wheel torque DODGE RAM 2001 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 504 of 2889

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear on the manual transmission flywheel or on

the automatic transmission torque converter or

torque converter drive plate.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.

Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing the

starter pinion gear to spin faster than the pinionshaft. When the driver releases the ignition switch to

the On position, the starter relay coil is de-energized.

This causes the relay contacts to open. When the

relay contacts open, the starter solenoid plunger

hold-in coil is de-energized.

When the solenoid plunger hold-in coil is de-ener-

gized, the solenoid plunger return spring returns the

plunger to its relaxed position. This causes the con-

tact disc to open the starter feed circuit, and the shift

lever to disengage the overrunning clutch and pinion

gear from the starter ring gear.

DIAGNOSIS AND TESTING - STARTING

SYSTEM

The battery, starting, and charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct starting/

charging system operation, all of the components

involved in these 3 systems must perform within

specifications.

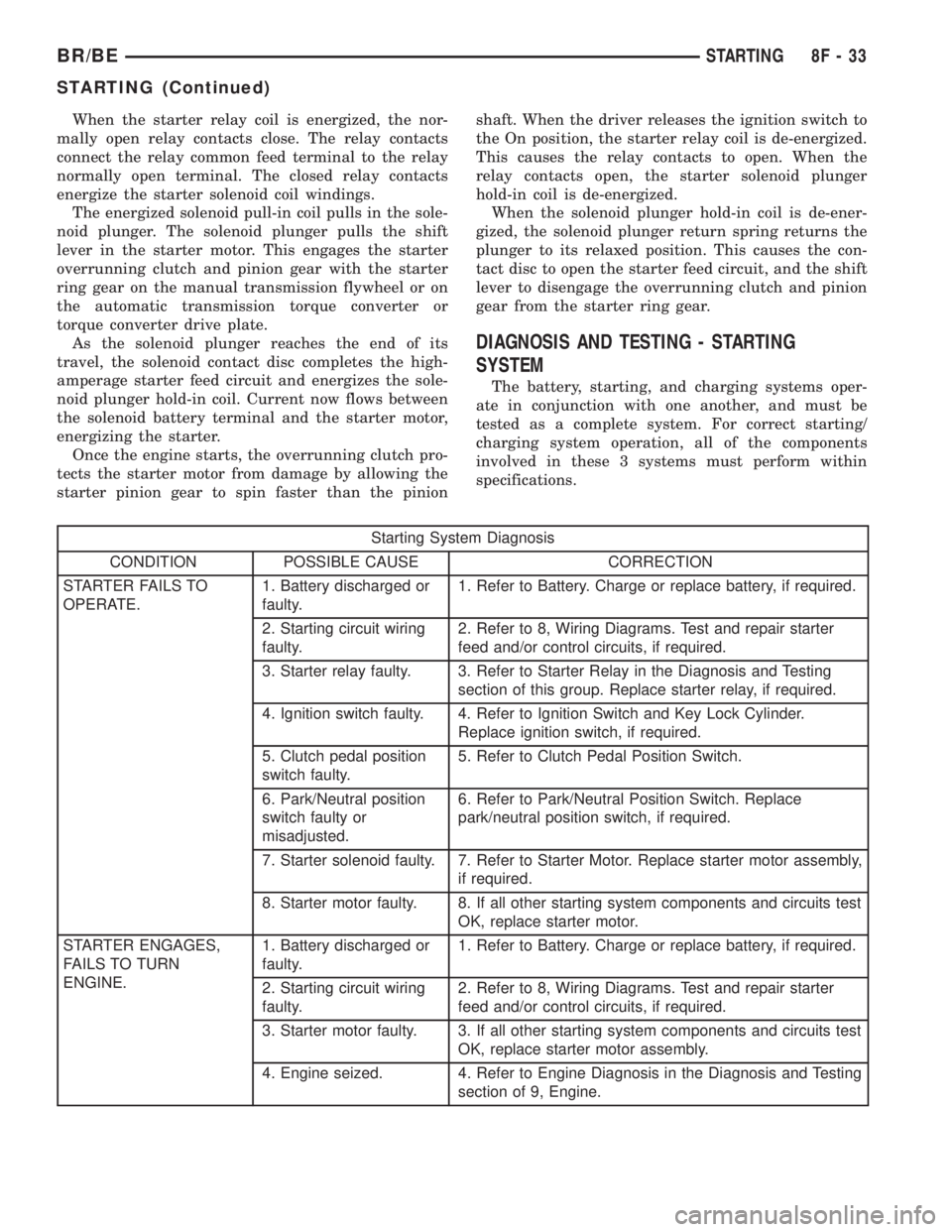

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace starter relay, if required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch, if required.

5. Clutch pedal position

switch faulty.5. Refer to Clutch Pedal Position Switch.

6. Park/Neutral position

switch faulty or

misadjusted.6. Refer to Park/Neutral Position Switch. Replace

park/neutral position switch, if required.

7. Starter solenoid faulty. 7. Refer to Starter Motor. Replace starter motor assembly,

if required.

8. Starter motor faulty. 8. If all other starting system components and circuits test

OK, replace starter motor.

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of 9, Engine.

BR/BESTARTING 8F - 33

STARTING (Continued)

Page 510 of 2889

ENGINE STARTER MOTOR

DESCRIPTION

The starter motors used for the 5.9L diesel engine

and the 8.0L gasoline engine available in this model

are not interchangeable with each other, or with the

starter motors used for the other available engines.

The starter motors used for the 3.9L, 5.2L and the

5.9L gasoline engines available in this model are

interchangeable.

The starter motor for the 5.9L diesel engine is

mounted with three screws to the flywheel housing

on the left side of the engine. The starter motor for

the 8.0L gasoline engine is mounted with two screws

to the flange on the left rear corner of the engine

block, while the starter motors for all of the other

engines are mounted with one screw, a stud and a

nut to the manual transmission clutch housing or

automatic transmission torque converter housing and

are located on the left side of the engine.

Each of these starter motors incorporates several

of the same features to create a reliable, efficient,

compact, lightweight and powerful unit. The electric

motors of all of these starters have four brushes con-

tacting the motor commutator, and feature four elec-

tromagnetic field coils wound around four pole shoes.

The 3.9L, 5.2L, 5.9L and 8.0L gasoline engine starter

motors are rated at 1.4 kilowatts (about 1.9 horse-

power) output at 12 volts, while the 5.9L diesel

engine starter motor is rated at 2.7 kilowatts (about

3.6 horsepower) output at 12 volts.

All of these starter motors are serviced only as a

unit with their starter solenoids, and cannot be

repaired. If either component is faulty or damaged,

the entire starter motor and starter solenoid unit

must be replaced.

OPERATION

These starter motors are equipped with a gear

reduction (intermediate transmission) system. The

gear reduction system consists of a gear that is inte-

gral to the output end of the electric motor armature

shaft that is in continual engagement with a larger

gear that is splined to the input end of the starter

pinion gear shaft. This feature makes it possible to

reduce the dimensions of the starter. At the same

time, it allows higher armature rotational speed and

delivers increased torque through the starter pinion

gear to the starter ring gear.

The starter motors for all engines are activated by

an integral heavy duty starter solenoid switch

mounted to the overrunning clutch housing. This

electromechanical switch connects and disconnects

the feed of battery voltage to the starter motor, also

engaging and disengaging the starter pinion gear

with the starter ring gear.All starter motors use an overrunning clutch and

starter pinion gear unit to engage and drive a starter

ring gear that is integral to the flywheel (manual

transmission), torque converter or torque converter

drive plate (automatic transmission) mounted on the

rear crankshaft flange.

