DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 421 of 2889

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

(1) Remove cover plate filler plug on Tool 6906-B.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906-B.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

NOTE: The converter drainback valve must be

removed and an appropriate replacement hose

installed to bridge the space between the transmis-

sion cooler line and the cooler fitting. Failure to

remove the drainback valve will prevent reverse

flushing the system. A suitable replacement hose

can be found in the adapter kit supplied with the

flushing tool.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.(11) Place CLEAR suction line into a one quart

container of MopartATF +4, type 9602, Automatic

Transmission Fluid.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

STANDARD PROCEDURE - FLUSHING COOLER

AND TUBES - WITHOUT RADIATOR IN-TANK

TRANSMISSION OIL COOLER

When a transmission failure has contaminated the

fluid, the oil cooler(s) must be flushed. The torque

converter must also be replaced. This will insure that

metal particles or sludged oil are not later trans-

ferred back into the reconditioned (or replaced) trans-

mission.

(1) Remove cover plate filler plug on Tool 6906B.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906B.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

NOTE: The converter drainback valve must be

removed and an appropriate replacement hose

installed to bridge the space between the transmis-

sion cooler line and the cooler fitting. Failure to

remove the drainback valve will prevent reverse

flushing the system. A suitable replacement hose

can be found in the adapter kit supplied with the

flushing tool.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Remove the transmission oil cooler from the

vehicle. (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - REMOVAL)

(8) Remove the transmission oil cooler thermostat.

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - DISASSEMBLY)

7 - 86 TRANSMISSIONBR/BE

TRANS COOLER - 5.9L DIESEL (Continued)

Page 422 of 2889

(9) Re-install the thermostat cover onto the oil

cooler and install the snap-ring.

(10) Re-connect the oil cooler to the transmission

cooler lines.

(11) Turn pump ON for two to three minutes to

flush cooler(s) and lines.

NOTE: This flushes the bypass circuit of the cooler

only.

(12) Turn pump OFF.

(13) Remove the thermostat cover from the oil

cooler.

(14) Install Special Tool Cooler Plug 8414 into the

transmission oil cooler.

(15) Re-install the thermostat cover onto the oil

cooler and install the snap-ring.

(16) Turn pump ON for two to three minutes to

flush cooler(s) and lines.

NOTE: This flushes the main oil cooler core pas-

sages only.

(17) Turn pump OFF.

(18) Remove the thermostat cover from the oil

cooler.

(19) Remove Special Tool Cooler Plug 8414 from

the transmission oil cooler.

(20) Install a new thermostat spring, thermostat,

cover, and snap-ring into the transmission oil cooler.

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - ASSEMBLY)

(21) Install the transmission oil cooler onto the

vehicle. (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION)

(22) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(23) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(24) Place CLEAR suction line into a one quart

container of MopartATF +4, type 9602, Automatic

Transmission fluid.

(25) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(26) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

REMOVALÐAIR TO OIL COOLER

(1) Remove front bumper.

(2) Place a drain pan under the oil cooler.

(3) Raise the vehicle.

(4) Disconnect the oil cooler quick-connect fittings

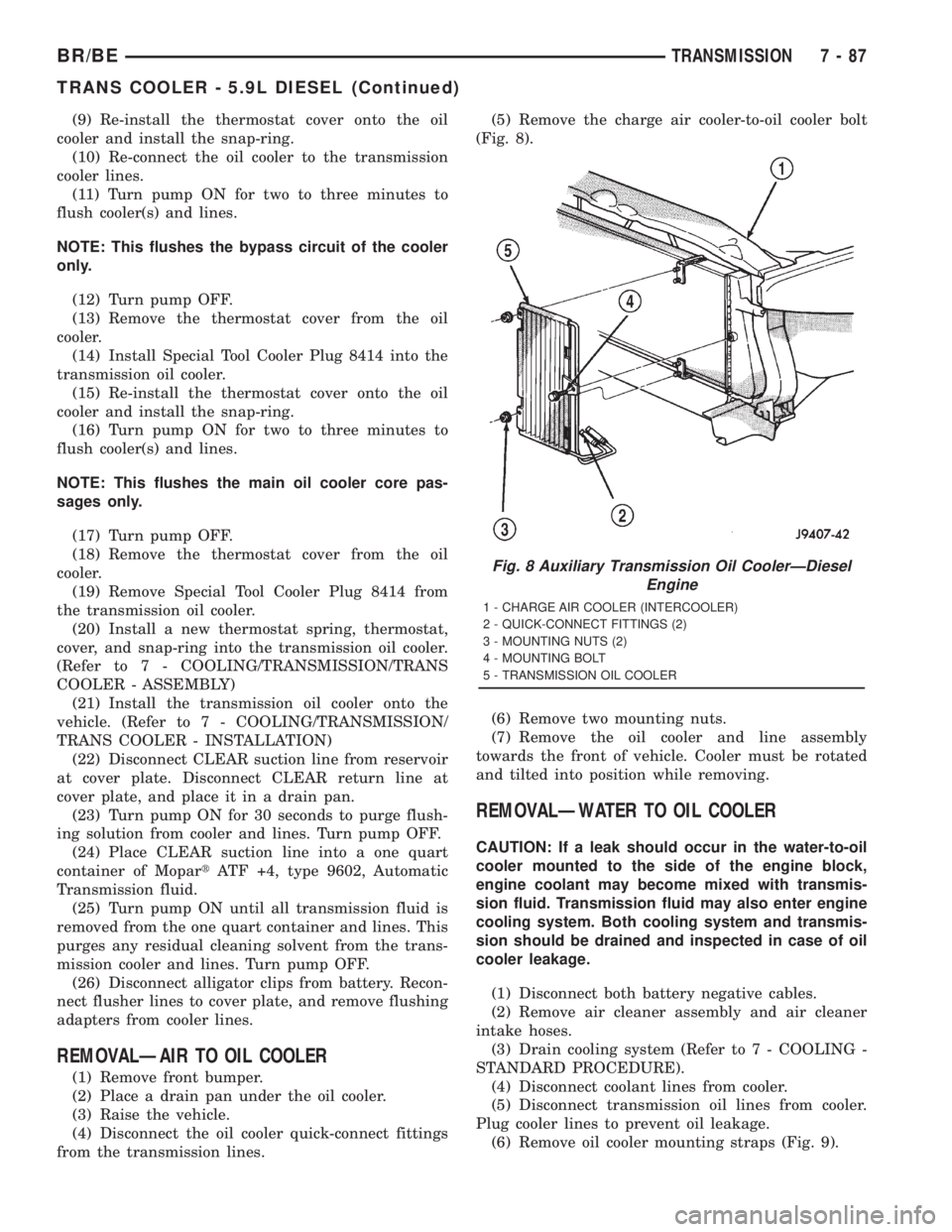

from the transmission lines.(5) Remove the charge air cooler-to-oil cooler bolt

(Fig. 8).

