window switch DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 432 of 2255

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED MIRRORS......................... 1 HEATED SEATSYSTEM..................... 5

HEATED MIRRORS

TABLE OF CONTENTS

page page

HEATED MIRRORS

DESCRIPTION - HEATED MIRROR SYSTEM . . . 1

OPERATION - HEATED MIRROR SYSTEM.....2

DIAGNOSIS AND TESTING - HEATED

MIRROR SYSTEM......................2

MIRROR SWITCH

DESCRIPTION..........................2

OPERATION............................3DIAGNOSIS AND TESTING - HEATED

MIRROR SWITCH......................3

HEATED MIRROR GRID

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - HEATED

MIRROR GRID.........................4

HEATED MIRRORS

DESCRIPTION - HEATED MIRROR SYSTEM

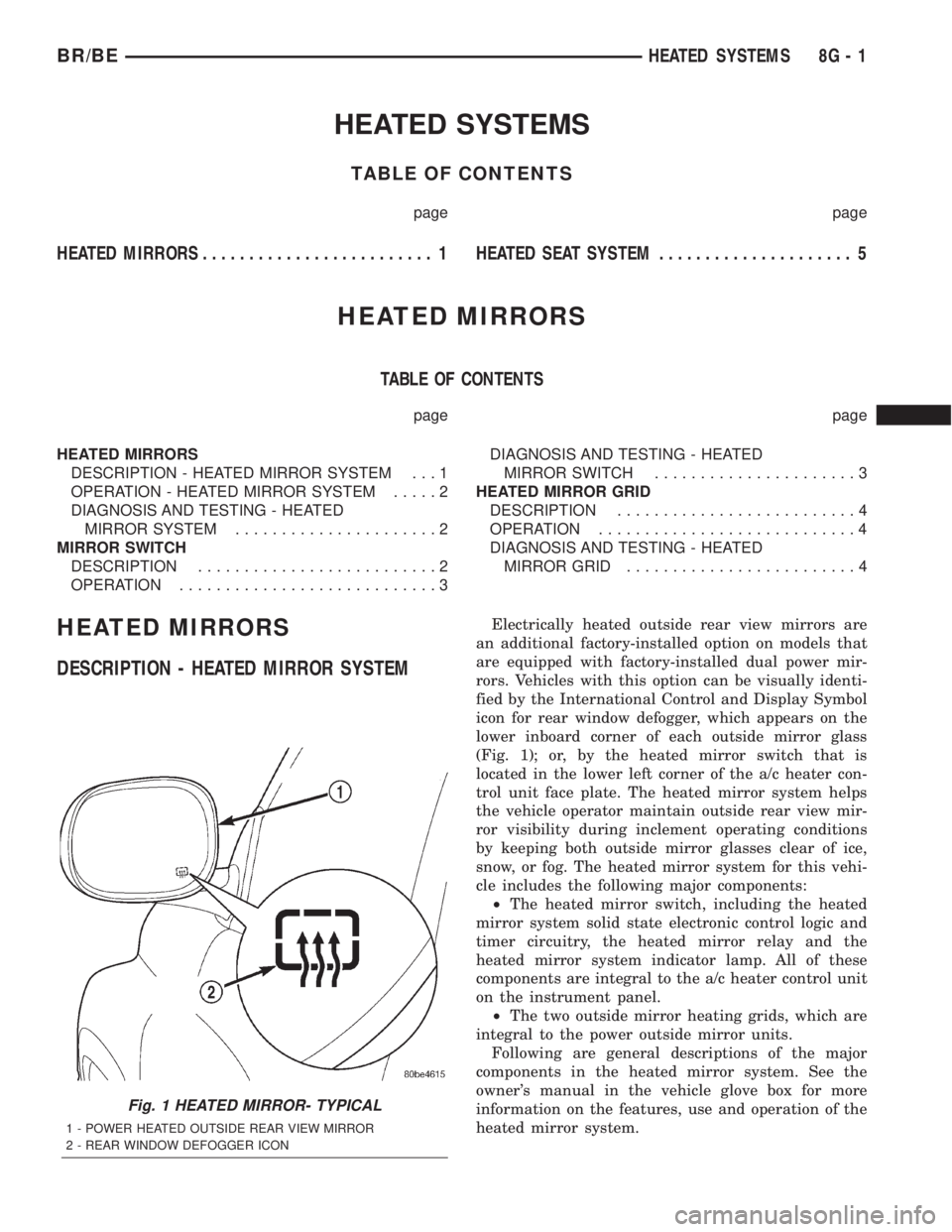

Electrically heated outside rear view mirrors are

an additional factory-installed option on models that

are equipped with factory-installed dual power mir-

rors. Vehicles with this option can be visually identi-

fied by the International Control and Display Symbol

icon for rear window defogger, which appears on the

lower inboard corner of each outside mirror glass

(Fig. 1); or, by the heated mirror switch that is

located in the lower left corner of the a/c heater con-

trol unit face plate. The heated mirror system helps

the vehicle operator maintain outside rear view mir-

ror visibility during inclement operating conditions

by keeping both outside mirror glasses clear of ice,

snow, or fog. The heated mirror system for this vehi-

cle includes the following major components:

²The heated mirror switch, including the heated

mirror system solid state electronic control logic and

timer circuitry, the heated mirror relay and the

heated mirror system indicator lamp. All of these

components are integral to the a/c heater control unit

on the instrument panel.

