brake sensor DODGE RAM 2002 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 376 of 2255

DIAGNOSIS AND TESTING - CCD DATA BUS

CCD BUS FAILURE

The CCD data bus can be monitored using the

DRBIIItscan tool. However, it is possible for the

data bus to pass all tests since the voltage parame-

ters will be in ªrangeª and false signals are being

sent. There are essentially 12 ªhard failuresª that

can occur with the CCD data bus:

²Bus Shorted to Battery

²Bus Shorted to 5 Volts

²Bus Shorted to Ground

²Bus (+) Shorted to Bus (±)

²Bus (±) and Bus (+) Open

²Bus (+) Open

²Bus (±) Open

²No Bus Bias

²Bus Bias Level Too High

²Bus Bias Level Too Low

²No Bus Termination

²Not Receiving Bus Messages Correctly

Refer to the appropriate diagnostic information for

details on how to diagnose these faults using a

DRBIIItscan tool.

BUS FAILURE VISUAL SYMPTOM DIAGNOSIS

The following visible symptoms or customer com-

plaints, alone or in combination, may indicate a CCD

data bus failure:

²Airbag Indicator and Malfunction Indicator

Lamp (MIL) Illuminated

²Instrument Cluster Gauges (All) Inoperative

²No Compass Mini-Trip Computer (CMTC) Oper-

ation (if equipped)

CONTROLLER ANTILOCK

BRAKE

DESCRIPTION

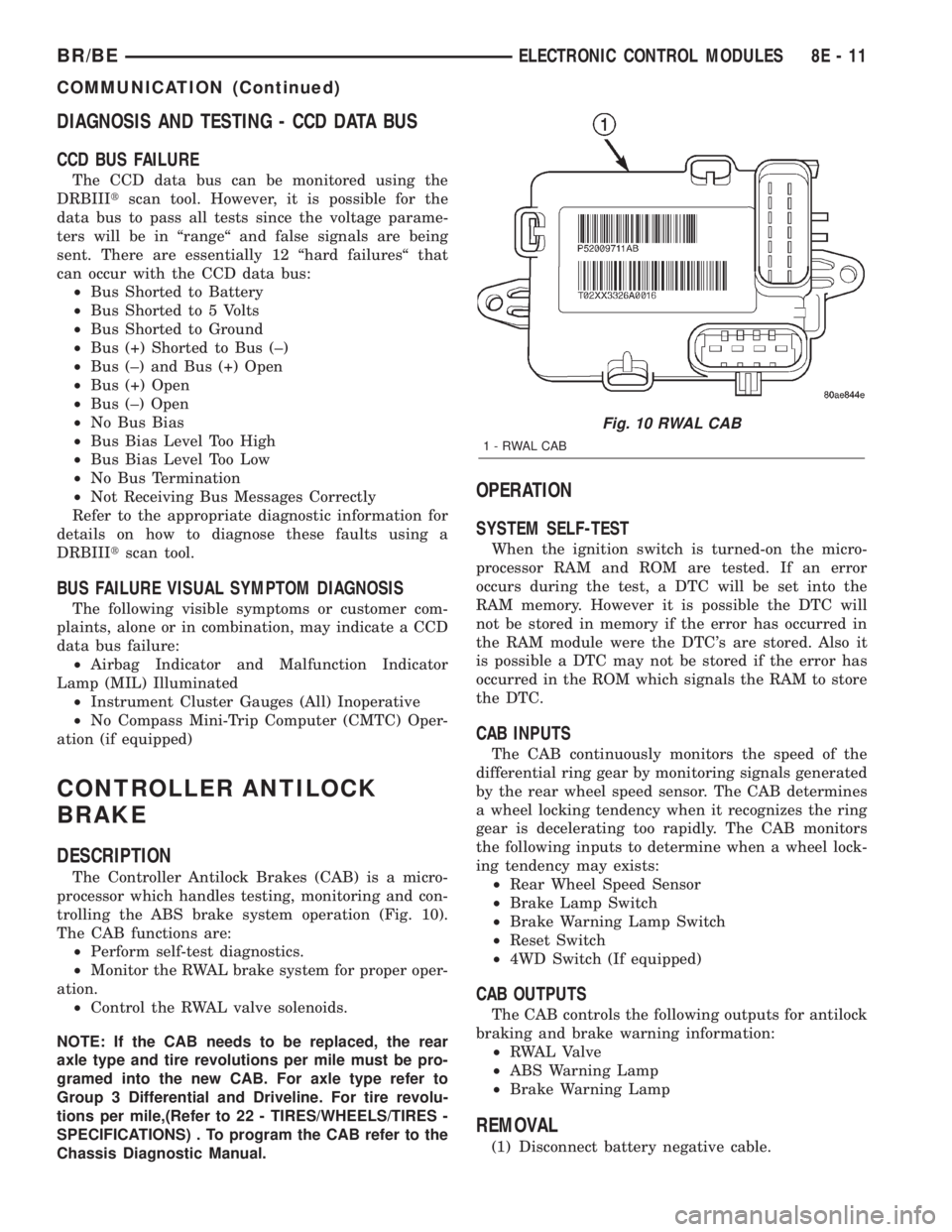

The Controller Antilock Brakes (CAB) is a micro-

processor which handles testing, monitoring and con-

trolling the ABS brake system operation (Fig. 10).

