stop start DODGE RAM 2001 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2803 of 2889

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

Catalyst and Fuel Monitors.

The O2S can fail in any or all of the following

manners:

²slow response rate

²reduced output voltage

²dynamic shift

²shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to volt-

age DTC, as well as a O2S heater DTC, the O2S

fault MUST be repaired first. Before checking the

O2S fault, verify that the heater circuit is operating

correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S sensor

are very temperature sensitive. The readings are not

accurate below 300ÉC. Heating of the O2S sensor is

done to allow the engine controller to shift to closed

loop control as soon as possible. The heating element

used to heat the O2S sensor must be tested to ensure

that it is heating the sensor properly.The O2S sensor circuit is monitored for a drop in

voltage. The sensor output is used to test the heater

by isolating the effect of the heater element on the

O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode: The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode: The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at .040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

25 - 16 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2805 of 2889

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3

good trips to turn the MIL OFF. In this case, it

depends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS -

GAS ENGINES

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of agreater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater,

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks, or any component

that has an associated limp-in, will set a fault after 1

trip with the malfunction present. Components with-

out an associated limp-in will take two trips to illu-

minate the MIL.

DESCRIPTION - COMPONENT MONITORS -

DIESEL ENGINES

There are several electrical components that will

affect vehicle emissions if they malfunction. If one of

these components is malfunctioning, a Diagnostic

Trouble Code (DTC) will be set by either the Power-

train Control Module (PCM) or the Engine Control

Module (ECM). The Malfunction Indicator Lamp

(MIL) will then be illuminated when the engine is

running.

These electrically operated components have input

(rationality) and output (functionality) checks. A

check is done by one or more components to check

the operation of another component.

Example:The Intake Manifold Air Temperature

(IAT) sensor is used to monitor intake manifold air

temperature over a period of time after a cold start.

If the temperature has not risen to a certain specifi-

cation during a specified time, a Diagnostic Trouble

Code (DTC) will be set for a problem in the manifold

air heater system.

All open/short circuit checks, or any component

that has an associated limp-in will set a DTC and

trigger the MIL after 1 trip with the malfunction

present. Components without an associated limp-in

will take two trips to illuminate the MIL.

OPERATION - GAS ENGINES

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

problem is repaired or ceases to exist, the PCM can-

cels the code after 40 warm-up cycles. Diagnostic

trouble codes that affect vehicle emissions illuminate

the Malfunction Indicator Lamp (MIL). The MIL is

displayed as an engine icon (graphic) on the instru-

ment panel. Refer to Malfunction Indicator Lamp in

this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

25 - 18 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2808 of 2889

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within6375

RPM and load is within610% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

BR/BEEMISSIONS CONTROL 25 - 21

EMISSIONS CONTROL (Continued)

