DODGE RAM 2002 Service Repair Manual

Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2051 of 2255

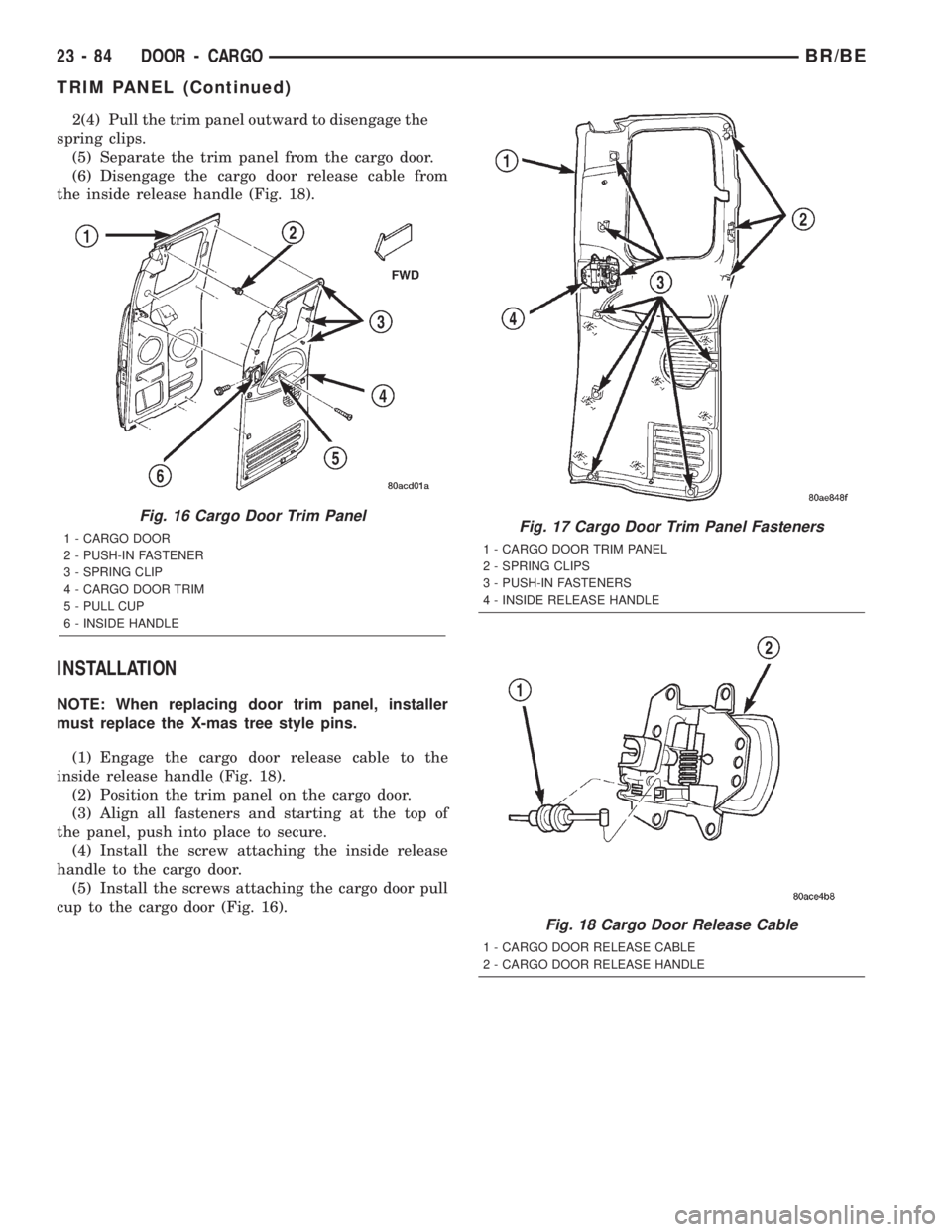

2(4) Pull the trim panel outward to disengage the

spring clips.

(5) Separate the trim panel from the cargo door.

(6) Disengage the cargo door release cable from

the inside release handle (Fig. 18).

INSTALLATION

NOTE: When replacing door trim panel, installer

must replace the X-mas tree style pins.

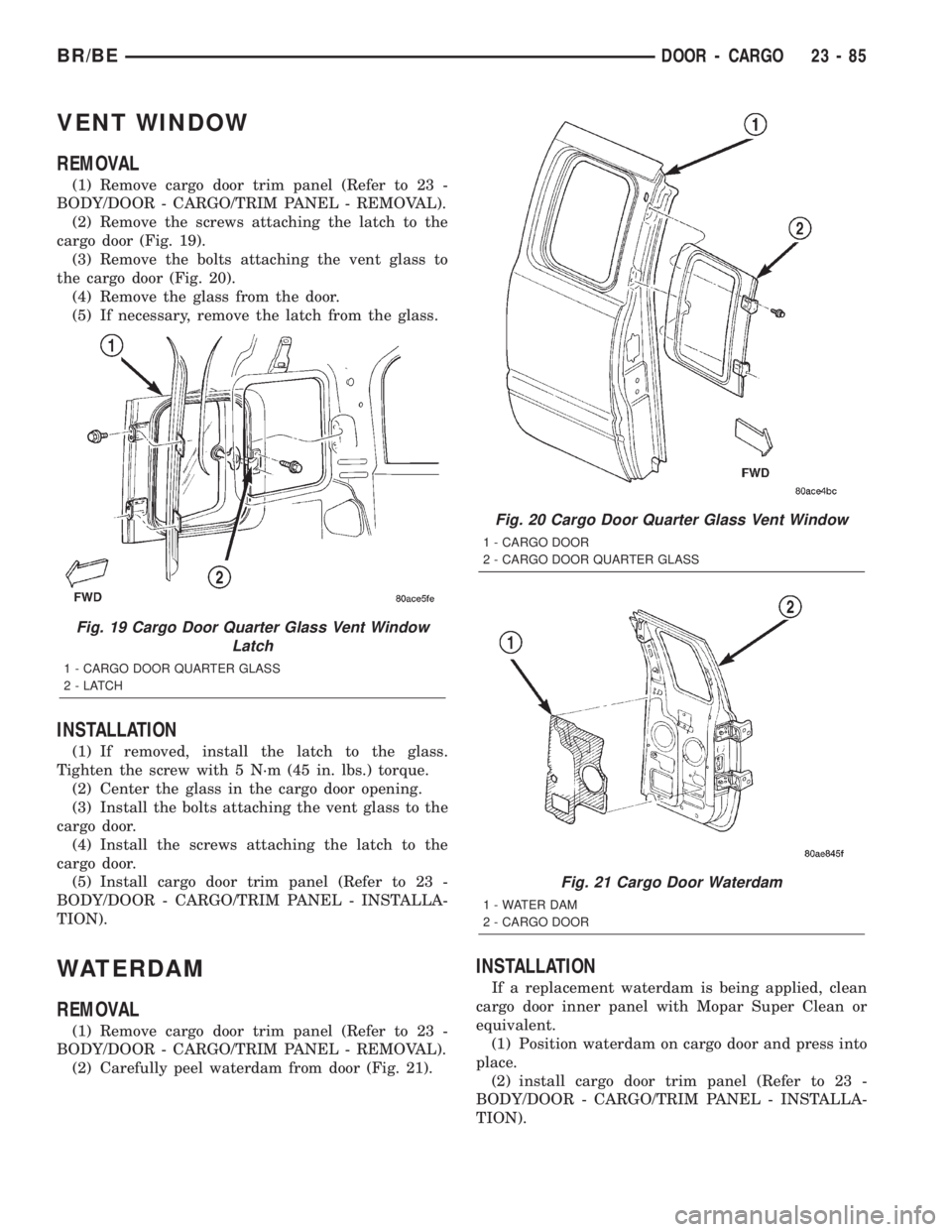

(1) Engage the cargo door release cable to the

inside release handle (Fig. 18).