²The two outside mirror heating grids, which are

integral to the power outside mirror units.

Following are general descriptions of the major

components in the heated mirror system. See the

owner's manual in the vehicle glove box for more

information on the features, use and operation of the

heated mirror system.

Fig. 1 HEATED MIRROR- TYPICAL

1 - POWER HEATED OUTSIDE REAR VIEW MIRROR

2 - REAR WINDOW DEFOGGER ICON

BR/BEHEATED SYSTEMS 8G - 1

Page 500 of 2255

instrument cluster housing with two screws. A face

plate on the indicator housing is visible through a

rectangular cutout in the lower right corner of the

instrument cluster overlay, just below the fuel gauge.

Vehicles with a manual transmission have a block-off

plate mounted to the back of the instrument cluster

behind this cutout in the overlay, in place of the gear

selector indicator. Near the top of this face plate the

following characters are imprinted from left to right:

ªP,º ªR,º ªN,º ªD,º ª2,º and ª1.º Respectively, these

characters represent the park, reverse, neutral,

drive, second gear, and first gear positions of the

transmission gear selector lever on the steering col-

umn. Directly below each character on the face plate

is a small, rectangular window, and behind these

windows is a single, movable red pointer.

The gear selector indicator graphics are white

against a black field except for the single red pointer,

making them clearly visible within the instrument

cluster in daylight. When illuminated from behind by

the panel lamps dimmer controlled cluster illumina-

tion lighting with the exterior lamps turned On, the

white graphics appear blue-green, while the red

pointer still appears red. Indicator illumination is

provided by replaceable incandescent bulb and bulb

holder units located on the instrument cluster elec-

tronic circuit board. The gear selector indicator is

available for service replacement separate from the

instrument cluster. The instrument cluster must be

removed from the instrument panel for service access

to the gear selector indicator. (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - REMOVAL).

OPERATION

The mechanical gear selector indicator gives an

indication of the transmission gear that has been

selected with the automatic transmission gear selec-

tor lever. A red pointer appears in a window below

the character in the indicator representing the trans-

mission gear that has been selected. The small,

spring-loaded pointer moves on a track through a

trolley-like mechanism within the indicator housing.

A short length of small diameter stranded cable is

attached to one side of the pointer trolley and is

encased in a tubular plastic housing that exits the

right side of the indicator. The cable is routed

through the instrument panel and under the steering

column to the left side of the column. The looped end

of the cable is hooked over the end of the PRNDL

driver lever on the steering column gearshift mecha-

nism, and the cable housing is secured in a molded

plastic adjuster and bracket on the column housing.

When the gear selector lever is moved the PRNDL

driver lever moves, which moves the pointer through

the mechanical actuator cable. The cable adjuster

and bracket unit mounted on the steering columnhousing provides a mechanical means of calibrating

the gear selector indicator mechanism. (Refer to 19 -

STEERING/COLUMN - INSTALLATION).

HIGH BEAM INDICATOR

DESCRIPTION

A high beam indicator is standard equipment on

all instrument clusters. The high beam indicator is

located near the upper edge of the instrument cluster

overlay, between the tachometer and the speedome-

ter. The high beam indicator consists of a stenciled

cutout of the International Control and Display Sym-

bol icon for ªHigh Beamº in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. A blue lens behind

the cutout in the opaque layer of the overlay causes

the icon to appear in blue through the translucent

outer layer of the overlay when it is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The high beam indicator is ser-

viced as a unit with the instrument cluster.

OPERATION

The high beam indicator gives an indication to the

vehicle operator when the headlamp high beams are

illuminated. This indicator is hard wired on the

instrument cluster electronic circuit board, and is

controlled by a headlamp beam select switch input to

the cluster. The headlamp high beam indicator bulb

receives battery current on the instrument cluster

electronic circuit board through a fused B(+) circuit

at all times; therefore, the indicator remains opera-

tional regardless of the ignition switch position. The

headlamp beam select switch is integral to the multi-

function switch on the left side of the steering col-

umn, and is connected in series between ground and

the headlamp high beam indicator. The indicator

bulb only illuminates when it is provided with a path

to ground through the high beam indicator driver cir-

cuit by the headlamp beam select switch. (Refer to 8

- ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - OPERATION). The

high beam indicator can be diagnosed using conven-

tional diagnostic tools and methods.

