check engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1253 of 2255

DIAGNOSIS AND TESTINGÐENGINE OIL

PRESSURE

(1) Remove the engine oil pressure sensor and

install Oil Pressure Line and Gauge Tool C-3292 with

a suitable adapter.

(2) Start engine and warm to operating tempera-

ture.

(3) Record engine oil pressure and compare with

engine oil pressure chart.

CAUTION: If engine oil pressure is zero at idle, DO

NOT RUN THE ENGINE.

Engine Oil Pressure (MIN)

At Idle 103.4 kPa (15 psi)

At 2000 rpm 310.2 kPa (45 psi)

If minimum engine oil pressure is below these

ranges, (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING).

(4) Remove oil pressure gauge and install the oil

pressure sensor. Tighten the sensor to 16 N´m (144

in. lbs.) torque.

OIL

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE OIL LEVEL

CAUTION: Do not overfill crankcase with engine oil,

oil foaming and oil pressure loss can result.

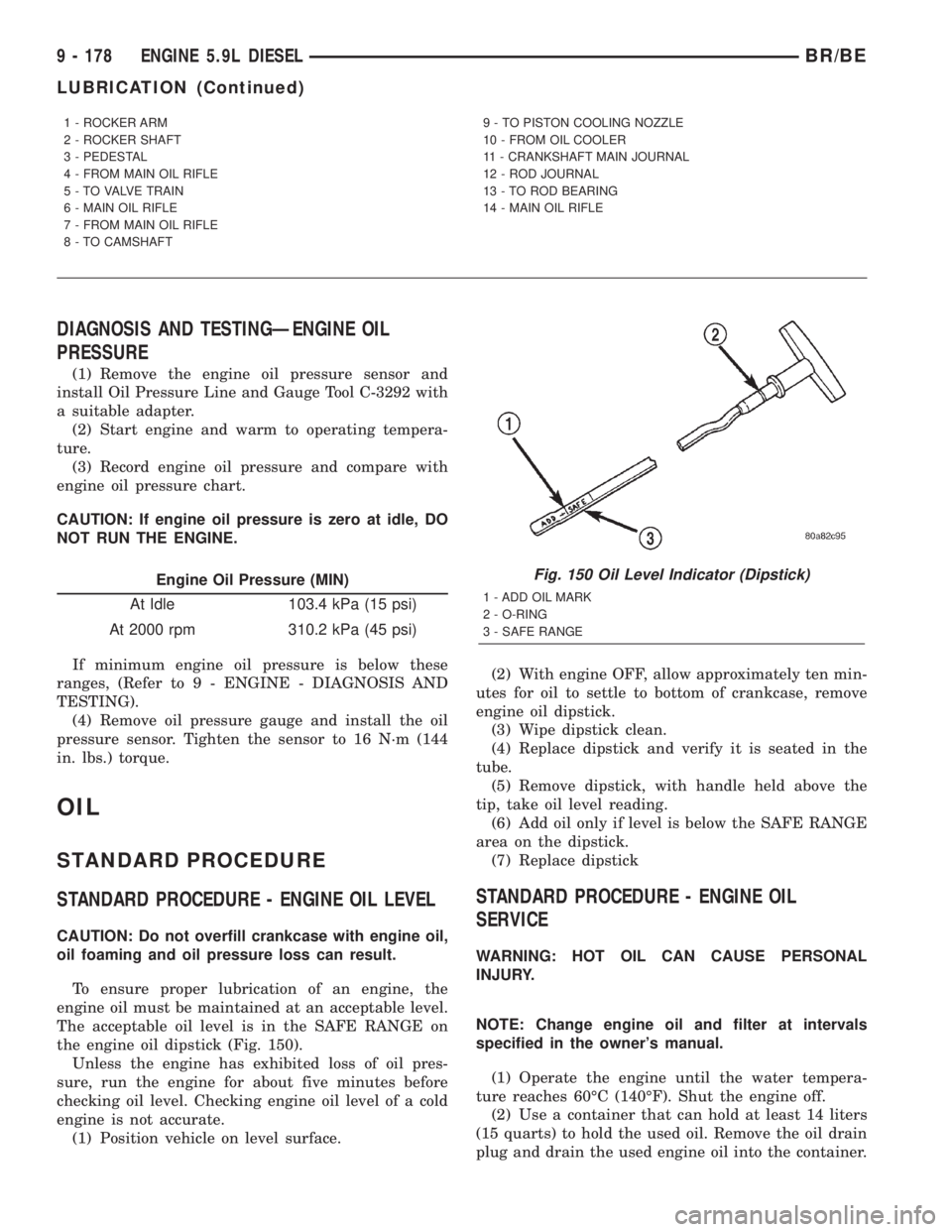

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable oil level is in the SAFE RANGE on

the engine oil dipstick (Fig. 150).

Unless the engine has exhibited loss of oil pres-

sure, run the engine for about five minutes before

checking oil level. Checking engine oil level of a cold

engine is not accurate.

(1) Position vehicle on level surface.(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Replace dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the SAFE RANGE

area on the dipstick.

(7) Replace dipstick

STANDARD PROCEDURE - ENGINE OIL

SERVICE

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

NOTE: Change engine oil and filter at intervals

specified in the owner's manual.

(1) Operate the engine until the water tempera-

ture reaches 60ÉC (140ÉF). Shut the engine off.

(2) Use a container that can hold at least 14 liters

(15 quarts) to hold the used oil. Remove the oil drain

plug and drain the used engine oil into the container.

1 - ROCKER ARM

2 - ROCKER SHAFT

3 - PEDESTAL

4 - FROM MAIN OIL RIFLE

5 - TO VALVE TRAIN

6 - MAIN OIL RIFLE

7 - FROM MAIN OIL RIFLE

8 - TO CAMSHAFT9 - TO PISTON COOLING NOZZLE

10 - FROM OIL COOLER

11 - CRANKSHAFT MAIN JOURNAL

12 - ROD JOURNAL

13 - TO ROD BEARING

14 - MAIN OIL RIFLE

Fig. 150 Oil Level Indicator (Dipstick)

1 - ADD OIL MARK

2 - O-RING

3 - SAFE RANGE

9 - 178 ENGINE 5.9L DIESELBR/BE

LUBRICATION (Continued)

Page 1254 of 2255

(3) Always check the condition of the used oil. This

can give you an indication of engine problems that

might exist.

²Thin, black oil indicates fuel dilution.

²Milky discoloration indicates coolant dilution.

(4) Clean the area around the oil filter head.