(6) Remove two mounting nuts.

(7) Remove the oil cooler and line assembly

towards the front of vehicle. Cooler must be rotated

and tilted into position while removing.

REMOVALÐWATER TO OIL COOLER

CAUTION: If a leak should occur in the water-to-oil

cooler mounted to the side of the engine block,

engine coolant may become mixed with transmis-

sion fluid. Transmission fluid may also enter engine

cooling system. Both cooling system and transmis-

sion should be drained and inspected in case of oil

cooler leakage.

(1) Disconnect both battery negative cables.

(2) Remove air cleaner assembly and air cleaner

intake hoses.

(3) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(4) Disconnect coolant lines from cooler.

(5) Disconnect transmission oil lines from cooler.

Plug cooler lines to prevent oil leakage.

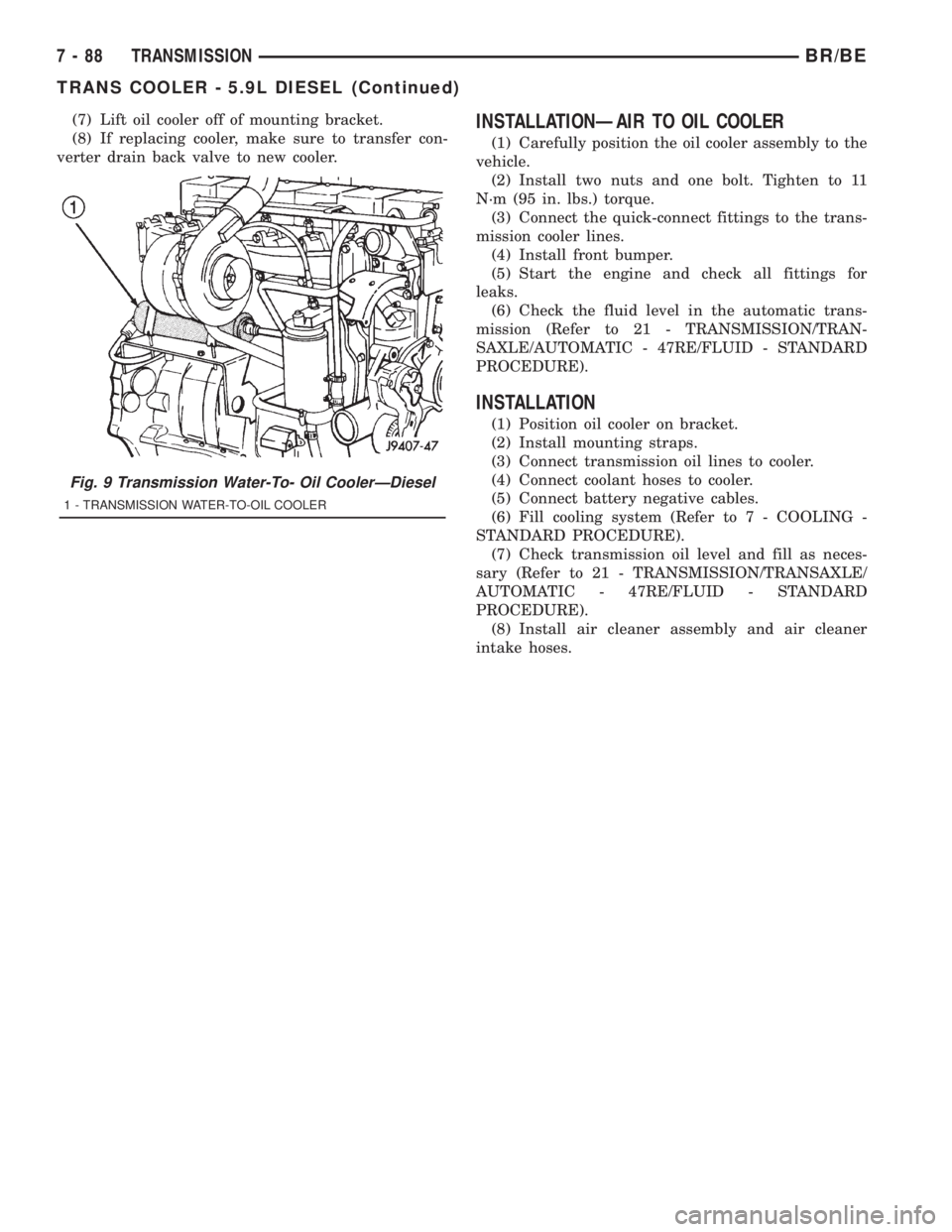

(6) Remove oil cooler mounting straps (Fig. 9).

Fig. 8 Auxiliary Transmission Oil CoolerÐDiesel

Engine

1 - CHARGE AIR COOLER (INTERCOOLER)

2 - QUICK-CONNECT FITTINGS (2)

3 - MOUNTING NUTS (2)

4 - MOUNTING BOLT

5 - TRANSMISSION OIL COOLER

BR/BETRANSMISSION 7 - 87

TRANS COOLER - 5.9L DIESEL (Continued)

Page 423 of 2889

(7) Lift oil cooler off of mounting bracket.

(8) If replacing cooler, make sure to transfer con-

verter drain back valve to new cooler.INSTALLATIONÐAIR TO OIL COOLER

(1) Carefully position the oil cooler assembly to the

vehicle.

(2) Install two nuts and one bolt. Tighten to 11

N´m (95 in. lbs.) torque.

(3) Connect the quick-connect fittings to the trans-

mission cooler lines.

(4) Install front bumper.

(5) Start the engine and check all fittings for

leaks.

(6) Check the fluid level in the automatic trans-

mission (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/AUTOMATIC - 47RE/FLUID - STANDARD

PROCEDURE).

INSTALLATION

(1) Position oil cooler on bracket.

(2) Install mounting straps.

(3) Connect transmission oil lines to cooler.

(4) Connect coolant hoses to cooler.

(5) Connect battery negative cables.

(6) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(7) Check transmission oil level and fill as neces-

sary (Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC - 47RE/FLUID - STANDARD

PROCEDURE).

(8) Install air cleaner assembly and air cleaner

intake hoses.

