clock DODGE RAM 2003 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1734 of 2895

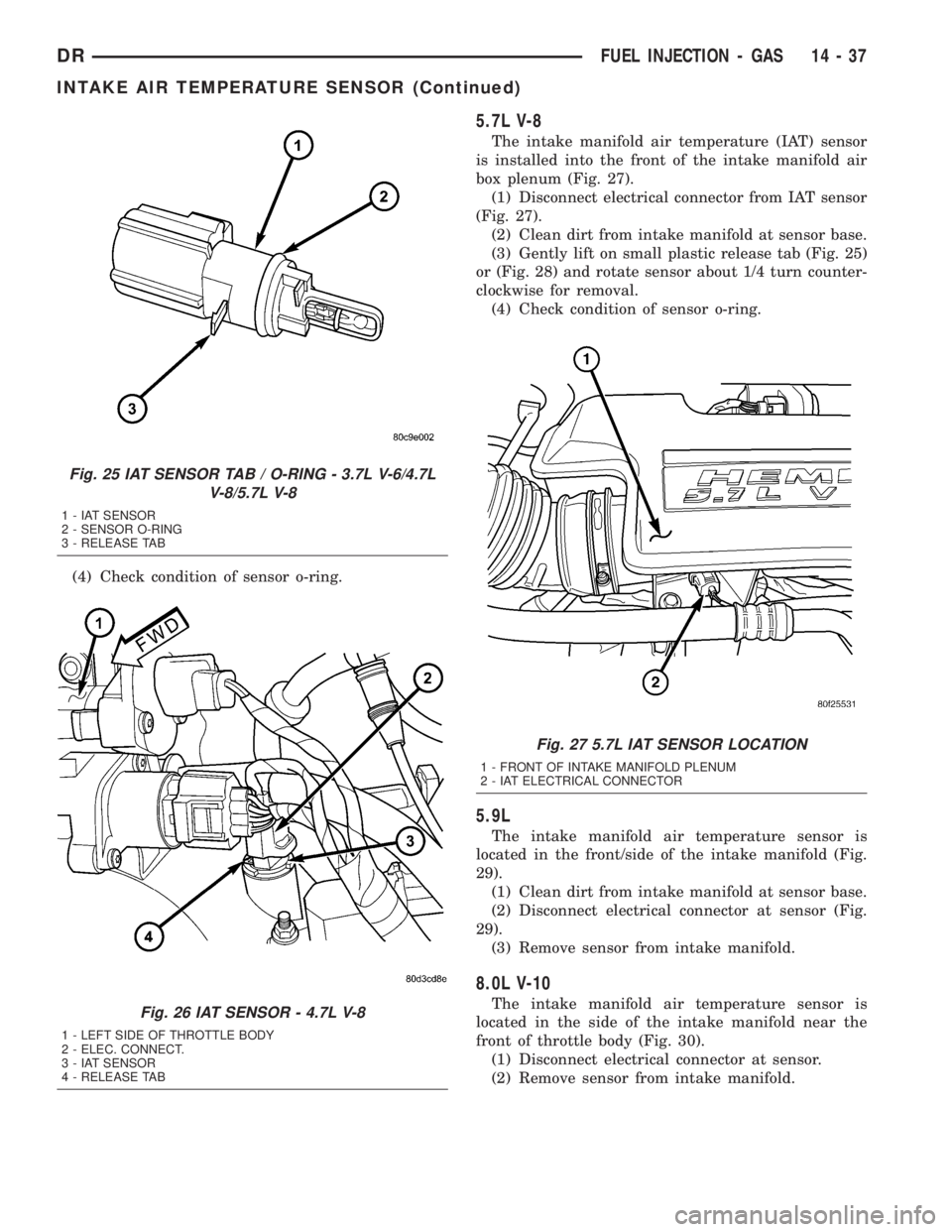

(4) Check condition of sensor o-ring.

5.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the front of the intake manifold air

box plenum (Fig. 27).

(1) Disconnect electrical connector from IAT sensor

(Fig. 27).

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 25)

or (Fig. 28) and rotate sensor about 1/4 turn counter-

clockwise for removal.

(4) Check condition of sensor o-ring.

5.9L

The intake manifold air temperature sensor is

located in the front/side of the intake manifold (Fig.

29).

(1) Clean dirt from intake manifold at sensor base.

(2) Disconnect electrical connector at sensor (Fig.

29).

(3) Remove sensor from intake manifold.

8.0L V-10

The intake manifold air temperature sensor is

located in the side of the intake manifold near the

front of throttle body (Fig. 30).

(1) Disconnect electrical connector at sensor.

(2) Remove sensor from intake manifold.

Fig. 25 IAT SENSOR TAB / O-RING - 3.7L V-6/4.7L

V-8/5.7L V-8

1 - IAT SENSOR

2 - SENSOR O-RING

3 - RELEASE TAB

Fig. 26 IAT SENSOR - 4.7L V-8

1 - LEFT SIDE OF THROTTLE BODY

2 - ELEC. CONNECT.

3 - IAT SENSOR

4 - RELEASE TAB

Fig. 27 5.7L IAT SENSOR LOCATION

1 - FRONT OF INTAKE MANIFOLD PLENUM

2 - IAT ELECTRICAL CONNECTOR

DRFUEL INJECTION - GAS 14 - 37

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1735 of 2895

INSTALLATION

3.7L V-6

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 24).

(1) Check condition of sensor o-ring.(2) Clean sensor mounting hole in intake manifold.

(3) Position sensor into intake manifold and rotate

clockwise until past release tab (Fig. 24).

(4) Install electrical connector.

4.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 26).

(1) Check condition of sensor o-ring.

(2) Clean sensor mounting hole in intake manifold.

(3) Position sensor into intake manifold and rotate

clockwise until past release tab.

(4) Install electrical connector.

