engine DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 1405 of 2255

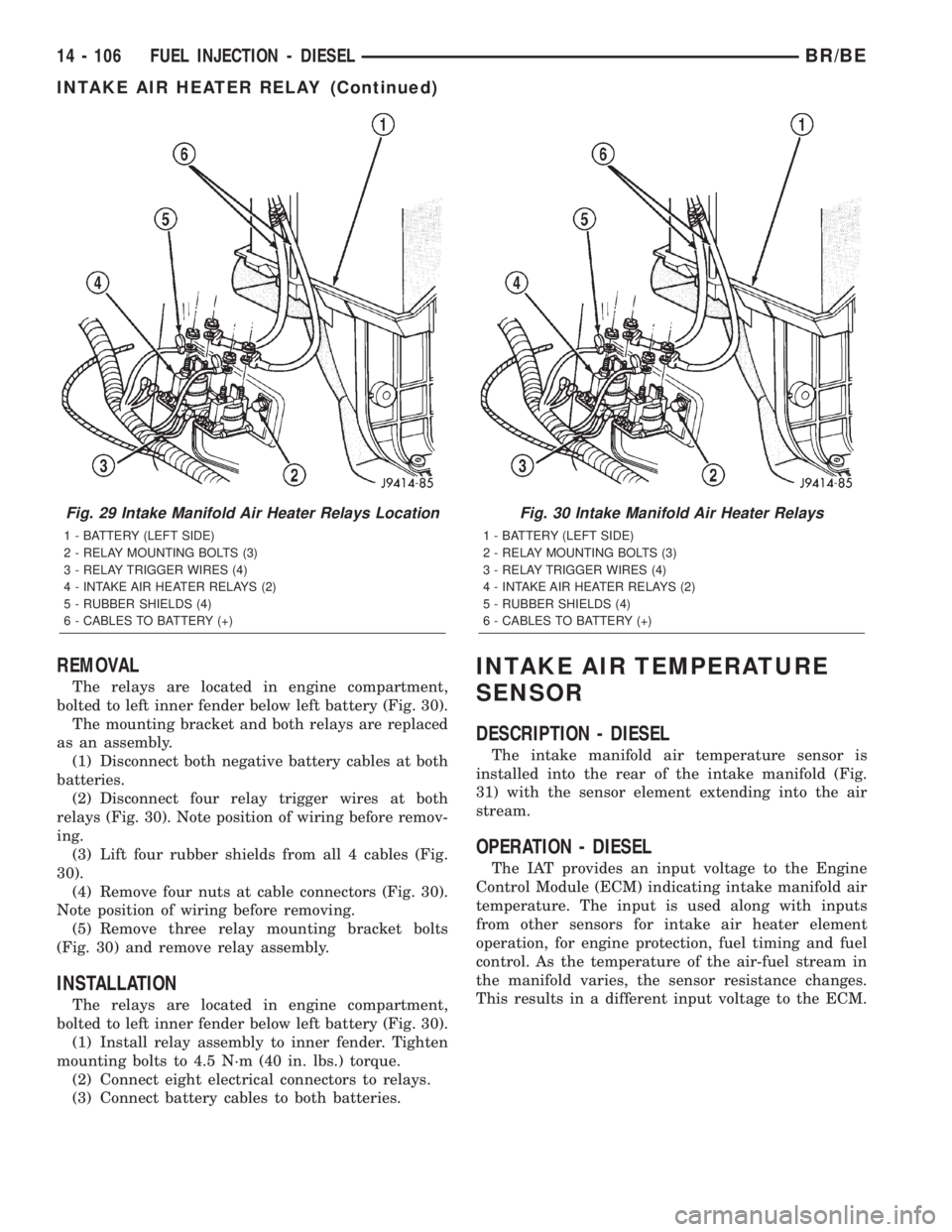

REMOVAL

The relays are located in engine compartment,

bolted to left inner fender below left battery (Fig. 30).

The mounting bracket and both relays are replaced

as an assembly.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect four relay trigger wires at both

relays (Fig. 30). Note position of wiring before remov-

ing.

(3) Lift four rubber shields from all 4 cables (Fig.

30).

(4) Remove four nuts at cable connectors (Fig. 30).

Note position of wiring before removing.

(5) Remove three relay mounting bracket bolts

(Fig. 30) and remove relay assembly.

INSTALLATION

The relays are located in engine compartment,

bolted to left inner fender below left battery (Fig. 30).

(1) Install relay assembly to inner fender. Tighten

mounting bolts to 4.5 N´m (40 in. lbs.) torque.

(2) Connect eight electrical connectors to relays.

(3) Connect battery cables to both batteries.