Page 2837 of 2889

BODY INTERIOR

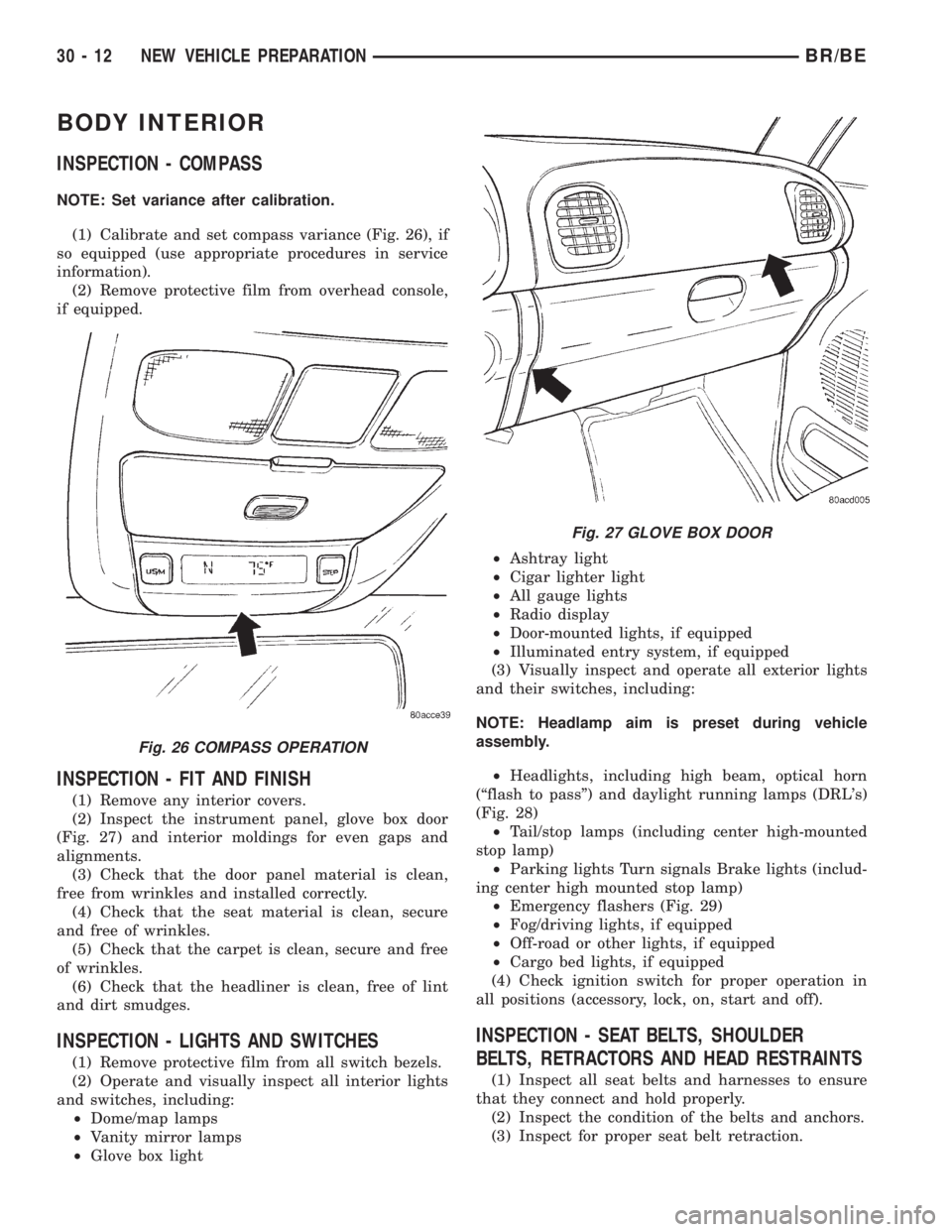

INSPECTION - COMPASS

NOTE: Set variance after calibration.

(1) Calibrate and set compass variance (Fig. 26), if

so equipped (use appropriate procedures in service

information).

(2) Remove protective film from overhead console,

if equipped.

INSPECTION - FIT AND FINISH

(1) Remove any interior covers.

(2) Inspect the instrument panel, glove box door

(Fig. 27) and interior moldings for even gaps and

alignments.

(3) Check that the door panel material is clean,

free from wrinkles and installed correctly.

(4) Check that the seat material is clean, secure

and free of wrinkles.

(5) Check that the carpet is clean, secure and free

of wrinkles.

(6) Check that the headliner is clean, free of lint

and dirt smudges.

INSPECTION - LIGHTS AND SWITCHES

(1) Remove protective film from all switch bezels.

(2) Operate and visually inspect all interior lights

and switches, including:

²Dome/map lamps

²Vanity mirror lamps

²Glove box light²Ashtray light

²Cigar lighter light

²All gauge lights

²Radio display

²Door-mounted lights, if equipped

²Illuminated entry system, if equipped

(3) Visually inspect and operate all exterior lights

and their switches, including:

NOTE: Headlamp aim is preset during vehicle

assembly.

²Headlights, including high beam, optical horn

(ªflash to passº) and daylight running lamps (DRL's)

(Fig. 28)

²Tail/stop lamps (including center high-mounted

stop lamp)

²Parking lights Turn signals Brake lights (includ-

ing center high mounted stop lamp)

²Emergency flashers (Fig. 29)

²Fog/driving lights, if equipped

²Off-road or other lights, if equipped

²Cargo bed lights, if equipped

(4) Check ignition switch for proper operation in

all positions (accessory, lock, on, start and off).

INSPECTION - SEAT BELTS, SHOULDER

BELTS, RETRACTORS AND HEAD RESTRAINTS

(1) Inspect all seat belts and harnesses to ensure

that they connect and hold properly.

(2) Inspect the condition of the belts and anchors.

(3) Inspect for proper seat belt retraction.

