clock DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 969 of 2255

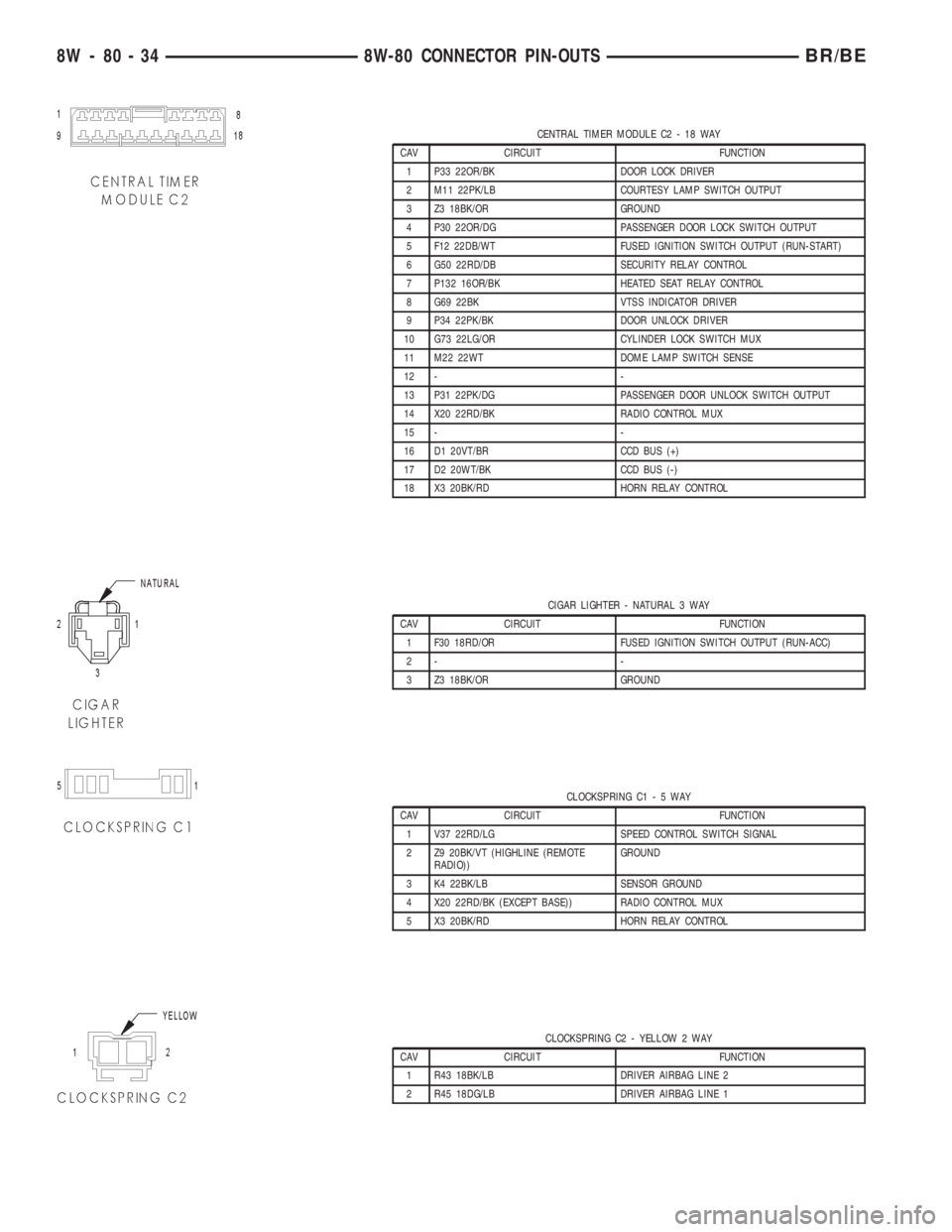

CENTRAL TIMER MODULE C2 - 18 WAY

CAV CIRCUIT FUNCTION

1 P33 22OR/BK DOOR LOCK DRIVER

2 M11 22PK/LB COURTESY LAMP SWITCH OUTPUT

3 Z3 18BK/OR GROUND

4 P30 22OR/DG PASSENGER DOOR LOCK SWITCH OUTPUT

5 F12 22DB/WT FUSED IGNITION SWITCH OUTPUT (RUN-START)

6 G50 22RD/DB SECURITY RELAY CONTROL

7 P132 16OR/BK HEATED SEAT RELAY CONTROL

8 G69 22BK VTSS INDICATOR DRIVER

9 P34 22PK/BK DOOR UNLOCK DRIVER

10 G73 22LG/OR CYLINDER LOCK SWITCH MUX

11 M22 22WT DOME LAMP SWITCH SENSE

12 - -

13 P31 22PK/DG PASSENGER DOOR UNLOCK SWITCH OUTPUT

14 X20 22RD/BK RADIO CONTROL MUX

15 - -

16 D1 20VT/BR CCD BUS (+)

17 D2 20WT/BK CCD BUS (-)

18 X3 20BK/RD HORN RELAY CONTROL

CIGAR LIGHTER - NATURAL 3 WAY

CAV CIRCUIT FUNCTION

1 F30 18RD/OR FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

2- -

3 Z3 18BK/OR GROUND

CLOCKSPRING C1-5WAY

CAV CIRCUIT FUNCTION

1 V37 22RD/LG SPEED CONTROL SWITCH SIGNAL

2 Z9 20BK/VT (HIGHLINE (REMOTE

RADIO))GROUND

3 K4 22BK/LB SENSOR GROUND

4 X20 22RD/BK (EXCEPT BASE)) RADIO CONTROL MUX

5 X3 20BK/RD HORN RELAY CONTROL

CLOCKSPRING C2 - YELLOW 2 WAY

CAV CIRCUIT FUNCTION

1 R43 18BK/LB DRIVER AIRBAG LINE 2

2 R45 18DG/LB DRIVER AIRBAG LINE 1

8W - 80 - 34 8W-80 CONNECTOR PIN-OUTSBR/BE

Page 970 of 2255

