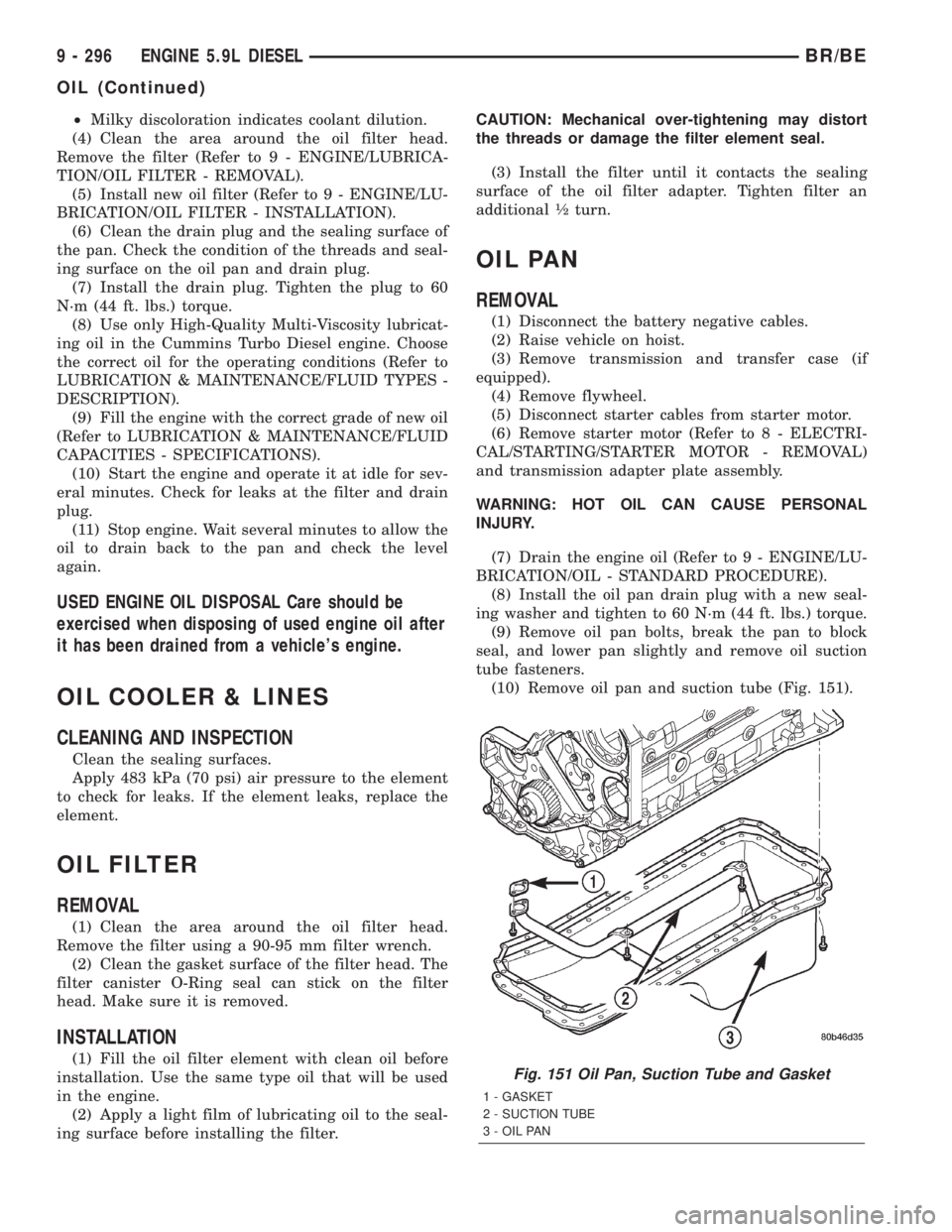

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove transmission and transfer case (if

equipped).

(4) Remove flywheel.

(5) Disconnect starter cables from starter motor.

(6) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(7) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).

(8) Install the oil pan drain plug with a new seal-

ing washer and tighten to 60 N´m (44 ft. lbs.) torque.

(9) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

(10) Remove oil pan and suction tube (Fig. 151).

Fig. 151 Oil Pan, Suction Tube and Gasket

1 - GASKET

2 - SUCTION TUBE

3 - OIL PAN

9 - 296 ENGINE 5.9L DIESELBR/BE

OIL (Continued)