Fig. 26 COMPASS OPERATION

Fig. 27 GLOVE BOX DOOR

30 - 12 NEW VEHICLE PREPARATIONBR/BE

Page 2841 of 2889

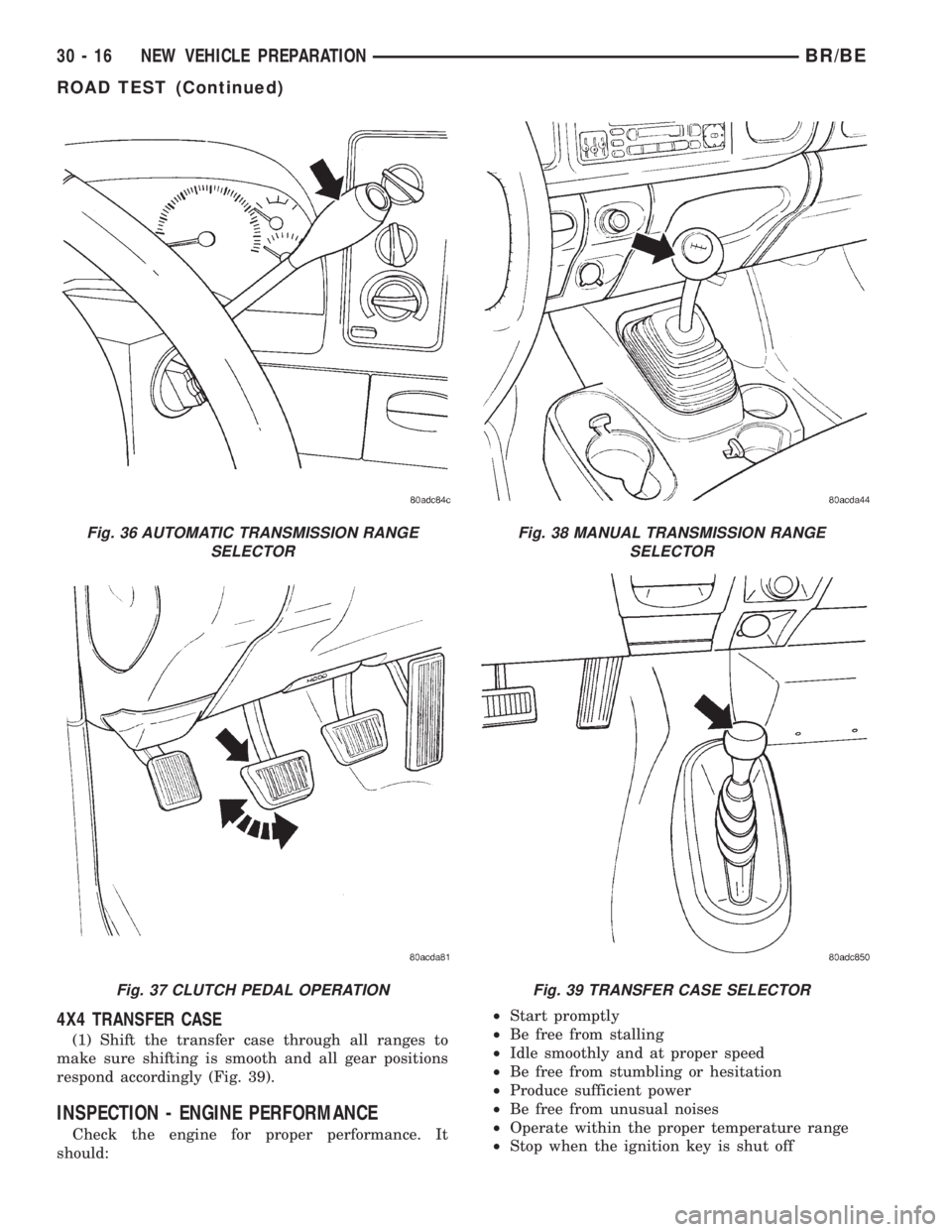

4X4 TRANSFER CASE

(1) Shift the transfer case through all ranges to

make sure shifting is smooth and all gear positions

respond accordingly (Fig. 39).

INSPECTION - ENGINE PERFORMANCE

Check the engine for proper performance. It

should:²Start promptly

²Be free from stalling

²Idle smoothly and at proper speed

²Be free from stumbling or hesitation

²Produce sufficient power

²Be free from unusual noises

²Operate within the proper temperature range

²Stop when the ignition key is shut off

Fig. 36 AUTOMATIC TRANSMISSION RANGE

SELECTOR

Fig. 37 CLUTCH PEDAL OPERATION

Fig. 38 MANUAL TRANSMISSION RANGE

SELECTOR

Fig. 39 TRANSFER CASE SELECTOR

30 - 16 NEW VEHICLE PREPARATIONBR/BE

ROAD TEST (Continued)

