DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 391 of 2889

FAN DRIVE VISCOUS CLUTCH

- 3.9L/5.2L/5.9L/8.0L

DESCRIPTION

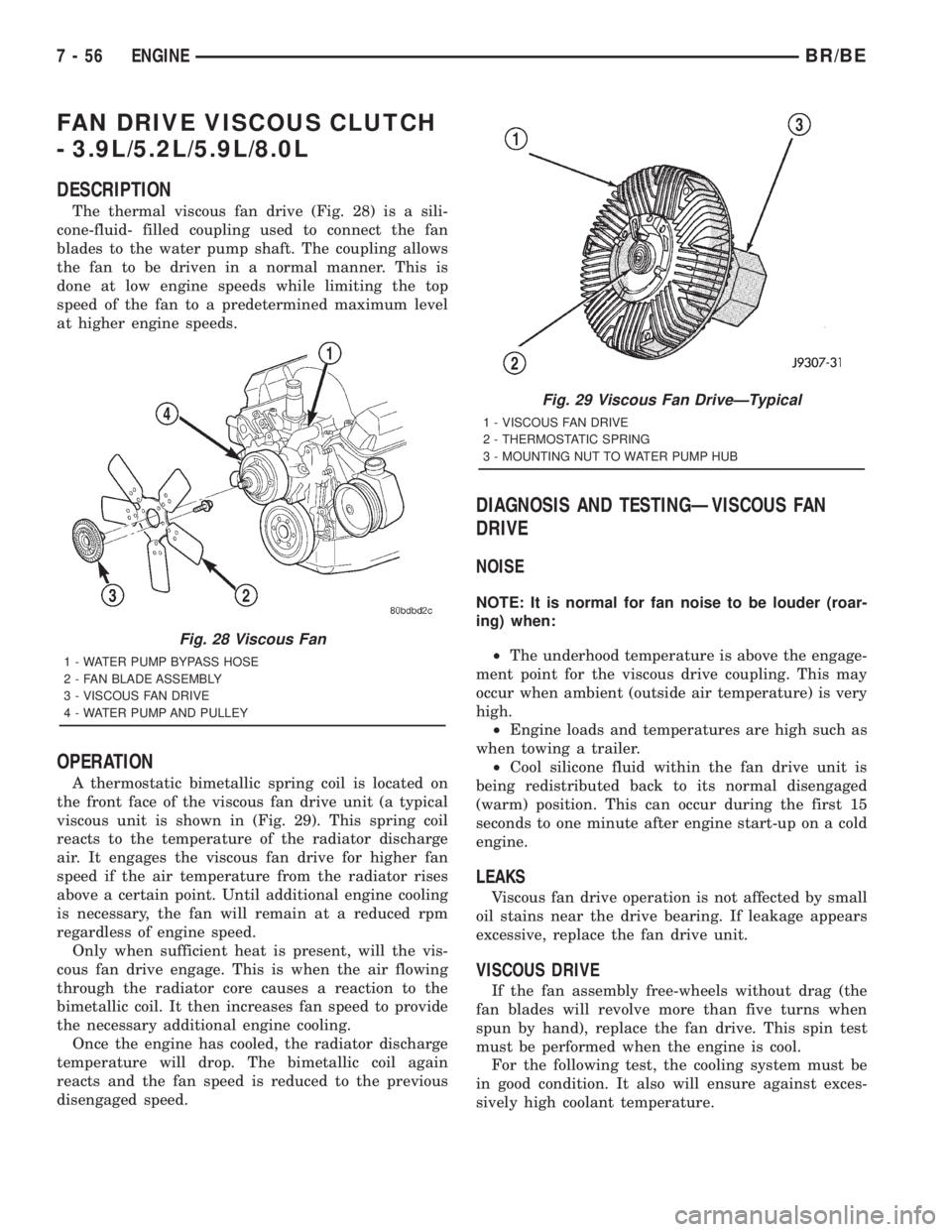

The thermal viscous fan drive (Fig. 28) is a sili-

cone-fluid- filled coupling used to connect the fan

blades to the water pump shaft. The coupling allows

the fan to be driven in a normal manner. This is

done at low engine speeds while limiting the top

speed of the fan to a predetermined maximum level

at higher engine speeds.