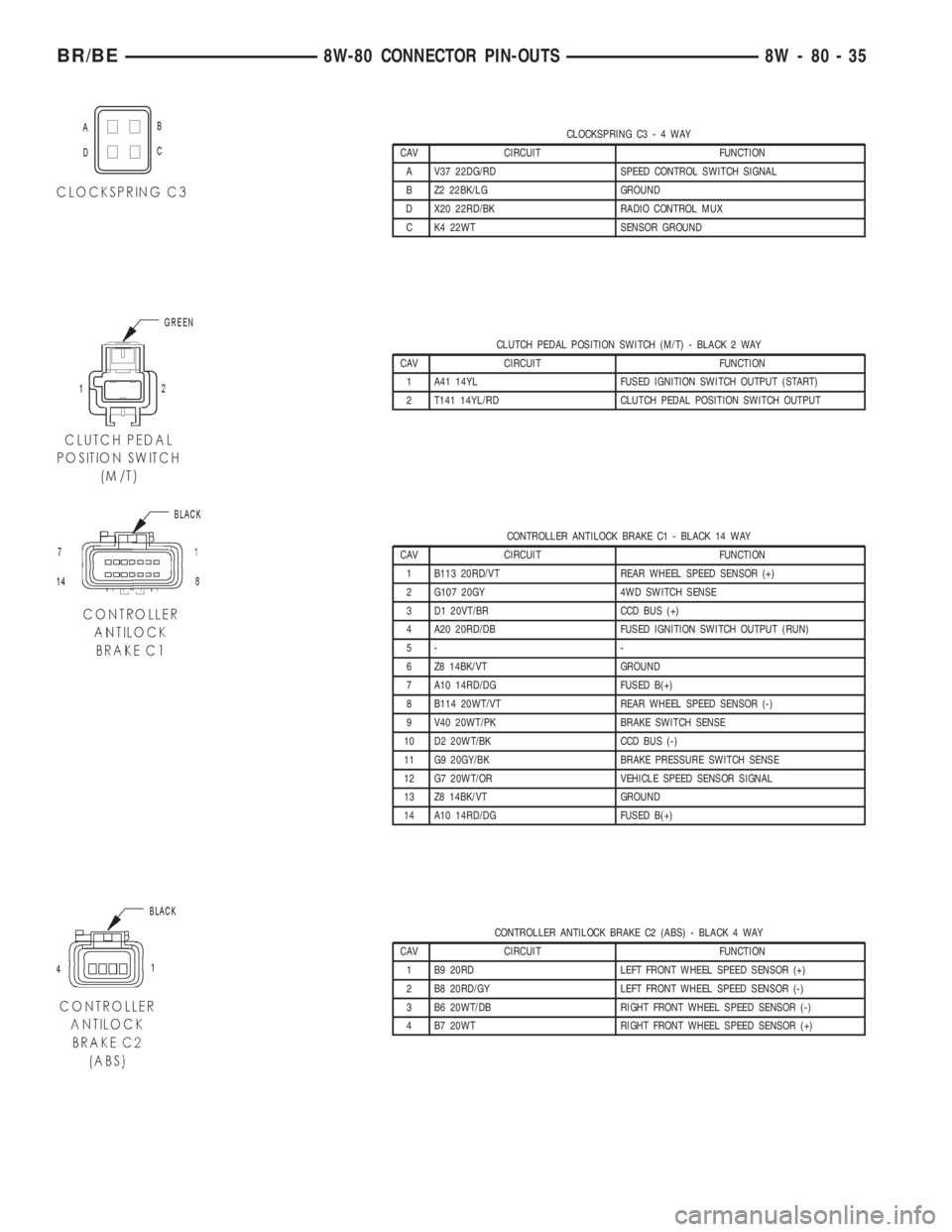

CLOCKSPRING C3-4WAY

CAV CIRCUIT FUNCTION

A V37 22DG/RD SPEED CONTROL SWITCH SIGNAL

B Z2 22BK/LG GROUND

D X20 22RD/BK RADIO CONTROL MUX

C K4 22WT SENSOR GROUND

CLUTCH PEDAL POSITION SWITCH (M/T) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 A41 14YL FUSED IGNITION SWITCH OUTPUT (START)

2 T141 14YL/RD CLUTCH PEDAL POSITION SWITCH OUTPUT

CONTROLLER ANTILOCK BRAKE C1 - BLACK 14 WAY

CAV CIRCUIT FUNCTION

1 B113 20RD/VT REAR WHEEL SPEED SENSOR (+)

2 G107 20GY 4WD SWITCH SENSE

3 D1 20VT/BR CCD BUS (+)

4 A20 20RD/DB FUSED IGNITION SWITCH OUTPUT (RUN)

5- -

6 Z8 14BK/VT GROUND

7 A10 14RD/DG FUSED B(+)

8 B114 20WT/VT REAR WHEEL SPEED SENSOR (-)

9 V40 20WT/PK BRAKE SWITCH SENSE

10 D2 20WT/BK CCD BUS (-)

11 G9 20GY/BK BRAKE PRESSURE SWITCH SENSE

12 G7 20WT/OR VEHICLE SPEED SENSOR SIGNAL

13 Z8 14BK/VT GROUND

14 A10 14RD/DG FUSED B(+)

CONTROLLER ANTILOCK BRAKE C2 (ABS) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 B9 20RD LEFT FRONT WHEEL SPEED SENSOR (+)

2 B8 20RD/GY LEFT FRONT WHEEL SPEED SENSOR (-)

3 B6 20WT/DB RIGHT FRONT WHEEL SPEED SENSOR (-)

4 B7 20WT RIGHT FRONT WHEEL SPEED SENSOR (+)

BR/BE8W-80 CONNECTOR PIN-OUTS 8W - 80 - 35

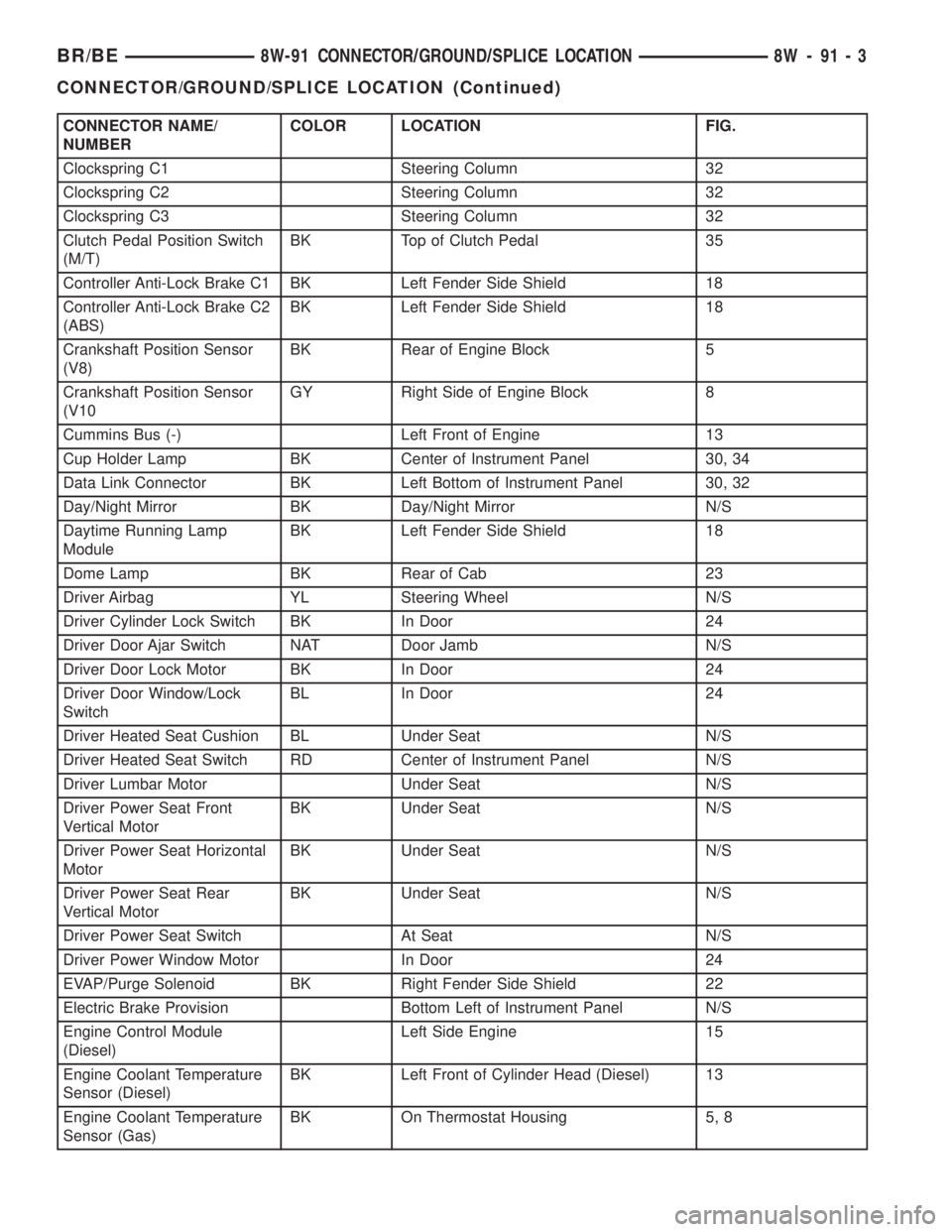

Page 1020 of 2255

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Clockspring C1 Steering Column 32

