clock DODGE RAM 2003 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 1574 of 2895

ring tool to keep the engine from rotating during

tightening operation.

(11) Install the fan support/hub assembly and

torque bolts to 32 N´m (24 ft. lbs.).

(12) Install hydraulic pump.

(13) Install accessory drive belt tensioner. Torque

bolt to 43 Nm (32 ft.lbs.).

(14) Install cooling fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(15) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(16) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(17) Connect battery negative cables.

(18) Start engine and check for oil leaks.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the transmission and transfer case (if

equipped).

(3) Remove the clutch cover and disc (if manual

transmission equipped) (Refer to 6 - CLUTCH/

CLUTCH DISC - REMOVAL).

(4) Remove the flywheel or converter drive plate.

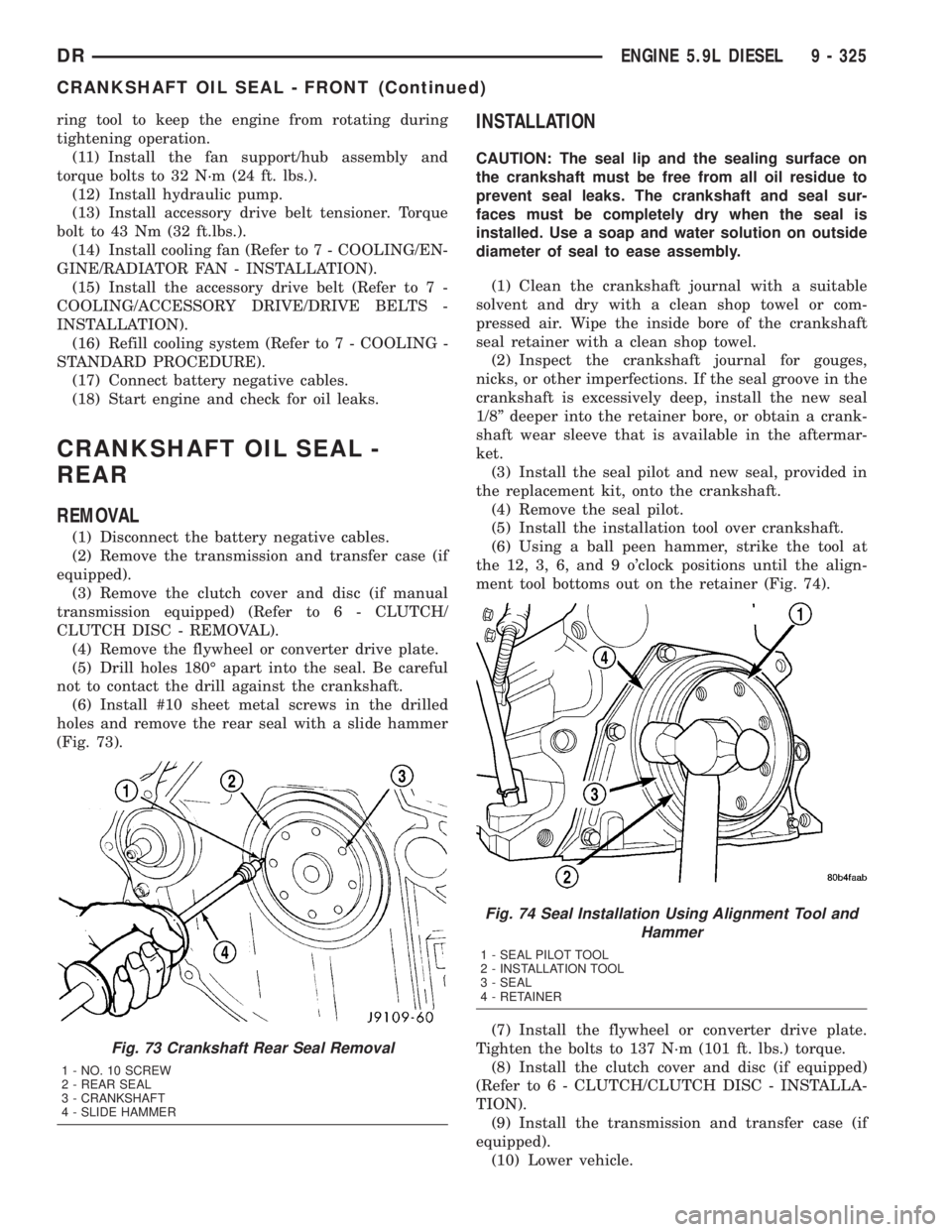

(5) Drill holes 180É apart into the seal. Be careful

not to contact the drill against the crankshaft.

(6) Install #10 sheet metal screws in the drilled

holes and remove the rear seal with a slide hammer

(Fig. 73).

INSTALLATION

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(1) Clean the crankshaft journal with a suitable

solvent and dry with a clean shop towel or com-

pressed air. Wipe the inside bore of the crankshaft

seal retainer with a clean shop towel.

(2) Inspect the crankshaft journal for gouges,

nicks, or other imperfections. If the seal groove in the

crankshaft is excessively deep, install the new seal

1/8º deeper into the retainer bore, or obtain a crank-

shaft wear sleeve that is available in the aftermar-

ket.