DIAGNOSIS AND TESTING - HIGH BEAM

INDICATOR

The diagnosis found here addresses an inoperative

headlamp high beam indicator condition. If the prob-

lem being diagnosed is related to inoperative head-

lamp high beams, be certain to repair the headlamp

system before attempting to diagnose or repair the

BR/BEINSTRUMENT CLUSTER 8J - 21

GEAR SELECTOR INDICATOR (Continued)

Page 503 of 2255

²PCM Lamp-On Message- Each time the clus-

ter receives a lamp-on message from the PCM or

ECM, the indicator will be illuminated. The indicator

can be flashed on and off, or illuminated solid, as dic-

tated by the PCM or ECM message. For some DTC's,

if a problem does not recur, the PCM or ECM will

send a lamp-off message automatically. Other DTC's

may require that a fault be repaired and the PCM or

ECM be reset before a lamp-off message will be sent.

For more information on the PCM, the ECM, and the

DTC set and reset parameters, (Refer to 25 - EMIS-

SIONS CONTROL - OPERATION).

²Communication Error- If the cluster receives

no lamp-on message from the PCM or ECM for

twenty seconds, the MIL is illuminated by the instru-

ment cluster to indicate a loss of bus communication.

The indicator remains controlled and illuminated by

the cluster until a valid lamp-on message is received

from the PCM or ECM.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The PCM/ECM continually monitor the fuel and

emissions system circuits and sensors to decide

whether the system is in good operating condition.

The PCM or ECM then sends the proper lamp-on or

lamp-off messages to the instrument cluster. For fur-

ther diagnosis of the MIL or the instrument cluster

circuitry that controls the LED, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). If the instrument cluster turns on

the MIL after the bulb test, it may indicate that a

malfunction has occurred and that the fuel and emis-

sions systems may require service. For proper diag-

nosis of the fuel and emissions systems, the PCM,

the ECM, the CCD data bus, or the message inputs

to the instrument cluster that control the MIL, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

ODOMETER

DESCRIPTION

An odometer and trip odometer are standard

equipment in all instrument clusters. The odometer

and trip odometer information are displayed in a

common electronic Vacuum-Fluorescent Display

(VFD), which is visible through a small window cut-

out located in the left lower quadrant of the cluster

overlay. However, the odometer and trip odometer

information are not displayed simultaneously. The

trip odometer reset switch on the instrument cluster

circuit board toggles the display between odometerand trip odometer modes by depressing the odometer/

trip odometer switch knob that extends through the

lower edge of the cluster lens, just right of the

tachometer. Both the odometer and the trip odometer

information is stored in the instrument cluster mem-

ory.

The odometer can display values up to 499,999

kilometers (499,999 miles). The odometer latches at

these values, and will not roll over to zero. The trip

odometer can display values up to 999.9 kilometers

(999.9 miles) before it rolls over to zero. The odome-

ter display does not have a decimal point and will

not show values less than a full unit (kilometer or

mile), the trip odometer display does have a decimal

point and will show tenths of a unit (kilometer or

mile). The unit of measure (kilometers or miles) for

the odometer and trip odometer display is not shown

in the VFD. The unit of measure for the instrument

cluster odometer/trip odometer is selected at the time

that it is manufactured, and cannot be changed. Dur-

ing daylight hours (exterior lamps Off) the VFD is

illuminated at full brightness for clear visibility. At

night (exterior lamps are On) the VFD lighting level

is adjusted with the other cluster illumination lamps

using the panel lamps dimmer thumbwheel on the

headlamp switch. However, a ªParadeº mode position

of the panel lamps dimmer thumbwheel allows the

VFD to be illuminated at full brightness while the

exterior lamps are turned On during daylight hours.

The VFD, the trip odometer switch, and the trip

odometer switch button are serviced as a unit with

the instrument cluster.

OPERATION

The odometer and trip odometer give an indication

to the vehicle operator of the distance the vehicle has

traveled. This gauge is controlled by the instrument

cluster circuit board based upon the cluster program-

ming and electronic messages received by the cluster

from the Powertrain Control Module (PCM) over the

Chrysler Collision Detection (CCD) data bus. The

odometer and trip odometer information is displayed

by the instrument cluster Vacuum Fluorescent Dis-

play (VFD), and the VFD will not display odometer

or trip odometer information after the ignition switch

is turned to the Off position. The instrument cluster

circuitry controls the VFD and provides the following

features:

²Odometer/Trip Odometer Display Toggling-

Actuating the trip odometer reset switch momen-

tarily with the ignition switch in the On position will

toggle the VFD between the odometer and trip odom-

eter display. Each time the ignition switch is turned

to the On position the VFD will automatically return

to the mode (odometer or trip odometer) last dis-

8J - 24 INSTRUMENT CLUSTERBR/BE

MALFUNCTION INDICATOR LAMP MIL (Continued)