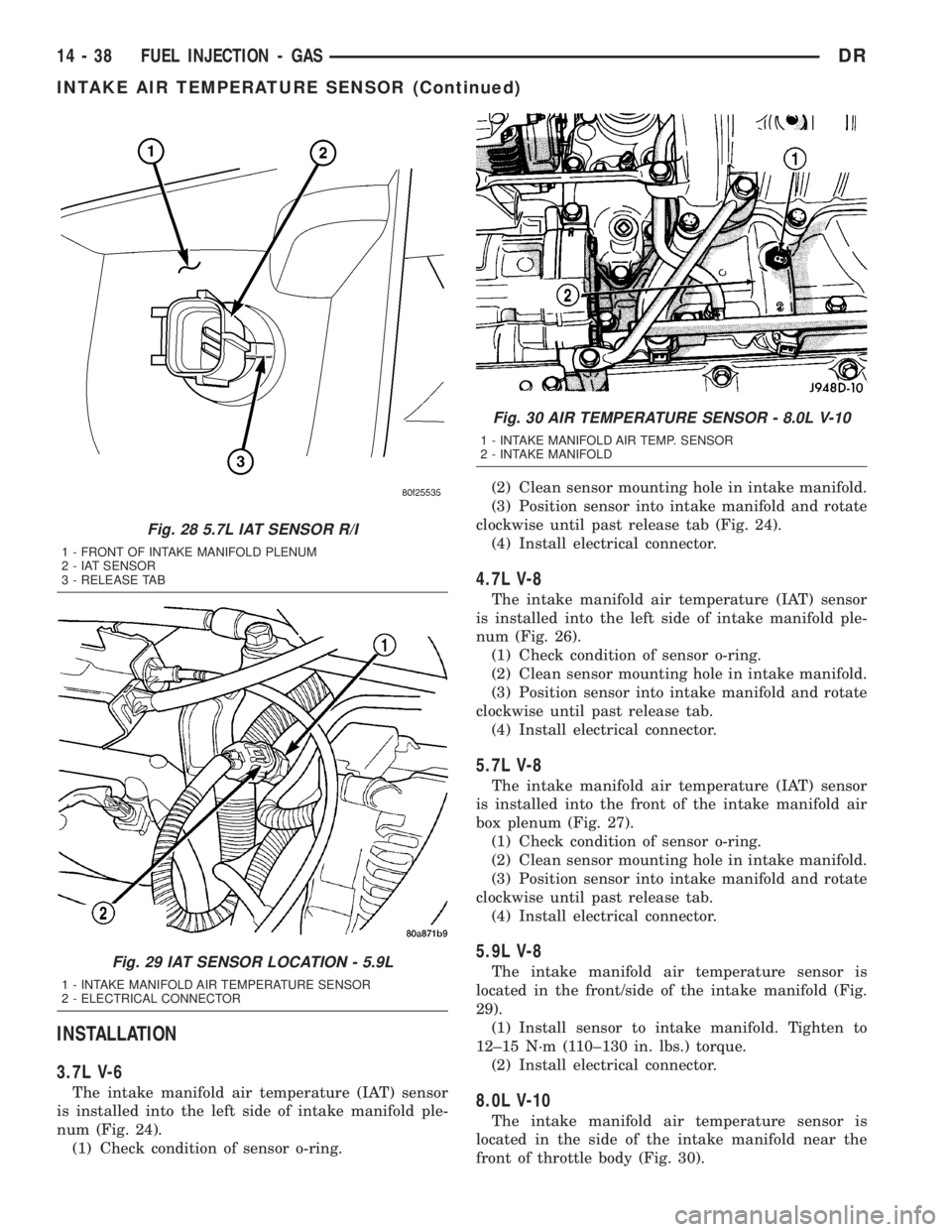

5.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the front of the intake manifold air

box plenum (Fig. 27).

(1) Check condition of sensor o-ring.

(2) Clean sensor mounting hole in intake manifold.

(3) Position sensor into intake manifold and rotate

clockwise until past release tab.

(4) Install electrical connector.

5.9L V-8

The intake manifold air temperature sensor is

located in the front/side of the intake manifold (Fig.

29).

(1) Install sensor to intake manifold. Tighten to

12±15 N´m (110±130 in. lbs.) torque.

(2) Install electrical connector.

8.0L V-10

The intake manifold air temperature sensor is

located in the side of the intake manifold near the

front of throttle body (Fig. 30).

Fig. 28 5.7L IAT SENSOR R/I

1 - FRONT OF INTAKE MANIFOLD PLENUM

2 - IAT SENSOR

3 - RELEASE TAB

Fig. 29 IAT SENSOR LOCATION - 5.9L

1 - INTAKE MANIFOLD AIR TEMPERATURE SENSOR

2 - ELECTRICAL CONNECTOR

Fig. 30 AIR TEMPERATURE SENSOR - 8.0L V-10

1 - INTAKE MANIFOLD AIR TEMP. SENSOR

2 - INTAKE MANIFOLD

14 - 38 FUEL INJECTION - GASDR

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1738 of 2895

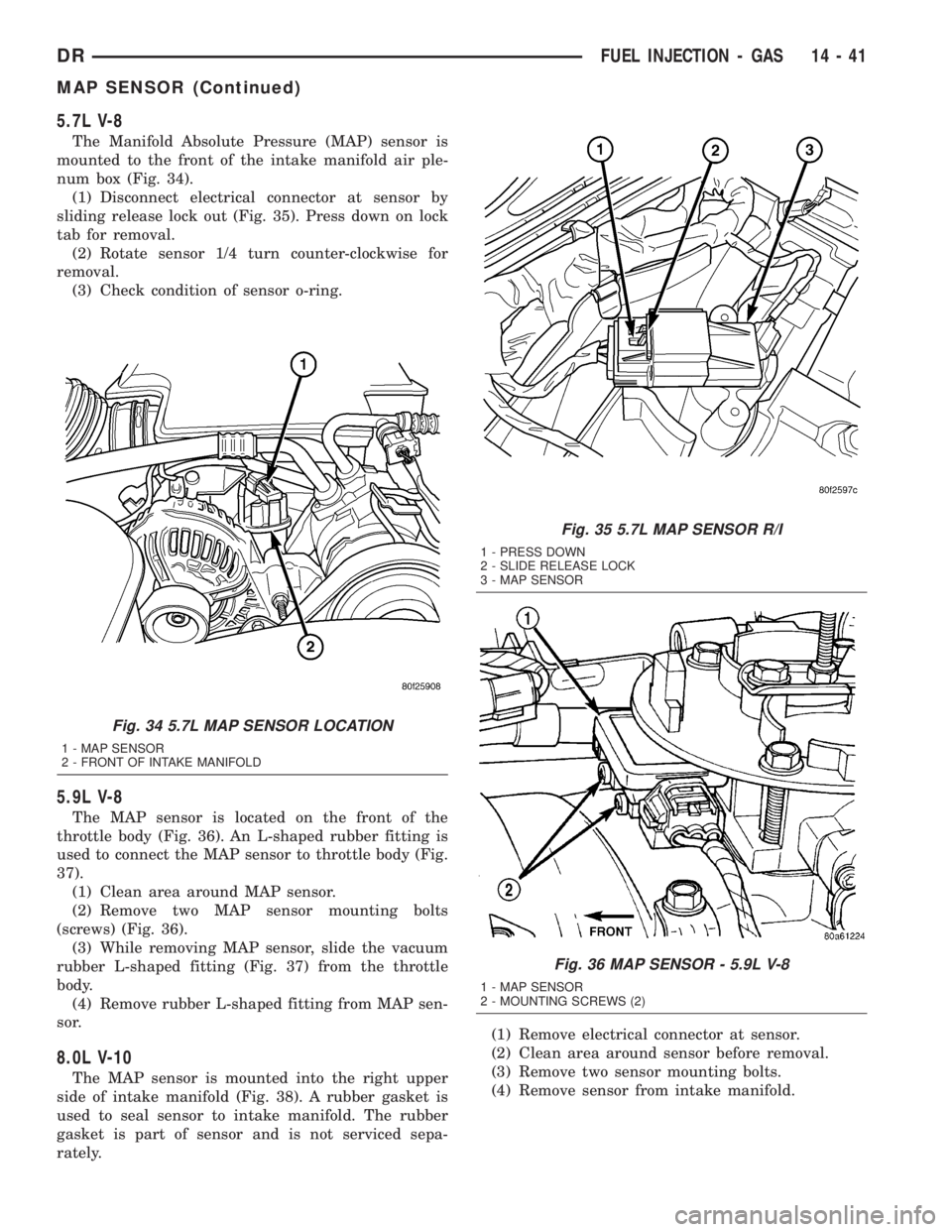

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the intake manifold air ple-

num box (Fig. 34).

(1) Disconnect electrical connector at sensor by

sliding release lock out (Fig. 35). Press down on lock

tab for removal.

(2) Rotate sensor 1/4 turn counter-clockwise for

removal.

(3) Check condition of sensor o-ring.

