engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1372 of 2255

CAUTION: To prevent pump/gear keyway from fall-

ing into gear housing, engine must be rotated until

keyway is at 12 o'clock position (Fig. 36). If gear

retainer nut, washer or key drops into gear housing,

cover may have to be removed to retrieve them

before engine is started.

(9) Remove nut and washer retaining injection

pump gear to injection pump shaft (Fig. 34).

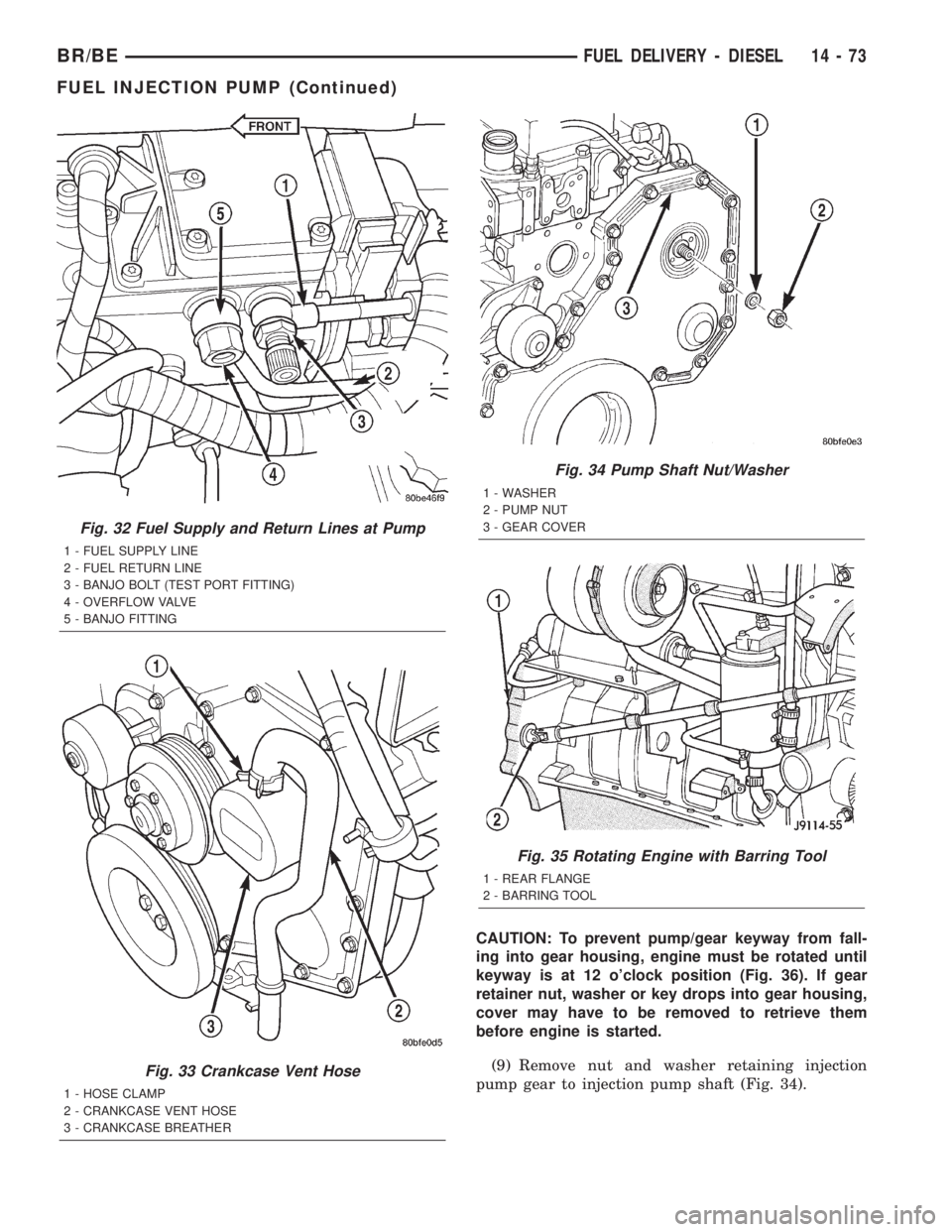

Fig. 32 Fuel Supply and Return Lines at Pump

1 - FUEL SUPPLY LINE

2 - FUEL RETURN LINE

3 - BANJO BOLT (TEST PORT FITTING)

4 - OVERFLOW VALVE

5 - BANJO FITTING

Fig. 33 Crankcase Vent Hose

1 - HOSE CLAMP

2 - CRANKCASE VENT HOSE

3 - CRANKCASE BREATHER

Fig. 34 Pump Shaft Nut/Washer

1 - WASHER

2 - PUMP NUT

3 - GEAR COVER

Fig. 35 Rotating Engine with Barring Tool

1 - REAR FLANGE

2 - BARRING TOOL

BR/BEFUEL DELIVERY - DIESEL 14 - 73

FUEL INJECTION PUMP (Continued)

