DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1831 of 2255

(11) Install pressure plate (Fig. 223). Ridged side

of plate faces downward (toward piston) and flat side

toward clutch pack.

(12) Install first clutch disc in retainer on top of

pressure plate. Then install a clutch plate followed

by a clutch disc until entire clutch pack is installed

(4 discs and 3 plates are required) (Fig. 223).

(13) Install the reaction plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

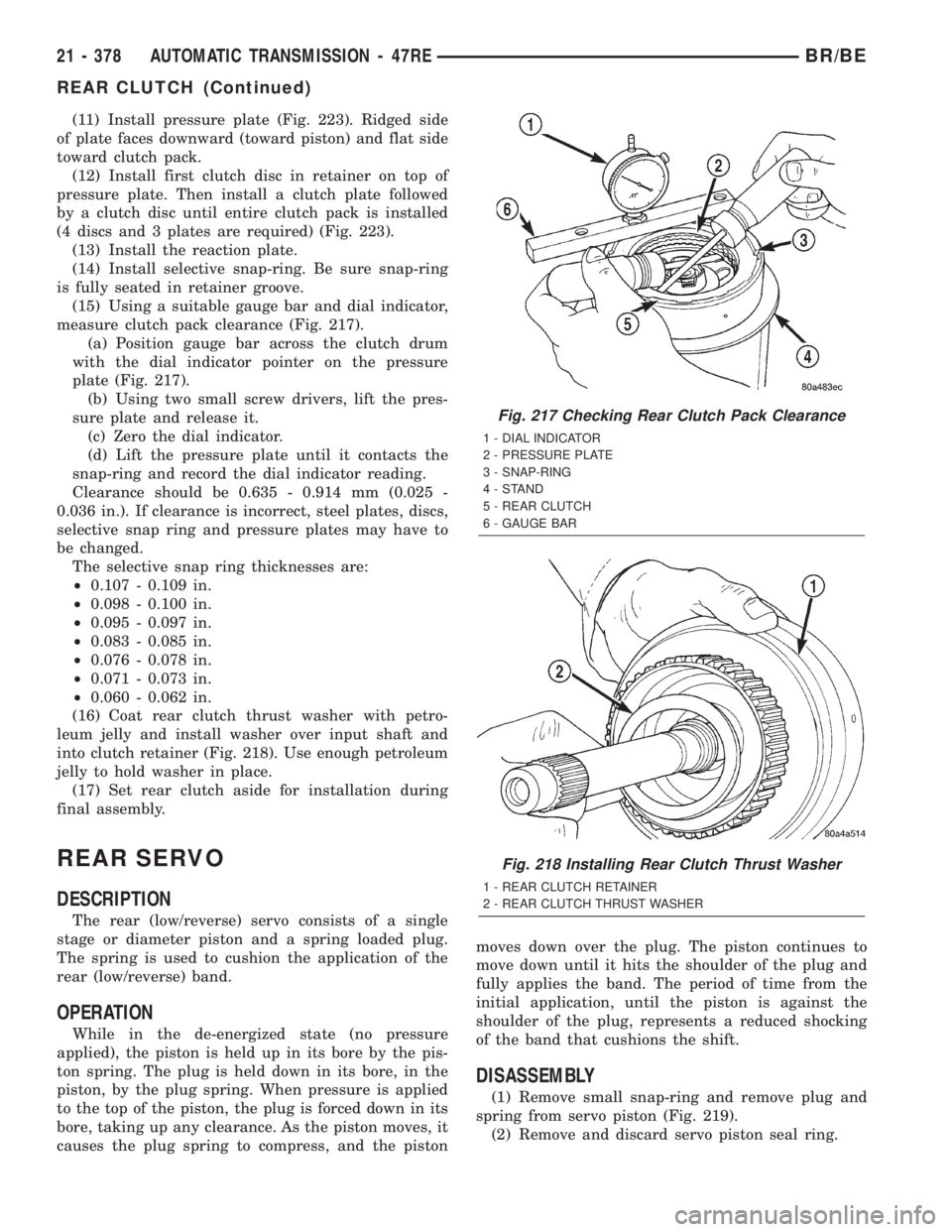

(15) Using a suitable gauge bar and dial indicator,

measure clutch pack clearance (Fig. 217).

(a) Position gauge bar across the clutch drum

with the dial indicator pointer on the pressure

plate (Fig. 217).

(b) Using two small screw drivers, lift the pres-

sure plate and release it.

(c) Zero the dial indicator.

(d) Lift the pressure plate until it contacts the

snap-ring and record the dial indicator reading.

Clearance should be 0.635 - 0.914 mm (0.025 -

0.036 in.). If clearance is incorrect, steel plates, discs,

selective snap ring and pressure plates may have to

be changed.

The selective snap ring thicknesses are:

²0.107 - 0.109 in.

²0.098 - 0.100 in.

²0.095 - 0.097 in.

²0.083 - 0.085 in.

²0.076 - 0.078 in.

²0.071 - 0.073 in.

²0.060 - 0.062 in.