Page 568 of 2255

POWER SYSTEMS

TABLE OF CONTENTS

page page

POWER LOCKS............................ 1

POWER MIRRORS........................ 11POWER SEAT SYSTEM..................... 16

POWER WINDOWS........................ 23

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION

DESCRIPTION - POWER LOCKS..........1

DESCRIPTION - REMOTE KEYLESS ENTRY

SYSTEM.............................2

OPERATION

OPERATION - POWER LOCKS............3

OPERATION - REMOTE KEYLESS ENTRY

SYSTEM.............................4

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

LOCKS..............................4

DIAGNOSIS AND TESTING - POWER LOCK

& REMOTE KEYLESS ENTRY SYSTEM.....5

DOOR CYLINDER LOCK SWITCH

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING - DOOR

CYLINDER LOCK SWITCH...............6

REMOVAL.............................6

INSTALLATION..........................6POWER LOCK MOTOR

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - POWER LOCK

MOTOR ..............................7

REMOTE KEYLESS ENTRY TRANSMITTER

DESCRIPTION..........................7

OPERATION............................8

DIAGNOSIS AND TESTING - REMOTE

KEYLESS ENTRY TRANSMITTER..........8

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE

TRANSMITTER PROGRAMMING...........8

STANDARD PROCEDURE - REMOTE

KEYLESS ENTRY TRANSMITTER

BATTERIES...........................8

POWER LOCK SWITCH

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - POWER LOCK

SWITCH.............................9

POWER LOCKS

DESCRIPTION

DESCRIPTION - POWER LOCKS

Two different power lock systems are offered as

optional factory-installed equipment on this model.

Both power lock systems are offered only on models

that are also equipped with power windows. On mod-

els without the optional Remote Keyless Entry (RKE)

system, a base version of the Central Timer Module

(CTM) is used. In this version of the power lock sys-

tem, the power lock switches provide the only controlover the operation of the power lock motors. On mod-

els with the optional RKE system, a high-line or pre-

mium version of the CTM is used to provide many

electronic features and conveniences that are not pos-

sible with the base version CTM. In this power lock

system, the power lock motors are controlled by the

microprocessor-based high-line or premium version of

the CTM based upon the CTM programming and

electronic message inputs received from other elec-

tronic modules in the vehicle over the Chrysler Col-

lision Detection (CCD) data bus network, Radio

Frequency (RF) inputs received from the RKE trans-

mitters, as well as many hard wired inputs.

BR/BEPOWER SYSTEMS 8N - 1

Page 569 of 2255

Both versions of the power lock system include the

following major components, which are described in

further detail elsewhere in this service manual:

²Power Lock Motors- A reversible electric

motor integral to the door latch of each front door

locks or unlocks the front door latch when provided

with the appropriate electrical inputs.

²Power Lock Switches- A power lock switch

integral to the power window/lock switch unit located

near the forward end of the arm rest on each front

door trim panel allows the power door lock system to

be operated by either the driver or the front seat pas-

senger.

On those models equipped with the optional RKE

system, the power lock system also includes the fol-

lowing components, which are described in further

detail elsewhere in this service manual:

²Central Timer Module- The high-line or pre-

mium Central Timer Module (CTM) is located under

the driver side end of the instrument panel, inboard

of the instrument panel steering column opening.

The high-line or premium CTM contains a micropro-

cessor and software that allow it to provide the many

electronic functions and features not available with

base version of the power lock system.

²Door Cylinder Lock Switches- A resistor-

multiplexed switch located on the back of each front

door lock cylinder allows the power door lock system

to be operated using a key inserted in either the

driver or passenger front door lock cylinder.

Some of the additional features of the power lock

system found in vehicles with the RKE system option

include:

²Automatic Door Lock- The high-line/premium

CTM provides an optional automatic door lock fea-

ture (also known as rolling door locks). This is a pro-

grammable feature.

²Central Locking- The high-line/premium CTM

provides an optional central locking/unlocking fea-

ture.

²Door Lock Inhibit- The high-line/premium

CTM provides a door lock inhibit feature.

²Enhanced Accident Response- The high-line/

premium CTM provides an optional enhanced acci-

dent response feature. This is a programmable

feature.

Hard wired circuitry connects the power lock sys-

tem components to the electrical system of the vehi-

cle. These hard wired circuits are integral to several

wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the power lock sys-

tem components through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectorsand insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

Many of the electronic features in the vehicle con-

trolled or supported by the high-line or premium ver-

sions of the CTM are programmable using the

DRBIIItscan tool. In addition, the high-line/pre-

mium CTM software is Flash compatible, which

means it can be reprogrammed using Flash repro-

gramming procedures. However, if any of the CTM

hardware components are damaged or faulty, the

entire CTM unit must be replaced. The power lock

system components and the hard wired inputs or out-

puts of the CTM can be diagnosed using conventional

diagnostic tools and methods; however, for diagnosis

of the high-line or premium versions of the CTM or

the CCD data bus, the use of a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

DESCRIPTION - REMOTE KEYLESS ENTRY

SYSTEM

A Remote Keyless Entry (RKE) system is an avail-

able option on this model. The Remote Keyless Entry

(RKE) system is a Radio Frequency (RF) system that

allows the remote operation of the power lock system

and, if the vehicle is so equipped, the Vehicle Theft

Security System (VTSS). (Refer to 8 - ELECTRICAL/

VEHICLE THEFT SECURITY - DESCRIPTION).

The RKE system includes the following major compo-

nents, which are described in further detail else-

where in this service manual:

²Central Timer Module- The high-line or pre-

mium Central Timer Module (CTM) is located under

the driver side end of the instrument panel, inboard

of the instrument panel steering column opening.