(2) Position the trim panel on the cargo door.

(3) Align all fasteners and starting at the top of

the panel, push into place to secure.

(4) Install the screw attaching the inside release

handle to the cargo door.

(5) Install the screws attaching the cargo door pull

cup to the cargo door (Fig. 16).

Fig. 16 Cargo Door Trim Panel

1 - CARGO DOOR

2 - PUSH-IN FASTENER

3 - SPRING CLIP

4 - CARGO DOOR TRIM

5 - PULL CUP

6 - INSIDE HANDLEFig. 17 Cargo Door Trim Panel Fasteners

1 - CARGO DOOR TRIM PANEL

2 - SPRING CLIPS

3 - PUSH-IN FASTENERS

4 - INSIDE RELEASE HANDLE

Fig. 18 Cargo Door Release Cable

1 - CARGO DOOR RELEASE CABLE

2 - CARGO DOOR RELEASE HANDLE

23 - 84 DOOR - CARGOBR/BE

TRIM PANEL (Continued)

Page 2052 of 2255

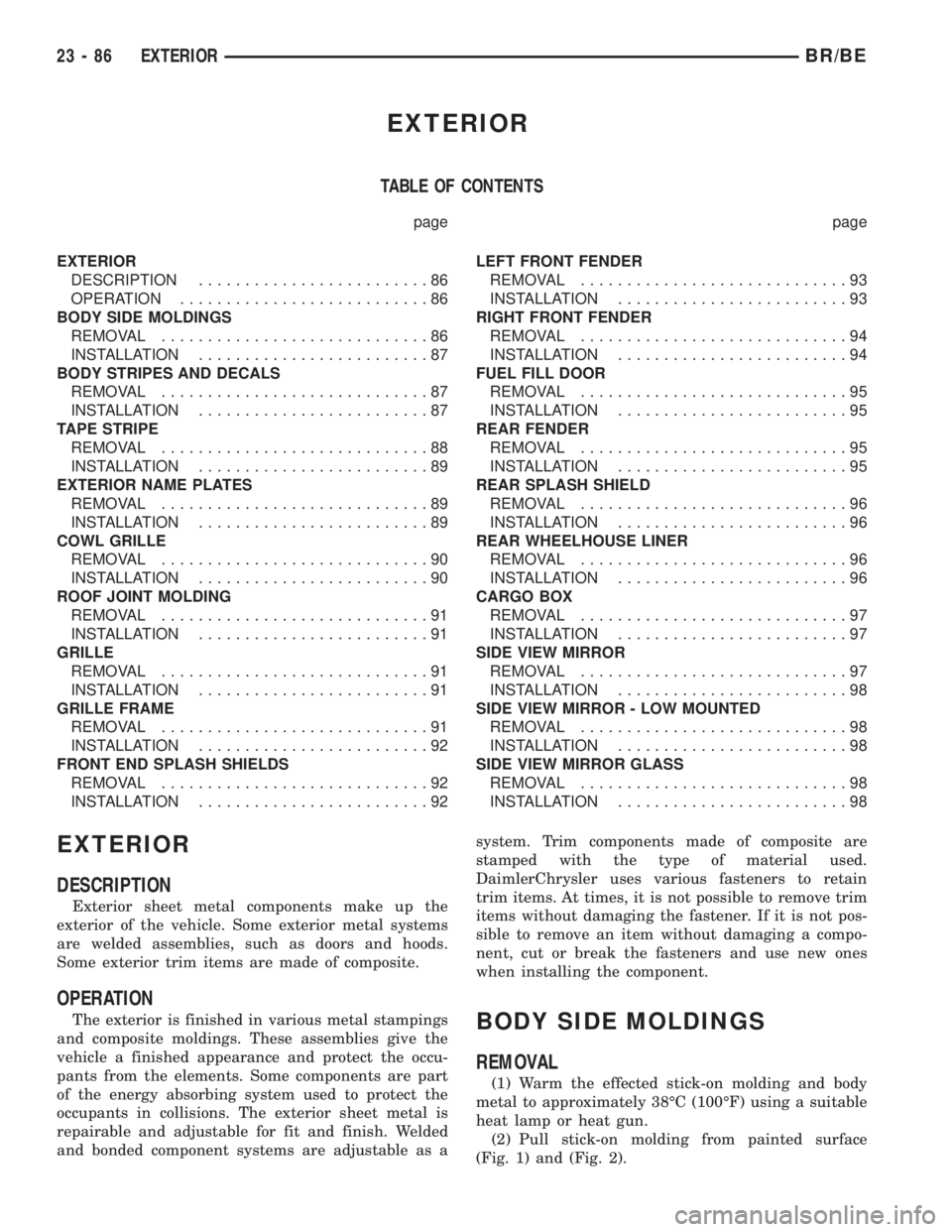

VENT WINDOW

REMOVAL

(1) Remove cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - REMOVAL).

(2) Remove the screws attaching the latch to the

cargo door (Fig. 19).

(3) Remove the bolts attaching the vent glass to

the cargo door (Fig. 20).

(4) Remove the glass from the door.

(5) If necessary, remove the latch from the glass.

INSTALLATION

(1) If removed, install the latch to the glass.

Tighten the screw with 5 N´m (45 in. lbs.) torque.

(2) Center the glass in the cargo door opening.

(3) Install the bolts attaching the vent glass to the

cargo door.

(4) Install the screws attaching the latch to the

cargo door.

(5) Install cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - INSTALLA-

TION).

WATERDAM

REMOVAL

(1) Remove cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - REMOVAL).

(2) Carefully peel waterdam from door (Fig. 21).

INSTALLATION

If a replacement waterdam is being applied, clean

cargo door inner panel with Mopar Super Clean or

equivalent.

(1) Position waterdam on cargo door and press into

place.

(2) install cargo door trim panel (Refer to 23 -

BODY/DOOR - CARGO/TRIM PANEL - INSTALLA-

TION).