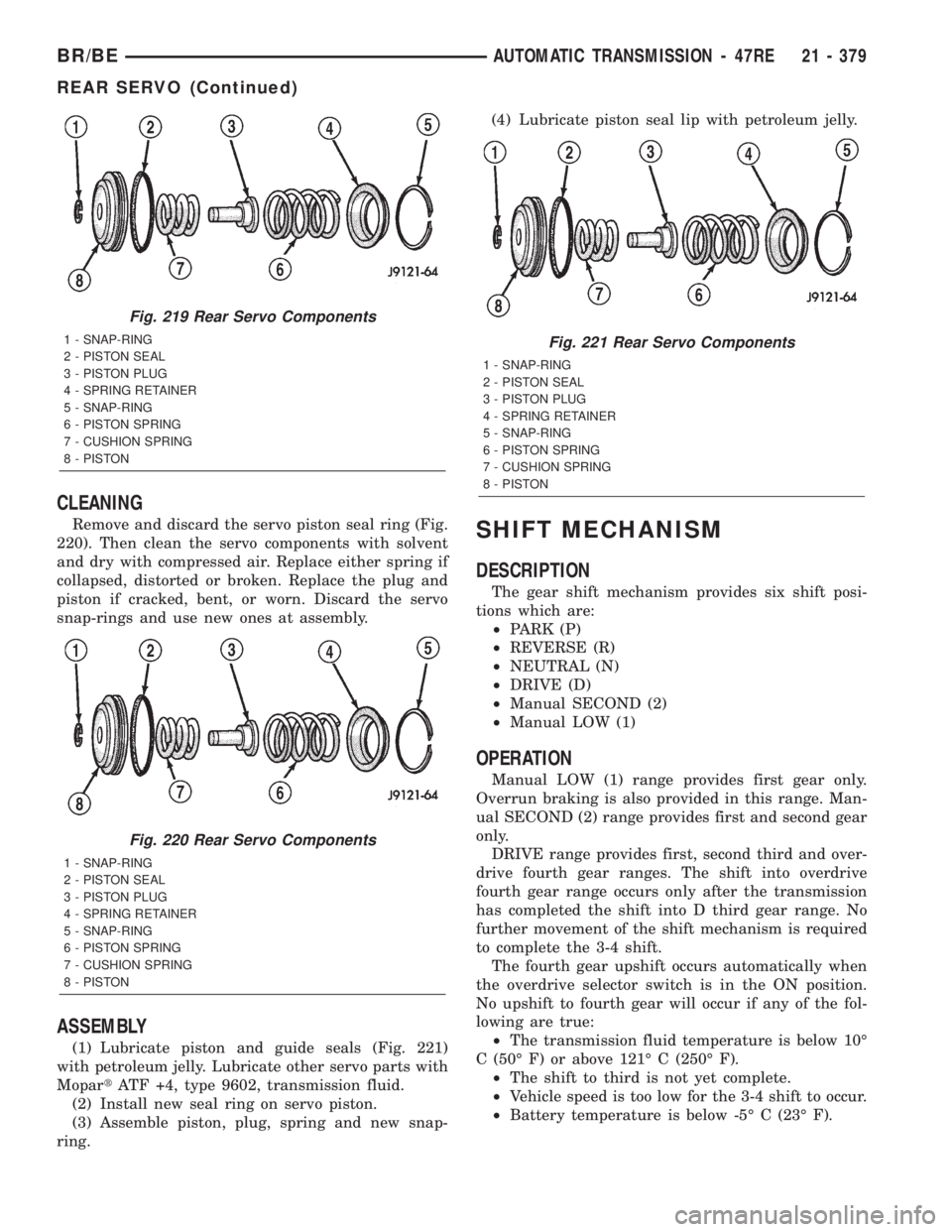

(16) Coat rear clutch thrust washer with petro-

leum jelly and install washer over input shaft and

into clutch retainer (Fig. 218). Use enough petroleum

jelly to hold washer in place.

(17) Set rear clutch aside for installation during

final assembly.

REAR SERVO

DESCRIPTION

The rear (low/reverse) servo consists of a single

stage or diameter piston and a spring loaded plug.

The spring is used to cushion the application of the

rear (low/reverse) band.

OPERATION

While in the de-energized state (no pressure

applied), the piston is held up in its bore by the pis-

ton spring. The plug is held down in its bore, in the

piston, by the plug spring. When pressure is applied

to the top of the piston, the plug is forced down in its

bore, taking up any clearance. As the piston moves, it

causes the plug spring to compress, and the pistonmoves down over the plug. The piston continues to

move down until it hits the shoulder of the plug and

fully applies the band. The period of time from the

initial application, until the piston is against the

shoulder of the plug, represents a reduced shocking

of the band that cushions the shift.

DISASSEMBLY

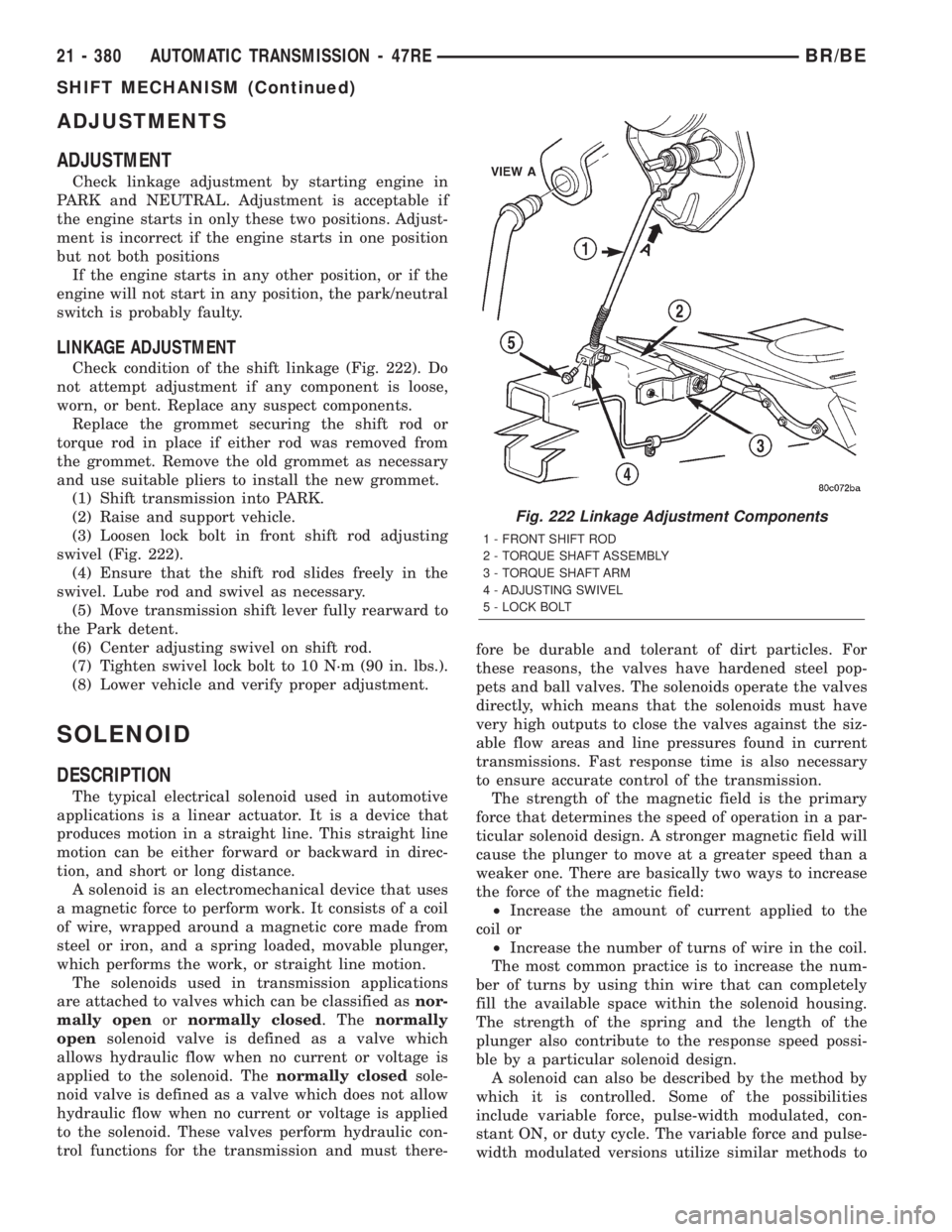

(1) Remove small snap-ring and remove plug and

spring from servo piston (Fig. 219).