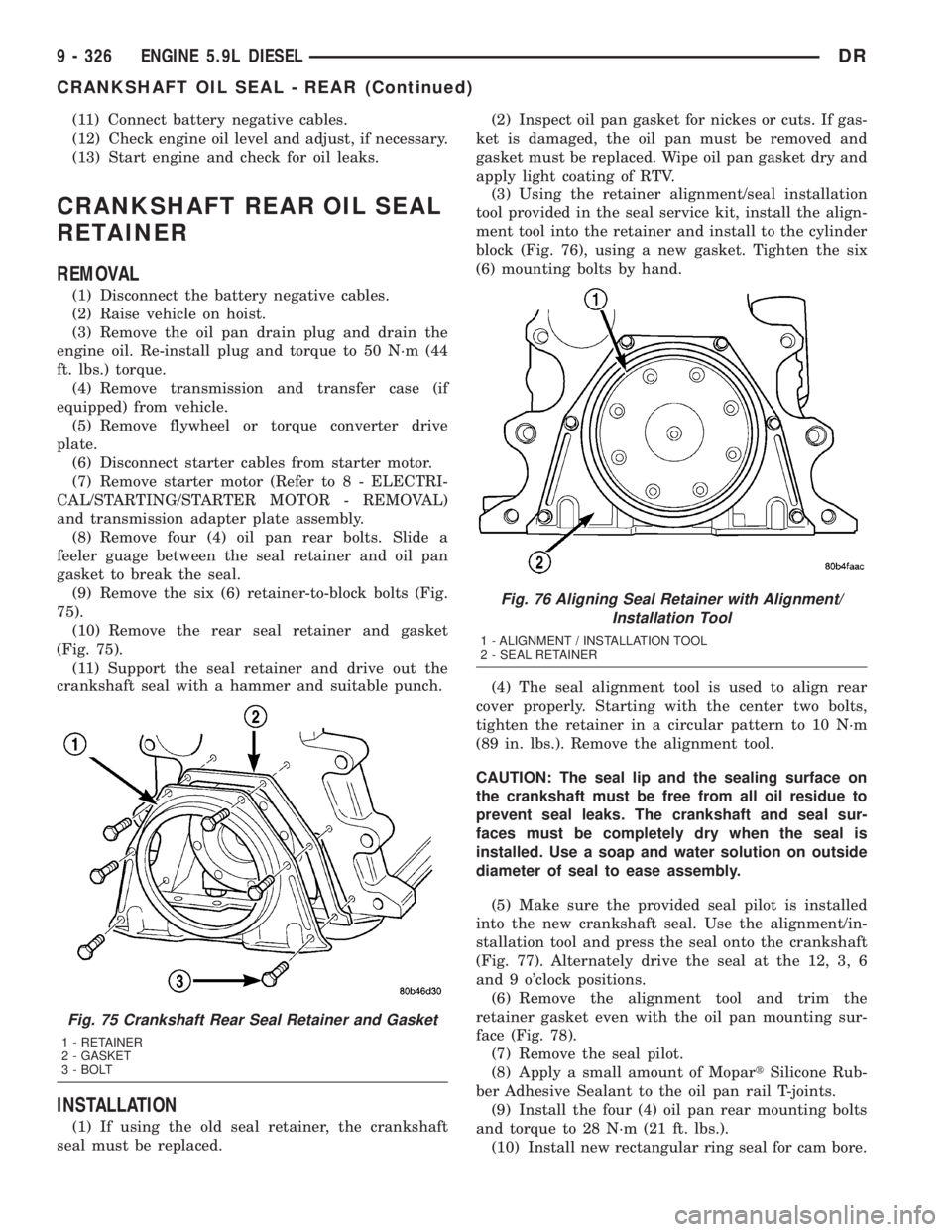

(3) Install the seal pilot and new seal, provided in

the replacement kit, onto the crankshaft.

(4) Remove the seal pilot.

(5) Install the installation tool over crankshaft.

(6) Using a ball peen hammer, strike the tool at

the 12, 3, 6, and 9 o'clock positions until the align-

ment tool bottoms out on the retainer (Fig. 74).

(7) Install the flywheel or converter drive plate.

Tighten the bolts to 137 N´m (101 ft. lbs.) torque.

(8) Install the clutch cover and disc (if equipped)

(Refer to 6 - CLUTCH/CLUTCH DISC - INSTALLA-

TION).

(9) Install the transmission and transfer case (if

equipped).

(10) Lower vehicle.

Fig. 73 Crankshaft Rear Seal Removal

1 - NO. 10 SCREW

2 - REAR SEAL

3 - CRANKSHAFT

4 - SLIDE HAMMER

Fig. 74 Seal Installation Using Alignment Tool and

Hammer

1 - SEAL PILOT TOOL

2 - INSTALLATION TOOL

3 - SEAL

4 - RETAINER

DRENGINE 5.9L DIESEL 9 - 325

CRANKSHAFT OIL SEAL - FRONT (Continued)

Page 1575 of 2895

(11) Connect battery negative cables.

(12) Check engine oil level and adjust, if necessary.

(13) Start engine and check for oil leaks.

CRANKSHAFT REAR OIL SEAL

RETAINER

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Remove the oil pan drain plug and drain the

engine oil. Re-install plug and torque to 50 N´m (44

ft. lbs.) torque.

(4) Remove transmission and transfer case (if

equipped) from vehicle.

(5) Remove flywheel or torque converter drive

plate.

(6) Disconnect starter cables from starter motor.

(7) Remove starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

and transmission adapter plate assembly.

(8) Remove four (4) oil pan rear bolts. Slide a

feeler guage between the seal retainer and oil pan

gasket to break the seal.

(9) Remove the six (6) retainer-to-block bolts (Fig.

75).

(10) Remove the rear seal retainer and gasket

(Fig. 75).

(11) Support the seal retainer and drive out the

crankshaft seal with a hammer and suitable punch.

INSTALLATION

(1) If using the old seal retainer, the crankshaft

seal must be replaced.(2) Inspect oil pan gasket for nickes or cuts. If gas-

ket is damaged, the oil pan must be removed and

gasket must be replaced. Wipe oil pan gasket dry and

apply light coating of RTV.

(3) Using the retainer alignment/seal installation

tool provided in the seal service kit, install the align-

ment tool into the retainer and install to the cylinder

block (Fig. 76), using a new gasket. Tighten the six

(6) mounting bolts by hand.

(4) The seal alignment tool is used to align rear

cover properly. Starting with the center two bolts,

tighten the retainer in a circular pattern to 10 N´m

(89 in. lbs.). Remove the alignment tool.

CAUTION: The seal lip and the sealing surface on

the crankshaft must be free from all oil residue to

prevent seal leaks. The crankshaft and seal sur-

faces must be completely dry when the seal is

installed. Use a soap and water solution on outside

diameter of seal to ease assembly.

(5) Make sure the provided seal pilot is installed

into the new crankshaft seal. Use the alignment/in-

stallation tool and press the seal onto the crankshaft

(Fig. 77). Alternately drive the seal at the 12, 3, 6

and 9 o'clock positions.

(6) Remove the alignment tool and trim the

retainer gasket even with the oil pan mounting sur-

face (Fig. 78).

(7) Remove the seal pilot.

(8) Apply a small amount of MopartSilicone Rub-

ber Adhesive Sealant to the oil pan rail T-joints.

(9) Install the four (4) oil pan rear mounting bolts

and torque to 28 N´m (21 ft. lbs.).

(10) Install new rectangular ring seal for cam bore.

Fig. 75 Crankshaft Rear Seal Retainer and Gasket

1 - RETAINER

2 - GASKET

3 - BOLT

Fig. 76 Aligning Seal Retainer with Alignment/

Installation Tool

1 - ALIGNMENT / INSTALLATION TOOL

2 - SEAL RETAINER

9 - 326 ENGINE 5.9L DIESELDR

CRANKSHAFT OIL SEAL - REAR (Continued)

Page 1582 of 2895

(8) Use clean engine oil to lubricate the threads

and under the heads of the connecting rod bolts.