Fig. 19 Cargo Door Quarter Glass Vent Window

Latch

1 - CARGO DOOR QUARTER GLASS

2-LATCH

Fig. 20 Cargo Door Quarter Glass Vent Window

1 - CARGO DOOR

2 - CARGO DOOR QUARTER GLASS

Fig. 21 Cargo Door Waterdam

1 - WATER DAM

2 - CARGO DOOR

BR/BEDOOR - CARGO 23 - 85

Page 2053 of 2255

EXTERIOR

TABLE OF CONTENTS

page page

EXTERIOR

DESCRIPTION.........................86

OPERATION...........................86

BODY SIDE MOLDINGS

REMOVAL.............................86

INSTALLATION.........................87

BODY STRIPES AND DECALS

REMOVAL.............................87

INSTALLATION.........................87

TAPE STRIPE

REMOVAL.............................88

INSTALLATION.........................89

EXTERIOR NAME PLATES

REMOVAL.............................89

INSTALLATION.........................89

COWL GRILLE

REMOVAL.............................90

INSTALLATION.........................90

ROOF JOINT MOLDING

REMOVAL.............................91

INSTALLATION.........................91

GRILLE

REMOVAL.............................91

INSTALLATION.........................91

GRILLE FRAME

REMOVAL.............................91

INSTALLATION.........................92

FRONT END SPLASH SHIELDS

REMOVAL.............................92

INSTALLATION.........................92LEFT FRONT FENDER

REMOVAL.............................93

INSTALLATION.........................93

RIGHT FRONT FENDER

REMOVAL.............................94

INSTALLATION.........................94

FUEL FILL DOOR

REMOVAL.............................95

INSTALLATION.........................95

REAR FENDER

REMOVAL.............................95

INSTALLATION.........................95

REAR SPLASH SHIELD

REMOVAL.............................96

INSTALLATION.........................96

REAR WHEELHOUSE LINER

REMOVAL.............................96

INSTALLATION.........................96

CARGO BOX

REMOVAL.............................97

INSTALLATION.........................97

SIDE VIEW MIRROR

REMOVAL.............................97

INSTALLATION.........................98

SIDE VIEW MIRROR - LOW MOUNTED

REMOVAL.............................98

INSTALLATION.........................98

SIDE VIEW MIRROR GLASS

REMOVAL.............................98

INSTALLATION.........................98

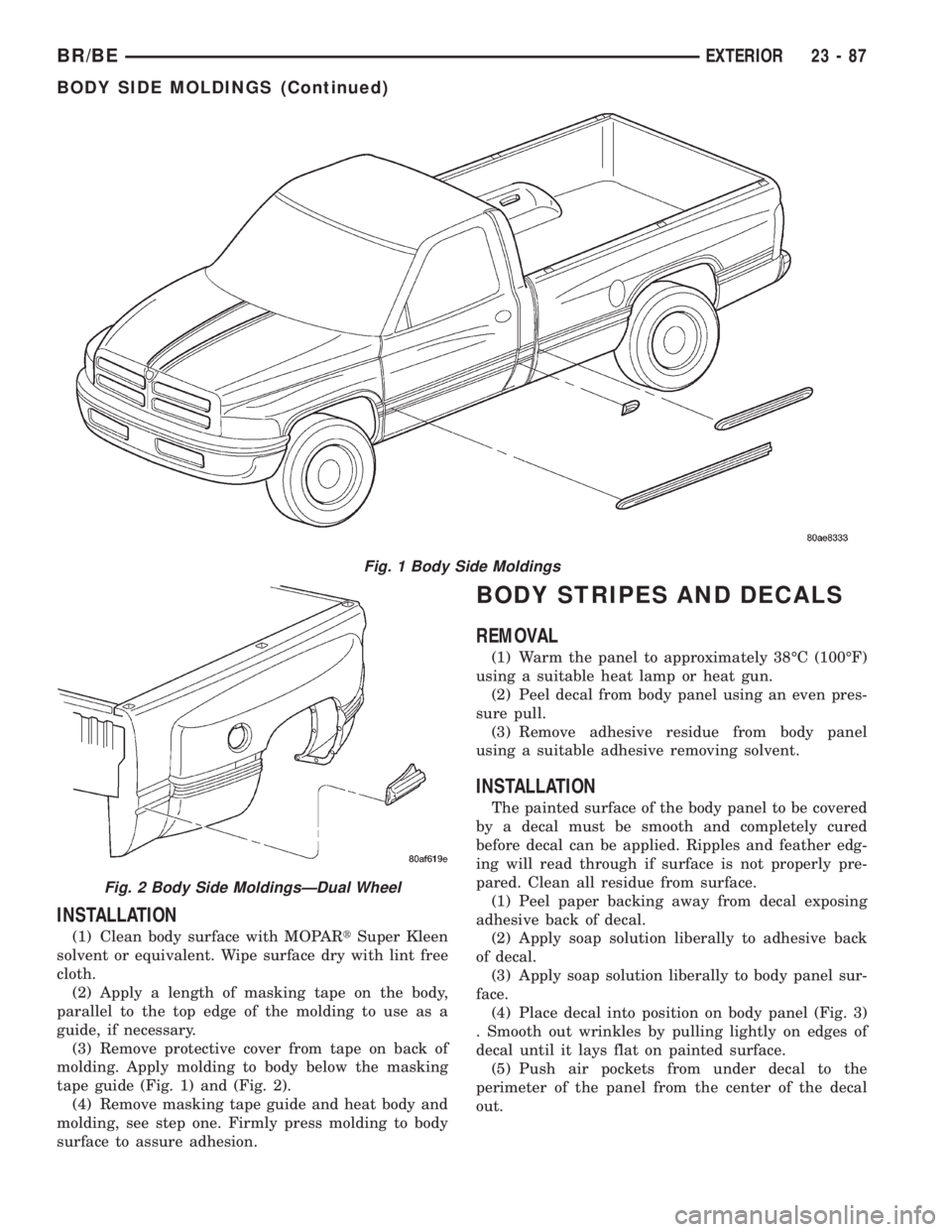

EXTERIOR

DESCRIPTION

Exterior sheet metal components make up the

exterior of the vehicle. Some exterior metal systems

are welded assemblies, such as doors and hoods.

Some exterior trim items are made of composite.

OPERATION

The exterior is finished in various metal stampings

and composite moldings. These assemblies give the

vehicle a finished appearance and protect the occu-

pants from the elements. Some components are part

of the energy absorbing system used to protect the

occupants in collisions. The exterior sheet metal is

repairable and adjustable for fit and finish. Welded

and bonded component systems are adjustable as asystem. Trim components made of composite are

stamped with the type of material used.

DaimlerChrysler uses various fasteners to retain

trim items. At times, it is not possible to remove trim

items without damaging the fastener. If it is not pos-

sible to remove an item without damaging a compo-

nent, cut or break the fasteners and use new ones

when installing the component.BODY SIDE MOLDINGS

REMOVAL

(1) Warm the effected stick-on molding and body

metal to approximately 38ÉC (100ÉF) using a suitable

heat lamp or heat gun.

(2) Pull stick-on molding from painted surface

(Fig. 1) and (Fig. 2).