Clockspring C2 Steering Column 32

Clockspring C3 Steering Column 32

Clutch Pedal Position Switch

(M/T)BK Top of Clutch Pedal 35

Controller Anti-Lock Brake C1 BK Left Fender Side Shield 18

Controller Anti-Lock Brake C2

(ABS)BK Left Fender Side Shield 18

Crankshaft Position Sensor

(V8)BK Rear of Engine Block 5

Crankshaft Position Sensor

(V10GY Right Side of Engine Block 8

Cummins Bus (-) Left Front of Engine 13

Cup Holder Lamp BK Center of Instrument Panel 30, 34

Data Link Connector BK Left Bottom of Instrument Panel 30, 32

Day/Night Mirror BK Day/Night Mirror N/S

Daytime Running Lamp

ModuleBK Left Fender Side Shield 18

Dome Lamp BK Rear of Cab 23

Driver Airbag YL Steering Wheel N/S

Driver Cylinder Lock Switch BK In Door 24

Driver Door Ajar Switch NAT Door Jamb N/S

Driver Door Lock Motor BK In Door 24

Driver Door Window/Lock

SwitchBL In Door 24

Driver Heated Seat Cushion BL Under Seat N/S

Driver Heated Seat Switch RD Center of Instrument Panel N/S

Driver Lumbar Motor Under Seat N/S

Driver Power Seat Front

Vertical MotorBK Under Seat N/S

Driver Power Seat Horizontal

MotorBK Under Seat N/S

Driver Power Seat Rear

Vertical MotorBK Under Seat N/S

Driver Power Seat Switch At Seat N/S

Driver Power Window Motor In Door 24

EVAP/Purge Solenoid BK Right Fender Side Shield 22

Electric Brake Provision Bottom Left of Instrument Panel N/S

Engine Control Module

(Diesel)Left Side Engine 15

Engine Coolant Temperature

Sensor (Diesel)BK Left Front of Cylinder Head (Diesel) 13

Engine Coolant Temperature

Sensor (Gas)BK On Thermostat Housing 5, 8

BR/BE8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1064 of 2255

to service. Refer toCharging Systemin the index of

this service manual for the charging system diagnos-

tic procedures.

(1) Position the generator cartridge fuse onto the

two B(+) terminal stud bus bars within the PDC.

(2) Install and tighten the two screws that secure

the generator cartridge fuse to the two B(+) terminal

stud bus bars within the PDC. Tighten the screws to

3.4 N´m (30 in. lbs.).Be certain that both screws

are tightened to the proper torque value.

(3) Install and latch the cover onto the PDC.

(4) Reconnect the battery negative cable.

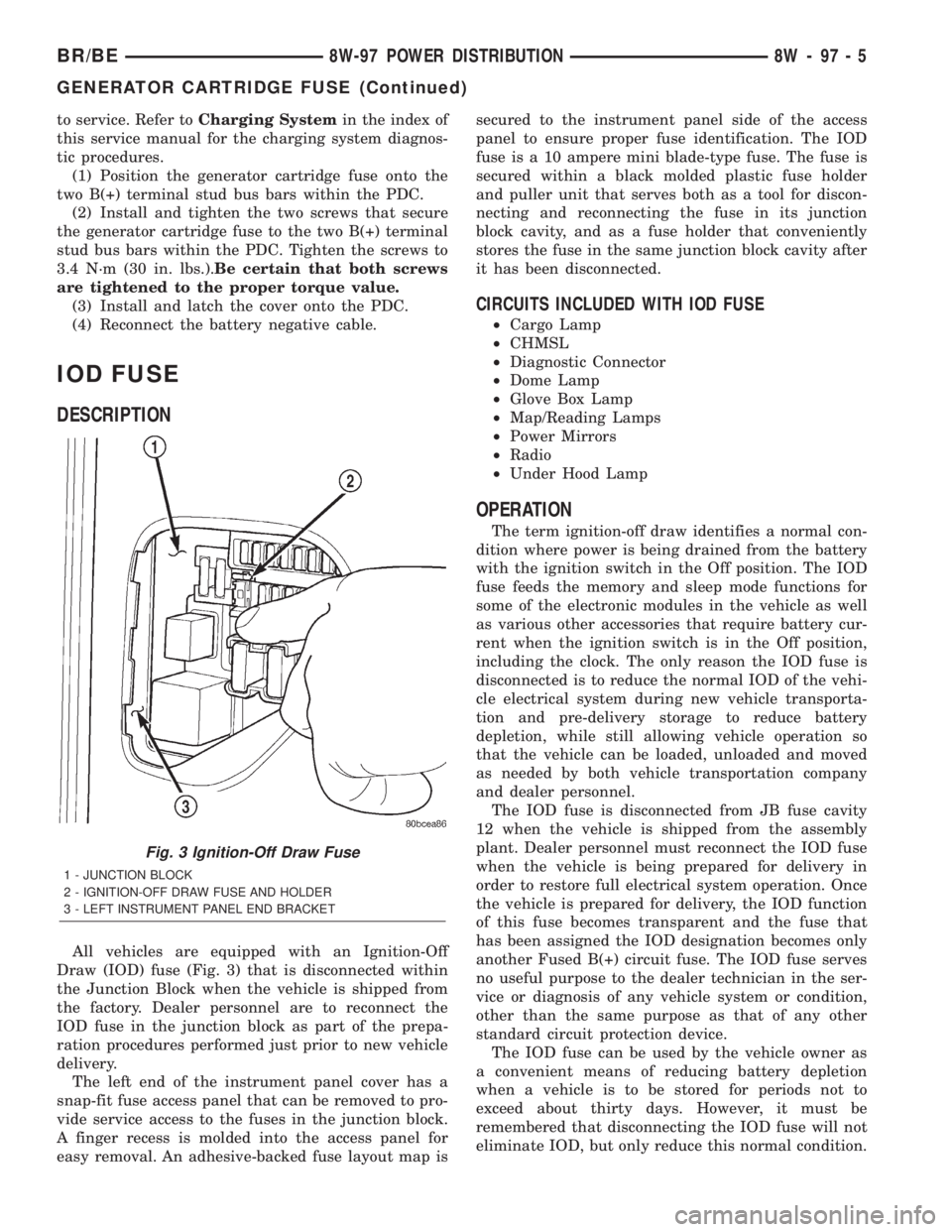

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse (Fig. 3) that is disconnected within

the Junction Block when the vehicle is shipped from

the factory. Dealer personnel are to reconnect the

IOD fuse in the junction block as part of the prepa-

ration procedures performed just prior to new vehicle

delivery.