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with starter motor

removed from vehicle. Refer to Starter Specifications

for starter motor specifications.

(1) Remove starter motor from vehicle. Refer to

Starter MotorRemoval and Installation.

(2) Mount starter motor securely in a soft-jawed

bench vise. The vise jaws should be clamped on

mounting flange of starter motor. Never clamp on

starter motor by field frame.

(3) Connect suitable volt-ampere tester and 12-volt

battery to starter motor in series, and set ammeter to

100 ampere scale (250 ampere scale for diesel engine

starters). See instructions provided by manufacturer

of volt-ampere tester being used.

(4) Install jumper wire from solenoid terminal to

solenoid battery terminal. The starter motor should

operate. If starter motor fails to operate, replace

faulty starter motor assembly.

(5) Adjust carbon pile load of tester to obtain free

running test voltage. Refer to Specifications for the

starter motor free running test voltage specifications.

(6) Note reading on ammeter and compare this

reading to free running test maximum amperage

draw. Refer to Specifications for starter motor free

running test maximum amperage draw specifica-

tions.

(7) If ammeter reading exceeds maximum amper-

age draw specification, replace faulty starter motor

assembly.

STARTER MOTOR SOLENOID

This test can only be performed with starter motor

removed from vehicle.

(1) Remove starter motor. Refer toStarter Motor

Removal and Installation.

(2) Disconnect wire from solenoid field coil termi-

nal.

(3) Check for continuity between solenoid terminal

and solenoid field coil terminal with continuity tester

(Fig. 7). There should be continuity. If OK, go to Step

4. If not OK, replace faulty starter motor assembly.

(4) Check for continuity between solenoid terminal

and solenoid case (Fig. 8). There should be continuity.

If not OK, replace faulty starter motor assembly.

BR/BESTARTING 8F - 39

Page 553 of 2889

SPARK PLUG

DESCRIPTION

The 3.9L V-6 and 5.2L/5.9L V-8 engines use resis-

tor type spark plugs. The 8.0L V-10 engine uses

inductive type spark plugs.

Spark plug resistance values range from 6,000 to

20,000 ohms (when checked with at least a 1000 volt

spark plug tester).Do not use an ohmmeter to

check the resistance values of the spark plugs.

Inaccurate readings will result.

OPERATION

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.

Always use the recommended torque when tighten-

ing spark plugs. Incorrect torque can distort the

spark plug and change plug gap. It can also pull the

plug threads and do possible damage to both the

spark plug and the cylinder head.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Also refer to Spark Plug Conditions.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will

remain on the spark plug insulator and will cause

plug misfire.

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

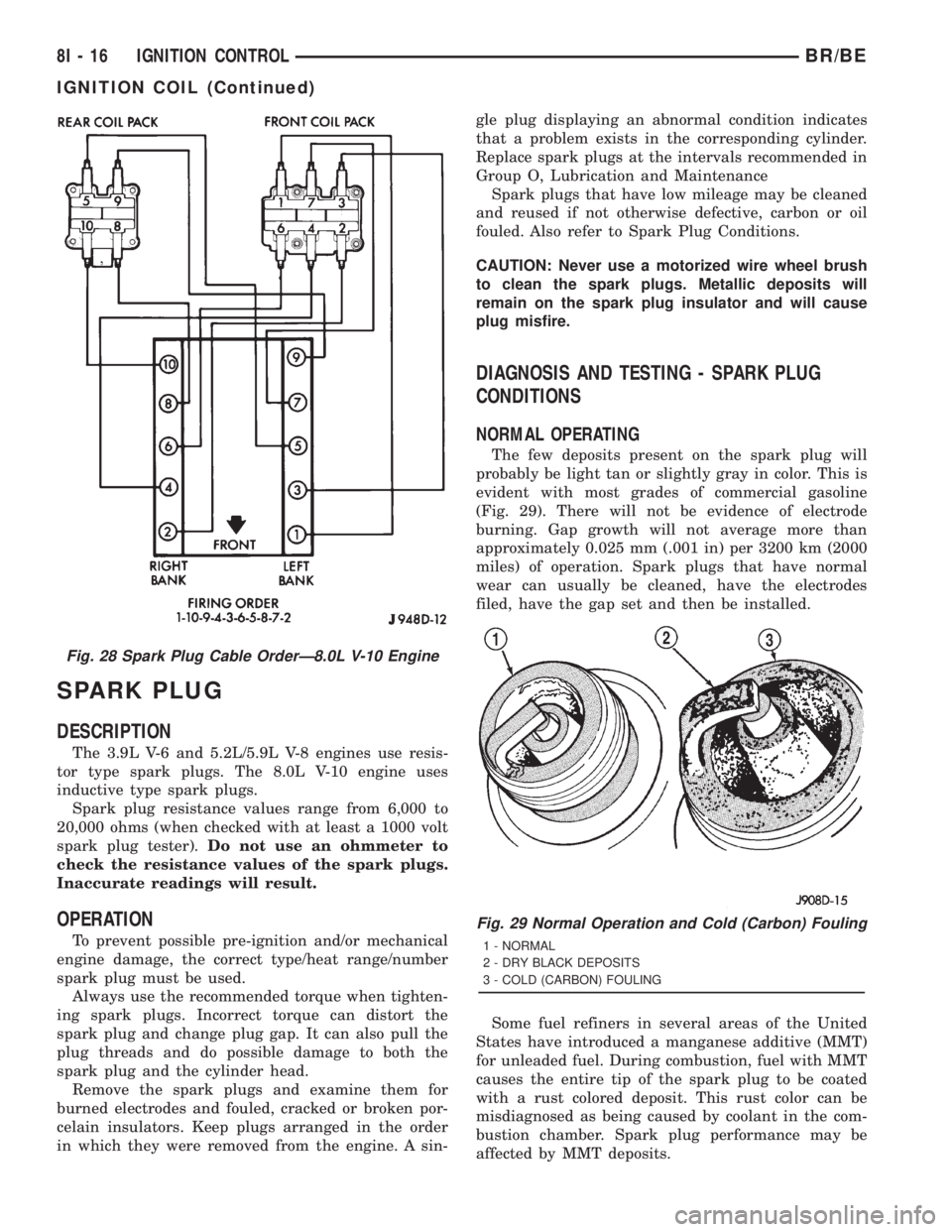

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 29). There will not be evidence of electrode

burning. Gap growth will not average more than

approximately 0.025 mm (.001 in) per 3200 km (2000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

causes the entire tip of the spark plug to be coated

with a rust colored deposit. This rust color can be

misdiagnosed as being caused by coolant in the com-

bustion chamber. Spark plug performance may be

affected by MMT deposits.