The CAB functions are:

²Perform self-test diagnostics.

²Monitor the RWAL brake system for proper oper-

ation.

²Control the RWAL valve solenoids.

NOTE: If the CAB needs to be replaced, the rear

axle type and tire revolutions per mile must be pro-

gramed into the new CAB. For axle type refer to

Group 3 Differential and Driveline. For tire revolu-

tions per mile,(Refer to 22 - TIRES/WHEELS/TIRES -

SPECIFICATIONS) . To program the CAB refer to the

Chassis Diagnostic Manual.

OPERATION

SYSTEM SELF-TEST

When the ignition switch is turned-on the micro-

processor RAM and ROM are tested. If an error

occurs during the test, a DTC will be set into the

RAM memory. However it is possible the DTC will

not be stored in memory if the error has occurred in

the RAM module were the DTC's are stored. Also it

is possible a DTC may not be stored if the error has

occurred in the ROM which signals the RAM to store

the DTC.

CAB INPUTS

The CAB continuously monitors the speed of the

differential ring gear by monitoring signals generated

by the rear wheel speed sensor. The CAB determines

a wheel locking tendency when it recognizes the ring

gear is decelerating too rapidly. The CAB monitors

the following inputs to determine when a wheel lock-

ing tendency may exists:

²Rear Wheel Speed Sensor

²Brake Lamp Switch

²Brake Warning Lamp Switch

²Reset Switch

²4WD Switch (If equipped)

CAB OUTPUTS

The CAB controls the following outputs for antilock

braking and brake warning information:

²RWAL Valve

²ABS Warning Lamp

²Brake Warning Lamp

REMOVAL

(1) Disconnect battery negative cable.

Fig. 10 RWAL CAB

1-RWALCAB

BR/BEELECTRONIC CONTROL MODULES 8E - 11

COMMUNICATION (Continued)

Page 383 of 2255

OPERATION

OPERATION - PCM - GAS ENGINES

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed and the

brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²Auto shutdown (ASD) sense

²Battery temperature

²Battery voltage

²Brake switch

²CCD bus (+) circuits

²CCD bus (-) circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connection for DRB scan tool

²Engine coolant temperature sensor

²Fuel level

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)

²Intake manifold air temperature sensor

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor²Oil pressure

²Output shaft speed sensor

²Overdrive/override switch

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transmission governor pressure sensor

²Transmission temperature sensor

²Vehicle speed inputs from ABS or RWAL system

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²CCD bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRB scan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Five volt sensor supply (primary)

²Five volt sensor supply (secondary)

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Generator lamp (if equipped)

²Idle air control (IAC) motor

²Ignition coil

²Leak detection pump (if equipped)

²Malfunction indicator lamp (Check engine lamp).

Driven through CCD circuits.

²Overdrive indicator lamp (if equipped)

²Service Reminder Indicator (SRI) Lamp (MAINT

REQ'D lamp). Driven through CCD circuits.

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through CCD

circuits.

²Transmission convertor clutch circuit

²Transmission 3±4 shift solenoid

²Transmission relay

²Transmission temperature lamp (if equipped)

²Transmission variable force solenoid

OPERATION - DIESEL

Two different control modules are used: The Pow-

ertrain Control Module (PCM), and the Engine Con-

trol Module (ECM). The ECMcontrolsthe fuel

system. The PCMdoes not controlthe fuel system.

The PCM's main function is to control: the vehicle

charging system, speed control system, transmission,

air conditioning system and certain bussed messages.

8E - 18 ELECTRONIC CONTROL MODULESBR/BE

POWERTRAIN CONTROL MODULE (Continued)

Page 384 of 2255

The PCM can adapt its programming to meet

changing operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to asPCM Outputs.The sensors

and switches that provide inputs to the PCM are con-

sideredPCM Inputs.

NOTE: PCM Inputs:

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²Accelerator Pedal Position Sensor (APPS) output

from ECM

²Auto shutdown (ASD) relay sense

²Battery temperature sensor

²Battery voltage

²Brake switch

²CCD bus (+) circuits

²CCD bus (-) circuits

²Crankshaft Position Sensor (CKP) output from

ECM

²Data link connection for DRB scan tool

²Fuel level sensor

²Generator (battery voltage) output

²Ignition sense

²Output shaft speed sensor

²Overdrive/override switch

²Park/neutral switch (auto. trans. only)

²Power ground

²Sensor return

²Signal ground

²Speed control resume switch

²Speed control set switch

²Speed control on/off switch

²Transmission governor pressure sensor

²Transmission temperature sensor

²Vehicle speed inputs from ABS or RWAL system

NOTE: PCM Outputs:

After inputs are received by the PCM, certain sen-

sors, switches and components are controlled or reg-

ulated by the PCM. These are consideredPCM

Outputs.These outputs are for:

²A/C clutch relay and A/C clutch

²Auto shutdown (ASD) relay

²CCD bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Data link connection for DRB scan tool

²Five volt sensor supply

²Generator field driver (-)

²Generator field driver (+)

²Generator lamp (if equipped)²Malfunction indicator lamp (Check engine lamp)

²Overdrive warning lamp (if equipped)

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped)

²Transmission convertor clutch circuit

²Transmission 3±4 shift solenoid

²Transmission relay

²Transmission temperature lamp (if equipped)

²Transmission variable force solenoid (governor

sol.)