Page 1373 of 2255

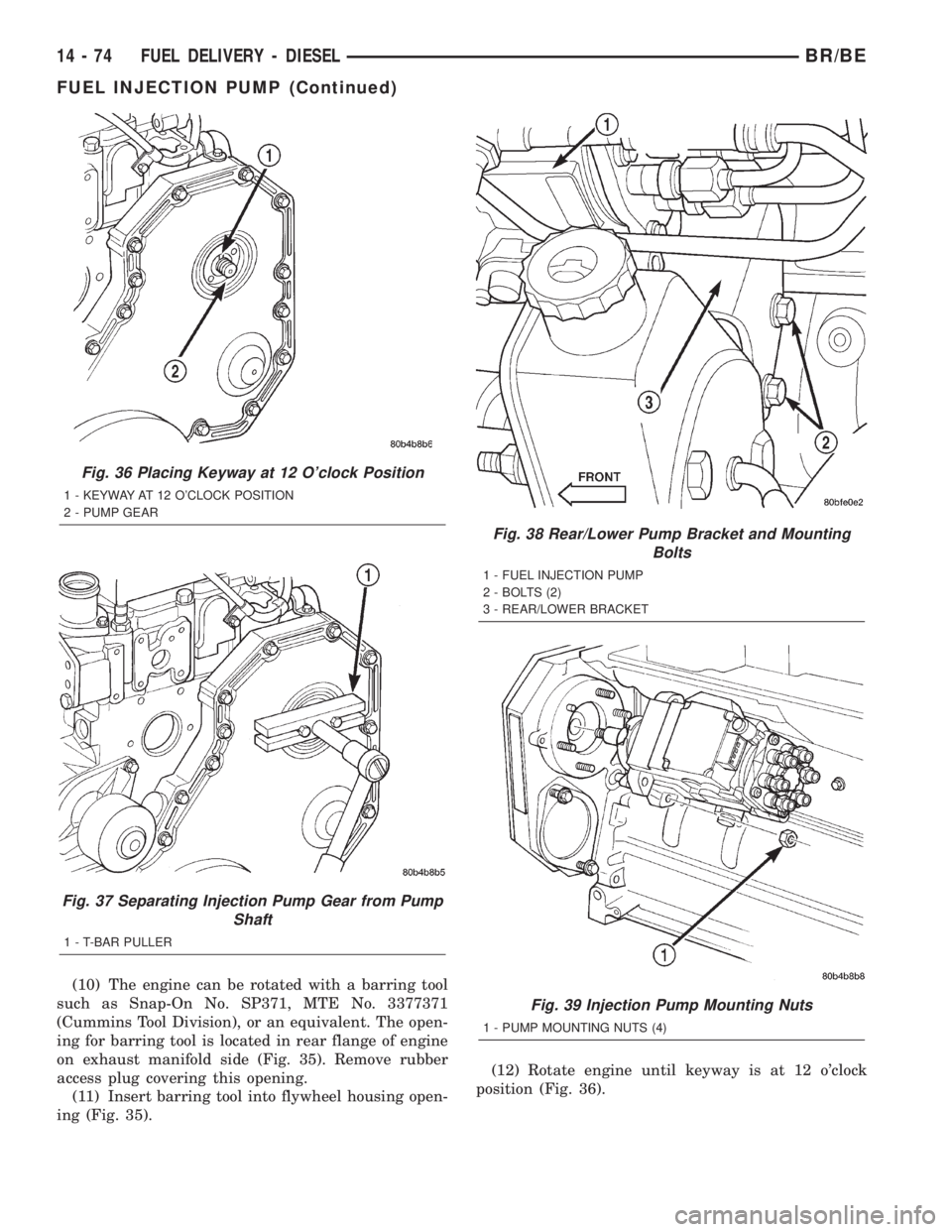

(10) The engine can be rotated with a barring tool

such as Snap-On No. SP371, MTE No. 3377371

(Cummins Tool Division), or an equivalent. The open-

ing for barring tool is located in rear flange of engine

on exhaust manifold side (Fig. 35). Remove rubber

access plug covering this opening.

(11) Insert barring tool into flywheel housing open-

ing (Fig. 35).(12) Rotate engine until keyway is at 12 o'clock

position (Fig. 36).

Fig. 36 Placing Keyway at 12 O'clock Position

1 - KEYWAY AT 12 O'CLOCK POSITION

2 - PUMP GEAR

Fig. 37 Separating Injection Pump Gear from Pump

Shaft

1 - T-BAR PULLER

Fig. 38 Rear/Lower Pump Bracket and Mounting

Bolts

1 - FUEL INJECTION PUMP

2 - BOLTS (2)

3 - REAR/LOWER BRACKET

Fig. 39 Injection Pump Mounting Nuts

1 - PUMP MOUNTING NUTS (4)

14 - 74 FUEL DELIVERY - DIESELBR/BE

FUEL INJECTION PUMP (Continued)

Page 1374 of 2255

(13) Use T-bar type puller (Fig. 37) to separate

injection pump gear from injection pump shaft.

Attach two M8 X 1.24 MM (metric) screws through

puller and into two threaded holes supplied in pump

gear. Pull injection pump gear forward until it loos-

ens from injection pump shaft.Pull on gear only

enough to loosen it from injection pump shaft.

Pulling gear too far may cause damage or

breakage to gear cover.(14) Remove 2 rear/lower pump bracket bolts (Fig.

38).

(15) Remove 4 injection pump-to-gear housing

mounting nuts (Fig. 39).

(16) Remove injection pump from gear housing.

Take care not to nick injection pump shaft on

aluminum gear housing when removing pump.

Also be very careful not to drop pump keyway

(Fig. 41) into gear housing.

CAUTION: Whenever the fuel injection pump is

removed from the engine, the pump drive gear is

laying loose on the camshaft drive gear. Never

attempt to crank or rotate the engine with the pump

removed from the engine. Serious damage will

occur.

INSTALLATION

(1) Inspect pump mounting surfaces at pump and

mounting flange for nicks, cuts or damage. Inspect

o-ring surfaces for nicks, cuts or damage.

(2) Clean injection pump mounting flange (Fig. 40)

at gear housing. Also clean front of injection pump.

(3) Install new rubber o-ring (Fig. 41) at pump

mounting area.