The high-line or premium CTM contains a micropro-

cessor, an RF receiver, and the software that allow it

to provide the many electronic functions and features

of the RKE system.

²Keyless Entry Transmitter- The keyless

entry transmitter is a small, battery-powered, RF

transmitter that is contained within a molded plastic

case that is designed to also serve as a convenient

key fob.

Some additional features of the RKE system

include:

²Horn Chirp- This feature provides a short,

sharp chirp of the vehicle horn to give an audible

confirmation that a valid Lock signal has been

received from the RKE transmitter. This feature can

be enabled or disabled and, if enabled, one of two

8N - 2 POWER LOCKSBR/BE

POWER LOCKS (Continued)

Page 575 of 2255

The RKE transmitter operates on two Duracell

DL2016, Panasonic CR2016 (or equivalent) batteries.

Typical battery life is from one to two years. The

RKE transmitter cannot be repaired and, if faulty or

damaged, it must be replaced.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the Remote Keyless Entry (RKE) transmitters.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY TRANSMITTER

(1) Replace the Remote Keyless Entry (RKE)

transmitter batteries. (Refer to 8 - ELECTRICAL/

POWER LOCKS/REMOTE KEYLESS ENTRY

TRANSMITTER - STANDARD PROCEDURE - RKE

TRANSMITTER BATTERIES). Test each of the RKE

transmitter functions. If OK, discard the faulty bat-

teries. If not OK, go to Step 2.

(2) Program the suspect RKE transmitter and

another known good transmitter into the RKE

receiver. (Refer to 8 - ELECTRICAL/POWER

LOCKS/REMOTE KEYLESS ENTRY TRANSMIT-

TER - STANDARD PROCEDURE - RKE TRANS-

MITTER PROGRAMMING).

(3) Test the RKE system operation with both

transmitters. If both transmitters fail to operate the

power lock system, a DRBIIItscan tool is required

for further diagnosis of the RKE system. Refer to the

appropriate diagnostic information. If the known

good RKE transmitter operates the power locks and

the suspect transmitter does not, replace the faulty

RKE transmitter.

NOTE: Be certain to perform the RKE Transmitter

Programming procedure again following this test.

This procedure will erase the access code of the

test transmitter from the RKE receiver.

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMMING

To program the Remote Keyless Entry (RKE)

transmitter access codes into the RKE receiver in the

high-line or premium Central Timer Module (CTM)

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

STANDARD PROCEDURE - REMOTE KEYLESS

ENTRY TRANSMITTER BATTERIES

The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:

(1) Using a trim stick or a thin coin, gently pry at

the notch in the center seam of the RKE transmitter

case halves located near the key ring until the two

halves unsnap.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.

(4) Replace the two batteries with new Duracell

DL2016, or their equivalent. Be certain that the bat-

teries are installed with their polarity correctly ori-

ented.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together using hand pressure until they snap back

into place.

POWER LOCK SWITCH

DESCRIPTION

The power lock system can be controlled by a two-

way momentary switch integral to the power window

and lock switch and bezel unit on the trim panel of

each front door. Each power lock switch is illumi-

nated by a Light-Emitting Diode (LED) that is inte-

gral to the switch paddle. The LED of each switch is

illuminated whenever the ignition switch is in the

On position.

The power lock switches and their LEDs cannot be

adjusted or repaired and, if faulty or damaged, the

entire power window and lock switch and bezel unit

must be replaced.

OPERATION

On models with a base version of the Central

Timer Module (CTM), the power lock switches are

hard-wired to the power lock motors. The power lock

switch provides the correct battery and ground feeds

to the power lock motors to lock or unlock the door

latches.

On models with a high-line or premium version of

the CTM, the power lock switch controls battery cur-

rent signals to the lock and unlock sense inputs of

the CTM. The CTM then relays the correct battery

and ground feeds to the power lock motors to lock or

unlock the door latches.

8N - 8 POWER LOCKSBR/BE

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 576 of 2255

DIAGNOSIS AND TESTING - POWER LOCK

SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

Junction Block (JB). If all of the LEDs are inopera-

tive in either or both power window and lock switch

and bezel units, be certain to diagnose the power

window system before replacing the switch unit.

(Refer to 8 - ELECTRICAL/POWER WINDOWS -

DIAGNOSIS AND TESTING). If only one LED in a

power window and lock switch and bezel unit is inop-

erative, replace the faulty switch and bezel unit.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Check the fused B(+) fuse (Fuse 13 - 10

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 13 - 10 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window and lock switch and

bezel unit from the door trim panel. Disconnect the

door wire harness connector for the power window

and lock switch unit from the switch connector recep-

tacle.