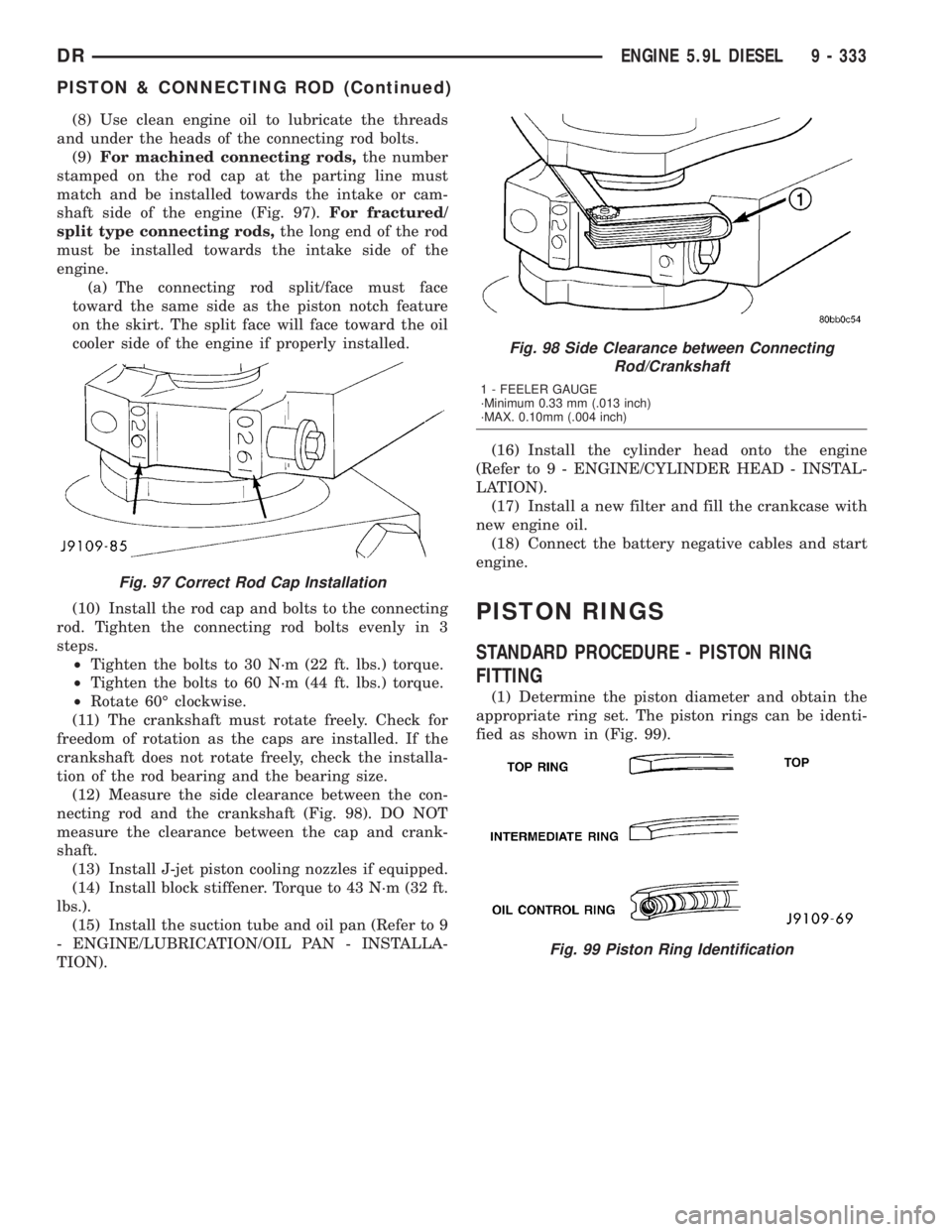

(9)For machined connecting rods,the number

stamped on the rod cap at the parting line must

match and be installed towards the intake or cam-

shaft side of the engine (Fig. 97).For fractured/

split type connecting rods,the long end of the rod

must be installed towards the intake side of the

engine.

(a) The connecting rod split/face must face

toward the same side as the piston notch feature

on the skirt. The split face will face toward the oil

cooler side of the engine if properly installed.

(10) Install the rod cap and bolts to the connecting

rod. Tighten the connecting rod bolts evenly in 3

steps.

²Tighten the bolts to 30 N´m (22 ft. lbs.) torque.

²Tighten the bolts to 60 N´m (44 ft. lbs.) torque.

²Rotate 60É clockwise.

(11) The crankshaft must rotate freely. Check for

freedom of rotation as the caps are installed. If the

crankshaft does not rotate freely, check the installa-

tion of the rod bearing and the bearing size.

(12) Measure the side clearance between the con-

necting rod and the crankshaft (Fig. 98). DO NOT

measure the clearance between the cap and crank-

shaft.

(13) Install J-jet piston cooling nozzles if equipped.

(14) Install block stiffener. Torque to 43 N´m (32 ft.

lbs.).

(15) Install the suction tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).(16) Install the cylinder head onto the engine

(Refer to 9 - ENGINE/CYLINDER HEAD - INSTAL-

LATION).

(17) Install a new filter and fill the crankcase with

new engine oil.

(18) Connect the battery negative cables and start

engine.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

(1) Determine the piston diameter and obtain the

appropriate ring set. The piston rings can be identi-

fied as shown in (Fig. 99).

Fig. 97 Correct Rod Cap Installation

Fig. 98 Side Clearance between Connecting

Rod/Crankshaft

1 - FEELER GAUGE

´Minimum 0.33 mm (.013 inch)

´MAX. 0.10mm (.004 inch)

Fig. 99 Piston Ring Identification

DRENGINE 5.9L DIESEL 9 - 333

PISTON & CONNECTING ROD (Continued)

Page 1592 of 2895

OIL PRESSURE RELIEF VALVE

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the threaded plug, spring and plunger

(Fig. 114). Insert a finger or a seal pick to lift the

plunger from the bore.

NOTE: If the plunger is stuck in the bore, it will be

necessary to remove the filter head.

CLEANING

(1) Clean the regulator spring and plunger with a

suitable solvent and blow dry with compressed air. If

the plunger bore requires cleaning, it is necessary to

remove the oil filter head to avoid getting debris into

the engine.

INSPECTION

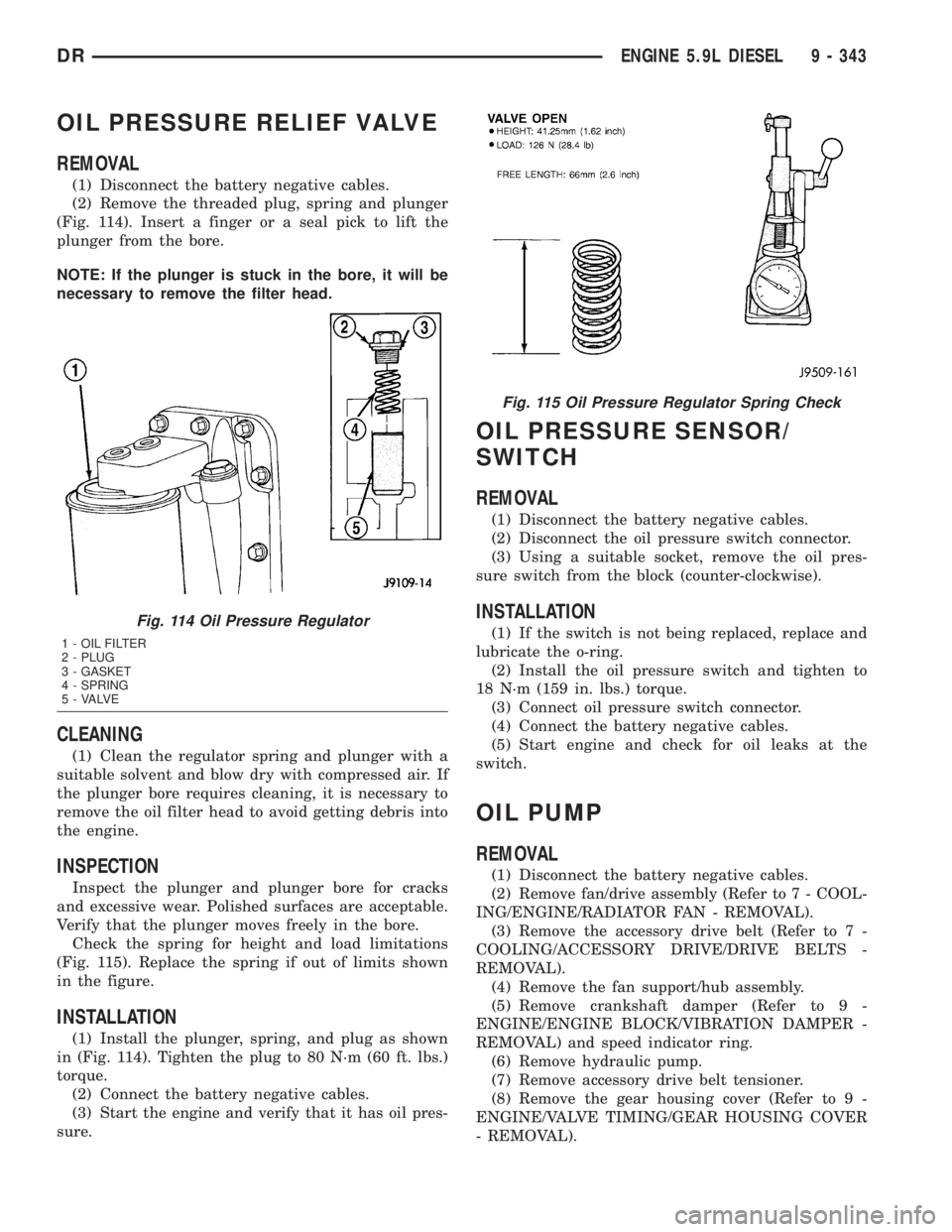

Inspect the plunger and plunger bore for cracks

and excessive wear. Polished surfaces are acceptable.