The left end of the instrument panel cover has a

snap-fit fuse access panel that can be removed to pro-

vide service access to the fuses in the junction block.

A finger recess is molded into the access panel for

easy removal. An adhesive-backed fuse layout map issecured to the instrument panel side of the access

panel to ensure proper fuse identification. The IOD

fuse is a 10 ampere mini blade-type fuse. The fuse is

secured within a black molded plastic fuse holder

and puller unit that serves both as a tool for discon-

necting and reconnecting the fuse in its junction

block cavity, and as a fuse holder that conveniently

stores the fuse in the same junction block cavity after

it has been disconnected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cargo Lamp

²CHMSL

²Diagnostic Connector

²Dome Lamp

²Glove Box Lamp

²Map/Reading Lamps

²Power Mirrors

²Radio

²Under Hood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

disconnected is to reduce the normal IOD of the vehi-

cle electrical system during new vehicle transporta-

tion and pre-delivery storage to reduce battery

depletion, while still allowing vehicle operation so

that the vehicle can be loaded, unloaded and moved

as needed by both vehicle transportation company

and dealer personnel.

The IOD fuse is disconnected from JB fuse cavity

12 when the vehicle is shipped from the assembly

plant. Dealer personnel must reconnect the IOD fuse

when the vehicle is being prepared for delivery in

order to restore full electrical system operation. Once

the vehicle is prepared for delivery, the IOD function

of this fuse becomes transparent and the fuse that

has been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not to

exceed about thirty days. However, it must be

remembered that disconnecting the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

Fig. 3 Ignition-Off Draw Fuse

1 - JUNCTION BLOCK

2 - IGNITION-OFF DRAW FUSE AND HOLDER

3 - LEFT INSTRUMENT PANEL END BRACKET

BR/BE8W-97 POWER DISTRIBUTION 8W - 97 - 5

GENERATOR CARTRIDGE FUSE (Continued)

Page 1106 of 2255

(14) Apply MopartSilicone Rubber Adhesive Seal-

ant, or equivalent, at bearing cap to block joint to

provide cap to block and oil pan sealing (Fig. 24).

Apply enough sealant until a small amount is

squeezed out. Withdraw nozzle and wipe excess seal-

ant off the oil pan seal groove.

(15) Install new front crankshaft oil seal (Refer to

9 - ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION).

(16) Immediately install the oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(17) If the transmission was removed, install the

transmission. Refer to 21 - TRANSMISSION/TRANS-

AXLE.

CRANKSHAFT MAIN

BEARINGS

DESCRIPTION

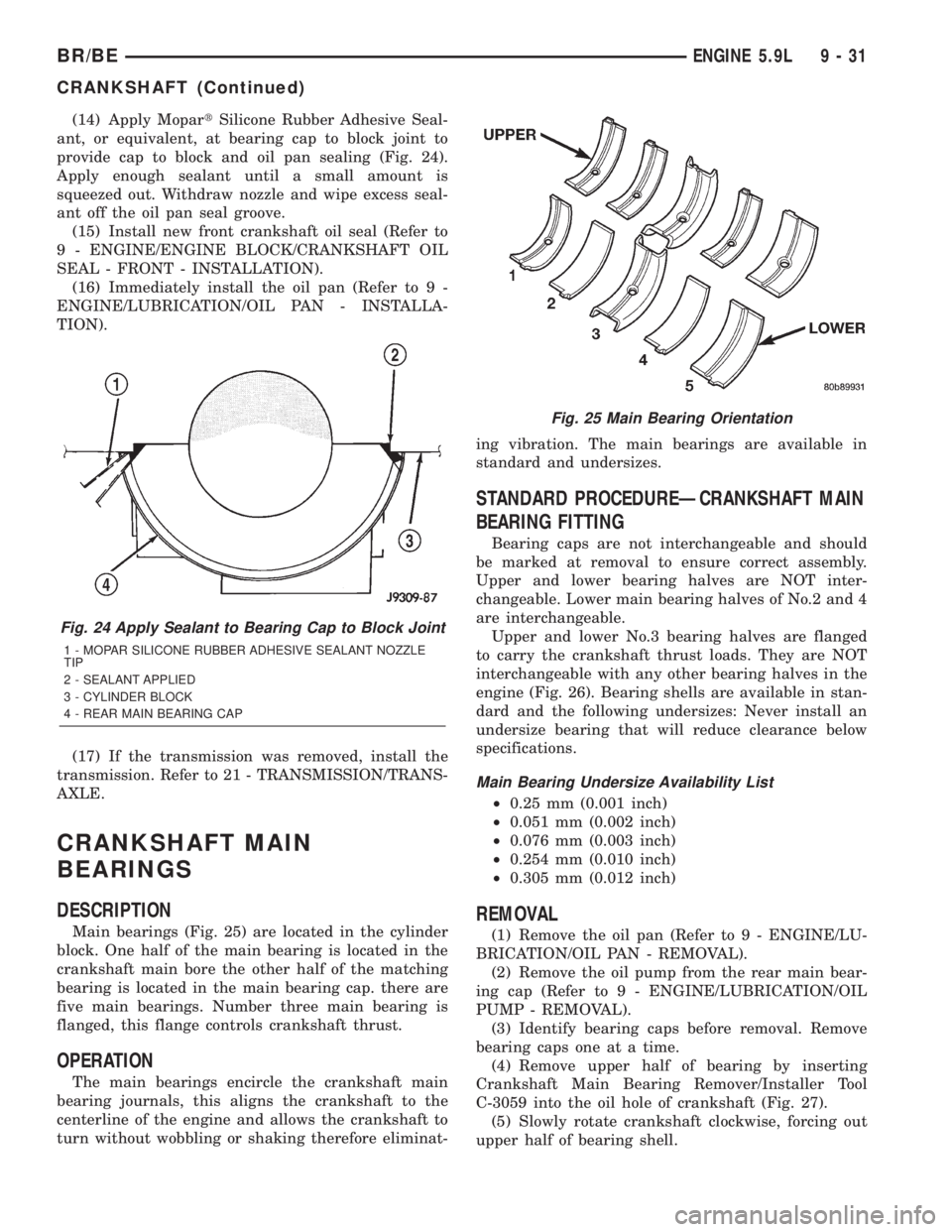

Main bearings (Fig. 25) are located in the cylinder

block. One half of the main bearing is located in the

crankshaft main bore the other half of the matching

bearing is located in the main bearing cap. there are

five main bearings. Number three main bearing is

flanged, this flange controls crankshaft thrust.

OPERATION

The main bearings encircle the crankshaft main

bearing journals, this aligns the crankshaft to the

centerline of the engine and allows the crankshaft to

turn without wobbling or shaking therefore eliminat-ing vibration. The main bearings are available in

standard and undersizes.