Fig. 9 Transmission Water-To- Oil CoolerÐDiesel

1 - TRANSMISSION WATER-TO-OIL COOLER

7 - 88 TRANSMISSIONBR/BE

TRANS COOLER - 5.9L DIESEL (Continued)

Page 424 of 2889

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION............................1

OPERATION.............................2

DIAGNOSIS AND TESTING..................2

AUDIO................................2

SPECIAL TOOLS..........................4

ANTENNA BODY & CABLE

DESCRIPTION............................4

OPERATION.............................4

DIAGNOSIS AND TESTING..................5

ANTENNA.............................5

REMOVAL...............................6

INSTALLATION............................7

RADIO CHOKE RELAY

DESCRIPTION............................8

OPERATION.............................8

DIAGNOSIS AND TESTING..................8

RADIO CHOKE RELAY....................8

REMOVAL...............................9

INSTALLATION............................9

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL...............................9

INSTALLATION...........................10

RADIO

DESCRIPTION...........................10

OPERATION.............................10

DIAGNOSIS AND TESTING.................10

RADIO...............................10

REMOVAL..............................11

INSTALLATION...........................12

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION...........................12

DIAGNOSIS AND TESTING.................12

RADIO NOISE SUPPRESSION

COMPONENTS.........................12ENGINE-TO-BODY GROUND STRAP

REMOVAL..............................13

INSTALLATION...........................13

CAB-TO- BED GROUND STRAP

REMOVAL..............................14

INSTALLATION...........................14

HEATER CORE GROUND STRAP

REMOVAL..............................14

INSTALLATION...........................15

REMOTE SWITCHES

DESCRIPTION...........................15

OPERATION.............................15

DIAGNOSIS AND TESTING.................16

REMOTE SWITCHES....................16

REMOVAL..............................16

INSTALLATION...........................17

SPEAKER

DESCRIPTION...........................17

OPERATION.............................17

DIAGNOSIS AND TESTING.................18

SPEAKER............................18

A-PILLAR TWEETER SPEAKER

REMOVAL..............................19

INSTALLATION...........................19

FRONT DOOR SPEAKER

REMOVAL..............................20

INSTALLATION...........................20

REAR CAB SIDE PANEL SPEAKER

REMOVAL..............................20

INSTALLATION...........................21

REAR DOOR SPEAKER

REMOVAL..............................21

INSTALLATION...........................21

AUDIO

DESCRIPTION

An audio system is standard factory-installed equip-

ment on this model, unless the vehicle is ordered with

an available radio delete option. The standard equip-

ment audio system includes an AM/FM/cassette (RAS

sales code) receiver, and speakers in four locations. Sev-

eral combinations of radio receivers and speaker systems

are offered as optional equipment on this model. The

audio system uses an ignition switched source of battery

current so that the system will only operate when theignition switch is in the On or Accessory positions. The

audio system includes the following components:

²Antenna

²Clockspring (with remote radio switches only)

²Filter, choke and speaker relay (with premium

speaker system only)

²High-line or premium Central Timer Module

(CTM) (with remote radio switches)

²Radio noise suppression components

²Radio receiver

²Remote radio switches (optional with RAZ radio

receiver only)

²Speakers

BR/BEAUDIO 8A - 1

Page 425 of 2889

Refer to Electrical, Restraints for more information

on the clockspring. Refer to Electrical, Body Control/

Central Control Module for more information on the

Central Timer Module. Refer to the appropriate wir-

ing information. The wiring information includes wir-

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. Following are general descriptions of

the remaining major components in the standard and

optional factory-installed audio systems.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also control some features of the audio

system when the vehicle is equipped with the

optional RAZ radio receiver and remote radio

switches. A high-line CTM is used on high-line ver-

sions of this vehicle. A premium CTM is used on

vehicles equipped with the optional heated seats. The

CTM combines the functions of a chime/buzzer mod-

ule, an intermittent wipe module, an illuminated

entry module, a remote keyless entry module, and a

vehicle theft security system module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.The RAZ radio receiver with a remote radio switch

option is one of the features that the CTM controls.

The CTM is programmed to send switch status mes-

sages over the Chrysler Collision Detection (CCD)

data bus to control the volume, seek, and pre-set sta-

tion advance functions of the RAZ radio receiver. The

CTM monitors the status of the remote radio

switches located on the steering wheel through a

hard wired circuit. The CTM then sends the proper

switch status messages to the radio receiver. The

electronic circuitry within the radio receiver responds

to the switch status messages it receives by adjusting

the radio settings as requested.

Refer to Electrical, Body Control/Central Timer

Module for more information on the high-line CTM.

Refer to Remote Radio Switch in Description and

Operation for more information on this component.

In addition, radio receivers connected to the CCD

data bus have several audio system functions that

can be diagnosed using a DRBIIItscan tool. Refer to

the proper Diagnostic Procedures manual for more

information on DRBIIIttesting of the audio systems.

DIAGNOSIS AND TESTING - AUDIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

8A - 2 AUDIOBR/BE

AUDIO (Continued)