OPERATION

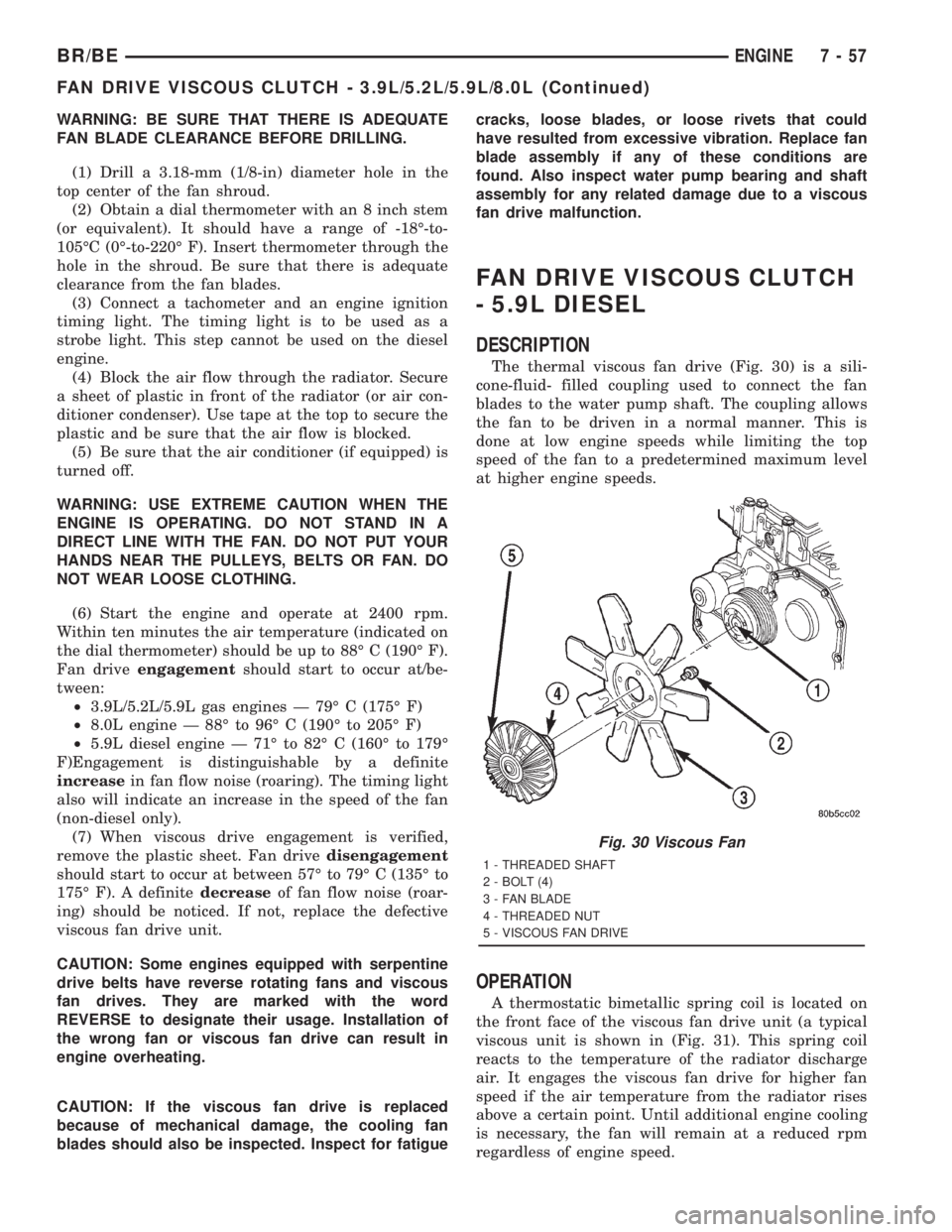

A thermostatic bimetallic spring coil is located on

the front face of the viscous fan drive unit (a typical

viscous unit is shown in (Fig. 29). This spring coil

reacts to the temperature of the radiator discharge

air. It engages the viscous fan drive for higher fan

speed if the air temperature from the radiator rises

above a certain point. Until additional engine cooling

is necessary, the fan will remain at a reduced rpm

regardless of engine speed.

Only when sufficient heat is present, will the vis-

cous fan drive engage. This is when the air flowing

through the radiator core causes a reaction to the

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again

reacts and the fan speed is reduced to the previous

disengaged speed.

DIAGNOSIS AND TESTINGÐVISCOUS FAN

DRIVE

NOISE

NOTE: It is normal for fan noise to be louder (roar-

ing) when:

²The underhood temperature is above the engage-

ment point for the viscous drive coupling. This may

occur when ambient (outside air temperature) is very

high.

²Engine loads and temperatures are high such as

when towing a trailer.

²Cool silicone fluid within the fan drive unit is

being redistributed back to its normal disengaged

(warm) position. This can occur during the first 15

seconds to one minute after engine start-up on a cold

engine.

LEAKS

Viscous fan drive operation is not affected by small

oil stains near the drive bearing. If leakage appears

excessive, replace the fan drive unit.

VISCOUS DRIVE

If the fan assembly free-wheels without drag (the

fan blades will revolve more than five turns when

spun by hand), replace the fan drive. This spin test

must be performed when the engine is cool.

For the following test, the cooling system must be

in good condition. It also will ensure against exces-

sively high coolant temperature.

Fig. 28 Viscous Fan

1 - WATER PUMP BYPASS HOSE

2 - FAN BLADE ASSEMBLY

3 - VISCOUS FAN DRIVE

4 - WATER PUMP AND PULLEY

Fig. 29 Viscous Fan DriveÐTypical

1 - VISCOUS FAN DRIVE

2 - THERMOSTATIC SPRING

3 - MOUNTING NUT TO WATER PUMP HUB

7 - 56 ENGINEBR/BE

Page 392 of 2889

WARNING: BE SURE THAT THERE IS ADEQUATE

FAN BLADE CLEARANCE BEFORE DRILLING.

(1) Drill a 3.18-mm (1/8-in) diameter hole in the

top center of the fan shroud.

(2) Obtain a dial thermometer with an 8 inch stem

(or equivalent). It should have a range of -18É-to-

105ÉC (0É-to-220É F). Insert thermometer through the

hole in the shroud. Be sure that there is adequate

clearance from the fan blades.

(3) Connect a tachometer and an engine ignition

timing light. The timing light is to be used as a

strobe light. This step cannot be used on the diesel

engine.

(4) Block the air flow through the radiator. Secure

a sheet of plastic in front of the radiator (or air con-

ditioner condenser). Use tape at the top to secure the

plastic and be sure that the air flow is blocked.

(5) Be sure that the air conditioner (if equipped) is

turned off.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 88É C (190É F).

Fan driveengagementshould start to occur at/be-

tween:

²3.9L/5.2L/5.9L gas engines Ð 79É C (175É F)

²8.0L engine Ð 88É to 96É C (190É to 205É F)

²5.9L diesel engine Ð 71É to 82É C (160É to 179É

F)Engagement is distinguishable by a definite

increasein fan flow noise (roaring). The timing light

also will indicate an increase in the speed of the fan

(non-diesel only).

(7) When viscous drive engagement is verified,

remove the plastic sheet. Fan drivedisengagement

should start to occur at between 57É to 79É C (135É to

175É F). A definitedecreaseof fan flow noise (roar-

ing) should be noticed. If not, replace the defective

viscous fan drive unit.

CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. They are marked with the word

REVERSE to designate their usage. Installation of

the wrong fan or viscous fan drive can result in

engine overheating.

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatiguecracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