Page 2842 of 2889

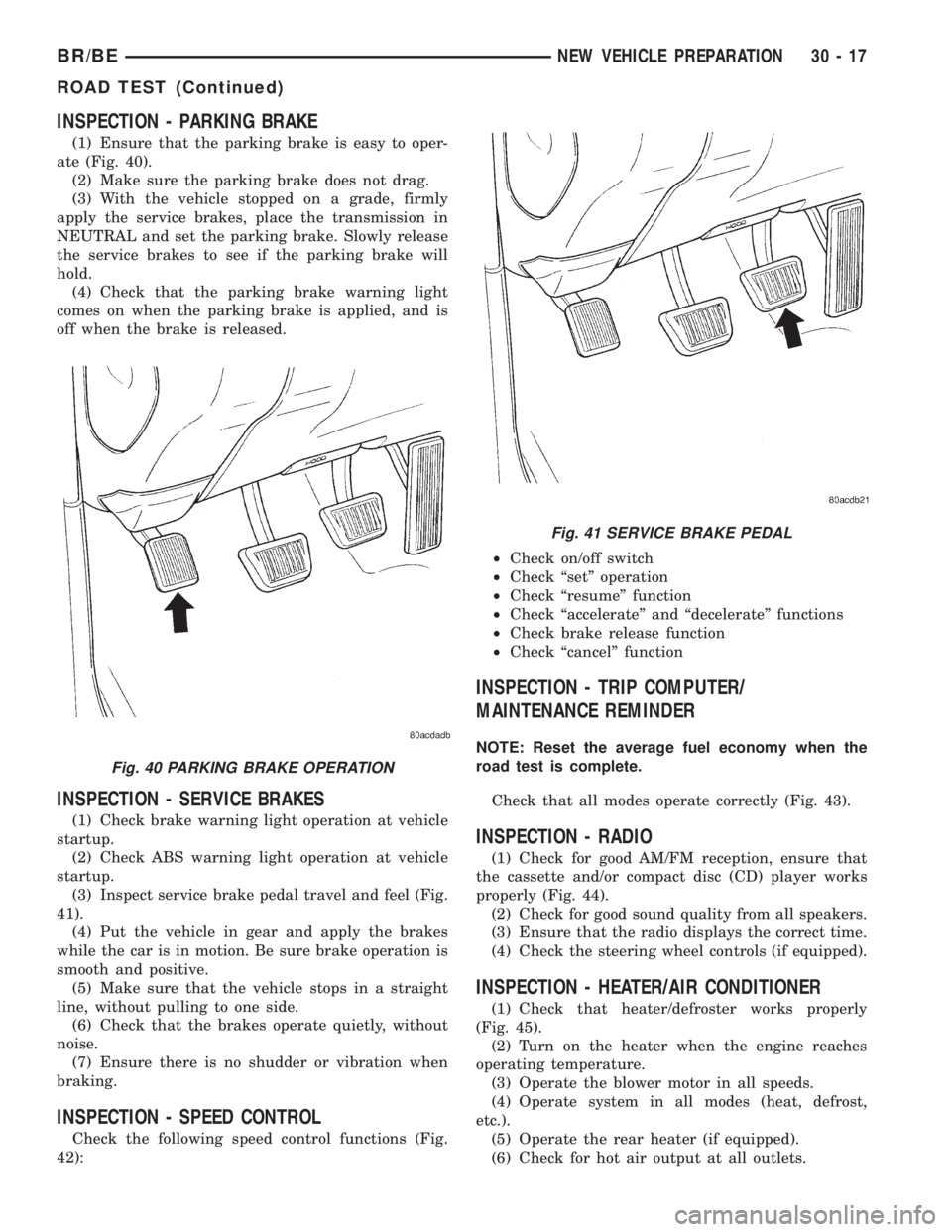

INSPECTION - PARKING BRAKE

(1) Ensure that the parking brake is easy to oper-

ate (Fig. 40).

(2) Make sure the parking brake does not drag.

(3) With the vehicle stopped on a grade, firmly

apply the service brakes, place the transmission in

NEUTRAL and set the parking brake. Slowly release

the service brakes to see if the parking brake will

hold.

(4) Check that the parking brake warning light

comes on when the parking brake is applied, and is

off when the brake is released.

INSPECTION - SERVICE BRAKES

(1) Check brake warning light operation at vehicle

startup.

(2) Check ABS warning light operation at vehicle

startup.

(3) Inspect service brake pedal travel and feel (Fig.

41).

(4) Put the vehicle in gear and apply the brakes

while the car is in motion. Be sure brake operation is

smooth and positive.

(5) Make sure that the vehicle stops in a straight

line, without pulling to one side.

(6) Check that the brakes operate quietly, without

noise.

(7) Ensure there is no shudder or vibration when

braking.

INSPECTION - SPEED CONTROL

Check the following speed control functions (Fig.

42):²Check on/off switch

²Check ªsetº operation

²Check ªresumeº function

²Check ªaccelerateº and ªdecelerateº functions

²Check brake release function

²Check ªcancelº function

INSPECTION - TRIP COMPUTER/

MAINTENANCE REMINDER

NOTE: Reset the average fuel economy when the

road test is complete.

Check that all modes operate correctly (Fig. 43).

INSPECTION - RADIO

(1) Check for good AM/FM reception, ensure that

the cassette and/or compact disc (CD) player works

properly (Fig. 44).

(2) Check for good sound quality from all speakers.

(3) Ensure that the radio displays the correct time.

(4) Check the steering wheel controls (if equipped).

INSPECTION - HEATER/AIR CONDITIONER

(1) Check that heater/defroster works properly

(Fig. 45).

(2) Turn on the heater when the engine reaches

operating temperature.

(3) Operate the blower motor in all speeds.

(4) Operate system in all modes (heat, defrost,

etc.).

(5) Operate the rear heater (if equipped).

(6) Check for hot air output at all outlets.

Fig. 40 PARKING BRAKE OPERATION

Fig. 41 SERVICE BRAKE PEDAL

BR/BENEW VEHICLE PREPARATION 30 - 17

ROAD TEST (Continued)

Page 2867 of 2889

INTAKE/EXHAUST VALVES & SEATS -

VALVE SERVICE......................9-195

IN-TANK TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLER AND TUBES - WITHOUT