Remove the filter (Refer to 9 - ENGINE/LUBRICA-

TION/OIL FILTER - REMOVAL).

(5) Install new oil filter (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION).

(6) Clean the drain plug and the sealing surface of

the pan. Check the condition of the threads and seal-

ing surface on the oil pan and drain plug.

(7) Install the drain plug. Tighten the plug to 50

N´m (37 ft. lbs.) torque.

(8) Use only High-Quality Multi-Viscosity lubricat-

ing oil in the Cummins Turbo Diesel engine. Choose

the correct oil for the operating conditions (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES -

DESCRIPTION).

(9) Fill the engine with the correct grade of new oil

(Refer to LUBRICATION & MAINTENANCE/FLUID

CAPACITIES - SPECIFICATIONS).

(10) Start the engine and operate it at idle for sev-

eral minutes. Check for leaks at the filter and drain

plug.

(11) Stop engine. Wait several minutes to allow the

oil to drain back to the pan and check the level

again.

USED ENGINE OIL DISPOSAL Care should be

exercised when disposing of used engine oil after

it has been drained from a vehicle's engine.

OIL COOLER & LINES

CLEANING AND INSPECTION

Clean the sealing surfaces.

Apply 483 kPa (70 psi) air pressure to the element

to check for leaks. If the element leaks, replace the

element.

OIL FILTER

REMOVAL

(1) Clean the area around the oil filter head.

Remove the filter using a 90-95 mm filter wrench.

(2) Clean the gasket surface of the filter head. The

filter canister O-Ring seal can stick on the filter

head. Make sure it is removed.

INSTALLATION

(1) Fill the oil filter element with clean oil before

installation. Use the same type oil that will be used

in the engine.

(2) Apply a light film of lubricating oil to the seal-

ing surface before installing the filter.

CAUTION: Mechanical over-tightening may distort

the threads or damage the filter element seal.

(3) Install the filter until it contacts the sealing

surface of the oil filter adapter. Tighten filter an

additional ó turn.

OIL PAN

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove transmission and transfer case (if

equipped).

(4) Remove flywheel.

(5) Disconnect starter cables from starter motor.

(6) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

WARNING: HOT OIL CAN CAUSE PERSONAL

INJURY.

(7) Drain the engine oil (Refer to 9 - ENGINE/LU-

BRICATION/OIL - STANDARD PROCEDURE).

(8) Install the oil pan drain plug with a new seal-

ing washer and tighten to 60 N´m (44 ft. lbs.) torque.

(9) Remove oil pan bolts, break the pan to block

seal, and lower pan slightly and remove oil suction

tube fasteners.

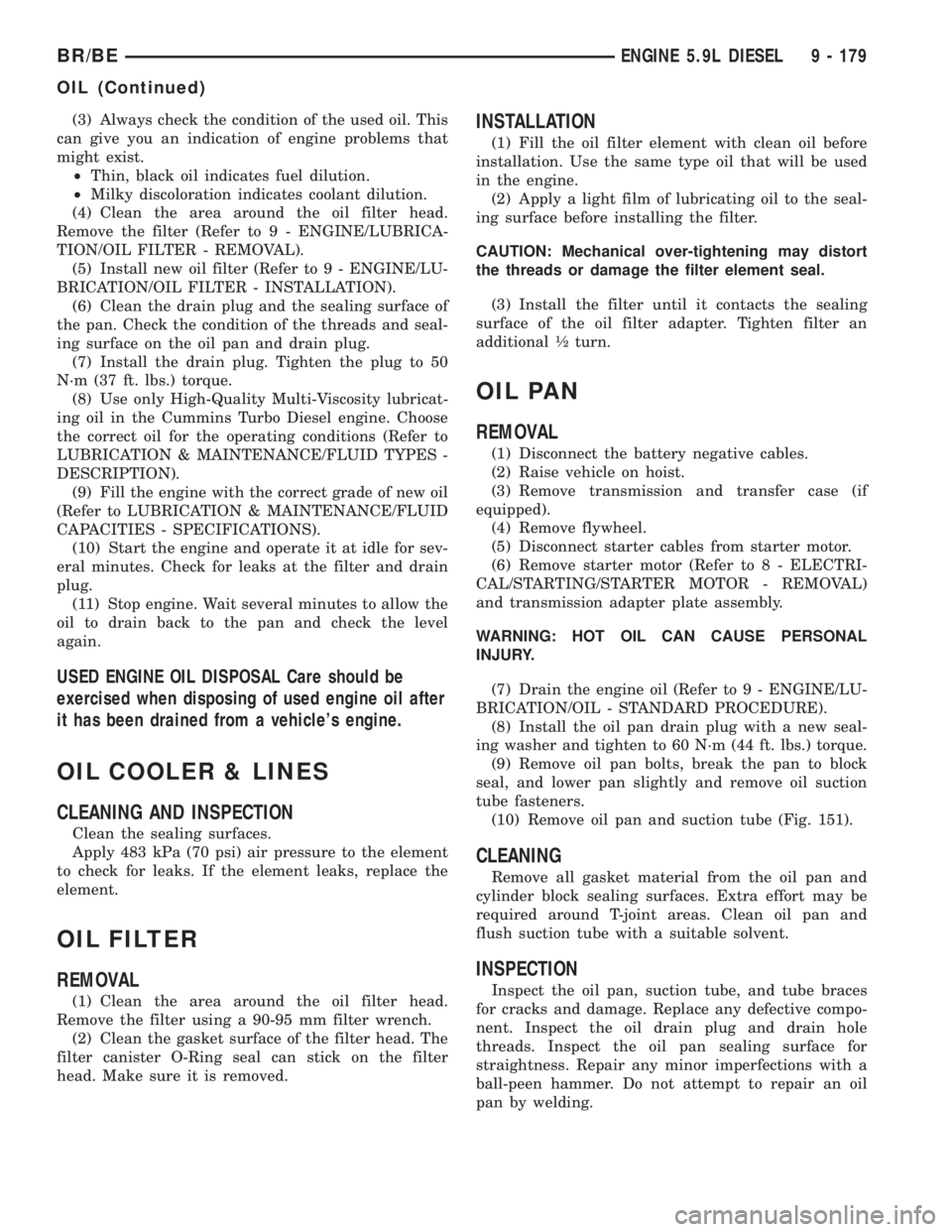

(10) Remove oil pan and suction tube (Fig. 151).

CLEANING

Remove all gasket material from the oil pan and

cylinder block sealing surfaces. Extra effort may be

required around T-joint areas. Clean oil pan and

flush suction tube with a suitable solvent.

