wheel torque DODGE RAM 2001 Service Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 263 of 2889

(14) Remove support and lower vehicle.

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKY

The most common problem is a chatter noise when

turning corners. Before removing a Trac-lokyunit

for repair, drain, flush and refill the axle with the

specified lubricant. A container of Mopar Trac-loky

Lubricant (friction modifier) should be added after

repair service or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

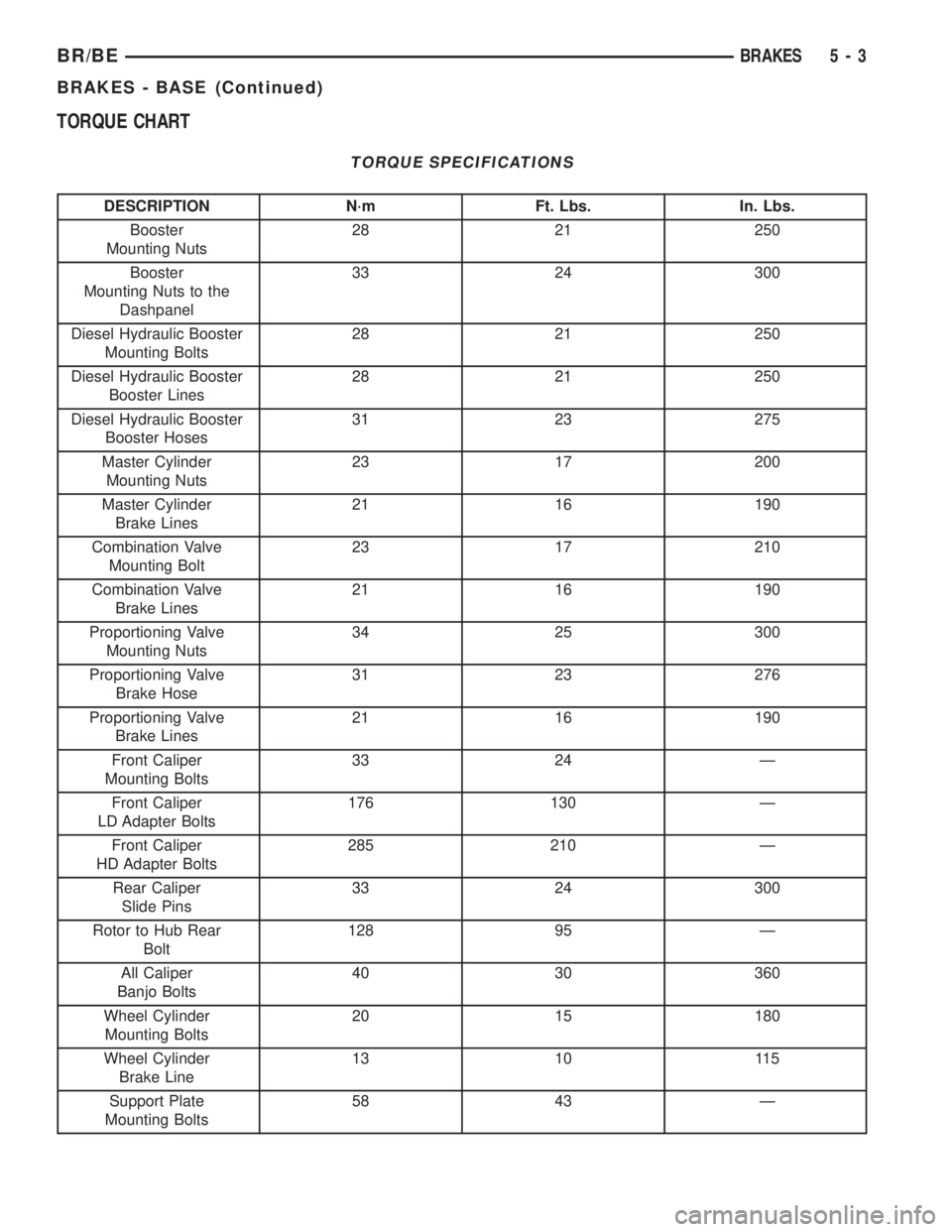

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 35).

(6) If rotating torque is less than 22 N´m (30 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

DISASSEMBLY

The Trac-Lokydifferential on this axle has a one-

piece cross shaft and uses one dished disc, regular 5

disc and 7 plates.

NOTE: Pay attention to the clutch pack arrangement

during disassembly. Note the direction of the con-

cave and convex side of the plates and discs.

(1) Mark the ring gear half and cover half for

installation reference (Fig. 36).

(2) Remove case attaching bolts and remove the

button cover half (Fig. 37).

(3) Remove top clutch pack.

(4) Remove top side gear clutch ring.

(5) Remove top side gear.

(6) Remove pinion mate gears and cross shaft.

(7) Remove the same parts listed above from the

ring gear flange half of the case. Keep these parts

with the flange cover half for installation in their

original positions.

ASSEMBLY

The Trac-Lokydifferential for this axle has a one-

piece cross shaft and uses one dished disc, 5 regular

disc and 7 plates for each clutch pack.

NOTE: The clutch discs are replaceable as com-

plete sets only. If one clutch disc pack is damaged,

both packs must be replaced.