RADIATOR...................7-80,7-83,7-86

IN-TANK TRANSMISSION OIL COOLER -

STANDARD PROCEDURE, FLUSHING

COOLERS AND TUBES - WITH

RADIATOR...................7-79,7-83,7-85

INTERIOR - CAUTION................23-118

INTERLOCK SYSTEM - INSPECTION,

SHIFT/CLUTCH.......................30-19

INTERMEDIATE - INSTALLATION, AXLE

SHAFTS.............................3-28

INTERMEDIATE - REMOVAL, AXLE

SHAFTS.............................3-28

INTERMEDIATE AXLE - INSTALLATION.....3-61

INTERMEDIATE AXLE - REMOVAL.........3-60

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-6

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-3

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS . . 9-118,9-173,9-3

INTRODUCTION - DIAGNOSIS AND

TESTING-ENGINE DIAGNOSIS............9-61

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE..................5-8

IOD FUSE - DESCRIPTION...........8W-97-4

IOD FUSE - INSTALLATION...........8W-97-5

IOD FUSE - OPERATION.............8W-97-5

IOD FUSE - REMOVAL................8W-97-5

ISO FLARING - STANDARD PROCEDURE....5-8

ITEMS - INSTALLATION, SHIPPED LOOSE . 30-14

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - DIAGNOSIS AND TESTING,

UPPER BALL.........................2-12

JOINT - INSTALLATION, LOWER BALL.....2-25

JOINT - INSTALLATION, UPPER BALL.....2-25

JOINT MOLDING - INSTALLATION, ROOF . . 23-91

JOINT MOLDING - REMOVAL, ROOF......23-91

JOINTS - DISASSEMBLY, SINGLE

CARDAN UNIVERSAL..................3-11

JOINTS - INSTALLATION, SINGLE

CARDAN UNIVERSAL..............3-34,3-66

JOINTS - REMOVAL, SINGLE CARDAN

UNIVERSAL......................3-33,3-65

JOUNCE BUMPER - DESCRIPTION.....2-28,2-9

JOUNCE BUMPER - OPERATION.......2-28,2-9

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-274

JUMP STARTING - STANDARD

PROCEDURE.........................0-27

JUNCTION BLOCK - DESCRIPTION.....8W-97-6

JUNCTION BLOCK - INSTALLATION....8W-97-7

JUNCTION BLOCK - OPERATION......8W-97-6

JUNCTION BLOCK - REMOVAL........8W-97-6

KEEPER - INSTALLATION, BACKLITE

LATCH ............................23-146

KEEPER - REMOVAL, BACKLITE LATCH . . 23-146

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-10

KEY-IN IGNITION SWITCH -

DESCRIPTION........................19-9

KEYLESS ENTRY - INSPECTION.........30-11

KEYLESS ENTRY SYSTEM -

DESCRIPTION, REMOTE................8N-2

KEYLESS ENTRY SYSTEM - DIAGNOSIS

AND TESTING, POWER LOCK &

REMOTE............................8N-4

KEYLESS ENTRY SYSTEM - OPERATION,

REMOTE............................8N-3

KEYLESS ENTRY TRANSMITTER -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-7

KEYLESS ENTRY TRANSMITTER -

OPERATION, REMOTE..................8N-7

KNOB - INSTALLATION, TURNING LOOP

HEIGHT ADJUSTER

...................8O-30

KNOB - REMOVAL, TURNING LOOP

HEIGHT ADJUSTER

...................8O-30

KNUCKLE - DESCRIPTION

............2-20,2-9

KNUCKLE - INSTALLATION

..........2-10,2-20

KNUCKLE - OPERATION

............2-10,2-20KNUCKLE - REMOVAL..............2-10,2-20

LABEL - DESCRIPTION, VECI.........Intro.-10

LABEL - DESCRIPTION, VEHICLE SAFETY

CERTIFICATION....................Intro.-12

LABEL - OPERATION, VECI...........Intro.-10

LABELS - STANDARD PROCEDURE,

INSPECTION - INFORMATION...........30-22

LAMP - DESCRIPTION, READING........8L-36

LAMP - DESCRIPTION, TAIL............8L-29

LAMP - DIAGNOSIS AND TESTING, FOG . . . 8L-9

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - INSTALLATION, CLEARANCE......8L-6

LAMP - INSTALLATION, DOME..........8L-33

LAMP - INSTALLATION, FOG............8L-11

LAMP - INSTALLATION, LICENSE PLATE . . 8L-22

LAMP - INSTALLATION, MARKER........8L-23

LAMP - INSTALLATION, OUTBOARD

IDENTIFICATION.....................8L-29

LAMP - INSTALLATION, PARK/TURN

SIGNAL............................8L-29

LAMP - INSTALLATION, READING........8L-36

LAMP - INSTALLATION, TAIL...........8L-30

LAMP - INSTALLATION, UNDERHOOD....8L-32

LAMP - INSTALLATION, VANITY.........8L-37

LAMP - OPERATION, READING..........8L-36

LAMP - OPERATION, TAIL..............8L-29

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP - REMOVAL, CLEARANCE..........8L-6

LAMP - REMOVAL, DOME..............8L-33

LAMP - REMOVAL, FOG...............8L-11

LAMP - REMOVAL, LICENSE PLATE......8L-22

LAMP - REMOVAL, MARKER...........8L-22

LAMP - REMOVAL, OUTBOARD

IDENTIFICATION.....................8L-28

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-29

LAMP - REMOVAL, READING...........8L-36

LAMP - REMOVAL, TAIL...............8L-29

LAMP - REMOVAL, UNDERHOOD........8L-31

LAMP - REMOVAL, VANITY.............8L-37

LAMP AND SWITCH - INSTALLATION,

GLOVE BOX.........................8L-35

LAMP AND SWITCH - REMOVAL, GLOVE

BOX ...............................8L-35

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-24

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-24

LAMP MODULE - DESCRIPTION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - INSTALLATION,