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION - DIESEL

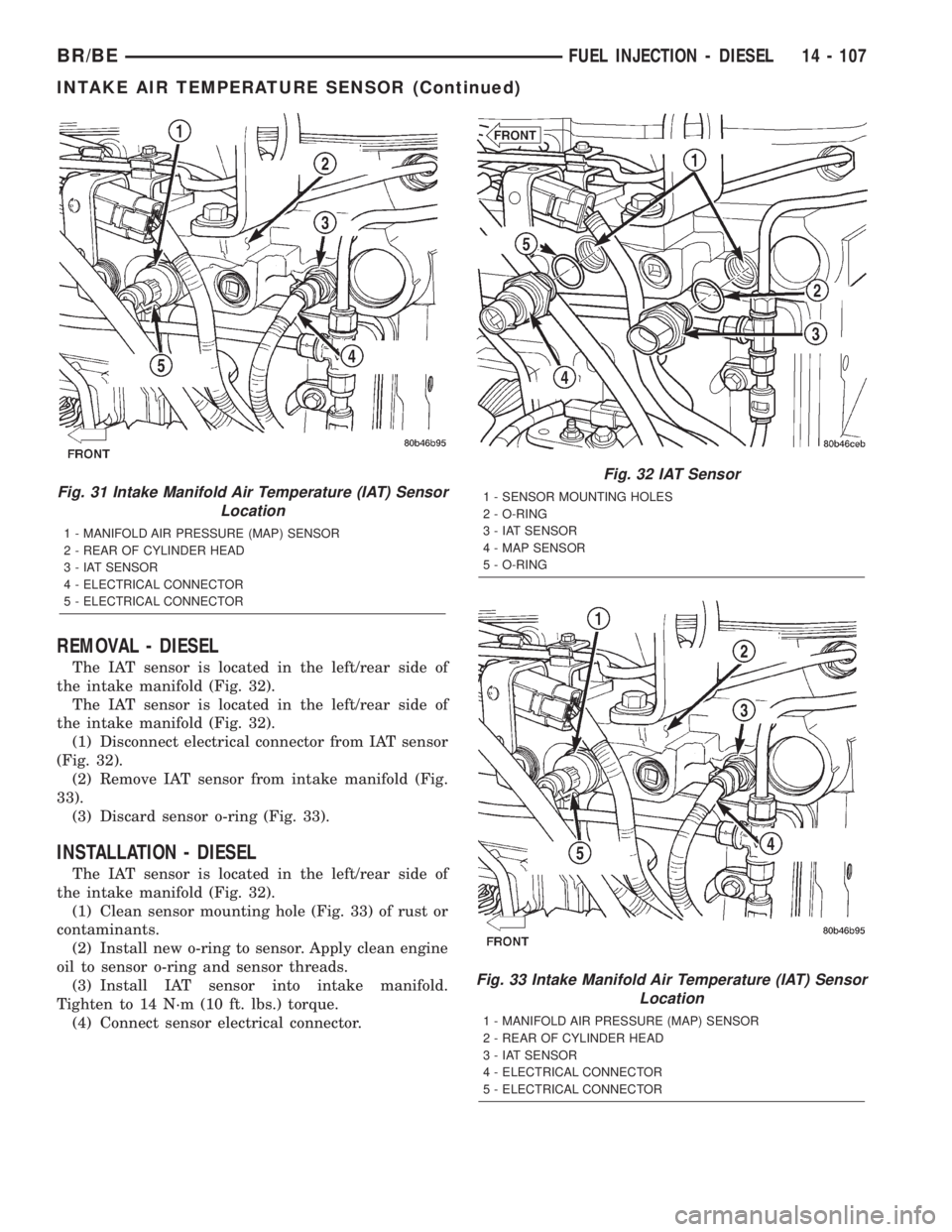

The intake manifold air temperature sensor is

installed into the rear of the intake manifold (Fig.

31) with the sensor element extending into the air

stream.

OPERATION - DIESEL

The IAT provides an input voltage to the Engine

Control Module (ECM) indicating intake manifold air

temperature. The input is used along with inputs

from other sensors for intake air heater element

operation, for engine protection, fuel timing and fuel

control. As the temperature of the air-fuel stream in

the manifold varies, the sensor resistance changes.

This results in a different input voltage to the ECM.

Fig. 29 Intake Manifold Air Heater Relays Location

1 - BATTERY (LEFT SIDE)

2 - RELAY MOUNTING BOLTS (3)

3 - RELAY TRIGGER WIRES (4)

4 - INTAKE AIR HEATER RELAYS (2)

5 - RUBBER SHIELDS (4)

6 - CABLES TO BATTERY (+)

Fig. 30 Intake Manifold Air Heater Relays

1 - BATTERY (LEFT SIDE)

2 - RELAY MOUNTING BOLTS (3)

3 - RELAY TRIGGER WIRES (4)

4 - INTAKE AIR HEATER RELAYS (2)

5 - RUBBER SHIELDS (4)

6 - CABLES TO BATTERY (+)

14 - 106 FUEL INJECTION - DIESELBR/BE

INTAKE AIR HEATER RELAY (Continued)

Page 1406 of 2255

REMOVAL - DIESEL

The IAT sensor is located in the left/rear side of

the intake manifold (Fig. 32).

The IAT sensor is located in the left/rear side of

the intake manifold (Fig. 32).

(1) Disconnect electrical connector from IAT sensor

(Fig. 32).

(2) Remove IAT sensor from intake manifold (Fig.

33).

(3) Discard sensor o-ring (Fig. 33).

INSTALLATION - DIESEL

The IAT sensor is located in the left/rear side of

the intake manifold (Fig. 32).

(1) Clean sensor mounting hole (Fig. 33) of rust or

contaminants.

(2) Install new o-ring to sensor. Apply clean engine

oil to sensor o-ring and sensor threads.

(3) Install IAT sensor into intake manifold.

Tighten to 14 N´m (10 ft. lbs.) torque.

(4) Connect sensor electrical connector.

Fig. 31 Intake Manifold Air Temperature (IAT) Sensor

Location

1 - MANIFOLD AIR PRESSURE (MAP) SENSOR

2 - REAR OF CYLINDER HEAD

3 - IAT SENSOR

4 - ELECTRICAL CONNECTOR

5 - ELECTRICAL CONNECTOR

Fig. 32 IAT Sensor

1 - SENSOR MOUNTING HOLES

2 - O-RING

3 - IAT SENSOR

4 - MAP SENSOR

5 - O-RING

Fig. 33 Intake Manifold Air Temperature (IAT) Sensor

Location

1 - MANIFOLD AIR PRESSURE (MAP) SENSOR

2 - REAR OF CYLINDER HEAD

3 - IAT SENSOR

4 - ELECTRICAL CONNECTOR

5 - ELECTRICAL CONNECTOR

BR/BEFUEL INJECTION - DIESEL 14 - 107

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1407 of 2255

MAP SENSOR

DESCRIPTION - DIESEL

The MAP sensor is installed into the rear of the

intake manifold (Fig. 31).

OPERATION - DIESEL

The MAP sensor reacts to air pressure changes in

the intake manifold. It provides an input voltage to

the Engine Control Module (ECM). As pressure

changes, MAP sensor voltage will change. The

change in MAP sensor voltage results in a different

input voltage to the ECM. The ECM uses this input,

along with inputs from other sensors to provide fuel

timing, fuel control and engine protection. Engine

protection is used to derate (drop power off) the

engine if turbocharger pressure becomes to high.