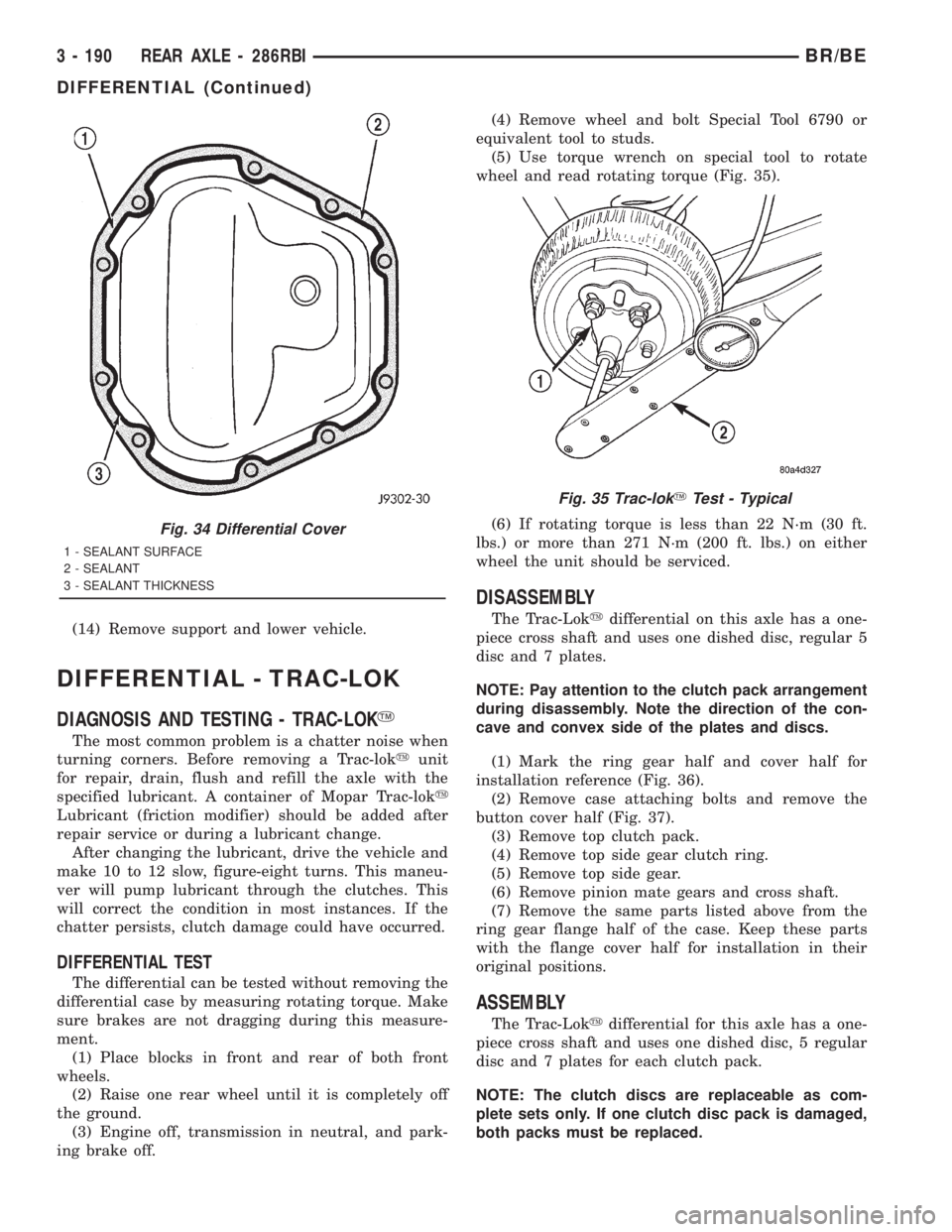

Fig. 34 Differential Cover

1 - SEALANT SURFACE

2 - SEALANT

3 - SEALANT THICKNESS

Fig. 35 Trac-lokYTest - Typical

3 - 190 REAR AXLE - 286RBIBR/BE

DIFFERENTIAL (Continued)

Page 274 of 2889

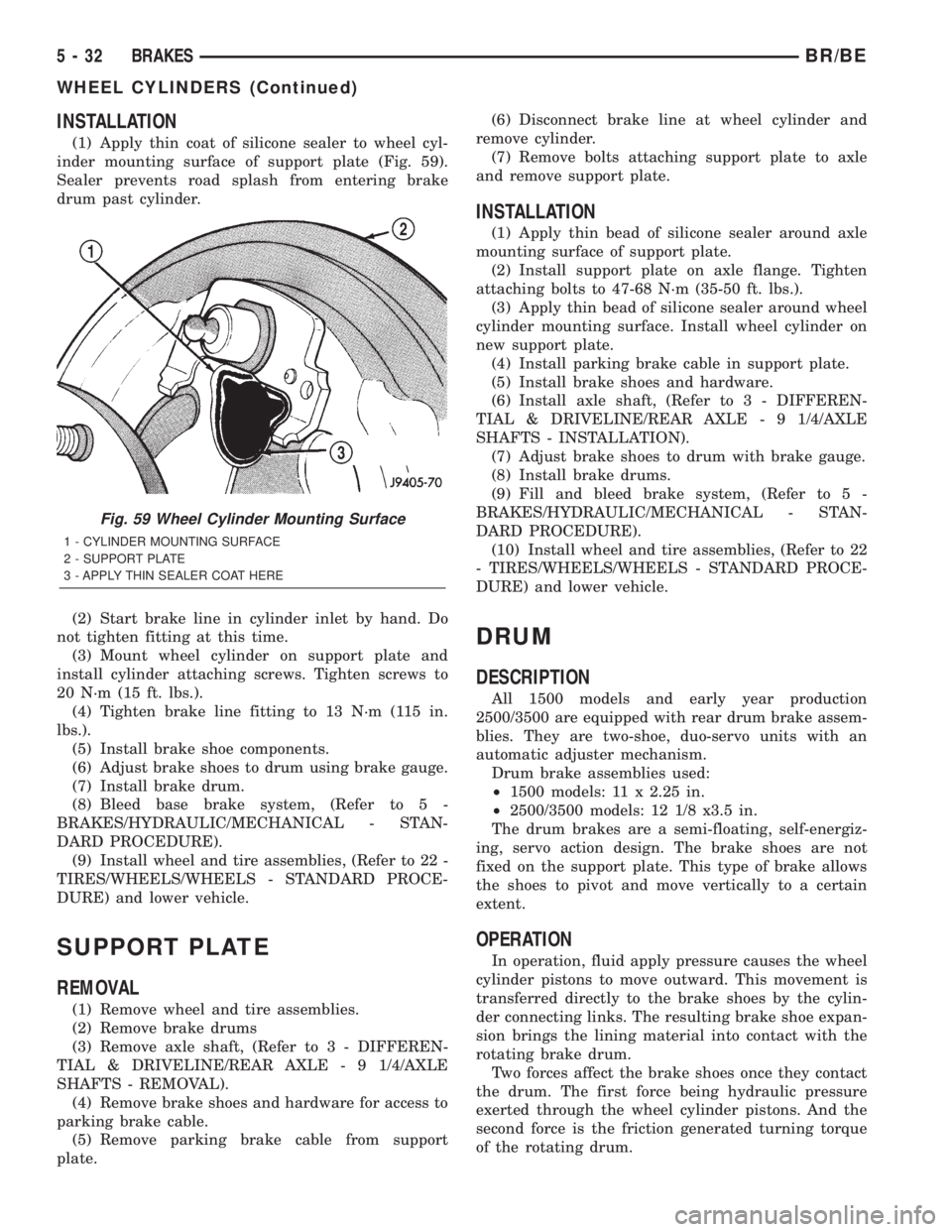

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Booster

Mounting Nuts28 21 250

Booster

Mounting Nuts to the

Dashpanel33 24 300

Diesel Hydraulic Booster

Mounting Bolts28 21 250

Diesel Hydraulic Booster

Booster Lines28 21 250

Diesel Hydraulic Booster

Booster Hoses31 23 275

Master Cylinder

Mounting Nuts23 17 200

Master Cylinder

Brake Lines21 16 190

Combination Valve

Mounting Bolt23 17 210

Combination Valve

Brake Lines21 16 190

Proportioning Valve

Mounting Nuts34 25 300

Proportioning Valve

Brake Hose31 23 276

Proportioning Valve

Brake Lines21 16 190

Front Caliper

Mounting Bolts33 24 Ð

Front Caliper

LD Adapter Bolts176 130 Ð

Front Caliper

HD Adapter Bolts285 210 Ð

Rear Caliper

Slide Pins33 24 300

Rotor to Hub Rear

Bolt128 95 Ð

All Caliper

Banjo Bolts40 30 360

Wheel Cylinder

Mounting Bolts20 15 180

Wheel Cylinder

Brake Line13 10 115

Support Plate

Mounting Bolts58 43 Ð

BR/BEBRAKES 5 - 3

BRAKES - BASE (Continued)