(4) Apply clean engine oilto injection pump

o-ring only.Fig. 40 Cleaning Pump Mounting Flange

1 - PUMP MOUNTING FLANGE

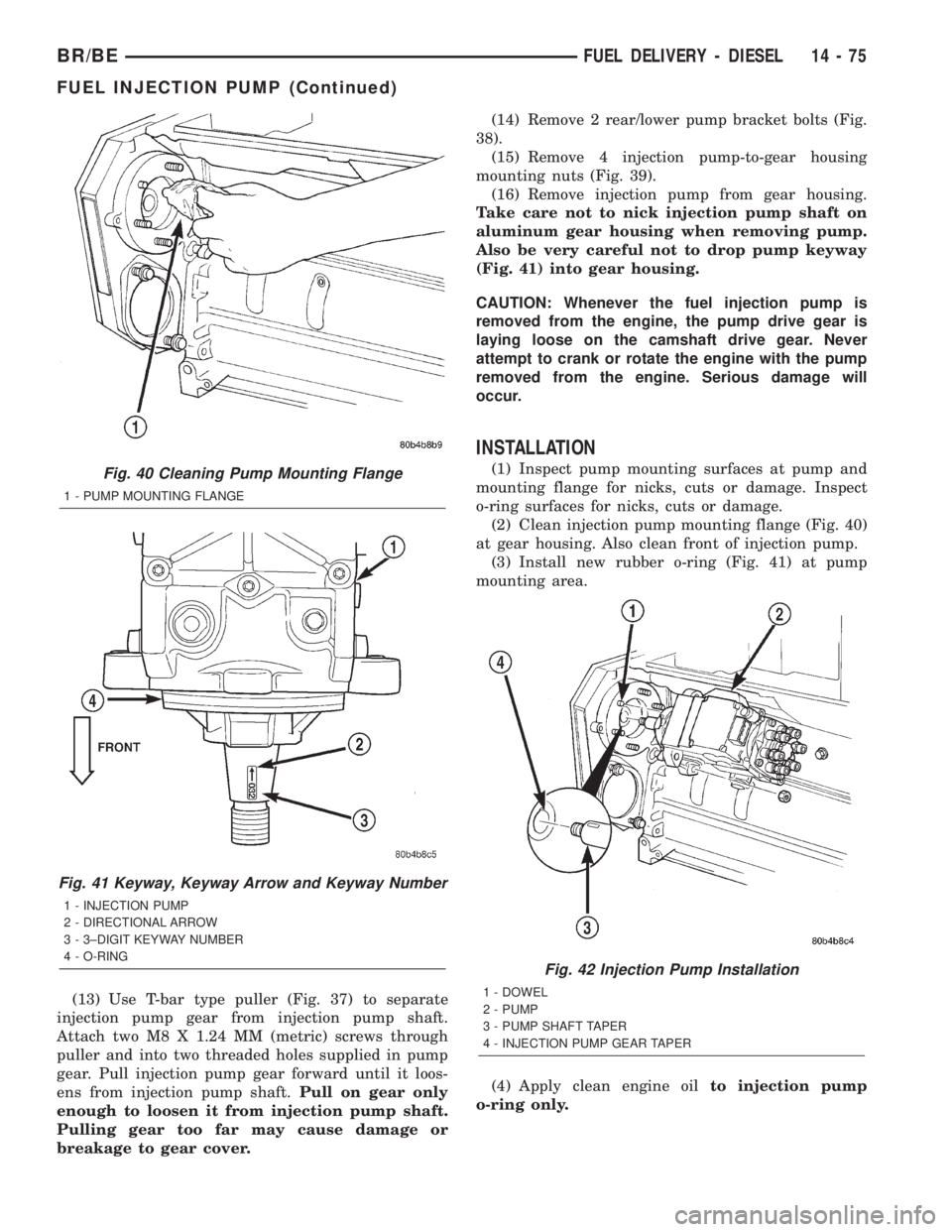

Fig. 41 Keyway, Keyway Arrow and Keyway Number

1 - INJECTION PUMP

2 - DIRECTIONAL ARROW

3 - 3±DIGIT KEYWAY NUMBER

4 - O-RING

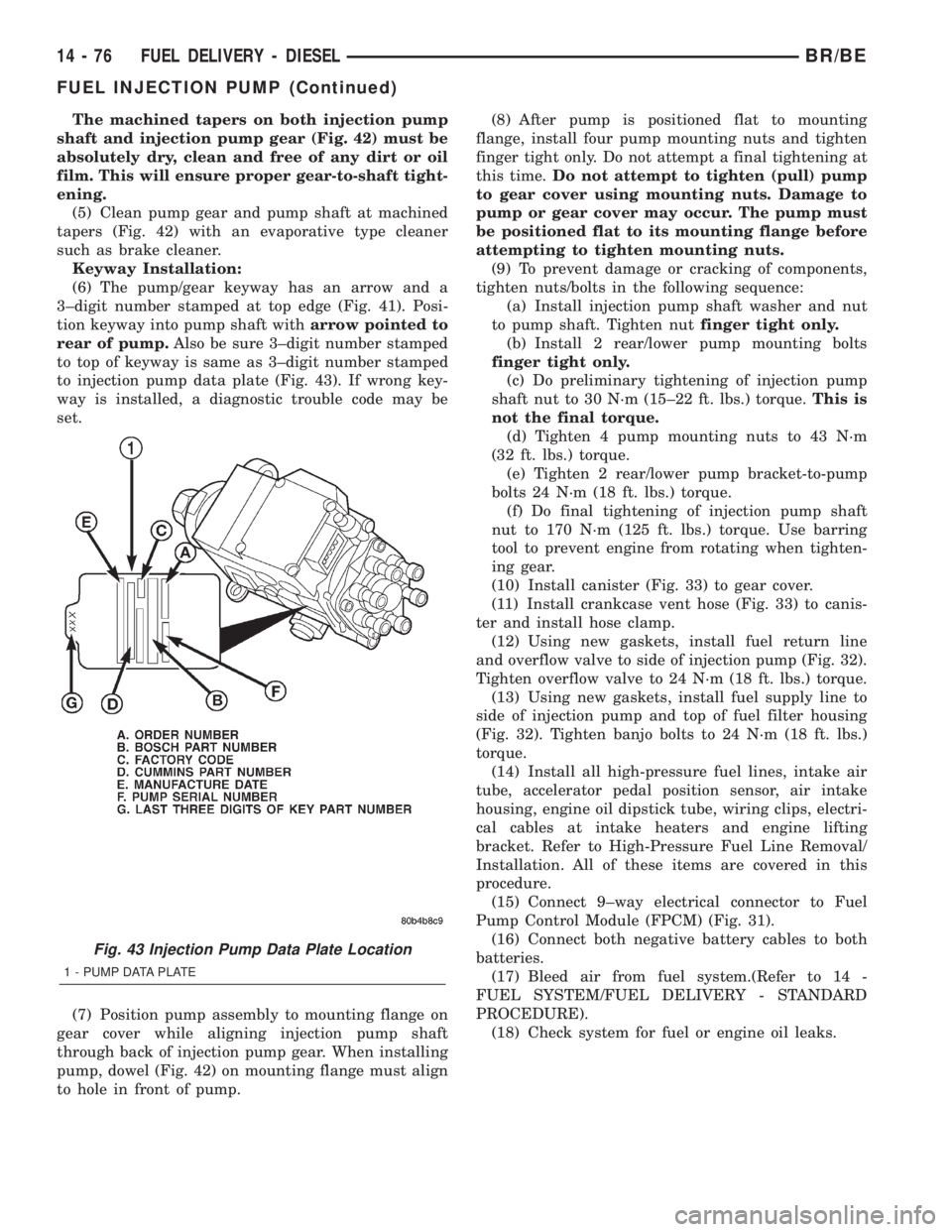

Fig. 42 Injection Pump Installation

1 - DOWEL

2 - PUMP

3 - PUMP SHAFT TAPER

4 - INJECTION PUMP GEAR TAPER

BR/BEFUEL DELIVERY - DIESEL 14 - 75

FUEL INJECTION PUMP (Continued)

Page 1375 of 2255

The machined tapers on both injection pump

shaft and injection pump gear (Fig. 42) must be

absolutely dry, clean and free of any dirt or oil

film. This will ensure proper gear-to-shaft tight-

ening.

(5) Clean pump gear and pump shaft at machined

tapers (Fig. 42) with an evaporative type cleaner

such as brake cleaner.

Keyway Installation:

(6) The pump/gear keyway has an arrow and a

3±digit number stamped at top edge (Fig. 41). Posi-

tion keyway into pump shaft witharrow pointed to

rear of pump.Also be sure 3±digit number stamped

to top of keyway is same as 3±digit number stamped

to injection pump data plate (Fig. 43). If wrong key-

way is installed, a diagnostic trouble code may be

set.

(7) Position pump assembly to mounting flange on

gear cover while aligning injection pump shaft

through back of injection pump gear. When installing

pump, dowel (Fig. 42) on mounting flange must align

to hole in front of pump.(8) After pump is positioned flat to mounting

flange, install four pump mounting nuts and tighten

finger tight only. Do not attempt a final tightening at

this time.Do not attempt to tighten (pull) pump

to gear cover using mounting nuts. Damage to

pump or gear cover may occur. The pump must

be positioned flat to its mounting flange before

attempting to tighten mounting nuts.

(9) To prevent damage or cracking of components,