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

²supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5±volt supply:

²supplies the required 5 volt power source to the

oil pressure sensor.

²supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

²supplies the 5 volt power source to the transmis-

sion pressure sensor (if equipped with an RE auto-

matic transmission).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the9ignition sense9circuit and is used to9wake up9

the PCM. Voltage on the ignition input can be as low

as 6 volts and the PCM will still function. Voltage is

supplied to this circuit to power the PCM's 8-volt reg-

ulator and to allow the PCM to perform fuel, ignition

and emissions control functions.

REMOVAL

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDEN-

TIFICATION NUMBER (VIN) AND THE VEHI-

CLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

The PCM is located in the engine compartment

(Fig. 18).

BR/BEELECTRONIC CONTROL MODULES 8E - 19

POWERTRAIN CONTROL MODULE (Continued)

Page 409 of 2255

VOLTAGE DROP TEST

WARNING: MODELS EQUIPPED WITH THE DIESEL

ENGINE OPTION ALSO HAVE AN AUTOMATIC

SHUTDOWN (ASD) RELAY LOCATED IN THE

POWER DISTRIBUTION CENTER (PDC), IN THE

ENGINE COMPARTMENT. HOWEVER, REMOVAL OF

THE ASD RELAY MAY NOT PREVENT THE DIESEL

ENGINE FROM STARTING. BE CERTAIN TO ALSO

DISCONNECT THE FUEL SHUTDOWN SOLENOID

WIRE HARNESS CONNECTOR ON MODELS WITH A

DIESEL ENGINE. FAILURE TO DO SO MAY RESULT

IN PERSONAL INJURY.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent a gasoline engine from starting,

remove the Automatic ShutDown (ASD) relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC), in the engine compartment. See the fuse

and relay layout label affixed to the underside of the

PDC cover for ASD relay identification and location.

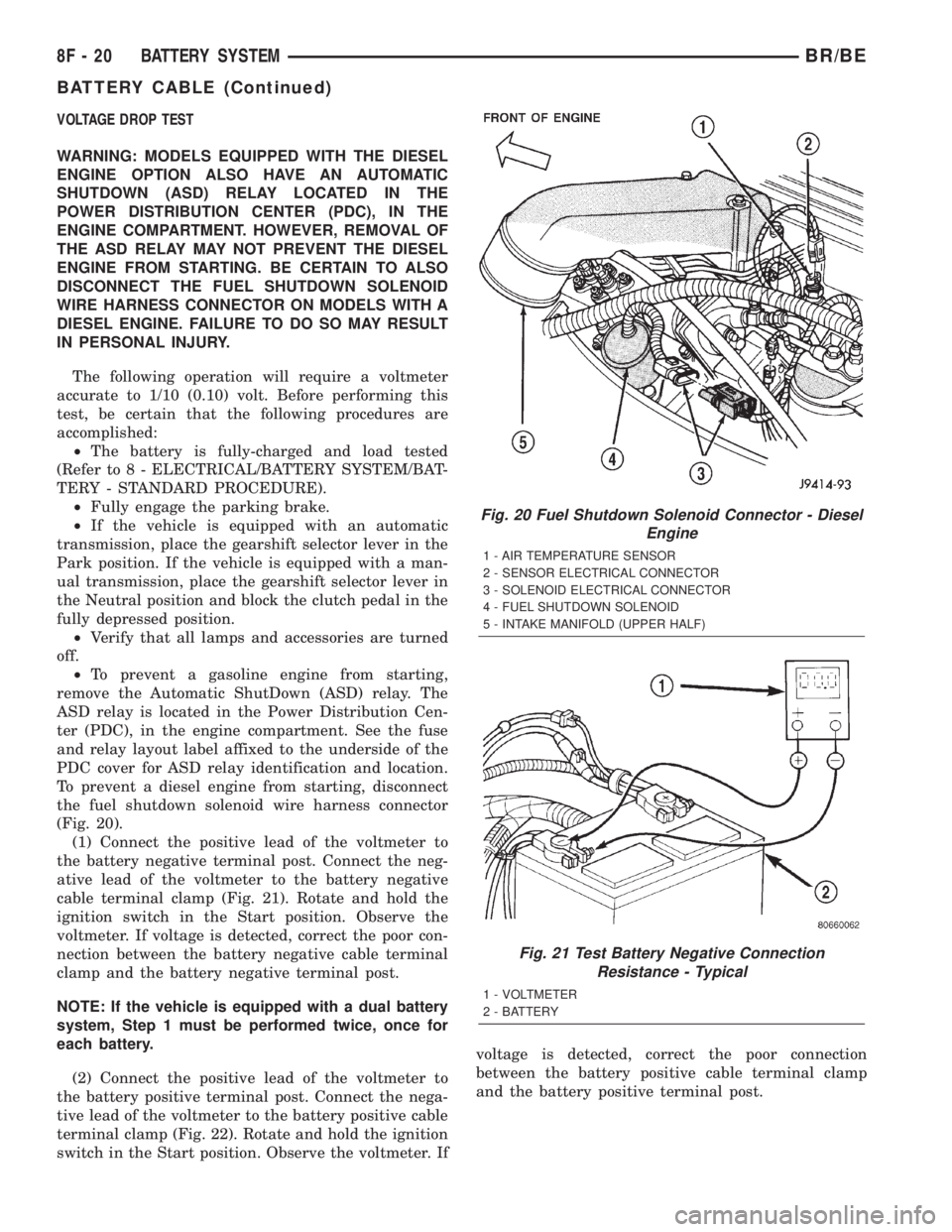

To prevent a diesel engine from starting, disconnect

the fuel shutdown solenoid wire harness connector

(Fig. 20).