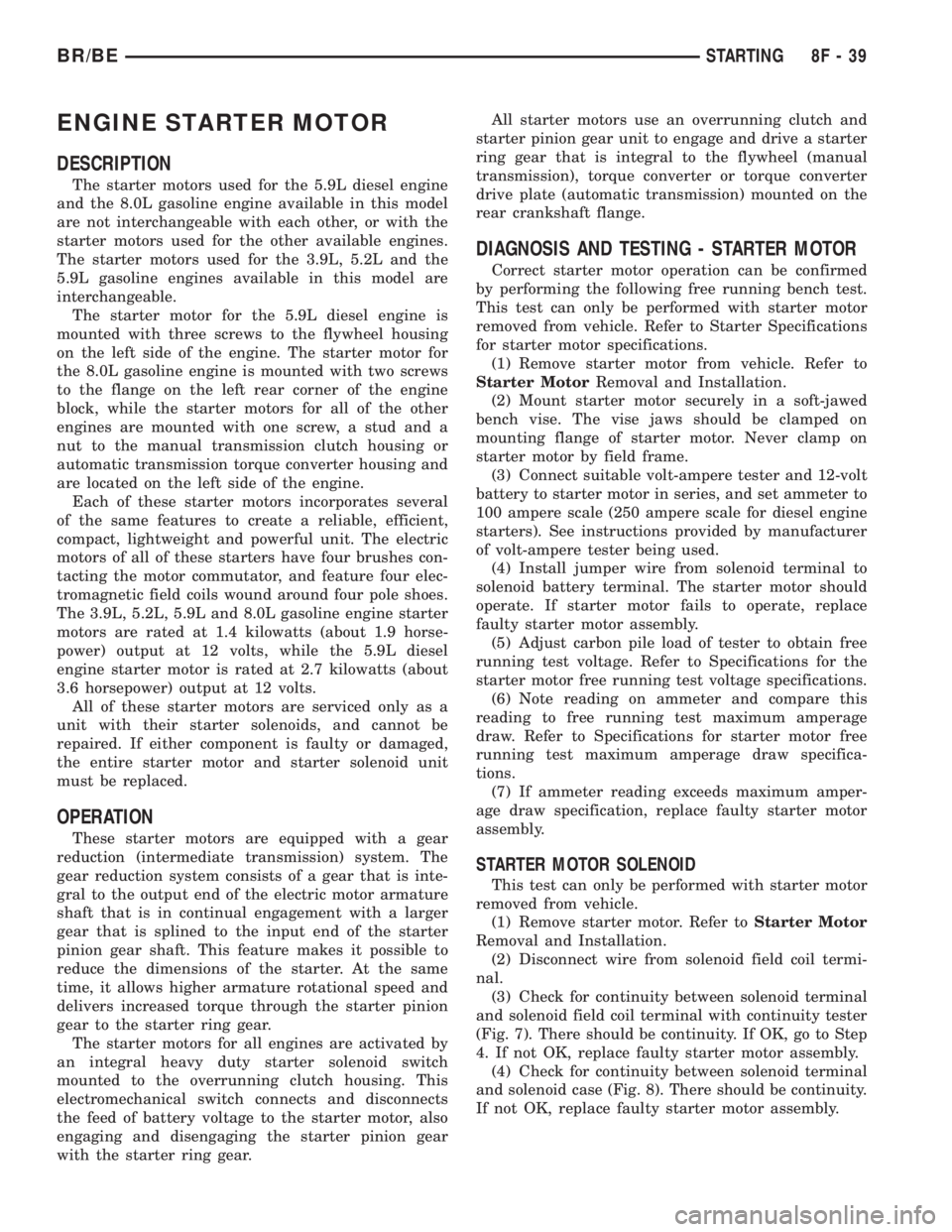

Fig. 28 Spark Plug Cable OrderÐ8.0L V-10 Engine

Fig. 29 Normal Operation and Cold (Carbon) Fouling

1 - NORMAL

2 - DRY BLACK DEPOSITS

3 - COLD (CARBON) FOULING

8I - 16 IGNITION CONTROLBR/BE

IGNITION COIL (Continued)

Page 556 of 2889

CLEANING

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After clean-

ing, file center electrode flat with a small point file or

jewelers file before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean spark plugs. Metallic deposits will remain

on spark plug insulator and will cause plug misfire.

INSTALLATION

Special care should be taken when installing spark

plugs into the cylinder head spark plug wells. Be

sure the plugs do not drop into the plug wells as elec-

trodes can be damaged.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap or a cracked porcelain

insulator.

When replacing the spark plug and ignition coil

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten spark plugs to 35-41 N´m (26-30 ft.

lbs.) torque.

(3) Install spark plug cables over spark plugs.

SPARK PLUG CABLE

DESCRIPTION

Spark plug cables are sometimes referred to as sec-

ondary ignition wires.

OPERATION

The spark plug cables transfer electrical current

from the ignition coil(s) and/or distributor, to individ-

ual spark plugs at each cylinder. The resistive spark

plug cables are of nonmetallic construction. The

cables provide suppression of radio frequency emis-

sions from the ignition system.

DIAGNOSIS AND TESTING - SPARK PLUG

CABLES

Cable routing is important on certain engines. To

prevent possible ignition crossfire, be sure the cables

are clipped into the plastic routing looms. Try to pre-

vent any one cable from contacting another. Before

removing cables, note their original location and

routing. Never allow one cable to be twisted around

another.

Check the spark plug cable connections for good

contact at the coil(s), distributor cap towers, and

spark plugs. Terminals should be fully seated. The

insulators should be in good condition and should fit

tightly on the coil, distributor and spark plugs. Spark

plug cables with insulators that are cracked or torn

must be replaced.

Clean high voltage ignition cables with a cloth

moistened with a non-flammable solvent. Wipe the

cables dry. Check for brittle or cracked insulation.