23 - 86 EXTERIORBR/BE

Page 2054 of 2255

INSTALLATION

(1) Clean body surface with MOPARtSuper Kleen

solvent or equivalent. Wipe surface dry with lint free

cloth.

(2) Apply a length of masking tape on the body,

parallel to the top edge of the molding to use as a

guide, if necessary.

(3) Remove protective cover from tape on back of

molding. Apply molding to body below the masking

tape guide (Fig. 1) and (Fig. 2).

(4) Remove masking tape guide and heat body and

molding, see step one. Firmly press molding to body

surface to assure adhesion.

BODY STRIPES AND DECALS

REMOVAL

(1) Warm the panel to approximately 38ÉC (100ÉF)

using a suitable heat lamp or heat gun.

(2) Peel decal from body panel using an even pres-

sure pull.

(3) Remove adhesive residue from body panel

using a suitable adhesive removing solvent.

INSTALLATION

The painted surface of the body panel to be covered

by a decal must be smooth and completely cured

before decal can be applied. Ripples and feather edg-

ing will read through if surface is not properly pre-

pared. Clean all residue from surface.

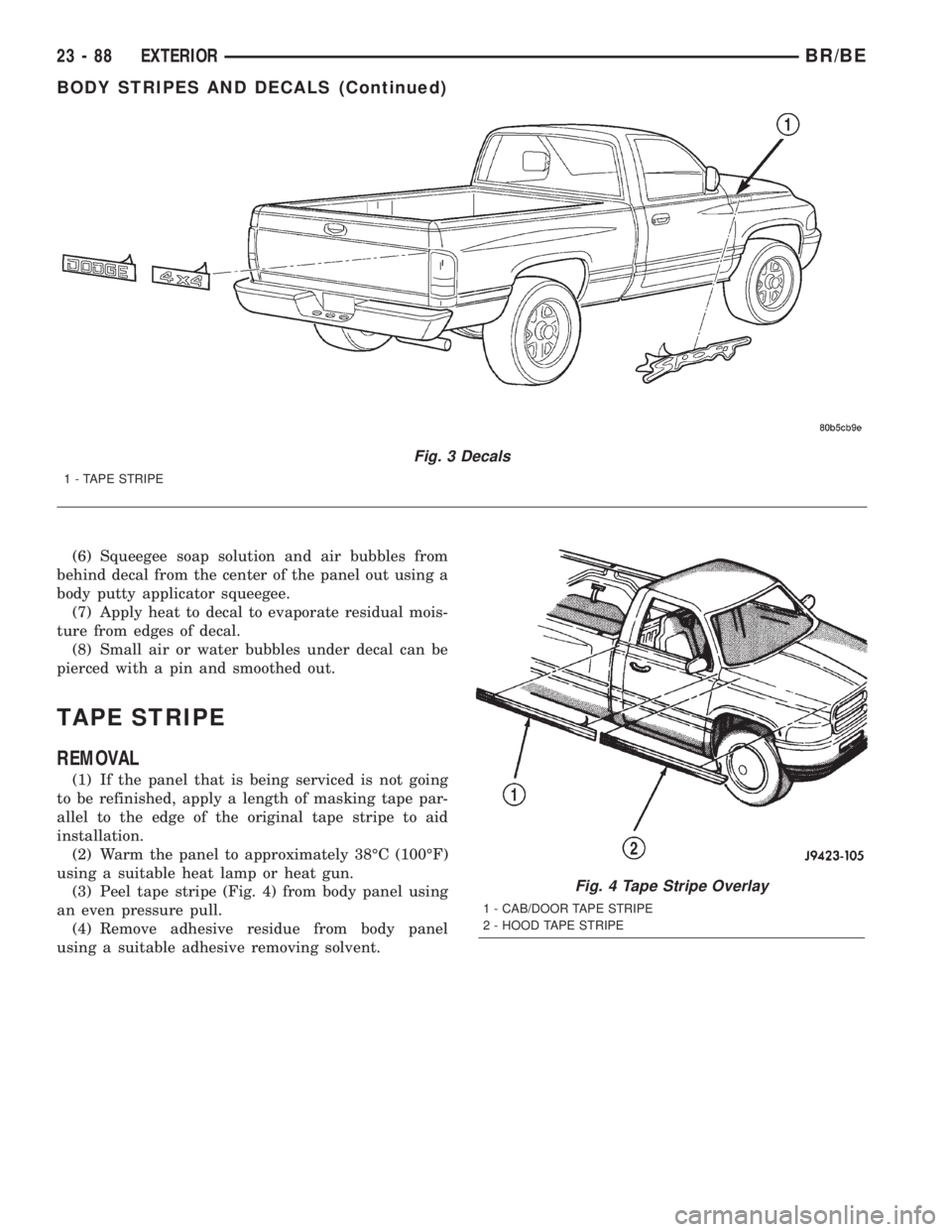

(1) Peel paper backing away from decal exposing

adhesive back of decal.

(2) Apply soap solution liberally to adhesive back

of decal.

(3) Apply soap solution liberally to body panel sur-

face.

(4) Place decal into position on body panel (Fig. 3)

. Smooth out wrinkles by pulling lightly on edges of

decal until it lays flat on painted surface.

(5) Push air pockets from under decal to the

perimeter of the panel from the center of the decal

out.

Fig. 1 Body Side Moldings

Fig. 2 Body Side MoldingsÐDual Wheel

BR/BEEXTERIOR 23 - 87

BODY SIDE MOLDINGS (Continued)

Page 2055 of 2255

(6) Squeegee soap solution and air bubbles from

behind decal from the center of the panel out using a

body putty applicator squeegee.

(7) Apply heat to decal to evaporate residual mois-

ture from edges of decal.

(8) Small air or water bubbles under decal can be

pierced with a pin and smoothed out.