(2) Remove and discard servo piston seal ring.

Fig. 217 Checking Rear Clutch Pack Clearance

1 - DIAL INDICATOR

2 - PRESSURE PLATE

3 - SNAP-RING

4-STAND

5 - REAR CLUTCH

6 - GAUGE BAR

Fig. 218 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER

21 - 378 AUTOMATIC TRANSMISSION - 47REBR/BE

REAR CLUTCH (Continued)

Page 1832 of 2255

CLEANING

Remove and discard the servo piston seal ring (Fig.

220). Then clean the servo components with solvent

and dry with compressed air. Replace either spring if

collapsed, distorted or broken. Replace the plug and

piston if cracked, bent, or worn. Discard the servo

snap-rings and use new ones at assembly.

ASSEMBLY

(1) Lubricate piston and guide seals (Fig. 221)

with petroleum jelly. Lubricate other servo parts with

MopartATF +4, type 9602, transmission fluid.

(2) Install new seal ring on servo piston.

(3) Assemble piston, plug, spring and new snap-

ring.(4) Lubricate piston seal lip with petroleum jelly.

SHIFT MECHANISM

DESCRIPTION

The gear shift mechanism provides six shift posi-

tions which are:

²PARK (P)

²REVERSE (R)

²NEUTRAL (N)

²DRIVE (D)

²Manual SECOND (2)

²Manual LOW (1)

OPERATION

Manual LOW (1) range provides first gear only.

Overrun braking is also provided in this range. Man-

ual SECOND (2) range provides first and second gear

only.

DRIVE range provides first, second third and over-

drive fourth gear ranges. The shift into overdrive

fourth gear range occurs only after the transmission

has completed the shift into D third gear range. No

further movement of the shift mechanism is required

to complete the 3-4 shift.

The fourth gear upshift occurs automatically when

the overdrive selector switch is in the ON position.

No upshift to fourth gear will occur if any of the fol-

lowing are true:

²The transmission fluid temperature is below 10É

C (50É F) or above 121É C (250É F).

²The shift to third is not yet complete.

²Vehicle speed is too low for the 3-4 shift to occur.

²Battery temperature is below -5É C (23É F).

Fig. 219 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

Fig. 220 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

Fig. 221 Rear Servo Components

1 - SNAP-RING

2 - PISTON SEAL

3 - PISTON PLUG

4 - SPRING RETAINER

5 - SNAP-RING

6 - PISTON SPRING

7 - CUSHION SPRING

8 - PISTON

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 379

REAR SERVO (Continued)

Page 1833 of 2255

ADJUSTMENTS

ADJUSTMENT

Check linkage adjustment by starting engine in

PARK and NEUTRAL. Adjustment is acceptable if

the engine starts in only these two positions. Adjust-

ment is incorrect if the engine starts in one position

but not both positions

If the engine starts in any other position, or if the

engine will not start in any position, the park/neutral

switch is probably faulty.

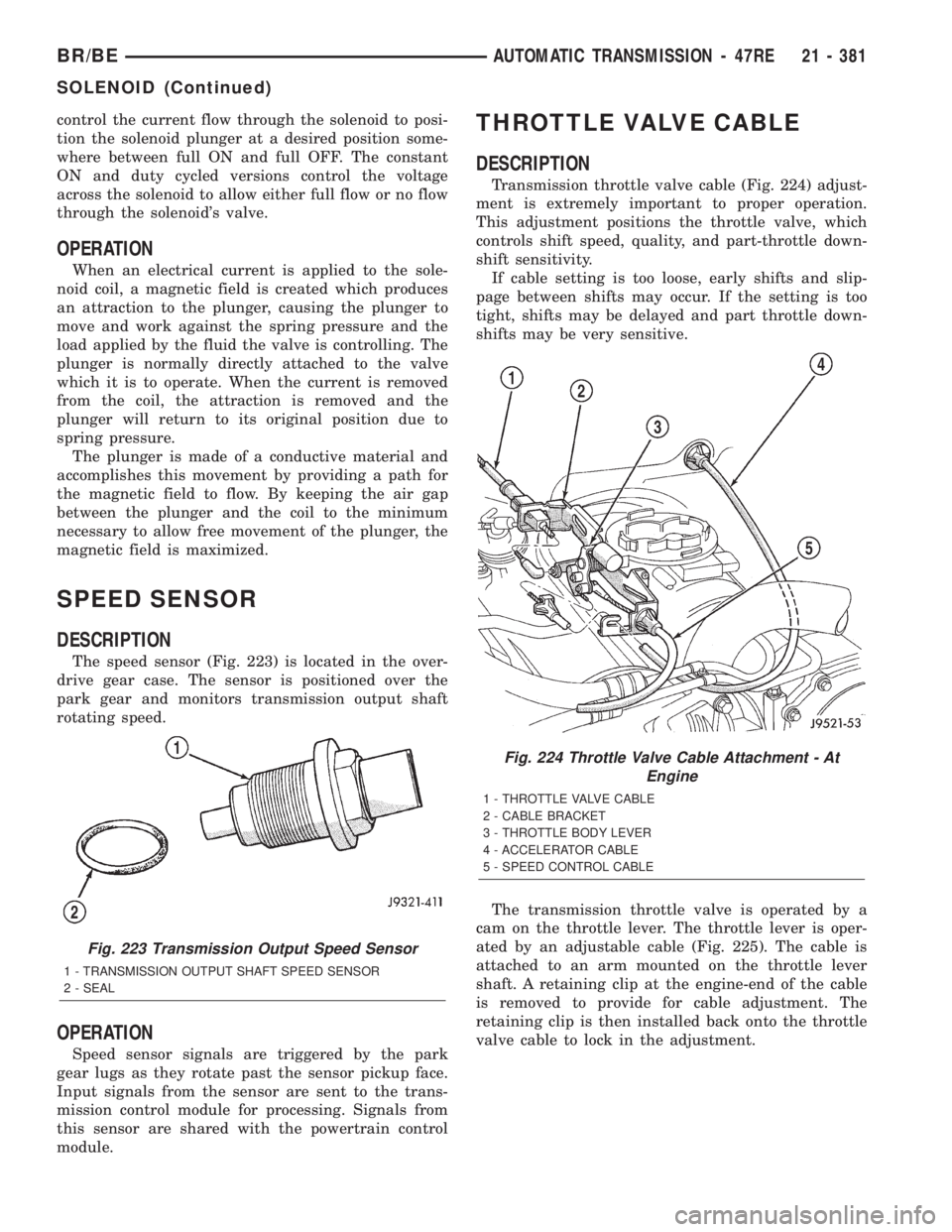

LINKAGE ADJUSTMENT

Check condition of the shift linkage (Fig. 222). Do

not attempt adjustment if any component is loose,

worn, or bent. Replace any suspect components.