Page 426 of 2889

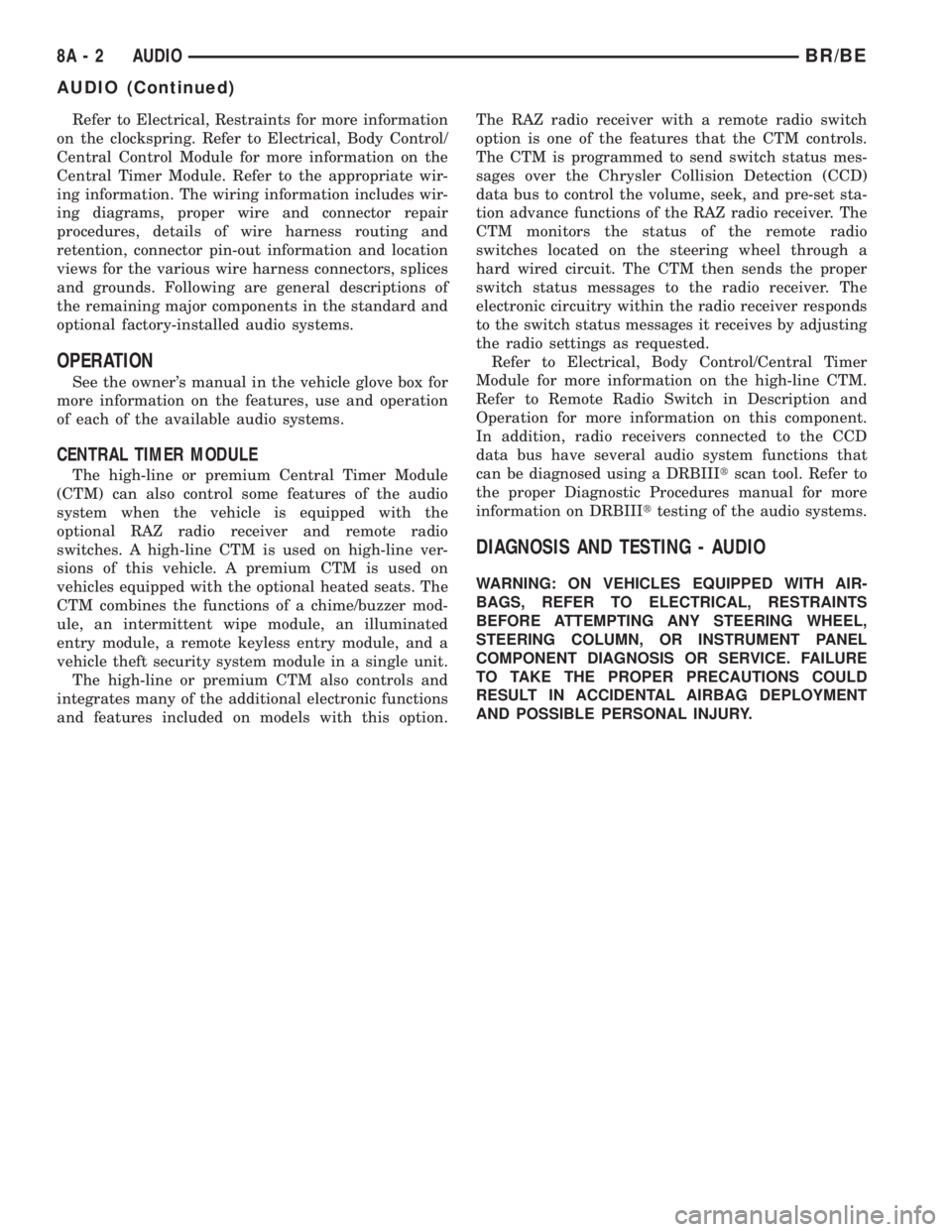

Audio System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuses in junction block. Replace faulty fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connections. Repair, if

required.

3. Wiring faulty. 3. Check for battery voltage at radio connector. Repair wiring,

if required.

4. Ground faulty. 4. Check for continuity between radio chassis and a known

good ground. There should be continuity. Repair ground, if

required.

5. Radio faulty. 5. Refer to Radio in the Diagnosis and Testing section of this

group.

6. Speakers faulty. 6. Refer to Speaker in the Diagnosis and Testing section of

this group.

7. Amplifier faulty (if

equipped).7. Refer to Speaker in the Diagnosis and Testing section of

this group.

NO DISPLAY 1. Fuse faulty. 1. Check radio fuses in junction block. Replace faulty fuses, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connections. Repair, if

required.

3. Wiring faulty. 3. Check for battery voltage at radio connector. Repair wiring,

if required.

4. Ground faulty. 4. Check for continuity between radio chassis and a known

good ground. There should be continuity. Repair ground, if

required.

5. Radio faulty. 5. Refer to Radio in the Diagnosis and Testing section of this

group.

CLOCK WILL NOT

KEEP SET TIME1. Fuse faulty. 1. Check ignition-off draw fuse. Replace faulty fuse, if

required.

2. Radio connector faulty. 2. Check for loose or corroded radio connections. Repair, if

required.

3. Wiring faulty. 3. Check for battery voltage at radio connector. Repair wiring,

if required.

4. Ground faulty. 4. Check for continuity between radio chassis and a known

good ground. There should be continuity. Repair ground, if

required.

5. Radio faulty. 5. Refer to Radio in the Diagnosis and Testing section of this

group.

POOR RADIO

RECEPTION1. Antenna faulty. 1. Refer to Antenna in the Diagnosis and Testing section of

this group.

2. Ground faulty. 2. Check for continuity between radio chassis and a known

good ground. There should be continuity. Repair ground, if

required.

3. Radio faulty. 3. Refer to Radio in the Diagnosis and Testing section of this

group.

4. Faulty EMI or RFI

noise suppression.4. Refer to Radio Frequency Interference in the Diagnosis

and Testing section of this group.

BR/BEAUDIO 8A - 3

AUDIO (Continued)