Page 303 of 2889

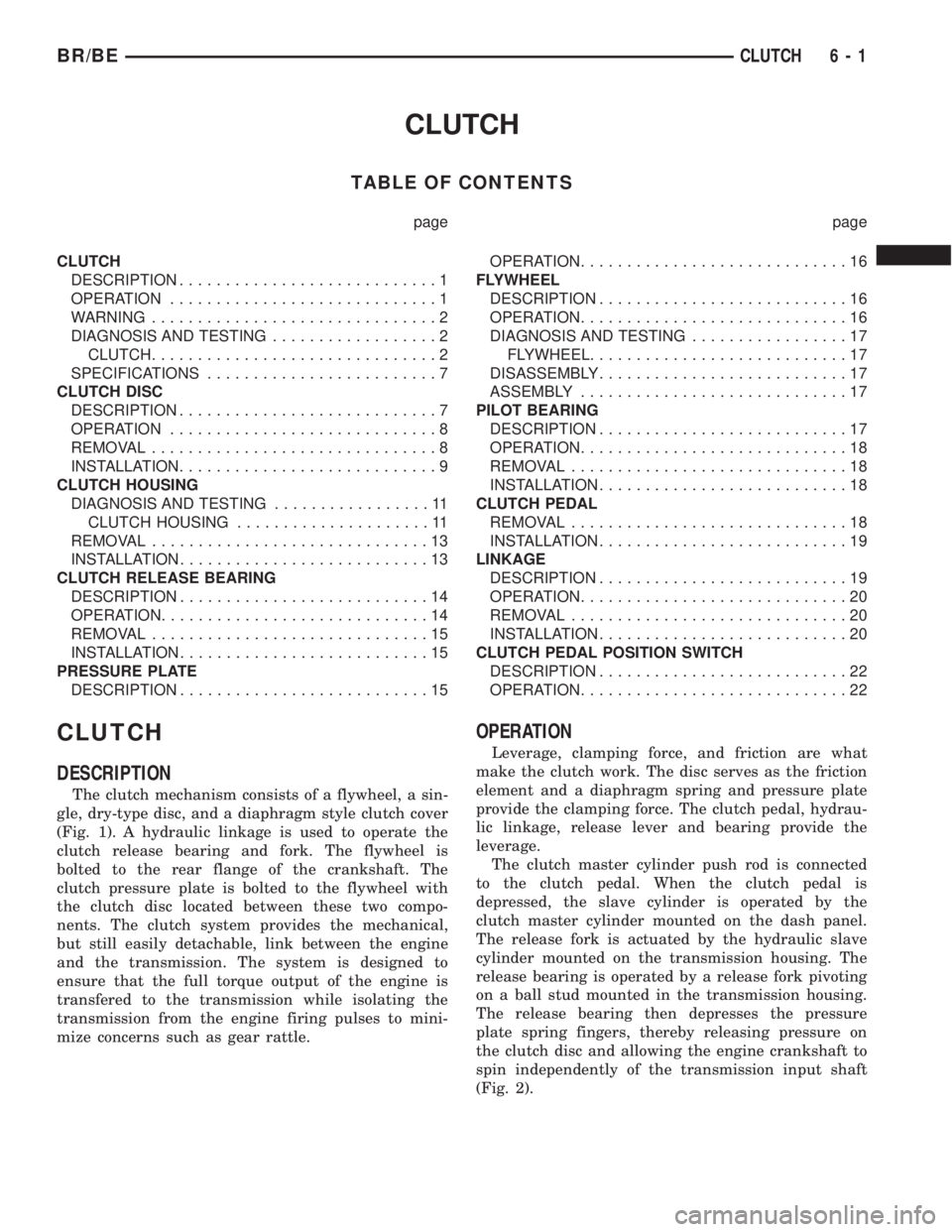

INSTALLATION

(1) Apply thin coat of silicone sealer to wheel cyl-

inder mounting surface of support plate (Fig. 59).

Sealer prevents road splash from entering brake

drum past cylinder.

(2) Start brake line in cylinder inlet by hand. Do

not tighten fitting at this time.

(3) Mount wheel cylinder on support plate and

install cylinder attaching screws. Tighten screws to

20 N´m (15 ft. lbs.).

(4) Tighten brake line fitting to 13 N´m (115 in.

lbs.).

(5) Install brake shoe components.

(6) Adjust brake shoes to drum using brake gauge.

(7) Install brake drum.

(8) Bleed base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(9) Install wheel and tire assemblies, (Refer to 22 -

TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE) and lower vehicle.

SUPPORT PLATE

REMOVAL

(1) Remove wheel and tire assemblies.

(2) Remove brake drums

(3) Remove axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - REMOVAL).

(4) Remove brake shoes and hardware for access to

parking brake cable.

(5) Remove parking brake cable from support

plate.(6) Disconnect brake line at wheel cylinder and

remove cylinder.

(7) Remove bolts attaching support plate to axle

and remove support plate.

INSTALLATION

(1) Apply thin bead of silicone sealer around axle

mounting surface of support plate.

(2) Install support plate on axle flange. Tighten

attaching bolts to 47-68 N´m (35-50 ft. lbs.).

(3) Apply thin bead of silicone sealer around wheel

cylinder mounting surface. Install wheel cylinder on

new support plate.

(4) Install parking brake cable in support plate.

(5) Install brake shoes and hardware.

(6) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(7) Adjust brake shoes to drum with brake gauge.

(8) Install brake drums.

(9) Fill and bleed brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(10) Install wheel and tire assemblies, (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE) and lower vehicle.

DRUM

DESCRIPTION

All 1500 models and early year production

2500/3500 are equipped with rear drum brake assem-

blies. They are two-shoe, duo-servo units with an

automatic adjuster mechanism.

Drum brake assemblies used:

²1500 models: 11 x 2.25 in.

²2500/3500 models: 12 1/8 x3.5 in.

The drum brakes are a semi-floating, self-energiz-

ing, servo action design. The brake shoes are not

fixed on the support plate. This type of brake allows

the shoes to pivot and move vertically to a certain

extent.

OPERATION

In operation, fluid apply pressure causes the wheel

cylinder pistons to move outward. This movement is

transferred directly to the brake shoes by the cylin-

der connecting links. The resulting brake shoe expan-

sion brings the lining material into contact with the

rotating brake drum.

Two forces affect the brake shoes once they contact

the drum. The first force being hydraulic pressure

exerted through the wheel cylinder pistons. And the

second force is the friction generated turning torque

of the rotating drum.