Replace the grommet securing the shift rod or

torque rod in place if either rod was removed from

the grommet. Remove the old grommet as necessary

and use suitable pliers to install the new grommet.

(1) Shift transmission into PARK.

(2) Raise and support vehicle.

(3) Loosen lock bolt in front shift rod adjusting

swivel (Fig. 222).

(4) Ensure that the shift rod slides freely in the

swivel. Lube rod and swivel as necessary.

(5) Move transmission shift lever fully rearward to

the Park detent.

(6) Center adjusting swivel on shift rod.

(7) Tighten swivel lock bolt to 10 N´m (90 in. lbs.).

(8) Lower vehicle and verify proper adjustment.

SOLENOID

DESCRIPTION

The typical electrical solenoid used in automotive

applications is a linear actuator. It is a device that

produces motion in a straight line. This straight line

motion can be either forward or backward in direc-

tion, and short or long distance.

A solenoid is an electromechanical device that uses

a magnetic force to perform work. It consists of a coil

of wire, wrapped around a magnetic core made from

steel or iron, and a spring loaded, movable plunger,

which performs the work, or straight line motion.

The solenoids used in transmission applications

are attached to valves which can be classified asnor-

mally openornormally closed. Thenormally

opensolenoid valve is defined as a valve which

allows hydraulic flow when no current or voltage is

applied to the solenoid. Thenormally closedsole-

noid valve is defined as a valve which does not allow

hydraulic flow when no current or voltage is applied

to the solenoid. These valves perform hydraulic con-

trol functions for the transmission and must there-fore be durable and tolerant of dirt particles. For

these reasons, the valves have hardened steel pop-

pets and ball valves. The solenoids operate the valves

directly, which means that the solenoids must have

very high outputs to close the valves against the siz-

able flow areas and line pressures found in current

transmissions. Fast response time is also necessary

to ensure accurate control of the transmission.

The strength of the magnetic field is the primary

force that determines the speed of operation in a par-

ticular solenoid design. A stronger magnetic field will

cause the plunger to move at a greater speed than a

weaker one. There are basically two ways to increase

the force of the magnetic field:

²Increase the amount of current applied to the

coil or

²Increase the number of turns of wire in the coil.

The most common practice is to increase the num-

ber of turns by using thin wire that can completely

fill the available space within the solenoid housing.

The strength of the spring and the length of the

plunger also contribute to the response speed possi-

ble by a particular solenoid design.

A solenoid can also be described by the method by

which it is controlled. Some of the possibilities

include variable force, pulse-width modulated, con-

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

Fig. 222 Linkage Adjustment Components

1 - FRONT SHIFT ROD

2 - TORQUE SHAFT ASSEMBLY

3 - TORQUE SHAFT ARM

4 - ADJUSTING SWIVEL

5 - LOCK BOLT

21 - 380 AUTOMATIC TRANSMISSION - 47REBR/BE

SHIFT MECHANISM (Continued)

Page 1834 of 2255

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

SPEED SENSOR

DESCRIPTION

The speed sensor (Fig. 223) is located in the over-

drive gear case. The sensor is positioned over the

park gear and monitors transmission output shaft

rotating speed.

OPERATION

Speed sensor signals are triggered by the park

gear lugs as they rotate past the sensor pickup face.

Input signals from the sensor are sent to the trans-

mission control module for processing. Signals from

this sensor are shared with the powertrain control

module.

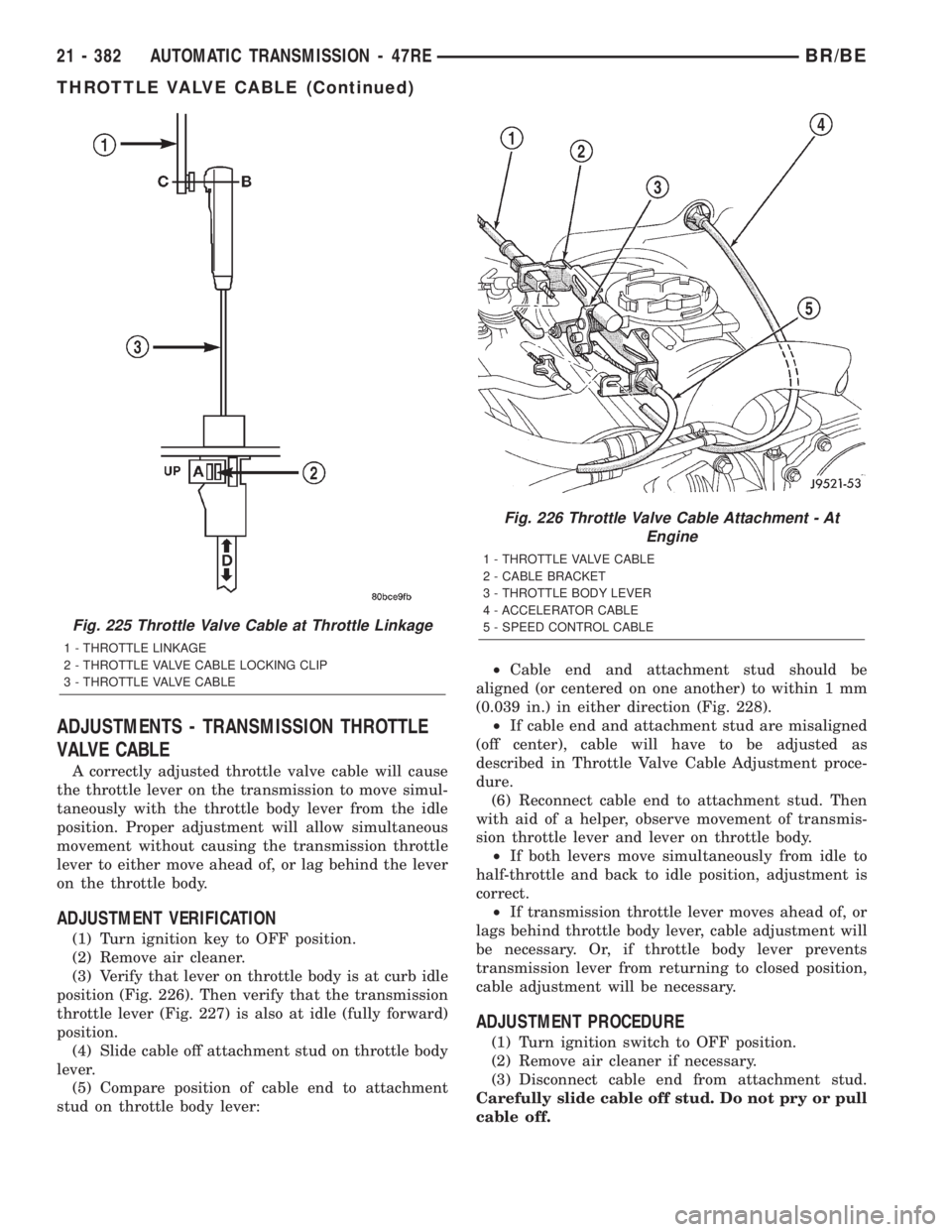

THROTTLE VALVE CABLE

DESCRIPTION

Transmission throttle valve cable (Fig. 224) adjust-

ment is extremely important to proper operation.