tighten nuts/bolts in the following sequence:

(a) Install injection pump shaft washer and nut

to pump shaft. Tighten nutfinger tight only.

(b) Install 2 rear/lower pump mounting bolts

finger tight only.

(c) Do preliminary tightening of injection pump

shaft nut to 30 N´m (15±22 ft. lbs.) torque.This is

not the final torque.

(d) Tighten 4 pump mounting nuts to 43 N´m

(32 ft. lbs.) torque.

(e) Tighten 2 rear/lower pump bracket-to-pump

bolts 24 N´m (18 ft. lbs.) torque.

(f) Do final tightening of injection pump shaft

nut to 170 N´m (125 ft. lbs.) torque. Use barring

tool to prevent engine from rotating when tighten-

ing gear.

(10) Install canister (Fig. 33) to gear cover.

(11) Install crankcase vent hose (Fig. 33) to canis-

ter and install hose clamp.

(12) Using new gaskets, install fuel return line

and overflow valve to side of injection pump (Fig. 32).

Tighten overflow valve to 24 N´m (18 ft. lbs.) torque.

(13) Using new gaskets, install fuel supply line to

side of injection pump and top of fuel filter housing

(Fig. 32). Tighten banjo bolts to 24 N´m (18 ft. lbs.)

torque.

(14) Install all high-pressure fuel lines, intake air

tube, accelerator pedal position sensor, air intake

housing, engine oil dipstick tube, wiring clips, electri-

cal cables at intake heaters and engine lifting

bracket. Refer to High-Pressure Fuel Line Removal/

Installation. All of these items are covered in this

procedure.

(15) Connect 9±way electrical connector to Fuel

Pump Control Module (FPCM) (Fig. 31).

(16) Connect both negative battery cables to both

batteries.

(17) Bleed air from fuel system.(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE).

(18) Check system for fuel or engine oil leaks.

Fig. 43 Injection Pump Data Plate Location

1 - PUMP DATA PLATE

14 - 76 FUEL DELIVERY - DIESELBR/BE

FUEL INJECTION PUMP (Continued)