Fig. 59 Wheel Cylinder Mounting Surface

1 - CYLINDER MOUNTING SURFACE

2 - SUPPORT PLATE

3 - APPLY THIN SEALER COAT HERE

5 - 32 BRAKESBR/BE

WHEEL CYLINDERS (Continued)

Page 314 of 2889

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

DESCRIPTION............................1

OPERATION.............................1

WARNING...............................2

DIAGNOSIS AND TESTING..................2

CLUTCH...............................2

SPECIFICATIONS.........................7

CLUTCH DISC

DESCRIPTION............................7

OPERATION.............................8

REMOVAL...............................8

INSTALLATION............................9

CLUTCH HOUSING

DIAGNOSIS AND TESTING.................11

CLUTCH HOUSING.....................11

REMOVAL..............................13

INSTALLATION...........................13

CLUTCH RELEASE BEARING

DESCRIPTION...........................14

OPERATION.............................14

REMOVAL..............................15

INSTALLATION...........................15

PRESSURE PLATE

DESCRIPTION...........................15OPERATION.............................16

FLYWHEEL

DESCRIPTION...........................16

OPERATION.............................16

DIAGNOSIS AND TESTING.................17

FLYWHEEL............................17

DISASSEMBLY...........................17

ASSEMBLY.............................17

PILOT BEARING

DESCRIPTION...........................17

OPERATION.............................18

REMOVAL..............................18

INSTALLATION...........................18

CLUTCH PEDAL

REMOVAL..............................18

INSTALLATION...........................19

LINKAGE

DESCRIPTION...........................19

OPERATION.............................20

REMOVAL..............................20

INSTALLATION...........................20

CLUTCH PEDAL POSITION SWITCH

DESCRIPTION...........................22

OPERATION.............................22

CLUTCH

DESCRIPTION

The clutch mechanism consists of a flywheel, a sin-

gle, dry-type disc, and a diaphragm style clutch cover

(Fig. 1). A hydraulic linkage is used to operate the

clutch release bearing and fork. The flywheel is

bolted to the rear flange of the crankshaft. The

clutch pressure plate is bolted to the flywheel with

the clutch disc located between these two compo-

nents. The clutch system provides the mechanical,

but still easily detachable, link between the engine

and the transmission. The system is designed to

ensure that the full torque output of the engine is

transfered to the transmission while isolating the

transmission from the engine firing pulses to mini-

mize concerns such as gear rattle.

OPERATION

Leverage, clamping force, and friction are what

make the clutch work. The disc serves as the friction

element and a diaphragm spring and pressure plate

provide the clamping force. The clutch pedal, hydrau-

lic linkage, release lever and bearing provide the

leverage.

The clutch master cylinder push rod is connected

to the clutch pedal. When the clutch pedal is

depressed, the slave cylinder is operated by the

clutch master cylinder mounted on the dash panel.

The release fork is actuated by the hydraulic slave

cylinder mounted on the transmission housing. The

release bearing is operated by a release fork pivoting

on a ball stud mounted in the transmission housing.

The release bearing then depresses the pressure

plate spring fingers, thereby releasing pressure on

the clutch disc and allowing the engine crankshaft to

spin independently of the transmission input shaft

(Fig. 2).

BR/BECLUTCH 6 - 1

Page 317 of 2889

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft. Oil leak-

age produces a residue of oil on the housing interior

and on the clutch cover and flywheel. Heat buildup

caused by slippage between the cover, disc and fly-

wheel, can sometimes bake the oil residue onto the

components. The glaze-like residue ranges in color

from amber to black.

Road splash contamination means dirt/water is

entering the clutch housing due to loose bolts, hous-

ing cracks or through hydraulic line openings. Driv-

ing through deep water puddles can force water/road

splash into the housing through such openings.

Clutch fluid leaks are usually from damaged slave

cylinder push rod seals.

IMPROPER RELEASE OR CLUTCH ENGAGEMENT

Clutch release or engagement problems are caused

by wear or damage to one or more clutch compo-

nents. A visual inspection of the release components

will usually reveal the problem part.

Release problems can result in hard shifting and

noise. Items to look for are: leaks at the clutch cylin-

ders and interconnecting line; loose slave cylinder

bolts; worn/loose release fork and pivot stud; dam-

aged release bearing; and a worn clutch disc, or pres-

sure plate.

Normal condensation in vehicles that are stored or

out of service for long periods of time can generate

enough corrosion to make the disc stick to the fly-

wheel, or pressure plate. If this condition is experi-

enced, correction only requires that the disc be

loosened manually through the inspection plate open-

ing.

Engagement problems usually result in slip, chat-

ter/shudder, and noisy operation. The primary causes

are clutch disc contamination; clutch disc wear; mis-

alignment, or distortion; flywheel damage; or a com-

bination of the foregoing. A visual inspection is

required to determine the part actually causing the

problem.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.

Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

CLUTCH COVER AND DISC RUNOUT

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain

another disc if runout is excessive.Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and con-

sequent misalignment) is improper bolt tightening.

CLUTCH FLYWHEEL RUNOUT

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on the rear face of the engine block.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. However,

minor flywheel scoring can be cleaned up by hand with

180 grit emery, or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock removal

isnot recommended.

Replace the flywheel if scoring

is severe and deeper than 0.076 mm (0.003 in.).

Excessive stock removal can result in flywheel crack-

ing or warpage after installation; it can also weaken

the flywheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with MopartLock And Seal. Tighten flywheel

bolts to specified torque only. Overtightening can dis-

tort the flywheel hub causing runout.

DIAGNOSIS CHART

The clutch inspection chart (Fig. 3) outlines items to

be checked before and during clutch installation. Use

the chart as a check list to help avoid overlooking

potential problem sources during service operations.

The diagnosis charts describe common clutch prob-

lems, causes and correction. Fault conditions are listed

at the top of each chart. Conditions, causes and correc-

tive action are outlined in the indicated columns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

6 - 4 CLUTCHBR/BE

CLUTCH (Continued)

Page 320 of 2889

CONDITION POSSIBLE CAUSES CORRECTION

Contact surface of release bearing

damaged.1. Clutch cover incorrect or release

fingers bent or distorted.1. Replace clutch cover and release

bearing.

2. Release bearing defective or

damaged.2. Replace the release bearing.

3. Release bearing misaligned. 3. Check and correct runout of

clutch components. Check front

bearing sleeve for damage/

alignment. Repair as necessary.

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.1. Clutch pressure plate position

incorrect.1. Replace clutch disc and cover.

2. Clutch cover, spring, or release

fingers bent or distorted.2. Replace clutch disc and cover.

3. Clutch disc damaged or

distorted.2. Replace clutch disc.

4. Clutch misalignment. 4. Check alignment and runout of

flywheel, disc, pressure plate, andùr

clutch housing. Correct as

necessary.