This adjustment positions the throttle valve, which

controls shift speed, quality, and part-throttle down-

shift sensitivity.

If cable setting is too loose, early shifts and slip-

page between shifts may occur. If the setting is too

tight, shifts may be delayed and part throttle down-

shifts may be very sensitive.

The transmission throttle valve is operated by a

cam on the throttle lever. The throttle lever is oper-

ated by an adjustable cable (Fig. 225). The cable is

attached to an arm mounted on the throttle lever

shaft. A retaining clip at the engine-end of the cable

is removed to provide for cable adjustment. The

retaining clip is then installed back onto the throttle

valve cable to lock in the adjustment.

Fig. 223 Transmission Output Speed Sensor

1 - TRANSMISSION OUTPUT SHAFT SPEED SENSOR

2 - SEAL

Fig. 224 Throttle Valve Cable Attachment - At

Engine

1 - THROTTLE VALVE CABLE

2 - CABLE BRACKET

3 - THROTTLE BODY LEVER

4 - ACCELERATOR CABLE

5 - SPEED CONTROL CABLE

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 381

SOLENOID (Continued)

Page 1835 of 2255

ADJUSTMENTS - TRANSMISSION THROTTLE

VALVE CABLE

A correctly adjusted throttle valve cable will cause

the throttle lever on the transmission to move simul-

taneously with the throttle body lever from the idle

position. Proper adjustment will allow simultaneous

movement without causing the transmission throttle

lever to either move ahead of, or lag behind the lever

on the throttle body.

ADJUSTMENT VERIFICATION

(1) Turn ignition key to OFF position.

(2) Remove air cleaner.

(3) Verify that lever on throttle body is at curb idle

position (Fig. 226). Then verify that the transmission

throttle lever (Fig. 227) is also at idle (fully forward)

position.

(4) Slide cable off attachment stud on throttle body

lever.

(5) Compare position of cable end to attachment

stud on throttle body lever:²Cable end and attachment stud should be

aligned (or centered on one another) to within 1 mm

(0.039 in.) in either direction (Fig. 228).

²If cable end and attachment stud are misaligned

(off center), cable will have to be adjusted as

described in Throttle Valve Cable Adjustment proce-

dure.

(6) Reconnect cable end to attachment stud. Then

with aid of a helper, observe movement of transmis-

sion throttle lever and lever on throttle body.

²If both levers move simultaneously from idle to

half-throttle and back to idle position, adjustment is

correct.

²If transmission throttle lever moves ahead of, or

lags behind throttle body lever, cable adjustment will

be necessary. Or, if throttle body lever prevents

transmission lever from returning to closed position,

cable adjustment will be necessary.

ADJUSTMENT PROCEDURE

(1) Turn ignition switch to OFF position.

(2) Remove air cleaner if necessary.

(3) Disconnect cable end from attachment stud.

Carefully slide cable off stud. Do not pry or pull

cable off.

Fig. 225 Throttle Valve Cable at Throttle Linkage

1 - THROTTLE LINKAGE

2 - THROTTLE VALVE CABLE LOCKING CLIP

3 - THROTTLE VALVE CABLE

Fig. 226 Throttle Valve Cable Attachment - At

Engine

1 - THROTTLE VALVE CABLE

2 - CABLE BRACKET

3 - THROTTLE BODY LEVER

4 - ACCELERATOR CABLE

5 - SPEED CONTROL CABLE

21 - 382 AUTOMATIC TRANSMISSION - 47REBR/BE

THROTTLE VALVE CABLE (Continued)