Page 1376 of 2255

FUEL INJECTION PUMP DATA

PLATE

SPECIFICATIONS

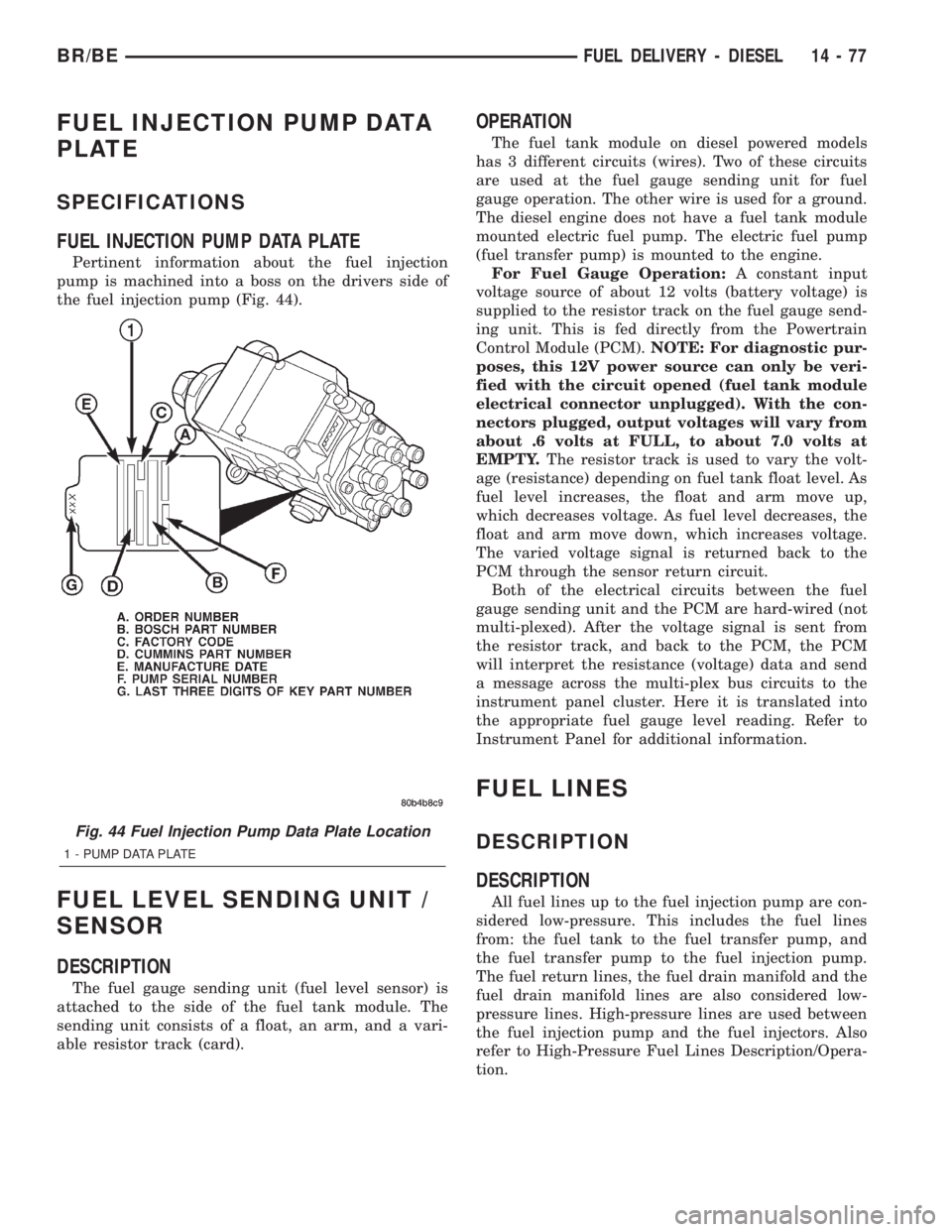

FUEL INJECTION PUMP DATA PLATE

Pertinent information about the fuel injection

pump is machined into a boss on the drivers side of

the fuel injection pump (Fig. 44).

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel tank module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel tank module on diesel powered models

has 3 different circuits (wires). Two of these circuits

are used at the fuel gauge sending unit for fuel

gauge operation. The other wire is used for a ground.

The diesel engine does not have a fuel tank module

mounted electric fuel pump. The electric fuel pump

(fuel transfer pump) is mounted to the engine.

For Fuel Gauge Operation:A constant input

voltage source of about 12 volts (battery voltage) is

supplied to the resistor track on the fuel gauge send-

ing unit. This is fed directly from the Powertrain

Control Module (PCM).NOTE: For diagnostic pur-

poses, this 12V power source can only be veri-

fied with the circuit opened (fuel tank module

electrical connector unplugged). With the con-

nectors plugged, output voltages will vary from

about .6 volts at FULL, to about 7.0 volts at

EMPTY.The resistor track is used to vary the volt-

age (resistance) depending on fuel tank float level. As

fuel level increases, the float and arm move up,

which decreases voltage. As fuel level decreases, the

float and arm move down, which increases voltage.

The varied voltage signal is returned back to the

PCM through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

FUEL LINES

DESCRIPTION

DESCRIPTION

All fuel lines up to the fuel injection pump are con-

sidered low-pressure. This includes the fuel lines

from: the fuel tank to the fuel transfer pump, and

the fuel transfer pump to the fuel injection pump.

The fuel return lines, the fuel drain manifold and the

fuel drain manifold lines are also considered low-

pressure lines. High-pressure lines are used between

the fuel injection pump and the fuel injectors. Also

refer to High-Pressure Fuel Lines Description/Opera-

tion.