INSPECTION

Inspect the oil pan, suction tube, and tube braces

for cracks and damage. Replace any defective compo-

nent. Inspect the oil drain plug and drain hole

threads. Inspect the oil pan sealing surface for

straightness. Repair any minor imperfections with a

ball-peen hammer. Do not attempt to repair an oil

pan by welding.

BR/BEENGINE 5.9L DIESEL 9 - 179

OIL (Continued)

Page 1255 of 2255

INSTALLATION

(1) Fill the T-joint between the pan rail/gear hous-

ing and pan rail/rear seal retainer with sealant. Use

MopartSilicone Rubber Adhesive Sealant or equiva-

lent.

(2) Apply a film of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the oil pan gasket.

Apply sealant only to the side that faces the oil pan.

(3) Place suction tube in oil pan and guide them

into place (Fig. 151). Using a new tube to oil pump

gasket, install and tighten the suction tube bolts by

hand. Starting with the oil pump inlet bolts, tighten

the bolts to 24 N´m (18 ft. lbs.) torque. Tighten the

remaining tube brace bolts to 24 N´m (18 ft. lbs.)

torque.

(4) Starting in the center and working outward,

tighten the oil pan bolts to 24 N´m (18 ft. lbs.)

torque.

(5) Install the flywheel housing assembly with the

starter motor attached and tighten bolts to 60 N´m

(44 ft. lbs.) torque.

(6) Connect starter motor cables.

(7) Install transmission and transfer case (if

equipped).

(8) Lower vehicle.

(9) Install battery negative cables.

(10) Fill the crankcase with new engine oil.

(11) Start engine and check for leaks. Stop engine,

check oil level, and adjust, if necessary.

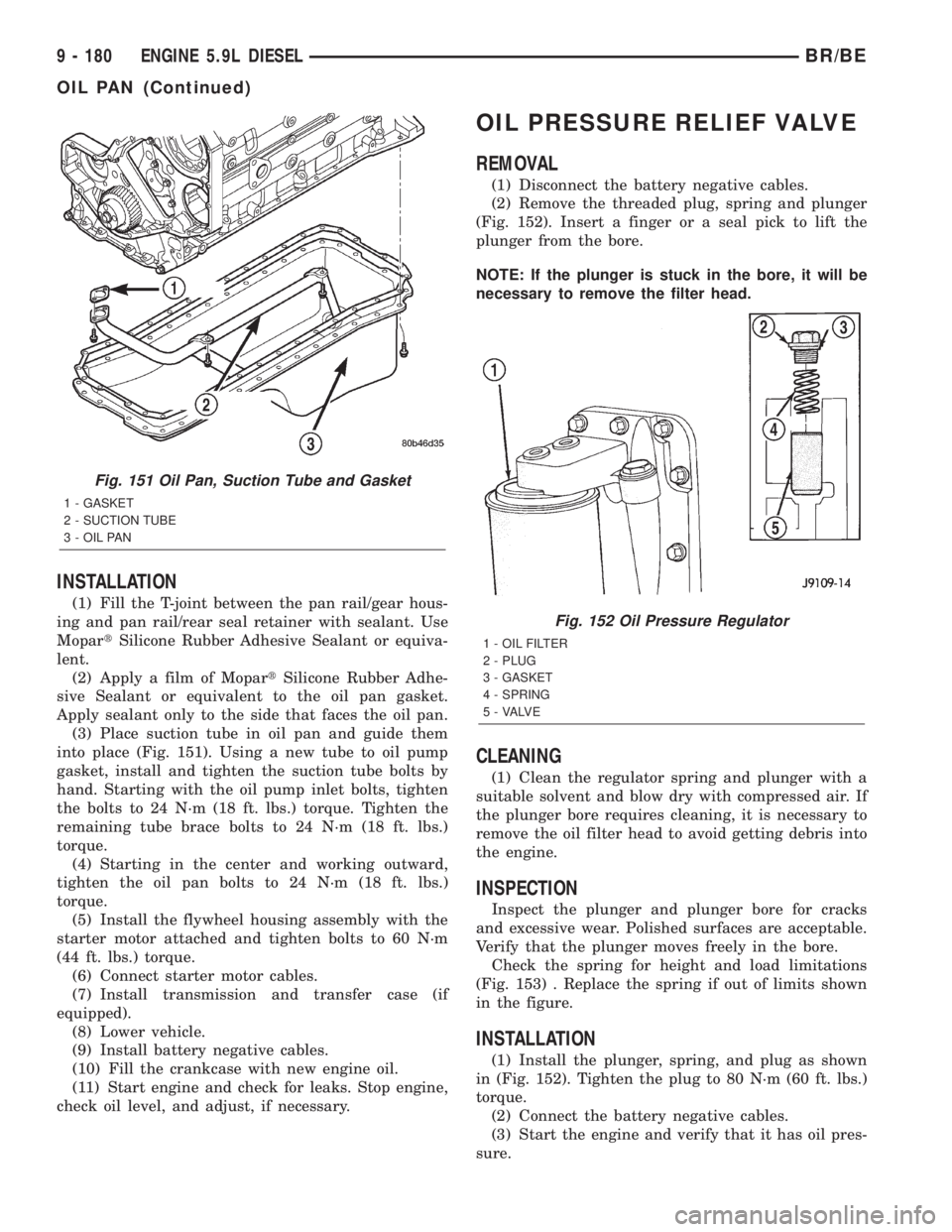

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the threaded plug, spring and plunger

(Fig. 152). Insert a finger or a seal pick to lift the

plunger from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

(1) Clean the regulator spring and plunger with a

suitable solvent and blow dry with compressed air. If

the plunger bore requires cleaning, it is necessary to

remove the oil filter head to avoid getting debris into

the engine.