Page 427 of 2889

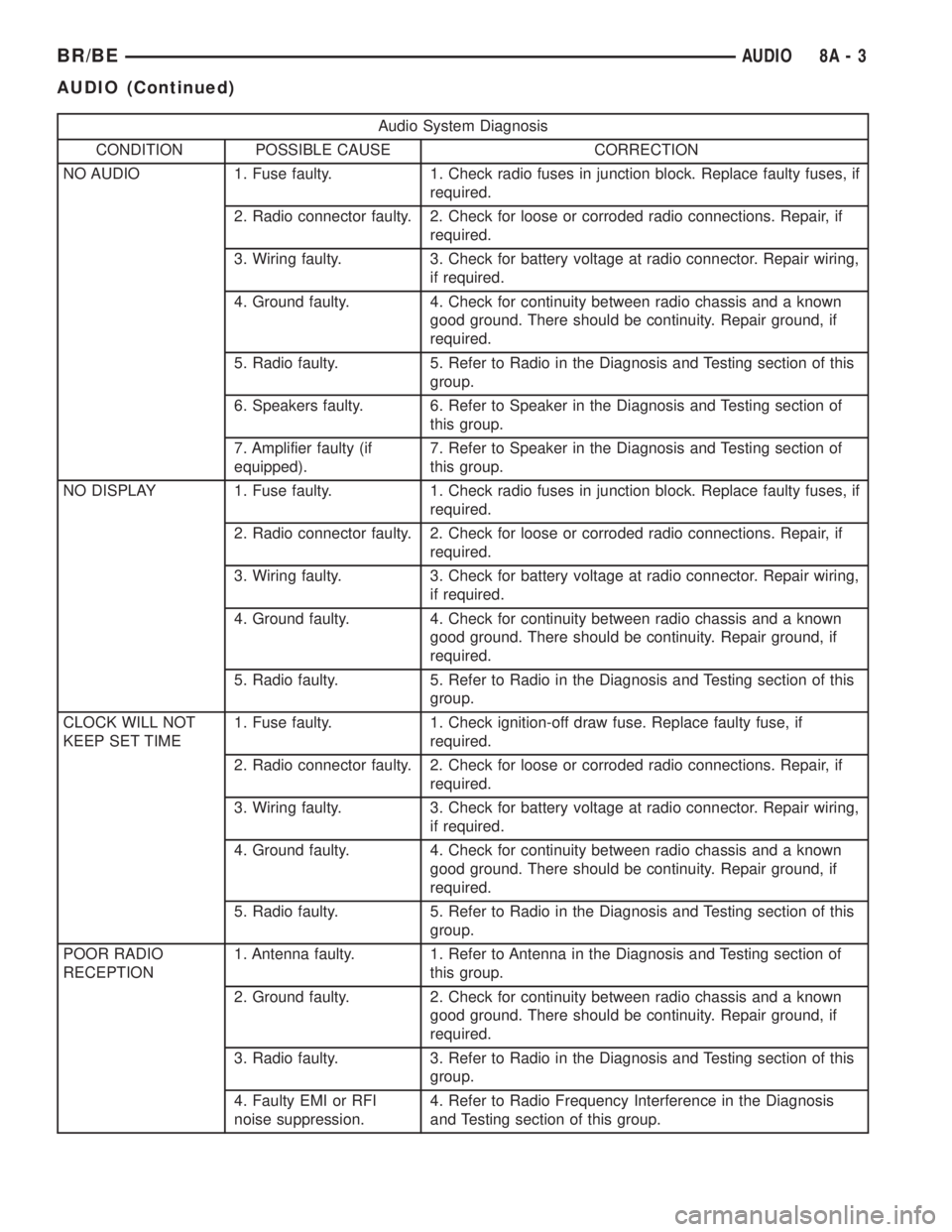

Audio System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

NO/POOR TAPE

OPERATION1. Faulty tape. 1. Insert known good tape and test operation.

2. Foreign objects behind

tape door.2. Remove foreign objects and test operation.

3. Dirty cassette tape

head.3. Clean head with Mopar Cassette Head Cleaner.

4. Faulty tape deck. 4. Exchange or replace radio, if required.

NO COMPACT DISC

OPERATION1. Faulty CD. 1. Insert known good CD and test operation.

2. Foreign material on

CD.2. Clean CD and test operation.

3. Condensation on CD

or optics.3. Allow temperature of vehicle interior to stabilize and test

operation.

4. Faulty CD player. 4. Exchange or replace radio, if required.

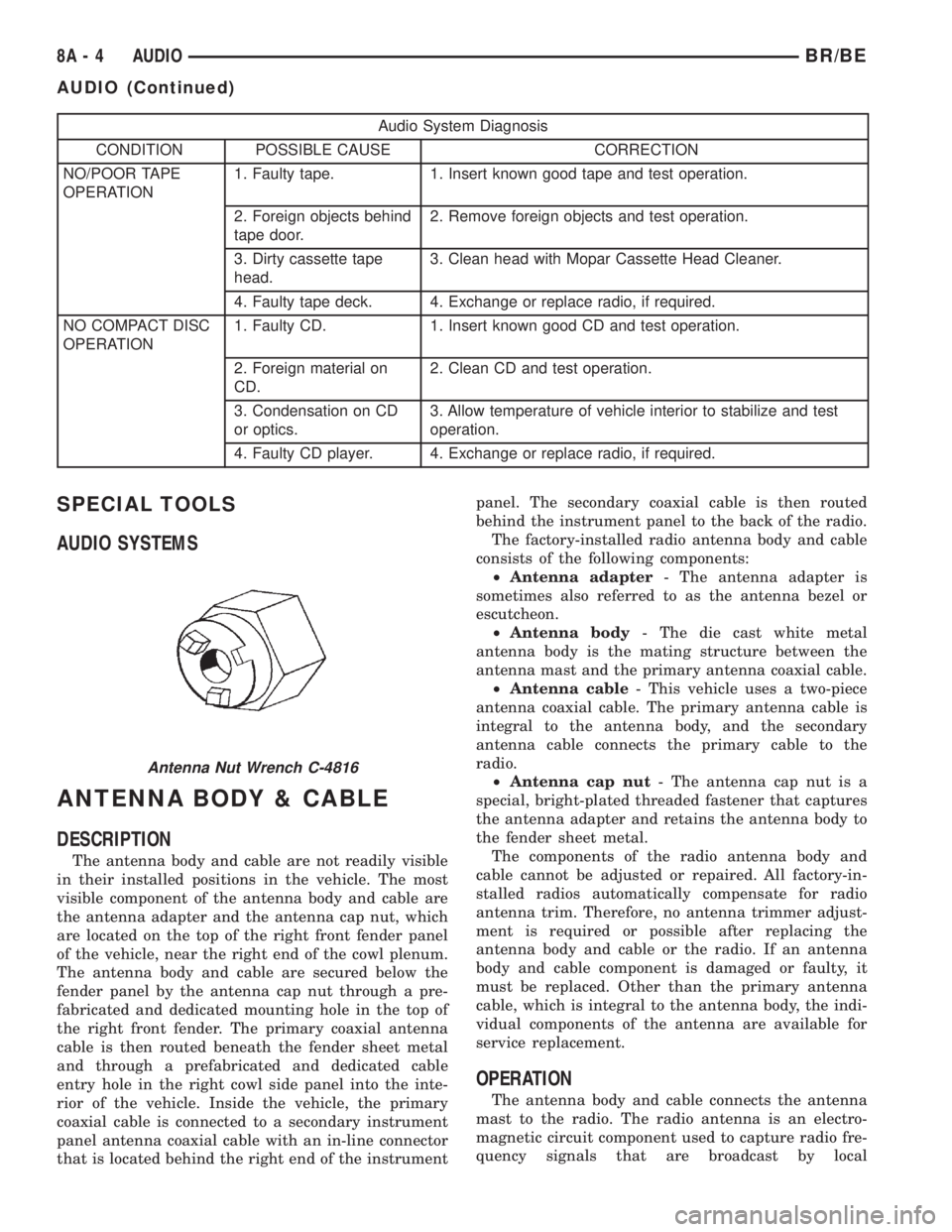

SPECIAL TOOLS

AUDIO SYSTEMS

ANTENNA BODY & CABLE

DESCRIPTION

The antenna body and cable are not readily visible

in their installed positions in the vehicle. The most

visible component of the antenna body and cable are

the antenna adapter and the antenna cap nut, which

are located on the top of the right front fender panel

of the vehicle, near the right end of the cowl plenum.

The antenna body and cable are secured below the

fender panel by the antenna cap nut through a pre-

fabricated and dedicated mounting hole in the top of

the right front fender. The primary coaxial antenna

cable is then routed beneath the fender sheet metal

and through a prefabricated and dedicated cable

entry hole in the right cowl side panel into the inte-

rior of the vehicle. Inside the vehicle, the primary

coaxial cable is connected to a secondary instrument

panel antenna coaxial cable with an in-line connector

that is located behind the right end of the instrumentpanel. The secondary coaxial cable is then routed

behind the instrument panel to the back of the radio.