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 21). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

NOTE: If the vehicle is equipped with a dual battery

system, Step 1 must be performed twice, once for

each battery.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 22). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. Ifvoltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

Fig. 20 Fuel Shutdown Solenoid Connector - Diesel

Engine

1 - AIR TEMPERATURE SENSOR

2 - SENSOR ELECTRICAL CONNECTOR

3 - SOLENOID ELECTRICAL CONNECTOR

4 - FUEL SHUTDOWN SOLENOID

5 - INTAKE MANIFOLD (UPPER HALF)

Fig. 21 Test Battery Negative Connection

Resistance - Typical

1 - VOLTMETER

2 - BATTERY

8F - 20 BATTERY SYSTEMBR/BE

BATTERY CABLE (Continued)

Page 493 of 2255

(Refer to 19 - STEERING/COLUMN - INSTALLA-

TION).

(8) Reconnect the battery negative cable.

NOTE: Some of the indicators in this instrument

cluster are either programmable (upshift indicator)

or automatically configured (cruise, overdrive-off,

and transmission overtemp indicators) when the

cluster is connected to the vehicle electrical sys-

tem. This feature allows those indicator lamps to be

enabled or disabled for compatibility with certain

optional equipment. If a new instrument cluster is

being installed, use a DRBIIITscan tool to program

the instrument cluster with the proper vehicle

equipment option setting to enable and/or disable

the upshift indicator lamp. Refer to the appropriate

diagnostic information.

ABS INDICATOR

DESCRIPTION

An Antilock Brake System (ABS) indicator is stan-

dard equipment on all instrument clusters. This indi-

cator serves both the standard equipment Rear

Wheel Anti-Lock (RWAL) and optional equipment

4-Wheel Anti-Lock (4WAL) brake systems. The ABS

indicator is located near the lower edge of the instru-

ment cluster overlay, to the left of center. The ABS

indicator consists of a stencilled cutout of the Inter-

national Control and Display Symbol icon for ªFail-

ure of Anti-lock Braking Systemº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

lens behind the cutout in the opaque layer of the

overlay causes the icon to appear in amber through

the translucent outer layer of the overlay when it is

illuminated from behind by a Light Emitting Diode

(LED) soldered onto the instrument cluster electronic

circuit board. The ABS indicator is serviced as a unit

with the instrument cluster.

OPERATION

The ABS indicator gives an indication to the vehi-

cle operator when the ABS system is faulty or inop-

erative. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Controller Antilock Brake (CAB)

over the Chrysler Collision Detection (CCD) data bus.

The ABS indicator Light Emitting Diode (LED)

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, theLED will always be off when the ignition switch is in

any position except On or Start. The LED only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the ABS indicator for the following rea-

sons:

²Bulb Test- Each time the ignition switch is

turned to the On position the ABS indicator is illu-

minated by the cluster for about two seconds as a

bulb test.

²ABS Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the CAB, the

ABS indicator will be illuminated. The indicator

remains illuminated until the cluster receives a

lamp-off message from the CAB, or until the ignition

switch is turned to the Off position, whichever occurs

first.

²Communication Error- If the cluster receives

no lamp-on or lamp-off messages from the CAB for

six consecutive seconds, the ABS indicator is illumi-

nated. The indicator remains illuminated until the

cluster receives a valid message from the CAB, or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the instrument clus-

ter is put through the actuator test, the ABS indica-

tor will be turned on during the bulb check portion of

the test to confirm the functionality of the LED and

the cluster control circuitry.

²ABS Diagnostic Test- The ABS indicator is

blinked on and off by lamp-on and lamp-off messages

from the CAB during the performance of the ABS

diagnostic tests.

The CAB continually monitors the ABS circuits

and sensors to decide whether the system is in good

operating condition. The CAB then sends the proper

lamp-on or lamp-off messages to the instrument clus-

ter. If the CAB sends a lamp-on message after the

bulb test, it indicates that the CAB has detected a

system malfunction and/or that the ABS system has

become inoperative. The CAB will store a Diagnostic

Trouble Code (DTC) for any malfunction it detects.

Each time the ABS indicator fails to light due to an

open or short in the cluster ABS indicator circuit, the

cluster sends a message notifying the CAB of the

condition, and the CAB will store a DTC. For proper

diagnosis of the antilock brake system, the CAB, the

CCD data bus, or the message inputs to the instru-

ment cluster that control the ABS indicator, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

8J - 14 INSTRUMENT CLUSTERBR/BE

INSTRUMENT CLUSTER (Continued)

Page 494 of 2255

AIRBAG INDICATOR

DESCRIPTION

An airbag indicator is standard equipment on all

instrument clusters. However, on vehicles not

equipped with airbags, this indicator is electronically

disabled. The airbag indicator is located near the

lower edge of the instrument cluster overlay, to the

right of center. The airbag indicator consists of a

stenciled cutout of the word ªAIRBAGº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

lens behind the cutout in the opaque layer of the

overlay causes the ªAIRBAGº text to appear in red

through the translucent outer layer of the overlay

when it is illuminated from behind by a Light Emit-

ting Diode (LED) soldered onto the instrument clus-

ter electronic circuit board. The airbag indicator is

serviced as a unit with the instrument cluster.