INSPECTION

Inspect the plunger and plunger bore for cracks

and excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

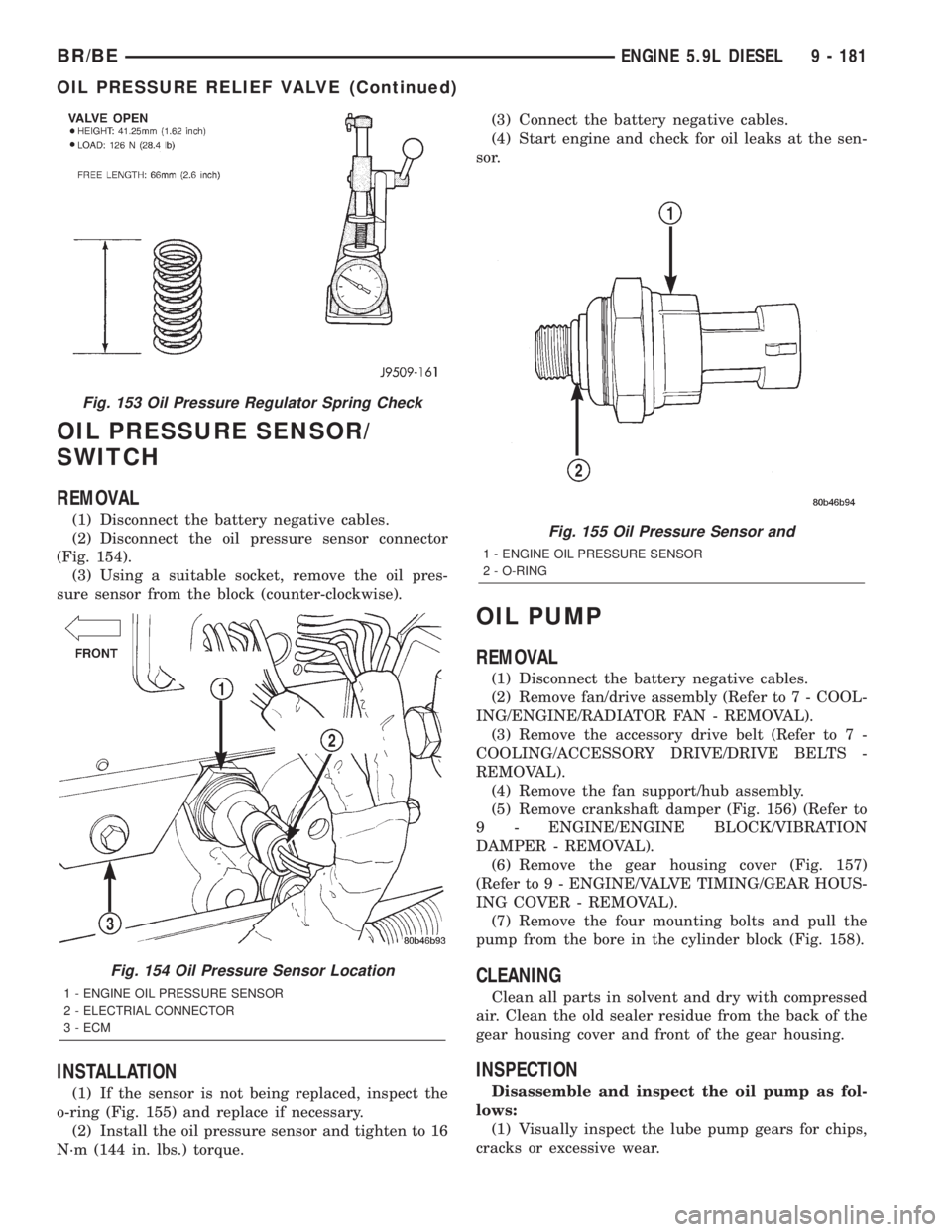

Check the spring for height and load limitations

(Fig. 153) . Replace the spring if out of limits shown

in the figure.

INSTALLATION

(1) Install the plunger, spring, and plug as shown

in (Fig. 152). Tighten the plug to 80 N´m (60 ft. lbs.)

torque.

(2) Connect the battery negative cables.

(3) Start the engine and verify that it has oil pres-

sure.

Fig. 151 Oil Pan, Suction Tube and Gasket

1 - GASKET

2 - SUCTION TUBE

3 - OIL PAN

Fig. 152 Oil Pressure Regulator

1 - OIL FILTER

2 - PLUG

3 - GASKET

4 - SPRING

5 - VALVE

9 - 180 ENGINE 5.9L DIESELBR/BE

OIL PAN (Continued)

Page 1256 of 2255

OIL PRESSURE SENSOR/

SWITCH

REMOVAL

(1) Disconnect the battery negative cables.

(2) Disconnect the oil pressure sensor connector

(Fig. 154).

(3) Using a suitable socket, remove the oil pres-

sure sensor from the block (counter-clockwise).

INSTALLATION

(1) If the sensor is not being replaced, inspect the

o-ring (Fig. 155) and replace if necessary.

(2) Install the oil pressure sensor and tighten to 16

N´m (144 in. lbs.) torque.(3) Connect the battery negative cables.

(4) Start engine and check for oil leaks at the sen-

sor.

OIL PUMP

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the fan support/hub assembly.

(5) Remove crankshaft damper (Fig. 156) (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(6) Remove the gear housing cover (Fig. 157)

(Refer to 9 - ENGINE/VALVE TIMING/GEAR HOUS-

ING COVER - REMOVAL).

(7) Remove the four mounting bolts and pull the

pump from the bore in the cylinder block (Fig. 158).

CLEANING

Clean all parts in solvent and dry with compressed

air. Clean the old sealer residue from the back of the

gear housing cover and front of the gear housing.

INSPECTION

Disassemble and inspect the oil pump as fol-

lows:

(1) Visually inspect the lube pump gears for chips,

cracks or excessive wear.

Fig. 155 Oil Pressure Sensor and

1 - ENGINE OIL PRESSURE SENSOR

2 - O-RING

Fig. 153 Oil Pressure Regulator Spring Check

Fig. 154 Oil Pressure Sensor Location

1 - ENGINE OIL PRESSURE SENSOR

2 - ELECTRIAL CONNECTOR

3 - ECM

BR/BEENGINE 5.9L DIESEL 9 - 181

OIL PRESSURE RELIEF VALVE (Continued)

Page 1259 of 2255

(7) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(8) Install the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

(9) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(10) Install the fan support/hub assembly and

torque bolts to 24 N´m (18 ft. lbs.).

(11) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(13) Connect battery negative cables.

(14) Start engine and check for oil leaks.

INTAKE MANIFOLD

REMOVAL

(1) Disconnect the battery negative cables.