Verify that the plunger moves freely in the bore.

Check the spring for height and load limitations

(Fig. 115). Replace the spring if out of limits shown

in the figure.

INSTALLATION

(1) Install the plunger, spring, and plug as shown

in (Fig. 114). Tighten the plug to 80 N´m (60 ft. lbs.)

torque.

(2) Connect the battery negative cables.

(3) Start the engine and verify that it has oil pres-

sure.

OIL PRESSURE SENSOR/

SWITCH

REMOVAL

(1) Disconnect the battery negative cables.

(2) Disconnect the oil pressure switch connector.

(3) Using a suitable socket, remove the oil pres-

sure switch from the block (counter-clockwise).

INSTALLATION

(1) If the switch is not being replaced, replace and

lubricate the o-ring.

(2) Install the oil pressure switch and tighten to

18 N´m (159 in. lbs.) torque.

(3) Connect oil pressure switch connector.

(4) Connect the battery negative cables.

(5) Start engine and check for oil leaks at the

switch.

OIL PUMP

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove fan/drive assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the fan support/hub assembly.

(5) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(6) Remove hydraulic pump.

(7) Remove accessory drive belt tensioner.

(8) Remove the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- REMOVAL).

Fig. 114 Oil Pressure Regulator

1 - OIL FILTER

2 - PLUG

3 - GASKET

4 - SPRING

5 - VALVE

Fig. 115 Oil Pressure Regulator Spring Check

DRENGINE 5.9L DIESEL 9 - 343

Page 1597 of 2895

(8) Install the oil drain tube and a new gasket to

the turbocharger. Tighten the drain tube bolts to 24

N´m (18 ft. lbs.) torque.

(9)Pre-lube the turbocharger.Pour 50 to 60 cc

(2 to 3 oz.) clean engine oil in the oil supply line fit-

ting on the turbo. Rotate the turbocharger impeller

by hand to distrubute the oil thoroughly.

(10) Install and tighten the oil supply line fitting

nut to 24 N´m (18 ft. lbs.) torque.

(11) Position the charge air cooler inlet pipe to the

turbocharger. With the clamp in position, tighten the

clamp nut to 8 N´m (72 in. lbs.) torque.

(12) Position the air inlet hose to the turbocharger.

Tighten the clamp to 8 N´m (72 in. lbs.) torque.

(13) Raise vehicle on hoist.

(14) Connect the exhaust pipe to the turbocharger

and tighten the bolts to 34 N´m (25 ft. lbs.) torque.

(15) Lower the vehicle.

(16) Connect the battery negative cables.

(17) Start the engine to check for leaks.

VALVE TIMING

STANDARD PROCEDURE - TIMING

VERIFICATION

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Remove fuel injector from cylinder number

1(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

FUEL INJECTOR - REMOVAL).

(3) Using Special Tool 7471B rotate the engine

until the TDC mark on the damper is at 12 o'clock.

(4) Using a 8 in.x 1/4 in. dowel rod inserted into

cylinder number 1, rock the crankshaft back and

forth to verify piston number 1 is at TDC.

(5) With cylinder number still at TDC, inspect the

keyway on the crankshaft gear for proper alignment

(12 o'clock position).

(6) If the keyway is not at 12 o'clock position

replace the crankshaft gear assembly.

(7) If the keyway is at 12 o'clock position, remove

front gear cover and verify timing mark alignment

between the camshaft gear and crankshaft gear, if

not aligned inspect keyway on camshaft gear.

(8) Inspect keyway on camshaft gear for proper

alignment with the key in the camshaft, if alignment

is off replace the camshaft/gear assembly.

(9) If timing marks alignment is off and no dam-

age is found at either the crankshaft or camshaft

gear keyways, realign timing marks as necessary.

GEAR HOUSING

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise vehicle on hoist.

(3) Partially drain engine coolant into container

suitable for re-use (Refer to 7 - COOLING - STAN-

DARD PROCEDURE).

(4) Lower vehicle.

(5) Remove radiator upper hose.

(6) Disconnect coolant recovery bottle hose from

radiator filler neck and lift bottle off of fan shroud.

(7) Disconnect windshield washer pump supply

hose and electrical connections and lift washer bottle

off of fan shroud.

(8) Remove lower fan shroud fasteners. Disconnect

fan drive wire harness.

(9) Remove the upper fan shroud-to-radiator

mounting bolts.

(10) Remove viscous fan/drive assembly (Refer to 7

- COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(12) Remove the cooling fan support/hub from the

front of the engine.

(13) Raise the vehicle on hoist.

(14) Remove the crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and speed indicator ring.

(15) Lower the vehicle.

(16) Remove the hydraulic pump.

(17) Remove the accessory drive belt tensioner.

(18) Remove the gear cover-to-housing bolts and

gently pry the cover away from the housing, taking

care not to mar the gasket surfaces.

(19) Remove the fuel injection pump (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(20) Disconnect the camshaft position sensor con-

nector.

(21) Disconnect and remove engine speed sensor.

(22) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(23) Remove the six front oil pan fasteners.

(24) Remove the gear housing fasteners.

NOTE: Use care when removing the gear housing,

to avoid damage to the oil pan gasket, as the gas-

ket will be reused if it is not damaged.

(25) Slide a feeler gauge between the gear housing

and oil pan gasket, to break the gasket seal.

(26) Remove the gear housing and gasket.

9 - 348 ENGINE 5.9L DIESELDR

EXHAUST MANIFOLD (Continued)

Page 1632 of 2895

INSTALLATION

When a crankshaft is replaced, all main and con-

necting rod bearings should be replaced with new

bearings. Therefore, selective fitting of the bearings

is not required when a crankshaft and bearings are

replaced.

NOTE: Lubricate crankshaft main bearings with

clean engine oil.

(1) Position upper main bearings into block.

(2) Position the crankshaft into the cylinder block.

(3) Lubricate the main journals with clean engine

oil. Install upper main bearings, caps and bolts. Fol-

low the 2 step tightening sequence, starting with

main bearing cap 1.

(4) Lubricate the connecting rod bearings and jour-

nals with clean engine oil. Carefully install connect-

ing rods to the crankshaft.

(5) Using Special Tool 8359 Seal Installer install

new oil into oil seal retainer.

(6) Using Special Tool 6687 Guide, install the rear

seal retainer with a new gasket.

(7) Install the timing chain cover with a new gas-

ket and oil seal.

(8) Prime oil pump by squirt oil in the oil filter

mounting hole and filling the J-trap of the front tim-

ing cover. When oil is running out, install oil filter

that has been filled with oil.(9) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeat

procedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(10) Install the oil pickup tube. Tighten the bolts

to 16 N´m (144 in. lbs.) torque.