(4) Reconnect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

door wire harness connector for the power window

and lock switch unit. If OK, go to Step 5. If not OK,

repair the open fused B(+) circuit between the power

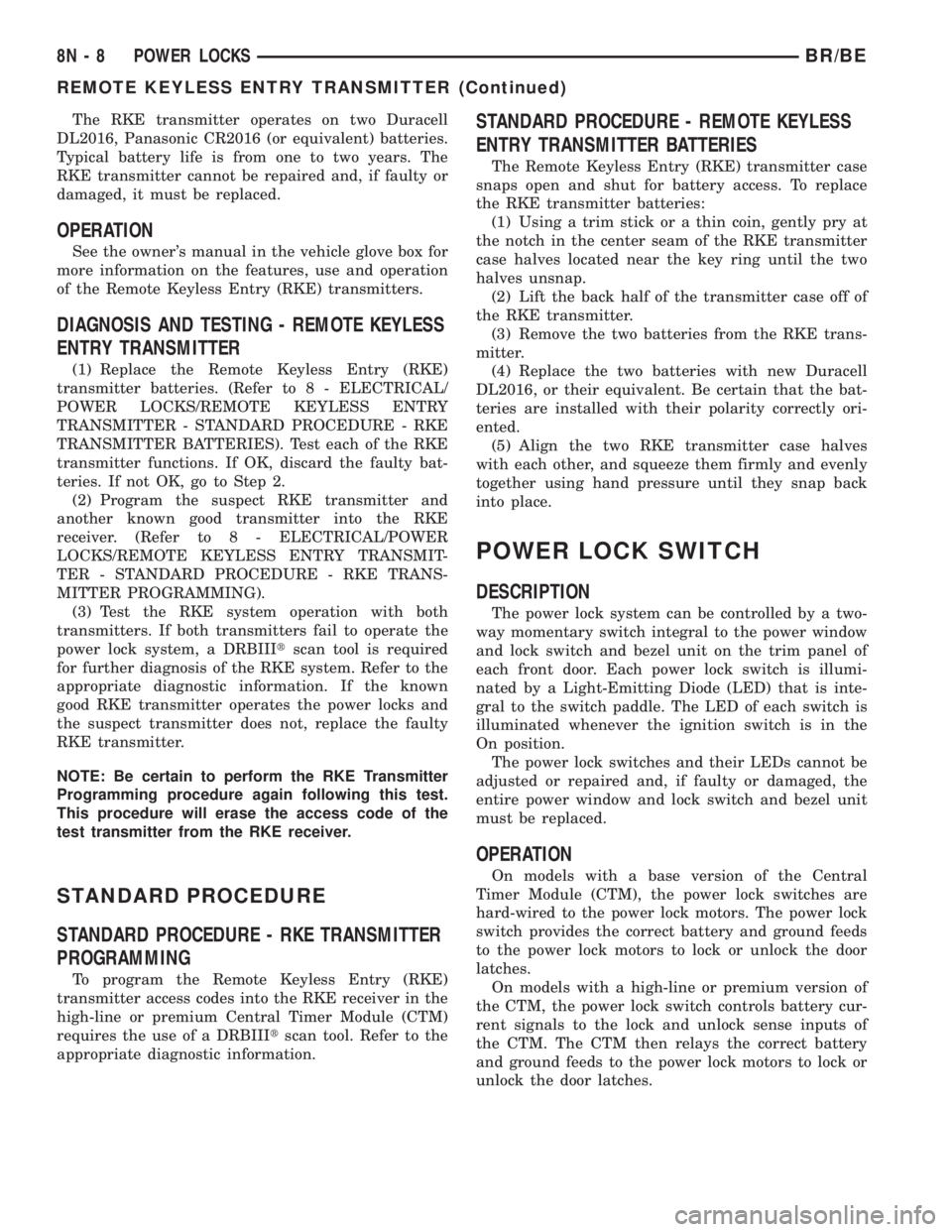

window and lock switch unit and the JB as required.(5) Test the power lock switch continuity. See the

Power Lock Switch Continuity charts to determine if

the continuity is correct in the Neutral, Lock, and

Unlock switch positions (Fig. 2) or (Fig. 3). If OK,

repair the door lock switch output (lock and/or

unlock) circuit(s) between the power window and lock

switch unit and the power lock motors (base Central

Timer Module [CTM]) or the CTM (high-line or pre-

mium CTM) as required. If not OK, replace the

faulty power window and lock switch and bezel unit.

DRIVER SIDE LOCK SWITCH

SWITCH POSITION CONTINUITY BETWEEN

NEUTRAL 7 & 9,8&9

LOCK 7 & 9,8&10

UNLOCK 7 & 10,8&9

LAMP 3 & 5

Fig. 2 Power Lock Switch Continuity - Driver Side

1 - VIEW OF SWITCH CONNECTOR RECEPTACLE

BR/BEPOWER LOCKS 8N - 9

POWER LOCK SWITCH (Continued)