DAYTIME RUNNING....................8L-9

LAMP MODULE - OPERATION, DAYTIME

RUNNING............................8L-9

LAMP MODULE - REMOVAL, DAYTIME

RUNNING............................8L-9

LAMP SWITCH - DESCRIPTION, BRAKE....8L-4

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE......................8L-5

LAMP SWITCH - INSTALLATION, BRAKE . . . 8L-5

LAMP SWITCH - OPERATION, BRAKE......8L-4

LAMP SWITCH - REMOVAL, BRAKE.......8L-5

LAMP UNIT - ADJUSTMENTS, FOG.......8L-12

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP.................8L-6

LAMP UNIT - INSTALLATION, FOG.......8L-12

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-22

LAMP UNIT - INSTALLATION, PARK/

TURN SIGNAL.......................8L-29

LAMP UNIT - INSTALLATION, TAIL.......8L-30

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-32

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP......................8L-6

LAMP UNIT - REMOVAL, FOG...........8L-11

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-22

LAMP UNIT - REMOVAL, PARK/TURN

SIGNAL............................8L-29

LAMP UNIT - REMOVAL, TAIL...........8L-30

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-32

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE

.......9-256

LATCH - ADJUSTMENT

...............23-100

LATCH - ADJUSTMENT, FRONT DOOR

....23-72

LATCH - INSTALLATION

....23-100,23-64,23-72

LATCH - INSTALLATION, SAFETY

.......23-102LATCH - LOWER - INSTALLATION........23-80

LATCH - LOWER - REMOVAL...........23-80

LATCH - REMOVAL........23-100,23-64,23-72

LATCH - REMOVAL, SAFETY...........23-102

LATCH - UPPER - INSTALLATION........23-81

LATCH - UPPER - REMOVAL............23-81

LATCH AND KEEPER - INSTALLATION,

BACKLITE.........................23-146

LATCH AND KEEPER - REMOVAL,

BACKLITE.........................23-146

LATCH HANDLE - INSTALLATION........23-65

LATCH HANDLE - REMOVAL............23-65

LATCH RELEASE CABLE - INSTALLATION . 23-101

LATCH RELEASE CABLE - REMOVAL....23-101

LATCH STRIKER - ADJUSTMENT.......23-102

LATCH STRIKER - INSTALLATION . 23-102,23-65,

23-73

LATCH STRIKER - INSTALLATION, GLOVE

BOX ..............................23-113

LATCH STRIKER - LOWER -

INSTALLATION.......................23-82

LATCH STRIKER - LOWER - REMOVAL....23-82

LATCH STRIKER - REMOVAL.....23-102,23-65,

23-73

LATCH STRIKER - REMOVAL, GLOVE

BOX ..............................23-113

LATCH STRIKER - UPPER -

INSTALLATION.......................23-82

LATCH STRIKER - UPPER - REMOVAL....23-82

LATCH/SAFETY CATCH - INSPECTION,

HOOD..............................30-4

LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING FLUID . . . 21-148,21-319,