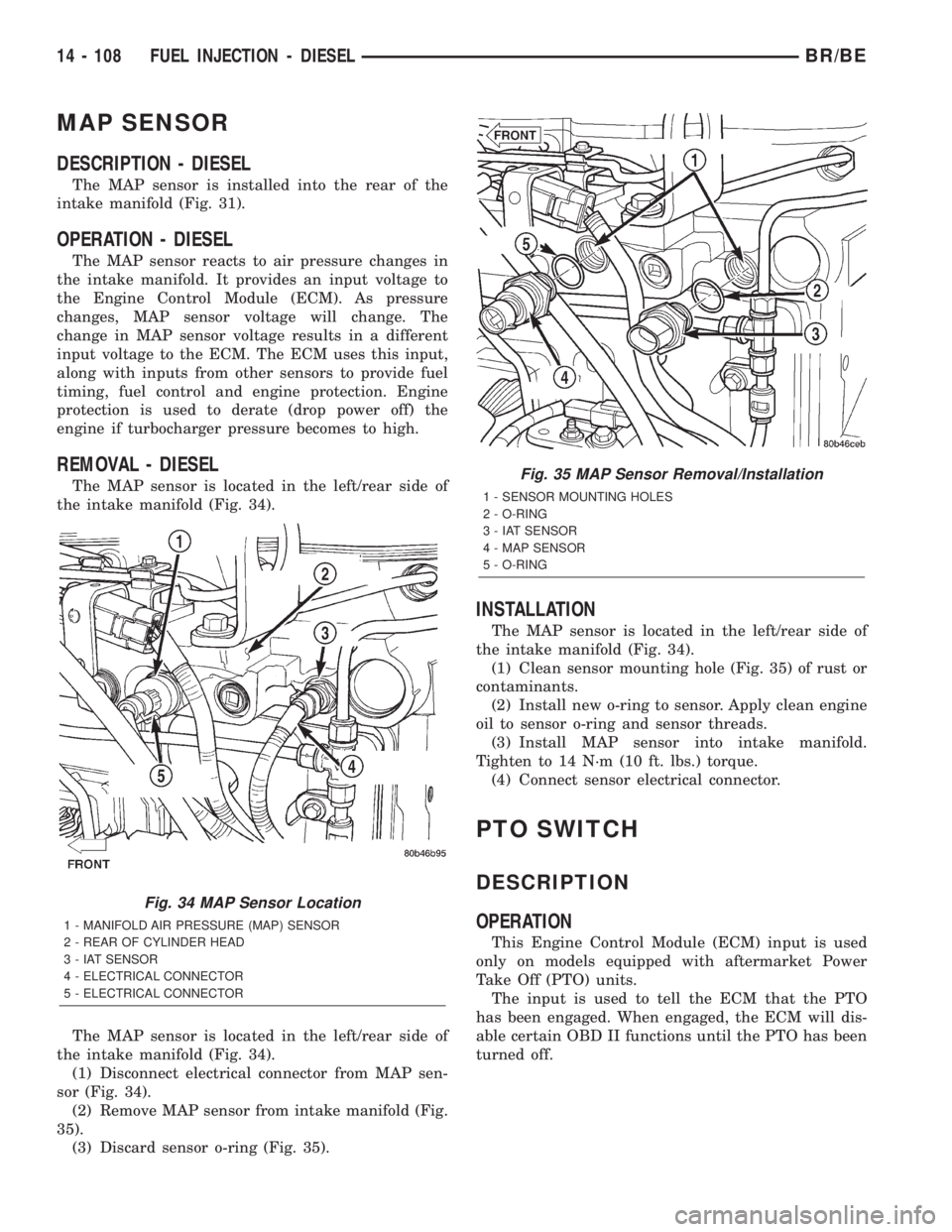

REMOVAL - DIESEL

The MAP sensor is located in the left/rear side of

the intake manifold (Fig. 34).

The MAP sensor is located in the left/rear side of

the intake manifold (Fig. 34).

(1) Disconnect electrical connector from MAP sen-

sor (Fig. 34).

(2) Remove MAP sensor from intake manifold (Fig.

35).

(3) Discard sensor o-ring (Fig. 35).

INSTALLATION

The MAP sensor is located in the left/rear side of

the intake manifold (Fig. 34).

(1) Clean sensor mounting hole (Fig. 35) of rust or

contaminants.

(2) Install new o-ring to sensor. Apply clean engine

oil to sensor o-ring and sensor threads.

(3) Install MAP sensor into intake manifold.

Tighten to 14 N´m (10 ft. lbs.) torque.

(4) Connect sensor electrical connector.

PTO SWITCH

DESCRIPTION

OPERATION

This Engine Control Module (ECM) input is used

only on models equipped with aftermarket Power

Take Off (PTO) units.

The input is used to tell the ECM that the PTO

has been engaged. When engaged, the ECM will dis-

able certain OBD II functions until the PTO has been

turned off.