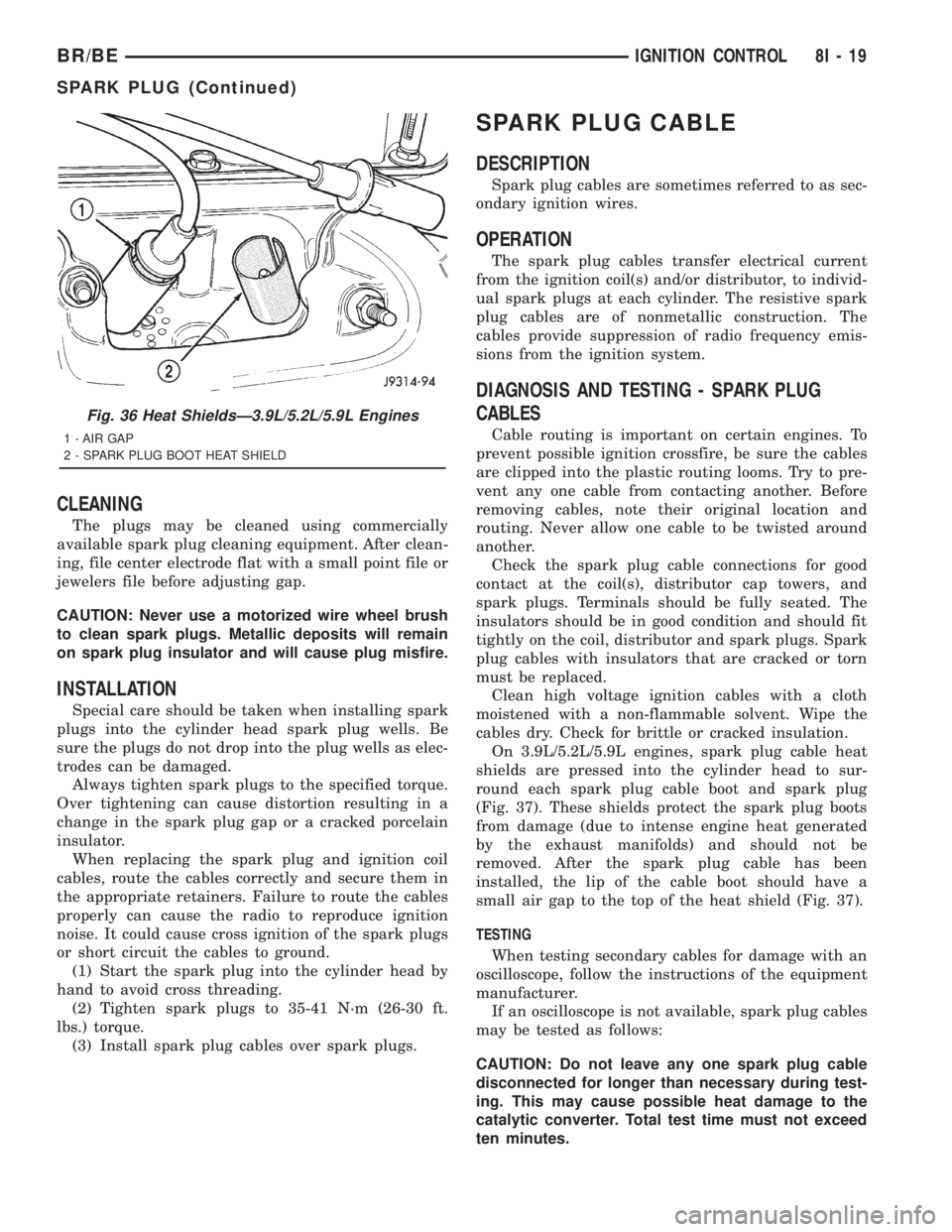

On 3.9L/5.2L/5.9L engines, spark plug cable heat

shields are pressed into the cylinder head to sur-

round each spark plug cable boot and spark plug

(Fig. 37). These shields protect the spark plug boots

from damage (due to intense engine heat generated

by the exhaust manifolds) and should not be

removed. After the spark plug cable has been

installed, the lip of the cable boot should have a

small air gap to the top of the heat shield (Fig. 37).

TESTING

When testing secondary cables for damage with an

oscilloscope, follow the instructions of the equipment

manufacturer.

If an oscilloscope is not available, spark plug cables

may be tested as follows:

CAUTION: Do not leave any one spark plug cable

disconnected for longer than necessary during test-

ing. This may cause possible heat damage to the

catalytic converter. Total test time must not exceed

ten minutes.

Fig. 36 Heat ShieldsÐ3.9L/5.2L/5.9L Engines

1 - AIR GAP

2 - SPARK PLUG BOOT HEAT SHIELD

BR/BEIGNITION CONTROL 8I - 19

SPARK PLUG (Continued)

Page 686 of 2889

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered and with the auto-locking tabs

engaged (raised). These auto-locking tabs should not

be disengaged until the clockspring has been

installed on the steering column. If the auto-locking

tabs are disengaged before the clockspring is

installed on a steering column, the clockspring cen-

tering procedure must be performed.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

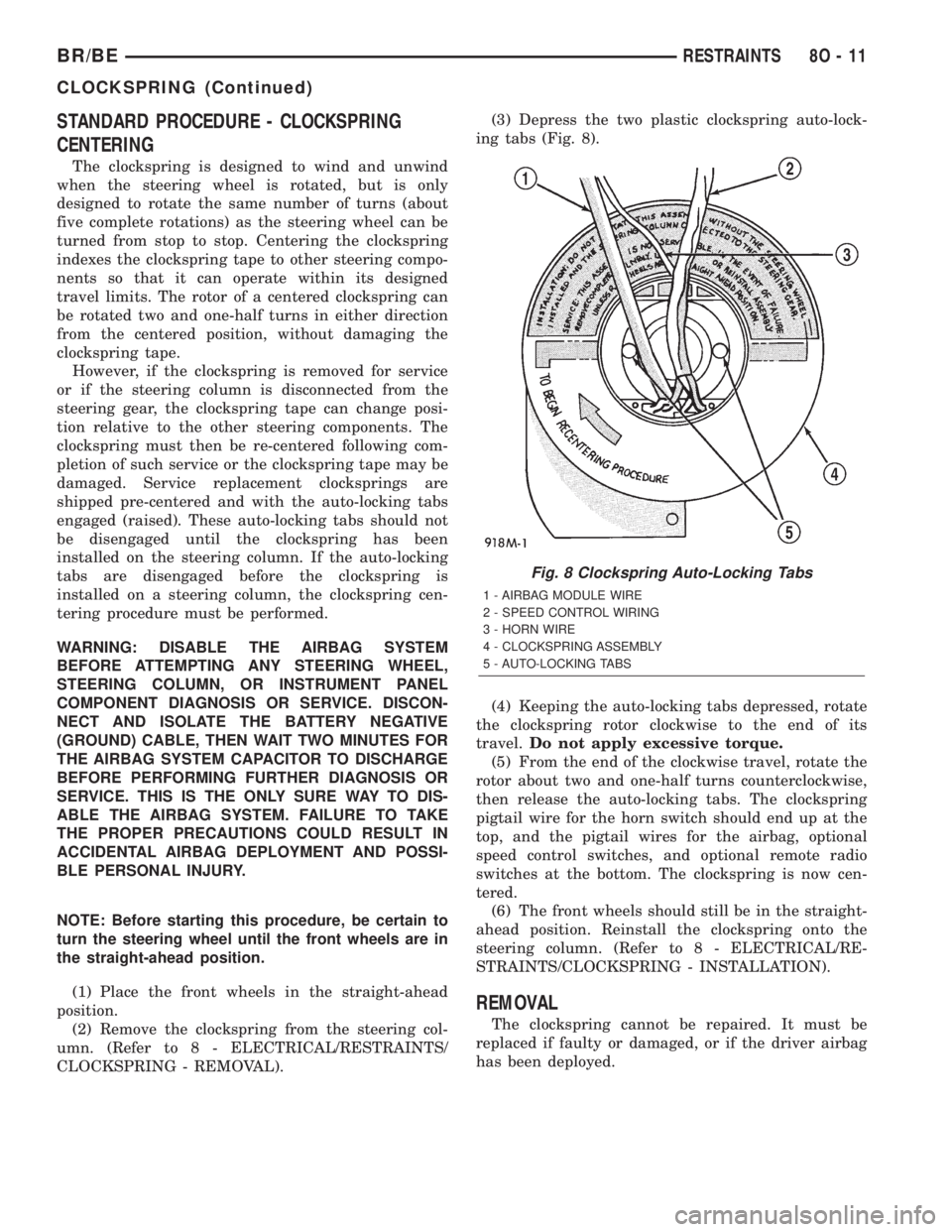

CLOCKSPRING - REMOVAL).(3) Depress the two plastic clockspring auto-lock-

ing tabs (Fig. 8).

(4) Keeping the auto-locking tabs depressed, rotate

the clockspring rotor clockwise to the end of its

travel.Do not apply excessive torque.

(5) From the end of the clockwise travel, rotate the

rotor about two and one-half turns counterclockwise,

then release the auto-locking tabs. The clockspring

pigtail wire for the horn switch should end up at the

top, and the pigtail wires for the airbag, optional

speed control switches, and optional remote radio

switches at the bottom. The clockspring is now cen-

tered.

(6) The front wheels should still be in the straight-

ahead position. Reinstall the clockspring onto the

steering column. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - INSTALLATION).

REMOVAL

The clockspring cannot be repaired. It must be

replaced if faulty or damaged, or if the driver airbag

has been deployed.

Fig. 8 Clockspring Auto-Locking Tabs

1 - AIRBAG MODULE WIRE

2 - SPEED CONTROL WIRING

3 - HORN WIRE

4 - CLOCKSPRING ASSEMBLY

5 - AUTO-LOCKING TABS

BR/BERESTRAINTS 8O - 11

CLOCKSPRING (Continued)

Page 718 of 2889

²If the actual speed is not within 20 mph of the

set speedThe previous disengagement conditions are

programmed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the ECM's RAM.