21-491,21-662

LEAK DETECTION PUMP - DESCRIPTION . . 25-33

LEAK DETECTION PUMP - INSTALLATION . 25-34

LEAK DETECTION PUMP - REMOVAL.....25-34

LEAK DOWN TEST - DIAGNOSIS AND

TESTING, FUEL PRESSURE..............14-2

LEAKAGE - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE....9-124,

9-179,9-67,9-9

LEAKAGE - DIAGNOSIS AND TESTING,

INTAKE MANIFOLD.....9-110,9-165,9-222,9-53

LEAKAGE - DIAGNOSIS AND TESTING,

POWER STEERING GEAR..............19-14

LEAKAGE - DIAGNOSIS AND TESTING,

PUMP.............................19-31

LEAKS - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-5

LEAKS - DIAGNOSIS AND TESTING,

ENGINE OIL...........9-104,9-160,9-215,9-47

LEAKS - DIAGNOSIS AND TESTING,

HIGH-PRESSURE FUEL LINE............14-74

LEAKS - DIAGNOSIS AND TESTING,

REAR SEAL AREA.....................9-10

LEAKS - DIAGNOSIS AND TESTING,

REFRIGERANT SYSTEM...............24-43

LEAKS - DIAGNOSIS AND TESTING,

WATER .............................23-2

LEAKS - STANDARD PROCEDURES,

REPAIRING..........................22-8

LEFT FRONT FENDER - INSTALLATION....23-93

LEFT FRONT FENDER - REMOVAL.......23-92

LEVEL - DIAGNOSIS AND TESTING,

EFFECTS OF INCORRECT FLUID . . 21-199,21-370,

21-545,21-715

LEVEL - STANDARD PROCEDURE,

BRAKE FLUID........................5-14

LEVEL - STANDARD PROCEDURE,

CHECKING BATTERY ELECTROLYTE.......8F-8

LEVEL - STANDARD PROCEDURE,

REFRIGERANT OIL...................24-57

LEVEL CHECK - STANDARD

PROCEDURE, COOLANT................7-16

LEVEL CHECK - STANDARD

PROCEDURE, FLUID.....21-199,21-370,21-545,

21-715

LEVEL, OIL - STANDARD PROCEDURE-

ENGINE OIL

.........................9-295

LEVEL SENDING UNIT / SENSOR -

DESCRIPTION, FUEL

..............14-7,14-73

LEVEL SENDING UNIT / SENSOR -

INSTALLATION, FUEL

..................14-9

LEVEL SENDING UNIT / SENSOR -

OPERATION, FUEL

................14-7,14-73

LEVEL SENDING UNIT / SENSOR -

REMOVAL, FUEL

......................14-8

20 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2880 of 2889

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................23-61

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................13-9

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................24-8

SPECIFICATIONS, TORQUE - FUEL

DELIVERY...........................14-4

SPECIFICATIONS, TORQUE - GAS FUEL

INJECTION..........................14-35

SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING SYSTEM........8F-28

SPECIFICATIONS, TORQUE - IGNITION.....8I-2

SPECIFICATIONS, TORQUE - STARTING

SYSTEM............................8F-38

SPEED CONTROL - INSPECTION.........30-17

SPEED CONTROL SERVO - DESCRIPTION . . 8P-5

SPEED CONTROL SERVO -

INSTALLATION.......................8P-10

SPEED CONTROL SERVO - OPERATION....8P-5

SPEED CONTROL SERVO - REMOVAL.....8P-6

SPEED CONTROL SYSTEM -

DESCRIPTION........................8P-1

SPEED CONTROL SYSTEM - OPERATION . . . 8P-2

SPEED CONTROL SYSTEM - TORQUE.....8P-4

SPEED INPUT - DESCRIPTION, VEHICLE . . . 8P-1

SPEED SENSOR - DESCRIPTION . 21-253,21-424,

21-597,21-770

SPEED SENSOR - OPERATION . . . 21-253,21-424,

21-597,21-770

SPEEDOMETER - DESCRIPTION...........8J-30

SPEEDOMETER - OPERATION...........8J-30

SPLASH SHIELD - INSTALLATION, REAR . . 23-96

SPLASH SHIELD - REMOVAL, REAR......23-96

SPLASH SHIELDS - INSTALLATION,

FRONT END.........................23-92

SPLASH SHIELDS - REMOVAL, FRONT

END ...............................23-92

SPLICE LOCATIONS - DESCRIPTION . . . 8W-95-1

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-12

SPLIT BENCH - INSTALLATION, SEAT....23-134

SPLIT BENCH - INSTALLATION, SEAT

BACK.............................23-136

SPLIT BENCH - INSTALLATION, SEAT

BACK COVER.......................23-138

SPLIT BENCH - INSTALLATION, SEAT

CUSHION COVER....................23-140

SPLIT BENCH - INSTALLATION, SEAT

TRACK............................23-142

SPLIT BENCH - REMOVAL, SEAT.......23-134

SPLIT BENCH - REMOVAL, SEAT BACK . . 23-135

SPLIT BENCH - REMOVAL, SEAT BACK

COVER............................23-137

SPLIT BENCH - REMOVAL, SEAT

CUSHION COVER....................23-139

SPLIT BENCH - REMOVAL, SEAT TRACK . 23-142

SPOOL VALVE - INSTALLATION..........19-26

SPOOL VALVE - REMOVAL.............19-24

SPRING - DESCRIPTION........2-11,2-22,2-28

SPRING - INSTALLATION.......2-12,2-22,2-29

SPRING - OPERATION..........2-11,2-22,2-28

SPRING - REMOVAL...........2-11,2-22,2-28

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-26

SPRINGS - INSTALLATION, VALVES AND

VALVE .............................9-199

SPRINGS - REMOVAL, VALVES AND

VALVE .............................9-197

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES.............9-138,9-25,9-82

SPRINGS, INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE-

VALVES,GUIDES.....................9-253

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN...........9-115,9-170,9-227,9-58

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN...........9-114,9-170,9-226,9-57

SQUEAKS, RATTLES AND WIND NOISE -

INSPECTION........................30-15

STABILIZER BAR - DESCRIPTION . 2-12,2-22,2-30

STABILIZER BAR - INSTALLATION....2-12,2-23,

2-30

STABILIZER BAR - OPERATION

. . 2-12,2-22,2-30

STABILIZER BAR - REMOVAL

....2-12,2-22,2-30

STANCHION COVER - INSTALLATION

....23-143

STANCHION COVER - REMOVAL

........23-143

STANDARD CAB - INSTALLATION

........8O-19STANDARD CAB - REMOVAL...........8O-18

STARTER MOTOR - DESCRIPTION,

ENGINE............................8F-39

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-39

STARTER MOTOR - INSTALLATION,

ENGINE............................8F-41

STARTER MOTOR - OPERATION, ENGINE . . 8F-39

STARTER MOTOR - REMOVAL, ENGINE . . . 8F-40

STARTER MOTOR RELAY -

DESCRIPTION, ENGINE................8F-42

STARTER MOTOR RELAY -

INSTALLATION, ENGINE................8F-43

STARTER MOTOR RELAY - OPERATION,

ENGINE............................8F-42

STARTER MOTOR RELAY - REMOVAL,

ENGINE............................8F-43

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-42

STARTING - DESCRIPTION.............8F-32

STARTING - OPERATION...............8F-32

STARTING - STANDARD PROCEDURE,

JUMP...............................0-27

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-33

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-38

STARTING SYSTEM, SPECIFICATIONS.....8F-38

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STATIONARY GLASS - DESCRIPTION....23-145

STATIONARY GLASS - OPERATION......23-145

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING AND HANDLING -

INSPECTION........................30-15

STEERING COLUMN OPENING COVER -

INSTALLATION......................23-116

STEERING COLUMN OPENING COVER -

REMOVAL.........................23-115

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING GEAR HOUSING PLUG -

INSTALLATION.......................19-27

STEERING GEAR HOUSING PLUG -

REMOVAL..........................19-27

STEERING GEAR LEAKAGE - DIAGNOSIS

AND TESTING, POWER................19-14

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-20

STEERING GEAR, SPECIFICATIONS -

POWER............................19-19

STEERING LINKAGE, SPECIAL TOOLS....19-39,

19-42

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-31

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-36

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER........19-32

STEERING WHEEL - INSTALLATION......19-13

STEERING WHEEL - REMOVAL..........19-13

STEM SEAL - INSTALLATION, VALVE.....9-198

STEM SEALS - REMOVAL, VALVE........9-197

STEPS - NEW VEHICLE PREPARATION

FORM, FINAL........................30-22

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED......................8L-6