OPERATION

The airbag indicator gives an indication to the

vehicle operator when the airbag system is faulty or

inoperative. The airbag indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Airbag Control

Module (ACM) over the Chrysler Collision Detection

(CCD) data bus. The airbag indicator Light Emitting

Diode (LED) receives battery current on the instru-

ment cluster electronic circuit board through the

fused ignition switch output (st-run) circuit whenever

the ignition switch is in the On or Start positions;

therefore, the indicator will always be off when the

ignition switch is in any position except On or Start.

The LED only illuminates when it is provided a path

to ground by the instrument cluster transistor. The

instrument cluster will turn on the airbag indicator

for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the airbag indicator is illu-

minated for about seven seconds. The first two sec-

onds is the cluster bulb test function, and the

remainder is the ACM bulb test function.

²ACM Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the ACM, the

airbag indicator will be illuminated. The indicator

remains illuminated for about twelve seconds or until

the cluster receives a lamp-off message from the

ACM, whichever is longer.

²Communication Error- If the cluster receives

no airbag messages for three consecutive seconds, the

airbag indicator is illuminated. The indicator

remains illuminated for about twelve seconds or untilthe cluster receives a single lamp-off message from

the ACM, whichever is longer.

²Actuator Test- Each time the cluster is put

through the actuator test, the airbag indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The ACM continually monitors the airbag system

circuits and sensors to decide whether the system is

in good operating condition. The ACM then sends the

proper lamp-on or lamp-off messages to the instru-

ment cluster. If the ACM sends a lamp-on message

after the bulb test, it indicates that the ACM has

detected a system malfunction and/or that the air-

bags may not deploy when required, or may deploy

when not required. The ACM will store a Diagnostic

Trouble Code (DTC) for any malfunction it detects.

Each time the airbag indicator fails to illuminate due

to an open or short in the cluster airbag indicator cir-

cuit, the cluster sends a message notifying the ACM

of the condition, the ACM will store a DTC, and the

cluster begins blinking the seat belt indicator. (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER/

SEATBELT INDICATOR - OPERATION). For proper

diagnosis of the airbag system, the ACM, the CCD

data bus, or the message inputs to the instrument

cluster that control the airbag indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

BRAKE/PARK BRAKE

INDICATOR

DESCRIPTION

A brake indicator is standard equipment on all

instrument clusters. The brake indicator is located

near the lower edge of the instrument cluster overlay,

to the right of center. The brake indicator consists of

a stenciled cutout of the word ªBRAKEº in the

opaque layer of the instrument cluster overlay. The

dark outer layer of the overlay prevents the indicator

from being clearly visible when it is not illuminated.

A red lens behind the cutout in the opaque layer of

the overlay causes the ªBRAKEº text to appear in

red through the translucent outer layer of the over-

lay when it is illuminated from behind by a Light

Emitting Diode (LED) soldered onto the instrument

cluster electronic circuit board. The brake indicator is

serviced as a unit with the instrument cluster.

OPERATION

The brake indicator gives an indication to the vehi-

cle operator when the parking brake is applied, or

when there are certain brake hydraulic system mal-

functions. This indicator is controlled by a transistor

BR/BEINSTRUMENT CLUSTER 8J - 15

Page 519 of 2255

(9) Disconnect the instrument panel wire harness

connector for the multi-function switch from the

switch connector receptacle. Check for continuity

between the hazard flasher signal circuit cavities in

the JB receptacle for the combination flasher and the

instrument panel wire harness connector for the

multi-function switch. There should be continuity. If

OK, go to Step 10. If not OK, repair the open hazard

flasher signal circuit between the JB and the multi-

function switch as required.

(10) Check for continuity between the flasher out-

put circuit cavities of the JB receptacle for the com-

bination flasher and in the instrument panel wire

harness connector for the multi-function switch.

There should be continuity. If OK, test the multi-

function switch. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/MULTI-FUNCTION

SWITCH - DIAGNOSIS AND TESTING). If not OK,

repair the open flasher output circuit between the JB

and the multi-function switch as required.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up 3157

Cargo 921

Center High Mounted

Stop921

Clearance Roof Mounted 168

Fog Lamps 896

Headlamp - SLT 9004LL

Headlamp - Sport Low

Beam9007

Headlamp - Sport High

Beam9004LL

License Plate w/o

Bumper1155

License Plate -Step

Bumper168

Park/Turn Signal 3157NA

Snow Plow Control 161

Tail/Brake/Turn Signal 3157

Tail/Brake/Cab - Chassis 1157

Underhood 105

SPECIAL TOOLS

HEADLAMP ALIGNMENT

BRAKE LAMP SWITCH

DESCRIPTION

The plunger type brake lamp switch is mounted on

a bracket attached to the brake pedal support under

the instrument panel.

CAUTION: The switch can only be adjusted during

initial installation. If the switch is not adjusted prop-

erly a new switch must be installed.