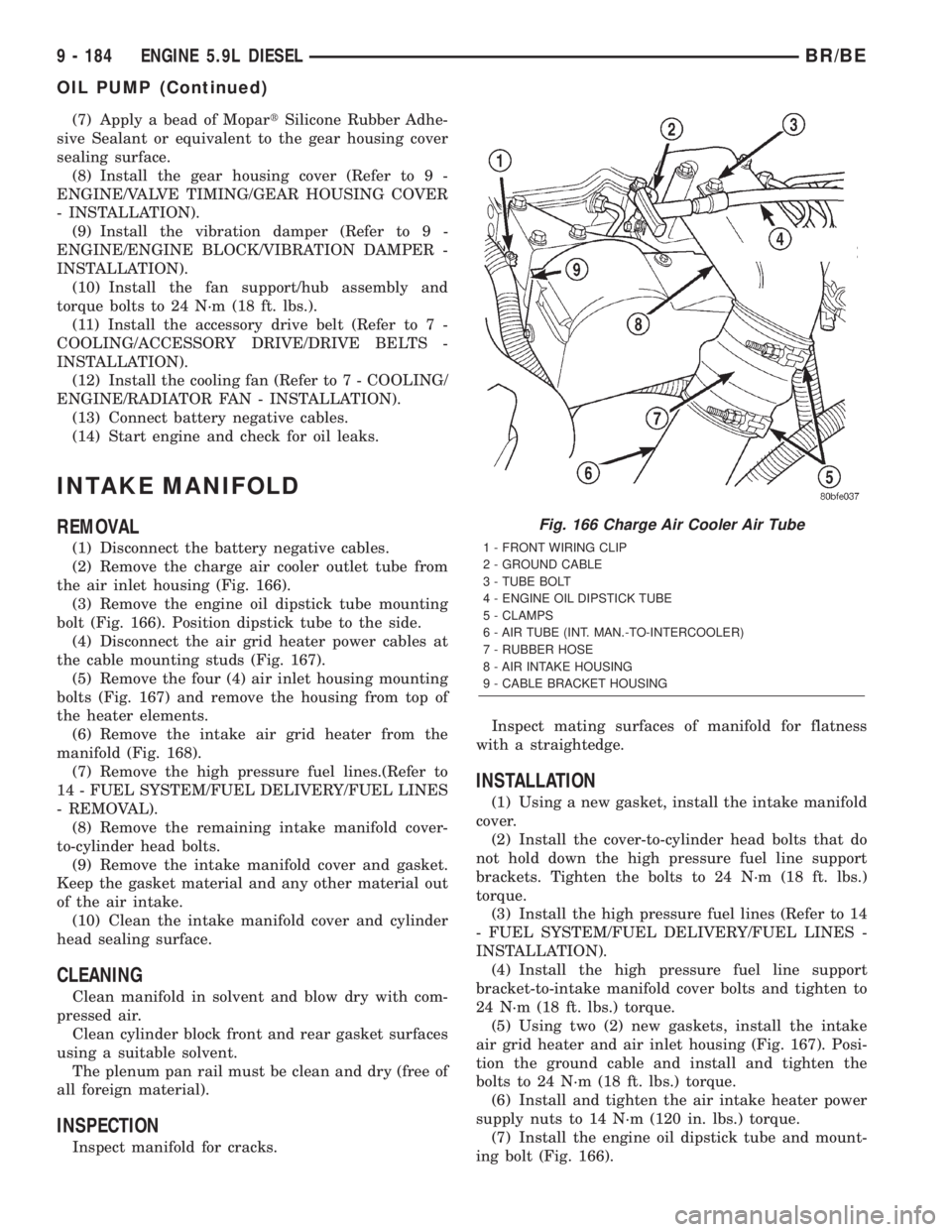

(2) Remove the charge air cooler outlet tube from

the air inlet housing (Fig. 166).

(3) Remove the engine oil dipstick tube mounting

bolt (Fig. 166). Position dipstick tube to the side.

(4) Disconnect the air grid heater power cables at

the cable mounting studs (Fig. 167).

(5) Remove the four (4) air inlet housing mounting

bolts (Fig. 167) and remove the housing from top of

the heater elements.

(6) Remove the intake air grid heater from the

manifold (Fig. 168).

(7) Remove the high pressure fuel lines.(Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- REMOVAL).

(8) Remove the remaining intake manifold cover-

to-cylinder head bolts.

(9) Remove the intake manifold cover and gasket.

Keep the gasket material and any other material out

of the air intake.

(10) Clean the intake manifold cover and cylinder

head sealing surface.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.Inspect mating surfaces of manifold for flatness

with a straightedge.

INSTALLATION

(1) Using a new gasket, install the intake manifold

cover.

(2) Install the cover-to-cylinder head bolts that do

not hold down the high pressure fuel line support

brackets. Tighten the bolts to 24 N´m (18 ft. lbs.)

torque.

(3) Install the high pressure fuel lines (Refer to 14

- FUEL SYSTEM/FUEL DELIVERY/FUEL LINES -

INSTALLATION).

(4) Install the high pressure fuel line support

bracket-to-intake manifold cover bolts and tighten to

24 N´m (18 ft. lbs.) torque.

(5) Using two (2) new gaskets, install the intake

air grid heater and air inlet housing (Fig. 167). Posi-

tion the ground cable and install and tighten the

bolts to 24 N´m (18 ft. lbs.) torque.

(6) Install and tighten the air intake heater power

supply nuts to 14 N´m (120 in. lbs.) torque.

(7) Install the engine oil dipstick tube and mount-

ing bolt (Fig. 166).

Fig. 166 Charge Air Cooler Air Tube

1 - FRONT WIRING CLIP

2 - GROUND CABLE

3 - TUBE BOLT

4 - ENGINE OIL DIPSTICK TUBE

5 - CLAMPS

6 - AIR TUBE (INT. MAN.-TO-INTERCOOLER)

7 - RUBBER HOSE

8 - AIR INTAKE HOUSING

9 - CABLE BRACKET HOUSING

9 - 184 ENGINE 5.9L DIESELBR/BE

OIL PUMP (Continued)

Page 1262 of 2255

(7) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 8 N´m (72 in. lbs.) torque.

(8) Position the air inlet hose to the turbocharger

(Fig. 170). Tighten the clamp to 8 N´m (72 in. lbs.)

torque.

(9) Raise vehicle on hoist.

(10) Connect the exhaust pipe to the turbocharger

(Fig. 169) and tighten the bolts to 34 N´m (25 ft. lbs.)

torque.

(11) Lower the vehicle.

(12) Connect the battery negative cables.

(13) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover.

(2) Remove fuel injector from cylinder number 1.

(3) Remove the crankcase breather from the gear

housing cover.

(4) Using Special Tool 7471B rotate the engine

until the timing mark on the fuel pump gear is

aligned with the TDC mark on the gear housing

cover.