TAPE STRIPE

REMOVAL

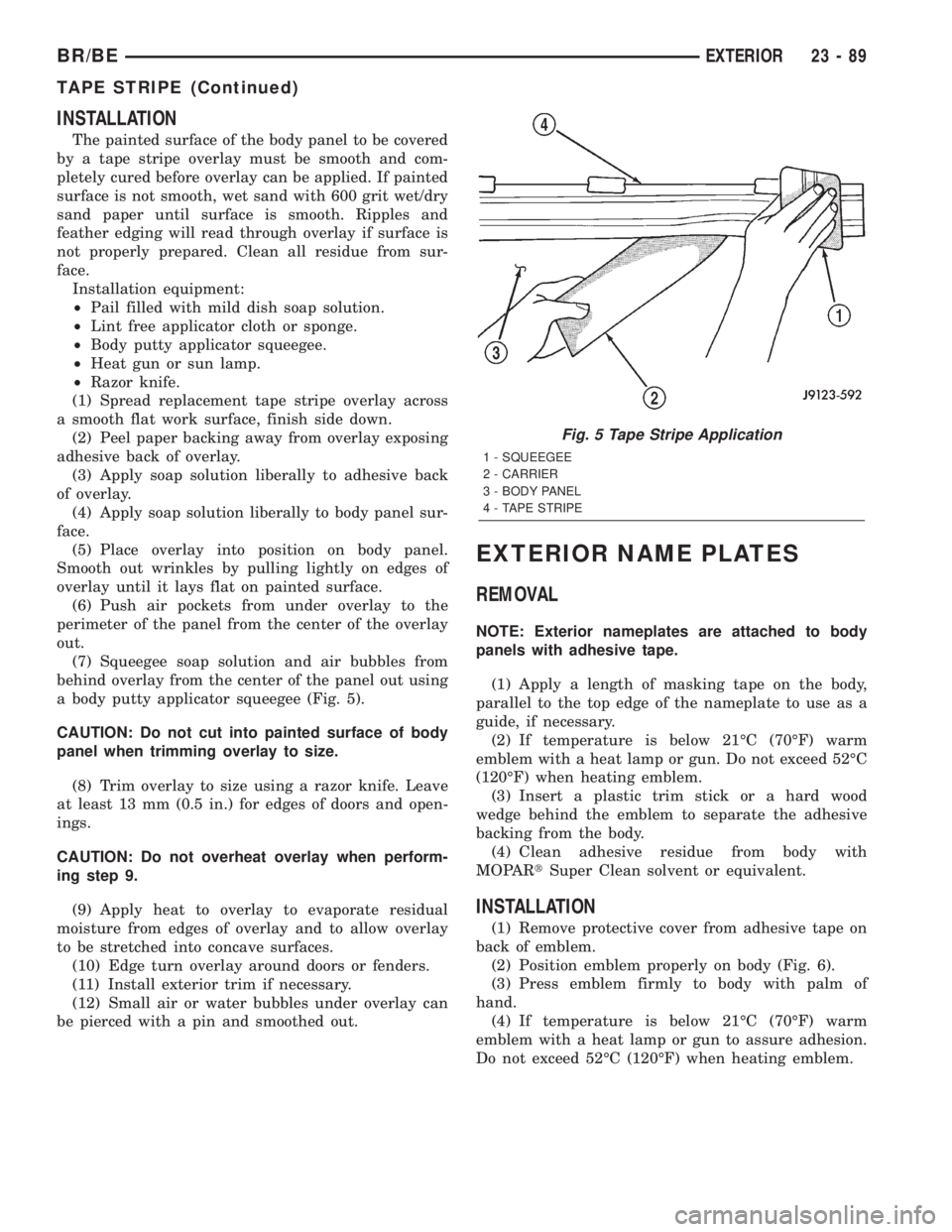

(1) If the panel that is being serviced is not going

to be refinished, apply a length of masking tape par-

allel to the edge of the original tape stripe to aid

installation.

(2) Warm the panel to approximately 38ÉC (100ÉF)

using a suitable heat lamp or heat gun.

(3) Peel tape stripe (Fig. 4) from body panel using

an even pressure pull.

(4) Remove adhesive residue from body panel

using a suitable adhesive removing solvent.

Fig. 3 Decals

1 - TAPE STRIPE

Fig. 4 Tape Stripe Overlay

1 - CAB/DOOR TAPE STRIPE

2 - HOOD TAPE STRIPE

23 - 88 EXTERIORBR/BE

BODY STRIPES AND DECALS (Continued)

Page 2056 of 2255

INSTALLATION

The painted surface of the body panel to be covered

by a tape stripe overlay must be smooth and com-

pletely cured before overlay can be applied. If painted

surface is not smooth, wet sand with 600 grit wet/dry

sand paper until surface is smooth. Ripples and

feather edging will read through overlay if surface is

not properly prepared. Clean all residue from sur-

face.

Installation equipment:

²Pail filled with mild dish soap solution.

²Lint free applicator cloth or sponge.

²Body putty applicator squeegee.

²Heat gun or sun lamp.

²Razor knife.

(1) Spread replacement tape stripe overlay across

a smooth flat work surface, finish side down.

(2) Peel paper backing away from overlay exposing

adhesive back of overlay.

(3) Apply soap solution liberally to adhesive back

of overlay.

(4) Apply soap solution liberally to body panel sur-

face.

(5) Place overlay into position on body panel.

Smooth out wrinkles by pulling lightly on edges of

overlay until it lays flat on painted surface.

(6) Push air pockets from under overlay to the

perimeter of the panel from the center of the overlay

out.