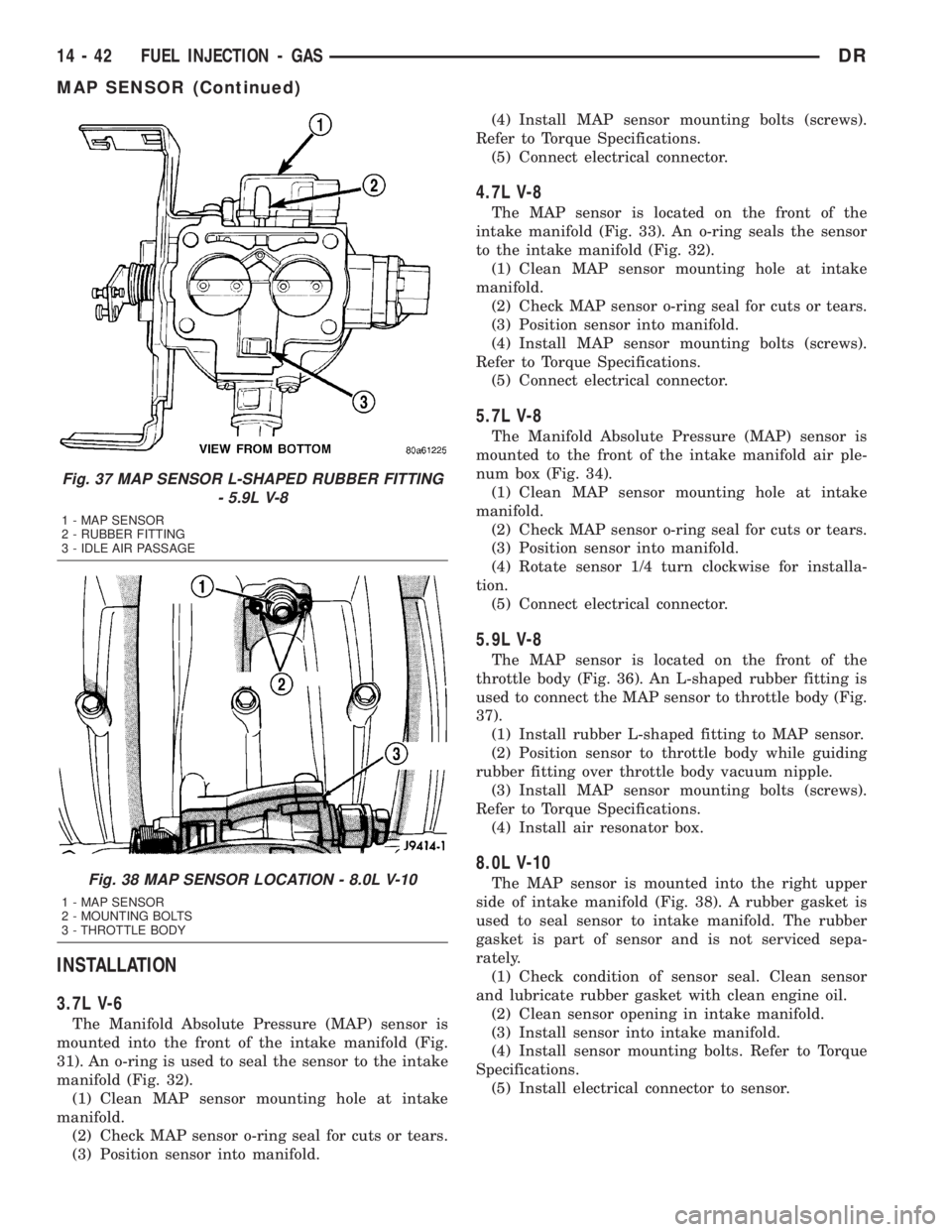

5.9L V-8

The MAP sensor is located on the front of the

throttle body (Fig. 36). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

37).

(1) Clean area around MAP sensor.

(2) Remove two MAP sensor mounting bolts

(screws) (Fig. 36).

(3) While removing MAP sensor, slide the vacuum

rubber L-shaped fitting (Fig. 37) from the throttle

body.

(4) Remove rubber L-shaped fitting from MAP sen-

sor.

8.0L V-10

The MAP sensor is mounted into the right upper

side of intake manifold (Fig. 38). A rubber gasket is

used to seal sensor to intake manifold. The rubber

gasket is part of sensor and is not serviced sepa-

rately.(1) Remove electrical connector at sensor.

(2) Clean area around sensor before removal.

(3) Remove two sensor mounting bolts.

(4) Remove sensor from intake manifold.

Fig. 34 5.7L MAP SENSOR LOCATION

1 - MAP SENSOR

2 - FRONT OF INTAKE MANIFOLD

Fig. 35 5.7L MAP SENSOR R/I

1 - PRESS DOWN

2 - SLIDE RELEASE LOCK

3 - MAP SENSOR

Fig. 36 MAP SENSOR - 5.9L V-8

1 - MAP SENSOR

2 - MOUNTING SCREWS (2)

DRFUEL INJECTION - GAS 14 - 41

MAP SENSOR (Continued)

Page 1739 of 2895

INSTALLATION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold (Fig.

31). An o-ring is used to seal the sensor to the intake

manifold (Fig. 32).

(1) Clean MAP sensor mounting hole at intake

manifold.

(2) Check MAP sensor o-ring seal for cuts or tears.

(3) Position sensor into manifold.(4) Install MAP sensor mounting bolts (screws).

Refer to Torque Specifications.

(5) Connect electrical connector.

4.7L V-8

The MAP sensor is located on the front of the

intake manifold (Fig. 33). An o-ring seals the sensor

to the intake manifold (Fig. 32).

(1) Clean MAP sensor mounting hole at intake

manifold.

(2) Check MAP sensor o-ring seal for cuts or tears.

(3) Position sensor into manifold.

(4) Install MAP sensor mounting bolts (screws).

Refer to Torque Specifications.

(5) Connect electrical connector.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the intake manifold air ple-

num box (Fig. 34).

(1) Clean MAP sensor mounting hole at intake

manifold.

(2) Check MAP sensor o-ring seal for cuts or tears.

(3) Position sensor into manifold.

(4) Rotate sensor 1/4 turn clockwise for installa-

tion.

(5) Connect electrical connector.

5.9L V-8

The MAP sensor is located on the front of the

throttle body (Fig. 36). An L-shaped rubber fitting is

used to connect the MAP sensor to throttle body (Fig.

37).

(1) Install rubber L-shaped fitting to MAP sensor.

(2) Position sensor to throttle body while guiding

rubber fitting over throttle body vacuum nipple.

(3) Install MAP sensor mounting bolts (screws).

Refer to Torque Specifications.

(4) Install air resonator box.

8.0L V-10

The MAP sensor is mounted into the right upper

side of intake manifold (Fig. 38). A rubber gasket is

used to seal sensor to intake manifold. The rubber

gasket is part of sensor and is not serviced sepa-

rately.

(1) Check condition of sensor seal. Clean sensor

and lubricate rubber gasket with clean engine oil.

(2) Clean sensor opening in intake manifold.

(3) Install sensor into intake manifold.

(4) Install sensor mounting bolts. Refer to Torque

Specifications.

(5) Install electrical connector to sensor.