NOTE: Depressing the OFF switch will erase the set

speed stored in the ECM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the ECM is pro-

grammed for an acceleration feature. With the

ACCEL switch held closed, the vehicle accelerates

slowly to the desired speed. The new target speed is

stored in the ECM's RAM when the ACCEL switch is

released. The ECM also has a9tap-up9feature in

which vehicle speed increases at a rate of approxi-

mately 2 mph for each momentary switch activation

of the ACCEL switch.

The ECM also provides a means to decelerate with-

out disengaging speed control. To decelerate from an

existing recorded target speed, depress and hold the

COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the ECM's ON, OFF input, and

the battery voltage to the brake switch, which powers

the speed control servo.

REMOVAL

WARNING: BEFORE BEGINNING ANY AIRBAG SYS-

TEM COMPONENT REMOVAL OR INSTALLATION,

REMOVE AND ISOLATE THE NEGATIVE (-)

CABLE(S) FROM THE BATTERY. THIS IS THE ONLY

SURE WAY TO DISABLE THE AIRBAG SYSTEM.

THEN WAIT TWO MINUTES FOR SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. FAILURE TO DO THIS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE INJURY.

(1) Disconnect and isolate negative battery

cable(s).

(2) Remove airbag module. Refer to 8, Restraint

Systems for procedures.

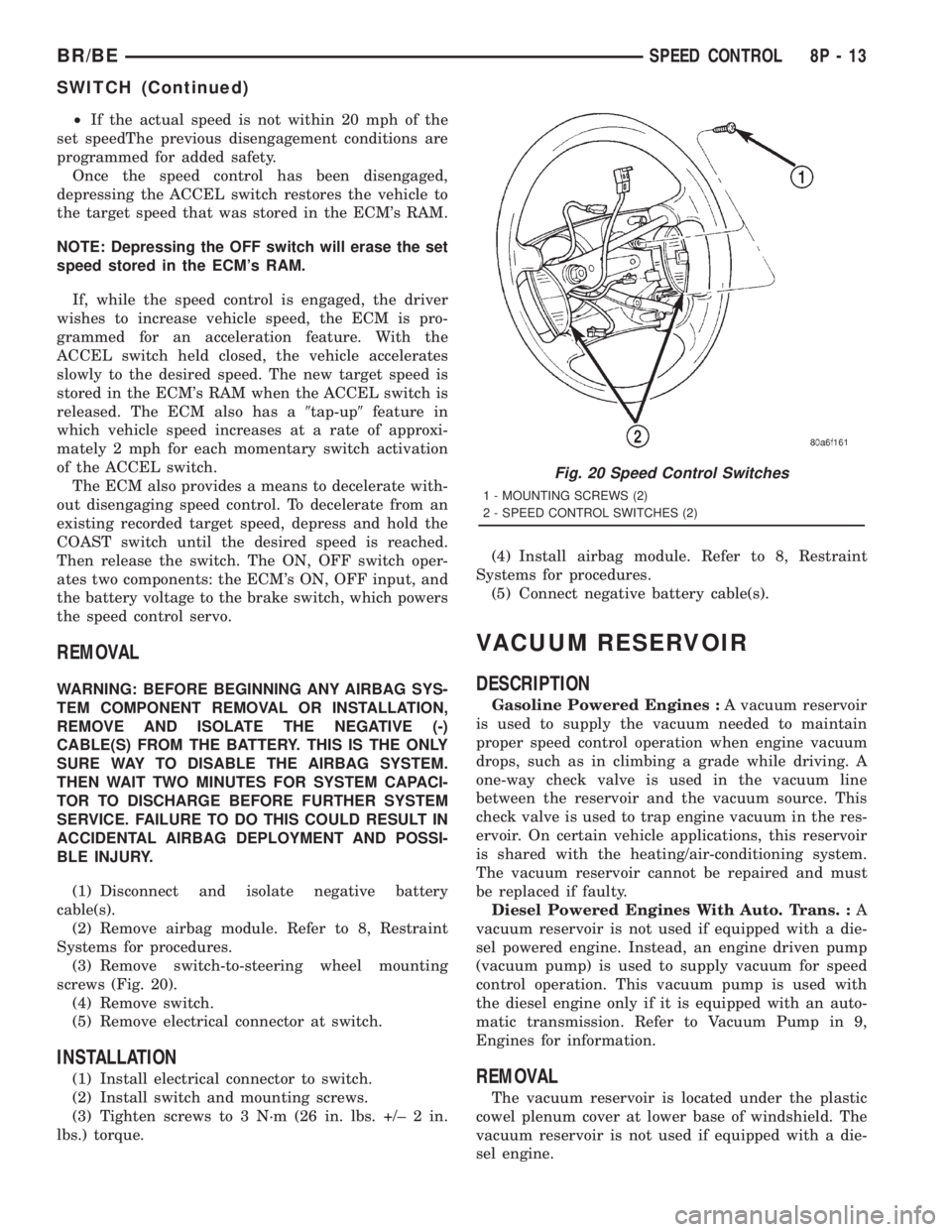

(3) Remove switch-to-steering wheel mounting

screws (Fig. 20).

(4) Remove switch.

(5) Remove electrical connector at switch.

INSTALLATION

(1) Install electrical connector to switch.

(2) Install switch and mounting screws.

(3) Tighten screws to 3 N´m (26 in. lbs. +/± 2 in.

lbs.) torque.(4) Install airbag module. Refer to 8, Restraint

Systems for procedures.

(5) Connect negative battery cable(s).

VACUUM RESERVOIR

DESCRIPTION

Gasoline Powered Engines :A vacuum reservoir

is used to supply the vacuum needed to maintain

proper speed control operation when engine vacuum

drops, such as in climbing a grade while driving. A

one-way check valve is used in the vacuum line

between the reservoir and the vacuum source. This

check valve is used to trap engine vacuum in the res-

ervoir. On certain vehicle applications, this reservoir

is shared with the heating/air-conditioning system.

The vacuum reservoir cannot be repaired and must

be replaced if faulty.

Diesel Powered Engines With Auto. Trans. :A

vacuum reservoir is not used if equipped with a die-

sel powered engine. Instead, an engine driven pump

(vacuum pump) is used to supply vacuum for speed

control operation. This vacuum pump is used with

the diesel engine only if it is equipped with an auto-

matic transmission. Refer to Vacuum Pump in 9,

Engines for information.

REMOVAL

The vacuum reservoir is located under the plastic

cowel plenum cover at lower base of windshield. The

vacuum reservoir is not used if equipped with a die-

sel engine.