FAN DRIVE VISCOUS CLUTCH

- 5.9L DIESEL

DESCRIPTION

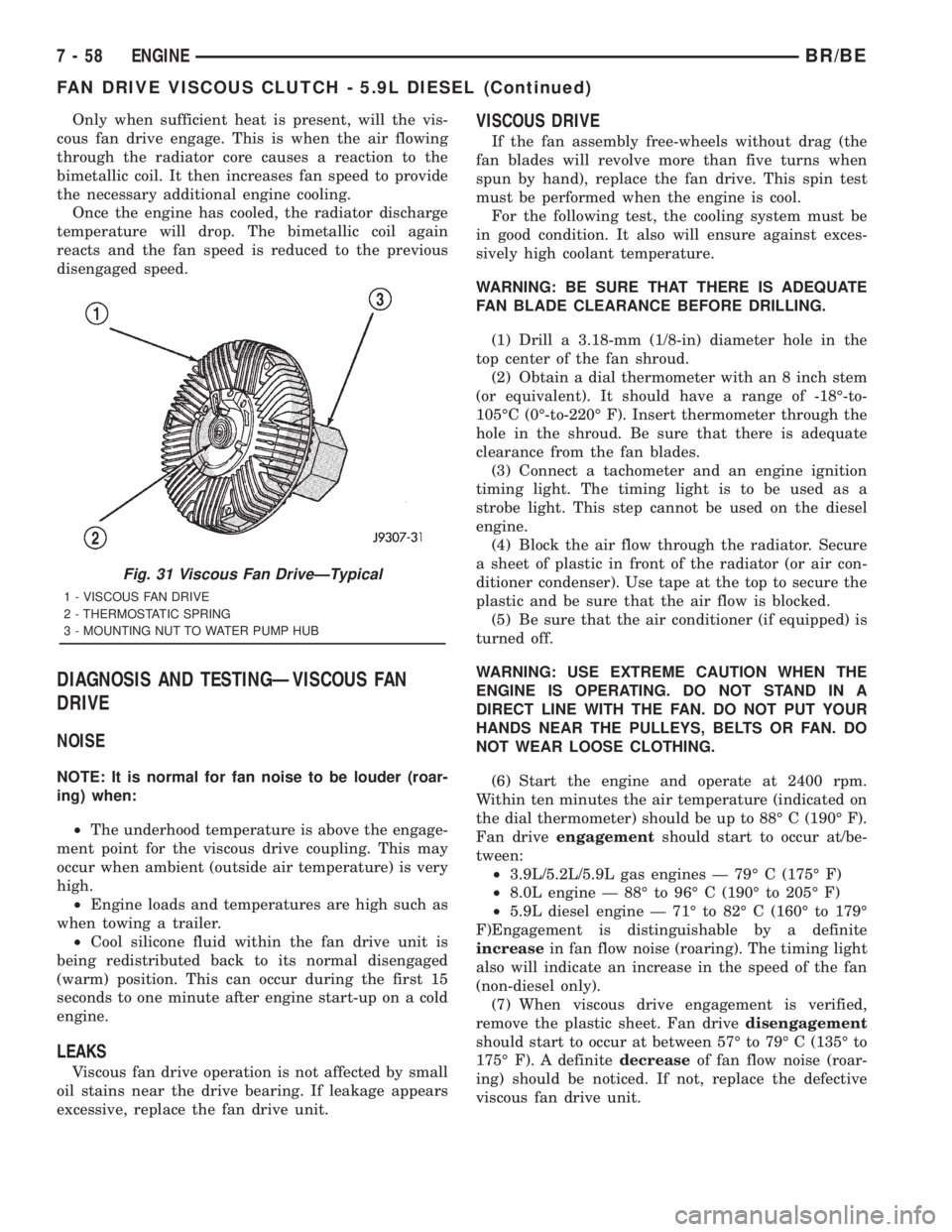

The thermal viscous fan drive (Fig. 30) is a sili-

cone-fluid- filled coupling used to connect the fan

blades to the water pump shaft. The coupling allows

the fan to be driven in a normal manner. This is

done at low engine speeds while limiting the top

speed of the fan to a predetermined maximum level

at higher engine speeds.

OPERATION

A thermostatic bimetallic spring coil is located on

the front face of the viscous fan drive unit (a typical

viscous unit is shown in (Fig. 31). This spring coil

reacts to the temperature of the radiator discharge

air. It engages the viscous fan drive for higher fan

speed if the air temperature from the radiator rises

above a certain point. Until additional engine cooling

is necessary, the fan will remain at a reduced rpm

regardless of engine speed.

Fig. 30 Viscous Fan

1 - THREADED SHAFT

2 - BOLT (4)

3 - FAN BLADE

4 - THREADED NUT

5 - VISCOUS FAN DRIVE

BR/BEENGINE 7 - 57

FAN DRIVE VISCOUS CLUTCH - 3.9L/5.2L/5.9L/8.0L (Continued)

Page 393 of 2889

Only when sufficient heat is present, will the vis-

cous fan drive engage. This is when the air flowing

through the radiator core causes a reaction to the

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again

reacts and the fan speed is reduced to the previous

disengaged speed.

DIAGNOSIS AND TESTINGÐVISCOUS FAN

DRIVE

NOISE

NOTE: It is normal for fan noise to be louder (roar-

ing) when:

²The underhood temperature is above the engage-

ment point for the viscous drive coupling. This may

occur when ambient (outside air temperature) is very

high.

²Engine loads and temperatures are high such as

when towing a trailer.

²Cool silicone fluid within the fan drive unit is

being redistributed back to its normal disengaged

(warm) position. This can occur during the first 15

seconds to one minute after engine start-up on a cold

engine.

LEAKS

Viscous fan drive operation is not affected by small

oil stains near the drive bearing. If leakage appears

excessive, replace the fan drive unit.

VISCOUS DRIVE

If the fan assembly free-wheels without drag (the

fan blades will revolve more than five turns when

spun by hand), replace the fan drive. This spin test

must be performed when the engine is cool.

For the following test, the cooling system must be

in good condition. It also will ensure against exces-

sively high coolant temperature.

WARNING: BE SURE THAT THERE IS ADEQUATE

FAN BLADE CLEARANCE BEFORE DRILLING.

(1) Drill a 3.18-mm (1/8-in) diameter hole in the

top center of the fan shroud.

(2) Obtain a dial thermometer with an 8 inch stem

(or equivalent). It should have a range of -18É-to-

105ÉC (0É-to-220É F). Insert thermometer through the

hole in the shroud. Be sure that there is adequate

clearance from the fan blades.

(3) Connect a tachometer and an engine ignition

timing light. The timing light is to be used as a

strobe light. This step cannot be used on the diesel

engine.

(4) Block the air flow through the radiator. Secure

a sheet of plastic in front of the radiator (or air con-

ditioner condenser). Use tape at the top to secure the

plastic and be sure that the air flow is blocked.

(5) Be sure that the air conditioner (if equipped) is

turned off.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(6) Start the engine and operate at 2400 rpm.

Within ten minutes the air temperature (indicated on

the dial thermometer) should be up to 88É C (190É F).

Fan driveengagementshould start to occur at/be-

tween:

²3.9L/5.2L/5.9L gas engines Ð 79É C (175É F)

²8.0L engine Ð 88É to 96É C (190É to 205É F)

²5.9L diesel engine Ð 71É to 82É C (160É to 179É

F)Engagement is distinguishable by a definite

increasein fan flow noise (roaring). The timing light

also will indicate an increase in the speed of the fan

(non-diesel only).

(7) When viscous drive engagement is verified,

remove the plastic sheet. Fan drivedisengagement

should start to occur at between 57É to 79É C (135É to

175É F). A definitedecreaseof fan flow noise (roar-

ing) should be noticed. If not, replace the defective

viscous fan drive unit.

Fig. 31 Viscous Fan DriveÐTypical

1 - VISCOUS FAN DRIVE

2 - THERMOSTATIC SPRING

3 - MOUNTING NUT TO WATER PUMP HUB

7 - 58 ENGINEBR/BE

FAN DRIVE VISCOUS CLUTCH - 5.9L DIESEL (Continued)

Page 394 of 2889

CAUTION: Some engines equipped with serpentine

drive belts have reverse rotating fans and viscous

fan drives. They are marked with the word

REVERSE to designate their usage. Installation of

the wrong fan or viscous fan drive can result in

engine overheating.