OPERATION

The brake lamp switch is used for the brake lamp,

speed control brake sensor circuits and electronic

brake distribution (EBD). The brake lamp circuit is

open until the plunger is depressed. The speed con-

trol and brake sensor circuits are closed until the

plunger is depressed.

When the brake light switch is activated, the Pow-

ertrain Control Module (PCM) receives an input indi-

cating that the brakes are being applied. After

receiving this input, the PCM maintains idle speed to

a scheduled rpm through control of the Idle Air Con-

trol (IAC) motor. The brake switch input is also used

to disable vent and vacuum solenoid output signals

to the speed control servo.

Vehicles equipped with the speed control option use

a dual function brake lamp switch. The PCM moni-

tors the state of the dual function brake lamp switch.

Refer to the Brake section for more information on

brake lamp switch service and adjustment proce-

dures.

Headlamp Aiming Kit C-4466±A

8L - 4 LAMPS/LIGHTING - EXTERIORBR/BE

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 579 of 2255

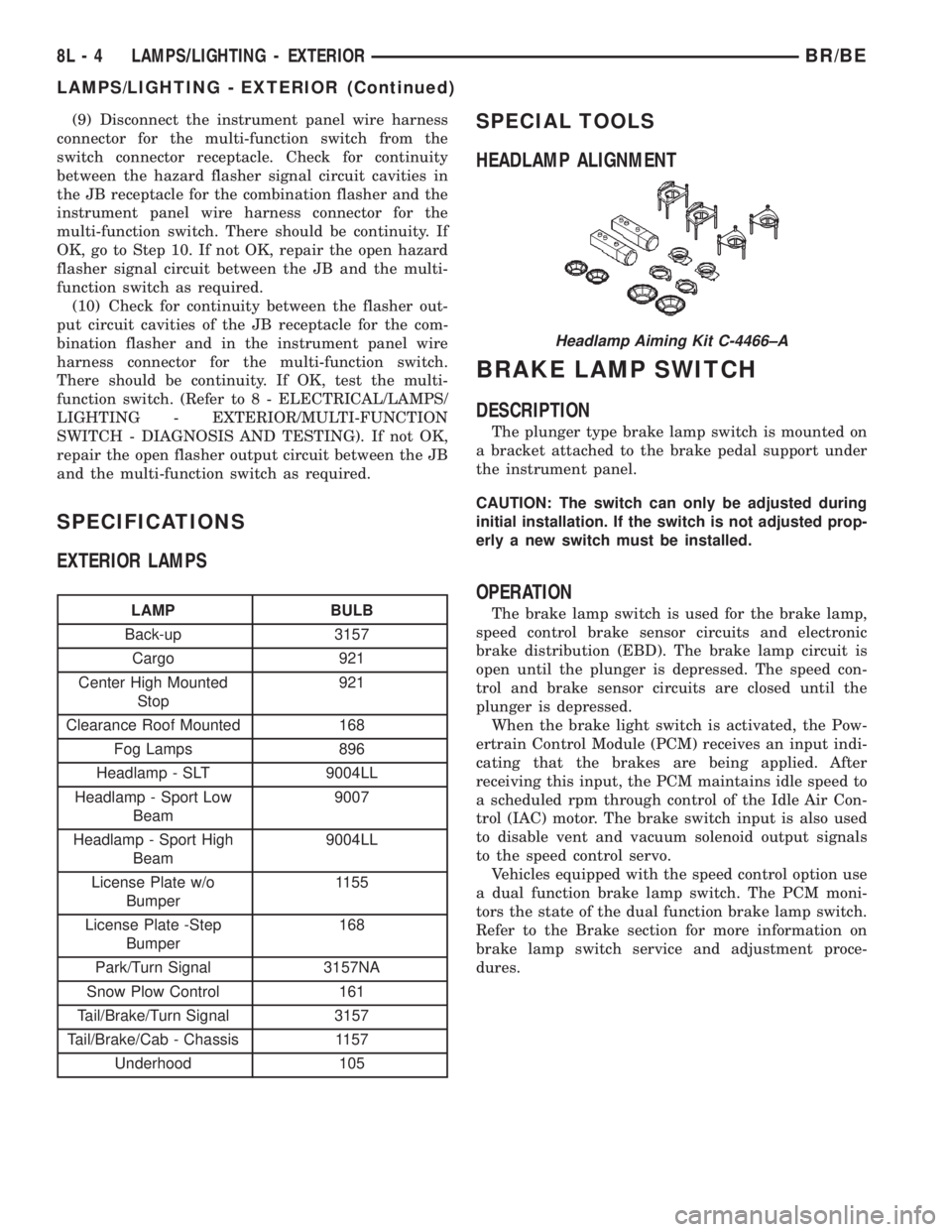

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 1). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the junction block as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (LED in the mirror switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

Fig. 1 Automatic Day/Night Mirror

8N - 12 POWER MIRRORSBR/BE

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 625 of 2255

DESCRIPTION - VEHICLE SPEED INPUT

Gas Engines and/or Diesel With Automatic Trans.

The Vehicle Speed Sensor (VSS) is no longer used

for any Dodge Truck.

Vehicle speed and distance covered are measured

by the Rear Wheel Speed Sensor. The sensor is

mounted to the rear axle. A signal is sent from this

sensor to the Controller Antilock Brake (CAB) com-

puter. A signal is then sent from the CAB to the Pow-

ertrain Control Module (PCM) to determine vehicle

speed and distance covered. The PCM will then

determine strategies for speed control system opera-

tion.