SPECIFICATIONS

SPECIFICATIONS - CLUTCH

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Nut, slave cylinder 19-26 14-19 170-230

Bolt, clutch cover-5/16 in. 23 17 -

Bolt, clutch cover-3/8 in. 41 30 -

Pivot, release bearing 23 17 -

Screw, fluid reservoir 5 - 40

CLUTCH DISC

DESCRIPTION

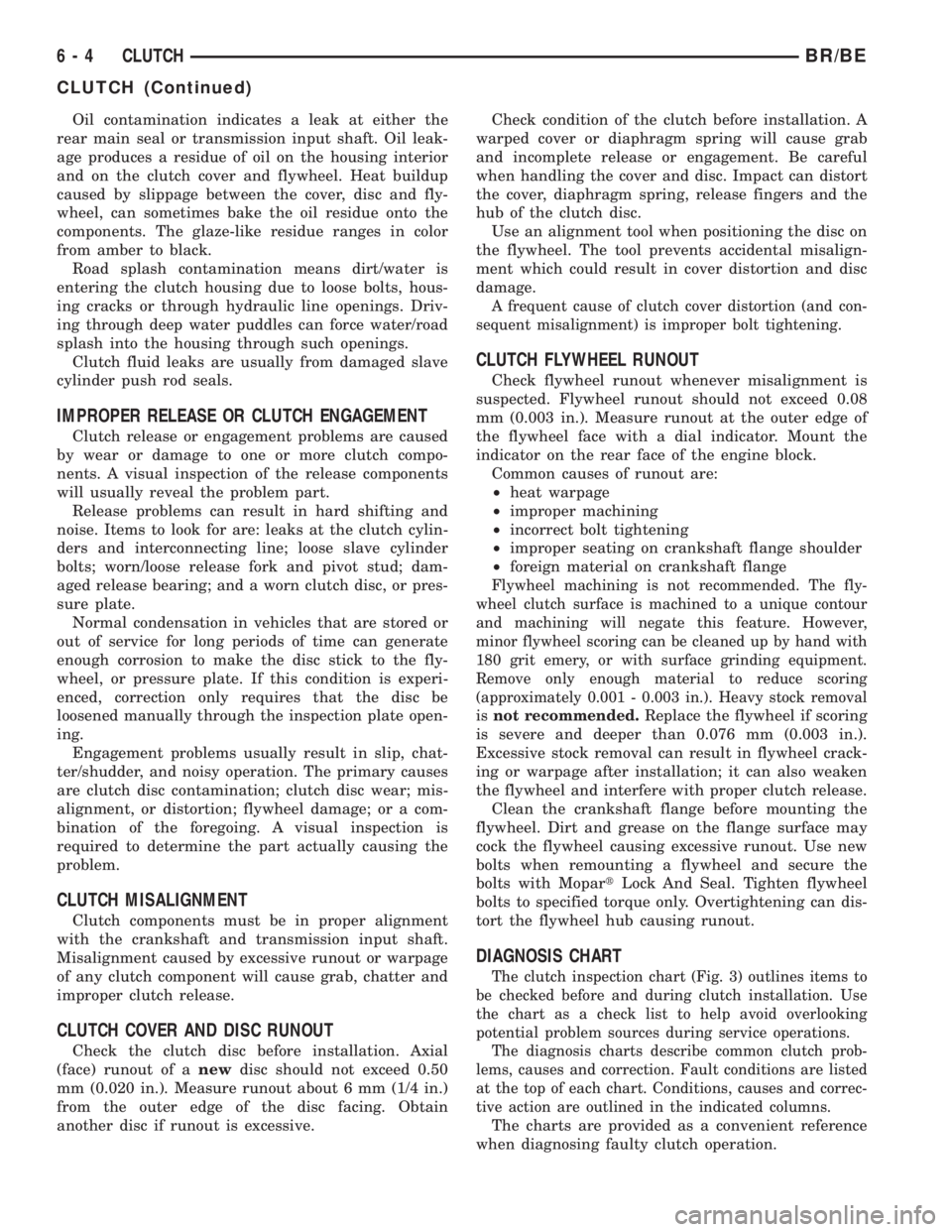

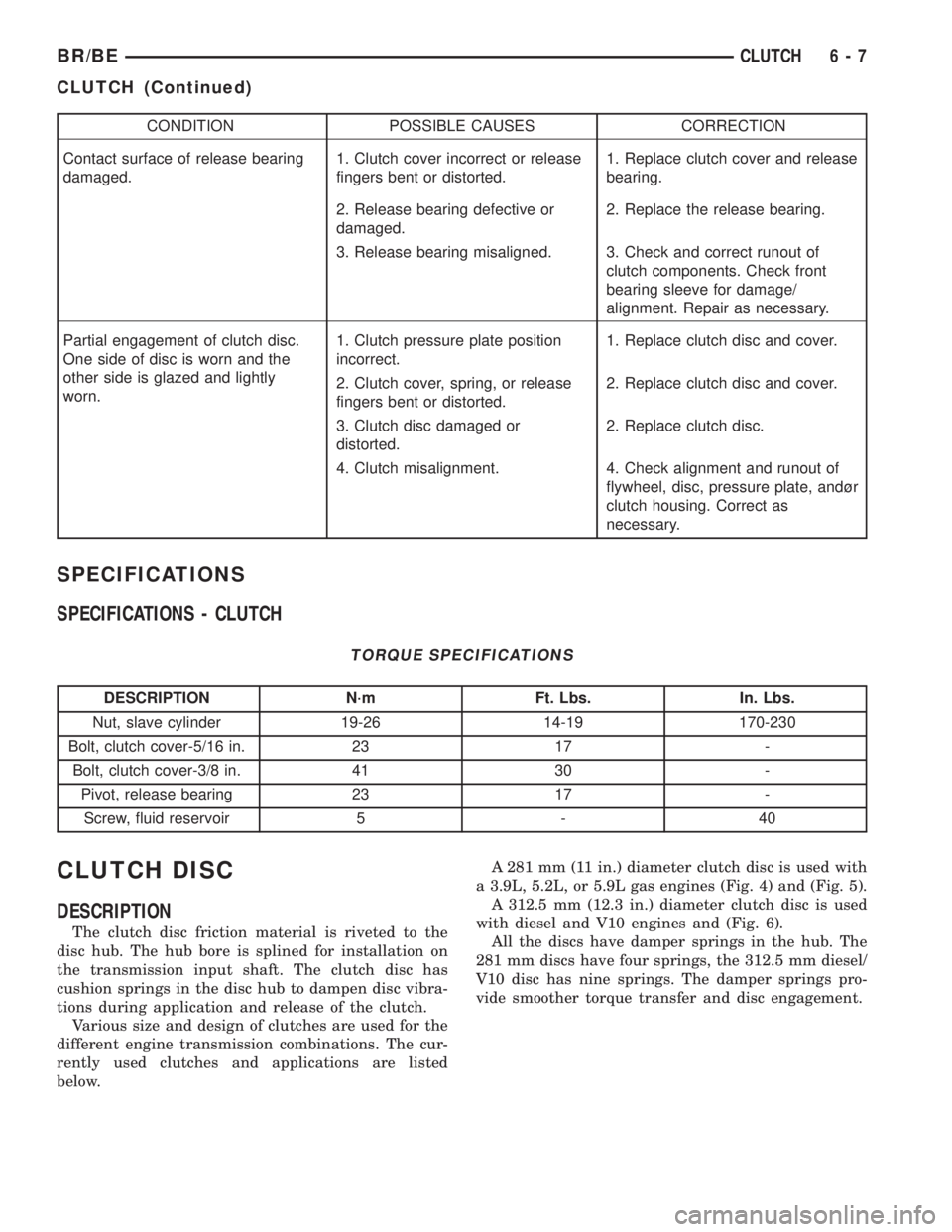

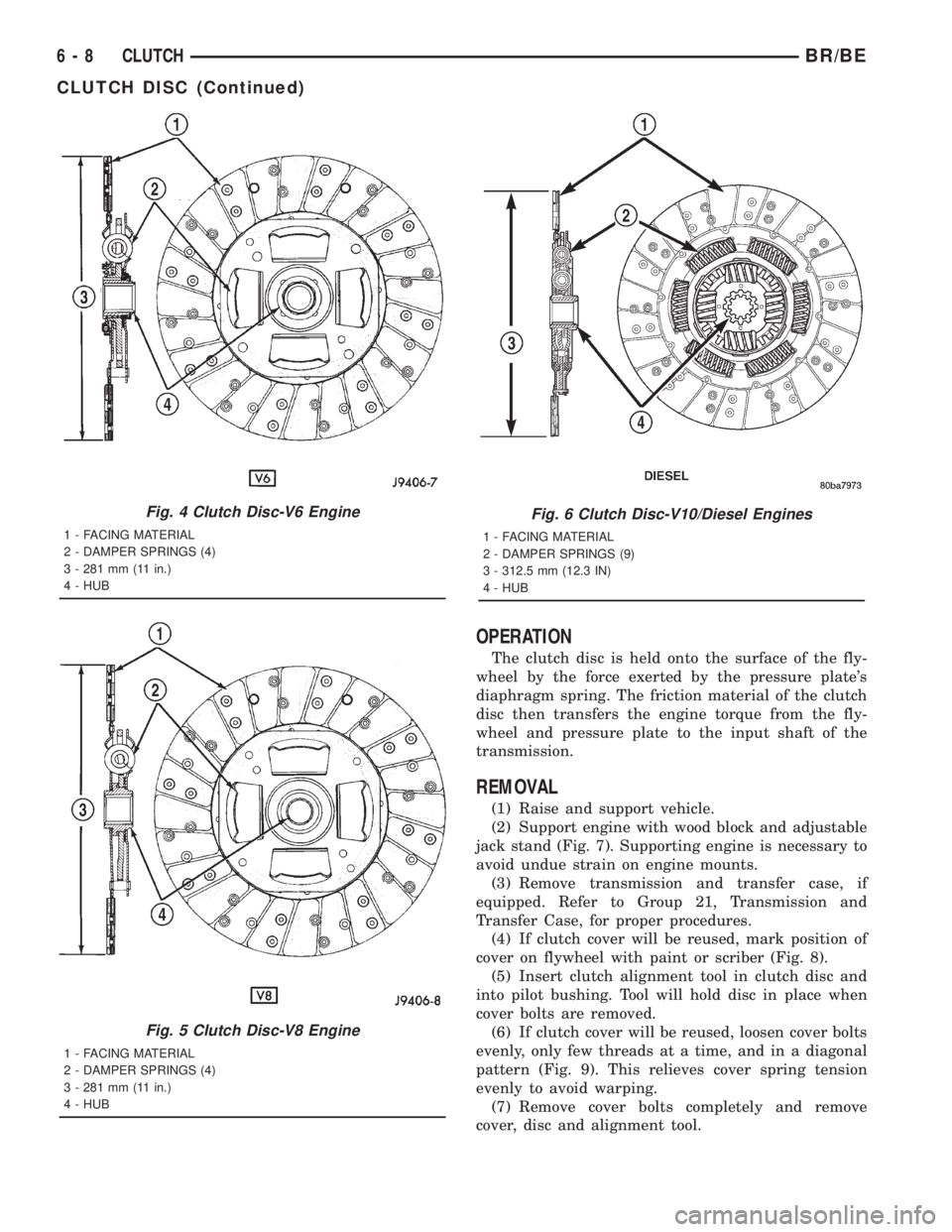

The clutch disc friction material is riveted to the

disc hub. The hub bore is splined for installation on

the transmission input shaft. The clutch disc has

cushion springs in the disc hub to dampen disc vibra-

tions during application and release of the clutch.

Various size and design of clutches are used for the

different engine transmission combinations. The cur-

rently used clutches and applications are listed

below.A 281 mm (11 in.) diameter clutch disc is used with

a 3.9L, 5.2L, or 5.9L gas engines (Fig. 4) and (Fig. 5).

A 312.5 mm (12.3 in.) diameter clutch disc is used

with diesel and V10 engines and (Fig. 6).

All the discs have damper springs in the hub. The

281 mm discs have four springs, the 312.5 mm diesel/

V10 disc has nine springs. The damper springs pro-

vide smoother torque transfer and disc engagement.

BR/BECLUTCH 6 - 7

CLUTCH (Continued)

Page 321 of 2889

OPERATION

The clutch disc is held onto the surface of the fly-

wheel by the force exerted by the pressure plate's

diaphragm spring. The friction material of the clutch

disc then transfers the engine torque from the fly-

wheel and pressure plate to the input shaft of the

transmission.