Fig. 20 Speed Control Switches

1 - MOUNTING SCREWS (2)

2 - SPEED CONTROL SWITCHES (2)

BR/BESPEED CONTROL 8P - 13

SWITCH (Continued)

Page 1154 of 2889

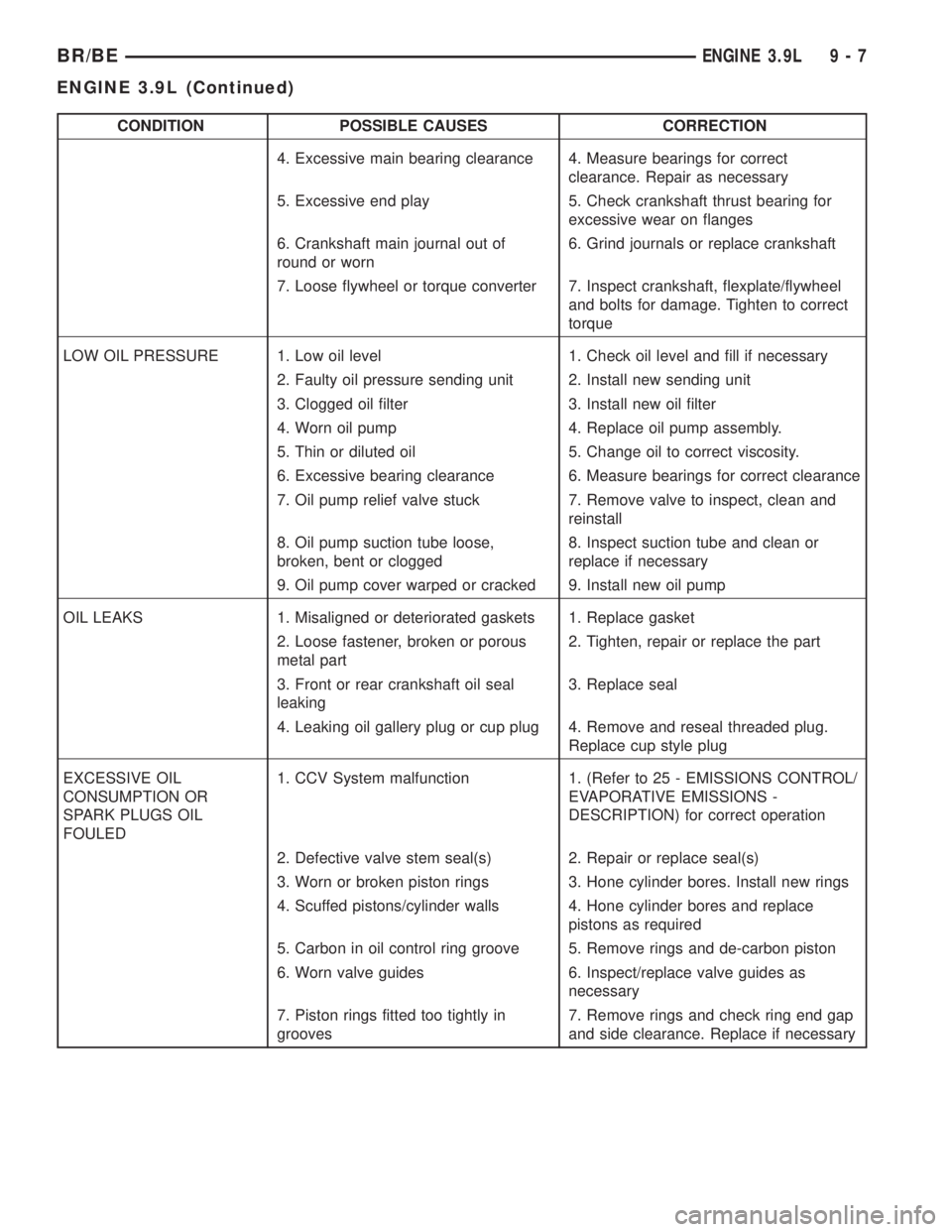

CONDITION POSSIBLE CAUSES CORRECTION

4. Excessive main bearing clearance 4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing for

excessive wear on flanges

6. Crankshaft main journal out of

round or worn6. Grind journals or replace crankshaft

7. Loose flywheel or torque converter 7. Inspect crankshaft, flexplate/flywheel

and bolts for damage. Tighten to correct

torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean and

reinstall

8. Oil pump suction tube loose,

broken, bent or clogged8. Inspect suction tube and clean or

replace if necessary

9. Oil pump cover warped or cracked 9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated gaskets 1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup plug 4. Remove and reseal threaded plug.

Replace cup style plug

EXCESSIVE OIL

CONSUMPTION OR

SPARK PLUGS OIL

FOULED1. CCV System malfunction 1. (Refer to 25 - EMISSIONS CONTROL/

EVAPORATIVE EMISSIONS -

DESCRIPTION) for correct operation

2. Defective valve stem seal(s) 2. Repair or replace seal(s)

3. Worn or broken piston rings 3. Hone cylinder bores. Install new rings

4. Scuffed pistons/cylinder walls 4. Hone cylinder bores and replace

pistons as required

5. Carbon in oil control ring groove 5. Remove rings and de-carbon piston

6. Worn valve guides 6. Inspect/replace valve guides as

necessary

7. Piston rings fitted too tightly in

grooves7. Remove rings and check ring end gap

and side clearance. Replace if necessary

BR/BEENGINE 3.9L 9 - 7

ENGINE 3.9L (Continued)

Page 1165 of 2889

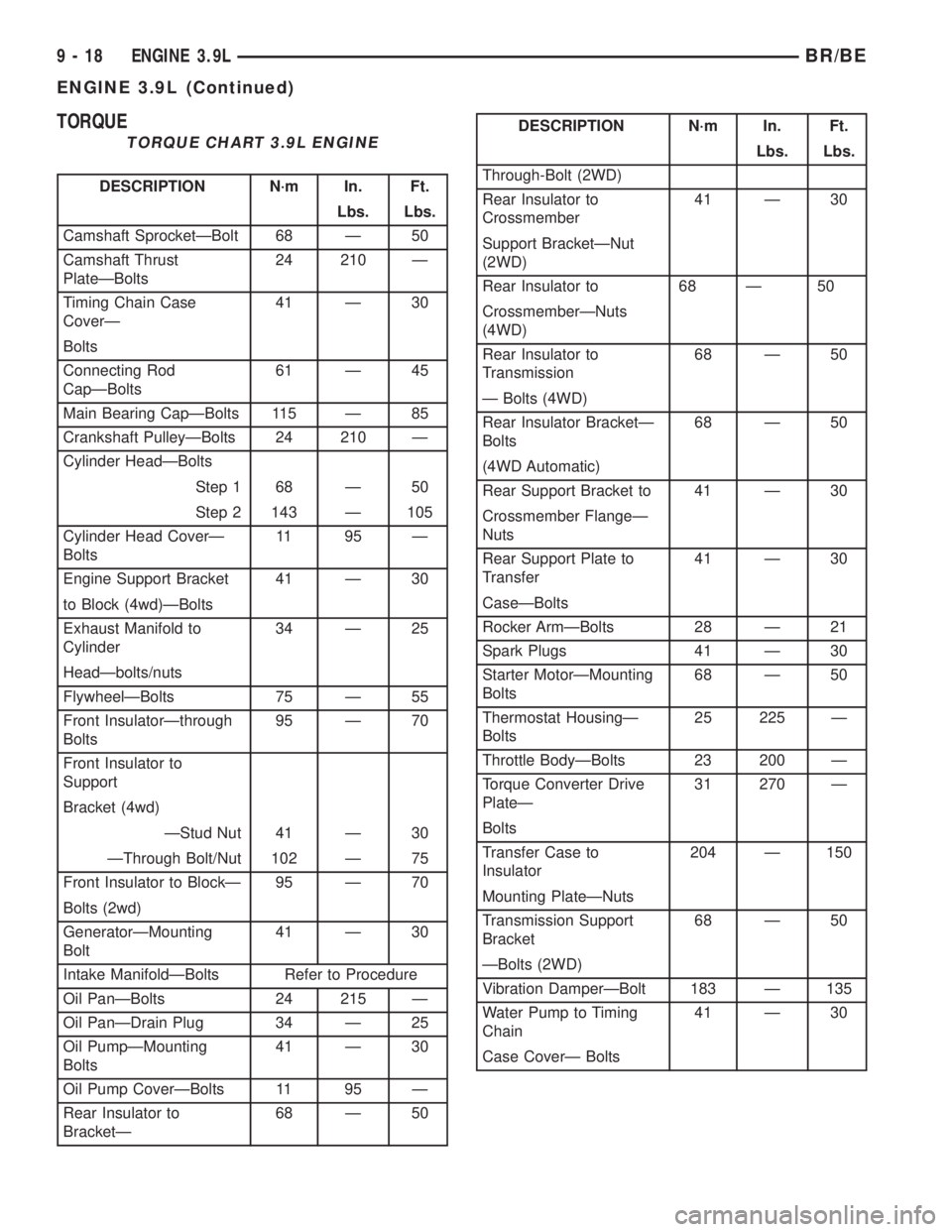

TORQUE

TORQUE CHART 3.9L ENGINE

DESCRIPTION N´m In. Ft.