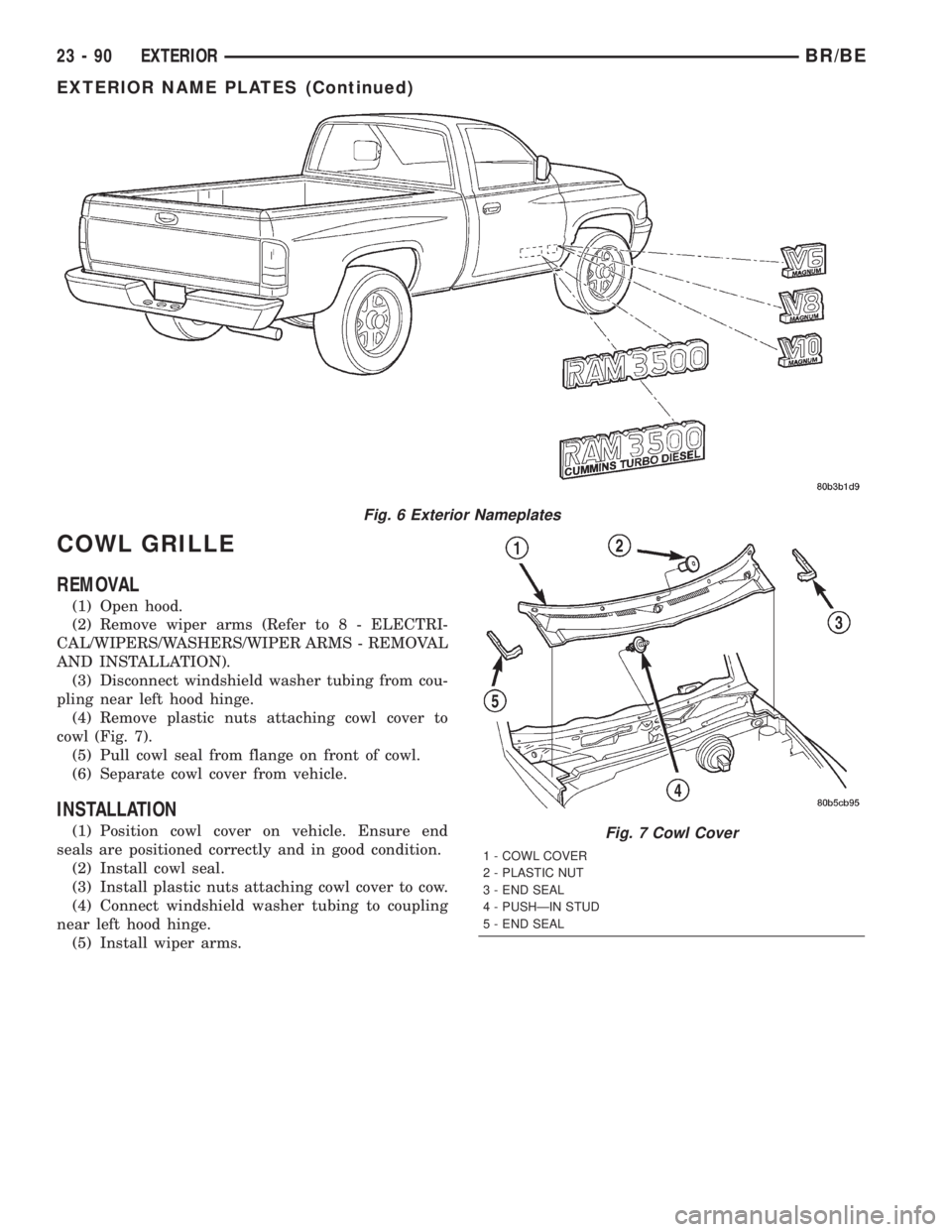

(7) Squeegee soap solution and air bubbles from

behind overlay from the center of the panel out using

a body putty applicator squeegee (Fig. 5).

CAUTION: Do not cut into painted surface of body

panel when trimming overlay to size.

(8) Trim overlay to size using a razor knife. Leave

at least 13 mm (0.5 in.) for edges of doors and open-

ings.

CAUTION: Do not overheat overlay when perform-

ing step 9.

(9) Apply heat to overlay to evaporate residual

moisture from edges of overlay and to allow overlay

to be stretched into concave surfaces.

(10) Edge turn overlay around doors or fenders.

(11) Install exterior trim if necessary.

(12) Small air or water bubbles under overlay can

be pierced with a pin and smoothed out.

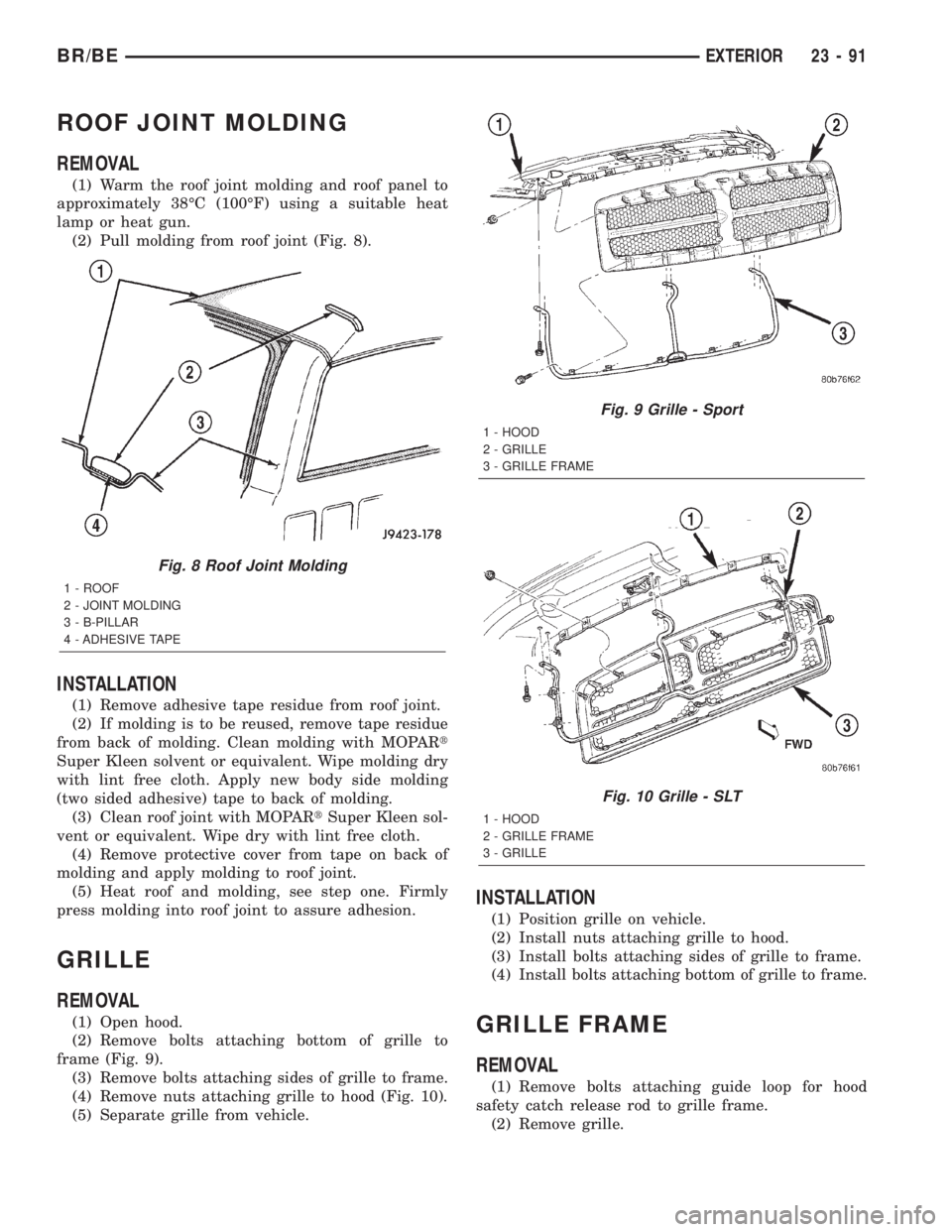

EXTERIOR NAME PLATES

REMOVAL

NOTE: Exterior nameplates are attached to body

panels with adhesive tape.

(1) Apply a length of masking tape on the body,

parallel to the top edge of the nameplate to use as a

guide, if necessary.

(2) If temperature is below 21ÉC (70ÉF) warm

emblem with a heat lamp or gun. Do not exceed 52ÉC

(120ÉF) when heating emblem.

(3) Insert a plastic trim stick or a hard wood

wedge behind the emblem to separate the adhesive

backing from the body.

(4) Clean adhesive residue from body with

MOPARtSuper Clean solvent or equivalent.

INSTALLATION

(1) Remove protective cover from adhesive tape on

back of emblem.

(2) Position emblem properly on body (Fig. 6).

(3) Press emblem firmly to body with palm of

hand.

(4) If temperature is below 21ÉC (70ÉF) warm

emblem with a heat lamp or gun to assure adhesion.

Do not exceed 52ÉC (120ÉF) when heating emblem.

Fig. 5 Tape Stripe Application

1 - SQUEEGEE

2 - CARRIER

3 - BODY PANEL

4 - TAPE STRIPE

BR/BEEXTERIOR 23 - 89

TAPE STRIPE (Continued)

Page 2057 of 2255

COWL GRILLE

REMOVAL

(1) Open hood.

(2) Remove wiper arms (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - REMOVAL

AND INSTALLATION).

(3) Disconnect windshield washer tubing from cou-

pling near left hood hinge.

(4) Remove plastic nuts attaching cowl cover to

cowl (Fig. 7).

(5) Pull cowl seal from flange on front of cowl.