(5) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(6) With piston number 1 at TDC the timing mark

on the fuel pump gear should be aligned with the

TDC mark on the gear housing cover. If marks do not

line up, remove the gear housing cover.

(7) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(8) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(9) If the keyway is at 12 o'clock position, verify

timing mark alignment between the camshaft gear,

crankshaft gear and the fuel pump gear, if not

aligned inspect keyway on camshaft gear.

(10) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(11) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove the fan shroud-to-radiator mounting

bolts.

(9) Remove viscous fan/drive assembly (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(10) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

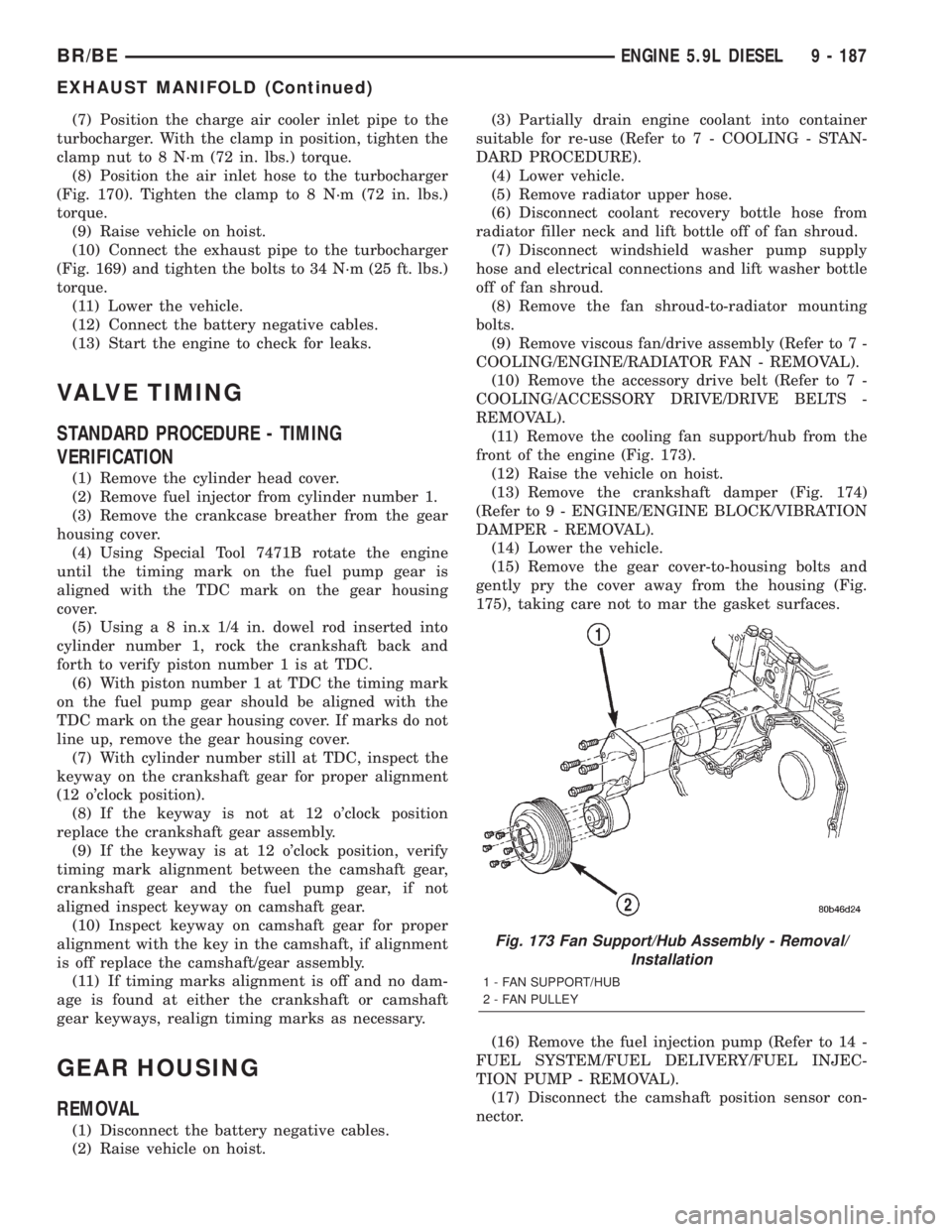

(11) Remove the cooling fan support/hub from the

front of the engine (Fig. 173).

(12) Raise the vehicle on hoist.

(13) Remove the crankshaft damper (Fig. 174)

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(14) Lower the vehicle.

(15) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing (Fig.

175), taking care not to mar the gasket surfaces.

(16) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(17) Disconnect the camshaft position sensor con-

nector.

Fig. 173 Fan Support/Hub Assembly - Removal/

Installation

1 - FAN SUPPORT/HUB

2 - FAN PULLEY

BR/BEENGINE 5.9L DIESEL 9 - 187

EXHAUST MANIFOLD (Continued)

Page 1284 of 2255

(b) Move the impeller shaft fore and aft and

record the measurement. Allowable end play is

0.038 mm (0.0015 in.) MIN. and 0.089 mm (0.0035

in.) MAX. If the recorded measurement falls out-

side these parameters, replace the turbocharger

assembly.