Fig. 34 MAP Sensor Location

1 - MANIFOLD AIR PRESSURE (MAP) SENSOR

2 - REAR OF CYLINDER HEAD

3 - IAT SENSOR

4 - ELECTRICAL CONNECTOR

5 - ELECTRICAL CONNECTOR

Fig. 35 MAP Sensor Removal/Installation

1 - SENSOR MOUNTING HOLES

2 - O-RING

3 - IAT SENSOR

4 - MAP SENSOR

5 - O-RING

14 - 108 FUEL INJECTION - DIESELBR/BE

Page 1408 of 2255

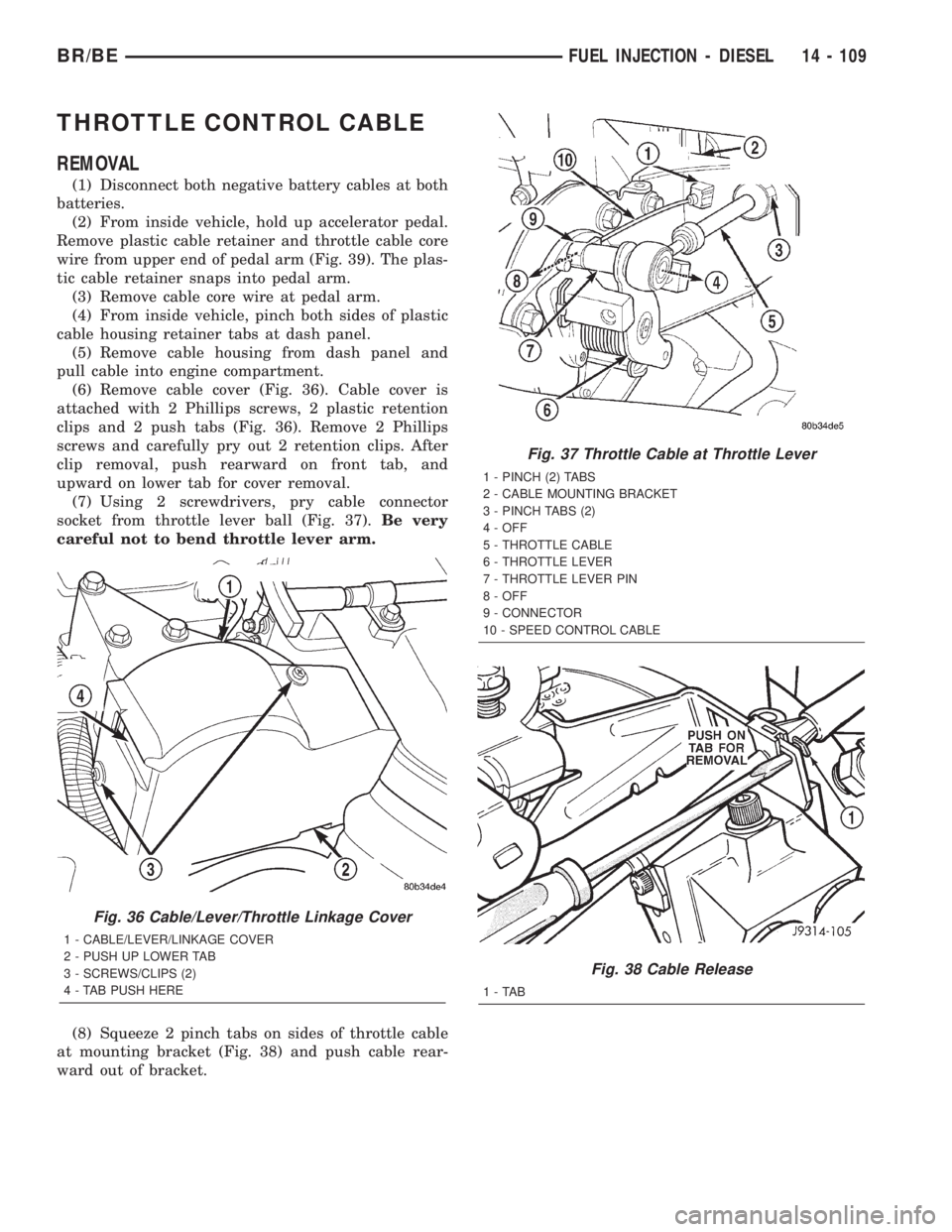

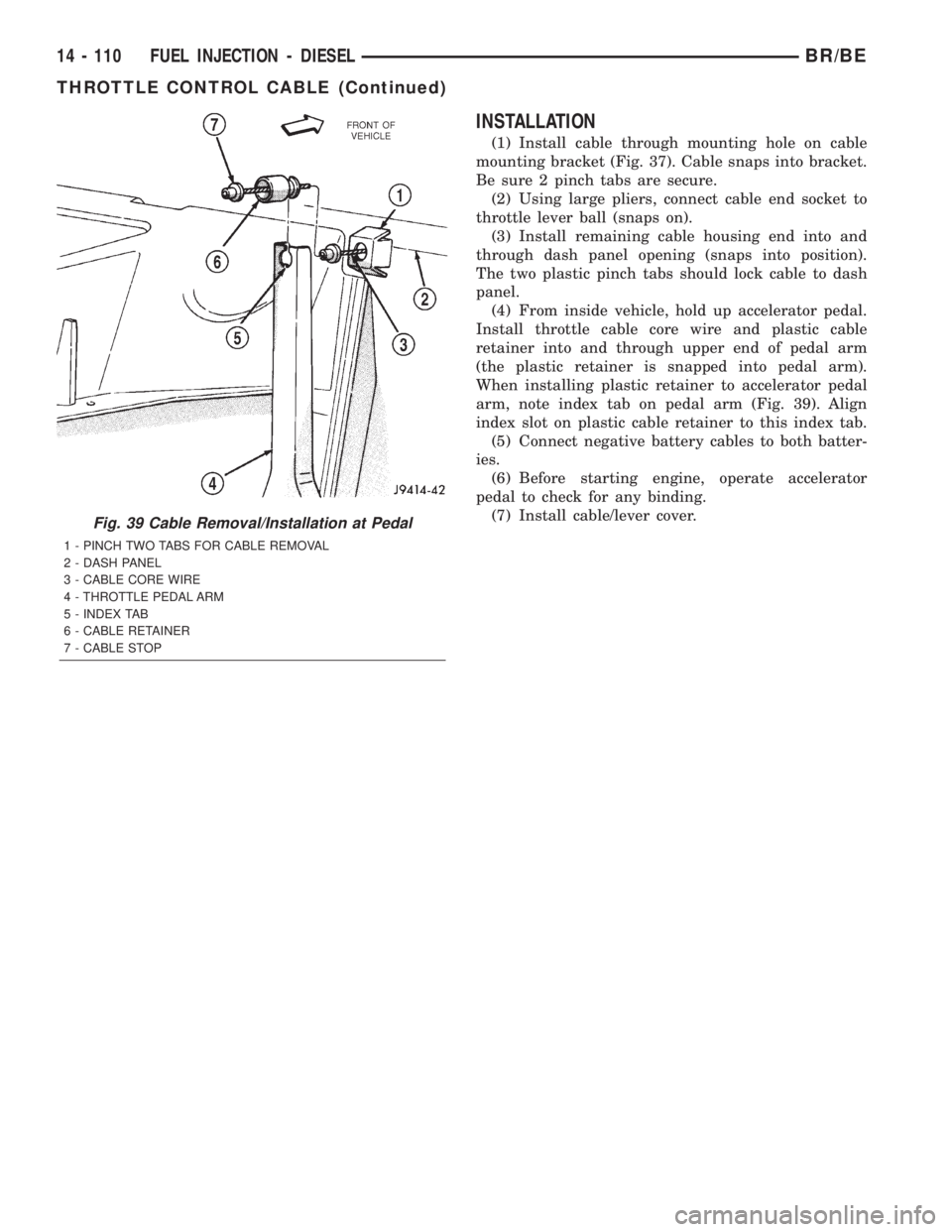

THROTTLE CONTROL CABLE

REMOVAL

(1) Disconnect both negative battery cables at both

batteries.

(2) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer and throttle cable core

wire from upper end of pedal arm (Fig. 39). The plas-

tic cable retainer snaps into pedal arm.

(3) Remove cable core wire at pedal arm.

(4) From inside vehicle, pinch both sides of plastic

cable housing retainer tabs at dash panel.

(5) Remove cable housing from dash panel and

pull cable into engine compartment.

(6) Remove cable cover (Fig. 36). Cable cover is

attached with 2 Phillips screws, 2 plastic retention

clips and 2 push tabs (Fig. 36). Remove 2 Phillips

screws and carefully pry out 2 retention clips. After

clip removal, push rearward on front tab, and

upward on lower tab for cover removal.

(7) Using 2 screwdrivers, pry cable connector

socket from throttle lever ball (Fig. 37).Be very

careful not to bend throttle lever arm.

(8) Squeeze 2 pinch tabs on sides of throttle cable

at mounting bracket (Fig. 38) and push cable rear-

ward out of bracket.