Page 579 of 2255

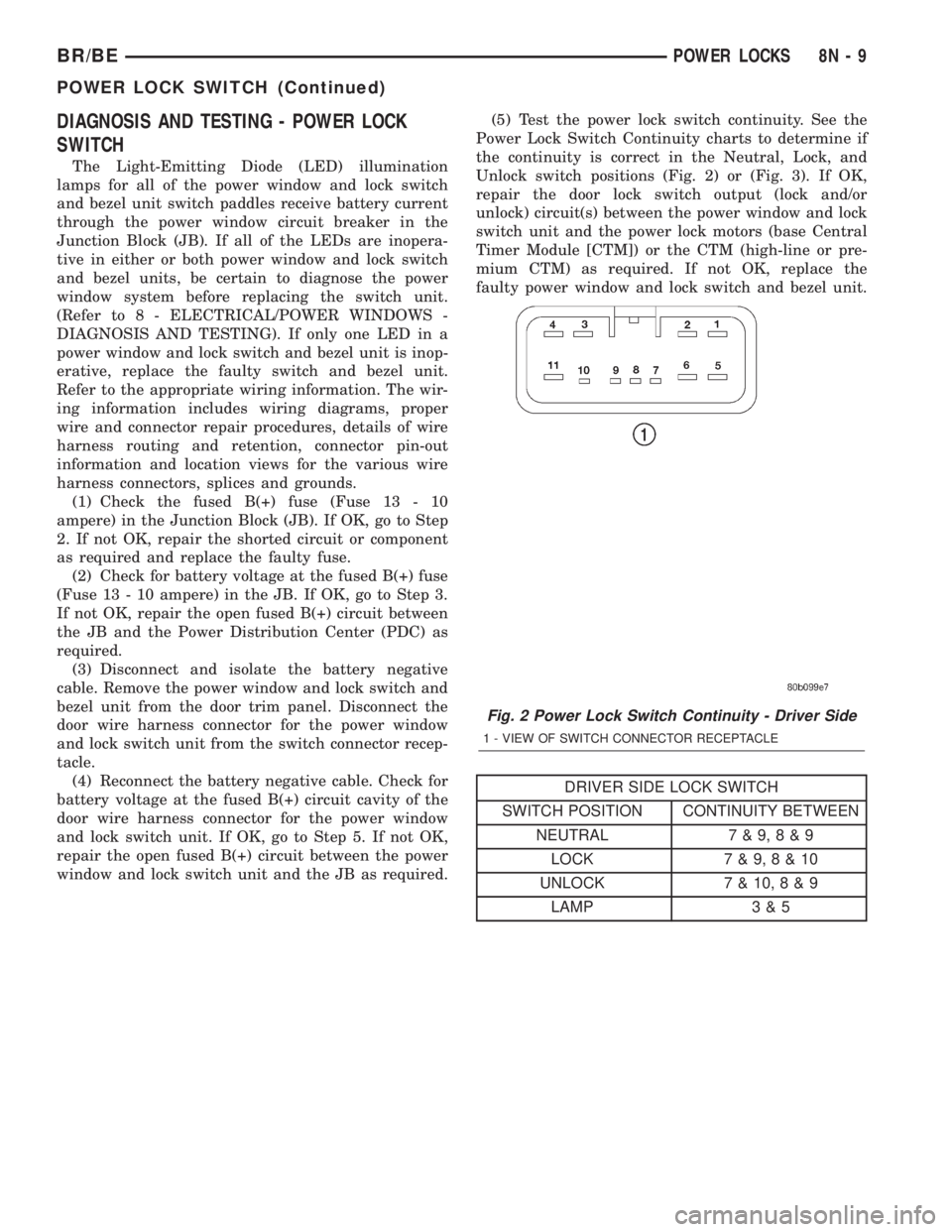

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the junction block. If OK, go

to Step 2. If not OK, repair the shorted circuit or

component as required replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 3. If not OK, repair the open

circuit to the ignition switch as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 1). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the junction block as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (LED in the mirror switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

Fig. 1 Automatic Day/Night Mirror

8N - 12 POWER MIRRORSBR/BE

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 590 of 2255

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................23

OPERATION...........................23

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................23

POWER WINDOW SWITCH

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING - POWER

WINDOW SWITCH.....................24REMOVAL.............................25

INSTALLATION.........................26

WINDOW MOTOR

DESCRIPTION.........................26

DIAGNOSIS AND TESTING - WINDOW

MOTOR .............................26

REMOVAL.............................26

POWER WINDOWS

DESCRIPTION

Power windows are available as factory-installed

optional equipment on this model. The power lock

system is included on vehicles equipped with the

power window option.

OPERATION

The power window system allows each of the front

door windows to be raised and lowered electrically by

actuating a switch on the trim panel of each respec-

tive door. Additionally, the master switch on the

driver side door trim panel allows the driver to raise

or lower the passenger side front door window. The

power window system receives battery feed through a

circuit breaker in the junction block, only when the

ignition switch is in the On position.

The power window system includes the power win-

dow switches on each front door trim panel, the cir-

cuit breaker in the junction block, and the power

window motors inside each front door. This group

covers diagnosis and service of only the electrical

components in the power window system. For service

of mechanical components, such as the regulator, lift

plate, window tracks, or glass refer to Group 23 -

Body.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power window system.

DIAGNOSIS AND TESTING - POWER

WINDOWS

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harnessrouting and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

ALL WINDOWS INOPERATIVE

(1) Check the circuit breaker in the junction block.