Page 1836 of 2255

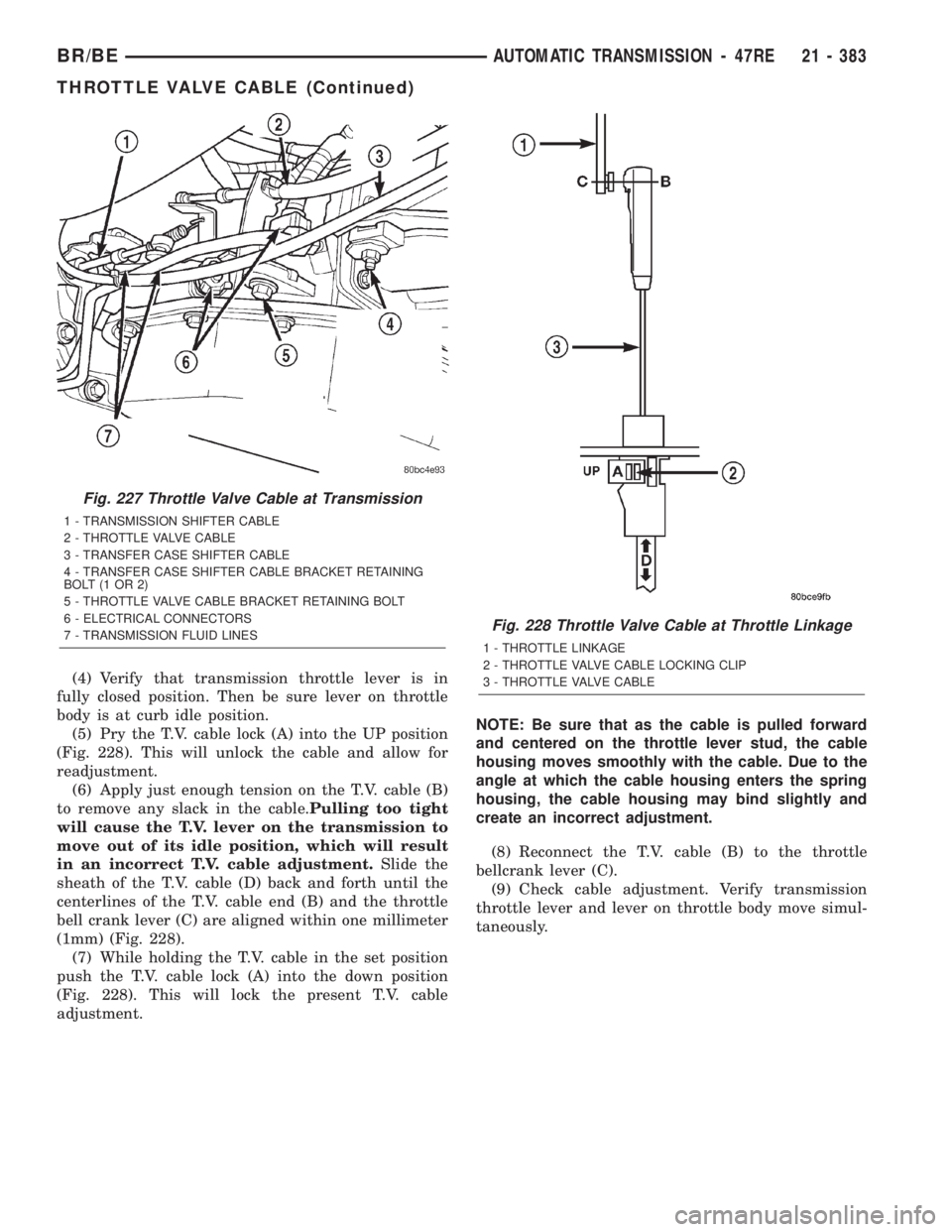

(4) Verify that transmission throttle lever is in

fully closed position. Then be sure lever on throttle

body is at curb idle position.

(5) Pry the T.V. cable lock (A) into the UP position

(Fig. 228). This will unlock the cable and allow for

readjustment.

(6) Apply just enough tension on the T.V. cable (B)

to remove any slack in the cable.Pulling too tight

will cause the T.V. lever on the transmission to

move out of its idle position, which will result

in an incorrect T.V. cable adjustment.Slide the

sheath of the T.V. cable (D) back and forth until the

centerlines of the T.V. cable end (B) and the throttle

bell crank lever (C) are aligned within one millimeter

(1mm) (Fig. 228).

(7) While holding the T.V. cable in the set position

push the T.V. cable lock (A) into the down position

(Fig. 228). This will lock the present T.V. cable

adjustment.NOTE: Be sure that as the cable is pulled forward

and centered on the throttle lever stud, the cable

housing moves smoothly with the cable. Due to the

angle at which the cable housing enters the spring

housing, the cable housing may bind slightly and

create an incorrect adjustment.

(8) Reconnect the T.V. cable (B) to the throttle

bellcrank lever (C).

(9) Check cable adjustment. Verify transmission

throttle lever and lever on throttle body move simul-

taneously.

Fig. 227 Throttle Valve Cable at Transmission

1 - TRANSMISSION SHIFTER CABLE

2 - THROTTLE VALVE CABLE

3 - TRANSFER CASE SHIFTER CABLE

4 - TRANSFER CASE SHIFTER CABLE BRACKET RETAINING

BOLT(1OR2)

5 - THROTTLE VALVE CABLE BRACKET RETAINING BOLT

6 - ELECTRICAL CONNECTORS

7 - TRANSMISSION FLUID LINES

Fig. 228 Throttle Valve Cable at Throttle Linkage

1 - THROTTLE LINKAGE

2 - THROTTLE VALVE CABLE LOCKING CLIP

3 - THROTTLE VALVE CABLE

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 383

THROTTLE VALVE CABLE (Continued)

Page 1837 of 2255

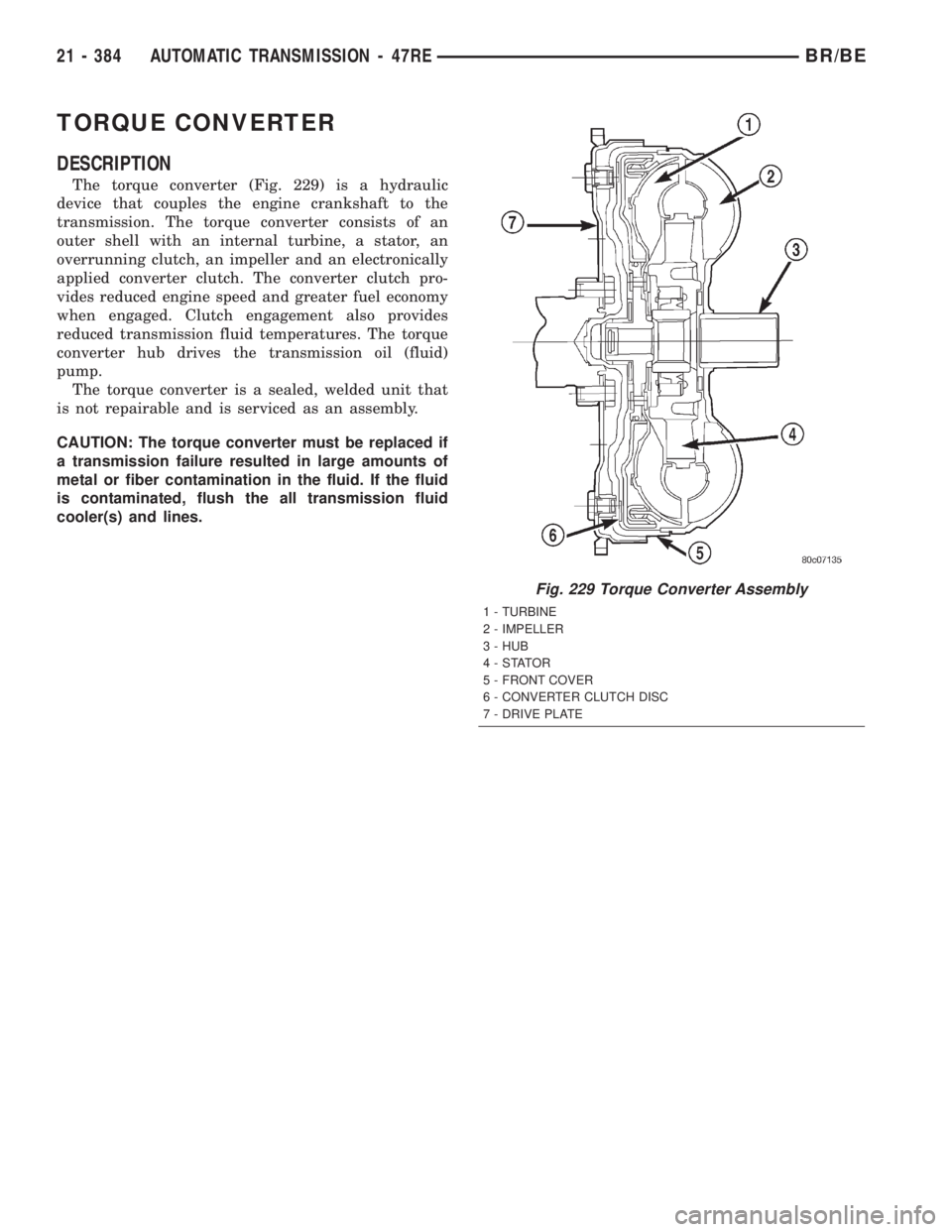

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 229) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The torque

converter hub drives the transmission oil (fluid)

pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the all transmission fluid

cooler(s) and lines.