Lbs. Lbs.

Camshaft SprocketÐBolt 68 Ð 50

Camshaft Thrust

PlateÐBolts24 210 Ð

Timing Chain Case

CoverÐ41 Ð 30

Bolts

Connecting Rod

CapÐBolts61 Ð 45

Main Bearing CapÐBolts 115 Ð 85

Crankshaft PulleyÐBolts 24 210 Ð

Cylinder HeadÐBolts

Step 1 68 Ð 50

Step 2 143 Ð 105

Cylinder Head CoverÐ

Bolts11 95 Ð

Engine Support Bracket 41 Ð 30

to Block (4wd)ÐBolts

Exhaust Manifold to

Cylinder34 Ð 25

HeadÐbolts/nuts

FlywheelÐBolts 75 Ð 55

Front InsulatorÐthrough

Bolts95 Ð 70

Front Insulator to

Support

Bracket (4wd)

ÐStud Nut 41 Ð 30

ÐThrough Bolt/Nut 102 Ð 75

Front Insulator to BlockÐ 95 Ð 70

Bolts (2wd)

GeneratorÐMounting

Bolt41 Ð 30

Intake ManifoldÐBolts Refer to Procedure

Oil PanÐBolts 24 215 Ð

Oil PanÐDrain Plug 34 Ð 25

Oil PumpÐMounting

Bolts41 Ð 30

Oil Pump CoverÐBolts 11 95 Ð

Rear Insulator to

BracketÐ68 Ð 50

DESCRIPTION N´m In. Ft.

Lbs. Lbs.

Through-Bolt (2WD)

Rear Insulator to

Crossmember41 Ð 30

Support BracketÐNut

(2WD)

Rear Insulator to 68 Ð 50

CrossmemberÐNuts

(4WD)

Rear Insulator to

Transmission68 Ð 50

Ð Bolts (4WD)

Rear Insulator BracketÐ

Bolts68 Ð 50

(4WD Automatic)

Rear Support Bracket to 41 Ð 30

Crossmember FlangeÐ

Nuts

Rear Support Plate to

Transfer41 Ð 30

CaseÐBolts

Rocker ArmÐBolts 28 Ð 21

Spark Plugs 41 Ð 30

Starter MotorÐMounting

Bolts68 Ð 50

Thermostat HousingÐ

Bolts25 225 Ð

Throttle BodyÐBolts 23 200 Ð

Torque Converter Drive

PlateÐ31 270 Ð

Bolts

Transfer Case to

Insulator204 Ð 150

Mounting PlateÐNuts

Transmission Support

Bracket68 Ð 50

ÐBolts (2WD)

Vibration DamperÐBolt 183 Ð 135

Water Pump to Timing

Chain41 Ð 30

Case CoverÐ Bolts

9 - 18 ENGINE 3.9LBR/BE

ENGINE 3.9L (Continued)

Page 1178 of 2889

(8) Turn crankshaft and camshaft to line up with

keyway location in crankshaft sprocket and in cam-

shaft sprocket.

(9) Lift sprockets and chain (keep sprockets tight

against the chain in position as described).

(10) Slide both sprockets evenly over their respec-

tive shafts and use a straightedge to check alignment

of timing marks (Fig. 22).

(11) Install the camshaft bolt/cup washer. Tighten

bolt to 68 N´m (50 ft. lbs.) torque.

(12) Measure camshaft end play (Fig. 23). (Refer to

9 - ENGINE - SPECIFICATIONS) for proper clear-

ance. If not within limits, install a new timing chain

tensioner.

(13) Each tappet reused must be installed in the

same position at which it was removed.When cam-

shaft is replaced, all of the tappets must be

replaced.Install hydraulic tappets (Refer to 9 -

ENGINE/ENGINE BLOCK/HYDRAULIC LIFTERS

(CAM IN BLOCK) - INSTALLATION).

(14) Install timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(15) Install intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - INSTALLA-

TION).

(16) Install distributor.

(17) Install cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(19) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(20) Connect battery negative cable.

(21) Start engine and check for leaks.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE-CONNECTING ROD

BEARING FITTING

Fit all rods on a bank until completed. DO NOT

alternate from one bank to another, because connect-

ing rods and pistons are not interchangeable from

one bank to another.

The bearing caps are not interchangeable and

should be marked at removal to ensure correct

assembly.

Each bearing cap has a small V-groove across the

parting face. When installing the lower bearing shell,

be certain that the V-groove in the shell is in line

with the V-groove in the cap. This provides lubrica-

tion of the cylinder wall in the opposite bank.The bearing shells must be installed so that the

tangs are in the machined grooves in the rods and

caps.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.025 mm (0.001 in.).

Bearings are available in 0.025 mm (0.001 in.), 0.051

mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm

(0.010 in.) and 0.305 mm (0.012 in.) undersize.

Install the bearings in pairs. DO NOT use a new

bearing half with an old bearing half. DO NOT

file the rods or bearing caps.