Fig. 37 MAP SENSOR L-SHAPED RUBBER FITTING

- 5.9L V-8

1 - MAP SENSOR

2 - RUBBER FITTING

3 - IDLE AIR PASSAGE

Fig. 38 MAP SENSOR LOCATION - 8.0L V-10

1 - MAP SENSOR

2 - MOUNTING BOLTS

3 - THROTTLE BODY

14 - 42 FUEL INJECTION - GASDR

MAP SENSOR (Continued)

Page 1758 of 2895

FUEL FILTER / WATER

SEPARATOR

DESCRIPTION

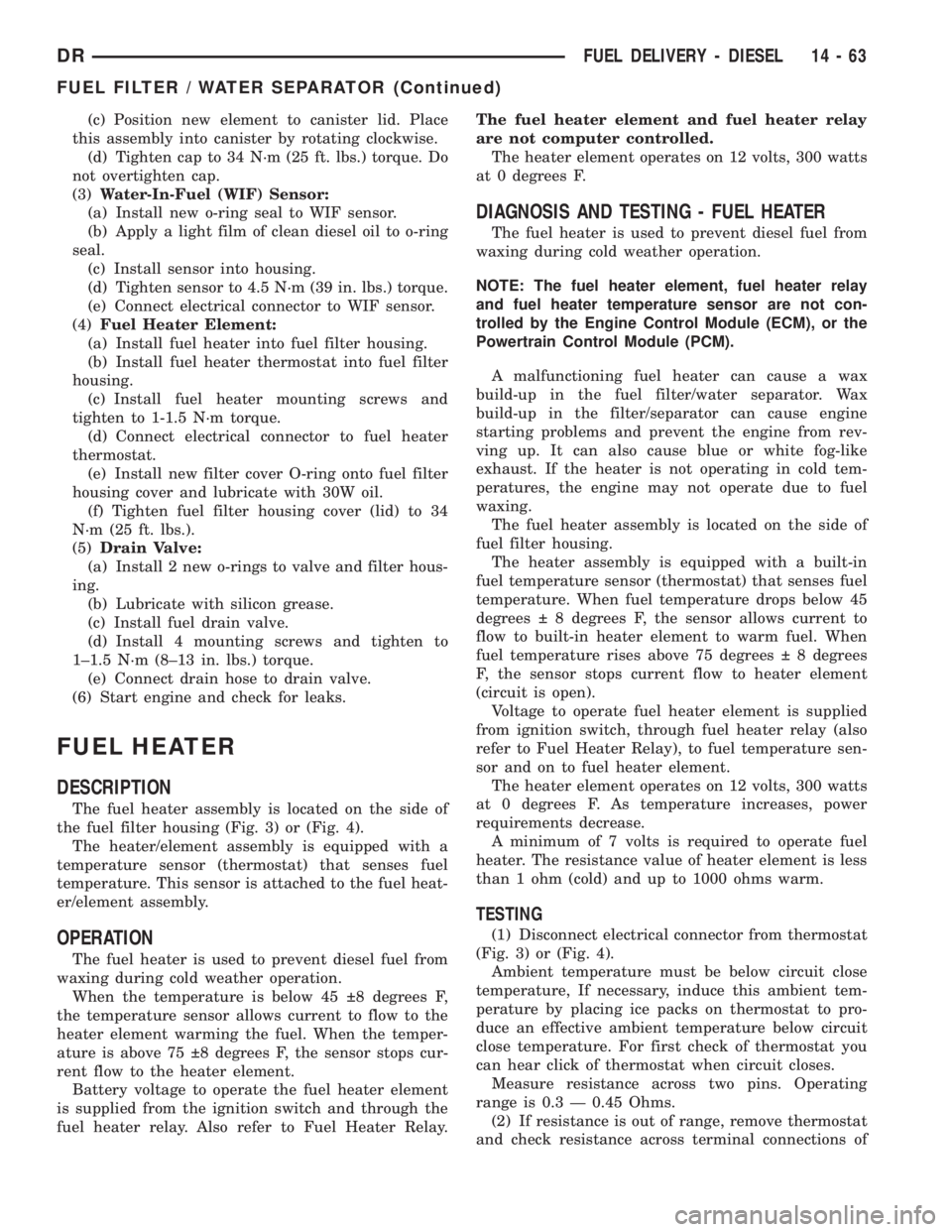

The fuel filter/water separator assembly is located

on left side of engine above starter motor. The assem-

bly also includes the fuel heater and Water-In-Fuel

(WIF) sensor, and fuel transfer pump.

OPERATION

The fuel filter/water separator protects the fuel

injection pump by removing water and contaminants

from the fuel. The construction of the filter/separator

allows fuel to pass through it, but helps prevent

moisture (water) from doing so. Moisture collects at

the bottom of the canister.

Refer to the maintenance schedules for the recom-

mended fuel filter replacement intervals.

For draining of water from canister, refer to Fuel

Filter/Water Separator Removal/Installation section.A Water-In-Fuel (WIF) sensor is attached to side of

canister. Refer to Water-In-Fuel Sensor Description/

Operation.

The fuel heater is installed into the top of the fil-

ter/separator housing. Refer to Fuel Heater Descrip-

tion/Operation.

REMOVAL

Refer to maintenance schedules in this manual for

recommended fuel filter replacement intervals.

Draining water from fuel filter/water separa-

tor housing:

The housing drain valve (Fig. 3) or (Fig. 4) serves

two purposes. One is topartiallydrain filter hous-

ing of excess water. The other is tocompletelydrain

housing for fuel filter, drain valve, heater element, ,

water-in-fuel sensor replacement or transfer pump

replacement.

The filter housing should be partially drained

whenever water-in-fuel warning lamp remains illumi-

nated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).

(1) A drain hose (Fig. 3) or (Fig. 4) is located at

bottom of drain valve. Place drain pan under drain.

(2)With engine not running,rotate drain valve

handle rearward to OPEN (DRAIN) position. Hold

drain valve open until all water and contaminants

have been removed and clean fuel exits.

(3) If drain valve, fuel heater element or Water-In-

Fuel (WIF) sensor is being replaced, drain housing

completely. Dispose of mixture in drain pan according

to applicable regulations.

(4) After draining operation, push valve handle

forward to CLOSE position.

(5)Fuel Filter Replacement:The fuel filter is

located inside of the fuel filter housing.

(a) Clean all debris from around canister.

(b) Remove filter lid (Fig. 5) using a socket.

Attach socket to large hex on top of lid (Fig. 5).

Rotate counter-clockwise for removal. Remove

o-ring.

(c) Remove filter element by twisting element

sideways from filter lid.

(6)Water-In-Fuel (WIF) Sensor Replacement:

The WIF sensor is located on the side of the fuel fil-

ter housing (Fig. 3) or (Fig. 4).

(a) Disconnect electrical connector at sensor.

(b) Clean area around sensor.

(c) Remove sensor by rotating counter-clockwise.

(d) Check condition of sensor o-ring. Replace if

damaged.

(7)Fuel Heater Element Replacement:The

heater element is located in the fuel filter housing

(Fig. 3) or (Fig. 4).

(a) Remove fuel filter. See previous steps.