STANDARD PROCEDUREÐCRANKSHAFT MAIN

BEARING FITTING

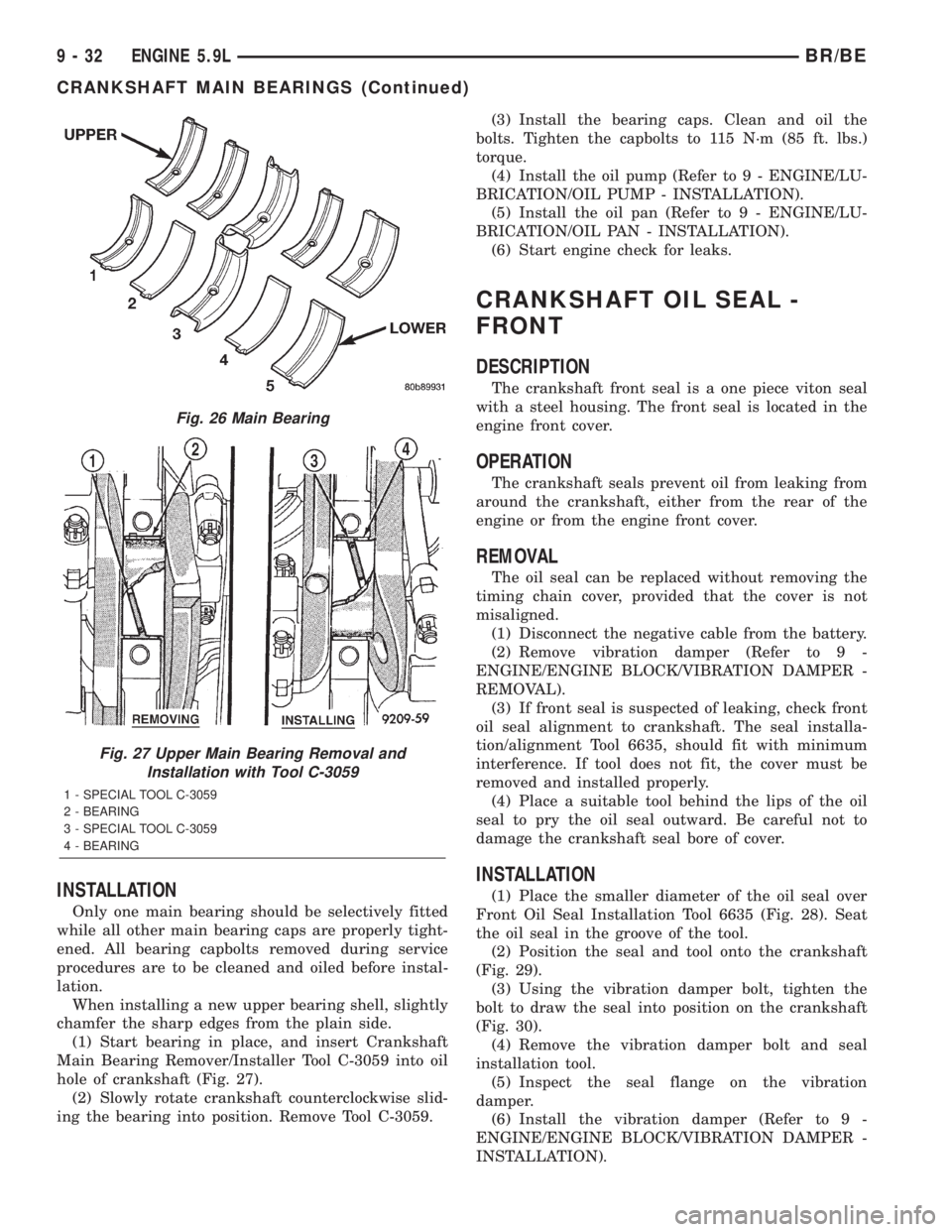

Bearing caps are not interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. Lower main bearing halves of No.2 and 4

are interchangeable.

Upper and lower No.3 bearing halves are flanged

to carry the crankshaft thrust loads. They are NOT

interchangeable with any other bearing halves in the

engine (Fig. 26). Bearing shells are available in stan-

dard and the following undersizes: Never install an

undersize bearing that will reduce clearance below

specifications.

Main Bearing Undersize Availability List

²0.25 mm (0.001 inch)

²0.051 mm (0.002 inch)

²0.076 mm (0.003 inch)

²0.254 mm (0.010 inch)

²0.305 mm (0.012 inch)

REMOVAL

(1) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(2) Remove the oil pump from the rear main bear-

ing cap (Refer to 9 - ENGINE/LUBRICATION/OIL

PUMP - REMOVAL).

(3) Identify bearing caps before removal. Remove

bearing caps one at a time.

(4) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 27).

(5) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

Fig. 24 Apply Sealant to Bearing Cap to Block Joint

1 - MOPAR SILICONE RUBBER ADHESIVE SEALANT NOZZLE

TIP

2 - SEALANT APPLIED

3 - CYLINDER BLOCK

4 - REAR MAIN BEARING CAP

Fig. 25 Main Bearing Orientation

BR/BEENGINE 5.9L 9 - 31

CRANKSHAFT (Continued)

Page 1107 of 2255

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 27).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.(3) Install the bearing caps. Clean and oil the

bolts. Tighten the capbolts to 115 N´m (85 ft. lbs.)

torque.

(4) Install the oil pump (Refer to 9 - ENGINE/LU-

BRICATION/OIL PUMP - INSTALLATION).

(5) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(6) Start engine check for leaks.

CRANKSHAFT OIL SEAL -

FRONT

DESCRIPTION

The crankshaft front seal is a one piece viton seal

with a steel housing. The front seal is located in the

engine front cover.

OPERATION

The crankshaft seals prevent oil from leaking from

around the crankshaft, either from the rear of the

engine or from the engine front cover.

REMOVAL

The oil seal can be replaced without removing the

timing chain cover, provided that the cover is not

misaligned.

(1) Disconnect the negative cable from the battery.

(2) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(3) If front seal is suspected of leaking, check front

oil seal alignment to crankshaft. The seal installa-

tion/alignment Tool 6635, should fit with minimum

interference. If tool does not fit, the cover must be

removed and installed properly.

(4) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal bore of cover.

INSTALLATION

(1) Place the smaller diameter of the oil seal over

Front Oil Seal Installation Tool 6635 (Fig. 28). Seat

the oil seal in the groove of the tool.

(2) Position the seal and tool onto the crankshaft

(Fig. 29).

(3) Using the vibration damper bolt, tighten the

bolt to draw the seal into position on the crankshaft

(Fig. 30).

(4) Remove the vibration damper bolt and seal

installation tool.

(5) Inspect the seal flange on the vibration

damper.