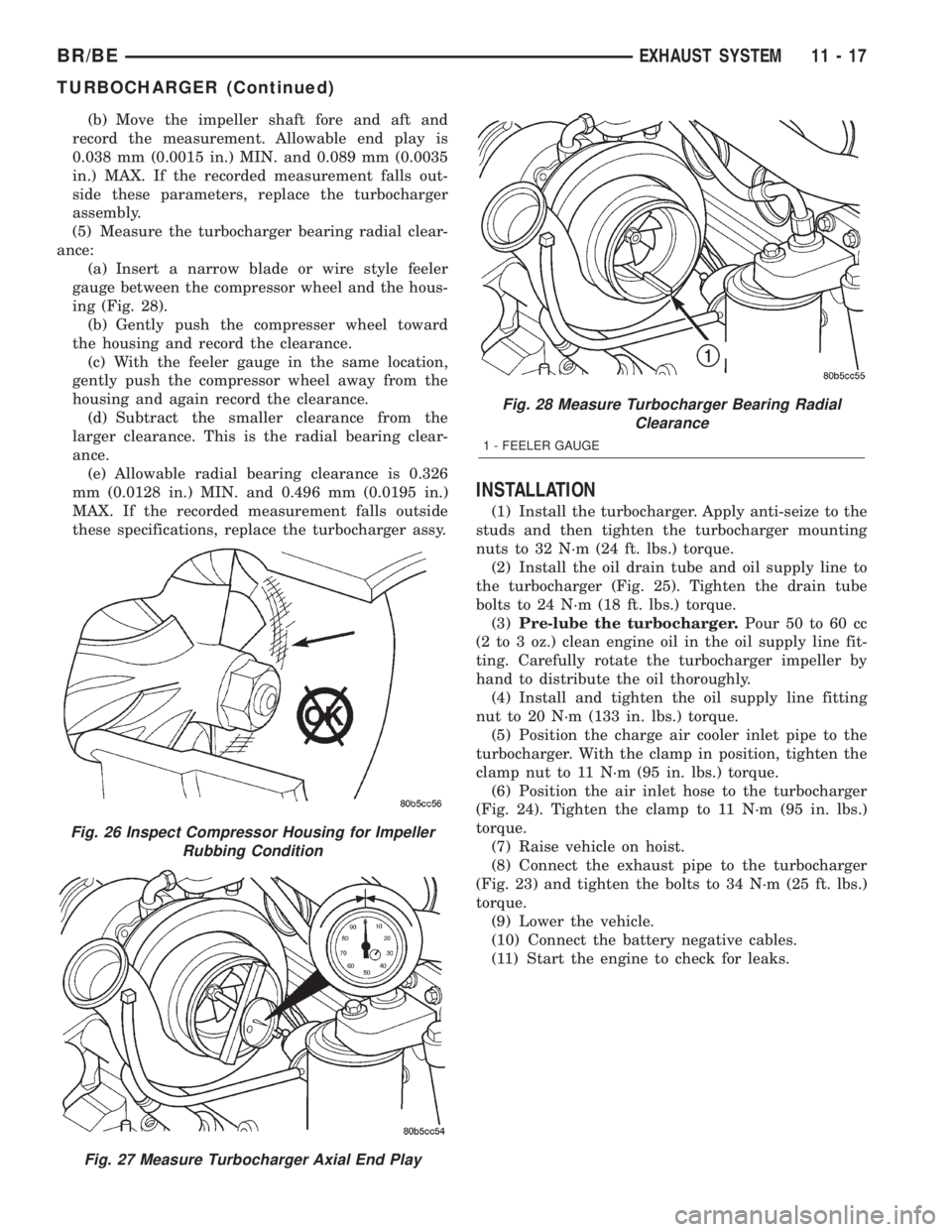

(5) Measure the turbocharger bearing radial clear-

ance:

(a) Insert a narrow blade or wire style feeler

gauge between the compressor wheel and the hous-

ing (Fig. 28).

(b) Gently push the compresser wheel toward

the housing and record the clearance.

(c) With the feeler gauge in the same location,

gently push the compressor wheel away from the

housing and again record the clearance.

(d) Subtract the smaller clearance from the

larger clearance. This is the radial bearing clear-

ance.

(e) Allowable radial bearing clearance is 0.326

mm (0.0128 in.) MIN. and 0.496 mm (0.0195 in.)

MAX. If the recorded measurement falls outside

these specifications, replace the turbocharger assy.

INSTALLATION

(1) Install the turbocharger. Apply anti-seize to the

studs and then tighten the turbocharger mounting

nuts to 32 N´m (24 ft. lbs.) torque.

(2) Install the oil drain tube and oil supply line to

the turbocharger (Fig. 25). Tighten the drain tube

bolts to 24 N´m (18 ft. lbs.) torque.

(3)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting. Carefully rotate the turbocharger impeller by

hand to distribute the oil thoroughly.

(4) Install and tighten the oil supply line fitting

nut to 20 N´m (133 in. lbs.) torque.

(5) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 11 N´m (95 in. lbs.) torque.

(6) Position the air inlet hose to the turbocharger

(Fig. 24). Tighten the clamp to 11 N´m (95 in. lbs.)

torque.

(7) Raise vehicle on hoist.

(8) Connect the exhaust pipe to the turbocharger

(Fig. 23) and tighten the bolts to 34 N´m (25 ft. lbs.)

torque.

(9) Lower the vehicle.

(10) Connect the battery negative cables.

(11) Start the engine to check for leaks.

Fig. 26 Inspect Compressor Housing for Impeller

Rubbing Condition

Fig. 27 Measure Turbocharger Axial End Play

Fig. 28 Measure Turbocharger Bearing Radial

Clearance

1 - FEELER GAUGE

BR/BEEXHAUST SYSTEM 11 - 17

TURBOCHARGER (Continued)