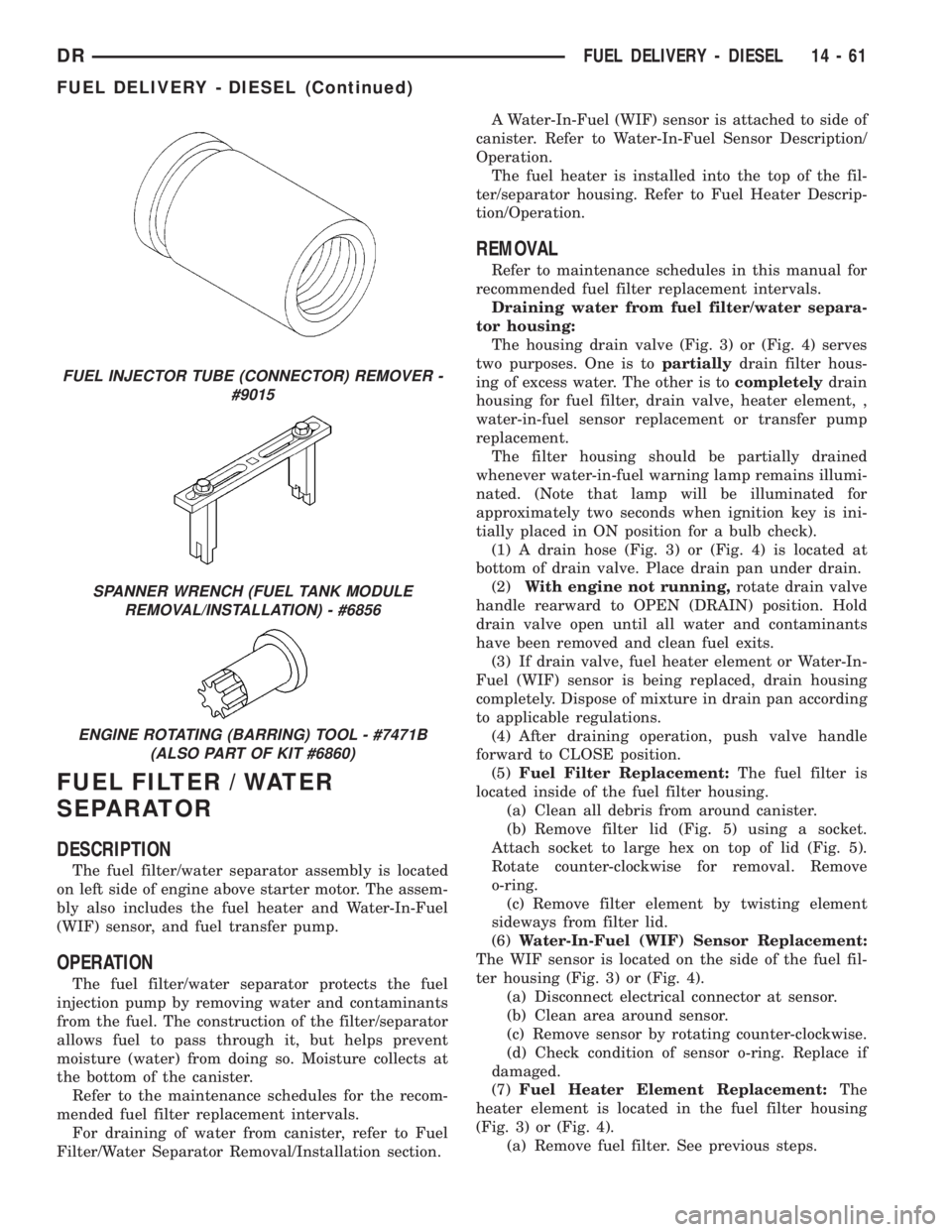

FUEL INJECTOR TUBE (CONNECTOR) REMOVER -

#9015

SPANNER WRENCH (FUEL TANK MODULE

REMOVAL/INSTALLATION) - #6856

ENGINE ROTATING (BARRING) TOOL - #7471B

(ALSO PART OF KIT #6860)

DRFUEL DELIVERY - DIESEL 14 - 61

FUEL DELIVERY - DIESEL (Continued)

Page 1760 of 2895

(c) Position new element to canister lid. Place

this assembly into canister by rotating clockwise.

(d) Tighten cap to 34 N´m (25 ft. lbs.) torque. Do

not overtighten cap.

(3)Water-In-Fuel (WIF) Sensor:

(a) Install new o-ring seal to WIF sensor.

(b) Apply a light film of clean diesel oil to o-ring

seal.

(c) Install sensor into housing.

(d) Tighten sensor to 4.5 N´m (39 in. lbs.) torque.

(e) Connect electrical connector to WIF sensor.

(4)Fuel Heater Element:

(a) Install fuel heater into fuel filter housing.

(b) Install fuel heater thermostat into fuel filter

housing.

(c) Install fuel heater mounting screws and

tighten to 1-1.5 N´m torque.

(d) Connect electrical connector to fuel heater

thermostat.

(e) Install new filter cover O-ring onto fuel filter

housing cover and lubricate with 30W oil.

(f) Tighten fuel filter housing cover (lid) to 34

N´m (25 ft. lbs.).

(5)Drain Valve:

(a) Install 2 new o-rings to valve and filter hous-

ing.

(b) Lubricate with silicon grease.

(c) Install fuel drain valve.

(d) Install 4 mounting screws and tighten to

1±1.5 N´m (8±13 in. lbs.) torque.

(e) Connect drain hose to drain valve.

(6) Start engine and check for leaks.

FUEL HEATER

DESCRIPTION

The fuel heater assembly is located on the side of

the fuel filter housing (Fig. 3) or (Fig. 4).

The heater/element assembly is equipped with a

temperature sensor (thermostat) that senses fuel

temperature. This sensor is attached to the fuel heat-

er/element assembly.

OPERATION

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

When the temperature is below 45 8 degrees F,

the temperature sensor allows current to flow to the

heater element warming the fuel. When the temper-

ature is above 75 8 degrees F, the sensor stops cur-

rent flow to the heater element.

Battery voltage to operate the fuel heater element

is supplied from the ignition switch and through the

fuel heater relay. Also refer to Fuel Heater Relay.The fuel heater element and fuel heater relay

are not computer controlled.

The heater element operates on 12 volts, 300 watts

at 0 degrees F.

DIAGNOSIS AND TESTING - FUEL HEATER

The fuel heater is used to prevent diesel fuel from

waxing during cold weather operation.

NOTE: The fuel heater element, fuel heater relay

and fuel heater temperature sensor are not con-

trolled by the Engine Control Module (ECM), or the

Powertrain Control Module (PCM).

A malfunctioning fuel heater can cause a wax

build-up in the fuel filter/water separator. Wax

build-up in the filter/separator can cause engine

starting problems and prevent the engine from rev-

ving up. It can also cause blue or white fog-like

exhaust. If the heater is not operating in cold tem-

peratures, the engine may not operate due to fuel

waxing.

The fuel heater assembly is located on the side of

fuel filter housing.

The heater assembly is equipped with a built-in

fuel temperature sensor (thermostat) that senses fuel

temperature. When fuel temperature drops below 45

degrees 8 degrees F, the sensor allows current to

flow to built-in heater element to warm fuel. When

fuel temperature rises above 75 degrees 8 degrees

F, the sensor stops current flow to heater element

(circuit is open).

Voltage to operate fuel heater element is supplied

from ignition switch, through fuel heater relay (also

refer to Fuel Heater Relay), to fuel temperature sen-

sor and on to fuel heater element.

The heater element operates on 12 volts, 300 watts

at 0 degrees F. As temperature increases, power

requirements decrease.

A minimum of 7 volts is required to operate fuel

heater. The resistance value of heater element is less

than 1 ohm (cold) and up to 1000 ohms warm.

TESTING

(1) Disconnect electrical connector from thermostat

(Fig. 3) or (Fig. 4).

Ambient temperature must be below circuit close

temperature, If necessary, induce this ambient tem-

perature by placing ice packs on thermostat to pro-

duce an effective ambient temperature below circuit

close temperature. For first check of thermostat you

can hear click of thermostat when circuit closes.

Measure resistance across two pins. Operating

range is 0.3 Ð 0.45 Ohms.

(2) If resistance is out of range, remove thermostat

and check resistance across terminal connections of

DRFUEL DELIVERY - DIESEL 14 - 63

FUEL FILTER / WATER SEPARATOR (Continued)

Page 1800 of 2895

NOTE: When servicing the coupler a new bolt must

be used when installing.