The factory-installed radio antenna body and cable

consists of the following components:

²Antenna adapter- The antenna adapter is

sometimes also referred to as the antenna bezel or

escutcheon.

²Antenna body- The die cast white metal

antenna body is the mating structure between the

antenna mast and the primary antenna coaxial cable.

²Antenna cable- This vehicle uses a two-piece

antenna coaxial cable. The primary antenna cable is

integral to the antenna body, and the secondary

antenna cable connects the primary cable to the

radio.

²Antenna cap nut- The antenna cap nut is a

special, bright-plated threaded fastener that captures

the antenna adapter and retains the antenna body to

the fender sheet metal.

The components of the radio antenna body and

cable cannot be adjusted or repaired. All factory-in-

stalled radios automatically compensate for radio

antenna trim. Therefore, no antenna trimmer adjust-

ment is required or possible after replacing the

antenna body and cable or the radio. If an antenna

body and cable component is damaged or faulty, it

must be replaced. Other than the primary antenna

cable, which is integral to the antenna body, the indi-

vidual components of the antenna are available for

service replacement.

OPERATION

The antenna body and cable connects the antenna

mast to the radio. The radio antenna is an electro-

magnetic circuit component used to capture radio fre-

quency signals that are broadcast by local

Antenna Nut Wrench C-4816

8A - 4 AUDIOBR/BE

AUDIO (Continued)

Page 428 of 2889

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

The antenna body includes an integral flange that

mates with and grounds the antenna body to the

underside of the fender panel sheet metal. Above the

fender panel, the antenna body has a short nipple

that is externally threaded to accept the antenna cap

nut. Inside the nipple is a plastic insulator tube, and

inside this insulator is an internally threaded metal

receptacle that accepts the adapter stud on the bot-

tom of the antenna mast. The antenna adapter

serves as an above fender interface to mount and

secure the antenna body to the vehicle. The antenna

adapter is a black molded plastic component that

provides a functional transition between the top of

the fender and the antenna cap nut, while concealing

the edges of the antenna mounting hole and protect-

ing the painted finish of the fender from marring as

the antenna cap nut is tightened. The adapter is

installed over and shrouds the threaded nipple of the

antenna body, which is installed from under and pro-

trudes through the top of the mounting hole in the

fender. The antenna cap nut is installed on top of the

antenna adapter and tightened onto the external

threads of the antenna body nipple to effectively

secure and ground the antenna body to the fender.

Three notches on the outer circumference of the cap

nut are engaged by matching projections of an

antenna nut wrench (Special Tool C-4816) to facili-

tate the removal and installation of this special fas-

tener. Proper tightening of the antenna cap nut is

critical to ensuring proper grounding of the antenna

body to the fender sheet metal, which is necessary

for clear radio signal reception.

A short length of coaxial cable serves as the pri-

mary antenna cable. The center conductor of the

cable is connected to the antenna mast receptacle.

The outer wire mesh of the cable is connected to and

grounded through the antenna body. One end of the

primary antenna cable is securely crimped to the

lower end of the antenna body, while the opposite

end features a simple push/pull-type male coaxial

cable connector that serves as the in-line connector tothe instrument panel (secondary) antenna coaxial

cable. The primary coaxial cable includes a grommet

that seals the cable to an entry hole in the right cowl

side outer panel where the cable passes into the pas-

senger compartment of the vehicle. The secondary

antenna cable has a push/pull-type male coaxial

cable connector on the radio end, and a push/pull-

type female coaxial cable connector on the opposite

end, which serves as the in-line connector to the pri-

mary antenna cable. In the passenger compartment

the primary cable is routed to the lower right side of

the instrument panel, where it is connected to the

secondary instrument panel antenna cable. The

instrument panel antenna cable is routed near the

instrument panel wire harness through the instru-

ment panel to the radio and is secured to the instru-

ment panel structural support with small metal

push-on retainers. This two-piece antenna cable

arrangement allows the instrument panel or the

antenna body and cable to be removed or installed

without disturbing the radio.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ANTENNA