Fig. 229 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - FRONT COVER

6 - CONVERTER CLUTCH DISC

7 - DRIVE PLATE

21 - 384 AUTOMATIC TRANSMISSION - 47REBR/BE

Page 1838 of 2255

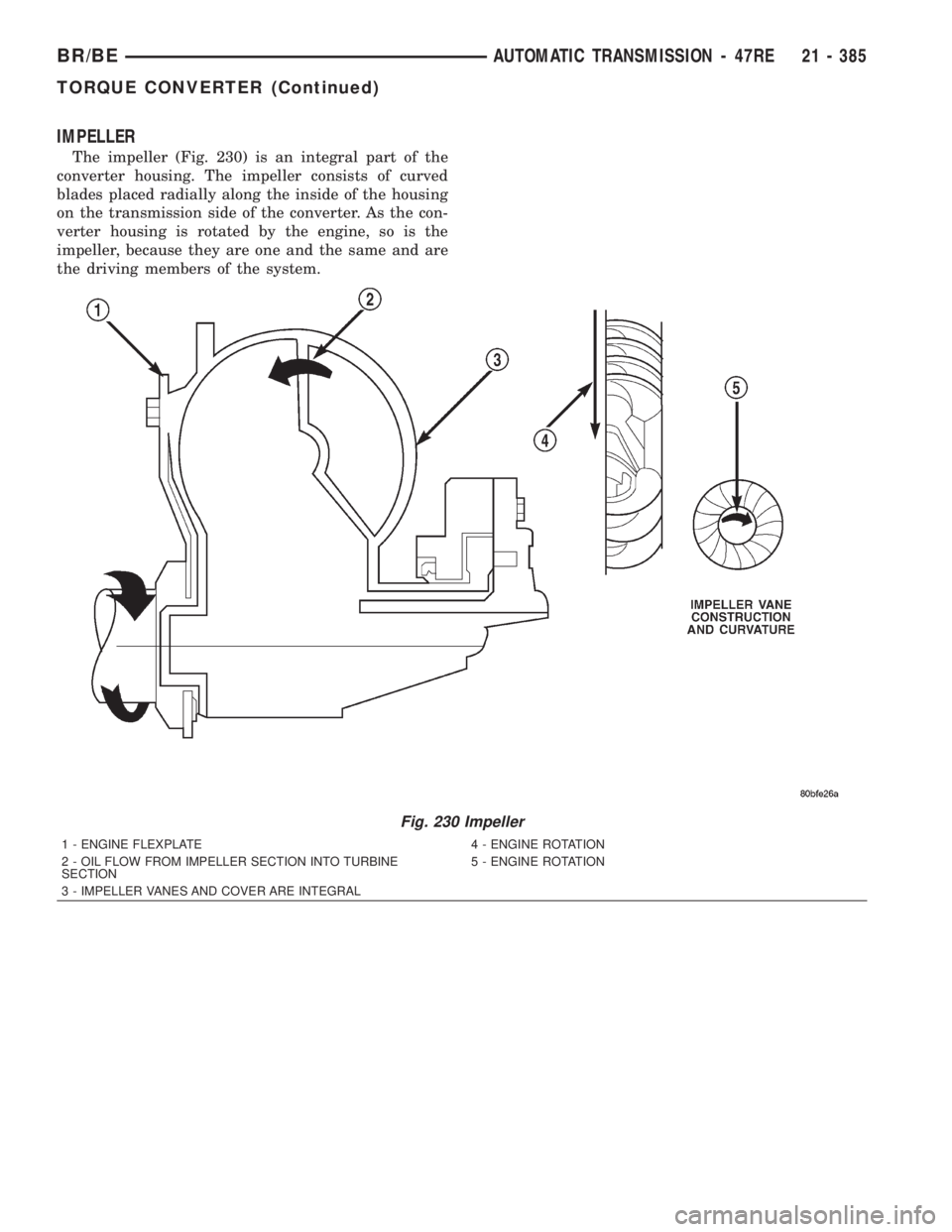

IMPELLER

The impeller (Fig. 230) is an integral part of the

converter housing. The impeller consists of curved

blades placed radially along the inside of the housing

on the transmission side of the converter. As the con-

verter housing is rotated by the engine, so is the

impeller, because they are one and the same and are

the driving members of the system.

Fig. 230 Impeller

1 - ENGINE FLEXPLATE 4 - ENGINE ROTATION

2 - OIL FLOW FROM IMPELLER SECTION INTO TURBINE

SECTION5 - ENGINE ROTATION

3 - IMPELLER VANES AND COVER ARE INTEGRAL

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 385

TORQUE CONVERTER (Continued)