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

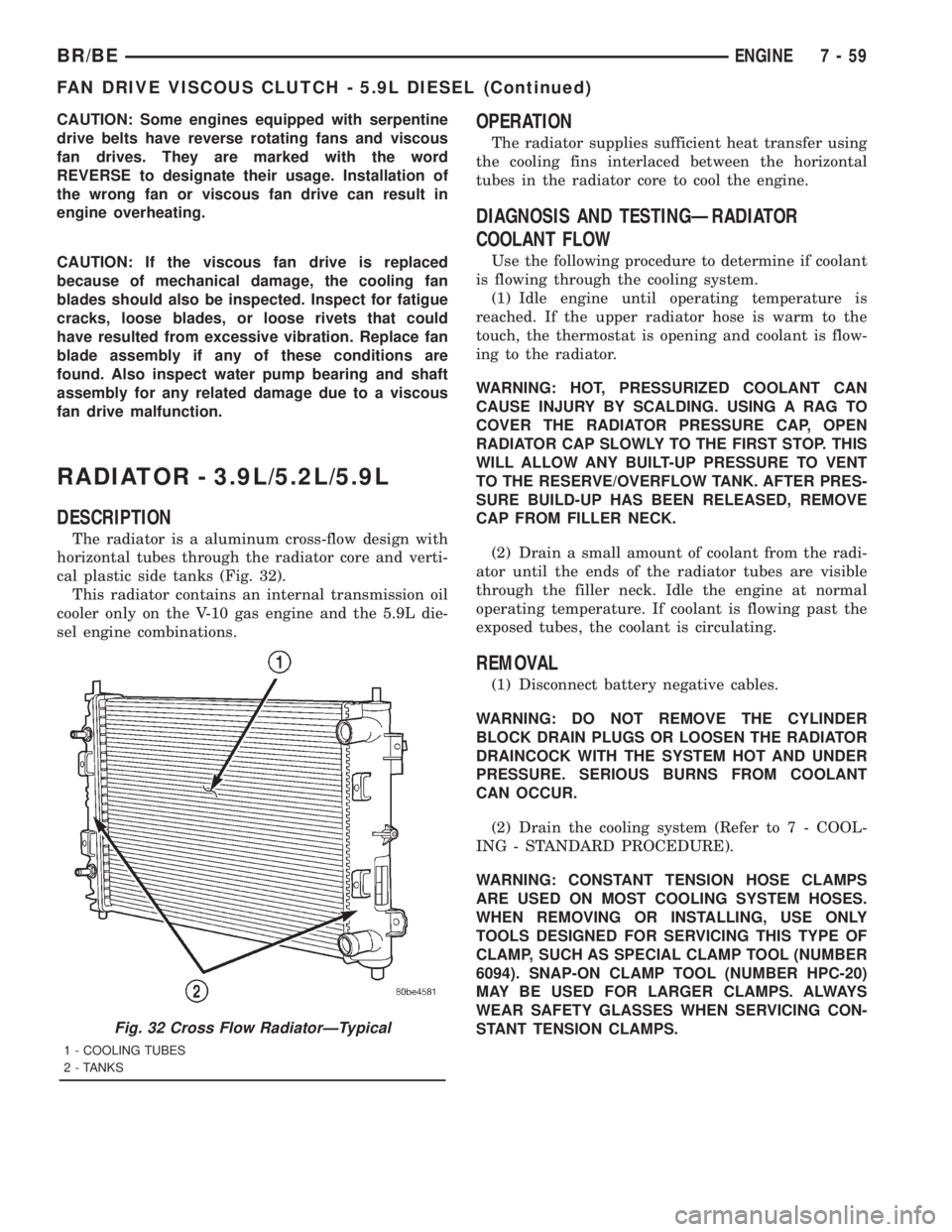

RADIATOR - 3.9L/5.2L/5.9L

DESCRIPTION

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 32).

This radiator contains an internal transmission oil

cooler only on the V-10 gas engine and the 5.9L die-

sel engine combinations.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTINGÐRADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

REMOVAL

(1) Disconnect battery negative cables.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

Fig. 32 Cross Flow RadiatorÐTypical

1 - COOLING TUBES

2 - TANKS

BR/BEENGINE 7 - 59

FAN DRIVE VISCOUS CLUTCH - 5.9L DIESEL (Continued)

Page 395 of 2889

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove hose clamps and hoses from radiator.

(4) Remove coolant reserve/overflow tank hose

from radiator filler neck nipple.

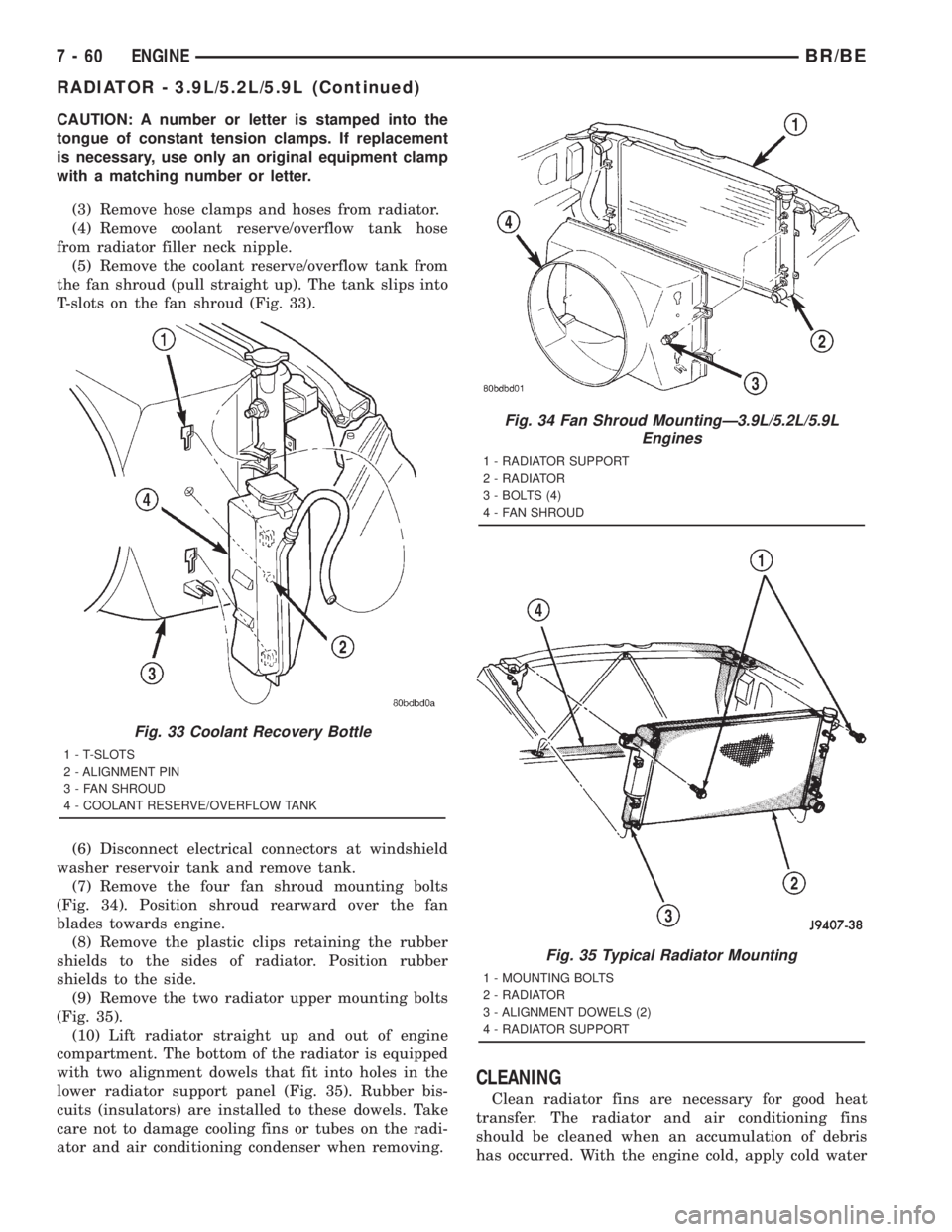

(5) Remove the coolant reserve/overflow tank from

the fan shroud (pull straight up). The tank slips into

T-slots on the fan shroud (Fig. 33).

(6) Disconnect electrical connectors at windshield

washer reservoir tank and remove tank.