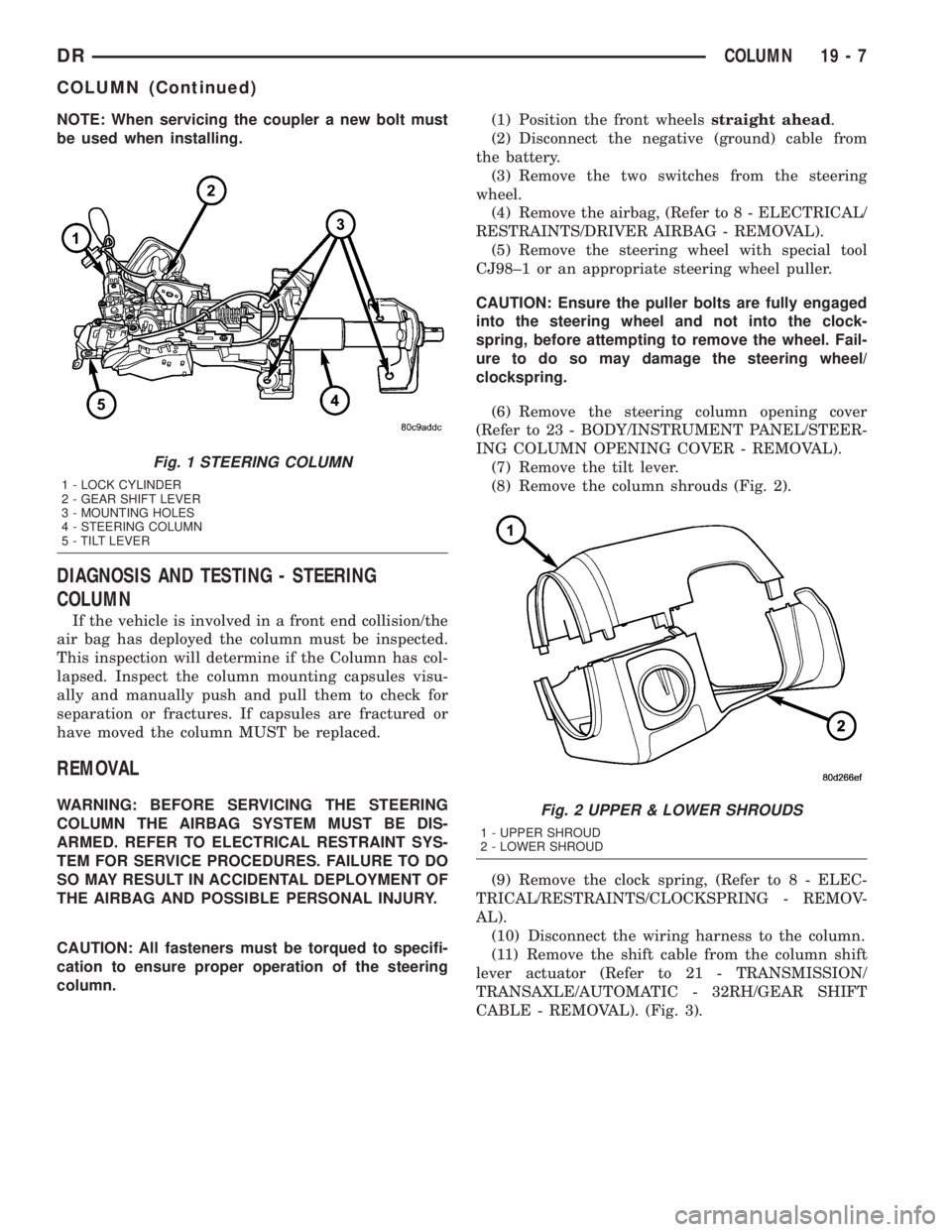

DIAGNOSIS AND TESTING - STEERING

COLUMN

If the vehicle is involved in a front end collision/the

air bag has deployed the column must be inspected.

This inspection will determine if the Column has col-

lapsed. Inspect the column mounting capsules visu-

ally and manually push and pull them to check for

separation or fractures. If capsules are fractured or

have moved the column MUST be replaced.

REMOVAL

WARNING: BEFORE SERVICING THE STEERING

COLUMN THE AIRBAG SYSTEM MUST BE DIS-

ARMED. REFER TO ELECTRICAL RESTRAINT SYS-

TEM FOR SERVICE PROCEDURES. FAILURE TO DO

SO MAY RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIRBAG AND POSSIBLE PERSONAL INJURY.

CAUTION: All fasteners must be torqued to specifi-

cation to ensure proper operation of the steering

column.(1) Position the front wheelsstraight ahead.

(2) Disconnect the negative (ground) cable from

the battery.

(3) Remove the two switches from the steering

wheel.

(4) Remove the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(5) Remove the steering wheel with special tool

CJ98±1 or an appropriate steering wheel puller.

CAUTION: Ensure the puller bolts are fully engaged

into the steering wheel and not into the clock-

spring, before attempting to remove the wheel. Fail-

ure to do so may damage the steering wheel/

clockspring.

(6) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(7) Remove the tilt lever.

(8) Remove the column shrouds (Fig. 2).

(9) Remove the clock spring, (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/CLOCKSPRING - REMOV-

AL).

(10) Disconnect the wiring harness to the column.

(11) Remove the shift cable from the column shift

lever actuator (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 32RH/GEAR SHIFT

CABLE - REMOVAL). (Fig. 3).

Fig. 1 STEERING COLUMN

1 - LOCK CYLINDER

2 - GEAR SHIFT LEVER

3 - MOUNTING HOLES

4 - STEERING COLUMN

5 - TILT LEVER

Fig. 2 UPPER & LOWER SHROUDS

1 - UPPER SHROUD

2 - LOWER SHROUD

DRCOLUMN 19 - 7

COLUMN (Continued)