(11) Install the oil pan.

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDUREÐFITTING

CRANKSHAFT MAIN BEARINGS

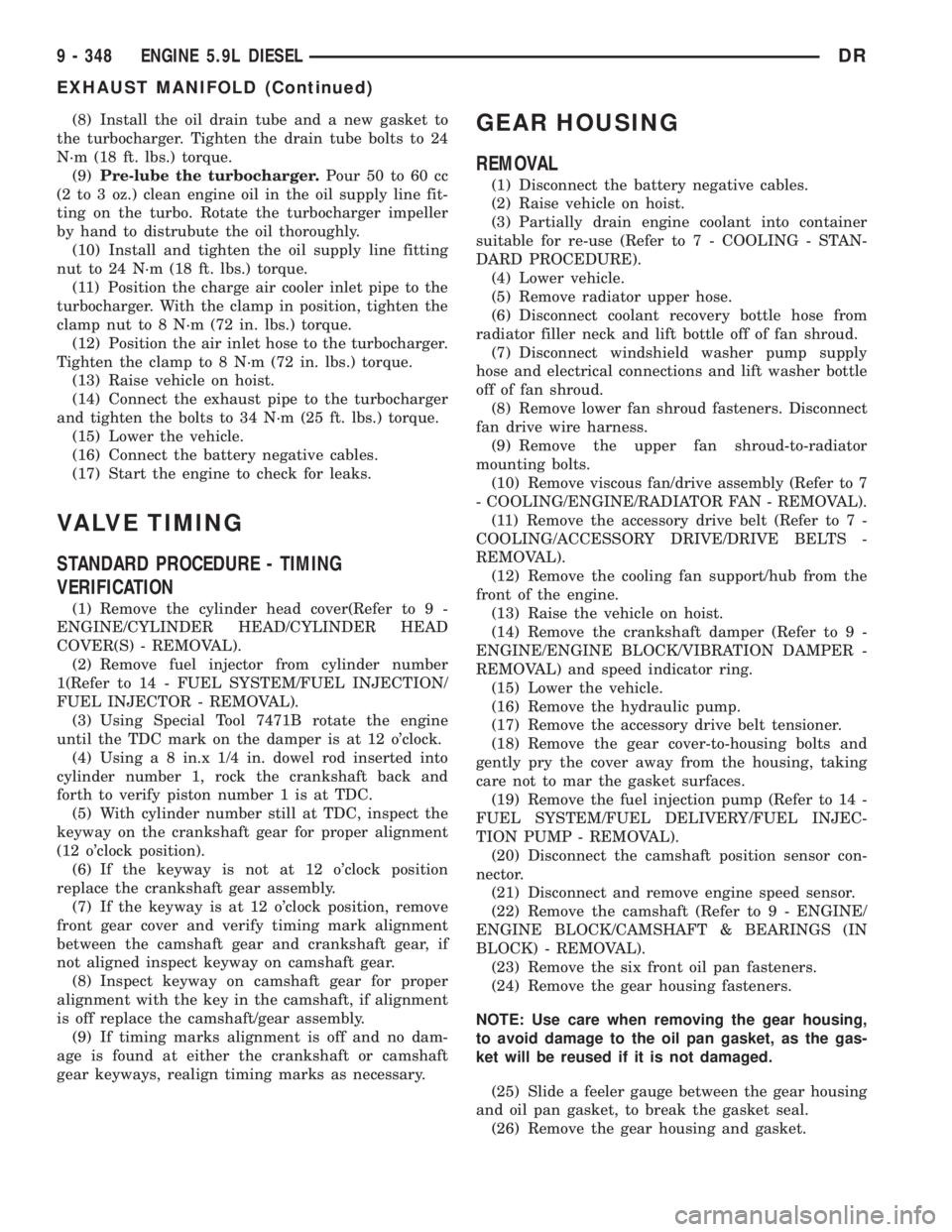

Bearing caps are not interchangeable and should

be marked at removal to ensure correct assembly.

Upper and lower bearing halves are NOT inter-

changeable. All lower main bearing halves are inter-

changeable. Upper main bearing halves of No. 2, 4,

and 5 are interchangeable. Upper main bearing

halves of No. 1 and 6 are interchangeable, this also

applies to the lower bearing halves.

The No.3 main bearing is flanged to carry the

crankshaft thrust loads. This bearing is NOT inter-

changeable with any other bearing halves in the

engine. Bearing shells are available in standard and

the following undersizes: 0.25 mm (0.001 inch), 0.051

mm (0.002 inch), 0.076 mm (0.003 inch), 0.254 mm

(0.010 inch) and 0.305 mm (0.012 inch). Never install

an undersize bearing that will reduce clearance

below specifications.

REMOVAL

(1) Remove the oil pan and oil pump pick-up tube

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

REMOVAL).

(2) Identify bearing caps before removal. Remove

bearing caps one at a time.