Fig. 36 Cable/Lever/Throttle Linkage Cover

1 - CABLE/LEVER/LINKAGE COVER

2 - PUSH UP LOWER TAB

3 - SCREWS/CLIPS (2)

4 - TAB PUSH HERE

Fig. 37 Throttle Cable at Throttle Lever

1 - PINCH (2) TABS

2 - CABLE MOUNTING BRACKET

3 - PINCH TABS (2)

4 - OFF

5 - THROTTLE CABLE

6 - THROTTLE LEVER

7 - THROTTLE LEVER PIN

8 - OFF

9 - CONNECTOR

10 - SPEED CONTROL CABLE

Fig. 38 Cable Release

1-TAB

BR/BEFUEL INJECTION - DIESEL 14 - 109

Page 1409 of 2255

INSTALLATION

(1) Install cable through mounting hole on cable

mounting bracket (Fig. 37). Cable snaps into bracket.

Be sure 2 pinch tabs are secure.

(2) Using large pliers, connect cable end socket to

throttle lever ball (snaps on).

(3) Install remaining cable housing end into and

through dash panel opening (snaps into position).

The two plastic pinch tabs should lock cable to dash

panel.

(4) From inside vehicle, hold up accelerator pedal.

Install throttle cable core wire and plastic cable

retainer into and through upper end of pedal arm

(the plastic retainer is snapped into pedal arm).

When installing plastic retainer to accelerator pedal

arm, note index tab on pedal arm (Fig. 39). Align

index slot on plastic cable retainer to this index tab.

(5) Connect negative battery cables to both batter-

ies.

(6) Before starting engine, operate accelerator

pedal to check for any binding.

(7) Install cable/lever cover.

Fig. 39 Cable Removal/Installation at Pedal

1 - PINCH TWO TABS FOR CABLE REMOVAL

2 - DASH PANEL

3 - CABLE CORE WIRE

4 - THROTTLE PEDAL ARM

5 - INDEX TAB

6 - CABLE RETAINER

7 - CABLE STOP

14 - 110 FUEL INJECTION - DIESELBR/BE

THROTTLE CONTROL CABLE (Continued)

Page 1413 of 2255

LOOSE STEERING AND VEHICLE LEAD

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE PLAY IN STEERING

WHEEL1. Worn or loose suspension or

steering components.1. Inspect and repair as necessary.

2. Worn or loose wheel bearings. 2. Inspect and repair or adjust

bearings.

3. Steering gear mounting. 3. Tighten gear mounting bolts to

specification.

4. Gear out of adjustment. 4. Adjust gear to specification.

5. Worn or loose steering coupler. 5. Inspect and replace as

necessary.

VEHICLE PULLS OR LEADS TO

ONE SIDE.1. Tire Pressure. 1. Adjust tire pressure.

2. Radial tire lead. 2. Rotate tires.

3. Brakes dragging. 3. Repair as necessary.

4. Wheel alignment. 4. Align front end.

DIAGNOSIS AND TESTING - POWER STEERING

FLOW AND PRESSURE

The following procedure is used to test the opera-

tion of the power steering system on the vehicle. This

test will provide the flow rate of the power steering

pump along with the maximum relief pressure. Per-

form test any time a power steering system problem

is present. This test will determine if the power

steering pump or power steering gear is not function-

ing properly. The following pressure and flow test is

performed using Power Steering Analyzer Tool kit

6815 (Fig. 2) and Adapter Kit 6893.

POWER STEERING ANALYZER INSTALLATION

WITHOUT HYDRAULIC BOOSTER

(1) Remove the high pressure hose from the power

steering pump.

(2) Connect Tube 6844 into the pump hose fitting.

(3) Connect pressure gauge hose from the Power

Steering Analyzer to Tube 6844.

(4) Connect Adapter 6826 to Power Steering Ana-

lyzer test valve end.

(5) Connect the power steering hose from the

steering gear to Adapter 6826.

WITH HYDRAULIC BOOSTER

(1) Remove high pressure hose which goes to the

steering gear from the tube coming out of the booster.

(2) Connect Adapter 6826 to the Power Steering

Analyzer pressure gauge hose.

(3) Connect pressure gauge hose to the tube com-

ing out of the booster.

(4) Connect Tube 6844 to the steering gear hose

and Power Steering Analyzer test valve end.

FLOW AND PRESSURE TEST

(1) Check belt condition and tension.

(2) Open the test valve completely.

(3) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

gauge and to get air out of the fluid. Then shut off

engine.

(4) Check fluid level, add fluid as necessary. Start

engine again and let idle.

(5) Gauge should read below 1034 kPa (150 psi), if

above, inspect the hoses for restrictions and repair as

Fig. 2 Pressure Test Gauge

1 - GAUGE HOSE

2 - TUBE

3 - ADAPTER FITTINGS

4 - ANALYZER

19 - 4 STEERINGBR/BE

STEERING (Continued)