(6) Separate cowl cover from vehicle.

INSTALLATION

(1) Position cowl cover on vehicle. Ensure end

seals are positioned correctly and in good condition.

(2) Install cowl seal.

(3) Install plastic nuts attaching cowl cover to cow.

(4) Connect windshield washer tubing to coupling

near left hood hinge.

(5) Install wiper arms.

Fig. 6 Exterior Nameplates

Fig. 7 Cowl Cover

1 - COWL COVER

2 - PLASTIC NUT

3 - END SEAL

4 - PUSHÐIN STUD

5 - END SEAL

23 - 90 EXTERIORBR/BE

EXTERIOR NAME PLATES (Continued)

Page 2058 of 2255

ROOF JOINT MOLDING

REMOVAL

(1) Warm the roof joint molding and roof panel to

approximately 38ÉC (100ÉF) using a suitable heat

lamp or heat gun.

(2) Pull molding from roof joint (Fig. 8).

INSTALLATION

(1) Remove adhesive tape residue from roof joint.

(2) If molding is to be reused, remove tape residue

from back of molding. Clean molding with MOPARt

Super Kleen solvent or equivalent. Wipe molding dry

with lint free cloth. Apply new body side molding

(two sided adhesive) tape to back of molding.

(3) Clean roof joint with MOPARtSuper Kleen sol-

vent or equivalent. Wipe dry with lint free cloth.

(4) Remove protective cover from tape on back of

molding and apply molding to roof joint.

(5) Heat roof and molding, see step one. Firmly

press molding into roof joint to assure adhesion.

GRILLE

REMOVAL

(1) Open hood.

(2) Remove bolts attaching bottom of grille to

frame (Fig. 9).

(3) Remove bolts attaching sides of grille to frame.

(4) Remove nuts attaching grille to hood (Fig. 10).

(5) Separate grille from vehicle.

INSTALLATION

(1) Position grille on vehicle.

(2) Install nuts attaching grille to hood.

(3) Install bolts attaching sides of grille to frame.

(4) Install bolts attaching bottom of grille to frame.

GRILLE FRAME

REMOVAL

(1) Remove bolts attaching guide loop for hood

safety catch release rod to grille frame.

(2) Remove grille.

Fig. 8 Roof Joint Molding

1 - ROOF

2 - JOINT MOLDING

3 - B-PILLAR

4 - ADHESIVE TAPE

Fig. 9 Grille - Sport

1 - HOOD

2 - GRILLE

3 - GRILLE FRAME

Fig. 10 Grille - SLT

1 - HOOD

2 - GRILLE FRAME

3 - GRILLE

BR/BEEXTERIOR 23 - 91

Page 2059 of 2255

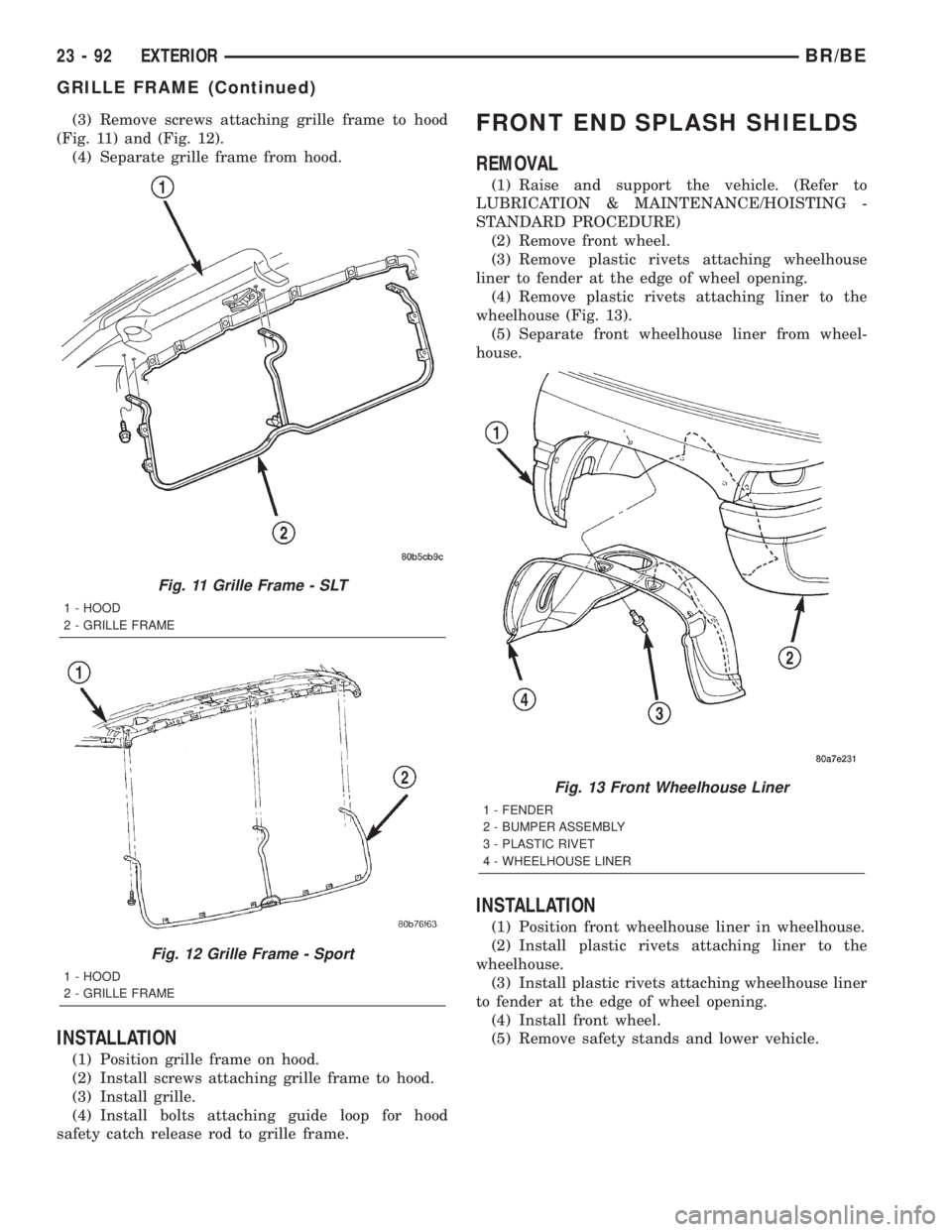

(3) Remove screws attaching grille frame to hood

(Fig. 11) and (Fig. 12).

(4) Separate grille frame from hood.

INSTALLATION

(1) Position grille frame on hood.

(2) Install screws attaching grille frame to hood.

(3) Install grille.

(4) Install bolts attaching guide loop for hood

safety catch release rod to grille frame.

FRONT END SPLASH SHIELDS

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Remove front wheel.

(3) Remove plastic rivets attaching wheelhouse

liner to fender at the edge of wheel opening.

(4) Remove plastic rivets attaching liner to the

wheelhouse (Fig. 13).

(5) Separate front wheelhouse liner from wheel-

house.