Diesel With Manual Trans.

The Vehicle Speed Sensor (VSS) is no longer used

for any Dodge Truck.

Vehicle speed and distance covered are measured

by the Rear Wheel Speed Sensor. The sensor is

mounted to the rear axle. A signal is sent from this

sensor to the Controller Antilock Brake (CAB) com-

puter. A signal is then sent from the CAB to the

Engine Control Module (ECM) to determine vehicle

speed and distance covered. The ECM will then

determine strategies for speed control system opera-

tion.

OPERATION - SPEED CONTROL SYSTEM

Gas Engines and/or Diesel With Automatic Trans.

When speed control is selected by depressing the

ON switch, the PCM allows a set speed to be stored

in PCM RAM for speed control. To store a set speed,

depress the SET switch while the vehicle is moving

at a speed between 35 and 85 mph. In order for the

speed control to engage, the brakes cannot be

applied, nor can the gear selector be indicating the

transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal.

²Depressing the OFF switch.

²Depressing the CANCEL switch.

²Depressing the clutch pedal (if equipped).

NOTE: Depressing the OFF switch or turning off the

ignition switch will erase the set speed stored in

the PCM.

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral.

²A rapid increase of rpm (indication that the

clutch has been disengaged).²Excessive engine rpm (indicates that the trans-

mission may be in a low gear).

²The speed signal increases at a rate of 10 mph

per second (indicates that the coefficient of friction

between the road surface and tires is extremely low).

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate).

Once the speed control has been disengaged,

depressing the RES/ACCEL switch (when speed is

greater than 30 mph) restores the vehicle to the tar-

get speed that was stored in the PCM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the RES/AC-

CEL switch. The new target speed is stored in the

PCM when the RES/ACCEL is released. The PCM

also has a9tap-up9feature in which vehicle speed

increases at a rate of approximately 2 mph for each

momentary switch activation of the RES/ACCEL

switch.

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

Diesel With Manual Trans.

When speed control is selected by depressing the

ON switch, the Engine Control Module (ECM) allows

a set speed to be stored in ECM RAM for speed con-

trol. To store a set speed, depress the SET switch

while the vehicle is moving at a speed between 35

and 85 mph. In order for the speed control to engage,

the brakes cannot be applied.The speed control can

be disengaged manually by:

²Stepping on the brake pedal.

²Depressing the OFF switch.

²Depressing the CANCEL switch.

²Depressing the clutch pedal.

NOTE: Depressing the OFF switch or turning off the

ignition switch will erase the set speed stored in

the ECM.

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²A rapid increase of rpm (indication that the

clutch has been disengaged).

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear).

²The speed signal increases at a rate of 10 mph

per second (indicates that the coefficient of friction

between the road surface and tires is extremely low).

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate).

8P - 2 SPEED CONTROLBR/BE

SPEED CONTROL (Continued)