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

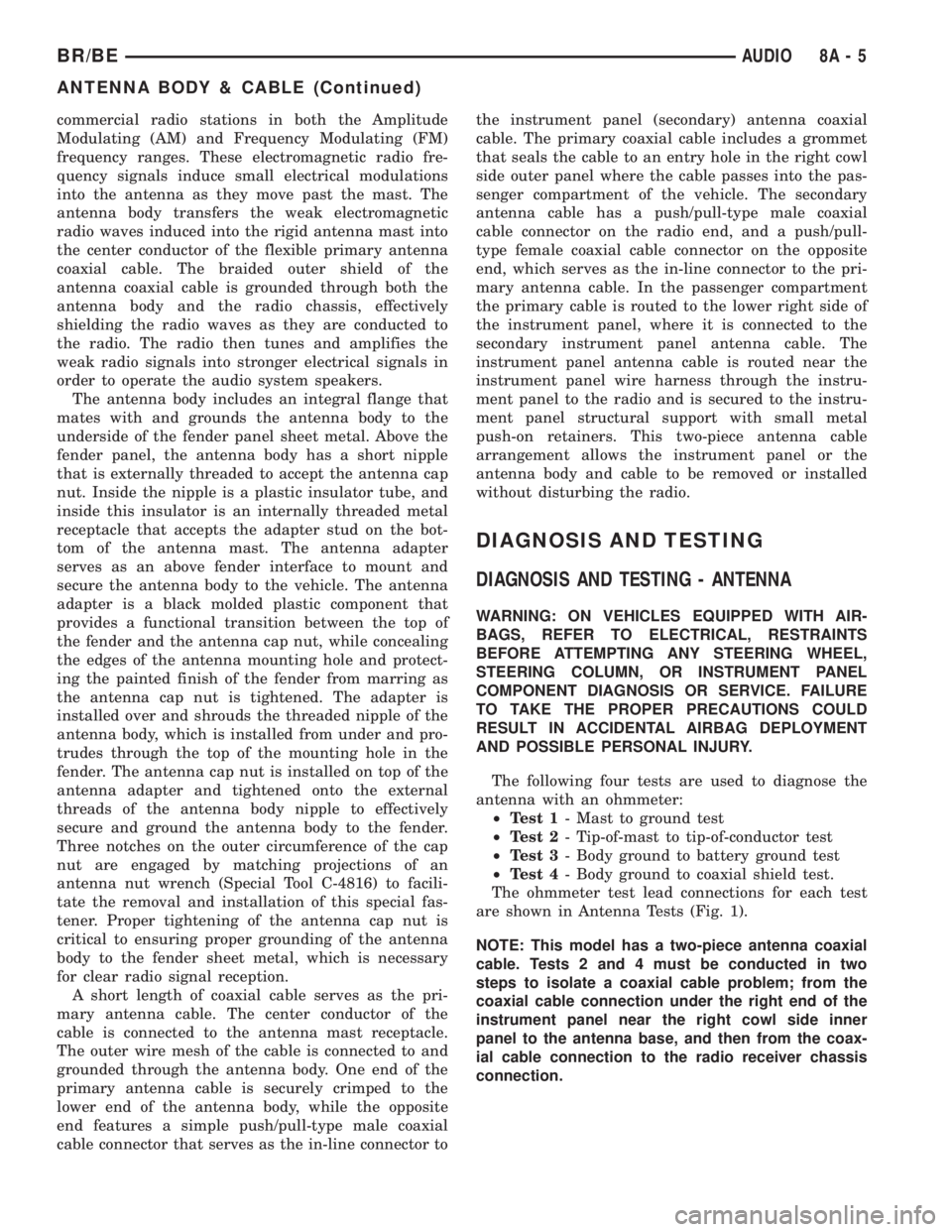

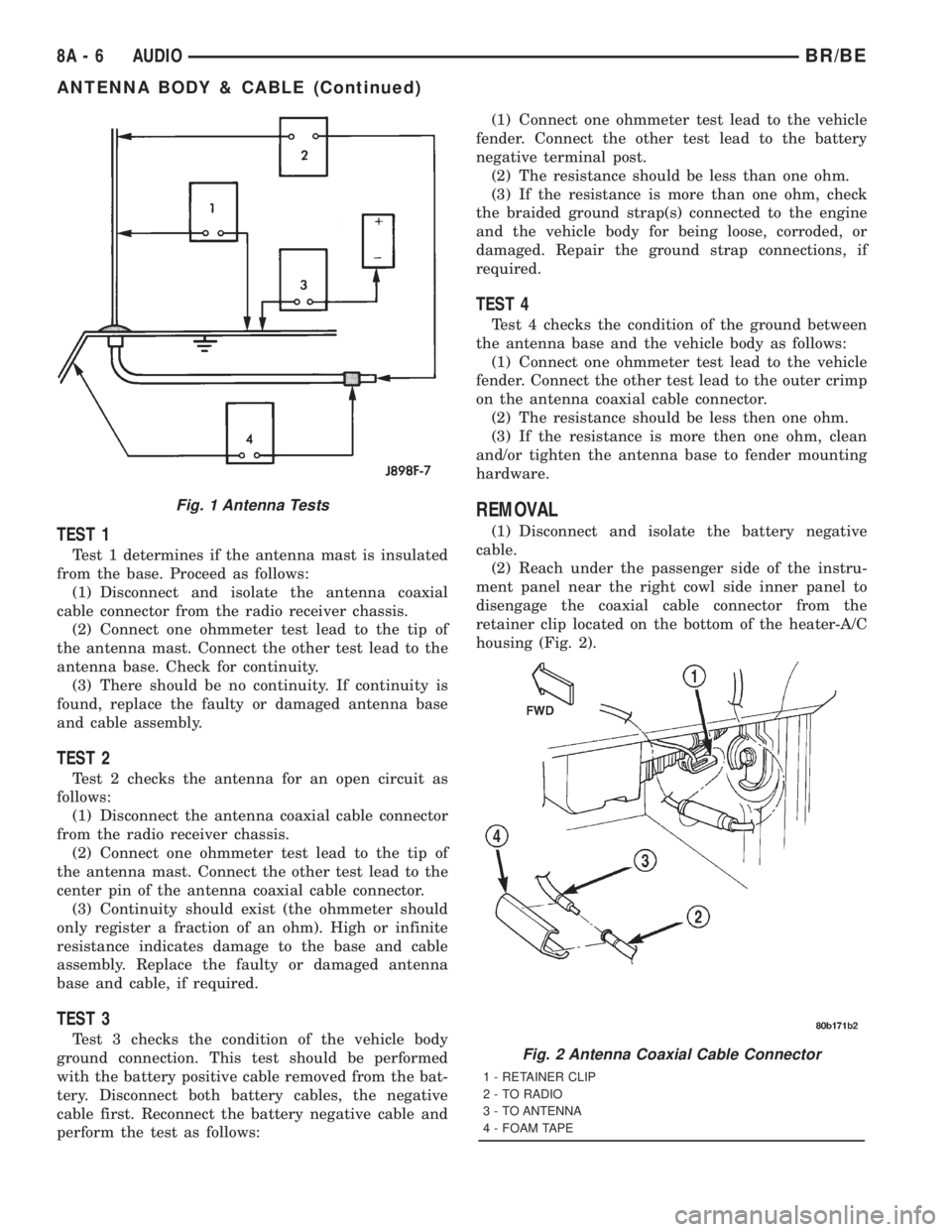

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to coaxial shield test.

The ohmmeter test lead connections for each test

are shown in Antenna Tests (Fig. 1).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate a coaxial cable problem; from the

coaxial cable connection under the right end of the

instrument panel near the right cowl side inner

panel to the antenna base, and then from the coax-

ial cable connection to the radio receiver chassis

connection.

BR/BEAUDIO 8A - 5

ANTENNA BODY & CABLE (Continued)

Page 429 of 2889

TEST 1

Test 1 determines if the antenna mast is insulated

from the base. Proceed as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector from the radio receiver chassis.

(2) Connect one ohmmeter test lead to the tip of

the antenna mast. Connect the other test lead to the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

TEST 2

Test 2 checks the antenna for an open circuit as

follows:

(1) Disconnect the antenna coaxial cable connector

from the radio receiver chassis.

(2) Connect one ohmmeter test lead to the tip of

the antenna mast. Connect the other test lead to the

center pin of the antenna coaxial cable connector.

(3) Continuity should exist (the ohmmeter should

only register a fraction of an ohm). High or infinite

resistance indicates damage to the base and cable

assembly. Replace the faulty or damaged antenna

base and cable, if required.

TEST 3

Test 3 checks the condition of the vehicle body

ground connection. This test should be performed

with the battery positive cable removed from the bat-

tery. Disconnect both battery cables, the negative

cable first. Reconnect the battery negative cable and

perform the test as follows:(1) Connect one ohmmeter test lead to the vehicle

fender. Connect the other test lead to the battery

negative terminal post.

(2) The resistance should be less than one ohm.

(3) If the resistance is more than one ohm, check

the braided ground strap(s) connected to the engine

and the vehicle body for being loose, corroded, or

damaged. Repair the ground strap connections, if

required.