Page 1802 of 2895

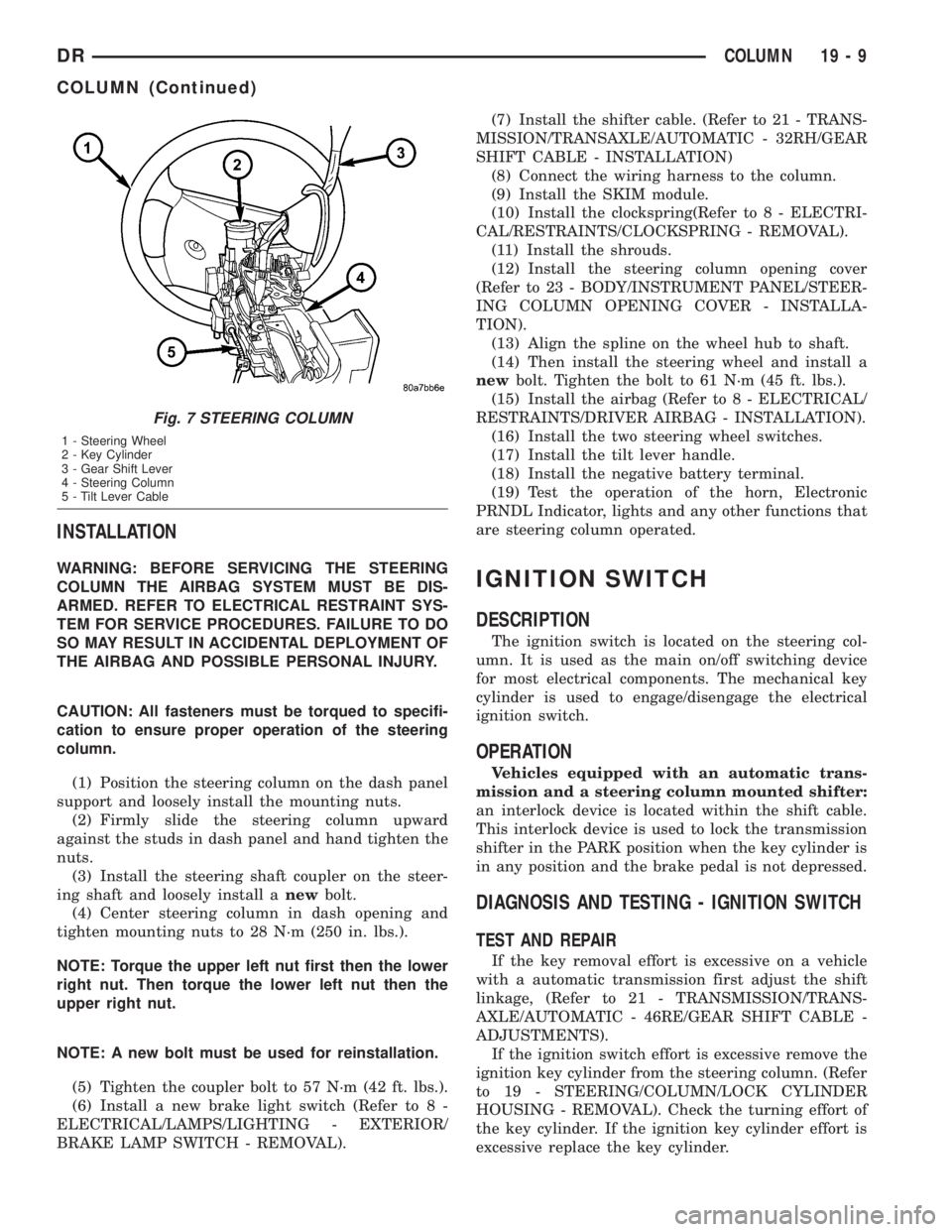

INSTALLATION

WARNING: BEFORE SERVICING THE STEERING

COLUMN THE AIRBAG SYSTEM MUST BE DIS-

ARMED. REFER TO ELECTRICAL RESTRAINT SYS-

TEM FOR SERVICE PROCEDURES. FAILURE TO DO

SO MAY RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIRBAG AND POSSIBLE PERSONAL INJURY.

CAUTION: All fasteners must be torqued to specifi-

cation to ensure proper operation of the steering

column.

(1) Position the steering column on the dash panel

support and loosely install the mounting nuts.

(2) Firmly slide the steering column upward

against the studs in dash panel and hand tighten the

nuts.

(3) Install the steering shaft coupler on the steer-

ing shaft and loosely install anewbolt.

(4) Center steering column in dash opening and

tighten mounting nuts to 28 N´m (250 in. lbs.).

NOTE: Torque the upper left nut first then the lower

right nut. Then torque the lower left nut then the

upper right nut.

NOTE: A new bolt must be used for reinstallation.

(5) Tighten the coupler bolt to 57 N´m (42 ft. lbs.).

(6) Install a new brake light switch (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).(7) Install the shifter cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 32RH/GEAR

SHIFT CABLE - INSTALLATION)

(8) Connect the wiring harness to the column.

(9) Install the SKIM module.

(10) Install the clockspring(Refer to 8 - ELECTRI-

CAL/RESTRAINTS/CLOCKSPRING - REMOVAL).

(11) Install the shrouds.

(12) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(13) Align the spline on the wheel hub to shaft.

(14) Then install the steering wheel and install a

newbolt. Tighten the bolt to 61 N´m (45 ft. lbs.).

(15) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(16) Install the two steering wheel switches.

(17) Install the tilt lever handle.

(18) Install the negative battery terminal.

(19) Test the operation of the horn, Electronic

PRNDL Indicator, lights and any other functions that

are steering column operated.IGNITION SWITCH

DESCRIPTION

The ignition switch is located on the steering col-

umn. It is used as the main on/off switching device

for most electrical components. The mechanical key

cylinder is used to engage/disengage the electrical

ignition switch.

OPERATION

Vehicles equipped with an automatic trans-

mission and a steering column mounted shifter:

an interlock device is located within the shift cable.

This interlock device is used to lock the transmission

shifter in the PARK position when the key cylinder is

in any position and the brake pedal is not depressed.

DIAGNOSIS AND TESTING - IGNITION SWITCH

TEST AND REPAIR

If the key removal effort is excessive on a vehicle

with a automatic transmission first adjust the shift

linkage, (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 46RE/GEAR SHIFT CABLE -

ADJUSTMENTS).

If the ignition switch effort is excessive remove the

ignition key cylinder from the steering column. (Refer

to 19 - STEERING/COLUMN/LOCK CYLINDER

HOUSING - REMOVAL). Check the turning effort of

the key cylinder. If the ignition key cylinder effort is

excessive replace the key cylinder.

Fig. 7 STEERING COLUMN

1 - Steering Wheel

2 - Key Cylinder

3 - Gear Shift Lever

4 - Steering Column

5 - Tilt Lever Cable

DRCOLUMN 19 - 9

COLUMN (Continued)

Page 1803 of 2895

REMOVAL

SERVICE PRECAUTIONS

NOTE: The steering column on vehicles equipped

with an automatic transmission is not equipped

with an internal locking shaft with the ignition cyl-

inder. Alternative methods of locking the steering

wheel for service will have to be used.

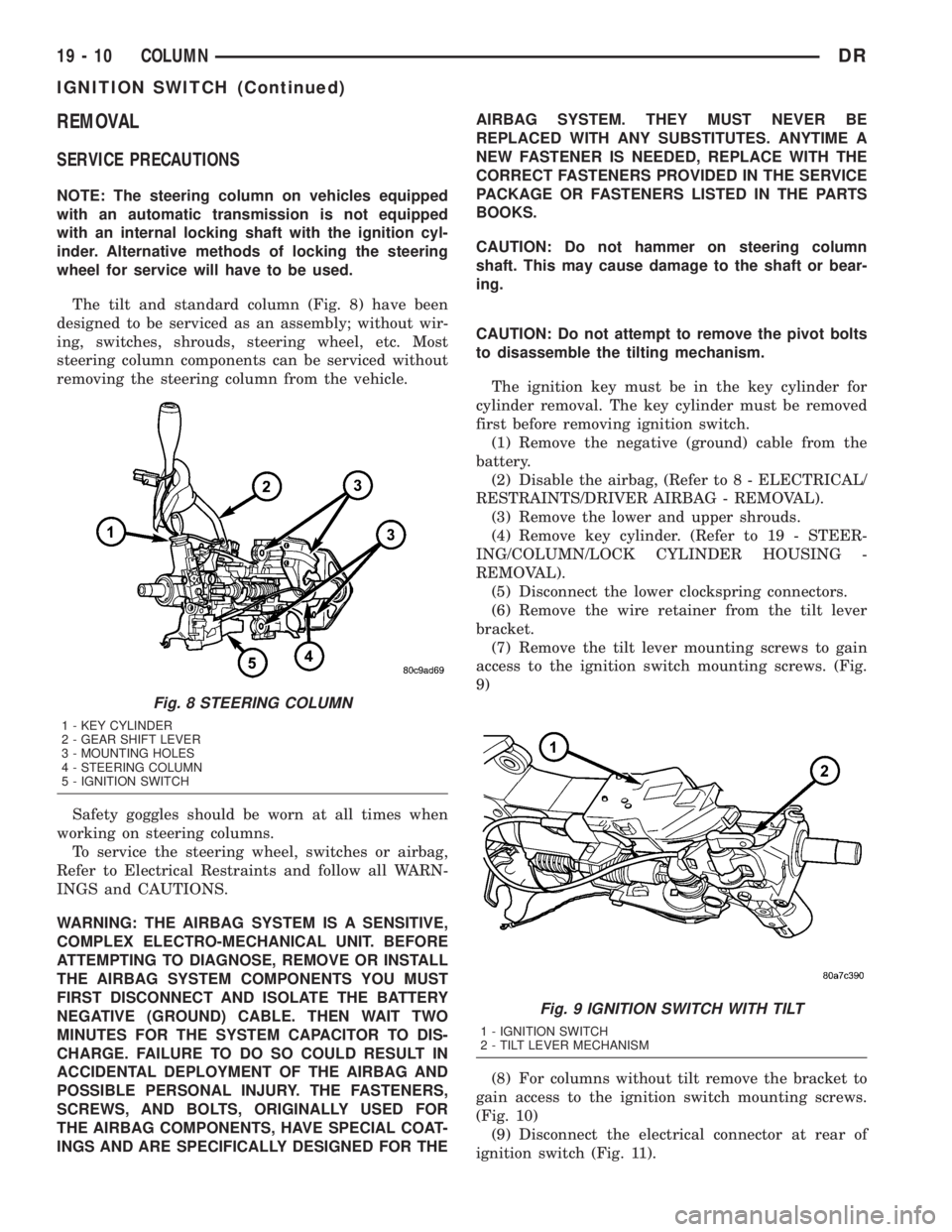

The tilt and standard column (Fig. 8) have been

designed to be serviced as an assembly; without wir-

ing, switches, shrouds, steering wheel, etc. Most

steering column components can be serviced without

removing the steering column from the vehicle.