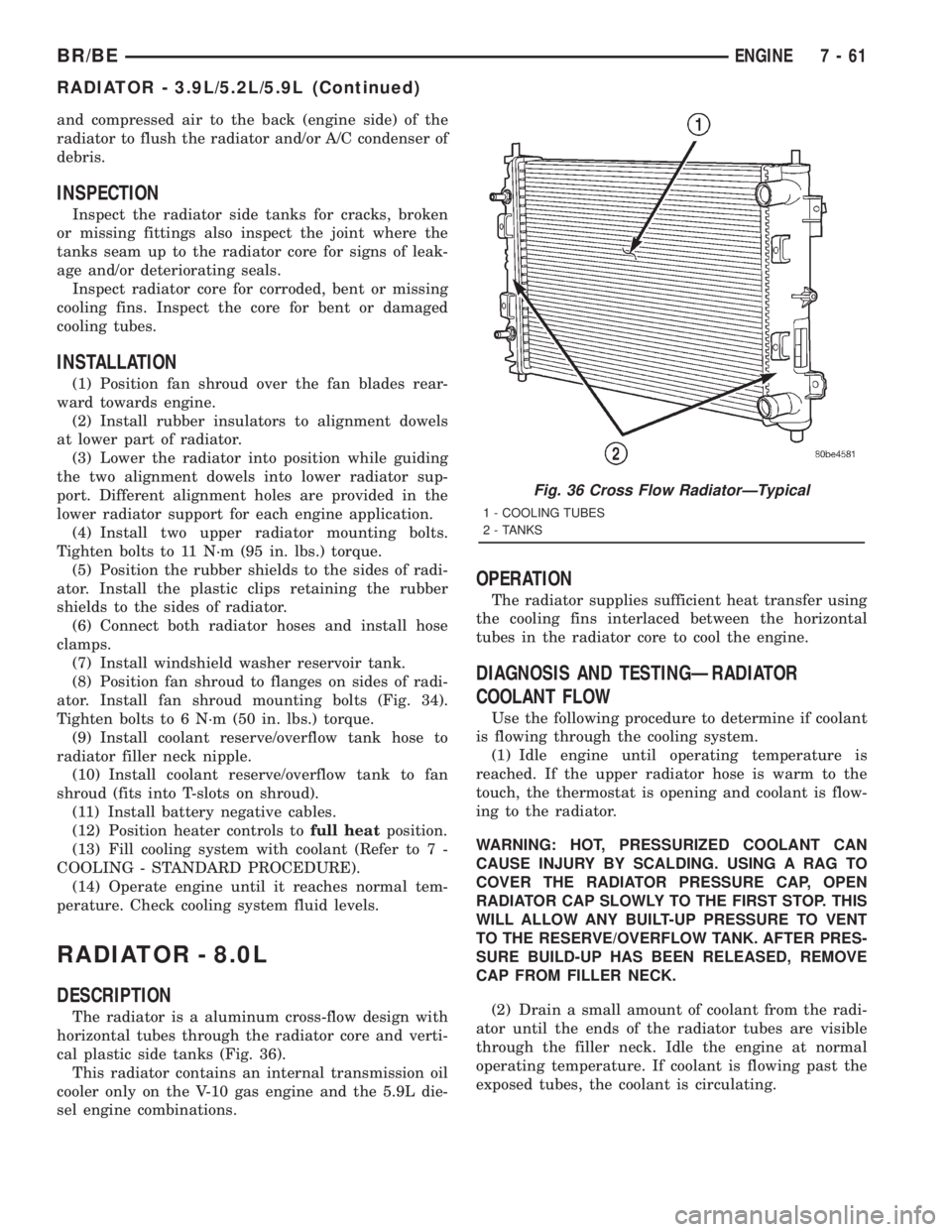

(7) Remove the four fan shroud mounting bolts

(Fig. 34). Position shroud rearward over the fan

blades towards engine.

(8) Remove the plastic clips retaining the rubber

shields to the sides of radiator. Position rubber

shields to the side.

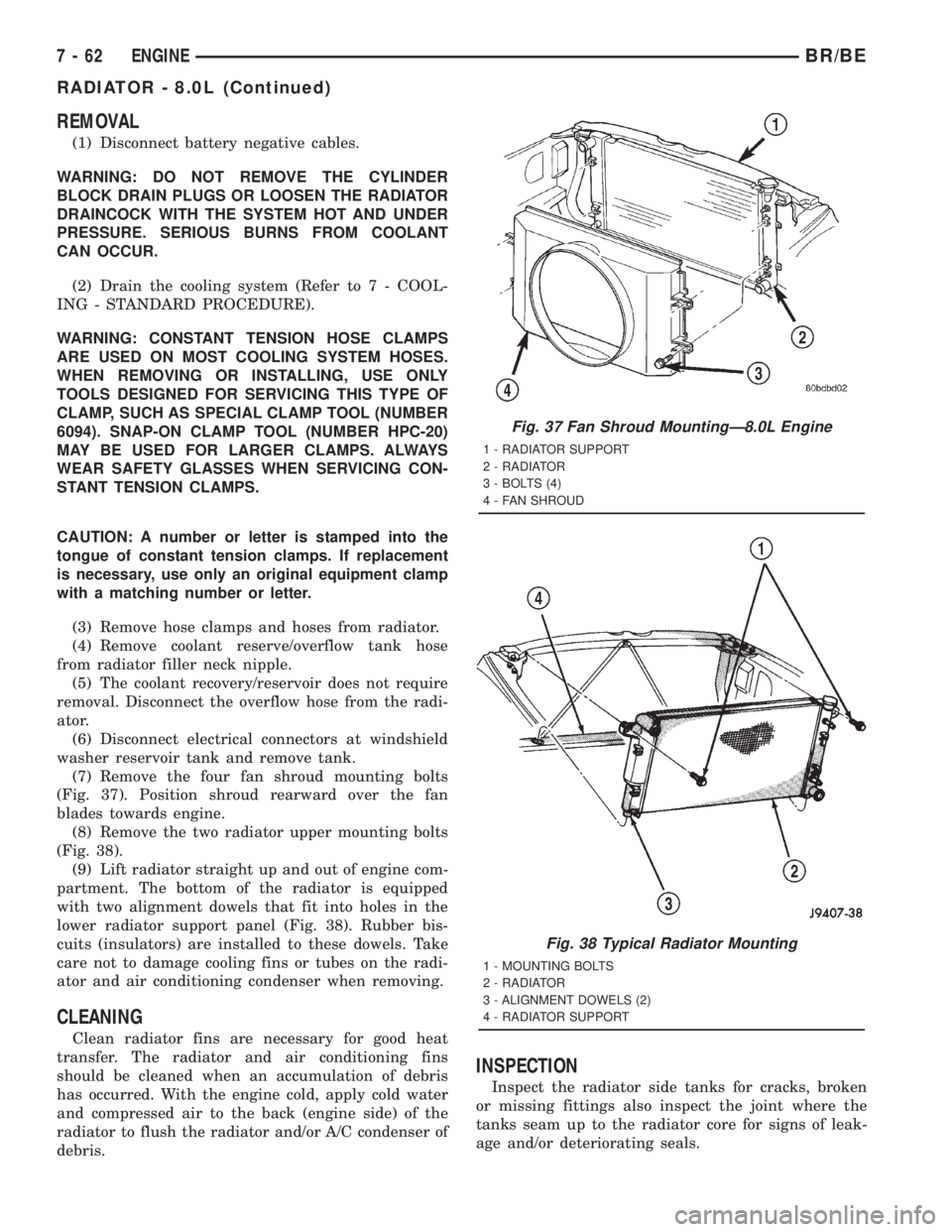

(9) Remove the two radiator upper mounting bolts

(Fig. 35).