Page 1839 of 2255

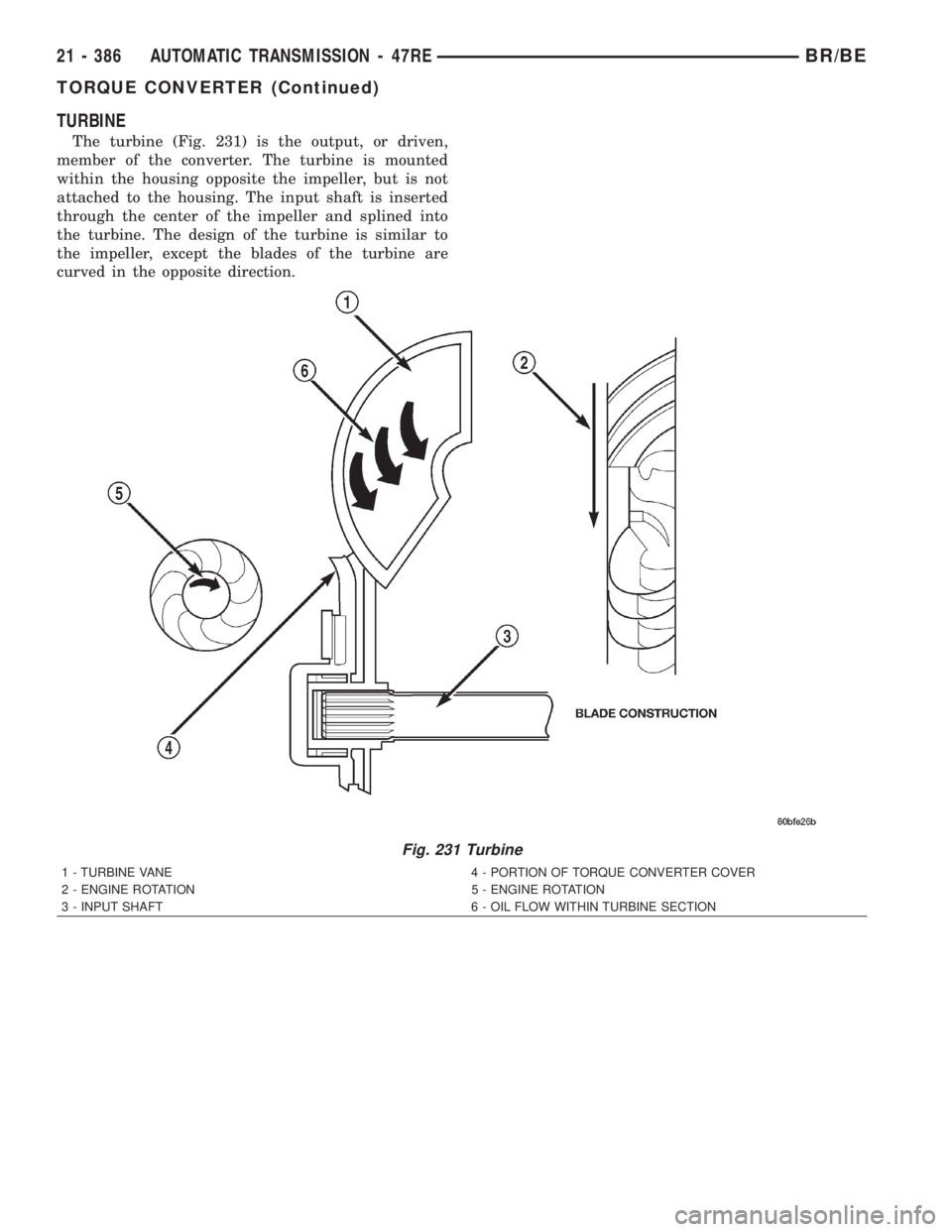

TURBINE

The turbine (Fig. 231) is the output, or driven,

member of the converter. The turbine is mounted

within the housing opposite the impeller, but is not

attached to the housing. The input shaft is inserted

through the center of the impeller and splined into

the turbine. The design of the turbine is similar to

the impeller, except the blades of the turbine are

curved in the opposite direction.

Fig. 231 Turbine

1 - TURBINE VANE 4 - PORTION OF TORQUE CONVERTER COVER

2 - ENGINE ROTATION 5 - ENGINE ROTATION

3 - INPUT SHAFT 6 - OIL FLOW WITHIN TURBINE SECTION

21 - 386 AUTOMATIC TRANSMISSION - 47REBR/BE

TORQUE CONVERTER (Continued)

Page 1840 of 2255

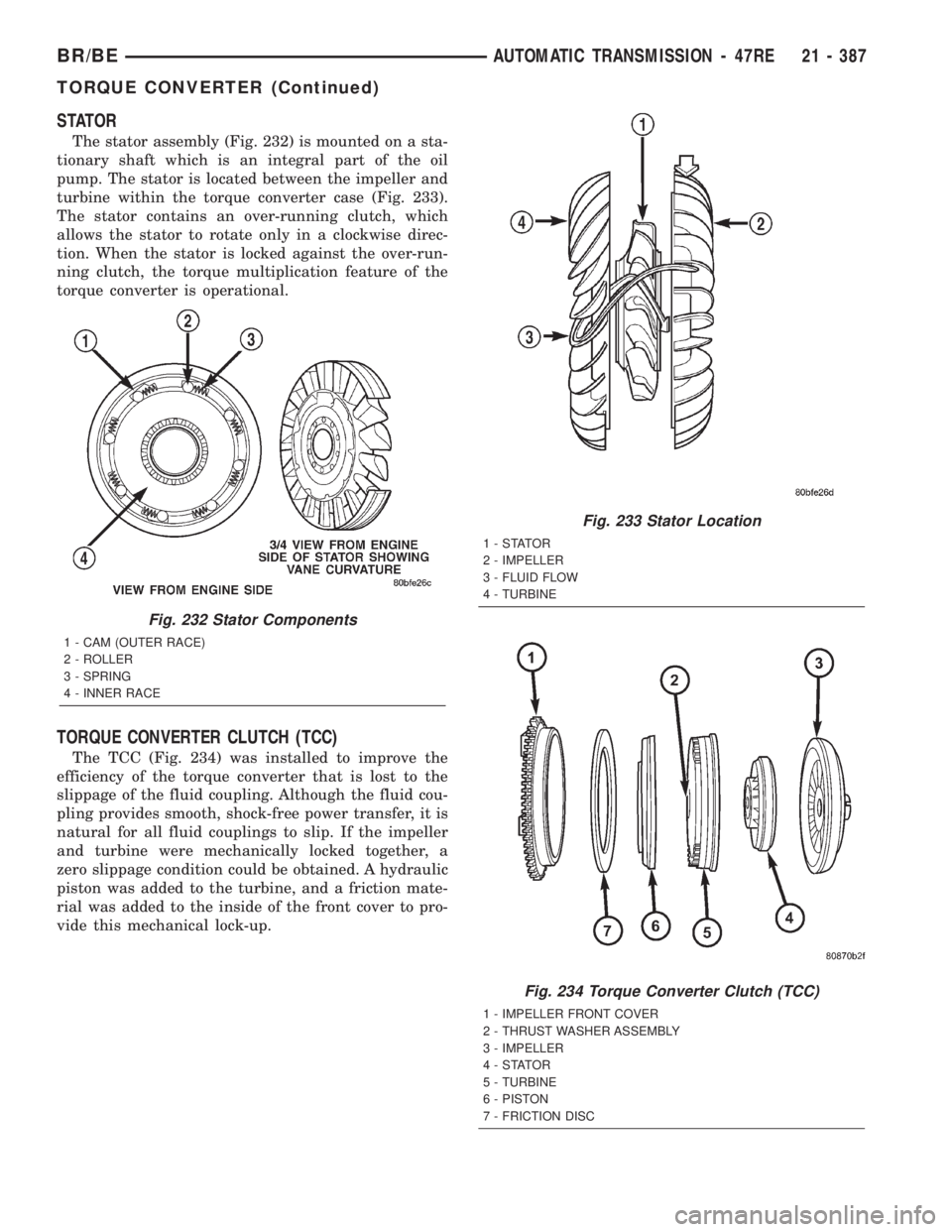

STATOR

The stator assembly (Fig. 232) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 233).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 234) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 232 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 233 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 234 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 387

TORQUE CONVERTER (Continued)