Fig. 44 Fuel Injection Pump Data Plate Location

1 - PUMP DATA PLATE

BR/BEFUEL DELIVERY - DIESEL 14 - 77

Page 1377 of 2255

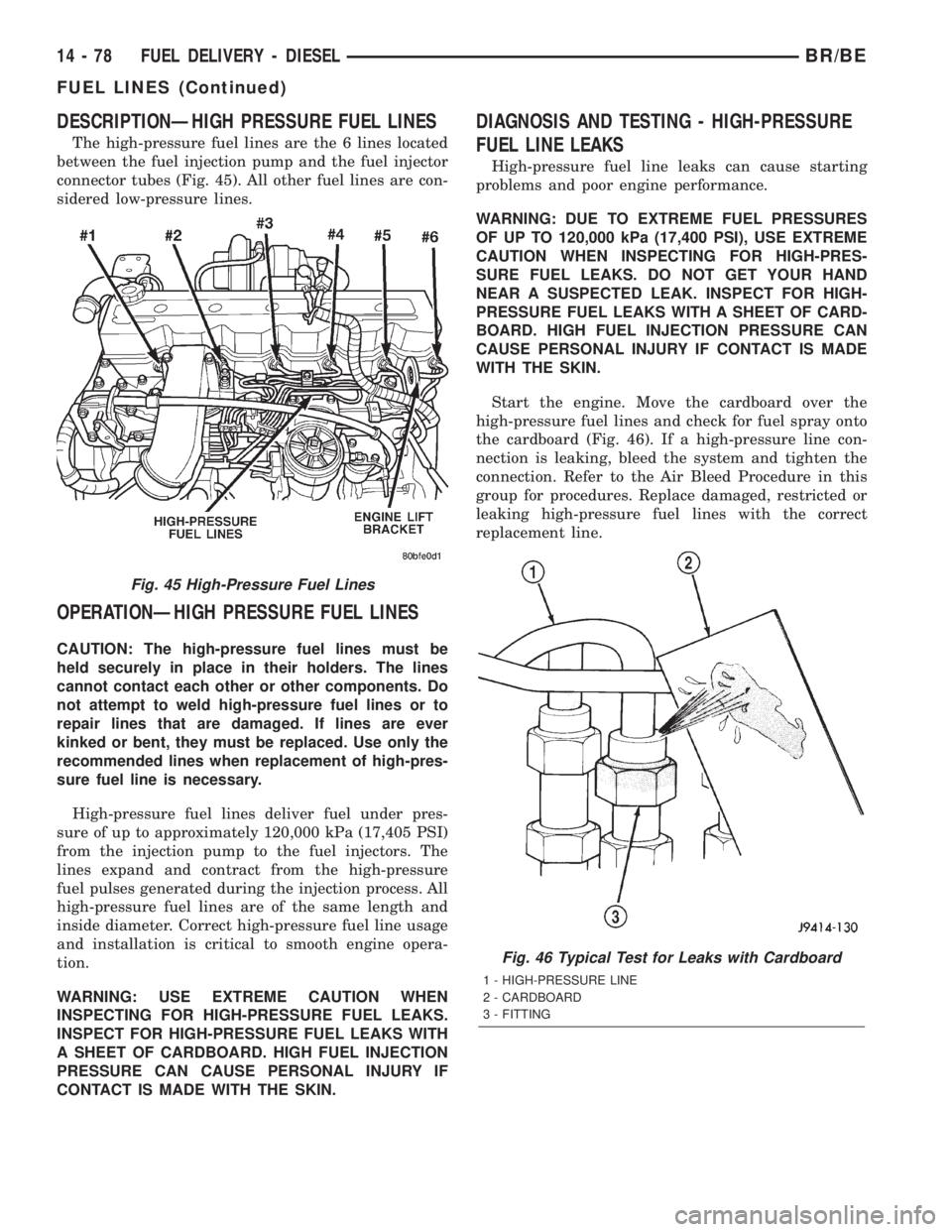

DESCRIPTIONÐHIGH PRESSURE FUEL LINES

The high-pressure fuel lines are the 6 lines located

between the fuel injection pump and the fuel injector

connector tubes (Fig. 45). All other fuel lines are con-

sidered low-pressure lines.

OPERATIONÐHIGH PRESSURE FUEL LINES

CAUTION: The high-pressure fuel lines must be

held securely in place in their holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. If lines are ever

kinked or bent, they must be replaced. Use only the

recommended lines when replacement of high-pres-

sure fuel line is necessary.

High-pressure fuel lines deliver fuel under pres-

sure of up to approximately 120,000 kPa (17,405 PSI)

from the injection pump to the fuel injectors. The

lines expand and contract from the high-pressure

fuel pulses generated during the injection process. All

high-pressure fuel lines are of the same length and

inside diameter. Correct high-pressure fuel line usage

and installation is critical to smooth engine opera-

tion.

WARNING: USE EXTREME CAUTION WHEN

INSPECTING FOR HIGH-PRESSURE FUEL LEAKS.

INSPECT FOR HIGH-PRESSURE FUEL LEAKS WITH

A SHEET OF CARDBOARD. HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

DIAGNOSIS AND TESTING - HIGH-PRESSURE

FUEL LINE LEAKS

High-pressure fuel line leaks can cause starting

problems and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES

OF UP TO 120,000 kPa (17,400 PSI), USE EXTREME

CAUTION WHEN INSPECTING FOR HIGH-PRES-

SURE FUEL LEAKS. DO NOT GET YOUR HAND

NEAR A SUSPECTED LEAK. INSPECT FOR HIGH-

PRESSURE FUEL LEAKS WITH A SHEET OF CARD-

BOARD. HIGH FUEL INJECTION PRESSURE CAN

CAUSE PERSONAL INJURY IF CONTACT IS MADE

WITH THE SKIN.