(10) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel (Fig. 35). Rubber bis-

cuits (insulators) are installed to these dowels. Take

care not to damage cooling fins or tubes on the radi-

ator and air conditioning condenser when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and air conditioning fins

should be cleaned when an accumulation of debris

has occurred. With the engine cold, apply cold water

Fig. 33 Coolant Recovery Bottle

1 - T-SLOTS

2 - ALIGNMENT PIN

3 - FAN SHROUD

4 - COOLANT RESERVE/OVERFLOW TANK

Fig. 34 Fan Shroud MountingÐ3.9L/5.2L/5.9L

Engines

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 35 Typical Radiator Mounting

1 - MOUNTING BOLTS

2 - RADIATOR

3 - ALIGNMENT DOWELS (2)

4 - RADIATOR SUPPORT

7 - 60 ENGINEBR/BE

RADIATOR - 3.9L/5.2L/5.9L (Continued)

Page 396 of 2889

and compressed air to the back (engine side) of the

radiator to flush the radiator and/or A/C condenser of

debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position fan shroud over the fan blades rear-

ward towards engine.

(2) Install rubber insulators to alignment dowels

at lower part of radiator.

(3) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(4) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(5) Position the rubber shields to the sides of radi-

ator. Install the plastic clips retaining the rubber

shields to the sides of radiator.

(6) Connect both radiator hoses and install hose

clamps.

(7) Install windshield washer reservoir tank.

(8) Position fan shroud to flanges on sides of radi-

ator. Install fan shroud mounting bolts (Fig. 34).

Tighten bolts to 6 N´m (50 in. lbs.) torque.

(9) Install coolant reserve/overflow tank hose to

radiator filler neck nipple.

(10) Install coolant reserve/overflow tank to fan

shroud (fits into T-slots on shroud).

(11) Install battery negative cables.

(12) Position heater controls tofull heatposition.

(13) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(14) Operate engine until it reaches normal tem-

perature. Check cooling system fluid levels.

RADIATOR - 8.0L

DESCRIPTION

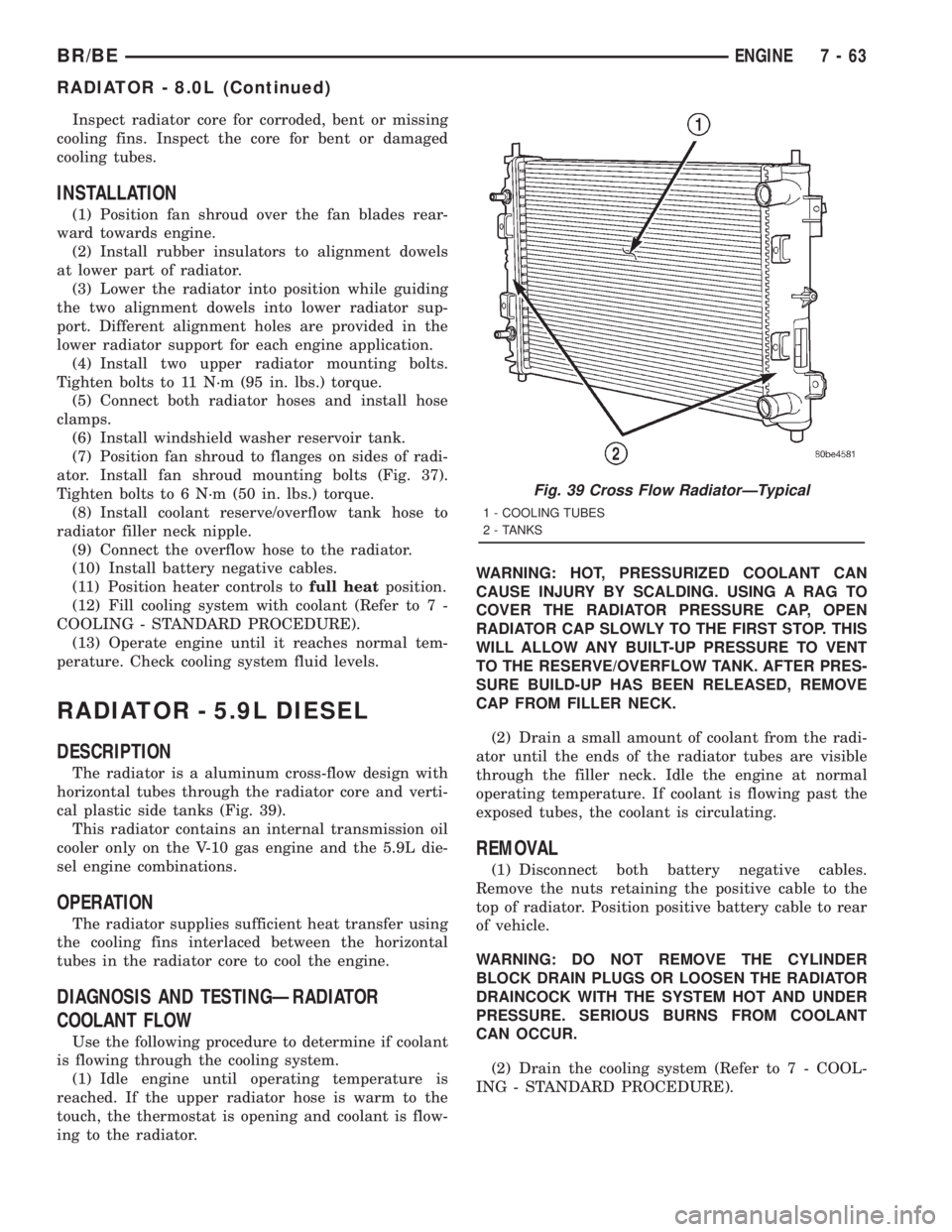

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 36).

This radiator contains an internal transmission oil

cooler only on the V-10 gas engine and the 5.9L die-

sel engine combinations.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTINGÐRADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

Fig. 36 Cross Flow RadiatorÐTypical

1 - COOLING TUBES

2 - TANKS

BR/BEENGINE 7 - 61

RADIATOR - 3.9L/5.2L/5.9L (Continued)

Page 397 of 2889

REMOVAL

(1) Disconnect battery negative cables.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove hose clamps and hoses from radiator.

(4) Remove coolant reserve/overflow tank hose

from radiator filler neck nipple.

(5) The coolant recovery/reservoir does not require

removal. Disconnect the overflow hose from the radi-

ator.

(6) Disconnect electrical connectors at windshield

washer reservoir tank and remove tank.