Page 1414 of 2255

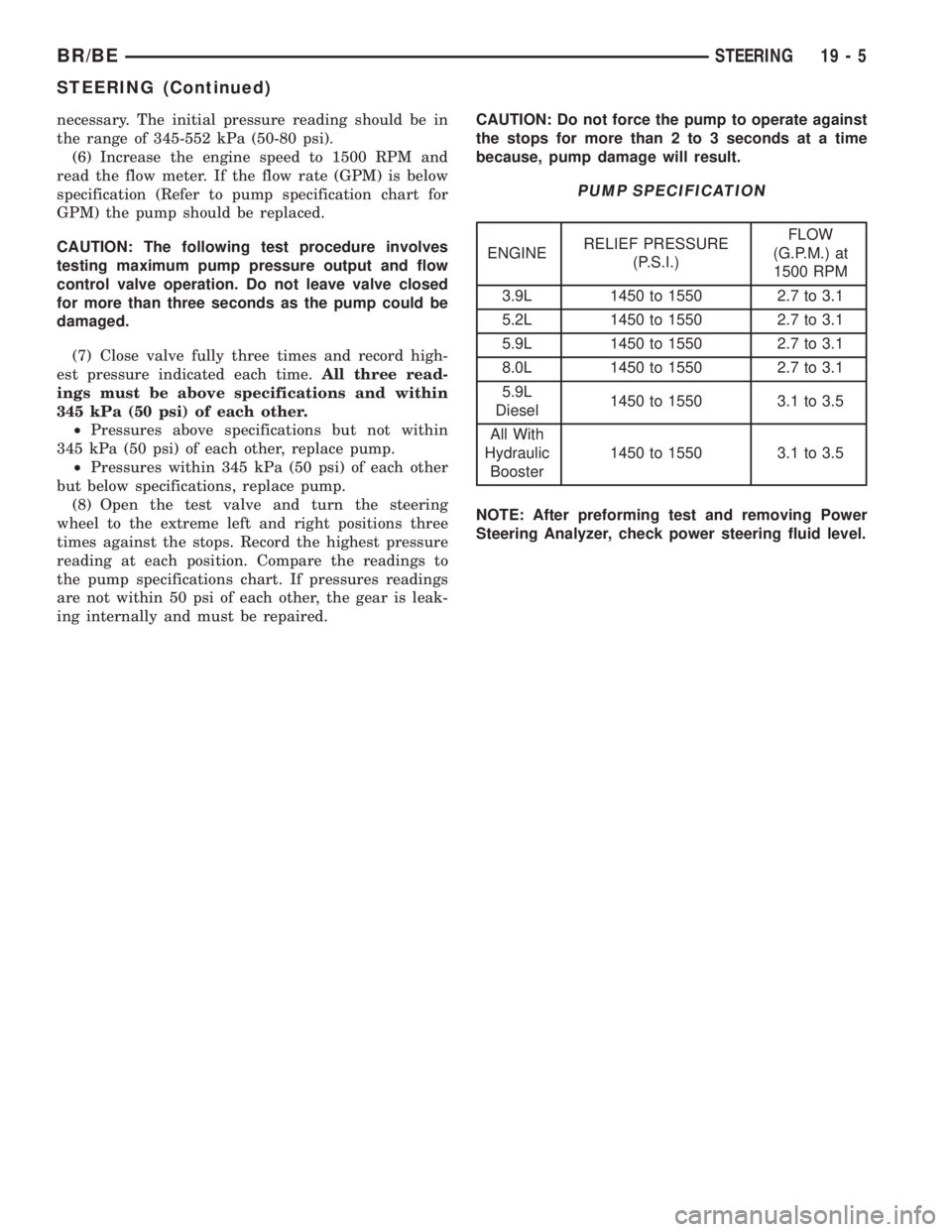

necessary. The initial pressure reading should be in

the range of 345-552 kPa (50-80 psi).

(6) Increase the engine speed to 1500 RPM and

read the flow meter. If the flow rate (GPM) is below

specification (Refer to pump specification chart for

GPM) the pump should be replaced.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than three seconds as the pump could be

damaged.

(7) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

²Pressures above specifications but not within

345 kPa (50 psi) of each other, replace pump.

²Pressures within 345 kPa (50 psi) of each other

but below specifications, replace pump.

(8) Open the test valve and turn the steering

wheel to the extreme left and right positions three

times against the stops. Record the highest pressure

reading at each position. Compare the readings to

the pump specifications chart. If pressures readings

are not within 50 psi of each other, the gear is leak-

ing internally and must be repaired.CAUTION: Do not force the pump to operate against

the stops for more than 2 to 3 seconds at a time

because, pump damage will result.

PUMP SPECIFICATION

ENGINERELIEF PRESSURE

(P.S.I.)FLOW

(G.P.M.) at

1500 RPM

3.9L 1450 to 1550 2.7 to 3.1

5.2L 1450 to 1550 2.7 to 3.1

5.9L 1450 to 1550 2.7 to 3.1

8.0L 1450 to 1550 2.7 to 3.1

5.9L

Diesel1450 to 1550 3.1 to 3.5

All With

Hydraulic

Booster1450 to 1550 3.1 to 3.5

NOTE: After preforming test and removing Power

Steering Analyzer, check power steering fluid level.

BR/BESTEERING 19 - 5

STEERING (Continued)

Page 1416 of 2255

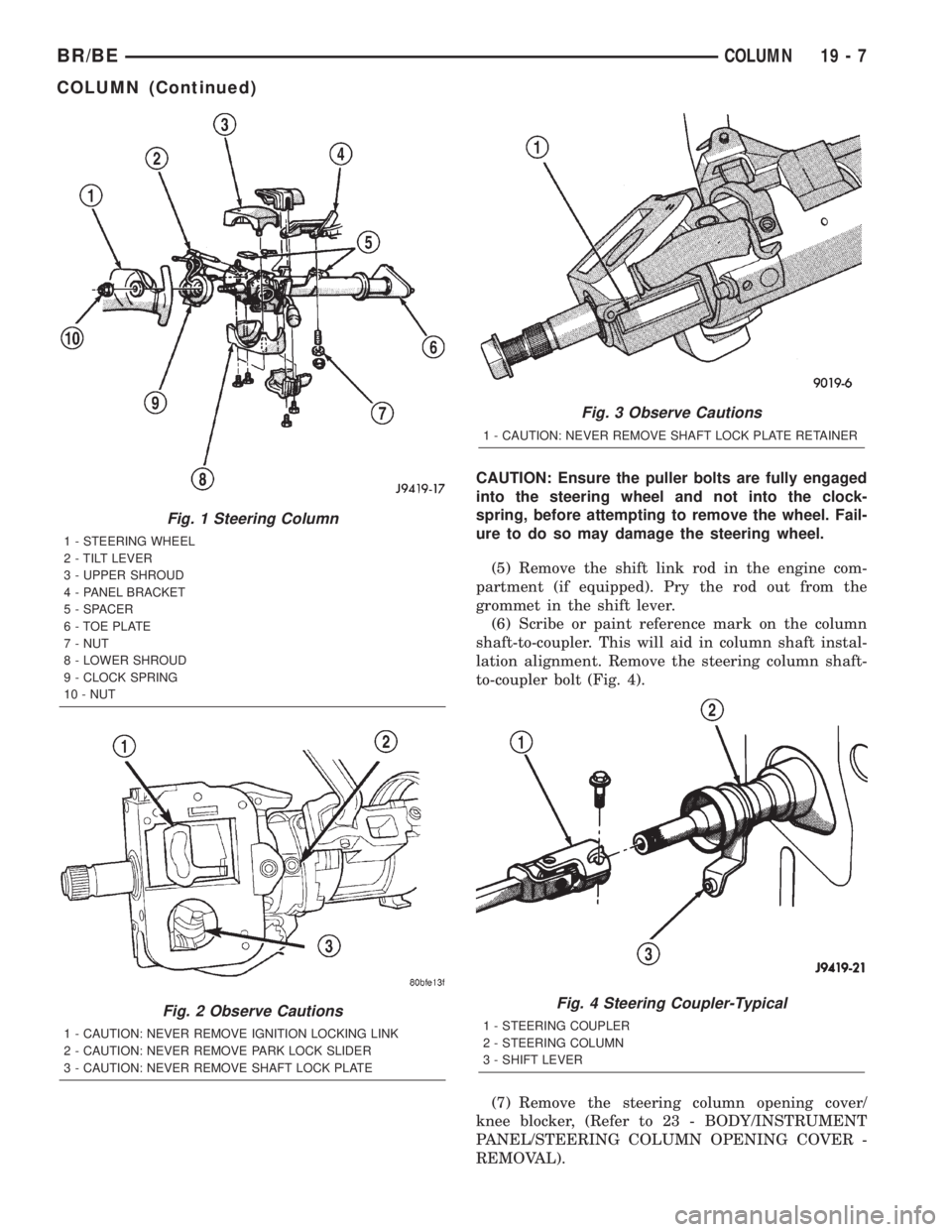

CAUTION: Ensure the puller bolts are fully engaged

into the steering wheel and not into the clock-

spring, before attempting to remove the wheel. Fail-

ure to do so may damage the steering wheel.