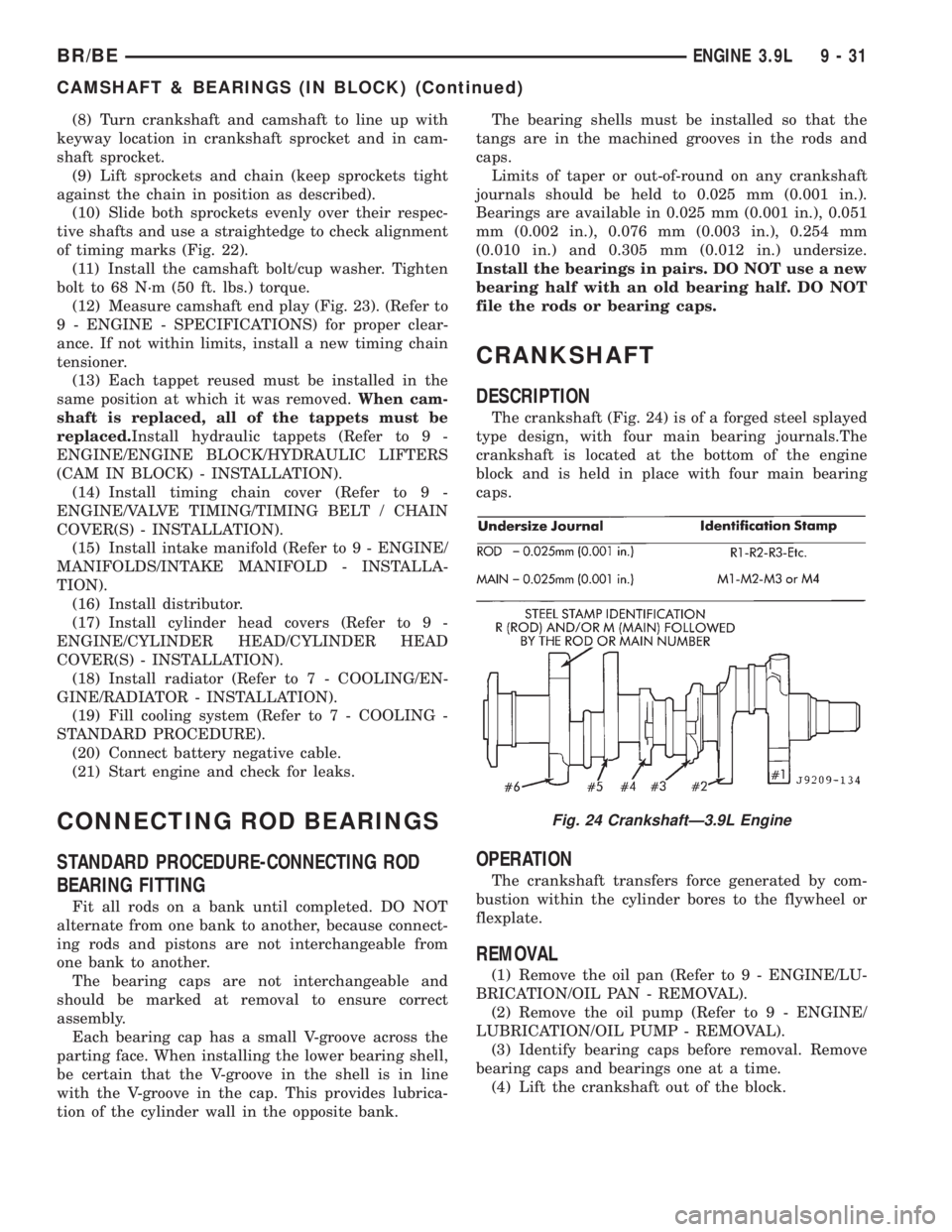

CRANKSHAFT

DESCRIPTION

The crankshaft (Fig. 24) is of a forged steel splayed

type design, with four main bearing journals.The

crankshaft is located at the bottom of the engine

block and is held in place with four main bearing

caps.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder bores to the flywheel or

flexplate.

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump (Refer to 9 - ENGINE/

LUBRICATION/OIL PUMP - REMOVAL).

(3) Identify bearing caps before removal. Remove

bearing caps and bearings one at a time.

(4) Lift the crankshaft out of the block.

Fig. 24 CrankshaftÐ3.9L Engine

BR/BEENGINE 3.9L 9 - 31

CAMSHAFT & BEARINGS (IN BLOCK) (Continued)

Page 1211 of 2889

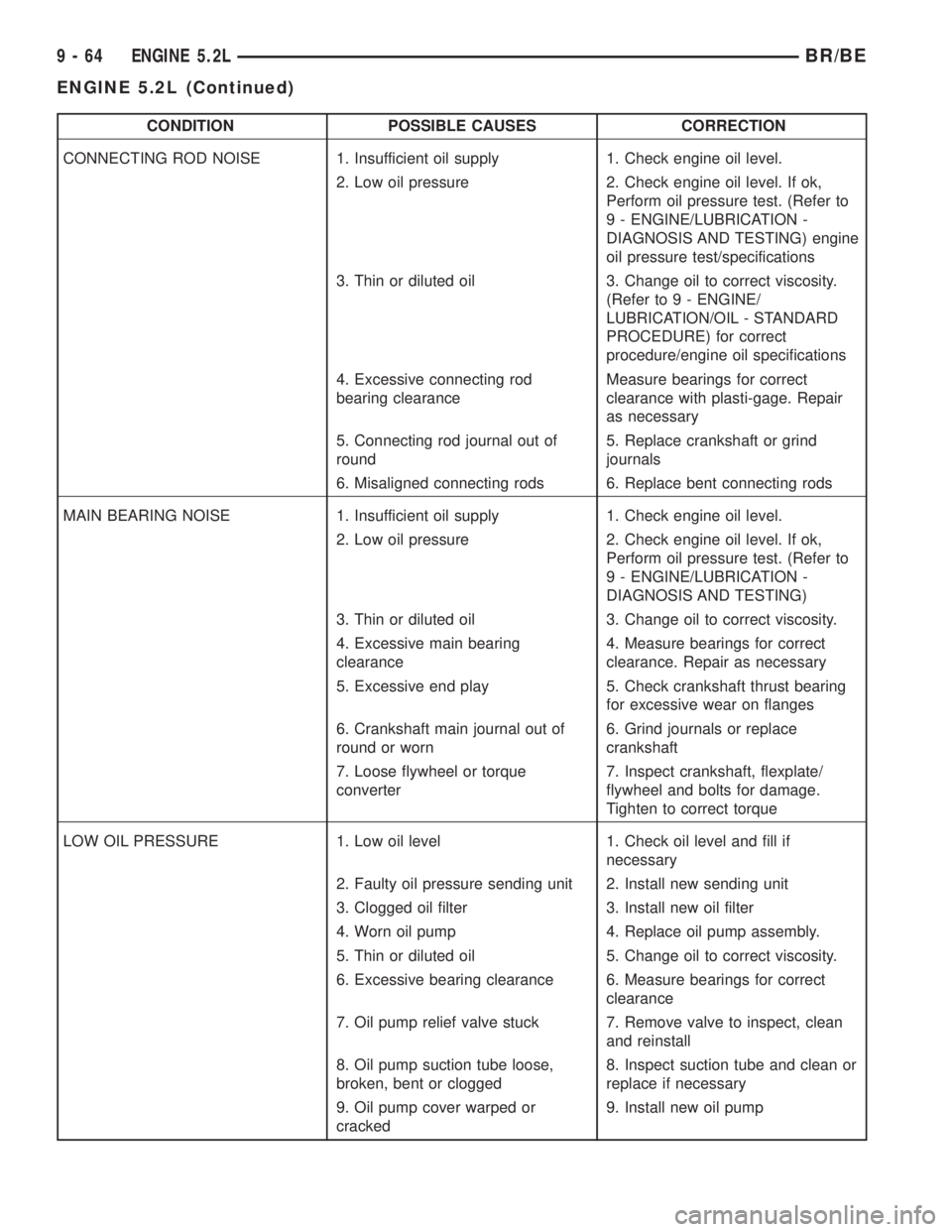

CONDITION POSSIBLE CAUSES CORRECTION

CONNECTING ROD NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING) engine

oil pressure test/specifications

3. Thin or diluted oil 3. Change oil to correct viscosity.

(Refer to 9 - ENGINE/

LUBRICATION/OIL - STANDARD

PROCEDURE) for correct

procedure/engine oil specifications

4. Excessive connecting rod

bearing clearanceMeasure bearings for correct

clearance with plasti-gage. Repair

as necessary

5. Connecting rod journal out of

round5. Replace crankshaft or grind

journals

6. Misaligned connecting rods 6. Replace bent connecting rods

MAIN BEARING NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to

9 - ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING)

3. Thin or diluted oil 3. Change oil to correct viscosity.

4. Excessive main bearing

clearance4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing

for excessive wear on flanges

6. Crankshaft main journal out of

round or worn6. Grind journals or replace

crankshaft

7. Loose flywheel or torque

converter7. Inspect crankshaft, flexplate/

flywheel and bolts for damage.

Tighten to correct torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if

necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean

and reinstall

8. Oil pump suction tube loose,

broken, bent or clogged8. Inspect suction tube and clean or

replace if necessary

9. Oil pump cover warped or

cracked9. Install new oil pump

9 - 64 ENGINE 5.2LBR/BE

ENGINE 5.2L (Continued)