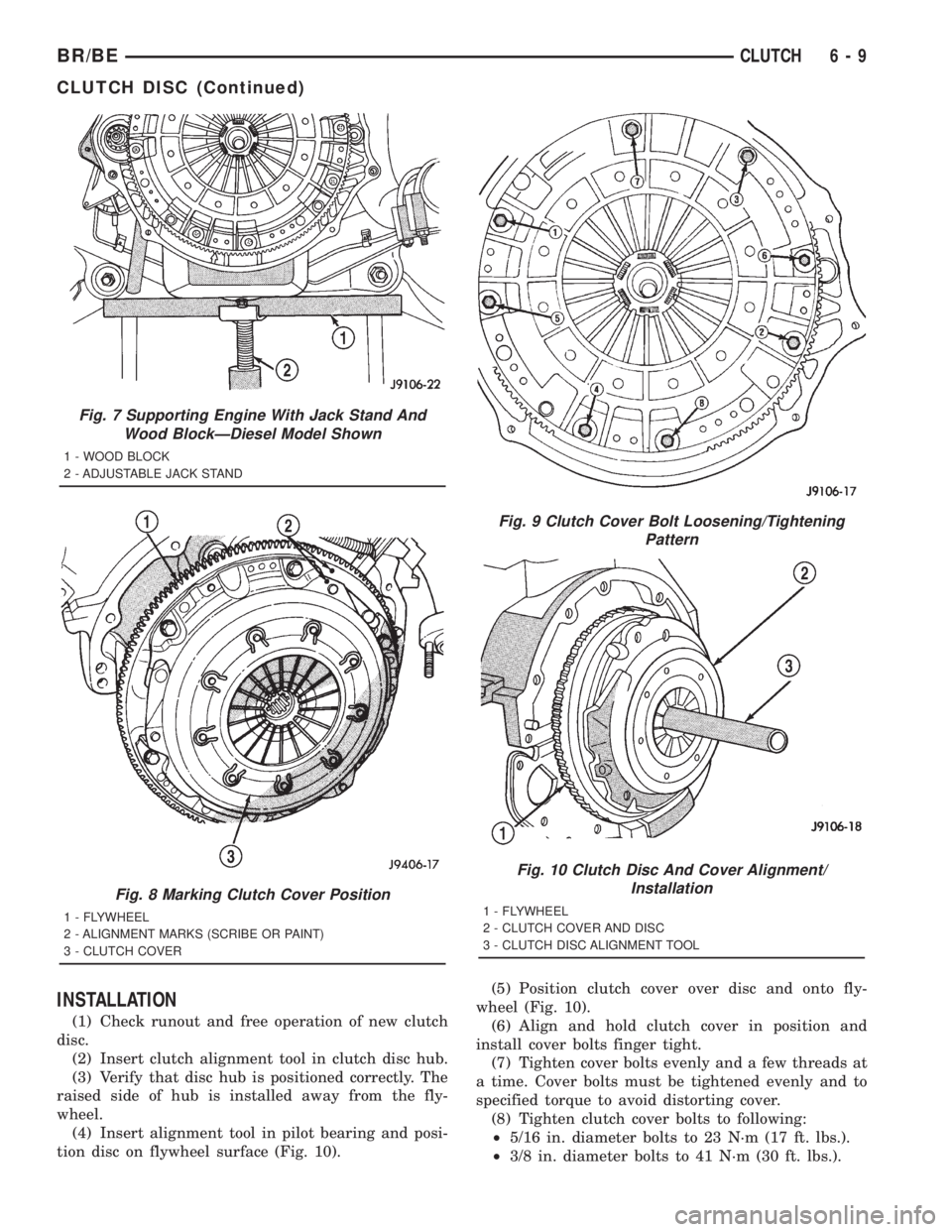

REMOVAL

(1) Raise and support vehicle.

(2) Support engine with wood block and adjustable

jack stand (Fig. 7). Supporting engine is necessary to

avoid undue strain on engine mounts.

(3) Remove transmission and transfer case, if

equipped. Refer to Group 21, Transmission and

Transfer Case, for proper procedures.

(4) If clutch cover will be reused, mark position of

cover on flywheel with paint or scriber (Fig. 8).

(5) Insert clutch alignment tool in clutch disc and

into pilot bushing. Tool will hold disc in place when

cover bolts are removed.

(6) If clutch cover will be reused, loosen cover bolts

evenly, only few threads at a time, and in a diagonal

pattern (Fig. 9). This relieves cover spring tension

evenly to avoid warping.

(7) Remove cover bolts completely and remove

cover, disc and alignment tool.

Fig. 4 Clutch Disc-V6 Engine

1 - FACING MATERIAL

2 - DAMPER SPRINGS (4)

3 - 281 mm (11 in.)

4 - HUB

Fig. 5 Clutch Disc-V8 Engine

1 - FACING MATERIAL

2 - DAMPER SPRINGS (4)

3 - 281 mm (11 in.)

4 - HUB

Fig. 6 Clutch Disc-V10/Diesel Engines

1 - FACING MATERIAL

2 - DAMPER SPRINGS (9)

3 - 312.5 mm (12.3 IN)

4 - HUB

6 - 8 CLUTCHBR/BE

CLUTCH DISC (Continued)

Page 322 of 2889

INSTALLATION

(1) Check runout and free operation of new clutch

disc.

(2) Insert clutch alignment tool in clutch disc hub.

(3) Verify that disc hub is positioned correctly. The

raised side of hub is installed away from the fly-

wheel.

(4) Insert alignment tool in pilot bearing and posi-

tion disc on flywheel surface (Fig. 10).(5) Position clutch cover over disc and onto fly-

wheel (Fig. 10).

(6) Align and hold clutch cover in position and

install cover bolts finger tight.

(7) Tighten cover bolts evenly and a few threads at

a time. Cover bolts must be tightened evenly and to

specified torque to avoid distorting cover.

(8) Tighten clutch cover bolts to following:

²5/16 in. diameter bolts to 23 N´m (17 ft. lbs.).

²3/8 in. diameter bolts to 41 N´m (30 ft. lbs.).

Fig. 7 Supporting Engine With Jack Stand And

Wood BlockÐDiesel Model Shown

1 - WOOD BLOCK

2 - ADJUSTABLE JACK STAND

Fig. 8 Marking Clutch Cover Position

1 - FLYWHEEL

2 - ALIGNMENT MARKS (SCRIBE OR PAINT)

3 - CLUTCH COVER

Fig. 9 Clutch Cover Bolt Loosening/Tightening

Pattern

Fig. 10 Clutch Disc And Cover Alignment/

Installation

1 - FLYWHEEL

2 - CLUTCH COVER AND DISC

3 - CLUTCH DISC ALIGNMENT TOOL

BR/BECLUTCH 6 - 9

CLUTCH DISC (Continued)