(7) Remove the four fan shroud mounting bolts

(Fig. 37). Position shroud rearward over the fan

blades towards engine.

(8) Remove the two radiator upper mounting bolts

(Fig. 38).

(9) Lift radiator straight up and out of engine com-

partment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel (Fig. 38). Rubber bis-

cuits (insulators) are installed to these dowels. Take

care not to damage cooling fins or tubes on the radi-

ator and air conditioning condenser when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and air conditioning fins

should be cleaned when an accumulation of debris

has occurred. With the engine cold, apply cold water

and compressed air to the back (engine side) of the

radiator to flush the radiator and/or A/C condenser of

debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Fig. 37 Fan Shroud MountingÐ8.0L Engine

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 38 Typical Radiator Mounting

1 - MOUNTING BOLTS

2 - RADIATOR

3 - ALIGNMENT DOWELS (2)

4 - RADIATOR SUPPORT

7 - 62 ENGINEBR/BE

RADIATOR - 8.0L (Continued)

Page 398 of 2889

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position fan shroud over the fan blades rear-

ward towards engine.

(2) Install rubber insulators to alignment dowels

at lower part of radiator.

(3) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(4) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(5) Connect both radiator hoses and install hose

clamps.

(6) Install windshield washer reservoir tank.

(7) Position fan shroud to flanges on sides of radi-

ator. Install fan shroud mounting bolts (Fig. 37).

Tighten bolts to 6 N´m (50 in. lbs.) torque.

(8) Install coolant reserve/overflow tank hose to

radiator filler neck nipple.

(9) Connect the overflow hose to the radiator.

(10) Install battery negative cables.

(11) Position heater controls tofull heatposition.

(12) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(13) Operate engine until it reaches normal tem-

perature. Check cooling system fluid levels.

RADIATOR - 5.9L DIESEL

DESCRIPTION

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 39).

This radiator contains an internal transmission oil

cooler only on the V-10 gas engine and the 5.9L die-

sel engine combinations.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTINGÐRADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

REMOVAL

(1) Disconnect both battery negative cables.

Remove the nuts retaining the positive cable to the

top of radiator. Position positive battery cable to rear

of vehicle.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

Fig. 39 Cross Flow RadiatorÐTypical

1 - COOLING TUBES

2 - TANKS

BR/BEENGINE 7 - 63

RADIATOR - 8.0L (Continued)

Page 399 of 2889

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094). SNAP-ON CLAMP TOOL (NUMBER HPC-20)

MAY BE USED FOR LARGER CLAMPS. ALWAYS

WEAR SAFETY GLASSES WHEN SERVICING CON-

STANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove hose clamps and hoses from radiator.

(4) Remove coolant reserve/overflow tank hose

from radiator filler neck nipple.

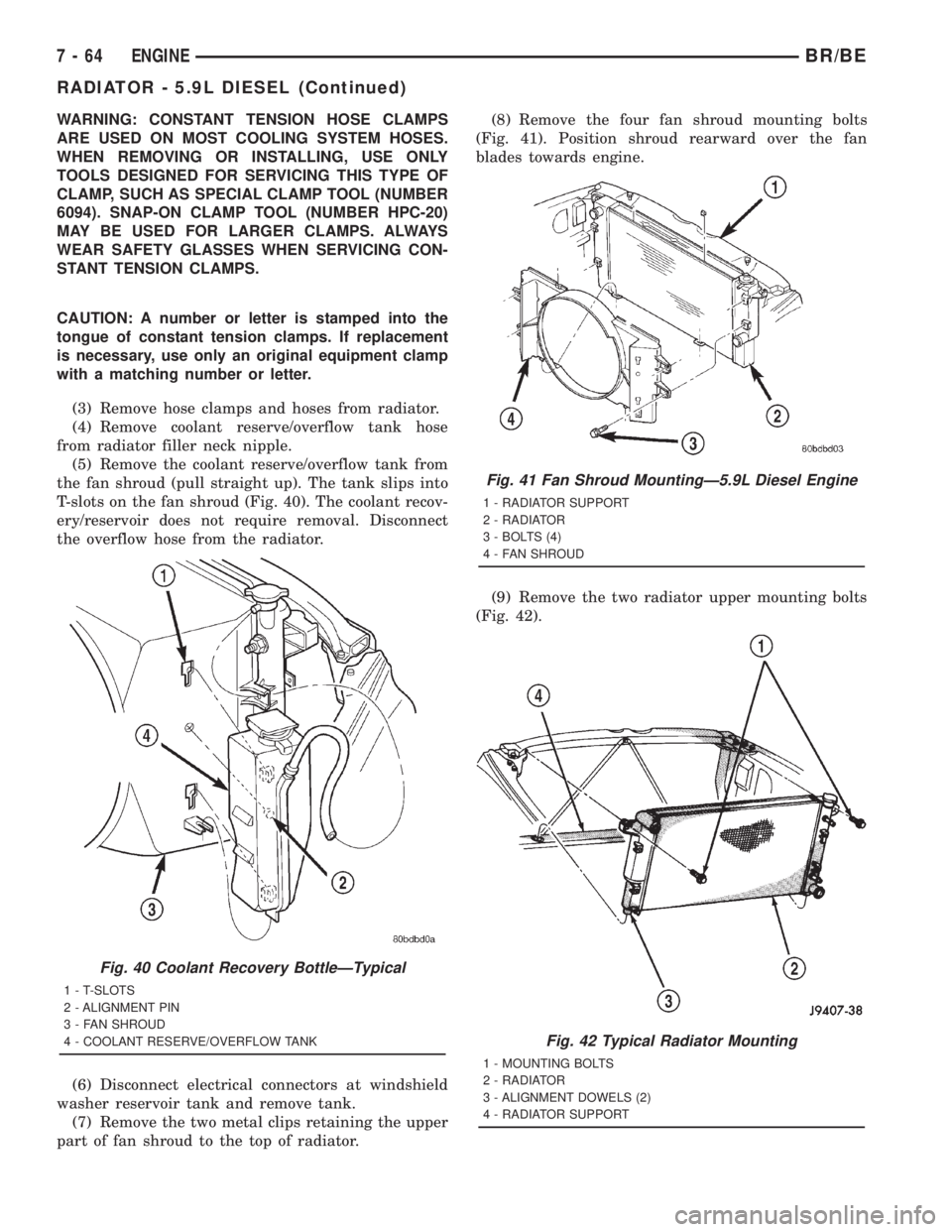

(5) Remove the coolant reserve/overflow tank from

the fan shroud (pull straight up). The tank slips into

T-slots on the fan shroud (Fig. 40). The coolant recov-

ery/reservoir does not require removal. Disconnect

the overflow hose from the radiator.

(6) Disconnect electrical connectors at windshield

washer reservoir tank and remove tank.