TEST 4

Test 4 checks the condition of the ground between

the antenna base and the vehicle body as follows:

(1) Connect one ohmmeter test lead to the vehicle

fender. Connect the other test lead to the outer crimp

on the antenna coaxial cable connector.

(2) The resistance should be less then one ohm.

(3) If the resistance is more then one ohm, clean

and/or tighten the antenna base to fender mounting

hardware.

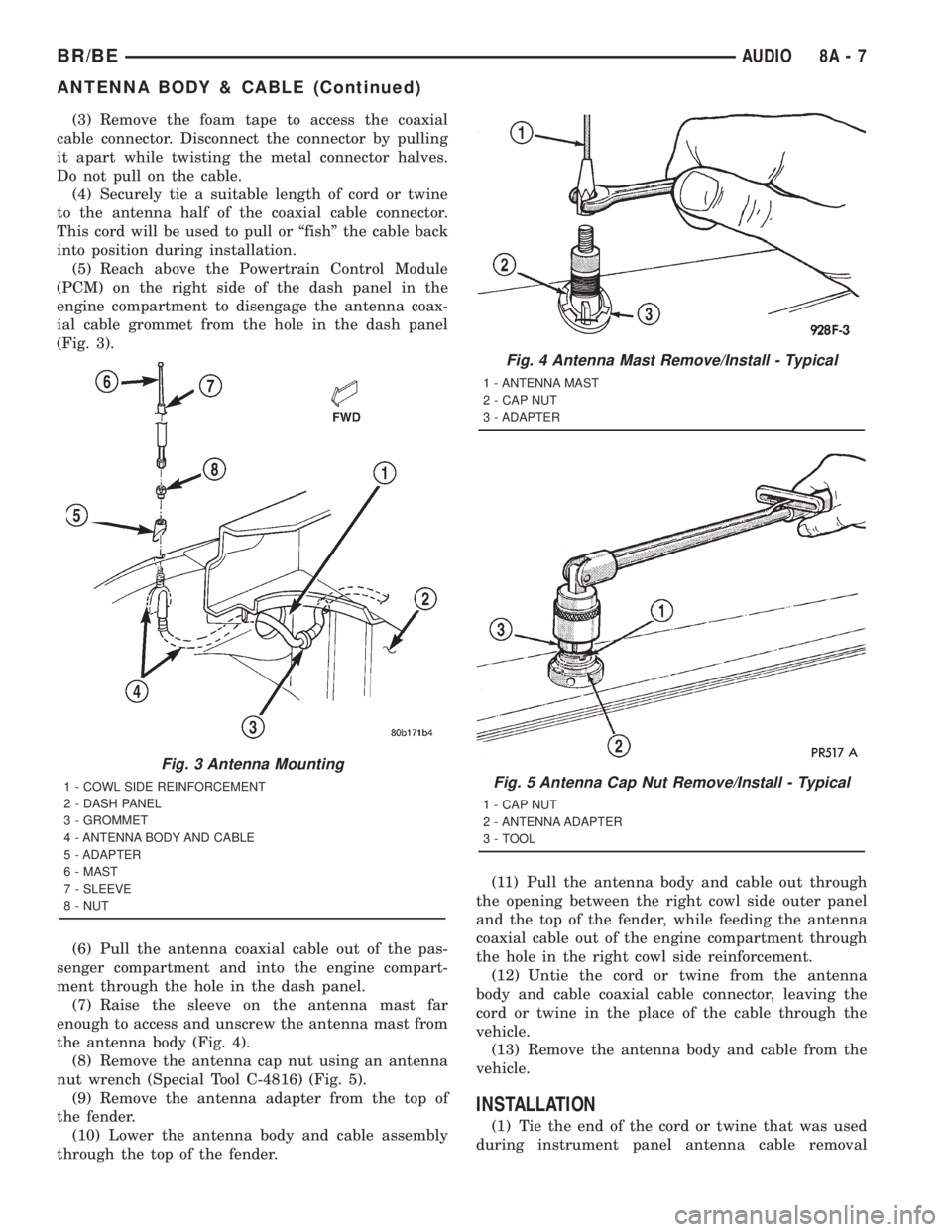

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

disengage the coaxial cable connector from the

retainer clip located on the bottom of the heater-A/C

housing (Fig. 2).

Fig. 1 Antenna Tests

Fig. 2 Antenna Coaxial Cable Connector

1 - RETAINER CLIP

2 - TO RADIO

3 - TO ANTENNA

4 - FOAM TAPE

8A - 6 AUDIOBR/BE

ANTENNA BODY & CABLE (Continued)

Page 430 of 2889

(3) Remove the foam tape to access the coaxial

cable connector. Disconnect the connector by pulling

it apart while twisting the metal connector halves.

Do not pull on the cable.

(4) Securely tie a suitable length of cord or twine

to the antenna half of the coaxial cable connector.

This cord will be used to pull or ªfishº the cable back

into position during installation.

(5) Reach above the Powertrain Control Module

(PCM) on the right side of the dash panel in the

engine compartment to disengage the antenna coax-

ial cable grommet from the hole in the dash panel

(Fig. 3).

(6) Pull the antenna coaxial cable out of the pas-

senger compartment and into the engine compart-

ment through the hole in the dash panel.

(7) Raise the sleeve on the antenna mast far

enough to access and unscrew the antenna mast from

the antenna body (Fig. 4).

(8) Remove the antenna cap nut using an antenna

nut wrench (Special Tool C-4816) (Fig. 5).

(9) Remove the antenna adapter from the top of

the fender.

(10) Lower the antenna body and cable assembly

through the top of the fender.(11) Pull the antenna body and cable out through

the opening between the right cowl side outer panel

and the top of the fender, while feeding the antenna

coaxial cable out of the engine compartment through

the hole in the right cowl side reinforcement.

(12) Untie the cord or twine from the antenna

body and cable coaxial cable connector, leaving the

cord or twine in the place of the cable through the

vehicle.

(13) Remove the antenna body and cable from the

vehicle.

INSTALLATION

(1) Tie the end of the cord or twine that was used

during instrument panel antenna cable removal

Fig. 3 Antenna Mounting

1 - COWL SIDE REINFORCEMENT

2 - DASH PANEL

3 - GROMMET

4 - ANTENNA BODY AND CABLE

5 - ADAPTER

6 - MAST

7 - SLEEVE

8 - NUT

Fig. 4 Antenna Mast Remove/Install - Typical

1 - ANTENNA MAST

2 - CAP NUT

3 - ADAPTER

Fig. 5 Antenna Cap Nut Remove/Install - Typical

1 - CAP NUT

2 - ANTENNA ADAPTER

3 - TOOL

BR/BEAUDIO 8A - 7

ANTENNA BODY & CABLE (Continued)