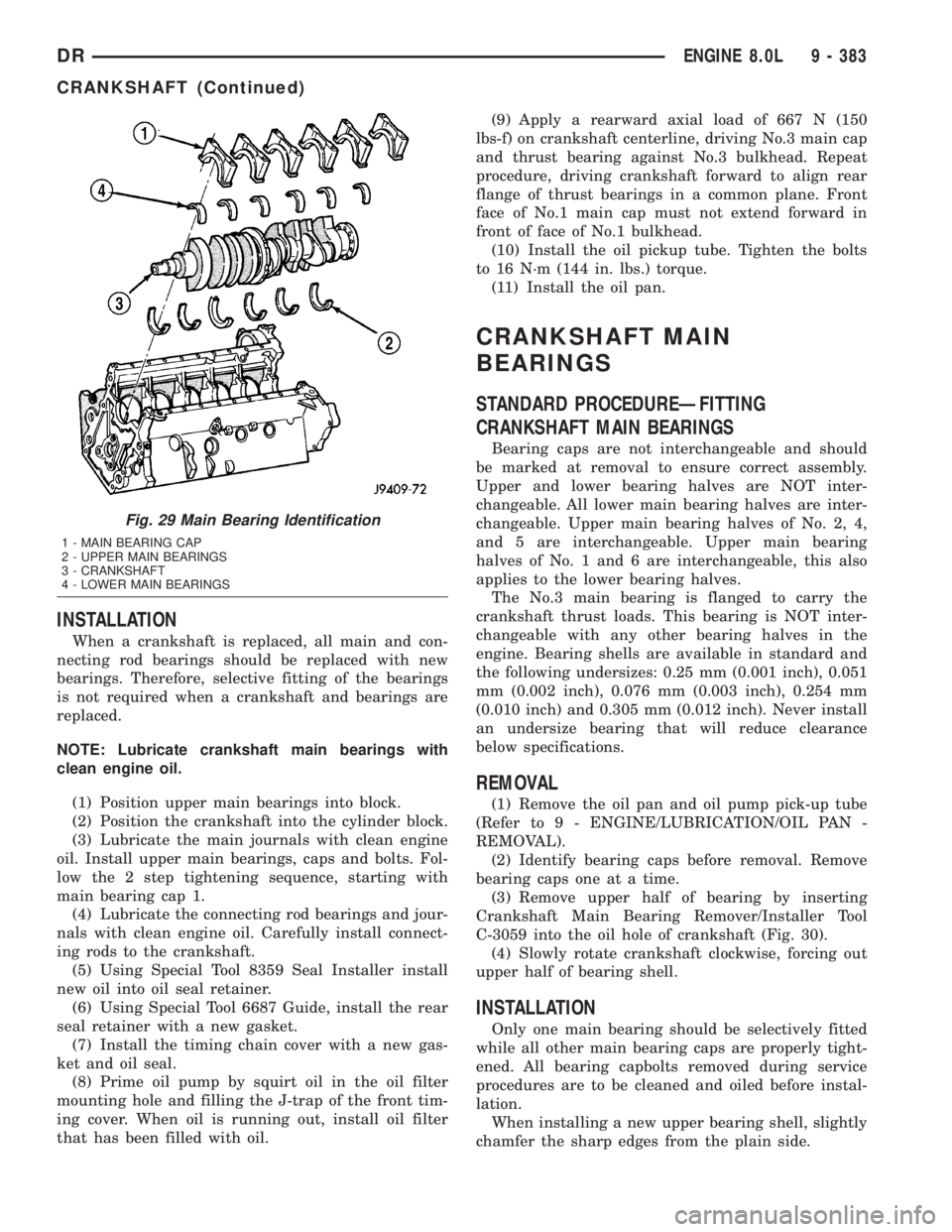

(3) Remove upper half of bearing by inserting

Crankshaft Main Bearing Remover/Installer Tool

C-3059 into the oil hole of crankshaft (Fig. 30).

(4) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

Only one main bearing should be selectively fitted

while all other main bearing caps are properly tight-

ened. All bearing capbolts removed during service

procedures are to be cleaned and oiled before instal-

lation.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

Fig. 29 Main Bearing Identification

1 - MAIN BEARING CAP

2 - UPPER MAIN BEARINGS

3 - CRANKSHAFT

4 - LOWER MAIN BEARINGS

DRENGINE 8.0L 9 - 383

CRANKSHAFT (Continued)

Page 1633 of 2895

(1) Start bearing in place, and insert Crankshaft

Main Bearing Remover/Installer Tool C-3059 into oil

hole of crankshaft (Fig. 30).

(2) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Tool C-3059.

(3) Lubricate the main journals with clean engine

oil. Install main bearing caps and bolts. Follow the 2

step tightening sequence, starting with No. 1 main

bearing cap.

(4) Apply a rearward axial load of 667 N (150

lbs-f) on crankshaft centerline, driving No.3 main cap

and thrust bearing against No.3 bulkhead. Repeat

procedure, driving crankshaft forward to align rear

flange of thrust bearings in a common plane. Front

face of No.1 main cap must not extend forward in

front of face of No.1 bulkhead.

(5) Install the oil pump pick-up tube and oil pan

(Refer to 9 - ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

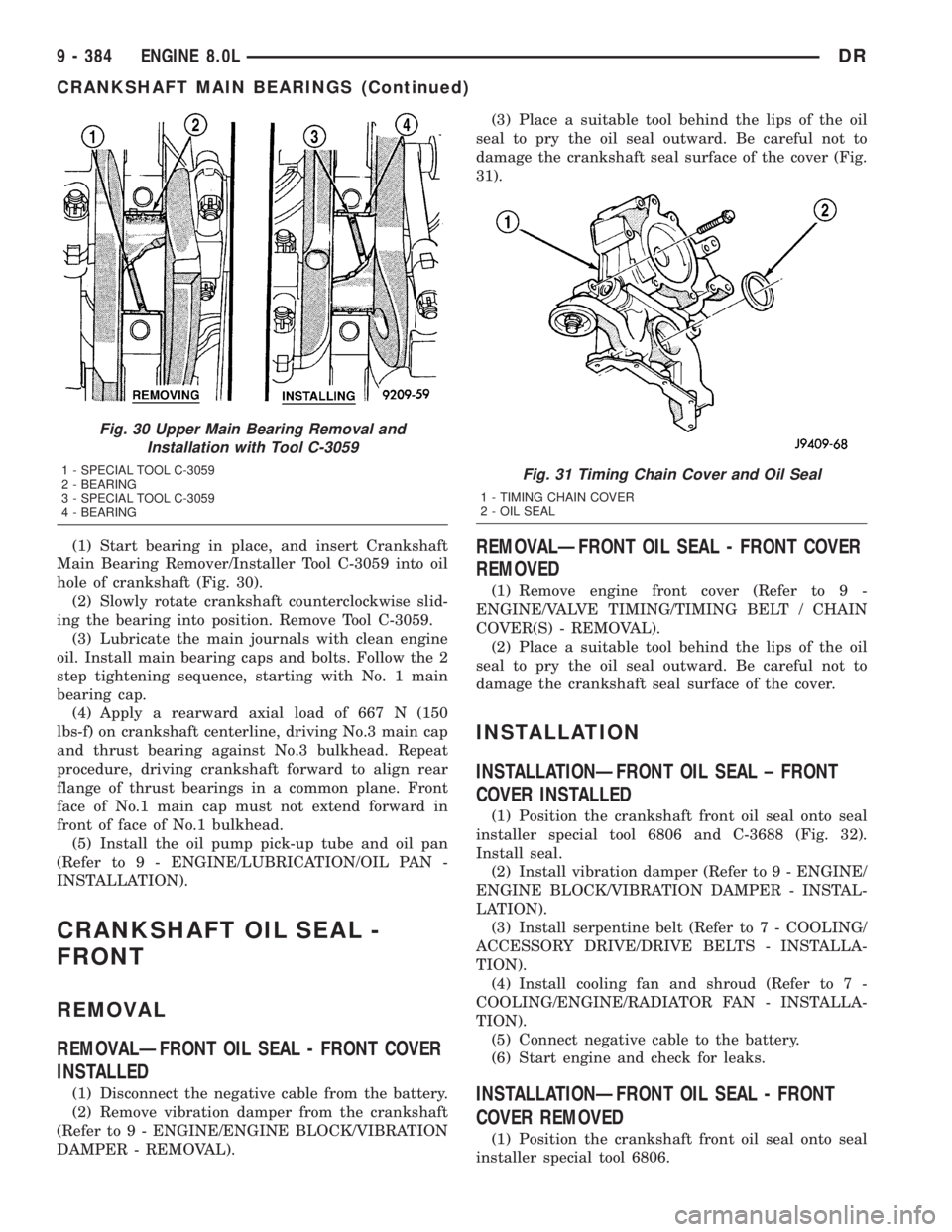

REMOVALÐFRONT OIL SEAL - FRONT COVER

INSTALLED

(1) Disconnect the negative cable from the battery.

(2) Remove vibration damper from the crankshaft

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).(3) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of the cover (Fig.

31).

REMOVALÐFRONT OIL SEAL - FRONT COVER

REMOVED

(1) Remove engine front cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(2) Place a suitable tool behind the lips of the oil

seal to pry the oil seal outward. Be careful not to

damage the crankshaft seal surface of the cover.

INSTALLATION

INSTALLATIONÐFRONT OIL SEAL ± FRONT

COVER INSTALLED

(1) Position the crankshaft front oil seal onto seal

installer special tool 6806 and C-3688 (Fig. 32).

Install seal.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install serpentine belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(4) Install cooling fan and shroud (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(5) Connect negative cable to the battery.

(6) Start engine and check for leaks.

INSTALLATIONÐFRONT OIL SEAL - FRONT

COVER REMOVED

(1) Position the crankshaft front oil seal onto seal

installer special tool 6806.