(6) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

Fig. 26 Main Bearing

Fig. 27 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

9 - 32 ENGINE 5.9LBR/BE

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1112 of 2255

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

LEAK-DOWN TEST

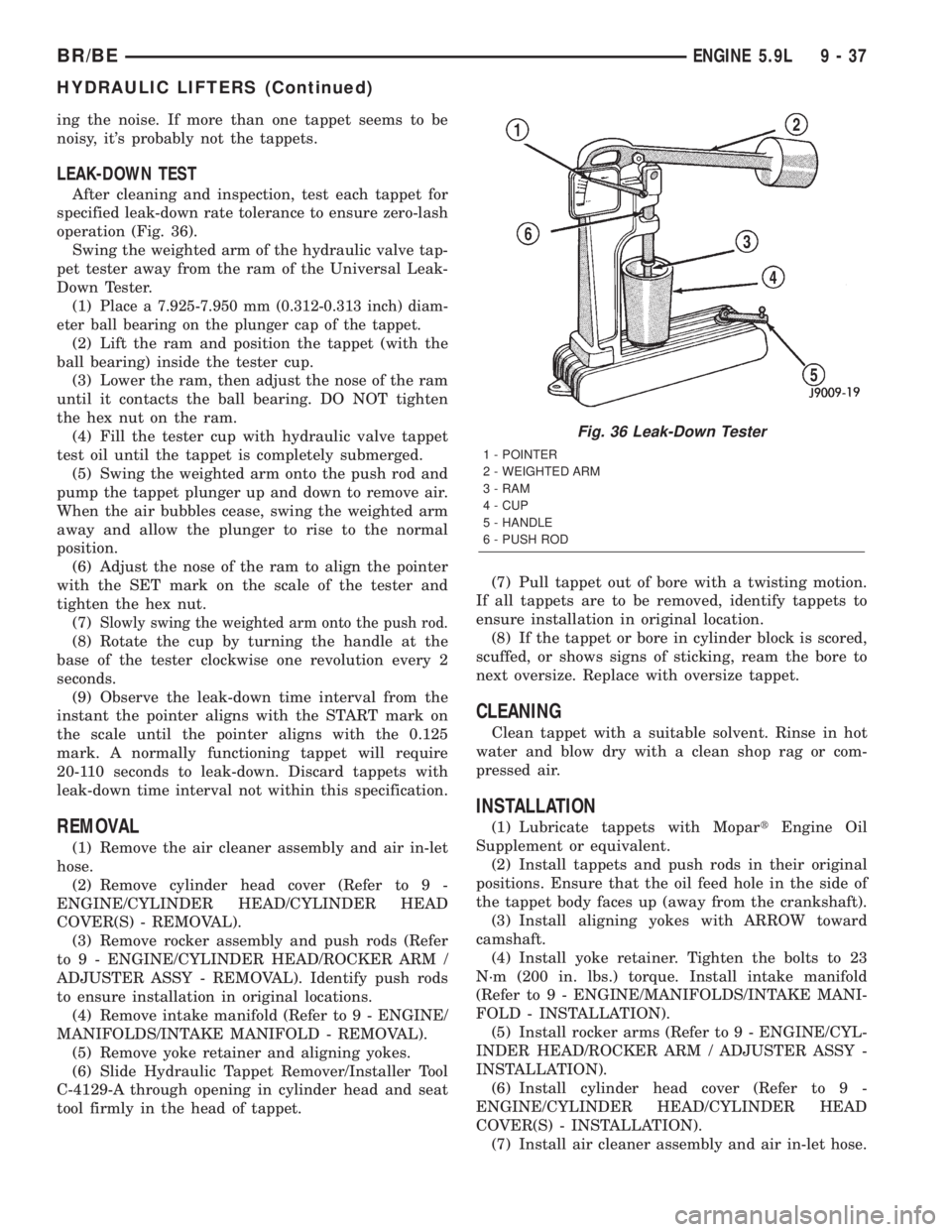

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 36).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1)

Place a 7.925-7.950 mm (0.312-0.313 inch) diam-

eter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7)

Slowly swing the weighted arm onto the push rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Remove the air cleaner assembly and air in-let

hose.

(2) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Remove rocker assembly and push rods (Refer

to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL). Identify push rods

to ensure installation in original locations.

(4) Remove intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(5) Remove yoke retainer and aligning yokes.

(6) Slide Hydraulic Tappet Remover/Installer Tool

C-4129-A through opening in cylinder head and seat

tool firmly in the head of tappet.(7) Pull tappet out of bore with a twisting motion.

If all tappets are to be removed, identify tappets to

ensure installation in original location.

(8) If the tappet or bore in cylinder block is scored,

scuffed, or shows signs of sticking, ream the bore to

next oversize. Replace with oversize tappet.

CLEANING

Clean tappet with a suitable solvent. Rinse in hot

water and blow dry with a clean shop rag or com-

pressed air.

INSTALLATION

(1) Lubricate tappets with MopartEngine Oil

Supplement or equivalent.

(2) Install tappets and push rods in their original

positions. Ensure that the oil feed hole in the side of

the tappet body faces up (away from the crankshaft).

(3) Install aligning yokes with ARROW toward

camshaft.

(4) Install yoke retainer. Tighten the bolts to 23

N´m (200 in. lbs.) torque. Install intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - INSTALLATION).

(5) Install rocker arms (Refer to 9 - ENGINE/CYL-

INDER HEAD/ROCKER ARM / ADJUSTER ASSY -

INSTALLATION).

(6) Install cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(7) Install air cleaner assembly and air in-let hose.

Fig. 36 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

BR/BEENGINE 5.9L 9 - 37

HYDRAULIC LIFTERS (Continued)

Page 1115 of 2255

lower rails. Insert oil rail spacer first, then side

rails.