(7) Remove the two metal clips retaining the upper

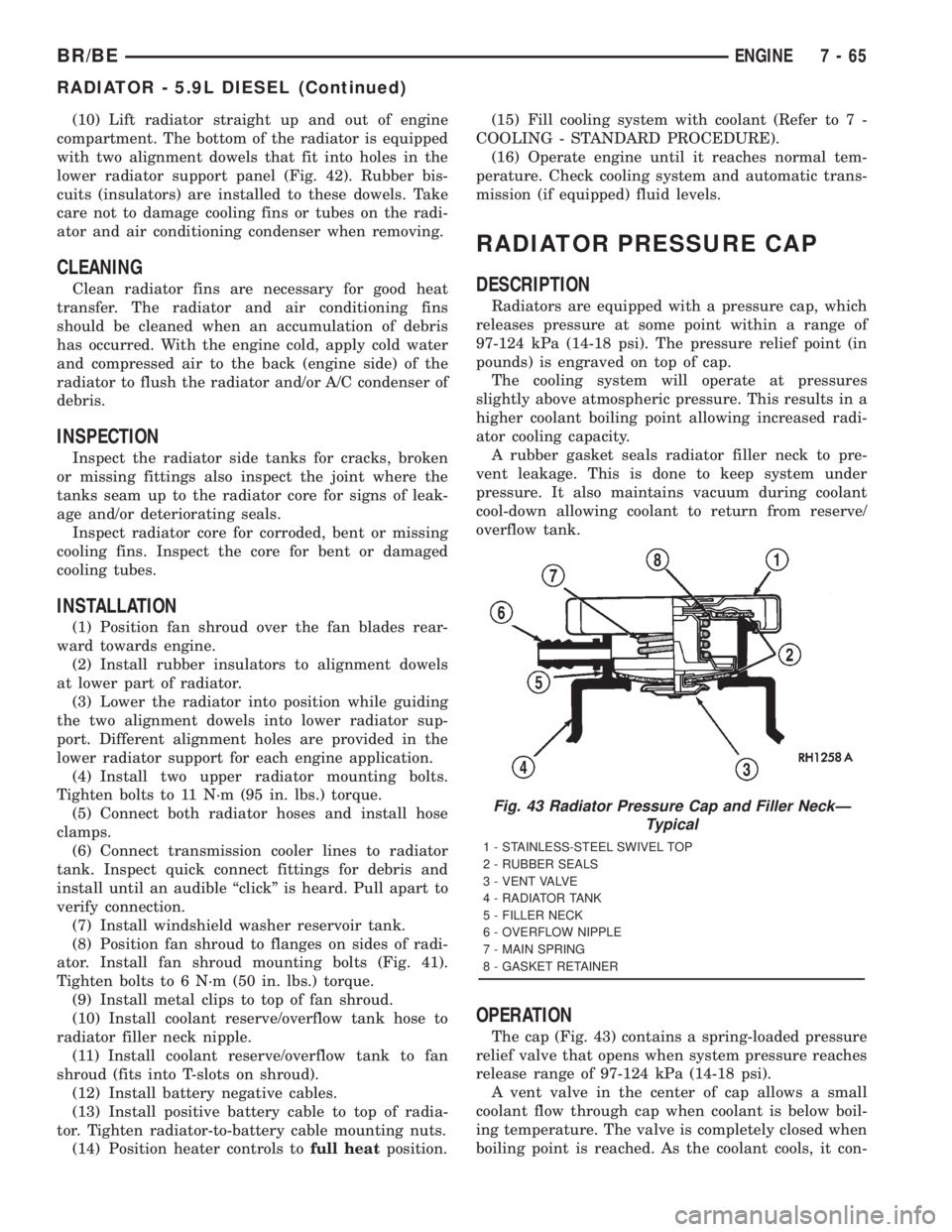

part of fan shroud to the top of radiator.(8) Remove the four fan shroud mounting bolts

(Fig. 41). Position shroud rearward over the fan

blades towards engine.

(9) Remove the two radiator upper mounting bolts

(Fig. 42).

Fig. 40 Coolant Recovery BottleÐTypical

1 - T-SLOTS

2 - ALIGNMENT PIN

3 - FAN SHROUD

4 - COOLANT RESERVE/OVERFLOW TANK

Fig. 41 Fan Shroud MountingÐ5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - RADIATOR

3 - BOLTS (4)

4 - FAN SHROUD

Fig. 42 Typical Radiator Mounting

1 - MOUNTING BOLTS

2 - RADIATOR

3 - ALIGNMENT DOWELS (2)

4 - RADIATOR SUPPORT

7 - 64 ENGINEBR/BE

RADIATOR - 5.9L DIESEL (Continued)

Page 400 of 2889

(10) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel (Fig. 42). Rubber bis-

cuits (insulators) are installed to these dowels. Take

care not to damage cooling fins or tubes on the radi-

ator and air conditioning condenser when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and air conditioning fins

should be cleaned when an accumulation of debris

has occurred. With the engine cold, apply cold water

and compressed air to the back (engine side) of the

radiator to flush the radiator and/or A/C condenser of

debris.

INSPECTION

Inspect the radiator side tanks for cracks, broken

or missing fittings also inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position fan shroud over the fan blades rear-

ward towards engine.

(2) Install rubber insulators to alignment dowels

at lower part of radiator.

(3) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(4) Install two upper radiator mounting bolts.

Tighten bolts to 11 N´m (95 in. lbs.) torque.

(5) Connect both radiator hoses and install hose

clamps.

(6) Connect transmission cooler lines to radiator

tank. Inspect quick connect fittings for debris and

install until an audible ªclickº is heard. Pull apart to

verify connection.

(7) Install windshield washer reservoir tank.

(8) Position fan shroud to flanges on sides of radi-

ator. Install fan shroud mounting bolts (Fig. 41).

Tighten bolts to 6 N´m (50 in. lbs.) torque.

(9) Install metal clips to top of fan shroud.

(10) Install coolant reserve/overflow tank hose to

radiator filler neck nipple.

(11) Install coolant reserve/overflow tank to fan

shroud (fits into T-slots on shroud).

(12) Install battery negative cables.

(13) Install positive battery cable to top of radia-

tor. Tighten radiator-to-battery cable mounting nuts.

(14) Position heater controls tofull heatposition.(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

Radiators are equipped with a pressure cap, which

releases pressure at some point within a range of

97-124 kPa (14-18 psi). The pressure relief point (in

pounds) is engraved on top of cap.

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity.

A rubber gasket seals radiator filler neck to pre-

vent leakage. This is done to keep system under

pressure. It also maintains vacuum during coolant

cool-down allowing coolant to return from reserve/

overflow tank.

OPERATION

The cap (Fig. 43) contains a spring-loaded pressure

relief valve that opens when system pressure reaches

release range of 97-124 kPa (14-18 psi).

A vent valve in the center of cap allows a small

coolant flow through cap when coolant is below boil-

ing temperature. The valve is completely closed when

boiling point is reached. As the coolant cools, it con-

Fig. 43 Radiator Pressure Cap and Filler NeckÐ

Typical

1 - STAINLESS-STEEL SWIVEL TOP

2 - RUBBER SEALS

3 - VENT VALVE

4 - RADIATOR TANK

5 - FILLER NECK

6 - OVERFLOW NIPPLE

7 - MAIN SPRING

8 - GASKET RETAINER

BR/BEENGINE 7 - 65

RADIATOR - 5.9L DIESEL (Continued)