Safety goggles should be worn at all times when

working on steering columns.

To service the steering wheel, switches or airbag,

Refer to Electrical Restraints and follow all WARN-

INGS and CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THEAIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.

CAUTION: Do not hammer on steering column

shaft. This may cause damage to the shaft or bear-

ing.

CAUTION: Do not attempt to remove the pivot bolts

to disassemble the tilting mechanism.

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Remove the negative (ground) cable from the

battery.

(2) Disable the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(3) Remove the lower and upper shrouds.

(4) Remove key cylinder. (Refer to 19 - STEER-

ING/COLUMN/LOCK CYLINDER HOUSING -

REMOVAL).

(5) Disconnect the lower clockspring connectors.

(6) Remove the wire retainer from the tilt lever

bracket.

(7) Remove the tilt lever mounting screws to gain

access to the ignition switch mounting screws. (Fig.

9)

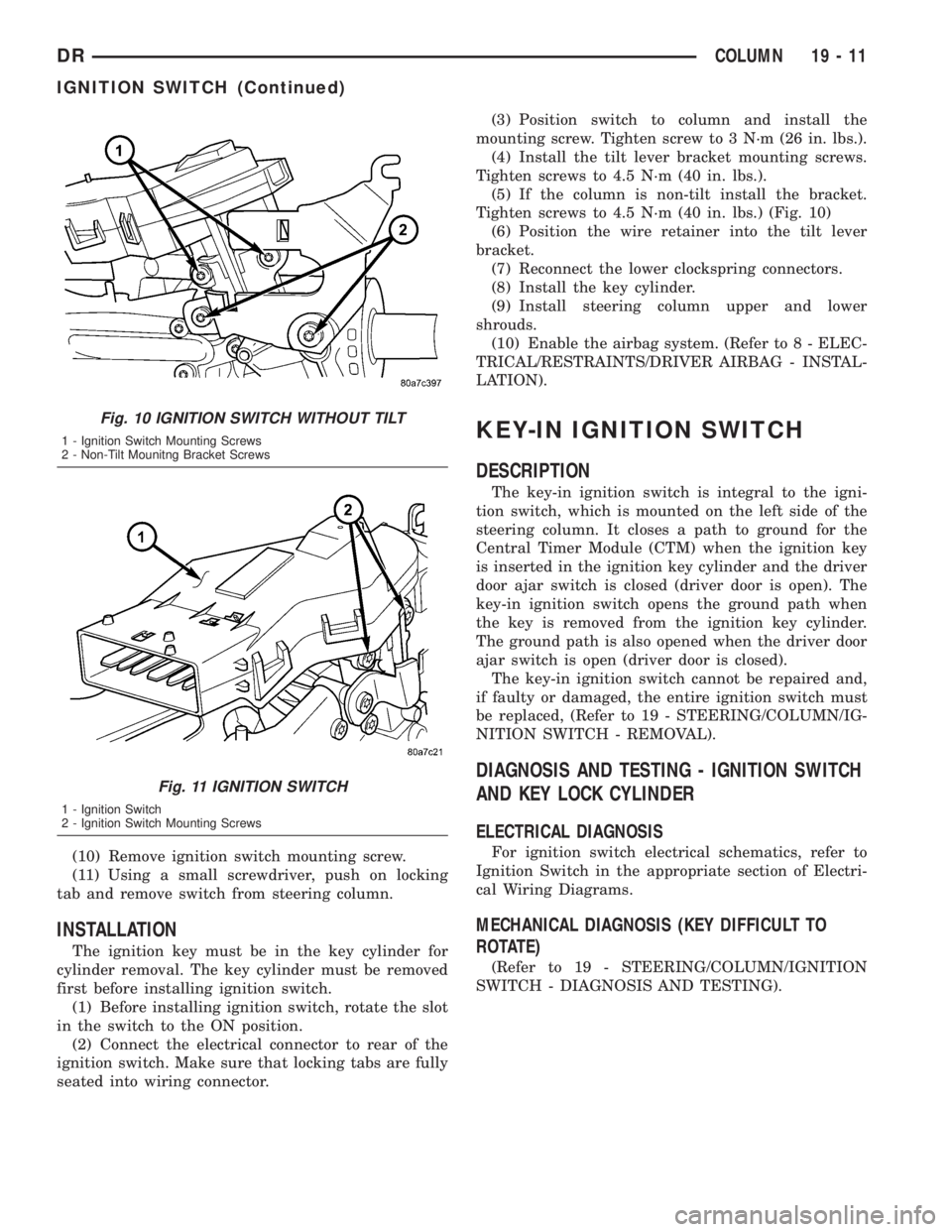

(8) For columns without tilt remove the bracket to

gain access to the ignition switch mounting screws.

(Fig. 10)

(9) Disconnect the electrical connector at rear of

ignition switch (Fig. 11).

Fig. 8 STEERING COLUMN

1 - KEY CYLINDER

2 - GEAR SHIFT LEVER

3 - MOUNTING HOLES

4 - STEERING COLUMN

5 - IGNITION SWITCH

Fig. 9 IGNITION SWITCH WITH TILT

1 - IGNITION SWITCH

2 - TILT LEVER MECHANISM

19 - 10 COLUMNDR

IGNITION SWITCH (Continued)

Page 1804 of 2895

(10) Remove ignition switch mounting screw.

(11) Using a small screwdriver, push on locking

tab and remove switch from steering column.

INSTALLATION

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before installing ignition switch.

(1) Before installing ignition switch, rotate the slot

in the switch to the ON position.

(2) Connect the electrical connector to rear of the

ignition switch. Make sure that locking tabs are fully

seated into wiring connector.(3) Position switch to column and install the

mounting screw. Tighten screw to 3 N´m (26 in. lbs.).

(4) Install the tilt lever bracket mounting screws.

Tighten screws to 4.5 N´m (40 in. lbs.).

(5) If the column is non-tilt install the bracket.

Tighten screws to 4.5 N´m (40 in. lbs.) (Fig. 10)

(6) Position the wire retainer into the tilt lever

bracket.

(7) Reconnect the lower clockspring connectors.

(8) Install the key cylinder.

(9) Install steering column upper and lower

shrouds.

(10) Enable the airbag system. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION).

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the left side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition key cylinder and the driver

door ajar switch is closed (driver door is open). The

key-in ignition switch opens the ground path when

the key is removed from the ignition key cylinder.

The ground path is also opened when the driver door

ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced, (Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

AND KEY LOCK CYLINDER

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in the appropriate section of Electri-

cal Wiring Diagrams.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

(Refer to 19 - STEERING/COLUMN/IGNITION

SWITCH - DIAGNOSIS AND TESTING).

Fig. 10 IGNITION SWITCH WITHOUT TILT

1 - Ignition Switch Mounting Screws

2 - Non-Tilt Mounitng Bracket Screws

Fig. 11 IGNITION SWITCH

1 - Ignition Switch

2 - Ignition Switch Mounting Screws

DRCOLUMN 19 - 11

IGNITION SWITCH (Continued)