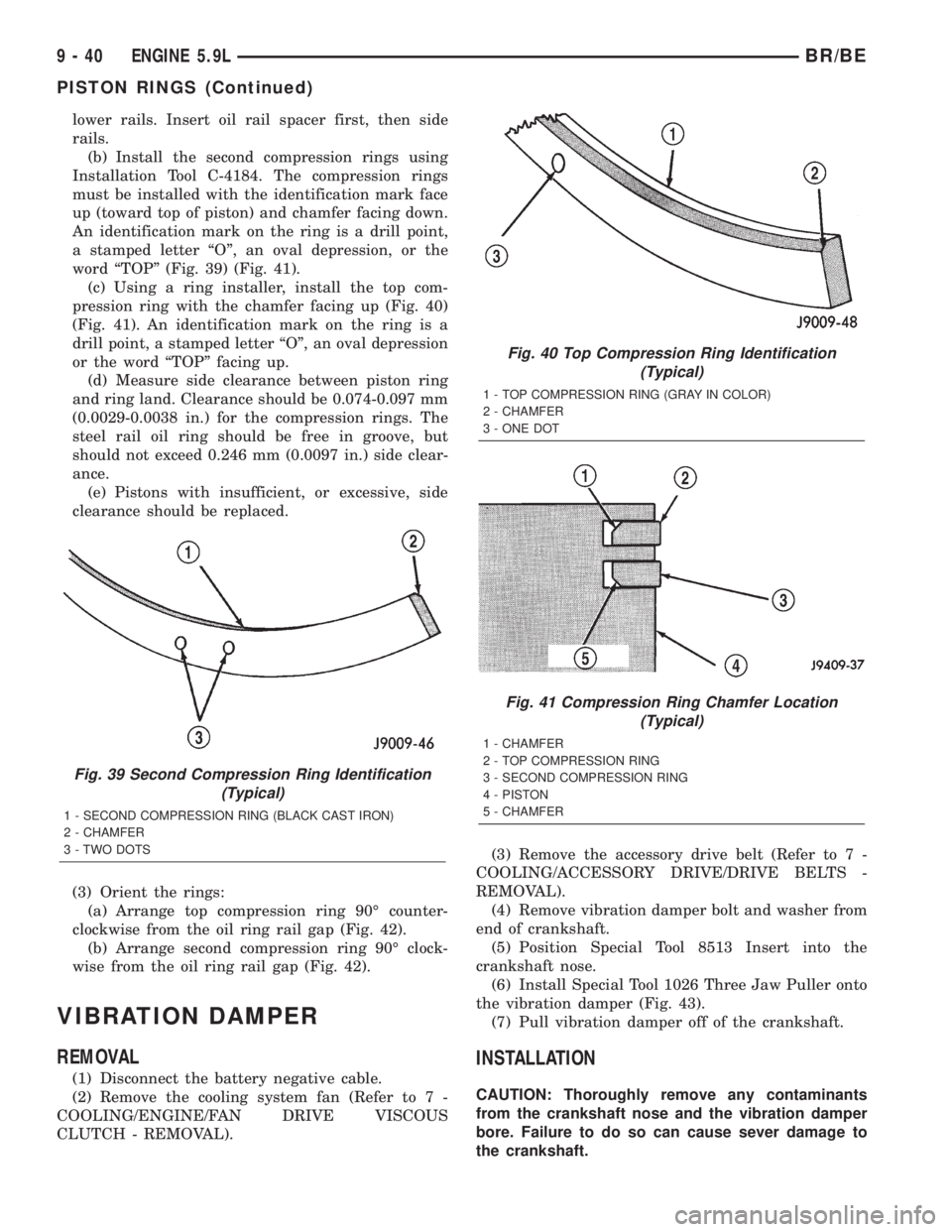

(b) Install the second compression rings using

Installation Tool C-4184. The compression rings

must be installed with the identification mark face

up (toward top of piston) and chamfer facing down.

An identification mark on the ring is a drill point,

a stamped letter ªOº, an oval depression, or the

word ªTOPº (Fig. 39) (Fig. 41).

(c) Using a ring installer, install the top com-

pression ring with the chamfer facing up (Fig. 40)

(Fig. 41). An identification mark on the ring is a

drill point, a stamped letter ªOº, an oval depression

or the word ªTOPº facing up.

(d) Measure side clearance between piston ring

and ring land. Clearance should be 0.074-0.097 mm

(0.0029-0.0038 in.) for the compression rings. The

steel rail oil ring should be free in groove, but

should not exceed 0.246 mm (0.0097 in.) side clear-

ance.

(e) Pistons with insufficient, or excessive, side

clearance should be replaced.

(3) Orient the rings:

(a) Arrange top compression ring 90É counter-

clockwise from the oil ring rail gap (Fig. 42).

(b) Arrange second compression ring 90É clock-

wise from the oil ring rail gap (Fig. 42).

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the cooling system fan (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove vibration damper bolt and washer from

end of crankshaft.

(5) Position Special Tool 8513 Insert into the

crankshaft nose.

(6) Install Special Tool 1026 Three Jaw Puller onto

the vibration damper (Fig. 43).

(7) Pull vibration damper off of the crankshaft.

INSTALLATION

CAUTION: Thoroughly remove any contaminants

from the crankshaft nose and the vibration damper

bore. Failure to do so can cause sever damage to

the crankshaft.

Fig. 39 Second Compression Ring Identification

(Typical)

1 - SECOND COMPRESSION RING (BLACK CAST IRON)

2 - CHAMFER

3 - TWO DOTS

Fig. 40 Top Compression Ring Identification

(Typical)

1 - TOP COMPRESSION RING (GRAY IN COLOR)

2 - CHAMFER

3 - ONE DOT

Fig. 41 Compression Ring Chamfer Location

(Typical)

1 - CHAMFER

2 - TOP COMPRESSION RING

3 - SECOND COMPRESSION RING

4 - PISTON

5 - CHAMFER

9 - 40 ENGINE 5.9LBR/BE

PISTON RINGS (Continued)

Page 1121 of 2255

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.

(7) Change oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Lower vehicle and fill crankcase with specified

type (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION) and amount of

engine oil (Refer to LUBRICATION & MAINTE-

NANCE - SPECIFICATIONS).

(9) Install oil fill cap.

(10) Start engine and inspect for leaks.

(11) Stop engine and inspect oil level.

OIL FILTER

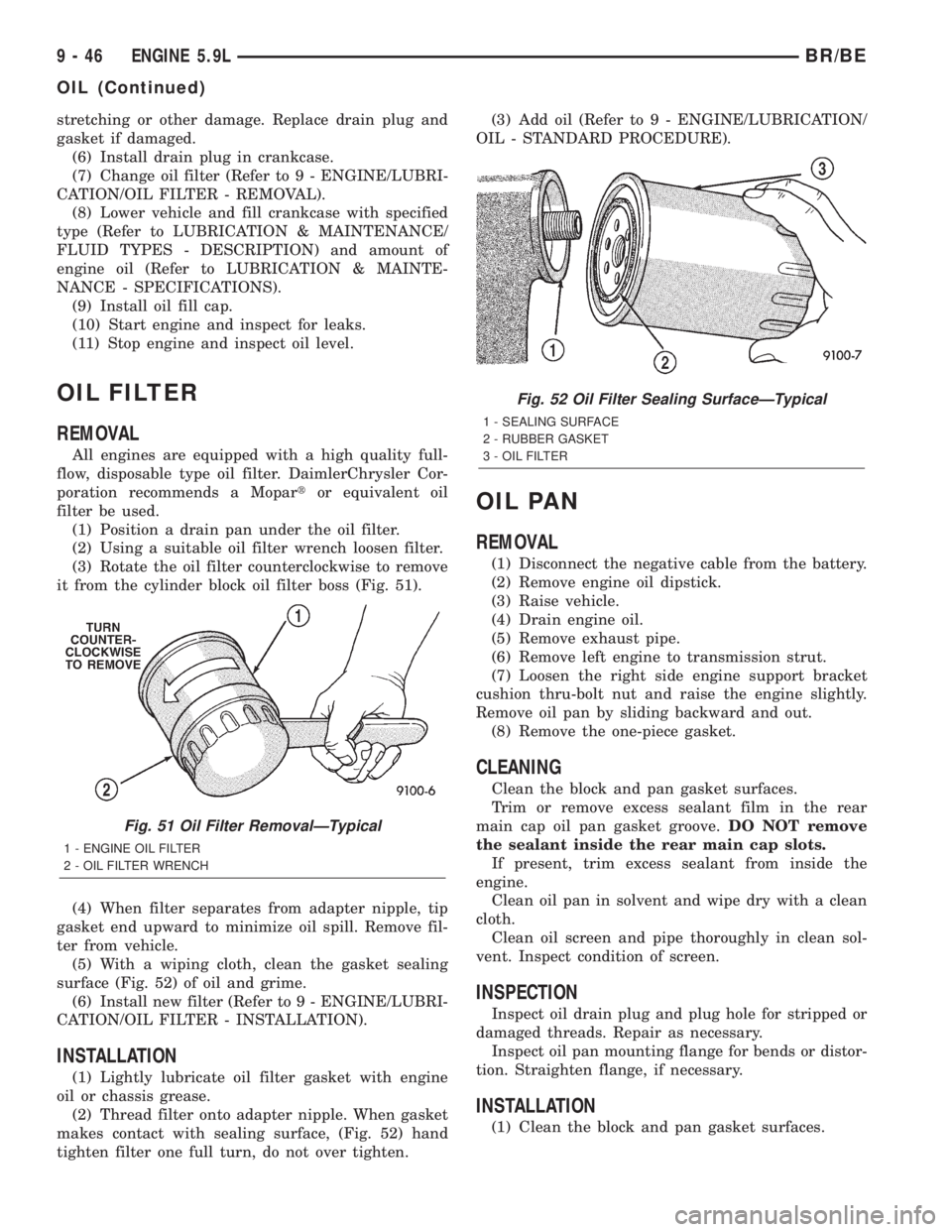

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 52) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove engine oil dipstick.