Page 678 of 2255

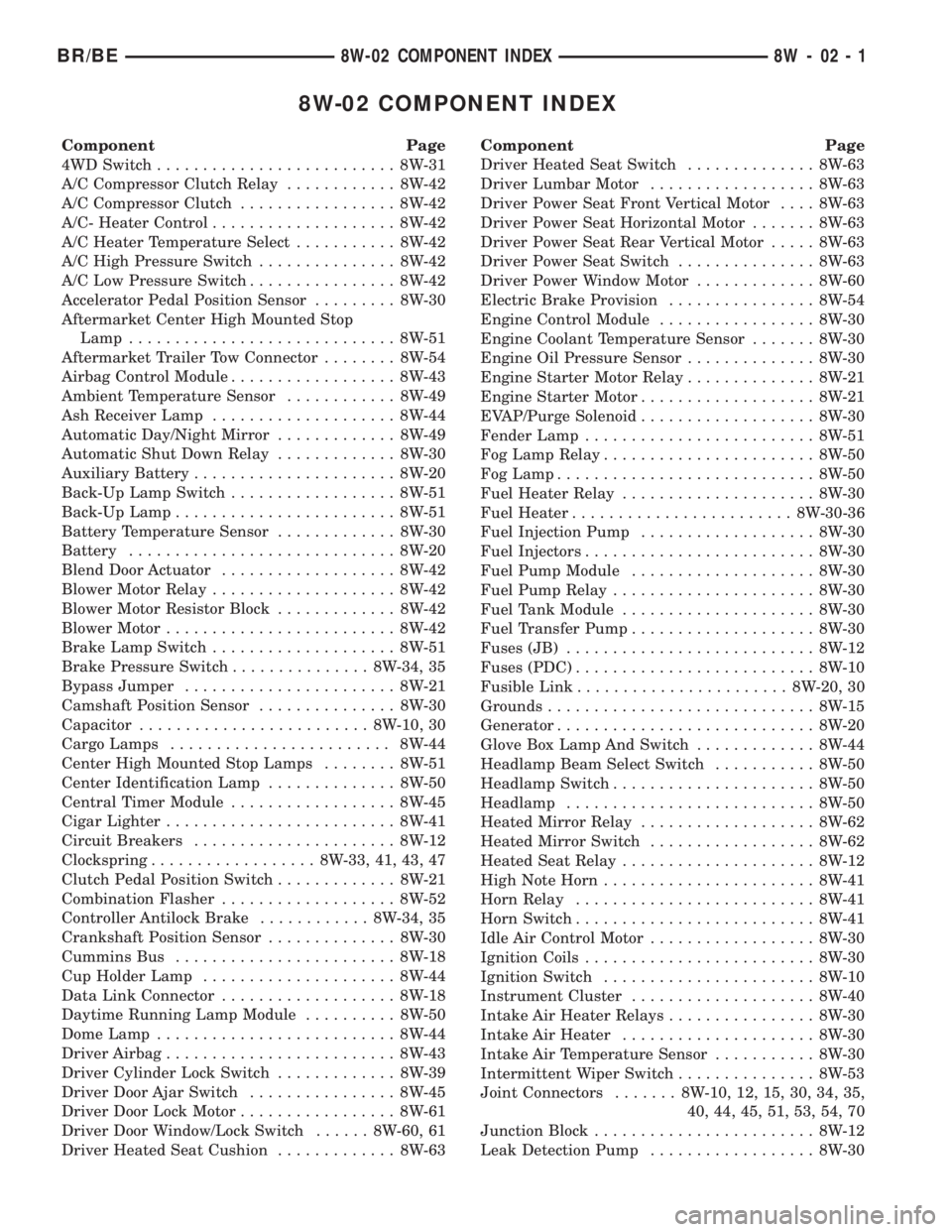

8W-02 COMPONENT INDEX

Component Page

4WD Switch.......................... 8W-31

A/C Compressor Clutch Relay............ 8W-42

A/C Compressor Clutch................. 8W-42

A/C- Heater Control.................... 8W-42

A/C Heater Temperature Select........... 8W-42

A/C High Pressure Switch............... 8W-42

A/C Low Pressure Switch................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Aftermarket Center High Mounted Stop

Lamp............................. 8W-51

Aftermarket Trailer Tow Connector........ 8W-54

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor............ 8W-49

Ash Receiver Lamp.................... 8W-44

Automatic Day/Night Mirror............. 8W-49

Automatic Shut Down Relay............. 8W-30

Auxiliary Battery...................... 8W-20

Back-Up Lamp Switch.................. 8W-51

Back-Up Lamp........................ 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Actuator................... 8W-42

Blower Motor Relay.................... 8W-42

Blower Motor Resistor Block............. 8W-42

Blower Motor......................... 8W-42

Brake Lamp Switch.................... 8W-51

Brake Pressure Switch............... 8W-34, 35

Bypass Jumper....................... 8W-21

Camshaft Position Sensor............... 8W-30

Capacitor......................... 8W-10, 30

Cargo Lamps........................ 8W-44

Center High Mounted Stop Lamps........ 8W-51

Center Identification Lamp.............. 8W-50

Central Timer Module.................. 8W-45

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Clutch Pedal Position Switch............. 8W-21

Combination Flasher................... 8W-52

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cummins Bus........................ 8W-18

Cup Holder Lamp..................... 8W-44

Data Link Connector................... 8W-18

Daytime Running Lamp Module.......... 8W-50

Dome Lamp.......................... 8W-44

Driver Airbag......................... 8W-43

Driver Cylinder Lock Switch............. 8W-39

Driver Door Ajar Switch................ 8W-45

Driver Door Lock Motor................. 8W-61

Driver Door Window/Lock Switch...... 8W-60, 61

Driver Heated Seat Cushion............. 8W-63Component Page

Driver Heated Seat Switch.............. 8W-63

Driver Lumbar Motor.................. 8W-63

Driver Power Seat Front Vertical Motor.... 8W-63

Driver Power Seat Horizontal Motor....... 8W-63

Driver Power Seat Rear Vertical Motor..... 8W-63

Driver Power Seat Switch............... 8W-63

Driver Power Window Motor............. 8W-60

Electric Brake Provision................ 8W-54

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor Relay.............. 8W-21

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fender Lamp......................... 8W-51

Fog Lamp Relay....................... 8W-50

Fog Lamp............................ 8W-50

Fuel Heater Relay..................... 8W-30

Fuel Heater........................ 8W-30-36

Fuel Injection Pump................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuel Tank Module..................... 8W-30

Fuel Transfer Pump.................... 8W-30

Fuses (JB)........................... 8W-12

Fuses (PDC).......................... 8W-10

Fusible Link....................... 8W-20, 30

Grounds............................. 8W-15

Generator............................ 8W-20

Glove Box Lamp And Switch............. 8W-44

Headlamp Beam Select Switch........... 8W-50

Headlamp Switch...................... 8W-50

Headlamp........................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Mirror Switch.................. 8W-62

Heated Seat Relay..................... 8W-12

High Note Horn....................... 8W-41

Horn Relay.......................... 8W-41

Horn Switch.......................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Coils......................... 8W-30

Ignition Switch....................... 8W-10

Instrument Cluster.................... 8W-40

Intake Air Heater Relays................ 8W-30

Intake Air Heater..................... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intermittent Wiper Switch............... 8W-53

Joint Connectors....... 8W-10, 12, 15, 30, 34, 35,

40, 44, 45, 51, 53, 54, 70

Junction Block........................ 8W-12

Leak Detection Pump.................. 8W-30

BR/BE8W-02 COMPONENT INDEX 8W - 02 - 1