Page 1285 of 2255

CHARGE AIR COOLER AND

PLUMBING

DESCRIPTION

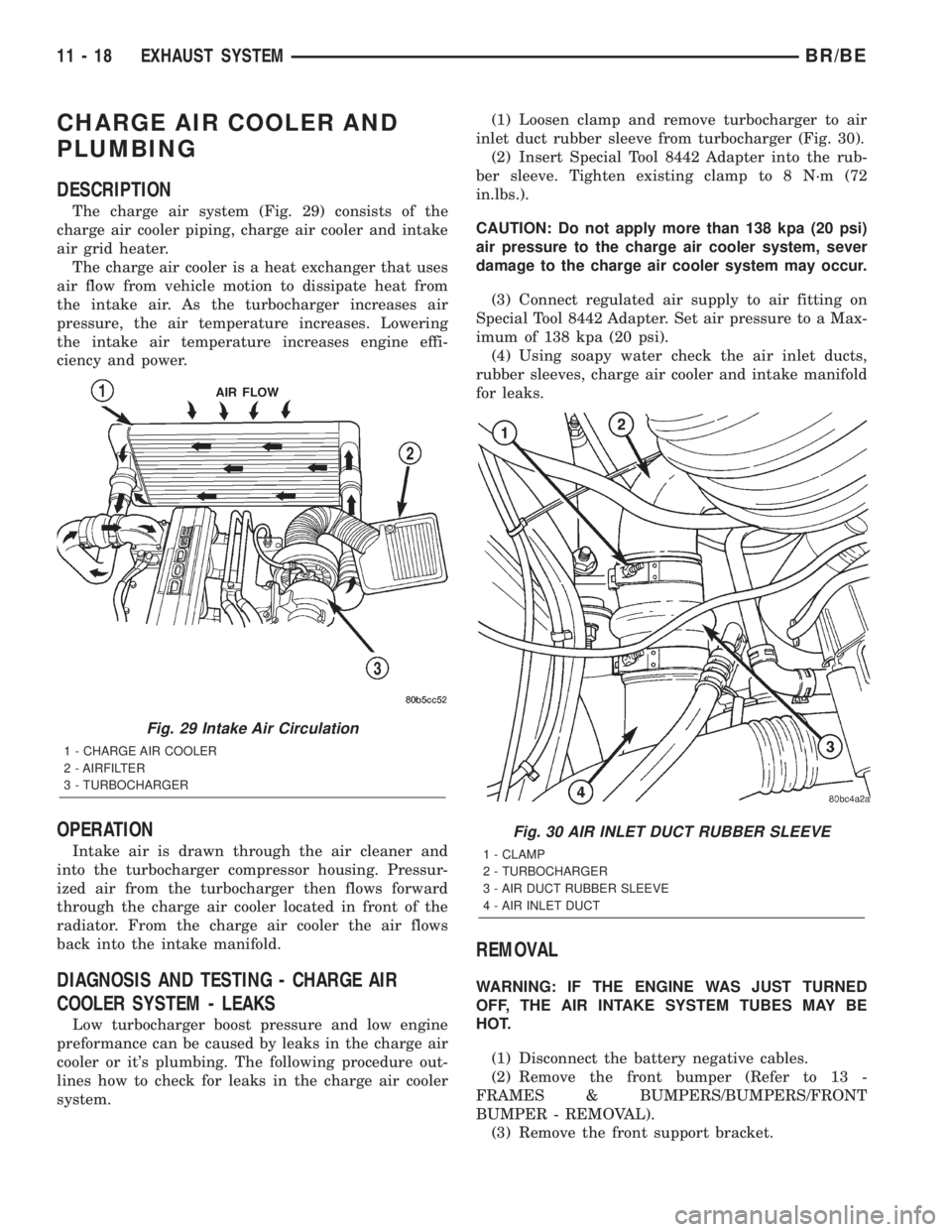

The charge air system (Fig. 29) consists of the

charge air cooler piping, charge air cooler and intake

air grid heater.

The charge air cooler is a heat exchanger that uses

air flow from vehicle motion to dissipate heat from

the intake air. As the turbocharger increases air

pressure, the air temperature increases. Lowering

the intake air temperature increases engine effi-

ciency and power.

OPERATION

Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressur-

ized air from the turbocharger then flows forward

through the charge air cooler located in front of the

radiator. From the charge air cooler the air flows

back into the intake manifold.

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS

Low turbocharger boost pressure and low engine

preformance can be caused by leaks in the charge air

cooler or it's plumbing. The following procedure out-

lines how to check for leaks in the charge air cooler

system.(1) Loosen clamp and remove turbocharger to air

inlet duct rubber sleeve from turbocharger (Fig. 30).

(2) Insert Special Tool 8442 Adapter into the rub-

ber sleeve. Tighten existing clamp to 8 N´m (72

in.lbs.).

CAUTION: Do not apply more than 138 kpa (20 psi)

air pressure to the charge air cooler system, sever

damage to the charge air cooler system may occur.

(3) Connect regulated air supply to air fitting on

Special Tool 8442 Adapter. Set air pressure to a Max-

imum of 138 kpa (20 psi).

(4) Using soapy water check the air inlet ducts,

rubber sleeves, charge air cooler and intake manifold

for leaks.

REMOVAL

WARNING: IF THE ENGINE WAS JUST TURNED

OFF, THE AIR INTAKE SYSTEM TUBES MAY BE

HOT.

(1) Disconnect the battery negative cables.

(2) Remove the front bumper (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - REMOVAL).

(3) Remove the front support bracket.

Fig. 29 Intake Air Circulation

1 - CHARGE AIR COOLER

2 - AIRFILTER

3 - TURBOCHARGER

Fig. 30 AIR INLET DUCT RUBBER SLEEVE

1 - CLAMP

2 - TURBOCHARGER

3 - AIR DUCT RUBBER SLEEVE

4 - AIR INLET DUCT

11 - 18 EXHAUST SYSTEMBR/BE

Page 1287 of 2255

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4) Install the A/C condenser (if A/C equipped)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).Recharge A/C system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(5) Install the front support bracket. Install and

tighten the bolts.

(6) Install the front bumper (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT

BUMPER - INSTALLATION).

(7) Connect the battery negative cables.

(8) Start engine and check for boost system leaks.

11 - 20 EXHAUST SYSTEMBR/BE

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1300 of 2255

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GASOLINE...............1

FUEL INJECTION - GASOLINE..............28FUEL DELIVERY - DIESEL.................54

FUEL INJECTION - DIESEL................91

FUEL DELIVERY - GASOLINE

TABLE OF CONTENTS

page page

FUEL DELIVERY - GASOLINE

DESCRIPTION - FUEL DELIVERY SYSTEM....2

OPERATION - FUEL DELIVERY SYSTEM......2

DIAGNOSIS AND TESTING - FUEL

PRESSURE LEAK DOWN TEST...........2

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE...................3

SPECIFICATIONS

SPECIFICATIONS - FUEL SYSTEM

PRESSURE - GAS ENGINES..............3

SPECIFICATIONS - TORQUE - FUEL

DELIVERY............................4

SPECIAL TOOLS

FUEL SYSTEM........................4

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................7

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - FUEL GAUGE

SENDING UNIT........................7

REMOVAL.............................7

INSTALLATION..........................8

FUEL LINES

DESCRIPTION..........................8

FUEL PUMP

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FUEL PUMP

CAPACITY TEST.......................9

DIAGNOSIS AND TESTING - FUEL PUMP

PRESSURE TEST......................9DIAGNOSIS AND TESTING - FUEL PUMP

AMPERAGE TEST.....................10

FUEL PUMP MODULE

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

FUEL RAIL

DESCRIPTION

DESCRIPTION - 5.9L...................14

DESCRIPTION - 8.0L...................14

OPERATION

OPERATION - 5.9L....................14

OPERATION - 8.0L....................15

REMOVAL

REMOVAL - 5.9L......................15

REMOVAL - 8.0L......................16

INSTALLATION

INSTALLATION - 5.9L..................17

INSTALLATION - 8.0L..................18

FUEL TANK

DESCRIPTION.........................18

OPERATION...........................18

REMOVAL.............................18

INSTALLATION.........................20

FUEL TANK CHECK VALVE

DESCRIPTION.........................21

REMOVAL.............................22

INSTALLATION.........................23

INLET FILTER

REMOVAL.............................23

INSTALLATION.........................23

QUICK CONNECT FITTING

DESCRIPTION.........................24

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS...........................24

BR/BEFUEL SYSTEM 14 - 1