Fig. 30 Upper Main Bearing Removal and

Installation with Tool C-3059

1 - SPECIAL TOOL C-3059

2 - BEARING

3 - SPECIAL TOOL C-3059

4 - BEARINGFig. 31 Timing Chain Cover and Oil Seal

1 - TIMING CHAIN COVER

2 - OIL SEAL

9 - 384 ENGINE 8.0LDR

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1636 of 2895

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

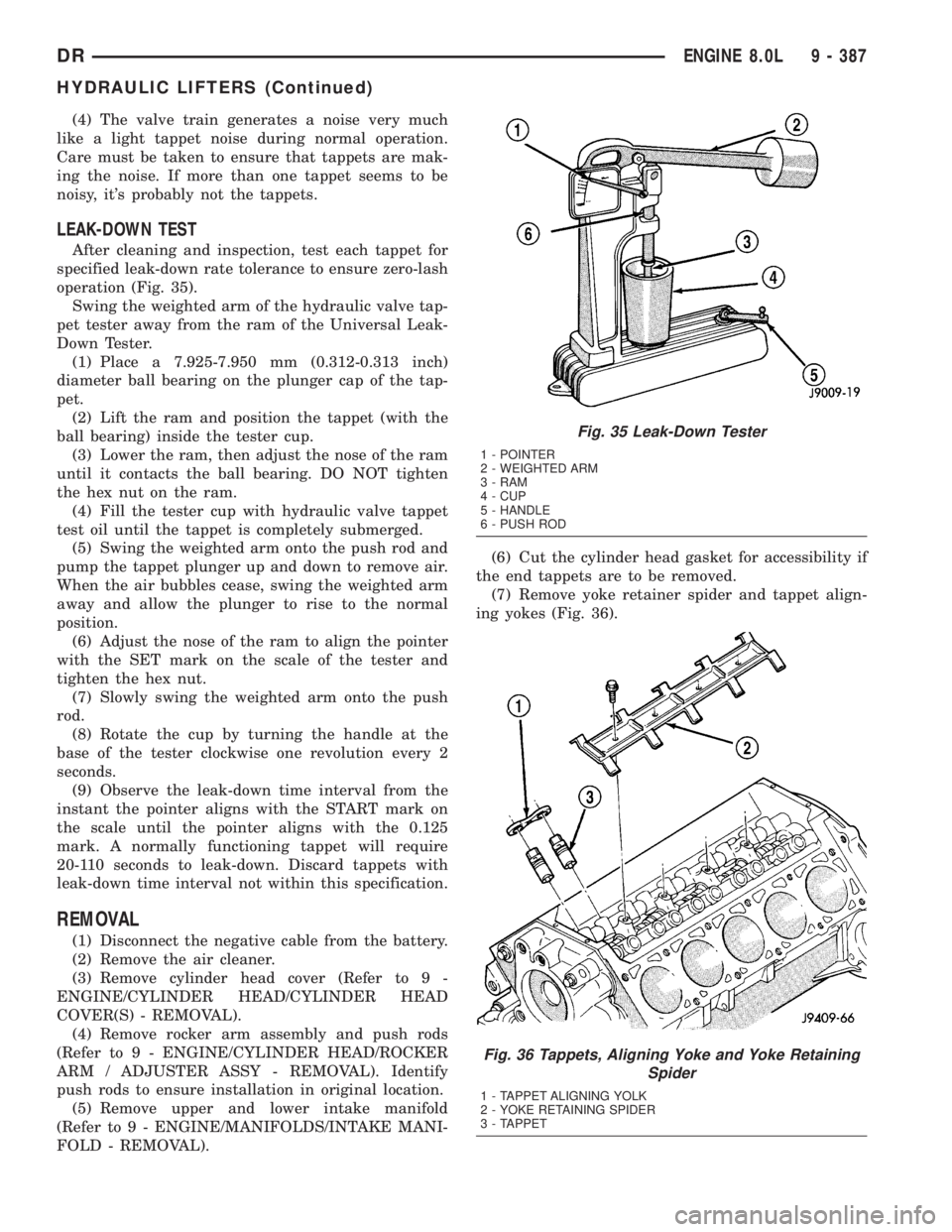

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 35).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Remove the air cleaner.

(3) Remove cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(4) Remove rocker arm assembly and push rods

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL). Identify

push rods to ensure installation in original location.

(5) Remove upper and lower intake manifold

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE MANI-

FOLD - REMOVAL).(6) Cut the cylinder head gasket for accessibility if

the end tappets are to be removed.

(7) Remove yoke retainer spider and tappet align-

ing yokes (Fig. 36).

Fig. 35 Leak-Down Tester

1 - POINTER

2 - WEIGHTED ARM

3 - RAM

4 - CUP

5 - HANDLE

6 - PUSH ROD

Fig. 36 Tappets, Aligning Yoke and Yoke Retaining

Spider

1 - TAPPET ALIGNING YOLK

2 - YOKE RETAINING SPIDER

3 - TAPPET

DRENGINE 8.0L 9 - 387

HYDRAULIC LIFTERS (Continued)