If OK, go to Step 2. If not OK, replace the faulty cir-

cuit breaker.

(2) Disconnect and isolate the battery negative

cable. Remove the power window and lock switch and

bezel unit from the driver side front door trim panel.

Unplug the wire harness connector from the switch

and bezel unit.

(3) Check for continuity between the ground cir-

cuit cavity of the switch and bezel unit wire harness

connector and a good ground. If OK, (Refer to 8 -

ELECTRICAL/POWER WINDOWS/POWER WIN-

DOW SWITCH - DIAGNOSIS AND TESTING). If not

OK, repair the circuit to ground as required.

ONE WINDOW INOPERATIVE

The window glass must be free to slide up and

down for the power window motor to function prop-

erly. If the glass is not free to move up and down, the

motor will overload and trip the integral circuit

breaker. To determine if the glass is free, disconnect

the regulator plate from the glass. Then slide the

window up and down by hand.

There is an alternate method to check if the glass

is free. Position the glass between the up and down

stops. Then, shake the glass in the door. Check that

the glass can be moved slightly from side to side,

front to rear, and up and down. Then check that the

glass is not bound tight in the tracks. If the glass is

free, proceed with the diagnosis that follows. If the

glass is not free, (Refer to 23 - BODY/DOOR -

FRONT/DOOR GLASS - REMOVAL).

BR/BEPOWER WINDOWS 8N - 23

Page 591 of 2255

(1) Disconnect and isolate the battery negative

cable. Remove the power window and lock switch and

bezel unit from the door trim panel on the side of the

vehicle with the inoperative window. Unplug the wire

harness connector from the switch and bezel unit.

(2) Connect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity in the body half of the switch and bezel

unit wire harness connector. If OK, and the inopera-

tive power window is on the driver side, go to Step 4.

If OK, and the inoperative power window is on the

passenger side, go to Step 3. If not OK, repair the

open circuit to the junction block as required.

(3) Disconnect and isolate the battery negative

cable. Check for continuity between each of the two

master window switch right up/down control circuit

cavities in the body half of the passenger side switch

and bezel unit wire harness connector and a good

ground. In each case, there should be continuity. If

OK, go to Step 4. If not OK, repair the open circuit to

the driver side switch and bezel unit as required.

(4) Test the power window switch continuity.

(Refer to 8 - ELECTRICAL/POWER WINDOWS/

POWER WINDOW SWITCH - DIAGNOSIS AND

TESTING). If OK, go to Step 5. If not OK, replace

the faulty power window and lock switch and bezel

unit.

(5) Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds. Check

the continuity in each circuit between the inoperative

power window and lock switch and bezel unit wire

harness connector cavities and the corresponding

power window motor wire harness connector cavities.

If OK, (Refer to 8 - ELECTRICAL/POWER WIN-

DOWS/WINDOW MOTOR - DIAGNOSIS AND TEST-

ING). If not OK, repair the open circuit(s) as

required.

NOTE: The passenger side power window switch

receives the ground feed for operating the passen-

ger side power window motor through the driver

side power window switch and wire harness con-

nector.

POWER WINDOW SWITCH

DESCRIPTION

The power windows are controlled by two-way

switches integral to the power window and lock

switch and bezel unit on the trim panel of each frontdoor. A second power window switch in the driver

side switch and bezel unit allows the driver to control

the passenger side window. A Light-Emitting Diode

(LED) in the paddle of each switch is illuminated

whenever the ignition switch is in the On position.

OPERATION

The power window switch for the driver side front

door has an Auto label on it. This switch has a sec-

ond detent position beyond the normal Down position

that provides an automatic one-touch window down

feature. This feature is controlled by an electronic

circuit and a relay that are integral to the driver side

front door power window and lock switch unit.

The power window switches control the battery

and ground feeds to the power window motors. The

passenger side power window switch receives a

ground feed through the driver side power window

switch for operating the passenger side power win-

dow motor.

The power window and lock switch and bezel unit

cannot be repaired and, if faulty or damaged, the

entire switch and bezel unit must be replaced.

DIAGNOSIS AND TESTING - POWER WINDOW

SWITCH

The auto down feature of the driver side power

window switch is controlled by an electronic circuit

within the switch unit. The auto down circuitry is

activated when the driver side power window switch

is moved to the second detent in the Down direction.

The outputs from the auto down circuitry are carried

through the same switch pins that provide the nor-

mal down function. The auto down circuit cannot be

tested. If the driver side power window switch conti-

nuity tests are passed, but the auto down feature is

inoperative, replace the faulty driver side power win-

dow switch unit.

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

junction block. If all of the LEDs are inoperative in

either or both power window and lock switch and

bezel units and the power windows are inoperative,

perform the diagnosis for Power Window System in

this group. If the power windows operate, but any or

all of the LEDs are inoperative, the power window

and lock switch and bezel unit with the inoperative

LED(s) is faulty and must be replaced. For circuit

descriptions and diagrams, refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

8N - 24 POWER WINDOWSBR/BE

POWER WINDOWS (Continued)