Page 327 of 2889

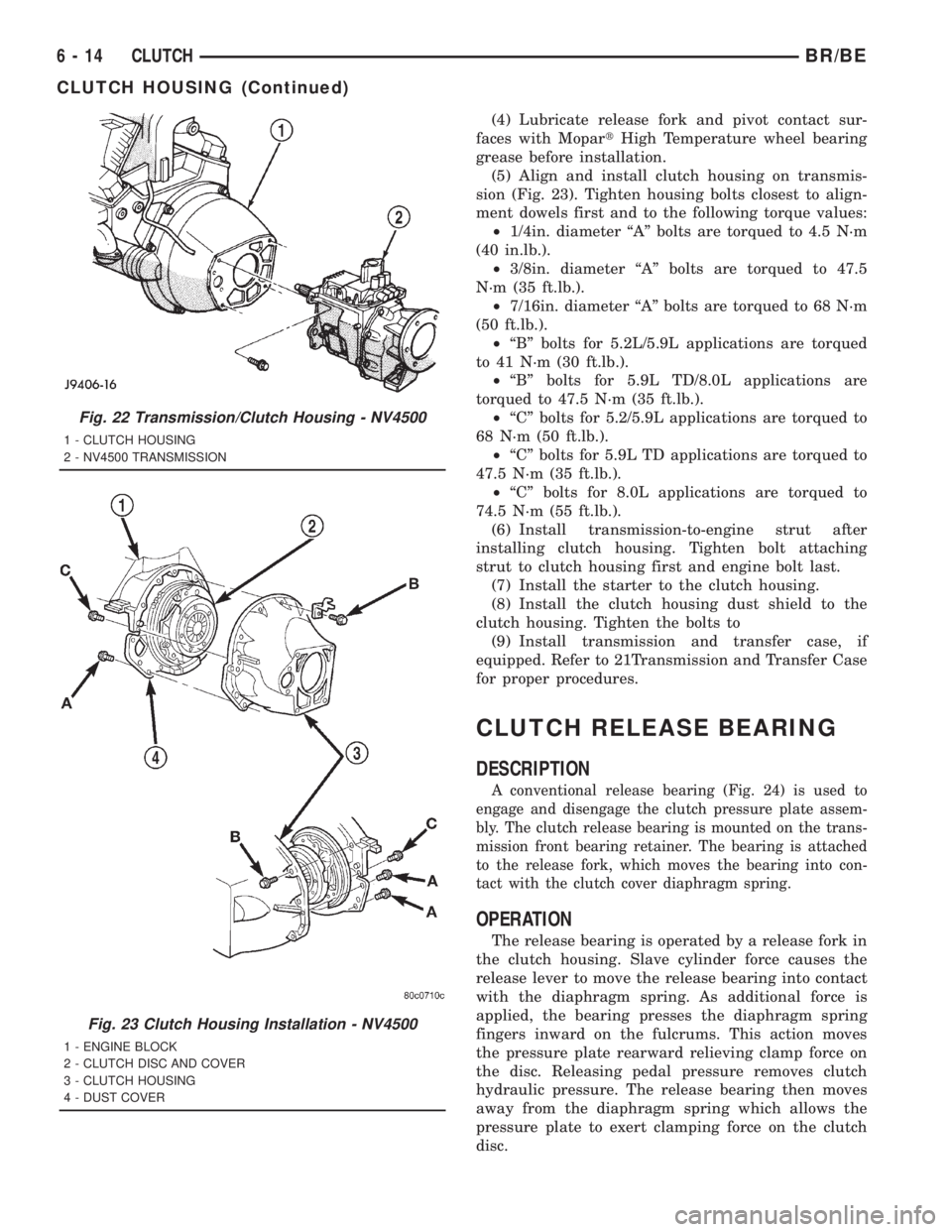

(4) Lubricate release fork and pivot contact sur-

faces with MopartHigh Temperature wheel bearing

grease before installation.

(5) Align and install clutch housing on transmis-

sion (Fig. 23). Tighten housing bolts closest to align-

ment dowels first and to the following torque values:

²1/4in. diameter ªAº bolts are torqued to 4.5 N´m

(40 in.lb.).

²3/8in. diameter ªAº bolts are torqued to 47.5

N´m (35 ft.lb.).

²7/16in. diameter ªAº bolts are torqued to 68 N´m

(50 ft.lb.).

²ªBº bolts for 5.2L/5.9L applications are torqued

to 41 N´m (30 ft.lb.).

²ªBº bolts for 5.9L TD/8.0L applications are

torqued to 47.5 N´m (35 ft.lb.).

²ªCº bolts for 5.2/5.9L applications are torqued to

68 N´m (50 ft.lb.).

²ªCº bolts for 5.9L TD applications are torqued to

47.5 N´m (35 ft.lb.).

²ªCº bolts for 8.0L applications are torqued to

74.5 N´m (55 ft.lb.).

(6) Install transmission-to-engine strut after

installing clutch housing. Tighten bolt attaching

strut to clutch housing first and engine bolt last.

(7) Install the starter to the clutch housing.

(8) Install the clutch housing dust shield to the

clutch housing. Tighten the bolts to

(9) Install transmission and transfer case, if

equipped. Refer to 21Transmission and Transfer Case

for proper procedures.

CLUTCH RELEASE BEARING

DESCRIPTION

A conventional release bearing (Fig. 24) is used to

engage and disengage the clutch pressure plate assem-

bly. The clutch release bearing is mounted on the trans-

mission front bearing retainer. The bearing is attached

to the release fork, which moves the bearing into con-

tact with the clutch cover diaphragm spring.

OPERATION

The release bearing is operated by a release fork in

the clutch housing. Slave cylinder force causes the

release lever to move the release bearing into contact

with the diaphragm spring. As additional force is

applied, the bearing presses the diaphragm spring

fingers inward on the fulcrums. This action moves

the pressure plate rearward relieving clamp force on

the disc. Releasing pedal pressure removes clutch

hydraulic pressure. The release bearing then moves

away from the diaphragm spring which allows the

pressure plate to exert clamping force on the clutch

disc.

Fig. 22 Transmission/Clutch Housing - NV4500

1 - CLUTCH HOUSING

2 - NV4500 TRANSMISSION

Fig. 23 Clutch Housing Installation - NV4500

1 - ENGINE BLOCK

2 - CLUTCH DISC AND COVER

3 - CLUTCH HOUSING

4 - DUST COVER

6 - 14 CLUTCHBR/BE

CLUTCH HOUSING (Continued)

Page 330 of 2889

shaft speeds and releasing the energy back into the

system when the crankshaft slows down.

DIAGNOSIS AND TESTING - FLYWHEEL

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on a stud installed in place of one of the fly-

wheel bolts.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. However,

minor flywheel scoring can be cleaned up by hand with

180 grit emery, or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock removal

isnot recommended.

Replace the flywheel if scoring

is severe and deeper than 0.076 mm (0.003 in.).

Excessive stock removal can result in flywheel crack-

ing or warpage after installation; it can also weaken

the flywheel and interfere with proper clutch release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with MopartLock And Seal. Tighten flywheel

bolts to specified torque only. Overtightening can dis-

tort the flywheel hub causing runout.

DISASSEMBLY

NOTE: If the teeth are worn or damaged, the fly-

wheel should be replaced as an assembly. This is

the recommended and preferred method of repair.

In cases where a new flywheel is not readily avail-

able, (V10/Diesel Engine only) a replacement ring

gear can be installed. The following procedure must

be observed to avoid damaging the flywheel and

replacement gear.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES WHILE CUTTING RING GEAR.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

ASSEMBLY

NOTE: The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it. The method of heating and

expanding the gear is extremely important. Every

surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem-

perature required for uniform expansion is approxi-

mately 375É F.

CAUTION: Do not use an oxy/acetylene torch to

remove the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES AND HEAT RESISTENT GLOVES

WHEN HANDLING A HEATED RING GEAR.

(1) The heated gear must be installed evenly to

avoid misalignment or distortion.

(2) Position and install the heated ring gear on the

flywheel with a shop press and a suitable press

plates.

(3) Place flywheel on work bench and let it cool in

normal shop air. Allow the ring gear to cool down

completely before installation it on the engine.

CAUTION: Do not use water or compressed air to

cool the flywheel. The rapid cooling produced by

water or compressed air will distort or crack the

new gear.

PILOT BEARING

DESCRIPTION

Vehicles equipped with a manual transmission uti-

lize a pilot bearing. This bearing is located in the

back of the engine crankshaft. Depending on the type

of engine or application, the pilot bearing can be a

solid soft metallic bushing or a fully caged needle

bearing. The pilot bearing's main functions are to

support the transmission input shaft, maintain

proper alignment of the clutch assembly and allow

the transmission main shaft to rotate at a different

speed than the engine mounted crankshaft.

BR/BECLUTCH 6 - 17

FLYWHEEL (Continued)