(5) Remove the shift link rod in the engine com-

partment (if equipped). Pry the rod out from the

grommet in the shift lever.

(6) Scribe or paint reference mark on the column

shaft-to-coupler. This will aid in column shaft instal-

lation alignment. Remove the steering column shaft-

to-coupler bolt (Fig. 4).

(7) Remove the steering column opening cover/

knee blocker, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

REMOVAL).

Fig. 1 Steering Column

1 - STEERING WHEEL

2 - TILT LEVER

3 - UPPER SHROUD

4 - PANEL BRACKET

5 - SPACER

6 - TOE PLATE

7 - NUT

8 - LOWER SHROUD

9 - CLOCK SPRING

10 - NUT

Fig. 2 Observe Cautions

1 - CAUTION: NEVER REMOVE IGNITION LOCKING LINK

2 - CAUTION: NEVER REMOVE PARK LOCK SLIDER

3 - CAUTION: NEVER REMOVE SHAFT LOCK PLATE

Fig. 3 Observe Cautions

1 - CAUTION: NEVER REMOVE SHAFT LOCK PLATE RETAINER

Fig. 4 Steering Coupler-Typical

1 - STEERING COUPLER

2 - STEERING COLUMN

3 - SHIFT LEVER

BR/BECOLUMN 19 - 7

COLUMN (Continued)

Page 1442 of 2255

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION.........................33

OPERATION...........................33

DIAGNOSIS AND TESTING - PUMP LEAKAGE . 33

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER

STEERING PUMP - INITIAL OPERATION....33

STANDARD PROCEDURE - FLUSHING

POWER STEERING SYSTEM............34

REMOVAL

REMOVAL - GASOLINE ENGINE..........35

REMOVAL - DIESEL ENGINE............36

INSTALLATION

INSTALLATION - GASOLINE ENGINE......37INSTALLATION - DIESEL ENGINE.........37

SPECIAL TOOLS

POWER STEERING PUMP..............38

PULLEY

REMOVAL.............................38

INSTALLATION.........................39

HOSES - PRESSURE

DESCRIPTION.........................39

OPERATION...........................39

HOSES - RETURN

DESCRIPTION.........................39

OPERATION...........................39

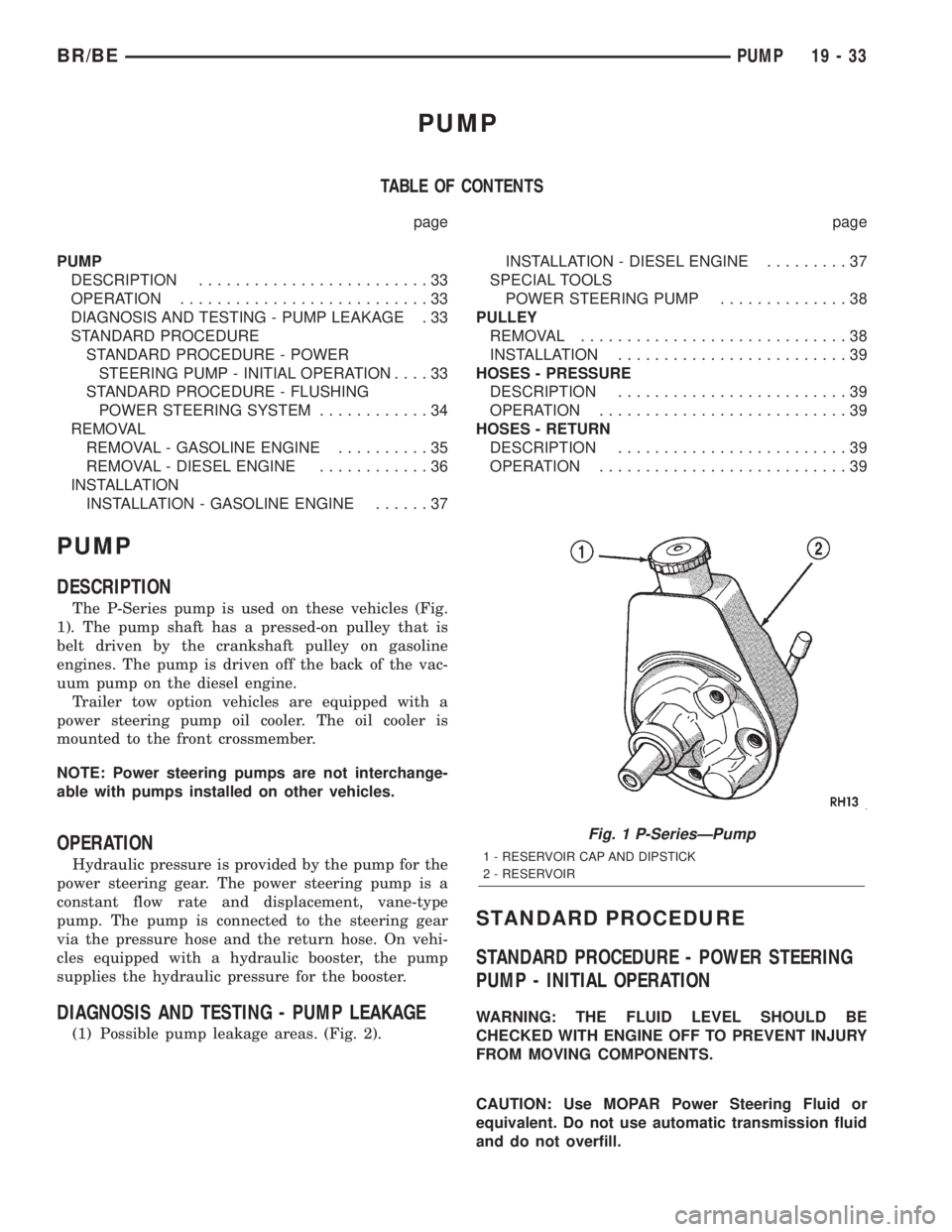

PUMP

DESCRIPTION

The P-Series pump is used on these vehicles (Fig.