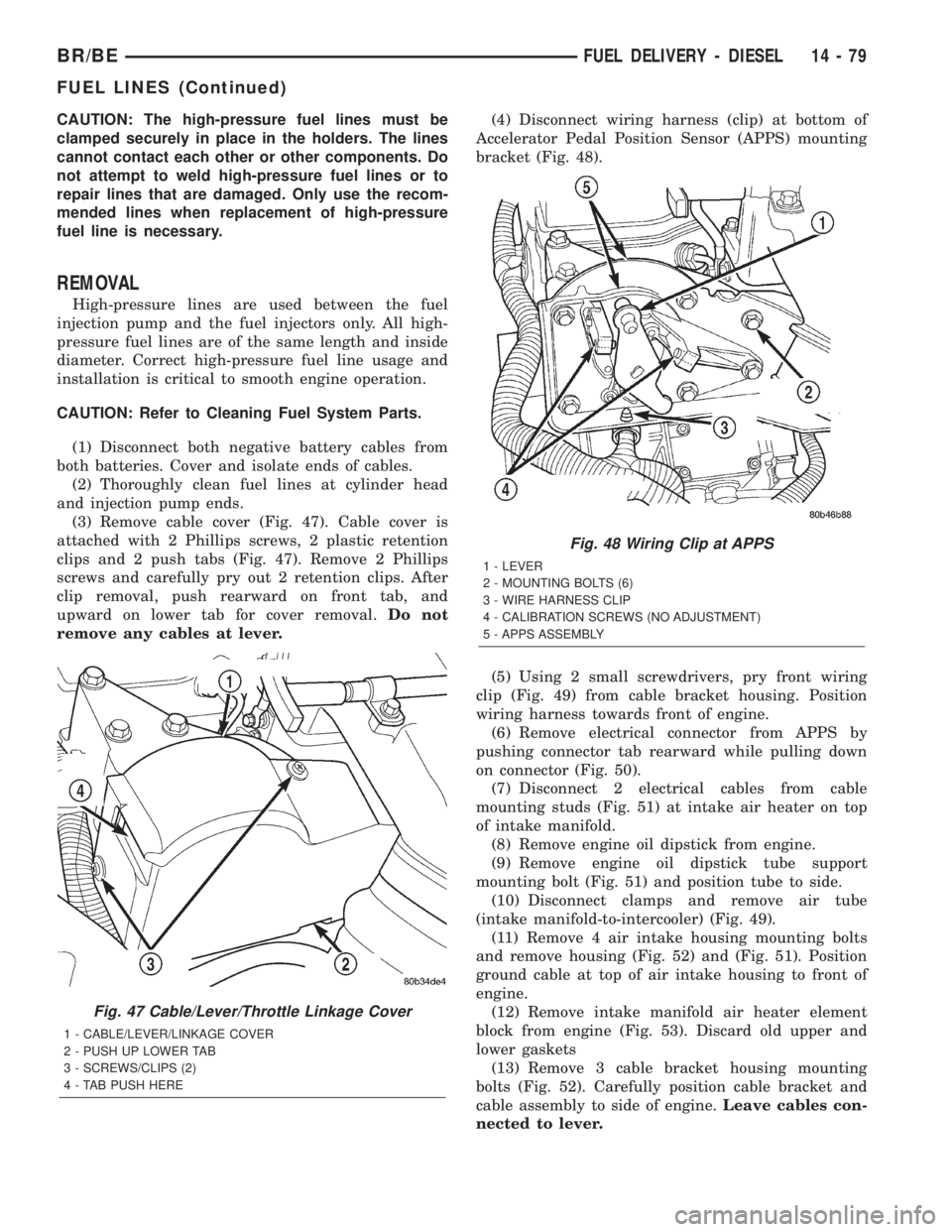

Start the engine. Move the cardboard over the

high-pressure fuel lines and check for fuel spray onto

the cardboard (Fig. 46). If a high-pressure line con-

nection is leaking, bleed the system and tighten the

connection. Refer to the Air Bleed Procedure in this

group for procedures. Replace damaged, restricted or

leaking high-pressure fuel lines with the correct

replacement line.

Fig. 45 High-Pressure Fuel Lines

Fig. 46 Typical Test for Leaks with Cardboard

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - FITTING

14 - 78 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1378 of 2255

CAUTION: The high-pressure fuel lines must be

clamped securely in place in the holders. The lines

cannot contact each other or other components. Do

not attempt to weld high-pressure fuel lines or to

repair lines that are damaged. Only use the recom-

mended lines when replacement of high-pressure

fuel line is necessary.

REMOVAL

High-pressure lines are used between the fuel

injection pump and the fuel injectors only. All high-

pressure fuel lines are of the same length and inside

diameter. Correct high-pressure fuel line usage and

installation is critical to smooth engine operation.

CAUTION: Refer to Cleaning Fuel System Parts.

(1) Disconnect both negative battery cables from

both batteries. Cover and isolate ends of cables.

(2) Thoroughly clean fuel lines at cylinder head

and injection pump ends.

(3) Remove cable cover (Fig. 47). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 47). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.Do not

remove any cables at lever.(4) Disconnect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 48).

(5) Using 2 small screwdrivers, pry front wiring

clip (Fig. 49) from cable bracket housing. Position

wiring harness towards front of engine.

(6) Remove electrical connector from APPS by

pushing connector tab rearward while pulling down

on connector (Fig. 50).

(7) Disconnect 2 electrical cables from cable

mounting studs (Fig. 51) at intake air heater on top

of intake manifold.

(8) Remove engine oil dipstick from engine.

(9) Remove engine oil dipstick tube support

mounting bolt (Fig. 51) and position tube to side.

(10) Disconnect clamps and remove air tube

(intake manifold-to-intercooler) (Fig. 49).

(11) Remove 4 air intake housing mounting bolts

and remove housing (Fig. 52) and (Fig. 51). Position

ground cable at top of air intake housing to front of

engine.

(12) Remove intake manifold air heater element

block from engine (Fig. 53). Discard old upper and

lower gaskets

(13) Remove 3 cable bracket housing mounting

bolts (Fig. 52). Carefully position cable bracket and

cable assembly to side of engine.Leave cables con-

nected to lever.

Fig. 47 Cable/Lever/Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 48 Wiring Clip at APPS

1 - LEVER

2 - MOUNTING BOLTS (6)

3 - WIRE HARNESS CLIP

4 - CALIBRATION SCREWS (NO ADJUSTMENT)

5 - APPS ASSEMBLY

BR/BEFUEL DELIVERY - DIESEL 14 - 79

FUEL LINES (Continued)

Page 1379 of 2255

Fig. 49 Air Tube (Typical)

1 - ENGINE OIL DIPSTICK TUBE

2 - TUBE BOLT

3 - CLAMPS

4 - AIR TUBE (INTAKE MANIFOLD TO CHARGE AIR COOLER

5 - CABLE BRACKET HOUSING

6 - FRONT WIRING CLIP

7 - GROUND CABLE

8 - RUBBER HOSE

9 - AIR INTAKE HOUSING

Fig. 50 Rear View of APPS

1 - APPS

2-TAB

3 - PUSH FOR REMOVAL

4 - APPS CONNECTOR

Fig. 51 Air Intake Housing (Rear View)

1 - TUBE MOUNTING BOLT

2 - HOUSING BOLTS (2)

3 - INTAKE HEATER CABLE MOUNTING STUDS (2)

4 - DIPSTICK TUBE

Fig. 52 Air Intake Housing (Front View)

1 - GROUND CABLE BOLT

2 - INTAKE AIR HOUSING

3 - CABLE BRACKET HOUSING BOLTS (3)

4 - GROUND CABLE

14 - 80 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)

Page 1380 of 2255

(14) Remove engine lifting bracket at rear of

intake manifold (2 bolts) (Fig. 54).

(15) Remove bolts from all fuel injection line sup-

port brackets at intake manifold.