(3) Raise vehicle.

(4) Drain engine oil.

(5) Remove exhaust pipe.

(6) Remove left engine to transmission strut.

(7) Loosen the right side engine support bracket

cushion thru-bolt nut and raise the engine slightly.

Remove oil pan by sliding backward and out.

(8) Remove the one-piece gasket.

CLEANING

Clean the block and pan gasket surfaces.

Trim or remove excess sealant film in the rear

main cap oil pan gasket groove.DO NOT remove

the sealant inside the rear main cap slots.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

INSTALLATION

(1) Clean the block and pan gasket surfaces.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

9 - 46 ENGINE 5.9LBR/BE

OIL (Continued)

Page 1163 of 2255

(8) Remove the upper main bearings from the

block.

INSTALLATION

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.

NOTE: Lubricate crankshaft main bearings with

clean engine oil.

(1) Position upper main bearings into block.

(2) Position the crankshaft into the cylinder block.

(3) Lubricate the main journals with clean engine

oil. Install upper main bearings, caps and bolts. Fol-

low the 2 step tightening sequence, starting with

main bearing cap 1.

(4) Lubricate the connecting rod bearings and jour-

nals with clean engine oil. Carefully install connect-

ing rods to the crankshaft.

(5) Using Special Tool 8359 Seal Installer install

new oil into oil seal retainer.

(6) Using Special Tool 6687 Guide, install the rear

seal retainer with a new gasket.

(7) Install the timing chain cover with a new gas-

ket and oil seal.

(8) Prime oil pump by squirt oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.

(9) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeat

procedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(10) Install the oil pickup tube. Tighten the bolts

to 16 N´m (144 in. lbs.) torque.

(11) Install the oil pan.

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐFITTING

CRANKSHAFT MAIN BEARINGS

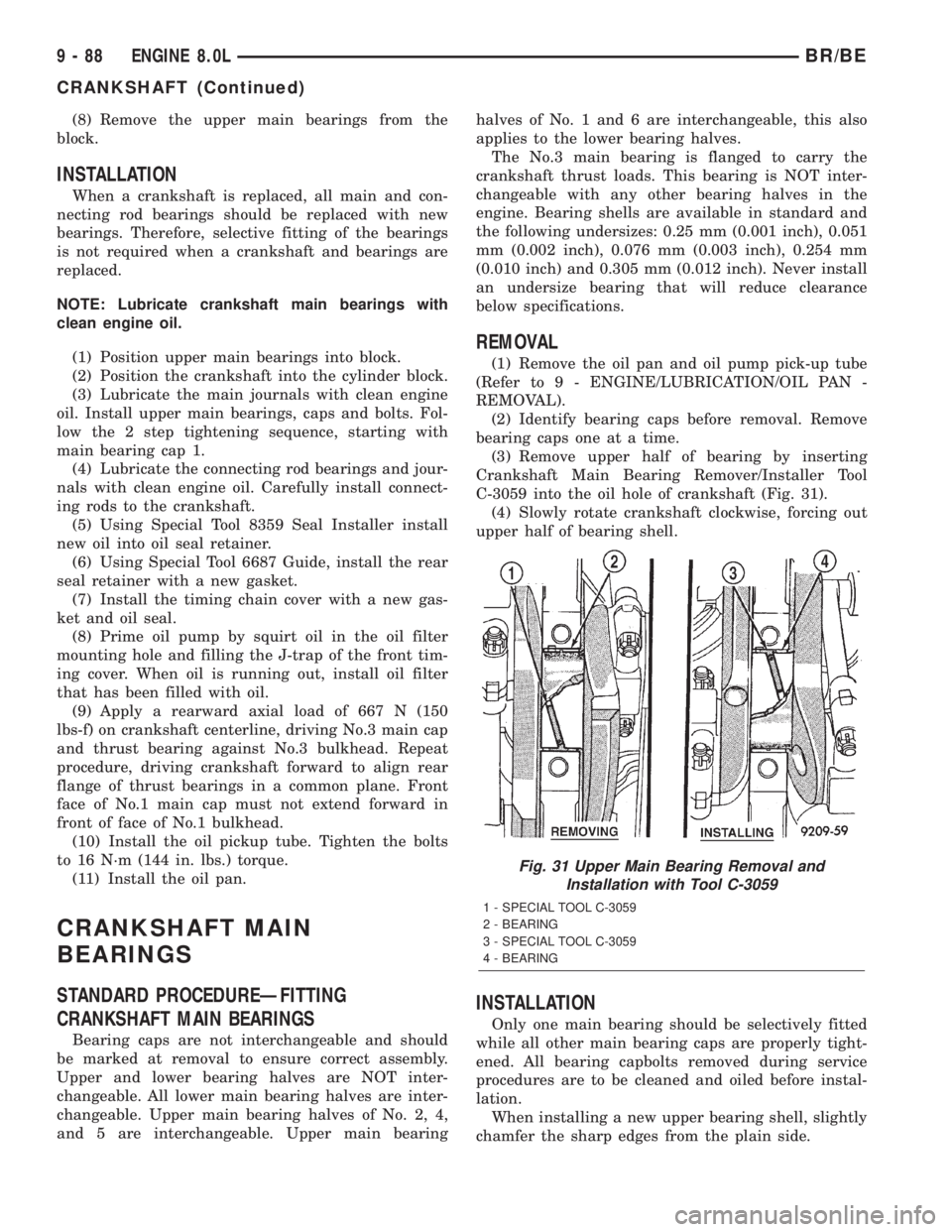

Bearing caps are not interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. All lower main bearing halves are inter-

changeable. Upper main bearing halves of No. 2, 4,

and 5 are interchangeable. Upper main bearinghalves of No. 1 and 6 are interchangeable, this also

applies to the lower bearing halves.

The No.3 main bearing is flanged to carry the

crankshaft thrust loads. This bearing is NOT inter-

changeable with any other bearing halves in the

engine. Bearing shells are available in standard and

the following undersizes: 0.25 mm (0.001 inch), 0.051

mm (0.002 inch), 0.076 mm (0.003 inch), 0.254 mm

(0.010 inch) and 0.305 mm (0.012 inch). Never install

an undersize bearing that will reduce clearance

below specifications.

REMOVAL

(1) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(2) Identify bearing caps before removal. Remove

bearing caps one at a time.

(3) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 31).

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

Fig. 31 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARING

9 - 88 ENGINE 8.0LBR/BE

CRANKSHAFT (Continued)