INSTALLATION

(1) Position front wheelhouse liner in wheelhouse.

(2) Install plastic rivets attaching liner to the

wheelhouse.

(3) Install plastic rivets attaching wheelhouse liner

to fender at the edge of wheel opening.

(4) Install front wheel.

(5) Remove safety stands and lower vehicle.

Fig. 11 Grille Frame - SLT

1 - HOOD

2 - GRILLE FRAME

Fig. 12 Grille Frame - Sport

1 - HOOD

2 - GRILLE FRAME

Fig. 13 Front Wheelhouse Liner

1 - FENDER

2 - BUMPER ASSEMBLY

3 - PLASTIC RIVET

4 - WHEELHOUSE LINER

23 - 92 EXTERIORBR/BE

GRILLE FRAME (Continued)

Page 2060 of 2255

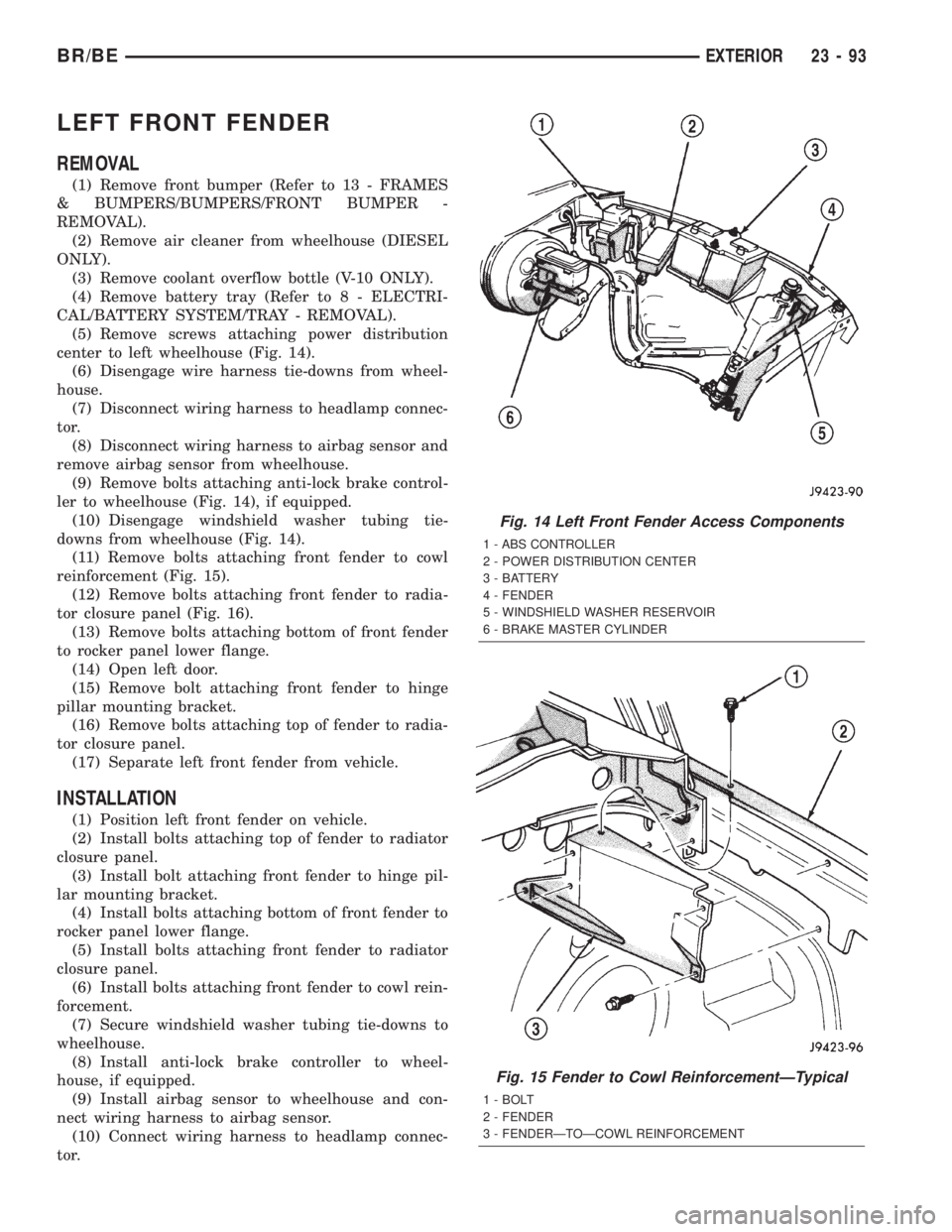

LEFT FRONT FENDER

REMOVAL

(1) Remove front bumper (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT BUMPER -

REMOVAL).

(2) Remove air cleaner from wheelhouse (DIESEL

ONLY).

(3) Remove coolant overflow bottle (V-10 ONLY).

(4) Remove battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL).

(5) Remove screws attaching power distribution

center to left wheelhouse (Fig. 14).

(6) Disengage wire harness tie-downs from wheel-

house.

(7) Disconnect wiring harness to headlamp connec-

tor.

(8) Disconnect wiring harness to airbag sensor and

remove airbag sensor from wheelhouse.

(9) Remove bolts attaching anti-lock brake control-

ler to wheelhouse (Fig. 14), if equipped.

(10) Disengage windshield washer tubing tie-

downs from wheelhouse (Fig. 14).

(11) Remove bolts attaching front fender to cowl

reinforcement (Fig. 15).

(12) Remove bolts attaching front fender to radia-

tor closure panel (Fig. 16).

(13) Remove bolts attaching bottom of front fender

to rocker panel lower flange.

(14) Open left door.

(15) Remove bolt attaching front fender to hinge

pillar mounting bracket.

(16) Remove bolts attaching top of fender to radia-

tor closure panel.

(17) Separate left front fender from vehicle.

INSTALLATION

(1) Position left front fender on vehicle.

(2) Install bolts attaching top of fender to radiator

closure panel.

(3) Install bolt attaching front fender to hinge pil-

lar mounting bracket.

(4) Install bolts attaching bottom of front fender to

rocker panel lower flange.

(5) Install bolts attaching front fender to radiator

closure panel.

(6) Install bolts attaching front fender to cowl rein-

forcement.

(7) Secure windshield washer tubing tie-downs to

wheelhouse.

(8) Install anti-lock brake controller to wheel-

house, if equipped.

(9) Install airbag sensor to wheelhouse and con-

nect wiring harness to airbag sensor.

(10) Connect wiring harness to headlamp connec-

tor.

Fig. 14 Left Front Fender Access Components

1 - ABS CONTROLLER

2 - POWER DISTRIBUTION CENTER

3 - BATTERY

4 - FENDER

5 - WINDSHIELD WASHER RESERVOIR

6 - BRAKE MASTER CYLINDER

Fig. 15 Fender to Cowl ReinforcementÐTypical

1 - BOLT

2 - FENDER

3 - FENDERÐTOÐCOWL REINFORCEMENT

BR/BEEXTERIOR 23 - 93