Page 1646 of 2895

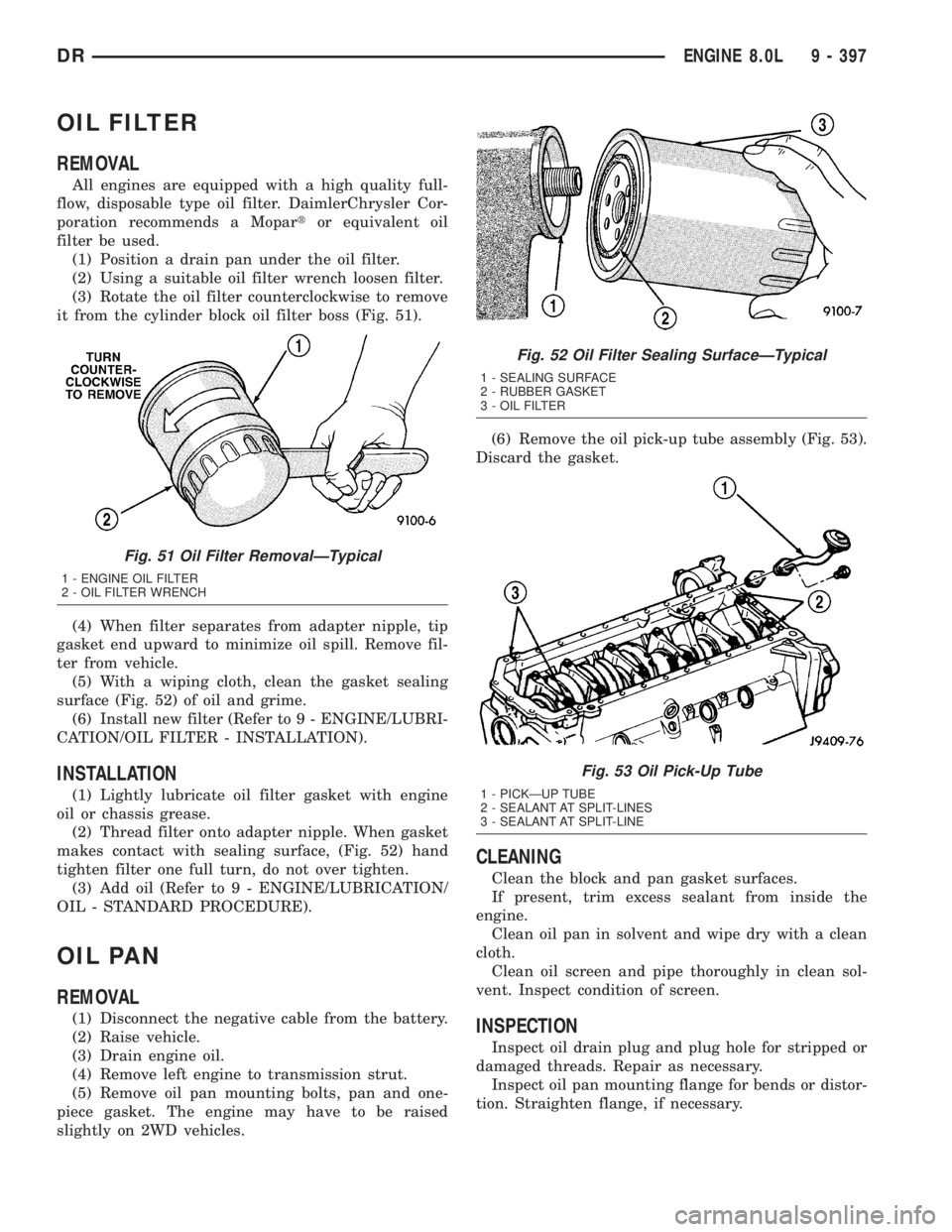

OIL FILTER

REMOVAL

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopartor equivalent oil

filter be used.

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 51).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 52) of oil and grime.

(6) Install new filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - INSTALLATION).

INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 52) hand

tighten filter one full turn, do not over tighten.

(3) Add oil (Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE).

OIL PAN

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle.

(3) Drain engine oil.

(4) Remove left engine to transmission strut.

(5) Remove oil pan mounting bolts, pan and one-

piece gasket. The engine may have to be raised

slightly on 2WD vehicles.(6) Remove the oil pick-up tube assembly (Fig. 53).

Discard the gasket.

CLEANING

Clean the block and pan gasket surfaces.

If present, trim excess sealant from inside the

engine.

Clean oil pan in solvent and wipe dry with a clean

cloth.

Clean oil screen and pipe thoroughly in clean sol-

vent. Inspect condition of screen.

INSPECTION

Inspect oil drain plug and plug hole for stripped or

damaged threads. Repair as necessary.

Inspect oil pan mounting flange for bends or distor-

tion. Straighten flange, if necessary.

Fig. 51 Oil Filter RemovalÐTypical

1 - ENGINE OIL FILTER

2 - OIL FILTER WRENCH

Fig. 52 Oil Filter Sealing SurfaceÐTypical

1 - SEALING SURFACE

2 - RUBBER GASKET

3 - OIL FILTER

Fig. 53 Oil Pick-Up Tube

1 - PICKÐUP TUBE

2 - SEALANT AT SPLIT-LINES

3 - SEALANT AT SPLIT-LINE

DRENGINE 8.0L 9 - 397

Page 1733 of 2895

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

5.9L V-8

The IAC motor is located on the back of the throt-

tle body (Fig. 22).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

8.0L V-10

The IAC motor is located on the back of the throt-

tle body (Fig. 23).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner housing to throttle body.

(5) Install 4 air cleaner housing mounting nuts.

Tighten nuts to 11 N´m (96 in. lbs.) torque.

(6) Install air cleaner housing cover.

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:

²Injector pulse-width²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

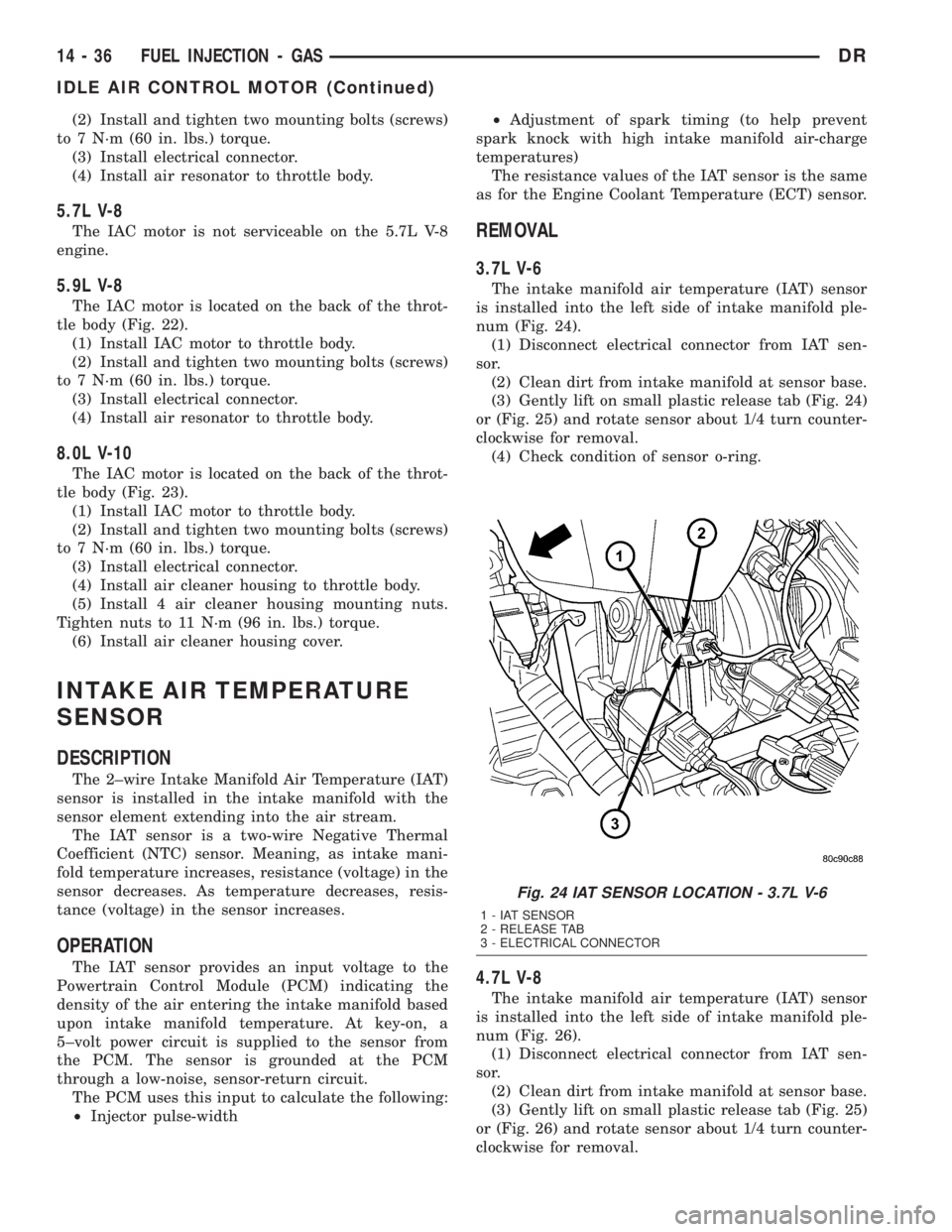

REMOVAL

3.7L V-6

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 24).

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 24)

or (Fig. 25) and rotate sensor about 1/4 turn counter-

clockwise for removal.

(4) Check condition of sensor o-ring.

4.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 26).

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 25)

or (Fig. 26) and rotate sensor about 1/4 turn counter-

clockwise for removal.

Fig. 24 IAT SENSOR LOCATION - 3.7L V-6

1 - IAT SENSOR

2 - RELEASE TAB

3 - ELECTRICAL CONNECTOR

14 - 36 FUEL INJECTION - GASDR

IDLE AIR CONTROL MOTOR (Continued)