(16) Place shop towels around fuel lines at fuel

injectors. Do not allow fuel to drip down side of

engine.CAUTION: WHEN LOOSENING OR TIGHTENING

HIGH-PRESSURE FITTINGS AT INJECTION PUMP,

USE A BACK-UP WRENCH ON DELIVERY VALVE AT

PUMP. DO NOT ALLOW DELIVERY VALVE TO

ROTATE.

(17) Loosen high-pressure line fittings at injection

pump (Fig. 55) beginning with cylinders 1, 2 and 4.

(18) Loosen high-pressure lines at cylinder head

for cylinders 1, 2 and 4 (Fig. 54).

(19) Carefully remove front line bundle from

engine.Do not bend lines while removing.While

removing front line bundle, note line position.

(20) Loosen high-pressure lines at injection pump

beginning with cylinders 3, 5 and 6.

(21) Loosen high-pressure lines at cylinder head

for cylinders 3, 5 and 6 (Fig. 54).

(22) Carefully remove rear line bundle from

engine.Do not bend lines while removing.While

removing rear line bundle, note line position.

INSTALLATION

High-pressure lines are used between the fuel

injection pump and the fuel injectors only. All high-

pressure fuel lines are of the same length and inside

diameter. Correct high-pressure fuel line usage and

installation is critical to smooth engine operation.

Fig. 53 Intake Manifold Air Heater (Elements)

1 - AIR HEATER ELEMENTS

2 - LOWER GASKET

3 - BLOCK

4 - UPPER GASKET

Fig. 54 High-Pressure Fuel Lines

Fig. 55 High Pressure Lines at Fuel Injection Pump

1 - FPCM ELECTRICAL CONNECTOR

2 - HIGH-PRESSURE FUEL LINES

3 - FITTINGS

4 - FUEL INJECTION PUMP

5 - FPCM

BR/BEFUEL DELIVERY - DIESEL 14 - 81

FUEL LINES (Continued)

Page 1381 of 2255

CAUTION: Be sure that the high-pressure fuel lines

are installed in the same order that they were

removed.

(1) Lubricate threads of injector line fittings with

clean engine oil.

(2) Loosen, but do not remove, all fuel line support

bracket bolts.

(3) Installrearinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(4) Tighten fittings at fuel injector ends for cylin-

ders number 6 and 5 to 38 N´m (28 ft. lbs.) torque.

Do not tighten number 3 line at this time. It

will be tightened during bleeding procedure.

(5) Tighten 3 fittings at fuel injection pump ends

to 24 N´m (18 ft. lbs.) torque.

(6) Installfrontinjection line bundle beginning

with cylinder head (fuel injector) connections, fol-

lowed by injection pump connections. Tighten all fit-

tings finger tight.

(7) Tighten fitting at fuel injector end for cylinder

number 2 to 38 N´m (28 ft. lbs.) torque.Do not

tighten lines number 1 or 4 at this time. They

will be tightened during bleeding procedure.

(8) Tighten remaining 3 fittings at fuel injection

pump ends to 24 N´m (18 ft. lbs.) torque.

(9) Install fuel line support bracket bolts to intake

manifold and tighten to 24 N´m (18 ft. lbs.) torque.

CAUTION: Be sure fuel lines are not contacting

each other or any other component. Noise will

result.

(10) Install engine lifting bracket at rear of intake

manifold. Tighten 2 bolts to 77 N´m (57 ft. lbs.)

torque.

(11) Install cable bracket housing/cable assembly

and tighten 3 mounting bolts to 24 N´m (18 ft. lbs.)

torque.

(12) Clean any old gasket material below and

above intake manifold air heater element block. Also

clean mating areas at intake manifold and air intake

housing.

(13) Using new gaskets, position intake manifold

air heater element block to engine.

(14) Install air intake housing and position ground

cable. Install 4 mounting bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(15) Install air tube (intake manifold-to-charge air

cooler) (Fig. 49). Tighten clamps to 8 N´m (72 in. lbs.)

torque.

(16) Install engine oil dipstick tube support mount-

ing bolt and tighten to 24 N´m (18 ft. lbs.) torque.

(17) Install engine oil dipstick to engine.(18) Connect 2 electrical cables to cable mounting

studs.

(19) Connect electrical connector to bottom of

APPS by pushing connector upward until it snaps

into position.

(20) Connect wiring harness (clip) at bottom of

Accelerator Pedal Position Sensor (APPS) mounting

bracket (Fig. 48).

(21) Connect front wiring clip (Fig. 49) to cable

bracket housing.

(22) Install cable cover (Fig. 47).

(23) Connect both negative battery cables to both

batteries.

(24) Bleed air from fuel system. Do this at fuel

injector ends of lines. Use cylinders numbers 1, 3 and

4 for bleeding. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE). After

bleeding, tighten fittings to 38 N´m (28 ft. lbs.)

torque.

(25) Check lines/fittings for leaks.

FUEL TANK

DESCRIPTION - DIESEL FUEL TANK

The fuel tank is similar to the tank used with gas-

oline powered models. The tank is equipped with a

separate fuel return line and a different fuel tank

module for diesel powered models. A fuel tank

mounted, electric fuel pump is not used with diesel

powered models. Refer to Fuel Tank Module for addi-

tional information.

For removal and installation procedures, refer to

Fuel Tank - Gasoline Engines.

FUEL TANK MODULE

DESCRIPTION

An electric fuel pump isnot usedin the fuel tank

module for diesel powered engines. Fuel is supplied

by the engine mounted fuel transfer pump and the

fuel injection pump.

The fuel tank module is installed in the top of the

fuel tank (Fig. 56). The fuel tank module (Fig. 56)

contains the following components:

²Fuel reservoir

²A separate in-tank fuel filter

²Rollover valve

²Fuel gauge sending unit (fuel level sensor)

²Fuel supply line connection

²Fuel return line connection

²Auxiliary non-pressurized fuel supply fitting

OPERATION

Refer to Fuel Gauge Sending Unit.

14 - 82 FUEL DELIVERY - DIESELBR/BE

FUEL LINES (Continued)