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED...........................8L-6

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED...............8L-6

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED......................8L-6

STORAGE - DESCRIPTION, PRE

DELIVERY..........................30-19

STORAGE - STANDARD PROCEDURE,

PRE DELIVERY......................30-20

STORAGE BIN - INSTALLATION

.........23-116

STORAGE BIN - REMOVAL

............23-116

STOWAGE TRAY - INSTALLATION, REAR

FLOOR

............................23-121

STOWAGE TRAY - REMOVAL, REAR

FLOOR

............................23-121

STRAP - INSTALLATION, CAB-TO- BED

GROUND

...........................8A-14STRAP - INSTALLATION, ENGINE-TO-

BODY GROUND......................8A-13

STRAP - INSTALLATION, HEATER CORE

GROUND...........................8A-15

STRAP - REMOVAL, CAB-TO- BED

GROUND...........................8A-14

STRAP - REMOVAL, ENGINE-TO-BODY

GROUND...........................8A-13

STRAP - REMOVAL, HEATER CORE

GROUND...........................8A-14

STRETCH - INSPECTION, MEASURING

TIMING CHAIN........9-114,9-170,9-227,9-58

STRIKER - ADJUSTMENT, LATCH.......23-102

STRIKER - INSTALLATION, GLOVE BOX

LATCH ............................23-113

STRIKER - INSTALLATION, LATCH . 23-102,23-65,

23-73

STRIKER - LOWER - INSTALLATION,

LATCH .............................23-82

STRIKER - LOWER - REMOVAL, LATCH . . . 23-82

STRIKER - REMOVAL, GLOVE BOX

LATCH ............................23-113

STRIKER - REMOVAL, LATCH....23-102,23-65,

23-73

STRIKER - UPPER - INSTALLATION,

LATCH .............................23-82

STRIKER - UPPER - REMOVAL, LATCH . . . 23-82

STRIPE - INSTALLATION, TAPE..........23-88

STRIPE - REMOVAL, TAPE.............23-88

STRIPES AND DECALS - INSTALLATION,

BODY..............................23-87

STRIPES AND DECALS - REMOVAL,

BODY..............................23-87

STRUCTURAL ADHESIVE LOCATIONS,

SPECIFICATIONS.....................23-44

STUDS - INSTALLATION...............22-12

STUDS - REMOVAL...................22-12

SUCTION AND DISCHARGE LINE -

INSTALLATION.......................24-51

SUCTION AND DISCHARGE LINE -

REMOVAL..........................24-50

SUN VISOR - INSTALLATION..........23-127

SUN VISOR - REMOVAL..............23-127

SUPPLIES - DESCRIPTION, 5 VOLT......8E-17

SUPPLIES - OPERATION, 5 VOLT........8E-19

SUPPLY - DIAGNOSIS AND TESTING,

VACUUM............................8P-2

SUPPLY RESTRICTIONS - DIAGNOSIS

AND TESTING, FUEL..................14-56

SUPPORT - INSTALLATION, LUMBAR....23-133

SUPPORT - REMOVAL, LUMBAR.......23-133

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR.................23-126

SUPPORT PLATE - INSTALLATION........5-32

SUPPORT PLATE - REMOVAL............5-32

SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO NOISE...........8A-12

SUPPRESSION COMPONENTS -

DIAGNOSIS AND TESTING, RADIO

NOISE.............................8A-12

SUSPENSION - STANDARD

PROCEDURES, ALIGNMENT LINK/COIL.....2-5

SUSPENSION, SPECIAL TOOLS -

INDEPENDENT FRONT...................2-9

SUSPENSION, SPECIAL TOOLS -

LINK/COIL...........................2-16

SUSPENSION-REAR, SPECIAL TOOLS.....2-28

SWITCH - DESCRIPTION

...............8P-12

SWITCH - DESCRIPTION, A/C HIGH

PRESSURE

.........................24-20

SWITCH - DESCRIPTION, A/C LOW

PRESSURE

.........................24-21

SWITCH - DESCRIPTION, BLOWER

MOTOR

............................24-24

SWITCH - DESCRIPTION, BRAKE LAMP

....8L-4

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION

.....................6-22

SWITCH - DESCRIPTION, DOOR AJAR

....8L-34

SWITCH - DESCRIPTION, DOOR

CYLINDER LOCK

......................8N-5

SWITCH - DESCRIPTION, DRIVER

POWER SEAT

.......................8N-16

SWITCH - DESCRIPTION, DRIVER SEAT

HEATER

.............................8G-7

SWITCH - DESCRIPTION, HEADLAMP

....8L-18

SWITCH - DESCRIPTION, HORN

..........8H-4

SWITCH - DESCRIPTION, IGNITION

......19-11

BR/BEINDEX 33

Description Group-Page Description Group-Page Description Group-Page