1). The pump shaft has a pressed-on pulley that is

belt driven by the crankshaft pulley on gasoline

engines. The pump is driven off the back of the vac-

uum pump on the diesel engine.

Trailer tow option vehicles are equipped with a

power steering pump oil cooler. The oil cooler is

mounted to the front crossmember.

NOTE: Power steering pumps are not interchange-

able with pumps installed on other vehicles.

OPERATION

Hydraulic pressure is provided by the pump for the

power steering gear. The power steering pump is a

constant flow rate and displacement, vane-type

pump. The pump is connected to the steering gear

via the pressure hose and the return hose. On vehi-

cles equipped with a hydraulic booster, the pump

supplies the hydraulic pressure for the booster.

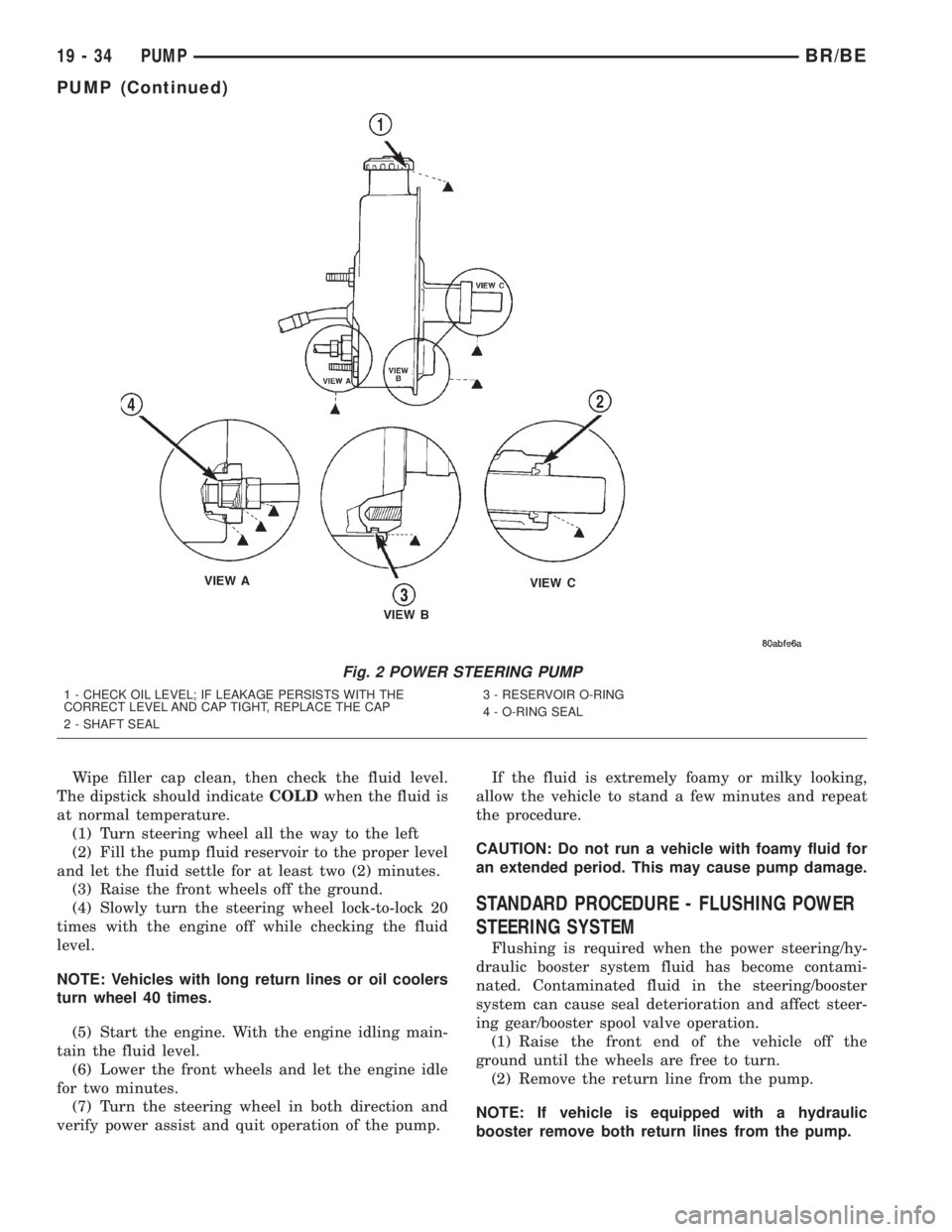

DIAGNOSIS AND TESTING - PUMP LEAKAGE

(1) Possible pump leakage areas. (Fig. 2).

STANDARD PROCEDURE

STANDARD PROCEDURE - POWER STEERING

PUMP - INITIAL OPERATION

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Fig. 1 P-SeriesÐPump

1 - RESERVOIR CAP AND DIPSTICK

2 - RESERVOIR

BR/BEPUMP 19 - 33

Page 1443 of 2255

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal temperature.

(1) Turn steering wheel all the way to the left

(2) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(3) Raise the front wheels off the ground.

(4) Slowly turn the steering wheel lock-to-lock 20

times with the engine off while checking the fluid

level.

NOTE: Vehicles with long return lines or oil coolers

turn wheel 40 times.

(5) Start the engine. With the engine idling main-

tain the fluid level.

(6) Lower the front wheels and let the engine idle

for two minutes.

(7) Turn the steering wheel in both direction and

verify power assist and quit operation of the pump.If the fluid is extremely foamy or milky looking,

allow the vehicle to stand a few minutes and repeat

the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - FLUSHING POWER

STEERING SYSTEM

Flushing is required when the power steering/hy-

draulic booster system fluid has become contami-

nated. Contaminated fluid in the steering/booster

system can cause seal deterioration and affect steer-

ing gear/booster spool valve operation.

(1) Raise the front end of the vehicle off the

ground until the wheels are free to turn.

(2) Remove the return line from the pump.

NOTE: If vehicle is equipped with a hydraulic

booster remove both return lines from the pump.

Fig. 2 POWER STEERING PUMP

1 - CHECK OIL LEVEL; IF LEAKAGE PERSISTS WITH THE

CORRECT LEVEL AND CAP TIGHT, REPLACE THE CAP

2 - SHAFT SEAL3 - RESERVOIR O-RING

4 - O-RING SEAL

19 - 34 PUMPBR/BE

PUMP (Continued)